State-of-the-Art Review of Enzyme-Induced Calcite Precipitation (EICP) for Ground Improvement: Applications and Prospects

Abstract

:1. Introduction

2. Bio-Mineralization via Enzyme Induced Carbonate Precipitation (EICP)

2.1. Development of EICP Technique

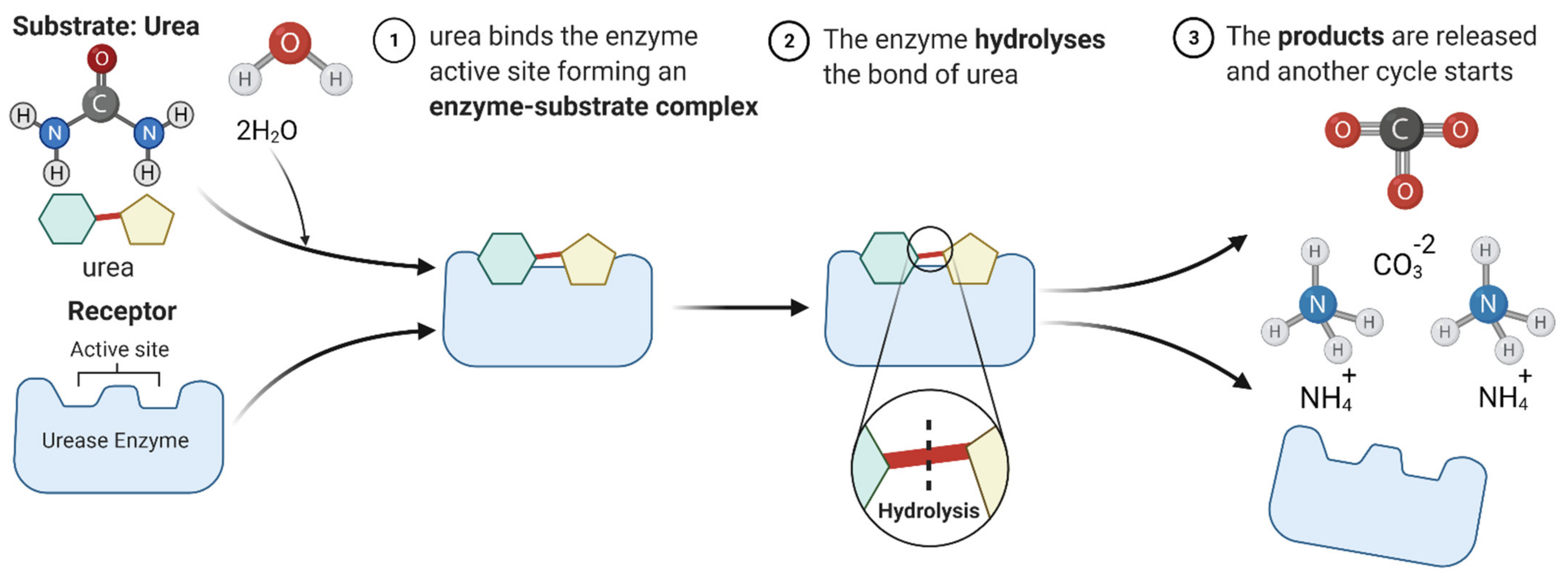

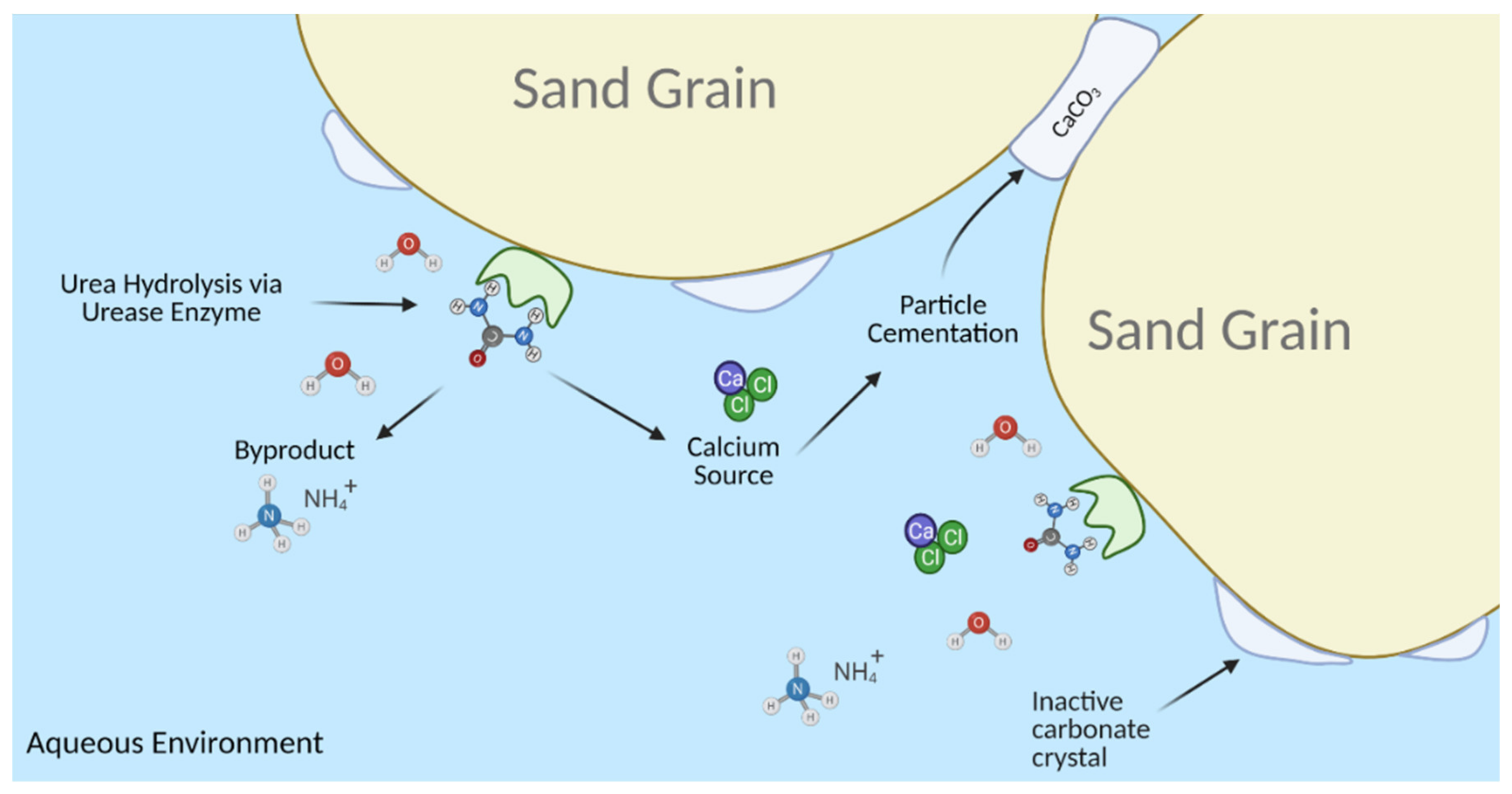

2.2. EICP Overview

Urease Enzyme Source

3. Factors Affecting Carbonate Crystallization in EICP Treatment

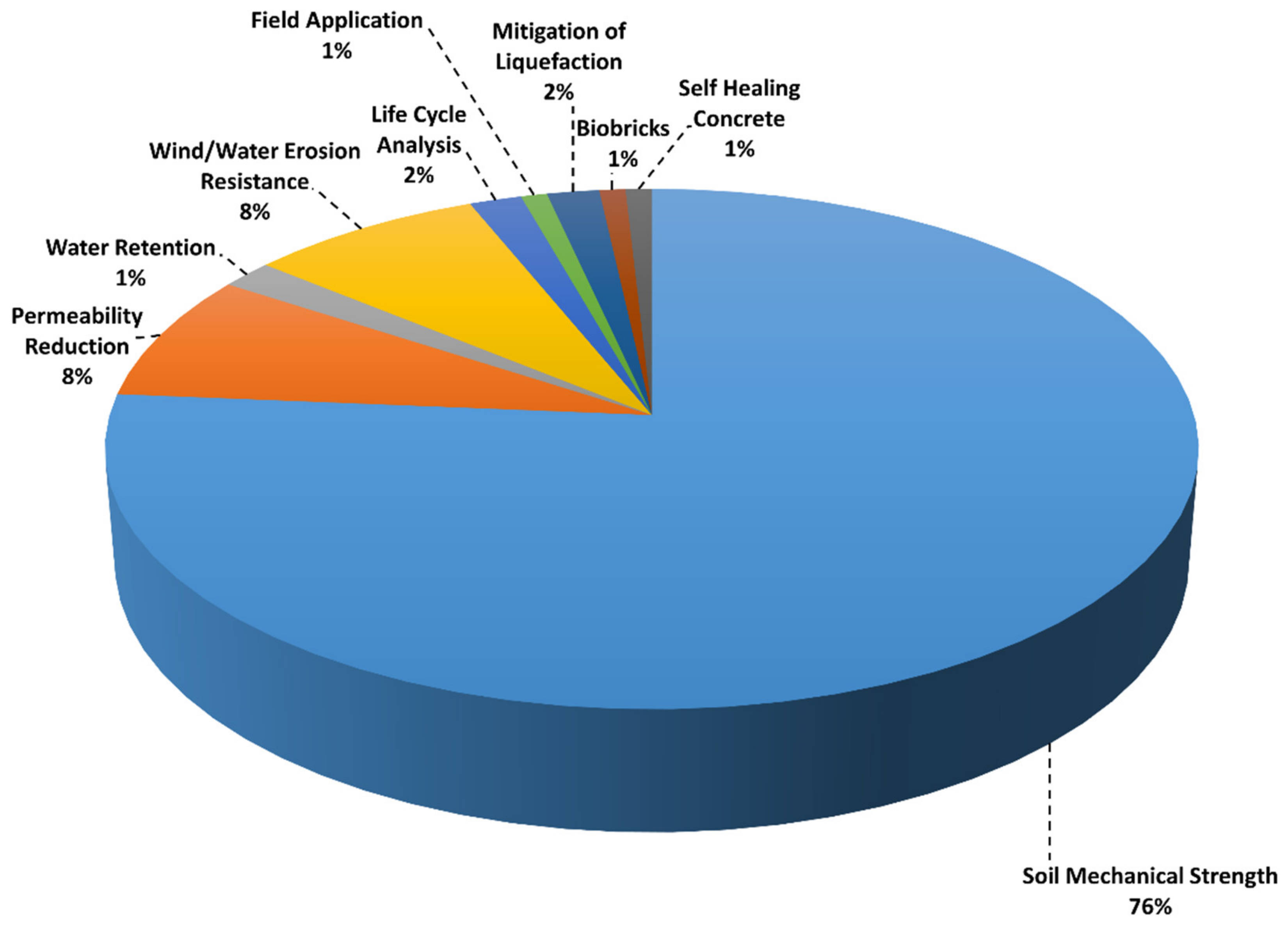

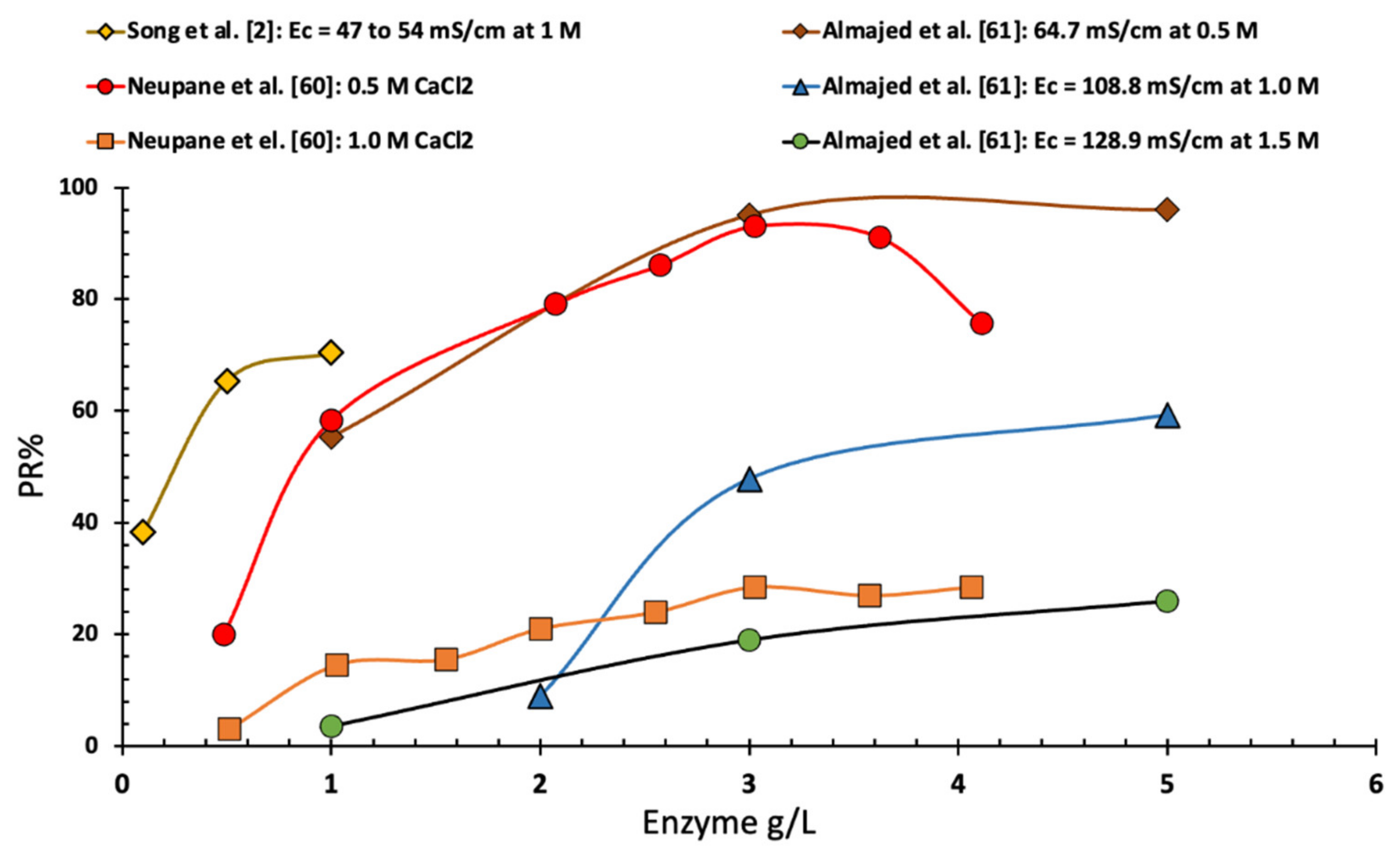

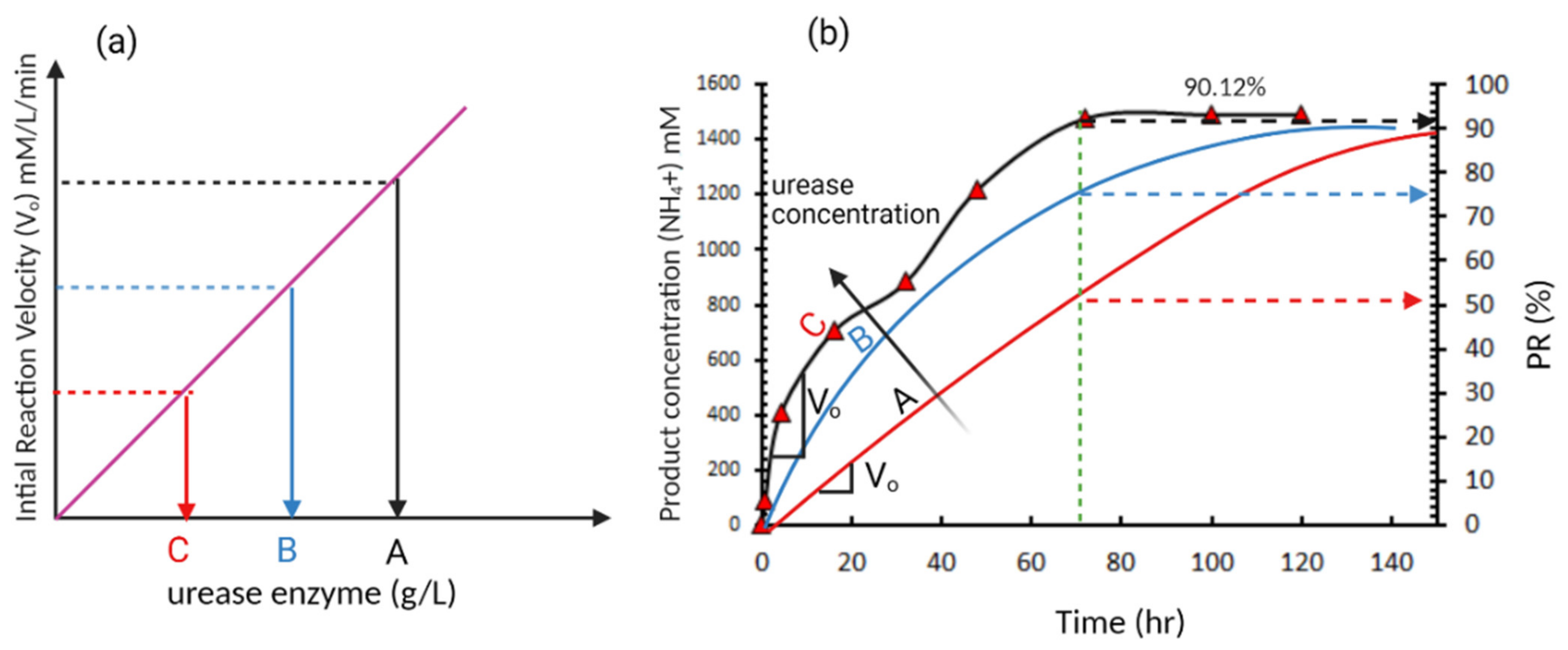

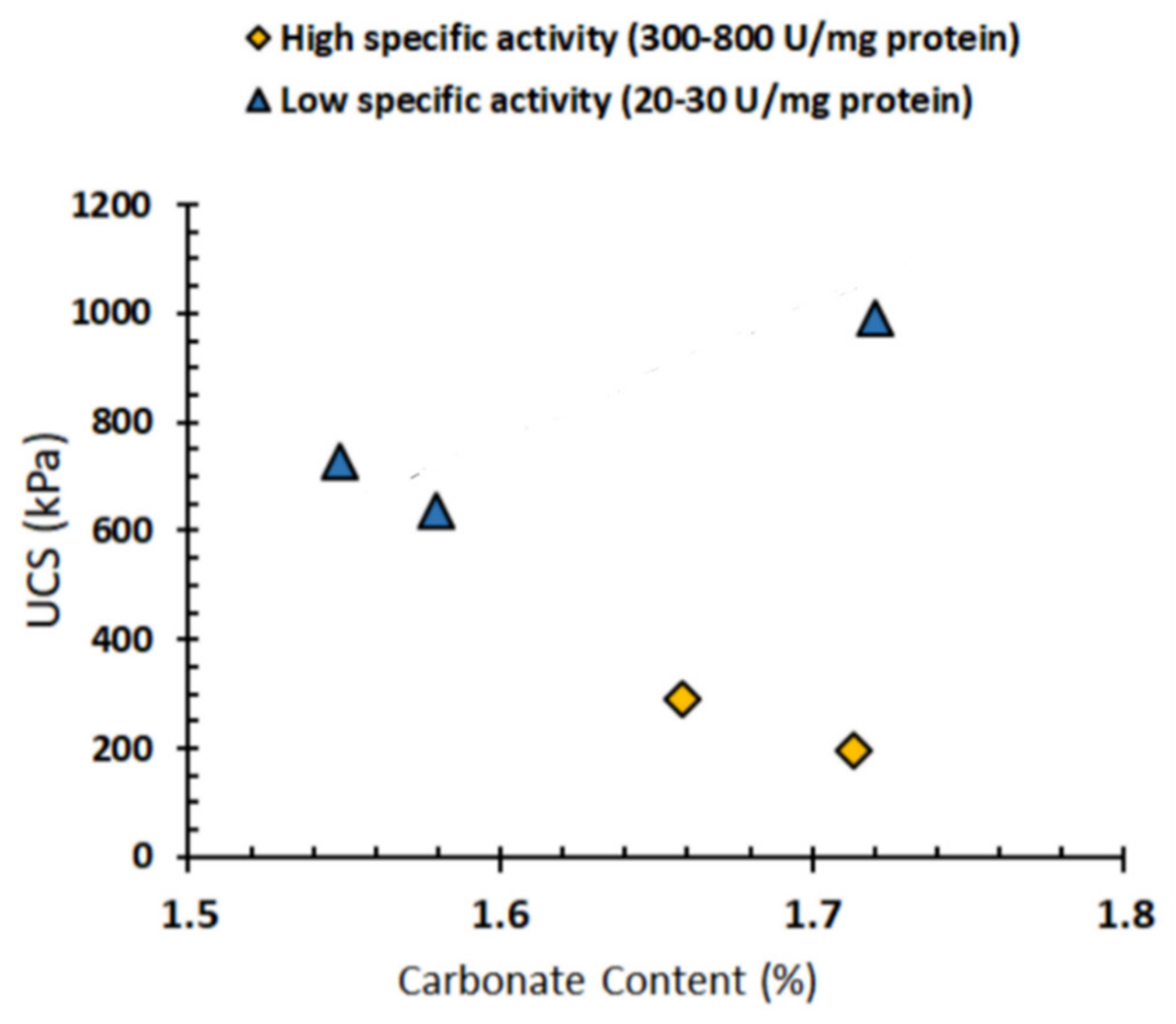

3.1. Effect of Urease Enzyme Activity and Concentration

3.2. Chemical Constituents Concentrations

3.3. Temperature

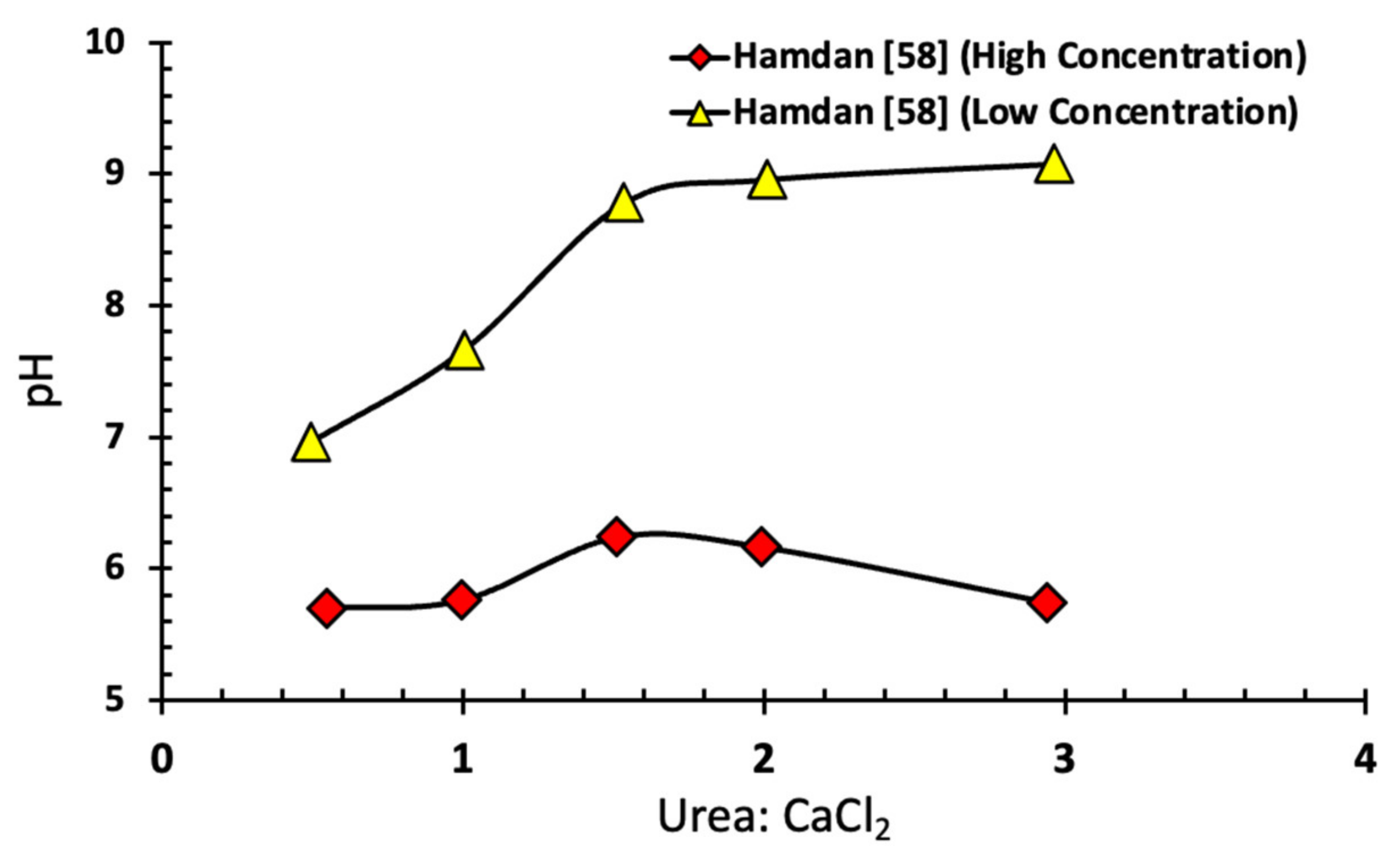

3.4. pH Level

4. Soil Cementation via EICP

4.1. Application Methods

4.1.1. Injection Method

4.1.2. Mix and Compact

4.1.3. Surface Percolation

4.1.4. Spraying

5. Geotechnical Properties of EICP Treated Soils

5.1. Hydraulic Conductivity

5.2. Treated Soil Strength

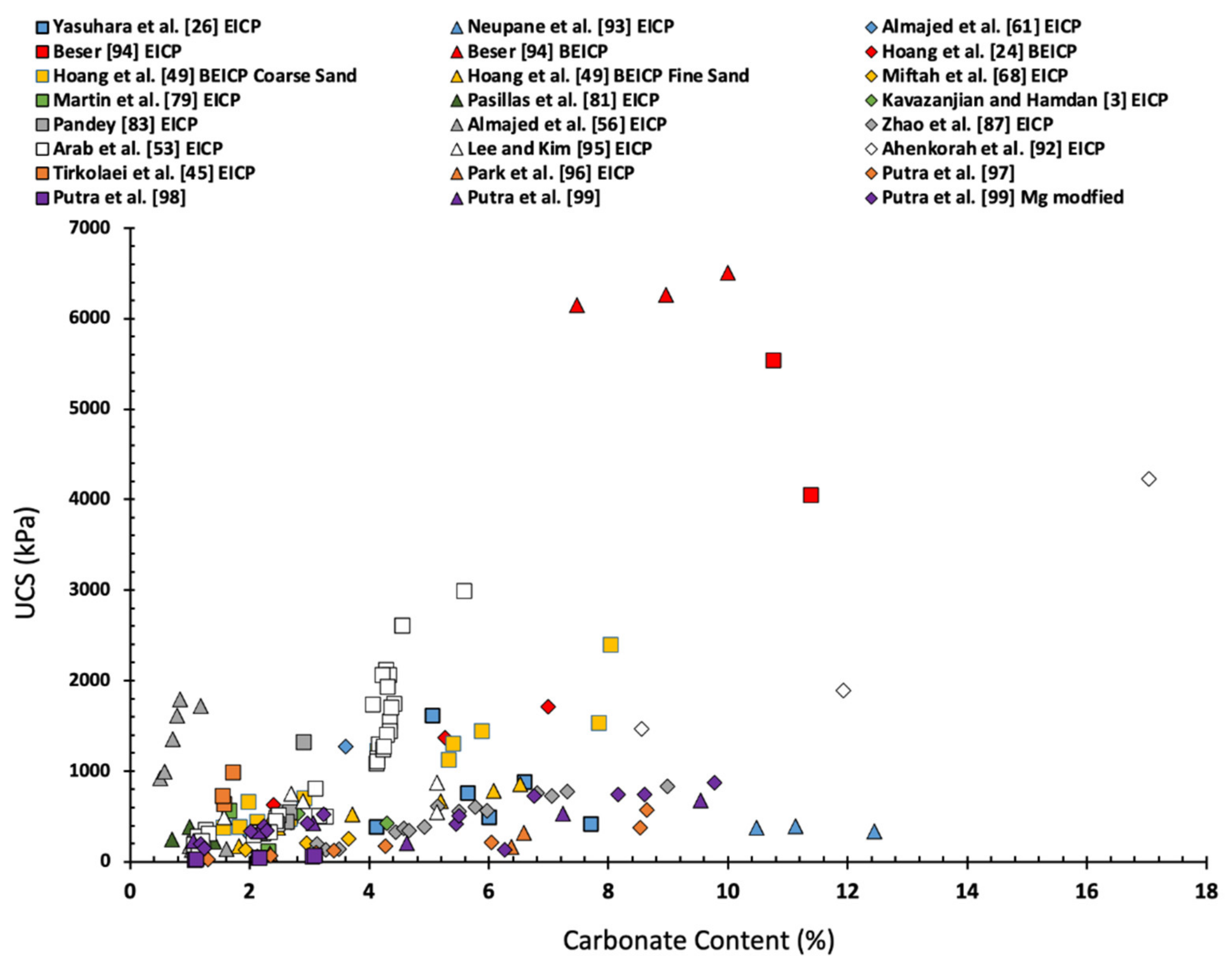

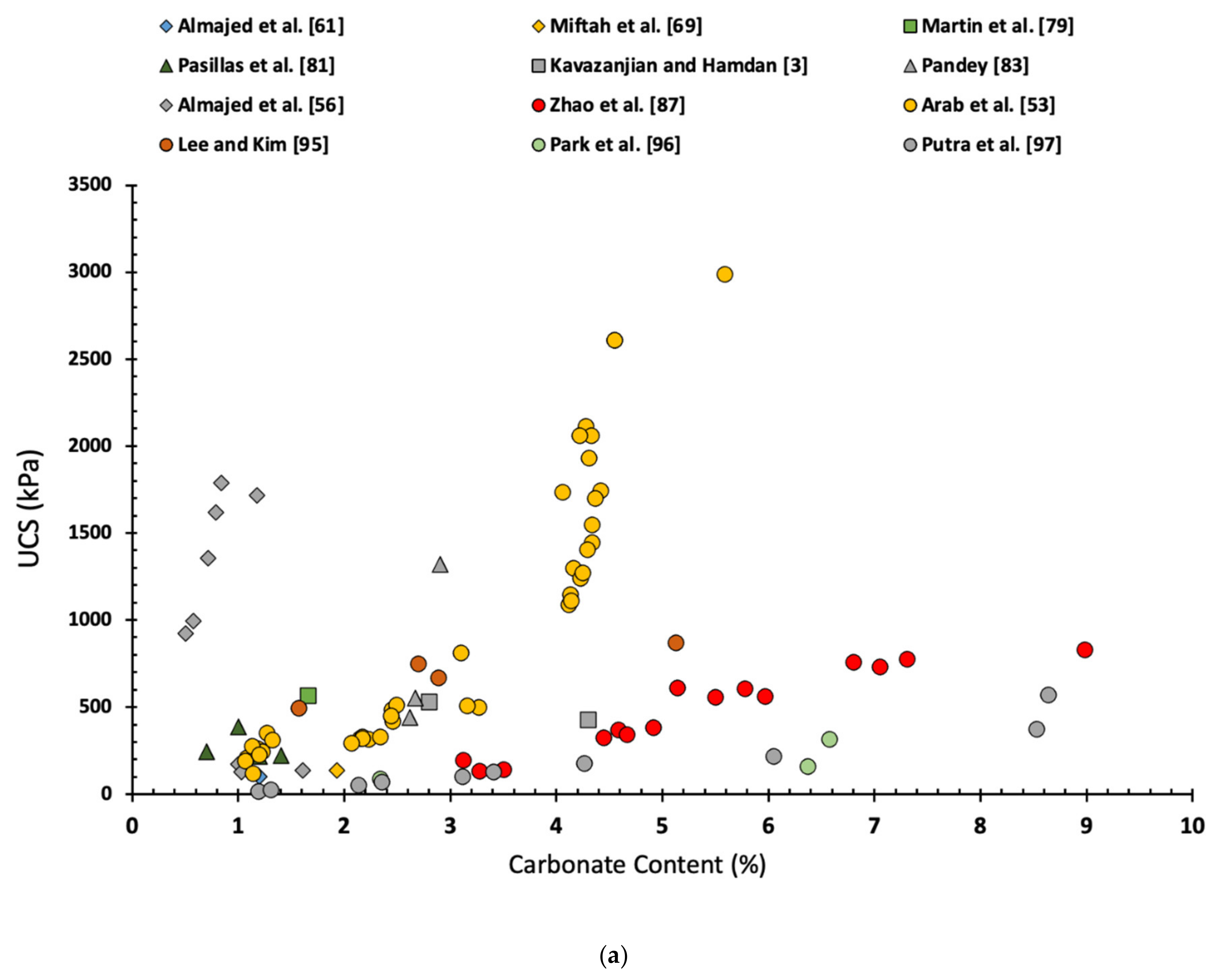

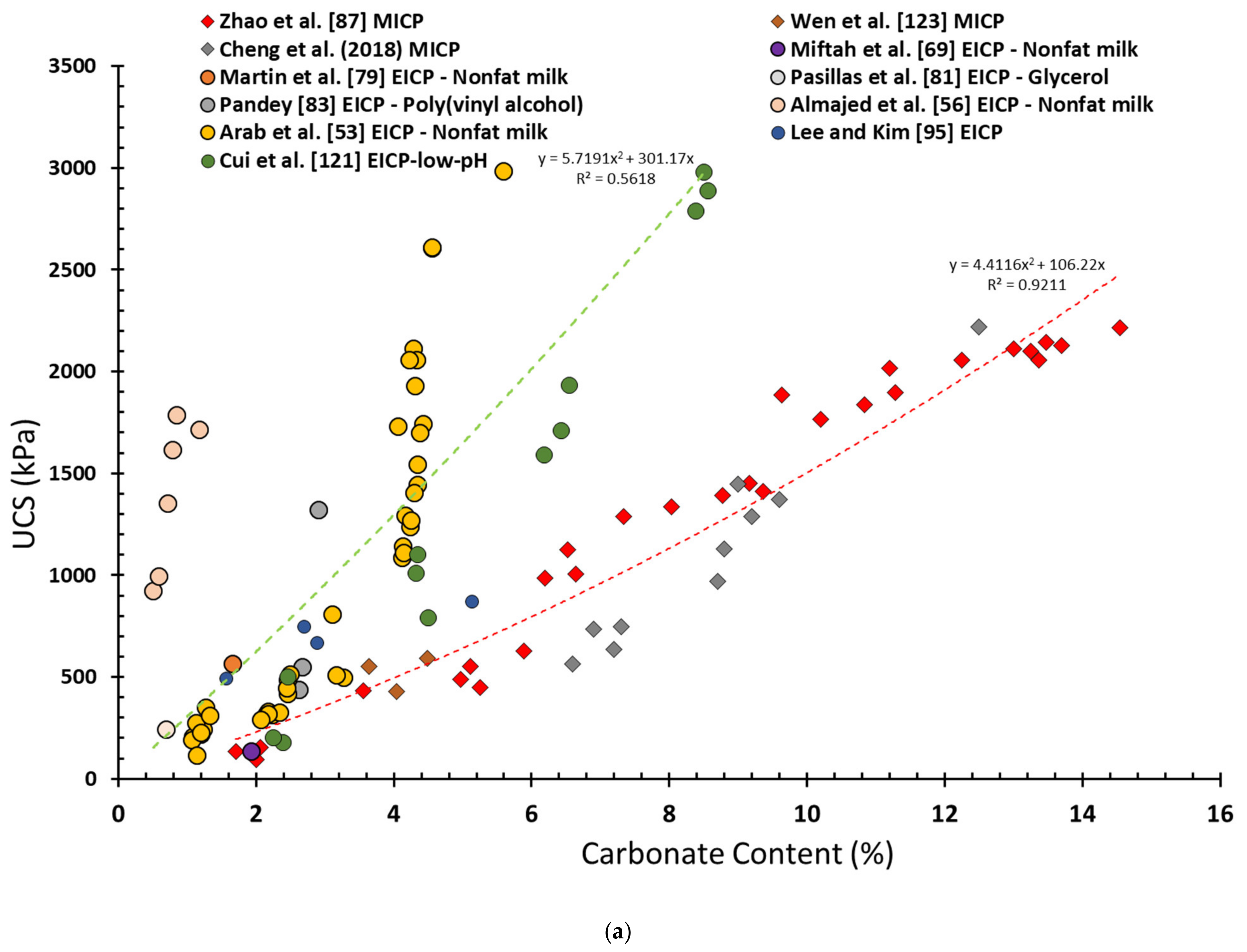

