Effect of Freeze–Thaw and Wetting–Drying Cycles on the Hydraulic Conductivity of Modified Tailings

Abstract

1. Introduction

2. Experimental Program

3. Soil Properties and Specimen Preparation

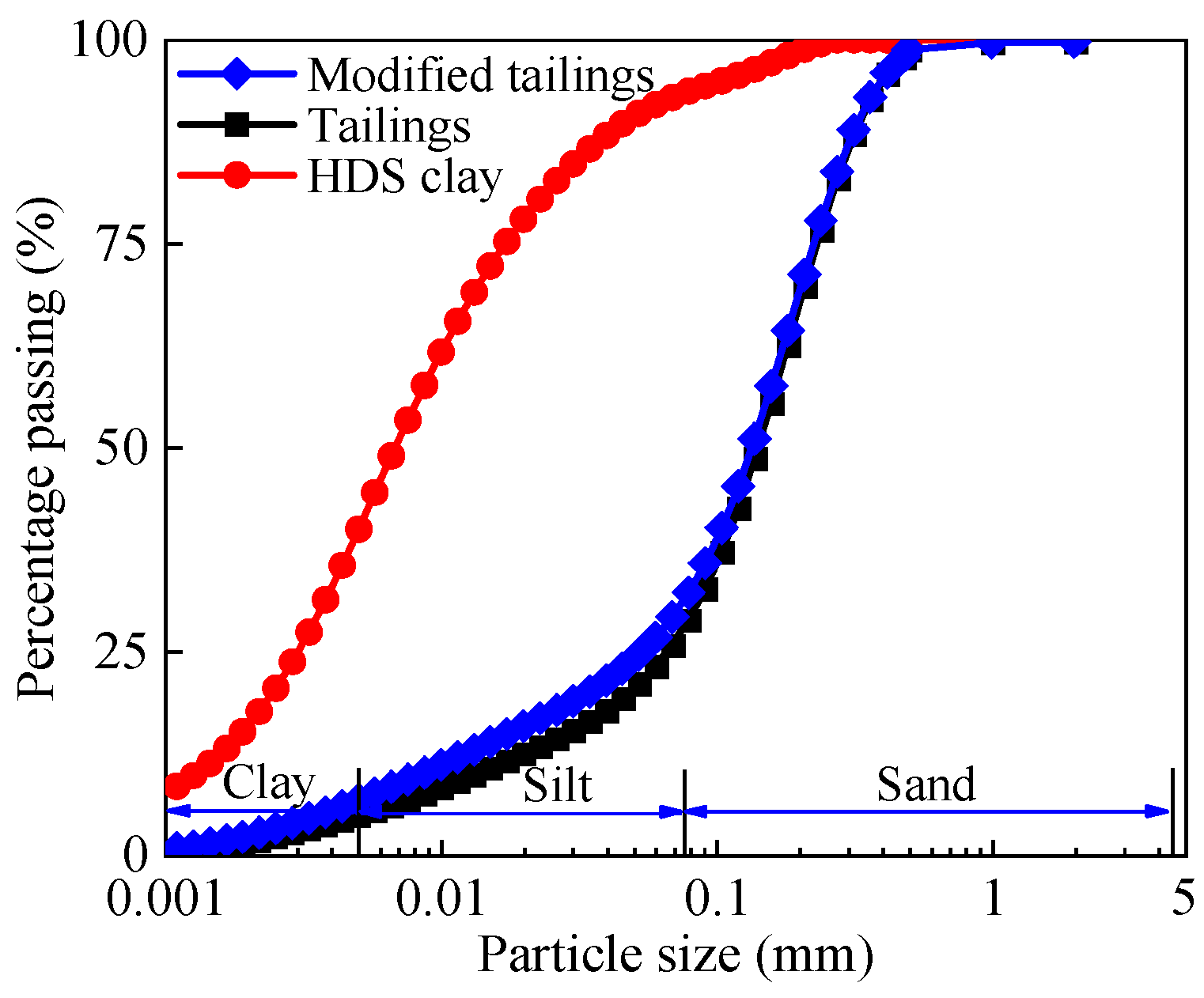

3.1. Soil Properties

3.2. Specimen Preparations

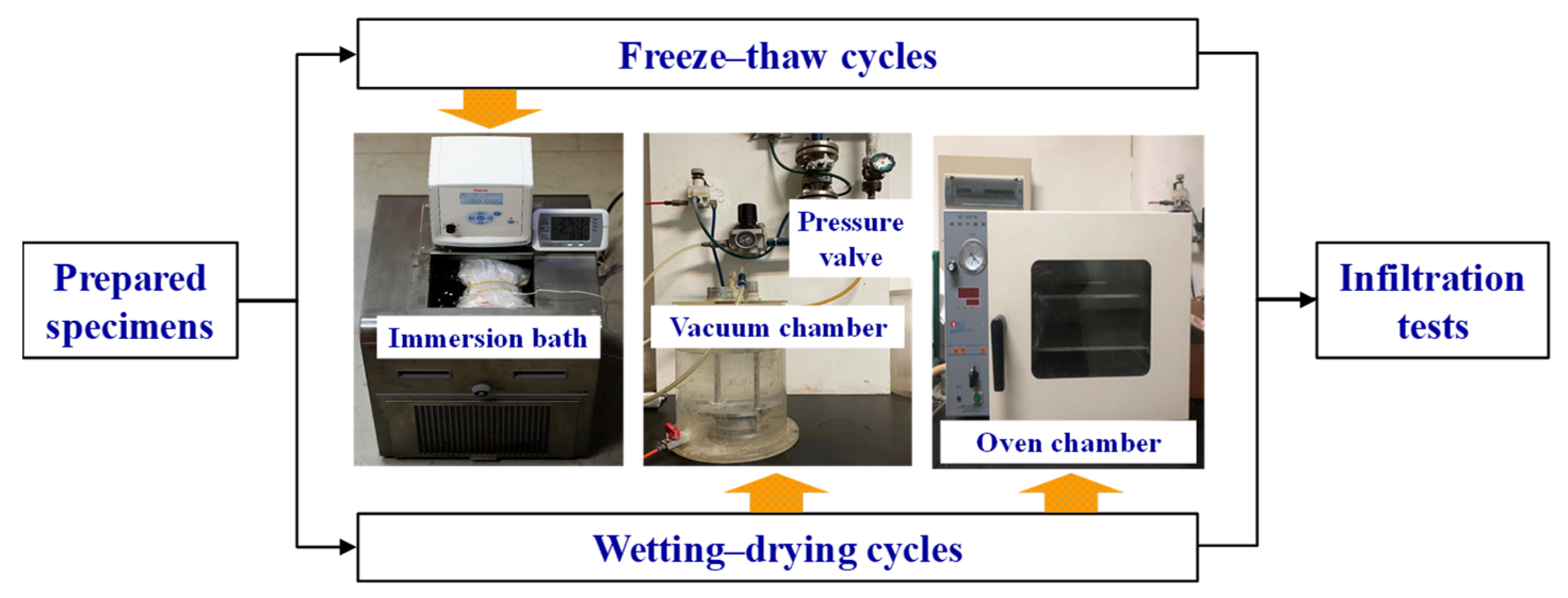

4. Test Apparatuses and Procedures

4.1. Test Apparatuses

4.2. Test Procedures

5. Interpretations of Experimental Results

5.1. Mineralogical Analysis of Tailings and HDS Clay

5.2. Freeze–Thaw Cycles

5.3. Wetting–Drying Cycles

5.4. Future Outlook

6. Conclusions

- (1)