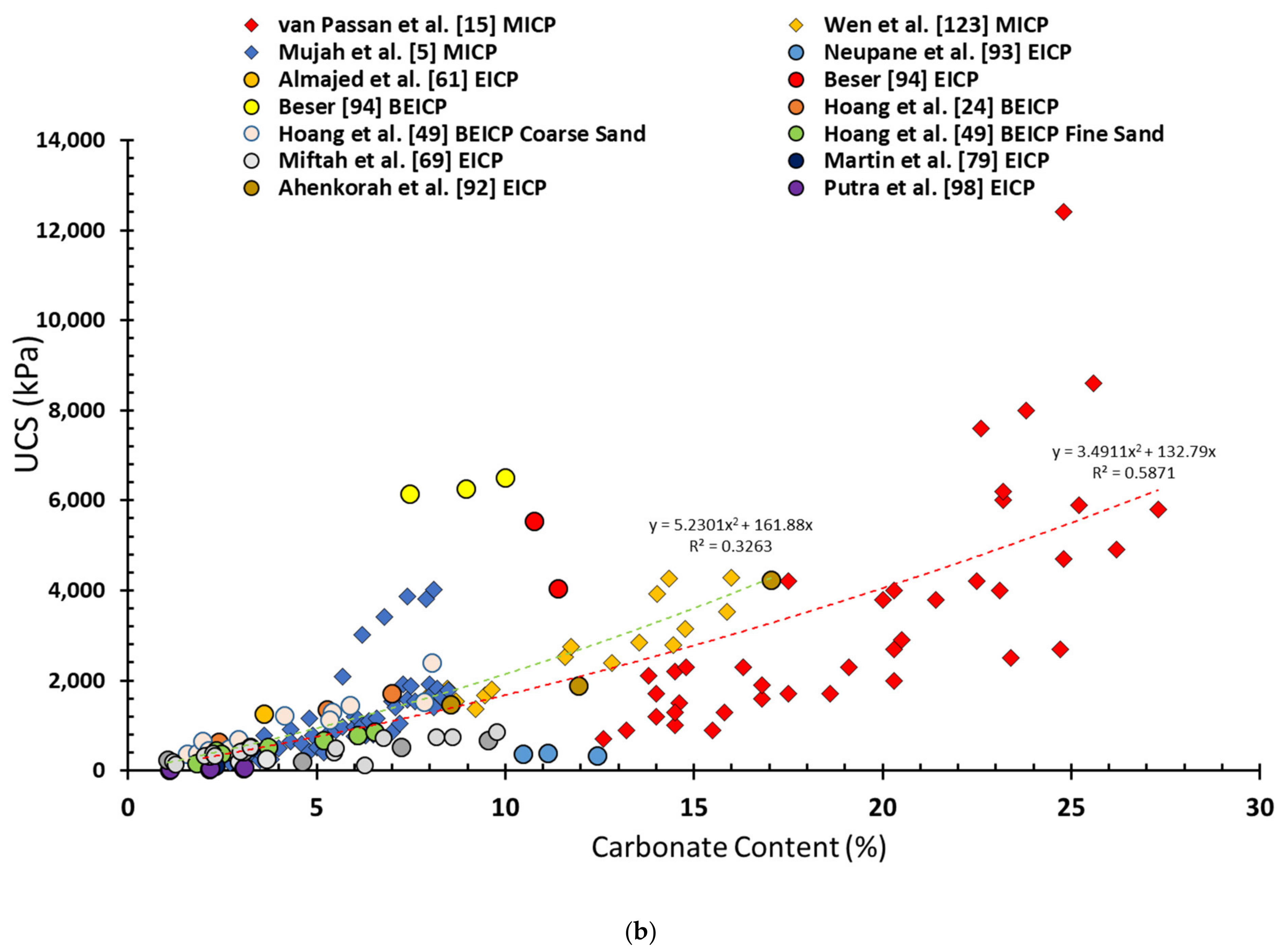

5.2.1. Unconfined Compressive Strength (UCS)

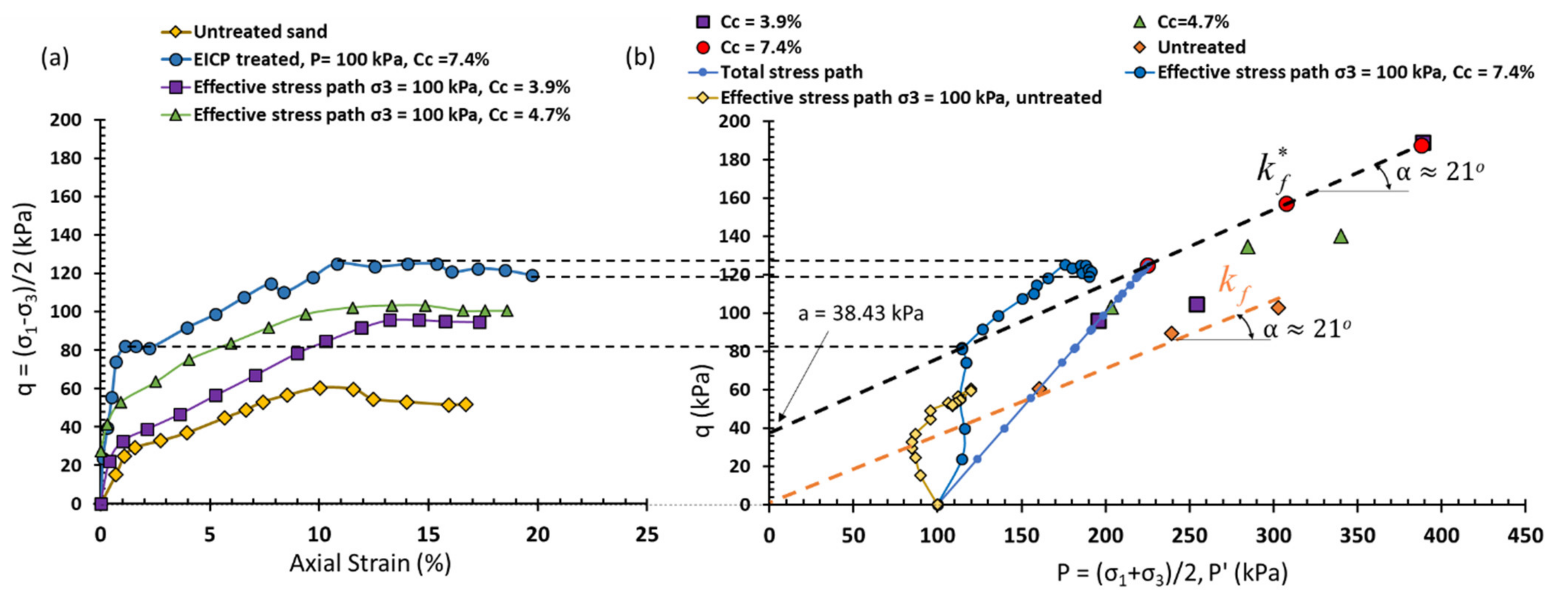

5.2.2. Triaxial Shear Test

5.2.3. Direct Shear Test

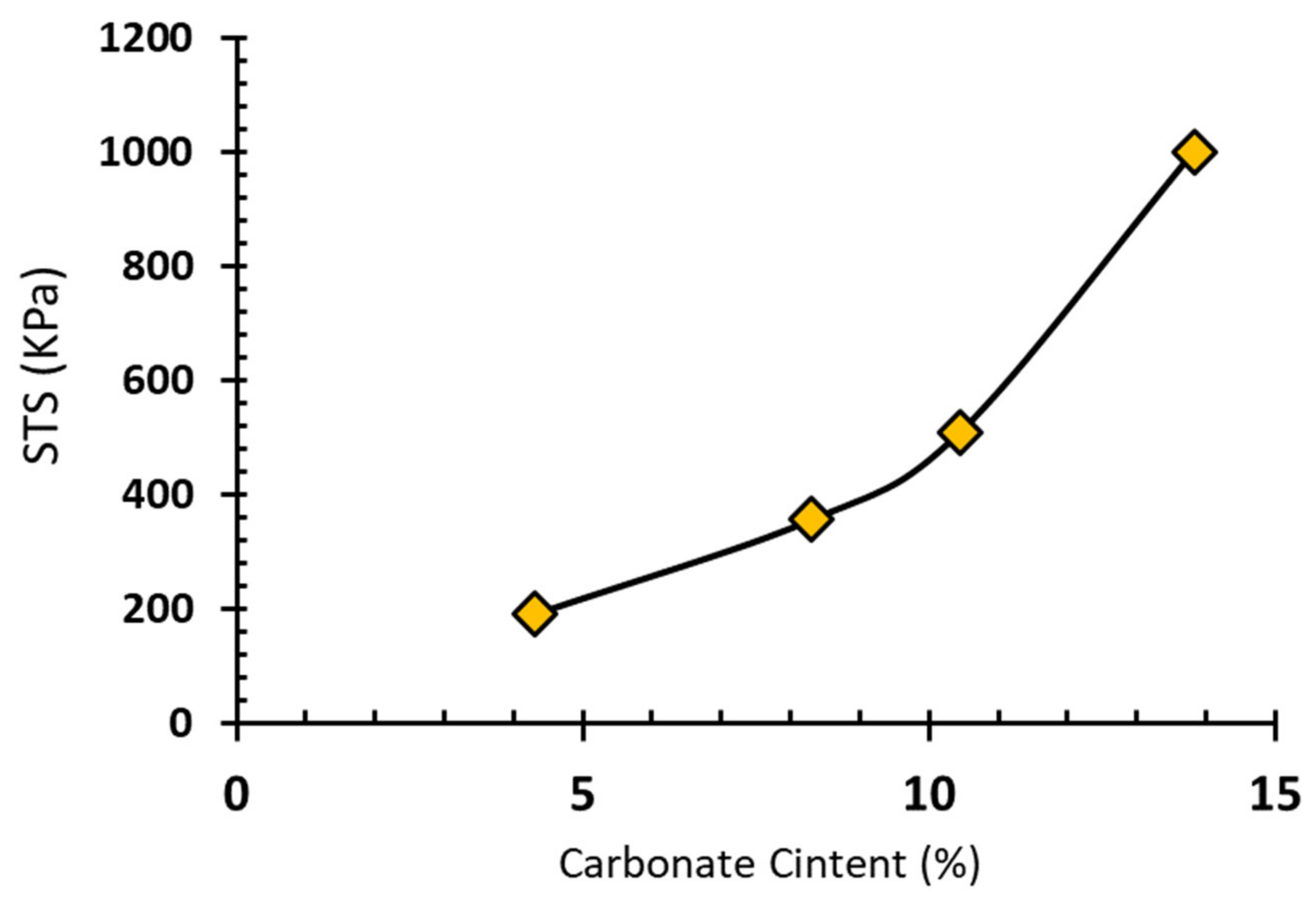

5.2.4. Splitting Tensile Strength (STS) and Flexural Strength

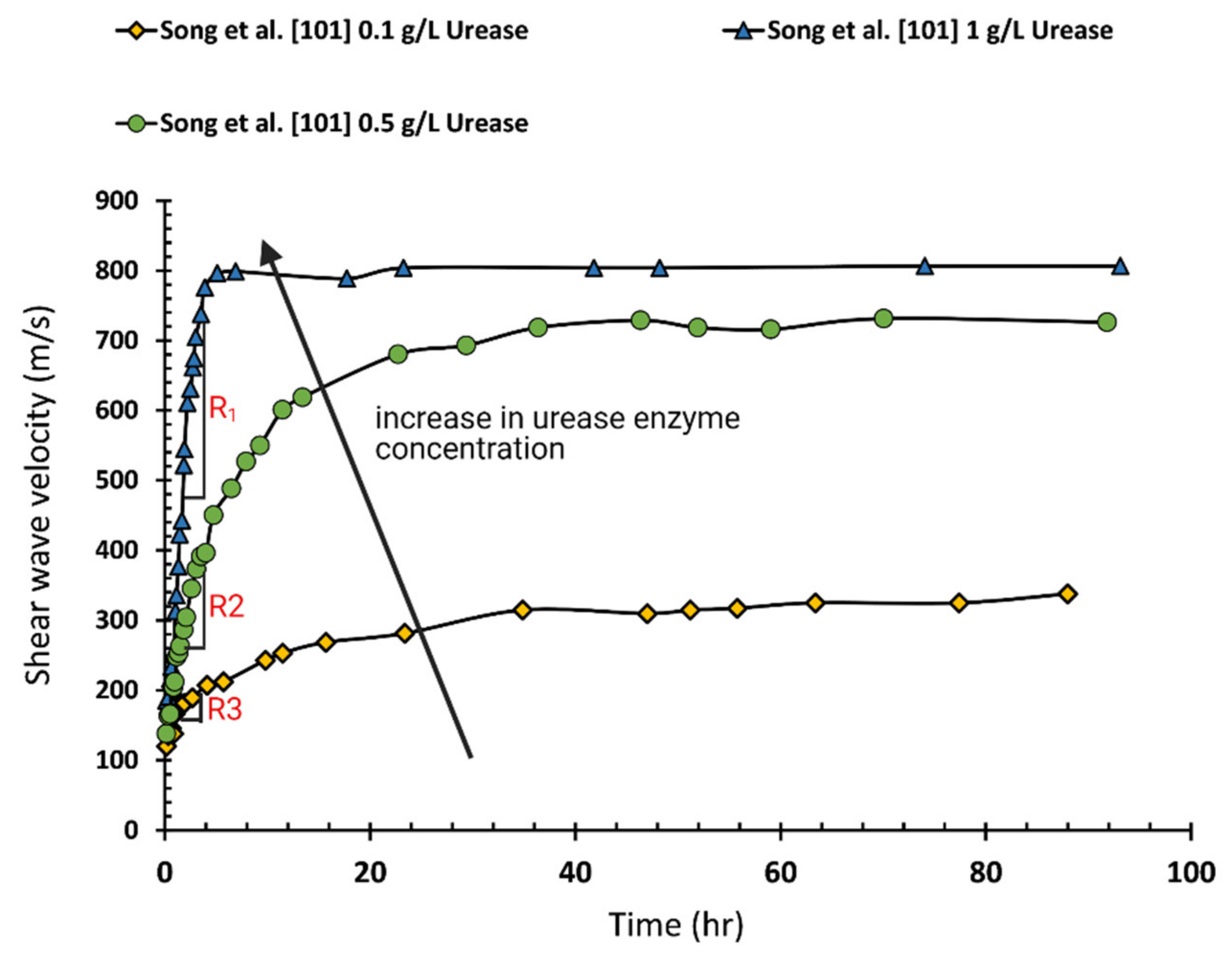

5.2.5. Shear Wave Velocity

6. Main Factors Affect EICP Treated Soil Properties

6.1. Effect of Soil Particle Shape and Particle Size Distribution

6.2. Effect of Soil Type

6.3. Nucleation Sites for Carbonate Precipitation

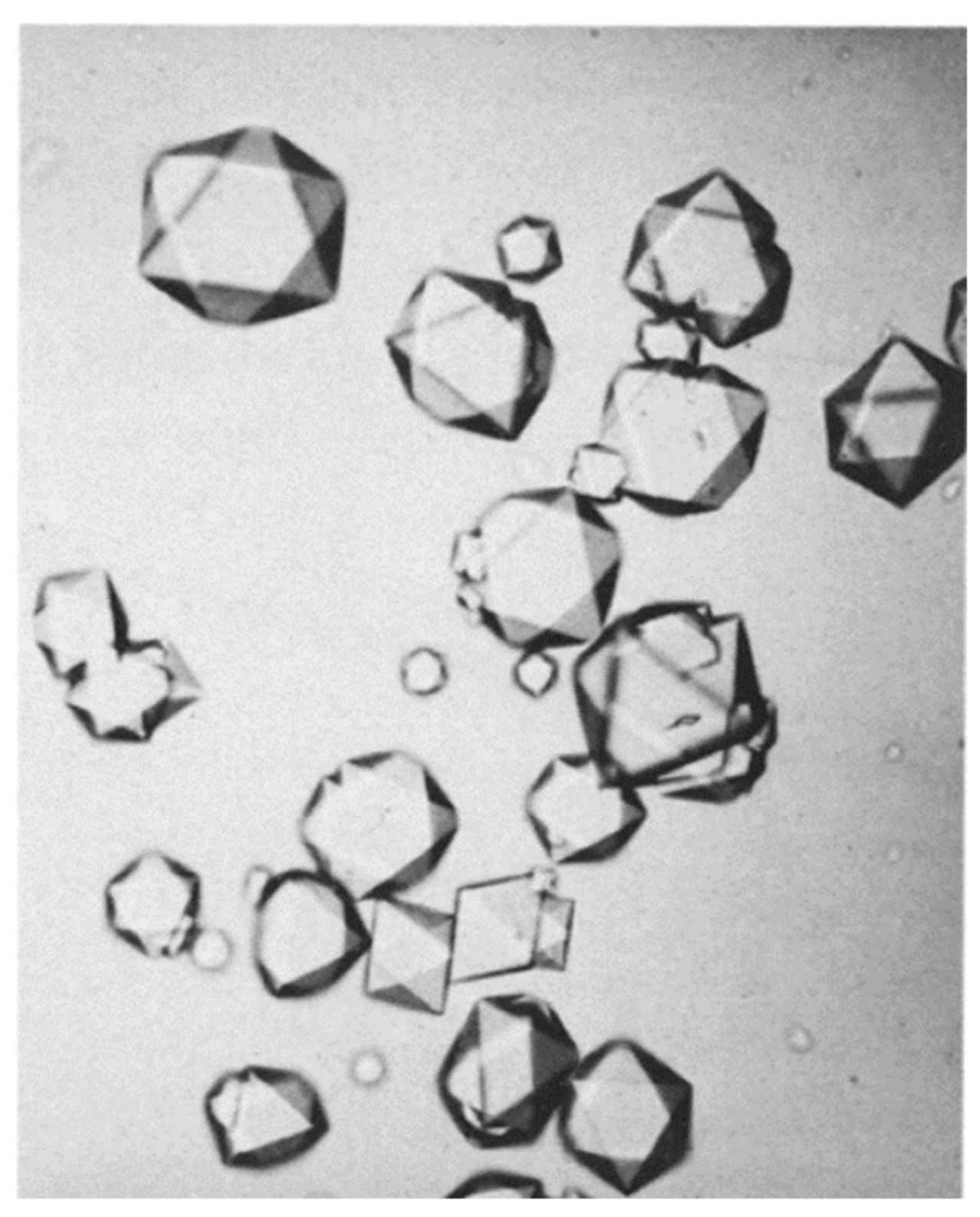

6.4. Carbonate Crystals Morphology

7. Comparison between EICP and MICP

8. Envisioned Applications of Soil Bio-Cementation via EICP

8.1. Advantages of EICP for Soil Improvement

- EICP can promote sustainability and provide a product that has a less harmful impact on the environment than other conventional methods. When compared to Ordinary Portland Cement (OPC), carbonate cementation can replace OPC for a variety of ground improvement applications while reducing carbon dioxide emissions. EICP is likely a less energy-extensive solution than OPC.

- Urease used in EICP is a powder-like material that is soluble in water with a size of around 12 nm per subunit, which facilitates penetration into fine-grained soils [19].

- Using a free urease enzyme to hydrolyse urea eliminates some of the complications and restrictions related to the microbial technique. Some of these restrictions include microbial cell transport in soil, oxygen availability for deep soil treatment (for bio-stimulation), the need to provide nutrients for bacterial activity, and interaction with other microorganisms. These restrictions can be easily avoided when employing a free urease enzyme for the process of hydrolysis [19,122].

- Another potential benefit of EICP is that it can be transported to the site as a dry powder without any strict measures regarding temperature or handling. However, in the case of MICP, If the bacteria are grown off-site, they would have to be transported as a liquid or slurry (probably refrigerated), which would increase the cost. Even if ureolytic bacteria are cultivated on-site, custom-built tools and reactors have to be utilized [125].

- EICP is a flexible treatment that can be adjusted for many engineering applications, as mentioned earlier. A slight change in the mixture and concentration of the solution can give a different response in terms of shear strength, permeability, and shear wave velocity [121].

8.2. Challenges of EICP for Soil Bio-Cementation

- Environmental concerns regarding the contamination of groundwater caused by the production of ammonium chloride (NH4Cl) as a by-product of the EICP process. Ammonium is potentially harmful and has a strong odour and can endanger the water supplies [29,126]. Furthermore, the choice to flush the ammonium from the soil is likely to be uneconomical [19,31]. To solve this problem, it was suggested to treat the cementation solution from ammonia-rich effluent before discharge and then back-feed the ammonia as a fertilizer to the surrounding plants [17]. Zehner et al. [115] successfully utilized crushed industrial quality limestone as a source of calcium instead of CaCl2. This process eliminated the production of chloride salts that may pollute water and lead to steel corrosion. However, this issue is still under investigation and considered one of the major challenges that face the wide applications of these techniques in the field.