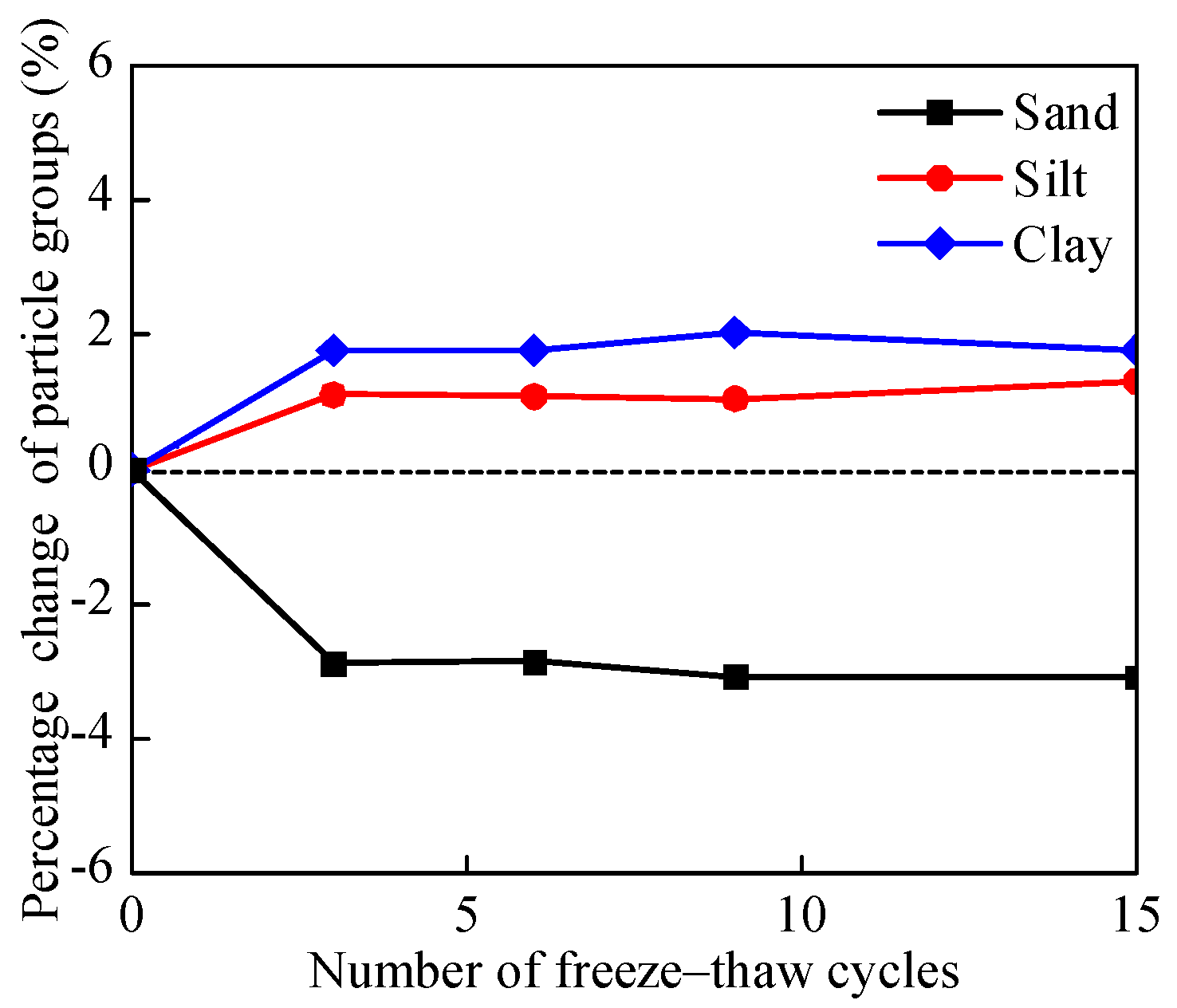

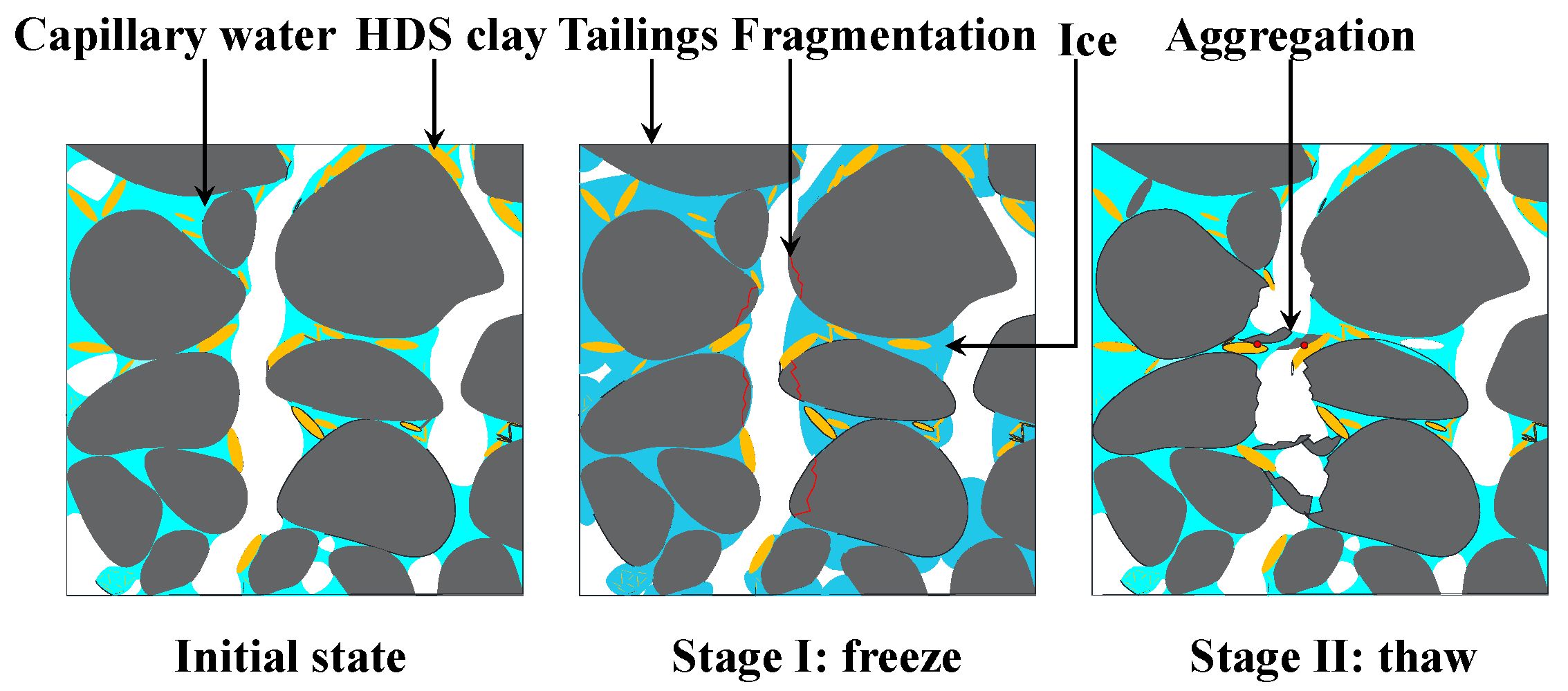

- For the changes in particle groups during freeze–thaw cycles, the fractions of clay and silt initially increased by 1.7% and 1.1% after three cycles and then changed by less than ± 0.3% in the subsequent cycles. As shown in the XRD results, this is probably because minerals with low hardness and coarse grains (i.e., muscovite and calcite) were broken by ice lenses during the initial several tests.

- (2)

- Compared to the initial ksat (i.e., 3.8 × 10−6 m/s) of modified tailings, the value after three freeze–thaw cycles decreased by 77.6% and then remained nearly unchanged in subsequent cycles. This is attributed to the increased fine content caused by ice lenses during freeze–thaw cycles. In addition, the potential clogging of pore throats by these fines may further reduce ksat through the redistribution of capillary water upon thawing and the effect of stress (e.g., gravity and electrical forces).