- The distribution and homogeneity of the EICP treatment should be addressed as well as the soil compatibility and particle size. Since the EICP solution is water-based with low viscosity, it is hard to control the treated soil mass. Attempts to increase the viscosity of the treatment solution using biopolymers or copolymers could be the solution to immobilize the treatment solution and enhance its distribution along the soil matrix [81]. It is also crucial to control the rate of precipitation to improve the spatial distribution of carbonate within the soil pores [122].

- Scale-up bio-cementation for field soil grouting applications is still under investigation. Few studies have investigated the use of industrial-grade economical chemical constituents for the use in the hydrolysis process [125,127]. Recently, Khodadadi et al. [45] have shown that crude extracted urease enzyme from jack beans through a simplified process that involves few steps that can be conducted in situ. The process was used for mid-scale EICP injection in the field in demonstration of the possibility of scaling the process up [115]. However, more economical strategies need to be developed to scale up the production of EICP for grouting in field applications.

- Replacing bacteria with free enzymes in EICP leads to the loss of nucleation sites and potentially fastens the decay of urease activity as the enzyme may break down easier when not protected by the bacterial cell wall. However, a recent study by Almajed et al. [56] reported that adding non-fat dry milk powder provides nucleation sites for the calcium carbonate and enhances the stability of the urease, which works as an alternative to the bacterial cell wall. It is believed the protein in the milk can bind the calcium ions in the EICP solution, resulting in aggregate calcite or precipitate that acts as a nucleation site for carbonate precipitation [128]. However, the effect of the protein in the EICP cementing solution needs further investigation.

- Long term durability of EICP treated soils needs further investigation. For example, Song et al. [129] studied the effect of loading cycles on the shear wave velocity of EICP treated soils. They concluded that the stiffness of EICP-treated soils degrades when stress increases beyond debonding stresses, and this stress threshold depends mainly on the void ratio. Additionally, the post erosion behaviour of EICP treated soil in light of available literature of the behaviour of untreated gap-graded sandy soil [130].

8.3. Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Application | Reference | EICP Cementing Solution | Soil Type | A Measure of Soil Improvement and General Remarks | |||

|---|---|---|---|---|---|---|---|

| Urea | CaCl2 | Jack Bean Urease | Additives | ||||

| Improve Soil Compressive Strength | Yasuhara et al. [26] | 0.5 and 1.0 mol/L | 0.5 and 1.0 mol/L | 0.5 and 1.0 g/300 g of sand (activity not reported) | - | Toyoura sand | UCS in the range 400 kPa to 1.6 MPa |

| Park et al. [96] | 5/50 to 25/50 g/mL | 10/50 g/mL Calcium Chloride, Calcium Hydroxide, or Calcium nitrate. | 0 to 25 mL Jack Bean extract | - | Local sand from Nakdong River | Achieved UCS ranging from 30 to 317 kPa | |

| Neupane et al. [60] | 1 mol/L | 1 mol/L | 15 g/L At 2970 units/g activity | - | Homogenous silica sand specimens | UCS of around 380 kPa | |

| Kavazanjian and Hamdan [3] | 1.38 M (mix and compact) 1.36 (injection) | 1.58 M (mix and compact) 0.765 (injection) | 0.40 g/L at 200 U/g activity (mix and compact) 0.44 g/L at 26,100 U/g activity (injection) | non-fat dry milk at 4.0 g/L | Ottawa 20/30 silica sand | UCS of 529 kPa at 0.8% axial strain and 425 kPa at 1.8% for mix and compact treatment | |

| Putra et al. [98] | 0.5 g/L | 0.5 g/L | 1 g/L | - | Keisa sand | Achieved UCS of 60 kPa at 3% carbonate precipitation | |

| Carmona et al. [62] | 0.25 to 1.25 M | 0.25 to 1.25 M | 0.12 g/L (4 kU/L) | - | Poorly graded sandy soil (ASTM D2487) | UCS of 140 kPa at 0.25 M solution | |

| Zhao et al. [74] | 1.5 M | 1 M | 0.450 mg/mL at activity of 15,000– 10,250,000 units/g) | 1 mL/mL of solution of polyacrylate gel | Ottawa F-60 | Hydrogel enhanced EICP was able to withstand up to 4.8 × 103 265 kPa | |

| Putra et al. [97] | 0.5 mol/L | 0.25 to 0.5 mol/L Calcium Chloride or 0 to 0.25 mol/L Magnesium Chloride | 1 g/L at Activity of 2950 U/g | - | Dry silica sand | Achieved 0.6 MPa at 8.3% of carbonate precipitation | |

| Putra et al. [99] | 0.5 and 1 mol/L | Mixtures of Calcium Chloride, Magnesium Chloride and Magnesium Sulfate at 0.04 to 1 mol/L | 1 or 2 g/L | - | Dry silica sand | Maximum UCS of 555 kPa was achieved at 10% carbonate precipitation | |

| Oliveira et al. [113] | 0.25 to 0.5 M | 0.25 to 0.5 M | 4 kU/L to 8 kU/L of activity 34,310 U/g | - | Sandy, silty, and organic soils | Strength gain: sandy soil (25 kPa), silty soil (250 kPa), organic soil (50 kPa) | |

| Almajed [44] | 0.875, 1.75 and 2.65 M | 0.5, 1 and 1.5 M | 0.85 g/L at activity of ≈ 1500–2500 U/g | 1.1% xanthan gum (w/w%) of sand and 4.0 g/L of dry nonfat milk | Ottawa 20/30 silica sand | The addition of xanthan gum resulted in UCS of 1461 kPa when mixed with a powder with the soil | |

| Almajed [61] | 1 M | 0.67 M | 3 g/L at activity of 3500 U/g) | - | Ottawa 20/30 sand | UCS of 1268 kPa after 4 cycles of treatment | |

| Chandra & Ravi [70] | 0.5 mol/L | 0.5 mol/L | 8 kU/L at activity of 40,150 U/g | - | silty sand (SM), clayey sand (SC), and silt (ML) | SM & ML achieved UCS of around (200 kPa), SC achieved UCS of (400 kPa) | |

| Beser [94] | 20 g/L | 49 g/L | 5 g/L (activity not reported) | - | 2095 granular silica sand | EICP achieved 66% and 77% UCS of the 28-day well cement and Type I cement mortars | |

| Almajed et al. [100] | 0.5 M | 0.875 M | 0.85 g/L at Activity of 3500 U/g | - | Ottawa 20/30 sand | UCS in the range of 25 kPa to 296 kPa when sisal fiber was mixed with soil | |

| Pasillas et al. [81] | 1 M | 0.67 M | 3 g/L (activity not reported) | Glycerol 50% (v/v) xanthan gum 0.25% (w/v) | Ottawa 20/30 and F-85 sands | The addition of xanthan gum reduces UCS by 25%. While glycerol does not produce an intact sample | |

| Beser [94] | 20 g/L | 49 g/L | 5 g/L (activity not reported) | 0.2% FORTA super-sweep fine fiber or 3 g/L nutrient broth | 2095 Granusil silica sand | addition of nutrient broth to the EICP samples increased UCS from 2 to 6 MPa while the addition of fiber does not have a significant effect | |

| Hoang et al. [24] | 0.3 M | 0.3 M | Bacterial enzyme specified by activity only (4–5 mM urea/min) | - | Ottawa 20/30 silica sand | Achieved an unconfined compressive strength of 1691 kPa using bacterially derived urease for EICP | |

| Pandey [83] | 60 g/L | 111 g/L | 5 g/L at activity of 678.70 μM urea/min | 7.5% (w/w) PVA | Ottawa graded sand Additionally, Recycled glass particles | EICP for 100% Ottawa graded sand results in 192 psi. Adding 20% of recycled glass reduces UCS by 70%. Adding PVA reduce UCS to 151 psi | |

| Almajed et al. [56] | 1.00 to 0.37 M | 0.67 to 0.25 M | 0.85 g/L at activity of 3500 U/g | 4 g/L of powdered milk | Ottawa 20/30 sand | Adding powdered milk to the solution increases the compressive strength from 0.12 MPa to up to 1.82 MPa | |

| Almajed [131] | 1 M | 0.67 M | 3 g/L at activity of 3500 U/g | 4 g/L of milk and 300, 500 or 700 of Biochar mixed with sand | Local Crushed clean silica sand | Adding biochar to EICP require 4 cycles to achieve UCS of obtained of EICP alone | |

| Krishnan et al. [112] | 1 M | 0.67 M | 3 g/L urease at activity of 4200 U/g | 4 g/L nonfat milk powder | Ottawa 20/30 | Achieved UCS of up to 1.6 MPa at carbonate precipitation of 1.3% | |

| Rohy et al. [91] | 1, 2 and 3 M | 0.67, 1.34 and 2 M | 3, 9 and 6 g/L of active Jack bean meal at activity of 1500 U/g | 4, 8 and 12 g/L of nonfat dry milk | ASTM C778 graded silica sand | 3 M solution treatment at a curing period of 14 days resulted in UCS of up to 3 MPa | |

| Refaei et al. [82] | 1, 2 and 3 M | 0.67, 1.5, and 2 M | 3, 6, and 9 g/L at activity of 1500 U/g | 4, 8 and 12 g/L of non-fat dry milk and sodium alginate at 0.25, 0.5 and 1% (w/w) of soil | ASTM C778 graded silica sand | 2 M solution at 6 g/L urease and sodium alginate of 1% resulted in a maximum UCS of 1800 kPa | |

| Hoang et al. [49] | 0.15 mol/L and 0.3 M | 0.15 mol/L and 0.3 M | The bacterial enzyme at 5 mM (urea/min) | - | coarse- and fine-grained sand | BEICP-treated sands ranged from 400 to 1500 kPa | |

| Almajed et al. [110] | 0.5, 1 and 2 M | 0.335, 0.5 and 1.34 M | 1.5, 3 and 6 g/L bean meal urease enzyme 1500 U/g | 4 g/L nonfat dry milk | Ottawa 20/30, filtration, Alrasheed, and Al-Nafud Sand | EICP treatment for the sand after one cycle resulted in higher compressive strength than the sands stabilized using 10% OPC | |

| Cui et al. [121] | 1.0 M; | 1.0 M; | 40 U/mL (Extracted from Bacteria) | - | Ottawa 20/30 sand | EICP resulted in 3 MPa compared to 1 MPa at the same carbonate content of 9% | |

| Martin et al. [37] | 1.5 M | 1 M | 9900 U/L of Urease | 6 g/L nonfat milk powder | local quarry sand | Achieved an average compressive strength of 154 kPa | |

| Lee & Kim [95] | 0.75, 1.5 and 3 M | 0.75, 1.5 and 3 M | 70 & 140 g/L (Soybean Solution) at Activity of 0.4705 Ammonium mg/L/min | - | Local Sand from Hantan River—South Korea | Achieved UCS up to 860 kPa | |

| Ahenkorah et al. [92] | 0.5 M | 0.5 M | 0.25 g/L at activity of 40,150 U/g | 4 g/L nonfat dry milk | Adelaide Industrial (AI) sand | Achieved UCS of up to 4.23 MPa | |

| Yuan et al. [132] | 4.2 M | 2.8 M | 100 g/L of Urease | Skim Milk powder or Rice Powder or Brown sugar (2 to 32 g/L) | Local soil from the Yellow River flood area in Kaifeng | Achieved average UCS of 1489.3 kPa for modified EICP with up increase of up to 32.62% over nonmodified. | |

| Martin et al. [118] | 1 M | 0.67 M | 12.6 kU/L | 4 g/L nonfat milk powder | Ottawa 20/30, F85, Glass Beads and Local washed Quarry | Reached UCS of 1600 kPa at 1.2 Carbonate Content for Ottawa 20/30 | |

| Miftah et al. [68] | 1 M | 0.67 M | 1.25 to 15 mL/L Crude Urease Extract at Activity of 465 U/mL | 4 g/L nonfat milk powder Additionally, 0%, 5% and 10% of Seawater | Local beach sand from Famagusta Bay—Cyprus | Achieved UCS of 0.255 MPa for control samples and 0.224 MPa for samples treated with 10% Seawater | |

| Pratama et al. [133] | 0.5 mol/L | 0.5 mol/L | 20 g/L at Activity of 1668.7 U | - | Keisha sand | Achieved UCS of 600 kPa after 3 cycles | |

| Shear Wave Velocity | Song et al. [2] | 1 M | 1 M | 0.1, 0.5 and 1 g/L at activity of 40,318 U/g | - | uniformly graded natural sand, | 0.8 ms to 1.5 ms reduction in electric conductivity and 800 m/s of shear wave velocity for 1 g/L of urease |

| Obeidy et al. [105] | NA | 0.1 and 0.2 M | NA | NA of dry non-fat milk | Ottawa 20/30 sands | Achieved 600 m/s of shear wave velocity for sand columns | |

| Song et al. [101] | 1 to 1.5 M | 0.5 and 1 M | 0.5 to 0.9 g/L of Urease | - | Ottawa 50/70 or Jumunjin | EICP treatment increase the sand’s shear stiffness of up to 30 times after 6 h of treatment. | |

| Nafisi et al. [104] | 333 mM | 100 mM | 0.55 g at activity of 200 unit/g | 0.3 g of nonfat powder milk | Ottawa 20/30 or Ottawa 50/70 | Achieved shear wave velocity of up to 700 m/s | |

| Permeability Reduction | Nemati & Voordouw [9] | 12 g/L | 30 g/L | 0.01, 0.03 and 0.1 g/L at 26,100 U/g | 4 g/L | Sand 70% & glass 30% (w/w%) | 98% reduction in permeability after 2 injections |

| Nemati et al. [69] | 36 g/L | 90 g/L | 0.3 g/L (activity not reported) | - | Sand 70% & glass 30% (w/w%) | 62% decrease in the permeability when using EICP | |

| Larsen et al. [51] | 88, 110 and 132 mol/L | 200, 250 and 300 mol/L | Urease active bean meal of 25 g/L at activity of 150 kU/g | 25 g/L bentonite or use of large-grained bean meal | - | The addition of bentonite highly increase the plugging efficiency from 1 to 2.9 bar | |

| Yasuhara et al. [26] | 0.5 and 1.0 mol/L | 0.5 and 1.0 mol/L | 1 and 2 g/300 g of sand (activity not reported) | - | Toyoura Sand | Permeability of treated sand is reduced from 10−1 to 10−3 cm/s | |

| Neupane et al. [60] | 0.5 mol/L | 0.5 mol/L | 2 g/L at activity of 2950 U/g | - | Sandy soil | Reduction of porosity from 0.41 to 0.382 | |

| Handley-Sidhu et al. [52] | 400 and 200 mM | 400 mM and 200 mM | 0.25 & 0.5 g/L (activity not reported) | - | borosilicate beads | Permeability was reduced from 9.99 to 0.175 Darcy | |

| Putra et al. [98] | 0.5 g/L | 0.5 g/L | 1 g/L | - | Keisa sand | Hydraulic Conductivity reduced to less than 0.02 cm/s | |

| Hoang et al. [24] | 0.3 M | 0.3 M | Bacterial enzyme specified by activity only (4–5 mM urea/min) | - | Ottawa 20/30 silica sand | one-log decrease in permeability after sixteenth cycle treatment | |

| Hoang et al. [49] | 0.15 mol/L and 0.3 M | 0.15 mol/L and 0.3 M | Bacterial enzyme at 5 mM (urea/min) | - | coarse- and fine-grained sand | Permeability reduction from 10−1 to 10−2 was achieved after BEICP treatment | |

| Water and Vapor Retention to Enhance Groutability | Hamdan et al. [125] | 0.6 and 3.0 M | 0.4 and 2.0 M | 0.44 g/L for high activity (26,100 units/g) and 0.85 g/L for low activity enzyme (200 g/U) | 4.0 g/L of unspecified stabilizer (0.1 to 5%) of guar gum and xanthan gum) and 5% to 30% of polyol-cellulose hydrogel | F-60 fine-grained silica sand | 17% reduction in vapor pressure at 2% guar gum and 47% reduction while using guar gum. |

| Pasillas et al. [37] | 1 M | 0.67 M | 3 g/L (activity not reported) | Glycerol 50% (v/v) xanthan gum 0.25% (w/v) | Ottawa 20/30 and F-85 sands | The addition of xanthan gum enhanced water retention the most at retaining 74% of the original solution | |

| Direct Shear Test | Aishwarya & Christy [102] | 1 and 2 M | 0.5, 1, and 2 M | 1 mg of this urease active the meal can hydrolyze 3 mg of urea in 30 min at 37°C | - | Gujarat and Yamuna sand | Shear strength increase in the range of 40–50% |

| Putra et al. [103] | 1 mol/L | 0.9 to 1 mol/L Calcium Chloride and 0 to 0.1 Magnesium Chloride | 2 g/L | - | Silica sand | Achieved a cohesion of 53 kPa at 4.1% carbonate content | |

| Fugitive Dust Control | Bang et al. [28] | 0.333 mol/L | 0.1 mol/L | 0.5 units/mL | 0% to 1% 1 L solution. | Poorly graded sand | EICP resulted in 0.01% weight loss at 9 m/s wind speed |

| Knorr [29] | 1 and 2 mol/L | 0.375 to 2 mol/L | 0.5 g/L (activity not reported) | 4 g/L | Arizona silty-sand, medium-grained silica sand, and mine tailings | Achieved average detachment velocity of >25 m/s | |

| Hamadan & Kavazanjian [27] | 0.075 to 3 M | 0.05 to 2 M | 0 g/L and 0.45 g/L at activity of 26,100 U/g | 4 g/L of powdered nonfat milk | uniform, fine-grained, clean Ottawa F-60 silica sand, well-graded native Arizona silty fine sand; and mine tailings obtained from a site in southern Arizona | Achieved a detachment velocity of >25 m/s for the 3 treated soil types | |

| Almajed et al. [32] | 1 mol/L | 0.67 and 1 mol/L | 3g/L at activity of 1500 U/g | 4 g/L of powdered milk and 0.5%, 1% or 2% of sodium alginate (w/w%) of solution | Nafud desert sand | Combinations of EICP and Sodium alginate had a 0% erosion rate compared to other combinations | |

| Miao et al. [84] | 0.75 mol/L | 0.75 mol/L calcium acetate | Urease from soybeans at 4000 U/L | - | Tengger desert sand | EICP Treated 29.1 m/s. Higher spray passes lead to more wind erosion resistance | |

| Martin et al. [37] | 1.5 M | 1 M | 9900 U/L of Urease | 6 g/L nonfat milk powder | local quarry sand | Needle penetrating test resulted in 348 N surface strength of treated sample compared to 35 N for the control sample | |

| Cyclic Triaxial Test | Hamdan [58] | 400 mM and 1M | 300 mM and 1 M | 2.0 g/L | - | Ottawa 20/30 sand and Ottawa F-60 silica sand | 20–30 silica sand resulted in a strength increase of 100 kPa at 2% carbonate content whereas F-60-treated silica sand increased up to 125 kPa at 1.6% |

| Simatupang and Okamura [33] | 0 to 0.3 mol/L | 0 to 0.3 mol/L | 0 to 35 g/L (activity not reported) | - | Tohoku Keisha No. 4 | Only 1% of carbonate content is required to double the liquefaction resistance for up to 0.4 | |

| Almajed [44] | 1 M | 0.67 M | 3 g/L at activity of 3500 U/g | 4 g/L non-fat dry milk | Ottawa 20/30 sand | Internal friction angle and effective stress cohesion were calculated as 34.58° and 332.96 kPa | |

| He et al. [50] | 0.5 mol/L | 0.5 mol/L | Bacterial enzyme at 0.33 mL/ mL (w/w) of solution (activity not reported) | - | Ottawa sand (ASTM graded) with quartz powder | 10 passes of treatment solution resulted in the highest deviator stress results of 1750 kPa | |

| Gao et al. [48] | 0.25 and 0.5 mol/L | 0.25 and 0.5 mol/L | 40 and 130 g/L Soybean concentration at an activity of 6.5 and 13.2 mM/min | - | Quartz sand and Ottawa sand | Achieved maximum axial stress of 250 kPa after 15 treatments. | |

| Crack Healing in Concrete | Dakhane et al. [36] | 0.6 and 1.2 M | 0.5 and 1 M | 1 g/L at activity of 200 U/g | 2 g/L of non-fat dry milk | - | 33% enhancement of flexural strength for mortars treated with EICP |

| Tensile Strength | Ahenkorah et al. [92] | 0.5 M | 0.5 M | 0.25 g/L at activity of 40,150 U/g | 4 g/L nonfat dry milk | Adelaide Industrial (AI) sand | Achieved a splitting tensile strength of 1 MPa at 11.6% carbonate content. |

| Water Erosion | Cuccurullo et al. [128] | 2 mol/L | 2 mol/L | Crude Soybean Extracts | - | Silty Clay from (Bouisset brickwork factory – France) | Treated soil reported significantly lower weight loss due to water erosion and did not experience any cracks or swelling. |

| Ossai et al. [35] | 1 and 2 M | 0.67 and 1.34 M | 3 g/L | 4 g/L nonfat dry milk | Two natural quartz sand and Ottawa 20/30 | The average percent loss of fines due to pre-rinsing was 1.6% for natural sands and almost 0% for Ottawa 20/30 | |

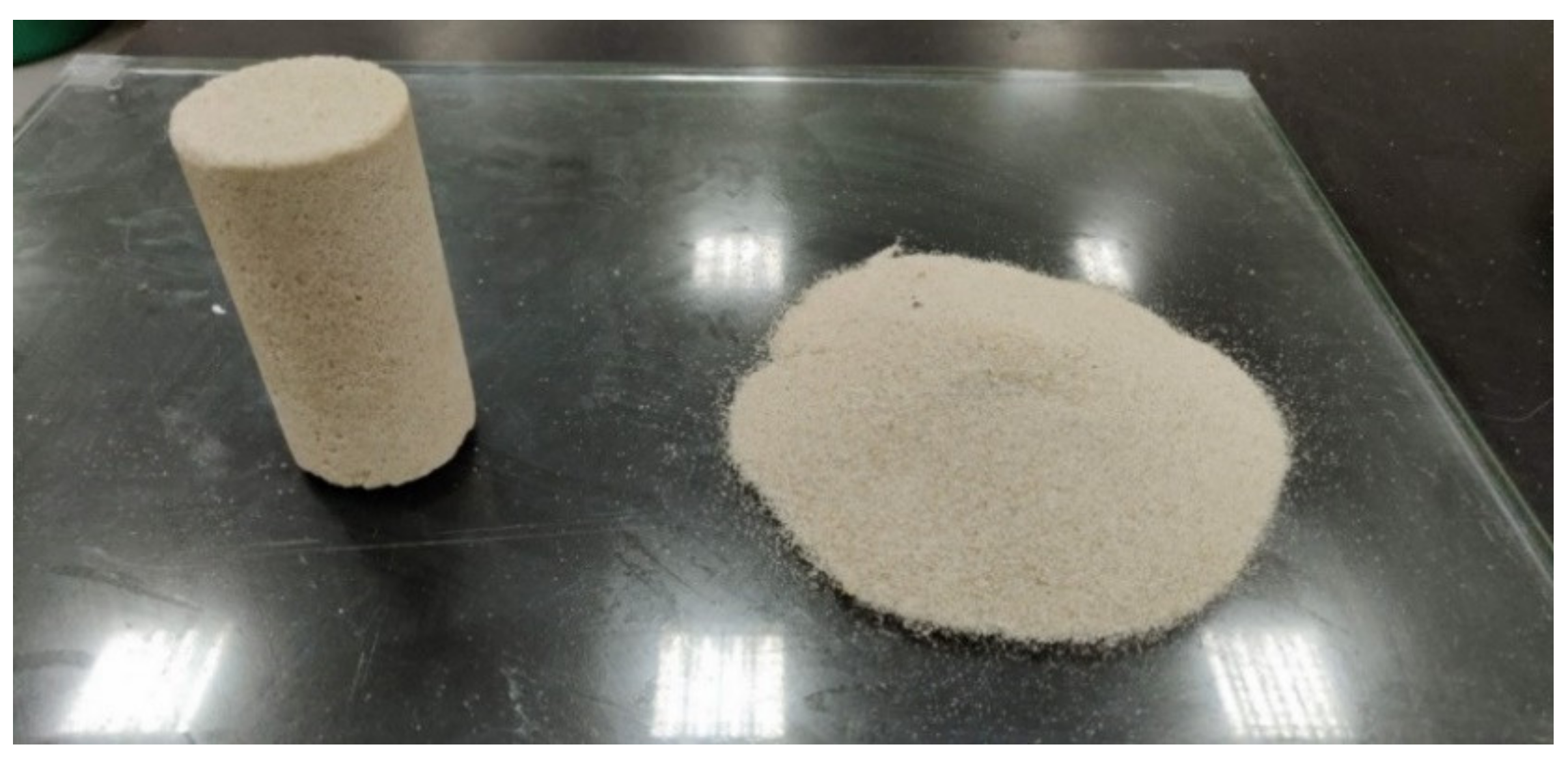

| Biobricks | Arab et al. [34] | 1, 2, and 3 M | 0.67, 1.34, and 2 M | 3 g/L | 4 g/L nonfat dry milk and 0. To 1.5% of soil dry mass Sodium Alginate | Graded silica sand ASTM C778 | Achieved UCS of 1800 kPa, and flexural strength of 2200 kPa and thermal conductivity of 0.25 W/mK, and initial rate of absorption of 16.29 g/min/50 cm2 |

References

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Song, J.Y.; Kim, Y.; Jang, J.; Yun, T.S.; Sim, Y. Microstructure of Bio-mediated Sand by Enzyme Induced Carbonate Precipitation: Relevance to Physio-Mechanical Properties. In Proceedings of the 7th International Conference on Unsaturated Soils, Hong Kong, China, 3–5 August 2018. [Google Scholar]

- Kavazanjian, E.; Hamdan, N. Enzyme Induced Carbonate Precipitation (EICP) Columns for Ground Improvement. In IFCEE 2015; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2015. [Google Scholar]

- Cheng, L.; Shahin, M.A. Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. In Ecological Wisdom Inspired Restoration Engineering; Springer: Singapore, 2019; pp. 47–68. [Google Scholar]

- Mujah, D.; Cheng, L.; Shahin, M. Microstructural and Geomechanical Study on Biocemented Sand for Optimization of MICP Process. J. Mater. Civ. Eng. 2019, 31, 04019025. [Google Scholar] [CrossRef] [Green Version]

- Holten-Andersen, N.; Jaishankar, A.; Harrington, M.J.; Fullenkamp, D.E.; DiMarco, G.; He, L.; McKinley, G.H.; Messersmith, P.B.; Lee, K.Y.C. Metal-coordination: Using one of nature’s tricks to control soft material mechanics. J. Mater. Chem. B 2014, 2, 2467–2472. [Google Scholar] [CrossRef] [Green Version]

- Castanier, S.; Le Métayer-Levrel, G.; Perthuisot, J.-P. Ca-carbonates precipitation and limestone genesis—The microbiogeologist point of view. Sediment. Geol. 1999, 126, 9–23. [Google Scholar] [CrossRef]

- Kavazanjian, E.; Karatas, I. Microbiological Improvement of the Physical Properties of Soil. In Proceedings of the 6th International Conference on Case Histories in Geotechnical Engineering, Arlington, VA, USA, 11–16 August 2008. [Google Scholar]

- Nemati, M.; Voordouw, G. Modification of porous media permeability, using calcium carbonate produced enzymatically in situ. Enzyme Microb. Technol. 2003, 33, 635–642. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, WA, Australia, 2004. [Google Scholar]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially Induced Cementation to Control Sand Response to Undrained Shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Whiffin, V.S.; van Paassen, L.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Harkes, M.P.; van Paassen, L.A.; Booster, J.L.; Whiffin, V.S.; van Loosdrecht, M.C.M. Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol. Eng. 2010, 36, 112–117. [Google Scholar] [CrossRef]

- Dejong, J.T.; Soga, K.; Kavazanjian, E.; Burns, S.; VAN Paassen, L.A.; AL Qabany, A.; Aydilek, A.; Bang, S.S.; Burbank, M.; Caslake, L.F.; et al. Biogeochemical processes and geotechnical applications: Progress, opportunities and challenges. In Bio- and Chemo-Mechanical Processes in Geotechnical Engineering; Thomas Telford Ltd.: London, UK, 2014; pp. 143–157. [Google Scholar]

- Van Paassen, L.A.; Ghose, R.; Van Der Linden, T.J.M.; Van Der Star, W.R.L.; Van Loosdrecht, M.C.M. Quantifying Biomediated Ground Improvement by Ureolysis: Large-Scale Biogrout Experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef]

- Mujah, D.; Shahin, M.A.; Cheng, L. State-of-the-Art Review of Biocementation by Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. Geomicrobiol. J. 2016, 34, 524–537. [Google Scholar] [CrossRef]