- (3)

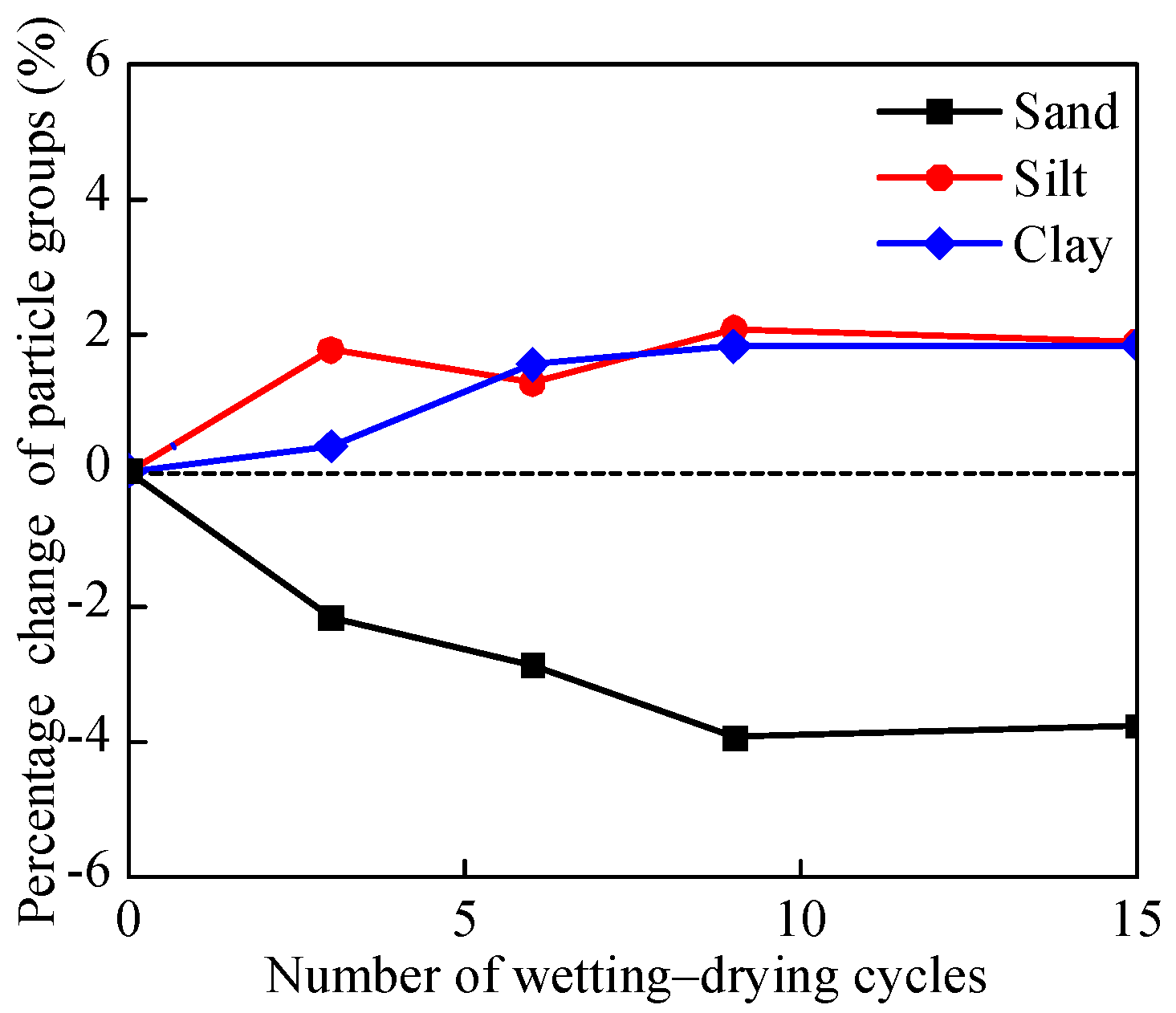

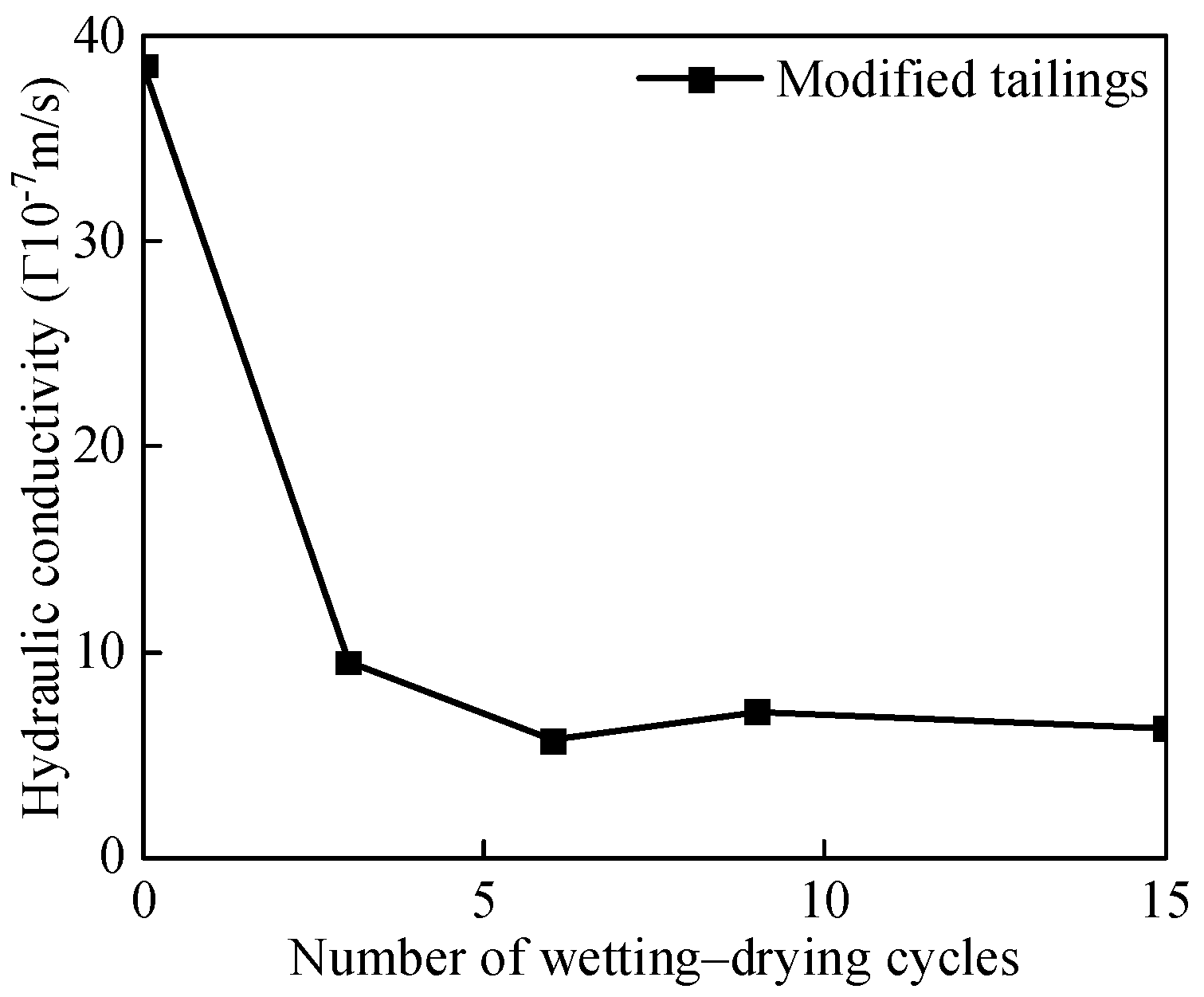

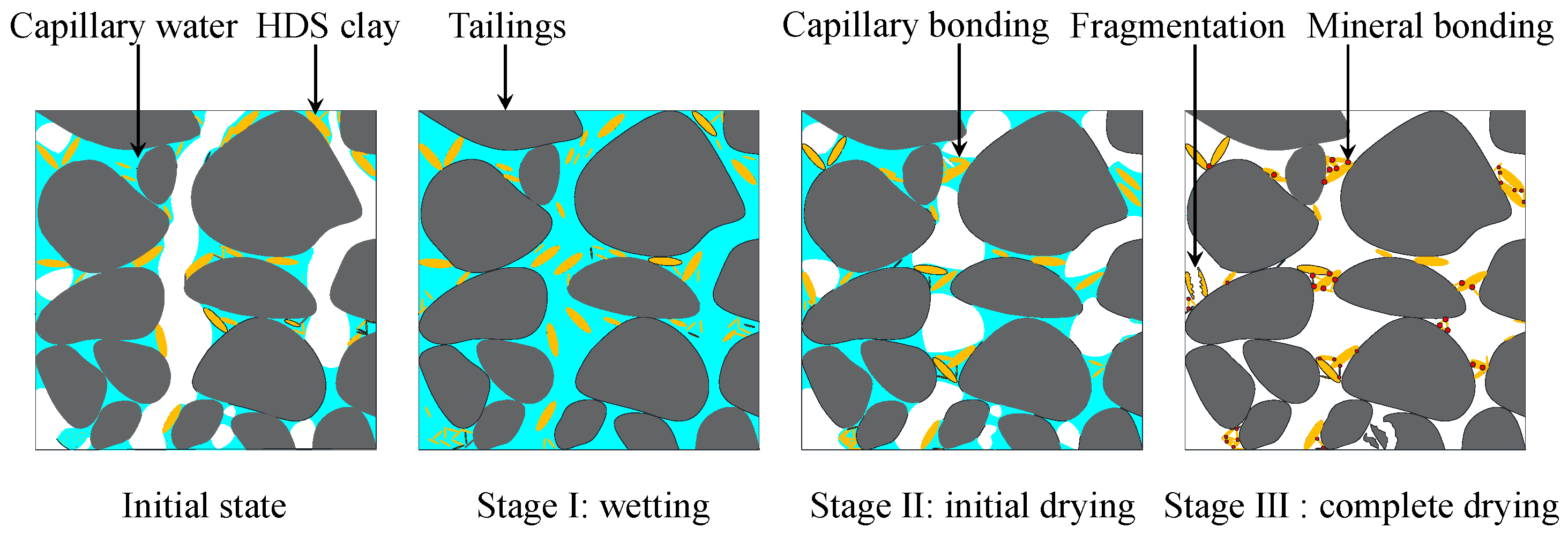

- For the wetting–drying cycles, the fraction changes in clay and silt gradually stabilized (i.e., 1.8% and 2.1%) until the ninth wetting–drying cycle. The stabilization of particle group changes induced by wetting–drying cycles took longer than those from freeze–thaw cycles, mainly because of the more complex physical processes of the former.

- (4)

- The ksat first decreased after three wetting–drying cycles (i.e., 3.9 × 10−6 m/s to 9.5 × 10−7 m/s) and then almost remained unchanged. The increase in fines and their preferential deposition near the pore throat area are certainly and possibly the governing mechanisms for this decreasing trend, respectively. Furthermore, the trends of ksat in wetting–drying cycles are similarly observed during freeze–thaw cycles, despite the longer stabilization process of particle groups for the former. This is probably because fragmentation is the main influencing factor for ksat, regardless of the type of cycle.

- (5)

- As another critical aspect of the present study, in further work, the water retention behavior of modified tailings will be investigated under different freeze–thaw cycles and wetting–drying cycles. The parameters of water retention curves (e.g., air–entry value and degree of hysteresis) will be discussed in detail.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhan, G.S.; Keller, J.; Milczarek, M.; Giraudo, J. 11 years of evapotranspiration cover performance at the AA leach pad at Barrick Goldstrike Mines. Mine Water Environ. 2014, 33, 195. [Google Scholar] [CrossRef]

- Bossé, B.; Bussière, B.; Hakkou, R.; Maqsoud, A.; Benzaazoua, M. Field experimental cells to assess hydrogeological behaviour of store-and-release covers made with phosphate mine waste. Can. Geotech. J. 2015, 52, 1255–1269. [Google Scholar] [CrossRef]

- Dong, Y.B.; Liu, Z.R.; Liu, W.; Lin, H. A new organosilane passivation agent prepared at ambient temperatures to inhibit pyrite oxidation for acid mine drainage control. J. Environ. Manag. 2022, 320, 115835. [Google Scholar] [CrossRef]

- Xia, L.X.; Chen, J.K.; Yang, Y.X.; Zhao, H.F.; Zhan, L.T.; Bate, B. Hydrogeochemical Responses of MTMS-Coated Capillary Cover Under Heavy Rainfalls. Sustainability 2023, 15, 6667. [Google Scholar] [CrossRef]

- Chen, J.K.; Xia, L.X.; Yang, Y.X.; Mulati, D.; Zhang, S.; Zhan, L.T.; Chen, Y.M.; Bate, B. Polymer-modified bentonites with low hydraulic conductivity and improved chemical compatibility as barriers for Cu2+ containment. Acta Geotech. 2023, 18, 1629–1649. [Google Scholar]

- Maqsoud, A.; Bussiere, B.; Aubertin, M.; Chouteau, M.; Mbonimpa, M. Field investigation of a suction break designed to control slope-induced desaturation in an oxygen barrier. Can. Geotech. J. 2022, 48, 53–71. [Google Scholar] [CrossRef]

- Harnas, F.R.; Rahardjo, H.; Leong, E.C.; Wang, J.Y. Experimental study on dual capillary barrier using recycled asphalt pavement materials. Can. Geotech. J. 2014, 51, 1165–1177. [Google Scholar] [CrossRef]

- Ng, C.W.; Coo, J.L.; Chen, Z.K.; Chen, R. Water infiltration into a new three-layer landfill cover system. J. Environ. Manag. 2016, 142, 04016007. [Google Scholar] [CrossRef]

- Zhan, L.T.; Li, G.Y.; Jiao, W.G.; Wu, T.; Lan, J.W.; Chen, Y.M. Field measurements of water storage capacity in a loess–gravel capillary barrier cover using rainfall simulation tests. Can. Geotech. J. 2017, 54, 1523–1536. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Guo, H.W.; Ni, J.J.; Chen, R.; Xue, Q.; Zhang, Y.M.; Feng, Y.; Chen, Z.K.; Feng, S.; Zhang, Q. Long-term field performance of non-vegetated and vegetated three-layer landfill cover systems using construction waste without geomembrane. Géotechnique 2022, 74, 155–173. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Dong, H.; Liao, H.J.; Zhou, C.; Li, S.B.; Zhang, J.W. Effects of in situ wetting–drying cycles on the mechanical behaviour of an intact loess. Can. Geotech. J. 2022, 59, 1281–1284. [Google Scholar] [CrossRef]

- Azizi, A.; Musso, G.; Jommi, C. Effects of repeated hydraulic loads on microstructure and hydraulic behaviour of a compacted clayey silt. Can. Geotech. J. 2020, 57, 100–114. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Meng, L.L.; Shen, Y.Q.; Zhou, C.; Gu, Z.L. Effects of clay content on the desiccation cracking behavior of low-plasticity soils. Bull. Eng. Geol. Environ. 2023, 82, 317. [Google Scholar] [CrossRef]

- Kim, W.H.; Daniel, D.E. Effects of freezing on hydraulic conductivity of compacted clay. J. Geotech. Geoenviron. 1992, 118, 1083–1097. [Google Scholar] [CrossRef]

- Albrecht, B.A.; Benson, C.H. Effect of desiccation on compacted natural clays. J. Geotech. Geoenviron. 2001, 127, 67–75. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Wong, H.N.; Tse, Y.M.; Pappin, J.W.; Sun, H.W.; Millis, S.W.; Leung, A.K. A field study of stress-dependent soil–water characteristic curves and permeability of a saprolitic slope in Hong Kong. Geotechnique 2011, 61, 511–521. [Google Scholar] [CrossRef]