- Shahin, M.A.; Jamieson, K.; Cheng, L. Microbial-induced carbonate precipitation for coastal erosion mitigation of sandy slopes. Géotechnique Lett. 2020, 10, 211–215. [Google Scholar] [CrossRef]

- Khodadadi, T.H.; Kavazanjian, E.; Van Paassen, L.; DeJong, J. Bio-Grout Materials: A Review. In Proceedings of the Grouting 2017; American Society of Civil Engineers: Reston, VA, USA, 2017; pp. 1–12. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2019, 14, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Al-Thawadi, S.M. High Strength in situ Biocementation of Soil by Calcite Precipitating Locally Isolated Ureolytic Bacteria. Ph.D. Thesis, Murdoch University, Perth, WA, Australia, 2008. [Google Scholar]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio/Technol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Li, M.; Wen, K.; Li, Y.; Zhu, L. Impact of Oxygen Availability on Microbially Induced Calcite Precipitation (MICP) Treatment. Geomicrobiol. J. 2017, 35, 15–22. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Ikuma, K.; Choi, S.-G. Sand and silty-sand soil stabilization using bacterial enzyme–induced calcite precipitation (BEICP). Can. Geotech. J. 2019, 56, 808–822. [Google Scholar] [CrossRef]

- Yasuhara, H.; Hayashi, K.; Okamura, M. Evolution in Mechanical and Hydraulic Properties of Calcite-Cemented Sand Mediated by Biocatalyst. In Geo-Frontiers 2011; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2011; pp. 3984–3992. [Google Scholar]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef] [Green Version]

- Hamdan, N.; Kavazanjian, E. Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 2016, 66, 546–555. [Google Scholar] [CrossRef]

- Bang, S.S.; Bang, S.; Frutiger, S.; Nehl, L.M.; Comes, B.L. Application of novel biological technique in dust suppression (No. 09-0831). In Proceedings of the Transportation Research Board 88th Annual Meeting, Washington, DC, USA, 11–15 January 2009. [Google Scholar]

- Knorr, B. Enzyme-Induced Carbonate Precipitation for the Mitigation of Fugitive Dust. Master’s Thesis, Arizona State University, Tempe, AZ, USA, 2014. [Google Scholar]

- Wu, M.; Hu, X.; Zhang, Q.; Zhao, Y.; Sun, J.; Cheng, W.; Fan, Y.; Zhu, S.; Lu, W.; Song, C. Preparation and performance evaluation of environment-friendly biological dust suppressant. J. Clean. Prod. 2020, 273, 123162. [Google Scholar] [CrossRef]

- Raymond, A.J.; Purdy, C.; Fox, T.; Kendall, A.; DeJong, J.T.; Kavazanjian, E., Jr.; Martin, K.; Woolley, M. Life cycle sustainability assessment of enzyme-induced carbonate precipitation (EICP) for fugitive dust control. Acad. J. Civ. Eng. 2019, 37, 600–607. [Google Scholar] [CrossRef]

- Almajed, A.; Lemboye, K.; Arab, M.G.; Alnuaim, A. Mitigating wind erosion of sand using biopolymer-assisted EICP technique. Soils Found. 2020, 60, 356–371. [Google Scholar] [CrossRef]

- Simatupang, M.; Okamura, M. Liquefaction resistance of sand remediated with carbonate precipitation at different degrees of saturation during curing. Soils Found. 2017, 57, 619–631. [Google Scholar] [CrossRef]

- Arab, M.G.; Omar, M.; Almajed, A.; Elbaz, Y.; Ahmed, A.H. Hybrid technique to produce bio-bricks using enzyme-induced carbonate precipitation (EICP) and sodium alginate biopolymer. Constr. Build. Mater. 2021, 284, 122846. [Google Scholar] [CrossRef]

- Ossai, R.; Rivera, L.; Bandini, P. Experimental Study to Determine an EICP Application Method Feasible for Field Treatment for Soil Erosion Control. In Geo-Congress 2020; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2020; pp. 205–213. [Google Scholar]

- Dakhane, A.; Das, S.; Hansen, H.; O’Donnell, S.; Hanoon, F.; Rushton, A.; Perla, C.; Neithalath, N. Crack Healing in Cementitious Mortars Using Enzyme-Induced Carbonate Precipitation: Quantification Based on Fracture Response. J. Mater. Civ. Eng. 2018, 30, 04018035. [Google Scholar] [CrossRef] [Green Version]

- Martin, K.K.; Khodadadi, T.H.; Kavazanjian, E., Jr. Enzyme-induced carbonate precipitation: Scale-up of bio-cemented soil columns. In Geo-Congress 2020: Biogeotechnics; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2020; pp. 96–103. [Google Scholar]

- Zimmer, M. Molecular Mechanics Evaluation of the Proposed Mechanisms for the Degradation of Urea by Urease. J. Biomol. Struct. Dyn. 2000, 17, 787–797. [Google Scholar] [CrossRef]

- Krajewska, B. Urease-aided calcium carbonate mineralization for engineering applications: A review. J. Adv. Res. 2018, 13, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.; Wijeratne, A.; Costa, M. Effect of different sources of urease on the treatment time and digestibility of urea-ammonia treated rice straw. Agric. Wastes 1985, 13, 197–205. [Google Scholar] [CrossRef]

- Mateer, J.G.; Marshall, E.K. The Urease Content of Certain Beans, with Special Reference to the Jack Bean. J. Biol. Chem. 1916, 25, 297–305. [Google Scholar] [CrossRef]

- Sumner, J.B. The isolation and crystallization of the enzyme urease. J. Biol. Chem. 1926, 69, 435–441. [Google Scholar] [CrossRef]

- Blakeley, R.L.; Zerner, B. Jack bean urease: The first nickel enzyme. J. Mol. Catal. 1984, 23, 263–292. [Google Scholar] [CrossRef]

- Almajed, A. Enzyme Induced Carbonate Precipitation (EICP) for Soil Improvement. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2017. [Google Scholar]

- Khodadadi Tirkolaei, H.; Javadi, N.; Krishnan, V.; Hamdan, N.; Kavazanjian, E., Jr. Crude urease extract for biocementation. J. Mater. Civ. Eng. 2020, 32, 4020374. [Google Scholar] [CrossRef]

- Kawasaki, D.R.A.S. Effective Use of Plant-Derived Urease in the Field of Geoenvironmental/Geotechnical Engineering. J. Civ. Environ. Eng. 2016, 6, 2. [Google Scholar] [CrossRef] [Green Version]

- Javadi, N.; Khodadadi, H.; Hamdan, N.; Kavazanjian, E., Jr. EICP Treatment of Soil by Using Urease Enzyme Extracted from Watermelon Seeds. In IFCEE 2018; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2018. [Google Scholar] [CrossRef]

- Gao, Y.; He, J.; Tang, X.; Chu, J. Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil. Soils Found. 2019, 59, 1631–1637. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Choi, S.-G. Engineering Properties of Biocementation Coarse- and Fine-Grained Sand Catalyzed by Bacterial Cells and Bacterial Enzyme. J. Mater. Civ. Eng. 2020, 32, 04020030. [Google Scholar] [CrossRef]

- He, J.; Gao, Y.; Gu, Z.; Chu, J.; Wang, L. Characterization of Crude Bacterial Urease for CaCO3 Precipitation and Cementation of Silty Sand. J. Mater. Civ. Eng. 2020, 32, 04020071. [Google Scholar] [CrossRef]

- Larsen, J.; Poulsen, M.; Lundgaard, T.; Agerbaek, M. Plugging of Fractures in Chalk Reservoirs by Enzyme-Induced Calcium Carbonate Precipitation. SPE Prod. Oper. 2008, 23, 478–483. [Google Scholar] [CrossRef]

- Handley-Sidhu, S.; Sham, E.; Cuthbert, M.O.; Nougarol, S.; Mantle, M.; Johns, M.L.; Macaskie, L.E.; Renshaw, J.C. Kinetics of urease mediated calcite precipitation and permeability reduction of porous media evidenced by magnetic resonance imaging. Int. J. Environ. Sci. Technol. 2013, 10, 881–890. [Google Scholar] [CrossRef] [Green Version]

- Arab, M.G.; Rohy, H.; Zeiada, W.; Almajed, A.; Omar, M. One-Phase EICP Biotreatment of Sand Exposed to Various Environmental Conditions. J. Mater. Civ. Eng. 2021, 33, 04020489. [Google Scholar] [CrossRef]

- Javadi, N.; Tirkolaei, H.K.; Hamdan, N.; Kavazanjian, E. Longevity of Raw and Lyophilized Crude Urease Extracts. Sustain. Chem. 2021, 2, 18. [Google Scholar] [CrossRef]

- Kutcherlapati, S.N.R.; Yeole, N.; Jana, T. Urease immobilized polymer hydrogel: Long-term stability and enhancement of enzymatic activity. J. Colloid Interface Sci. 2016, 463, 164–172. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E., Jr.; Hamdan, N. Enzyme Induced Biocementated Sand with High Strength at Low Carbonate Content. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Lo, C.-Y.; Tirkolaei, H.K.; Hua, M.; De Rosa, I.; Carlson, L.; Kavazanjian, E.; He, X. Durable and ductile double-network material for dust control. Geoderma 2020, 361, 114090. [Google Scholar] [CrossRef]

- Hamdan, N.M. Applications of Enzyme Induced Carbonate Precipitation (EICP) for Soil Improvement. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2015. [Google Scholar]

- Kim, D.; Mahabadi, N.; Jang, J.; van Paassen, L.A. Assessing the Kinetics and Pore-Scale Characteristics of Biological Calcium Carbonate Precipitation in Porous Media using a Microfluidic Chip Experiment. Water Resour. Res. 2020, 56, e2019WR025420. [Google Scholar] [CrossRef]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Unno, T. Applicability of Enzymatic Calcium Carbonate Precipitation as a Soil-Strengthening Technique. J. Geotech. Geoenviron. Eng. 2013, 139, 2201–2211. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E., Jr. Baseline Investigation on Enzyme-Induced Calcium Carbonate Precipitation. J. Geotech. Geoenviron. Eng. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Carmona, J.P.; Oliveira, P.V.; Lemos, L. Biostabilization of a Sandy Soil Using Enzymatic Calcium Carbonate Precipitation. Procedia Eng. 2016, 143, 1301–1308. [Google Scholar] [CrossRef] [Green Version]

- Ahenkorah, I.; Rahman, M.; Karim, R.; Teasdale, P.R. Optimization of Enzyme Induced Carbonate Precipitation (EICP) as a Ground Improvement Technique. In Geo-Congress 2020; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2020; pp. 552–561. [Google Scholar]

- Johnson, K.A.; Goody, R.S. The Original Michaelis Constant: Translation of the 1913 Michaelis–Menten Paper. Biochemistry 2011, 50, 8264–8269. [Google Scholar] [CrossRef] [Green Version]

- Leszko, M.; Zaborska, W.; Krajewska, B. Urease-catalyzed hydrolysis of urea differential vs. integration kinetic methods. Bull. Pol. Acad. Sci. Chem. 1997, 45, 129–138. [Google Scholar]

- Laidler, K.J.; Hoare, J.P. The Molecular Kinetics of the Urea-Urease System. III. Heats and Entropies of Complex Formation and Reaction1. J. Am. Chem. Soc. 1950, 72, 2489–2494. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.; Karim, R.; Beecham, S.; Saint, C. A Review of Enzyme Induced Carbonate Precipitation (EICP): The Role of Enzyme Kinetics. Sustain. Chem. 2021, 2, 7. [Google Scholar] [CrossRef]

- Miftah, A.; Tirkolaei, H.K.; Bilsel, H. Biocementation of Calcareous Beach Sand Using Enzymatic Calcium Carbonate Precipitation. Crystals 2020, 10, 888. [Google Scholar] [CrossRef]

- Nemati, M.; Greene, E.A.; Voordouw, G. Permeability profile modification using bacterially formed calcium carbonate: Comparison with enzymic option. Process. Biochem. 2005, 40, 925–933. [Google Scholar] [CrossRef]

- Chandra, A.; Ravi, K. Application of Enzyme-Induced Carbonate Precipitation (EICP) to Improve the Shear Strength of Different Type of Soils. In Lecture Notes in Civil Engineering; Springer: Singapore, 2020; pp. 617–632. [Google Scholar]

- Ahenkorah, I.; Rahman, M.; Karim, R.; Beecham, S. Optimisation of chemical constituents on enzyme-induced carbonate precipitation in test-tube and soil. Geotech. Res. 2021, 8, 66–84. [Google Scholar] [CrossRef]

- Krajewska, B. A combined temperature-pH study of urease kinetics. Assigning pKa values to ionizable groups of the active site involved in the catalytic reaction. J. Mol. Catal. B Enzym. 2016, 124, 70–76. [Google Scholar] [CrossRef]

- Goličnik, M. The integrated Michaelis-Menten rate equation: Déjà vu or vu jàdé? J. Enzyme. Inhib. Med. Chem. 2013, 28, 879–893. [Google Scholar] [CrossRef]

- Zhao, Z.; Hamdan, N.; Shen, L.; Nan, H.; Almajed, A.; Kavazanjian, E.; He, X. Biomimetic Hydrogel Composites for Soil Stabilization and Contaminant Mitigation. Environ. Sci. Technol. 2016, 50, 12401–12410. [Google Scholar] [CrossRef]

- Rebata-Landa, V. Microbial Activity in Sediments: Effects on Soil Behavior. Ph.D. Thesis, Georgia Institution of Technology, Atlanta, GA, USA, 2007. [Google Scholar]

- Jacob, D.J. Introduction to Atmospheric Chemistry; Princeton University Press: Princeton, NJ, USA, 1999. [Google Scholar]

- Chouhan, S.; Gayathri, R. Extraction and partial purification of urease enzyme from Jack fruit. Int. J. Res. Pharm. Sci. 2018, 9, 438–441. [Google Scholar]

- Kavazanjian, E., Jr.; Almajed, A.; Hamdan, N. Bio-Inspired Soil Improvement Using EICP Soil Columns and Soil Nails. In Grouting 2017; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2017. [Google Scholar]

- Martin, K.K.; Tirkolaei, H.K.; Kavazanjian, E., Jr. Mid-scale biocemented soil columns via enzyme-induced carbonate precipitation (EICP). Soils Found. 2021. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Pasillas, J.N.; Khodadadi, H.; Martin, K.; Bandini, P.; Newtson, C.M.; Kavazanjian, E. Viscosity-Enhanced EICP Treatment of Soil. In IFCEE 2018; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2018. [Google Scholar] [CrossRef]

- Refaei, M.; Arab, M.G.; Omar, M. Sandy Soil Improvement through Biopolymer Assisted EICP. In Geo-Congress 2020; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2020. [Google Scholar] [CrossRef]