- Tang, Y.Q.; Yan, J.J. Effect of freeze–thaw on hydraulic conductivity and microstructure of soft soil in Shanghai area. Environ. Earth Sci. 2015, 73, 7679–7690. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Julina, M. Effect of pore fluid and wet-dry cycles on structure and hydraulic conductivity of clay. Geotech. Lett. 2019, 9, 348–354. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.F.; Wang, B.; Wang, Z.F.; Wang, S.H. Microstructure and Permeability of Bentonite-Modified Loess after Wetting–Drying Cycles. Int. J. Geomech. 2023, 23, 04023052. [Google Scholar] [CrossRef]

- Shen, J.J.; Wang, Q.; Chen, Y.T.; Han, Y.; Zhang, X.D.; Liu, Y.W. Evolution process of the microstructure of saline soil with different compaction degrees during freeze-thaw cycles. Eng. Geol. 2022, 304, 106699. [Google Scholar] [CrossRef]

- Smesrud, J.K.; Selker, J.S. Effect of soil-particle size contrast on capillary barrier performance. J. Geotech. Geoenviron. Eng. 2001, 127, 885–888. [Google Scholar] [CrossRef]

- Parent, S.-É.; Cabral, A. Design of inclined covers with capillary barrier effect. Geotech. Geol. Eng. 2006, 24, 689–710. [Google Scholar] [CrossRef]

- ASTM D4318-10; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D2487-11; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2011.

- Scarfone, R.; Wheeler, S.J.; Smith, C.C. Numerical modelling of the application of capillary barrier systems for prevention of rainfall-induced slope instability. Acta Geotech. 2023, 18, 355–378. [Google Scholar] [CrossRef]

- Zhang, G.P.; Germaine, J.T.; Martin, R.T.; Whittle, A.J. A simple sample-mounting method for random powder X-ray diffraction. Clays Clay Miner. 2003, 51, 218–225. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Liu, J.K.; Li, X.; Fang, J.H. Experimental study on the volume and strength change of an unsaturated silty clay upon freezing. Cold Reg. Sci. Technol. 2019, 157, 1–12. [Google Scholar] [CrossRef]

- Villagran, X.S.; Poch, R.M. A new form of needle-fiber calcite produced by physical weathering of shells. Geoderma 2014, 213, 173–177. [Google Scholar] [CrossRef]

- Wild, B.; Daval, D.; Guyot, F.; Knauss, K.G.; Pollet-Villard, M.; Imfeld, G. pH dependent control of feldspar dissolution rate by altered surface layers. Chem. Geol. 2016, 442, 148–159. [Google Scholar] [CrossRef]

- Garcia Giménez, R.; Vigil de la Villa, R.; González Martín, J.A. Characterization of loess in central Spain: A microstructural study. Environ. Earth Sci. 2012, 65, 2125–2137. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.Y.; Ma, F.L.; Wang, M.; Bai, X.H.; Zheng, Y.L.; Yin, H.; Zhang, G.P. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef]

- Yao, G.; Zang, H.; Wang, J.X.; Wu, P.; Qiu, J.; Lyu, X.J. Effect of mechanical activation on the pozzolanic activity of muscovite. Clays Clay Miner. 2019, 67, 209–216. [Google Scholar] [CrossRef]

- Zhai, J.B.; Zhang, Z.; Melnikov, A.; Zhang, M.Y.; Yang, L.Z.; Jin, D.D. Experimental study on the effect of freeze-thaw cycles on the mineral particle fragmentation and aggregation with different soil types. Minerals 2021, 11, 913. [Google Scholar] [CrossRef]

- Zhou, W.; Cheng, J.L.; Zhang, G.K.; Li, H.B.; Cheng, Y.G.; Ma, G.; Ji, X. Effects of wetting–drying cycles on the breakage characteristics of slate rock grains. Rock Mech. Rock Eng. 2021, 54, 6323–6337. [Google Scholar] [CrossRef]

- Li, X.M.; Di, S.J.; Shi, L.; Zhang, Y.; Huang, P.; Mu, Q.Y. Effects of in-situ drying–wetting cycles on the stress-dependent water retention behavior of intact loess. Adv. Civ. Eng. 2023, 2023, 2994986. [Google Scholar] [CrossRef]

- Khanlari, G.; Abdilor, Y. Influence of wet–dry, freeze–thaw, and heat–cool cycles on the physical and mechanical properties of Upper Red sandstones in central Iran. Bull. Eng. Geol. Environ. 2015, 74, 1287–1300. [Google Scholar] [CrossRef]

- Xu, W.S.; Li, K.S.; Chen, L.X.; Kong, W.H.; Liu, C.X. The impacts of freeze–thaw cycles on saturated hydraulic conductivity and microstructure of saline–alkali soils. Sci. Rep. 2021, 11, 18655. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.T.; Han, Z.; Zou, W.L.; Wang, X.Q. Evolution of mechanical behaviours of an expansive soil during drying-wetting, freeze–thaw, and drying-wetting-freeze–thaw cycles. Bull. Eng. Geol. Environ. 2021, 80, 8109–8121. [Google Scholar] [CrossRef]