- Pandey, G. Feasibility Study of Water Based/Polymer Modified EICP for Soil Improvement Involving Recycled Glass Aggregate. Master’s Thesis, University of Akron, Akron, OH, USA, 2018. [Google Scholar]

- Miao, L.; Wu, L.; Sun, X. Enzyme-catalysed mineralisation experiment study to solidify desert sands. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Cho, G.-C.; Dodds, J.; Santamarina, J.C. Particle Shape Effects on Packing Density, Stiffness, and Strength: Natural and Crushed Sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, V.; Chu, J.; Stabnikov, V.; Li, B. Strengthening of Soft Marine Clay Using Bioencapsulation. Mar. Georesources Geotechnol. 2015, 33, 320–324. [Google Scholar] [CrossRef]

- Zhao, Q.; Li, L.; Li, C.; Li, M.; Amini, F.; Zhang, H. Factors Affecting Improvement of Engineering Properties of MICP-Treated Soil Catalyzed by Bacteria and Urease. J. Mater. Civ. Eng. 2014, 26, 04014094. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Pieron, M.; Mulder, A.; Ngan-Tillard, D.J.M.; Van Der Linden, T.J.M. Strength and deformation of biologically cemented sandstone. In Proceedings of the ISRM Regional conference EUROCK, Dubrovnik, Croatia, 29–31 October 2009; pp. 405–410. [Google Scholar]

- Al Qabany, A.; Soga, K. Effect of chemical treatment used in MICP on engineering properties of cemented soils. Géotechnique 2013, 63, 331. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R. Selective enrichment and production of highly urease active bacteria by non-sterile (open) chemostat culture. J. Ind. Microbiol. Biotechnol. 2013, 40, 1095–1104. [Google Scholar] [CrossRef]

- Rohy, H.; Arab, M.; Zeiada, W.; Omar, M.; Almajed, A.; Tahmaz, A. One Phase Soil Bio-Cementation with EICP-Soil Mixing. In Proceedings of the 4th World Congress on Civil, Structural, and Environmental Engineering, Rome, Italy, 7–9 April 2019. [Google Scholar]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Teasdale, P.R. A comparison of mechanical responses for microbial- and enzyme-induced cemented sand. Géotech. Lett. 2020, 10, 559–567. [Google Scholar] [CrossRef]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Ando, Y. Distribution of mineralized carbonate and its quantification method in enzyme mediated calcite precipitation technique. Soils Found. 2015, 55, 447–457. [Google Scholar] [CrossRef] [Green Version]

- Beser, G.D. Ureolysis Induced Mineral Precipitation Material Properties. Master’s Thesis, Montana State University, Bozeman, MT, USA, 2018. [Google Scholar]

- Lee, S.; Kim, J. An Experimental Study on Enzymatic-Induced Carbonate Precipitation Using Yellow Soybeans for Soil Stabilization. KSCE J. Civ. Eng. 2020, 24, 2026–2037. [Google Scholar] [CrossRef]

- Park, S.-S.; Choi, S.-G.; Nam, I.-H. Effect of Plant-Induced Calcite Precipitation on the Strength of Sand. J. Mater. Civ. Eng. 2014, 26, 06014017. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Neupane, D.; Lu, C.-W. Effect of Magnesium as Substitute Material in Enzyme-Mediated Calcite Precipitation for Soil-Improvement Technique. Front. Bioeng. Biotechnol. 2016, 4, 37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Neupane, D. Optimization of Calcite Precipitation as a Soil Improvement Technique. In Proceedings of the 2nd Makassar International Conference in Civil Engineering, Makassar, Indonesia, 11–12 August 2015; pp. 9–14. [Google Scholar]

- Putra, H.; Yasuhara, H.; Kinoshita, N. Optimum condition for the application of enzyme-mediated calcite precipitation technique as soil improvement method. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 2145–2151. [Google Scholar] [CrossRef]

- Almajed, A.; Khodadadi, H.; Kavazanjian, E., Jr. Sisal Fiber Reinforcement of EICP-Treated Soil. In IFCEE 2018; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2018. [Google Scholar] [CrossRef]

- Song, J.Y.; Ha, S.J.; Jang, J.W.; Yun, T.S. Analysis of Improved Shear Stiffness and Strength for Sandy Soils Treated by EICP. J. Korean Geotech. Soc. 2020, 36, 17–28. [Google Scholar]

- Aishwarya, A.; Christy, A. Bio cemented Sands. In Proceedings of the Indian Geotechnical Conference 2017 GeoNEst, Guwahati, India, 14–16 December 2017; pp. 14–17. [Google Scholar]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Sudibyo, T. Improving Shear Strength Parameters of Sandy Soil using Enzyme-Mediated Calcite Precipitation Technique. Civ. Eng. Dimens. 2018, 20, 91–95. [Google Scholar] [CrossRef]

- Nafisi, A.; Montoya, B.M.; Evans, T.M. Shear Strength Envelopes of Biocemented Sands with Varying Particle Size and Cementation Level. J. Geotech. Geoenviron. Eng. 2020, 146, 04020002. [Google Scholar] [CrossRef]

- Obeidy, C.S.; Savavisadeh, S.; Montoya, B. Assessing the Mechanical Stability of Coal Ash via Enzyme Induced Calcium Carbonate Precipitation. In Proceedings of the Tampa, Florida, USA, 22–25 October 2017. [Google Scholar]

- Xiao, P.; Liu, H.; Stuedlein, A.; Evans, T.M.; Xiao, Y. Effect of relative density and biocementation on cyclic response of calcareous sand. Can. Geotech. J. 2019, 56, 1849–1862. [Google Scholar] [CrossRef] [Green Version]

- Mehdizadeh, A.; Disfani, M.M.; Evans, R.; Arulrajah, A.; Ong, D.E.L. Discussion of “development of an internal camera-based volume determination system for triaxial testing” by se Salazar, a. Barnes and Ra Coffman. The technical note was published in geotechnical testing journal, vol. 38, no. 4, 2015. Geotech. Test. J. 2016, 39, 165–168. [Google Scholar] [CrossRef]

- Xiao, Y.; Stuedlein, A.W.; Ran, J.; Evans, T.M.; Cheng, L.; Liu, H.; Van Paassen, L.A.; Chu, J. Effect of Particle Shape on Strength and Stiffness of Biocemented Glass Beads. J. Geotech. Geoenviron. Eng. 2019, 145, 06019016. [Google Scholar] [CrossRef]

- Ismail, M.A.; Joer, H.A.; Randolph, M.F.; Meritt, A. Cementation of porous materials using calcite. Geotechnique 2002, 52, 313–324. [Google Scholar] [CrossRef]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based methods for ecofriendly stabilization of different types of natural sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Krishnan, V.; Khodadadi, H.T.; Martin, K.; Hamdan, N.M.; Kavazanjian, E.; Van Paassen, L.A. Variation in strength of EICP treated “standard” sand. In Proceedings of the B2G Atlanta 2018, Atlanta, GA, USA, 10–13 September 2019. [Google Scholar]

- Krishnan, V.; Tirkolaei, H.K.; Martin, K.; Hamdan, N.; van Paassen, L.A.; Kavazanjian, E. Variability in the Unconfined Compressive Strength of EICP-Treated “Standard” Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 06021001. [Google Scholar] [CrossRef]

- Oliveira, P.V.; Freitas, L.D.; Carmona, J.P.S.F. Effect of Soil Type on the Enzymatic Calcium Carbonate Precipitation Process Used for Soil Improvement. J. Mater. Civ. Eng. 2017, 29, 04016263. [Google Scholar] [CrossRef]

- Zango, M.U.; Kassim, K.A.; Muhammed, A.S.; Ahmad, K.; Makinda, J. Effect of Biocementation via Enzymatic Induced Calcium Carbonate Precipitation (EICP) on the Shear Strength of Compacted Clay Liner. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1153, 012008. [Google Scholar] [CrossRef]

- Zehner, J.; Røyne, A.; Sikorski, P. A sample cell for the study of enzyme-induced carbonate precipitation at the grain-scale and its implications for biocementation. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Chahal, N.; Rajor, A.; Siddique, R. Calcium carbonate precipitation by different bacterial strains. Afr. J. Biotechnol. 2011, 10, 8359–8372. [Google Scholar]

- Dupraz, C.; Visscher, P.T.; Baumgartner, L.K.; Reid, R.P. Microbe-mineral interactions: Early carbonate precipitation in a hypersaline lake (Eleuthera Island, Bahamas). Sedimentology 2004, 51, 745–765. [Google Scholar] [CrossRef]

- Martin, K.; Tirkolaei, H.K.; Kavazanjian, E. Enhancing the strength of granular material with a modified enzyme-induced carbonate precipitation (EICP) treatment solution. Constr. Build. Mater. 2021, 271, 121529. [Google Scholar] [CrossRef]

- Nafisi, A.; Safavizadeh, S.; Montoya, B.M. Influence of Microbe and Enzyme-Induced Treatments on Cemented Sand Shear Response. J. Geotech. Geoenviron. Eng. 2019, 145, 06019008. [Google Scholar] [CrossRef]

- Kiasari, M.A.; Pakbaz, M.S.; Ghezelbash, G.R. Comparison of Effects of Different Nutrients on Stimulating Indigenous Soil Bacteria for Biocementation. J. Mater. Civ. Eng. 2019, 31, 04019067. [Google Scholar] [CrossRef]

- Cui, M.-J.; Lai, H.-J.; Hoang, T.; Chu, J. One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement. Acta Geotech. 2021, 16, 481–489. [Google Scholar] [CrossRef]

- Cui, M.J.; Lai, H.J.; Hoang, T.; Chu, J. Modified one-phase-low-pH method for bacteria or enzyme-induced carbonate precipitation for soil improvement. Acta Geotech. 2011, 1–11. [Google Scholar] [CrossRef]

- Wen, K.; Li, Y.; Li, L.; Amini, F. Development of a Multiple Treatment Laboratory Method to Enhance Microbial-Induced Soil Stabilization. In IFCEE 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 12–18. [Google Scholar] [CrossRef]

- Nething, C.; Smirnova, M.; Gröning, J.A.; Haase, W.; Stolz, A.; Sobek, W. A method for 3D printing bio-cemented spatial structures using sand and urease active calcium carbonate powder. Mater. Des. 2020, 195, 109032. [Google Scholar] [CrossRef]

- Omoregie, A.I.; Palombo, E.A.; Ong, D.E.; Nissom, P.M. A feasible scale-up production of Sporosarcina pasteurii using custom-built stirred tank reactor for in-situ soil biocementation. Biocatal. Agric. Biotechnol. 2020, 24, 101544. [Google Scholar] [CrossRef]

- Martin, K.K.; Khodadadi, T.H.; Chester, M.; Kavazanjian, E., Jr. Hotspot Life Cycle Assessment for Environmental Impacts of EICP for Ground Improvement. In Geo-Congress 2020; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Hirata, A. Optimization of Enzyme-Mediated Calcite Precipitation as a Soil-Improvement Technique: The Effect of Aragonite and Gypsum on the Mechanical Properties of Treated Sand. Crystals 2017, 7, 59. [Google Scholar] [CrossRef] [Green Version]

- Farrell, H., Jr.; Kumosinski, T.; Malin, E.; Brown, E. The caseins of milk as calcium-binding proteins. Biochemistry 1988, 23, 5912–5923. [Google Scholar]

- Song, J.Y.; Sim, Y.; Yeom, S.; Jang, J.; Yun, T.S. Stiffness loss in enzyme-induced carbonate precipitated sand with stress scenarios. Geomech. Eng. 2020, 20, 165–174. [Google Scholar] [CrossRef]

- Mehdizadeh, A.; Disfani, M.M.; Evans, R.; Arulrajah, A.; Ong, D.E.L. Mechanical Consequences of Suffusion on Undrained Behaviour of a Gap-Graded Cohesionless Soil–An Experimental Approach. Geotech. Test. J. 2017, 40, 1026–1042. [Google Scholar] [CrossRef] [Green Version]

- Pratama, G.B.S.; Yasuhara, H.; Kinoshita, N.; Putra, H. Application of soybean powder as urease enzyme replacement on EICP method for soil improvement technique. IOP Conf. Ser. Earth Environ. Sci. 2021, 622, 012035. [Google Scholar] [CrossRef]

- Hamdan, N.; Zhao, Z.; Mujica, M.; Kavazanjian, E.; He, X. Hydrogel-Assisted Enzyme-Induced Carbonate Mineral Precipitation. J. Mater. Civ. Eng. 2016, 28, 04016089. [Google Scholar] [CrossRef]

- Cuccurullo, A.; Gallipoli, D.; Bruno, A.W.; Augarde, C.; Hughes, P.; La Borderie, C. Soil Stabilization against Water Erosion via Calcite Precipitation by Plant-Derived Urease. In Proceedings of FORM 2021; Springer: Singapore, 2019; pp. 753–762. [Google Scholar]

| Enzyme Source | Reported Enzyme Activity (mg NH3/g/h at 30 °C) |

|---|---|

| Soya Bean Seeds | 360 |

| Watermelon Seeds | 355 |

| Pumpkin Seeds | 755 |

| Jack Bean Seeds | 4871 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arab, M.G.; Alsodi, R.; Almajed, A.; Yasuhara, H.; Zeiada, W.; Shahin, M.A. State-of-the-Art Review of Enzyme-Induced Calcite Precipitation (EICP) for Ground Improvement: Applications and Prospects. Geosciences 2021, 11, 492. https://doi.org/10.3390/geosciences11120492

Arab MG, Alsodi R, Almajed A, Yasuhara H, Zeiada W, Shahin MA. State-of-the-Art Review of Enzyme-Induced Calcite Precipitation (EICP) for Ground Improvement: Applications and Prospects. Geosciences. 2021; 11(12):492. https://doi.org/10.3390/geosciences11120492

Chicago/Turabian StyleArab, Mohamed G., Rami Alsodi, Abdullah Almajed, Hideaki Yasuhara, Waleed Zeiada, and Mohamed A. Shahin. 2021. "State-of-the-Art Review of Enzyme-Induced Calcite Precipitation (EICP) for Ground Improvement: Applications and Prospects" Geosciences 11, no. 12: 492. https://doi.org/10.3390/geosciences11120492

APA StyleArab, M. G., Alsodi, R., Almajed, A., Yasuhara, H., Zeiada, W., & Shahin, M. A. (2021). State-of-the-Art Review of Enzyme-Induced Calcite Precipitation (EICP) for Ground Improvement: Applications and Prospects. Geosciences, 11(12), 492. https://doi.org/10.3390/geosciences11120492