- Eigenbrod, K.D. Effects of cyclic freezing and thawing on volume changes and permeabilities of soft fine-gained soils. Can. Geotech. J. 1996, 33, 529–537. [Google Scholar] [CrossRef]

- Liu, P.F.; Nie, S.K.; Wang, W.Y.; Zhang, S.; Bate, B.; Chen, Y. CFD-DEM study on transport and retention behaviors of nZVI-clay colloids in porous media. J. Hazard. Mater. 2023, 465, 133048. [Google Scholar] [CrossRef]

- Valdes, J.R.; Santamarina, J.C. Particle clogging in radial flow: Microscale mechanisms. Spe J. 2006, 11, 193–198. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, B.; Santamarina, J.C. Particle migration and clogging in porous media: A convergent flow microfluidics study. J. Geophys. Res. Solid Earth. 2019, 124, 9495–9504. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Dong, H.; Liao, H.J.; Dang, Y.J.; Zhou, C. Water-retention curves of loess under wetting−drying cycles. Geotech. Lett. 2020, 10, 135–140. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Peprah-Manu, D. Pore structure effects on the water retention behaviour of a compacted silty sand soil subjected to drying-wetting cycles. Eng. Geol. 2023, 313, 106963. [Google Scholar] [CrossRef]

- Zhao, G.T.; Zou, W.L.; Han, Z.; Wang, D.X.; Wang, X.Q. Evolution of soil-water and shrinkage characteristics of an expansive clay during freeze-thaw and drying-wetting cycles. Cold Reg. Sci. Technol. 2021, 186, 103275. [Google Scholar] [CrossRef]

| References | Layer Thickness (m) | |

|---|---|---|

| Fine–Grained Layer | Coarse–Grained Layer | |

| Maqsoud et al. (2011) [6] | 0.8 | 0.2 |

| Harnas et al. (2014) [7] | 0.5 | 0.5 |

| Bossé et al. (2015) [2] | 0.5–1.0 | 0.3 |

| Ng et al. (2016) [8] | 0.4 | 0.2 |

| Zhan et al. (2017) [9] | 0.6 | 0.3 |

| Ng et al. (2022) [10] | 0.6 | 0.4 |

| Xia et al. (2023) [4] | 0.6 | 0.4 |

| Series | Test ID | Material Type | Initial State after Specimen Preparation | ||

|---|---|---|---|---|---|

| ρd (g/cm3) | w0 (%) | Sr0 (%) | |||

| I (Infiltration tests after freeze–thaw cycles) | FT–0 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 |

| FT–3 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| FT–6 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| FT–9 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| FT–15 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| II (Infiltration tests after wetting–drying cycles) | WD–0 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 |

| WD–3 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| WD–6 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| WD–9 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| WD–15 | Tailings/HDS clay (95:5) | 1.50 | 11.8 | 39.6 | |

| Parameter | Modified Tailings | Tailings | HDS Clay |

|---|---|---|---|

| pH | 6.7 | 6.7 | 7.9 |

| Specific gravity | 2.71 | 2.73 | 2.37 |

| Particle size distribution | |||

| Sand (0.075–4.75 mm, %) | 69.2 | 72.5 | 6.6 |

| Silt (0.005–0.075 mm, %) | 24.2 | 22.6 | 53.5 |

| Clay (≤0.005 mm, %) | 6.6 | 4.9 | 39.9 |

| Atterberg limits | |||

| Liquid limit (%) | 22.4 | 20.5 | 61.6 |

| Plastic limit (%) | 3.8 | 1.8 | 40.4 |

| Compaction parameters | |||

| Standard maximum dry density (g/cm3) | 1.73 | 1.77 | 1.16 |

| Optimum water content (%) | 13.9 | 12.4 | 47.5 |

| Unified soil classification (ASTM D 2487–11, 2011) | |||

| SM | SM | MH |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, L.; Xia, L.; Xia, M.; Nie, S.; Chen, J.; Wang, W.; Du, A.; Guo, H.; Bate, B. Effect of Freeze–Thaw and Wetting–Drying Cycles on the Hydraulic Conductivity of Modified Tailings. Geosciences 2024, 14, 93. https://doi.org/10.3390/geosciences14040093

Meng L, Xia L, Xia M, Nie S, Chen J, Wang W, Du A, Guo H, Bate B. Effect of Freeze–Thaw and Wetting–Drying Cycles on the Hydraulic Conductivity of Modified Tailings. Geosciences. 2024; 14(4):93. https://doi.org/10.3390/geosciences14040093

Chicago/Turabian StyleMeng, Longlong, Liangxiong Xia, Min Xia, Shaokai Nie, Jiakai Chen, Wenyuan Wang, Aifang Du, Haowen Guo, and Bate Bate. 2024. "Effect of Freeze–Thaw and Wetting–Drying Cycles on the Hydraulic Conductivity of Modified Tailings" Geosciences 14, no. 4: 93. https://doi.org/10.3390/geosciences14040093

APA StyleMeng, L., Xia, L., Xia, M., Nie, S., Chen, J., Wang, W., Du, A., Guo, H., & Bate, B. (2024). Effect of Freeze–Thaw and Wetting–Drying Cycles on the Hydraulic Conductivity of Modified Tailings. Geosciences, 14(4), 93. https://doi.org/10.3390/geosciences14040093