Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale

Abstract

1. Introduction

2. Methods and Materials

2.1. Study Area

2.2. Recording of Field Traffic

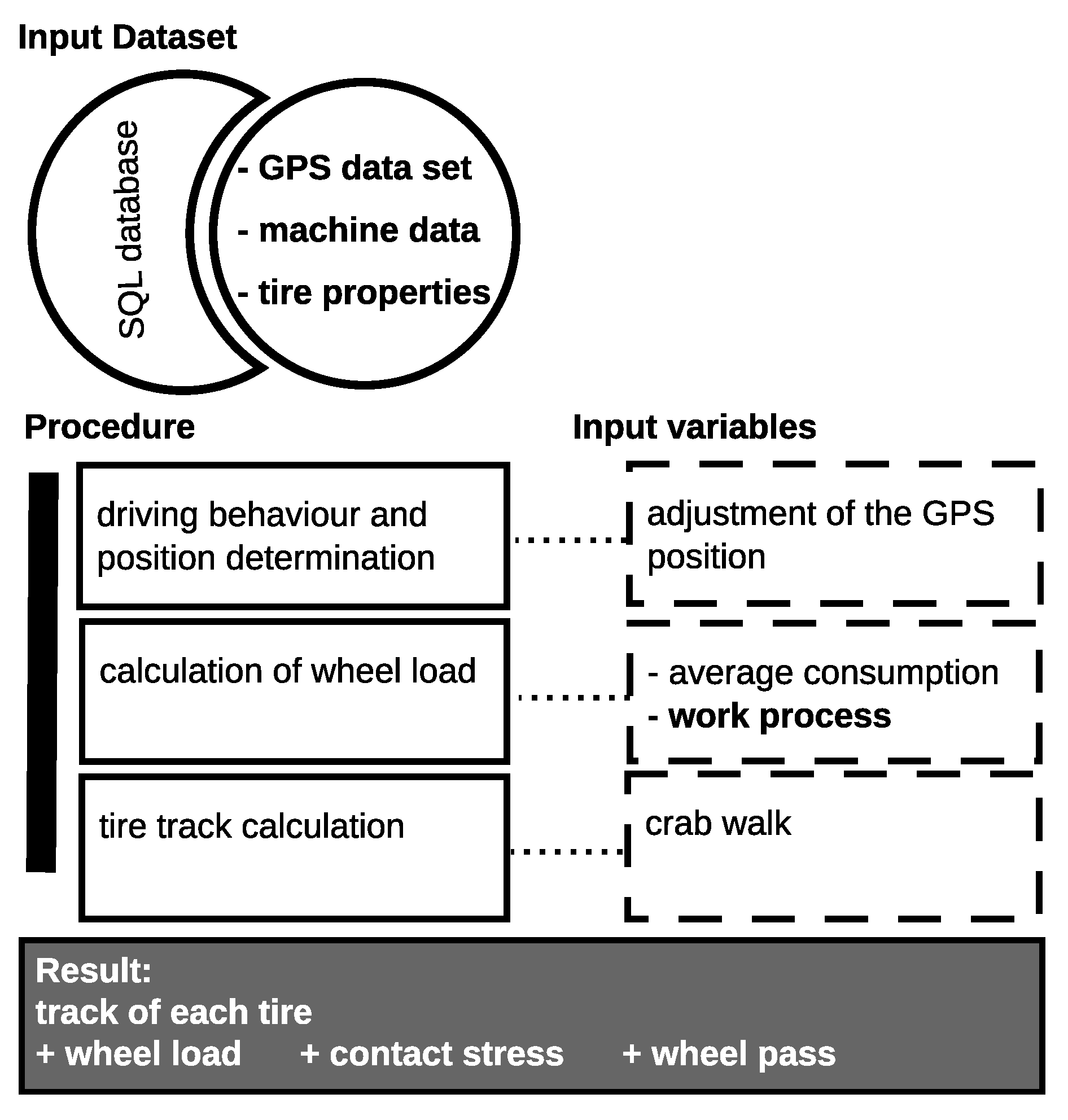

2.3. Modeling of Tracks and Traffic Intensity

3. Results and Discussion

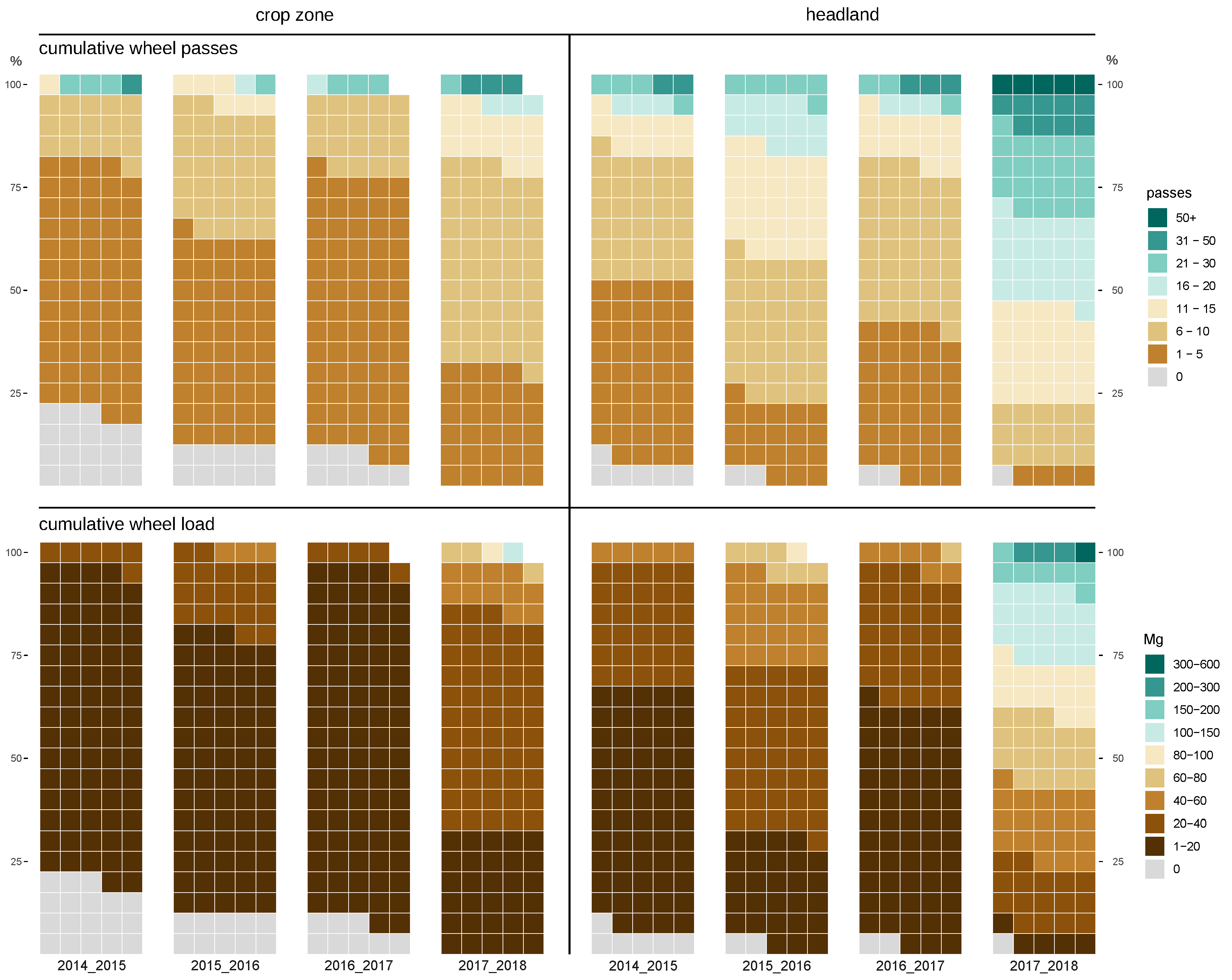

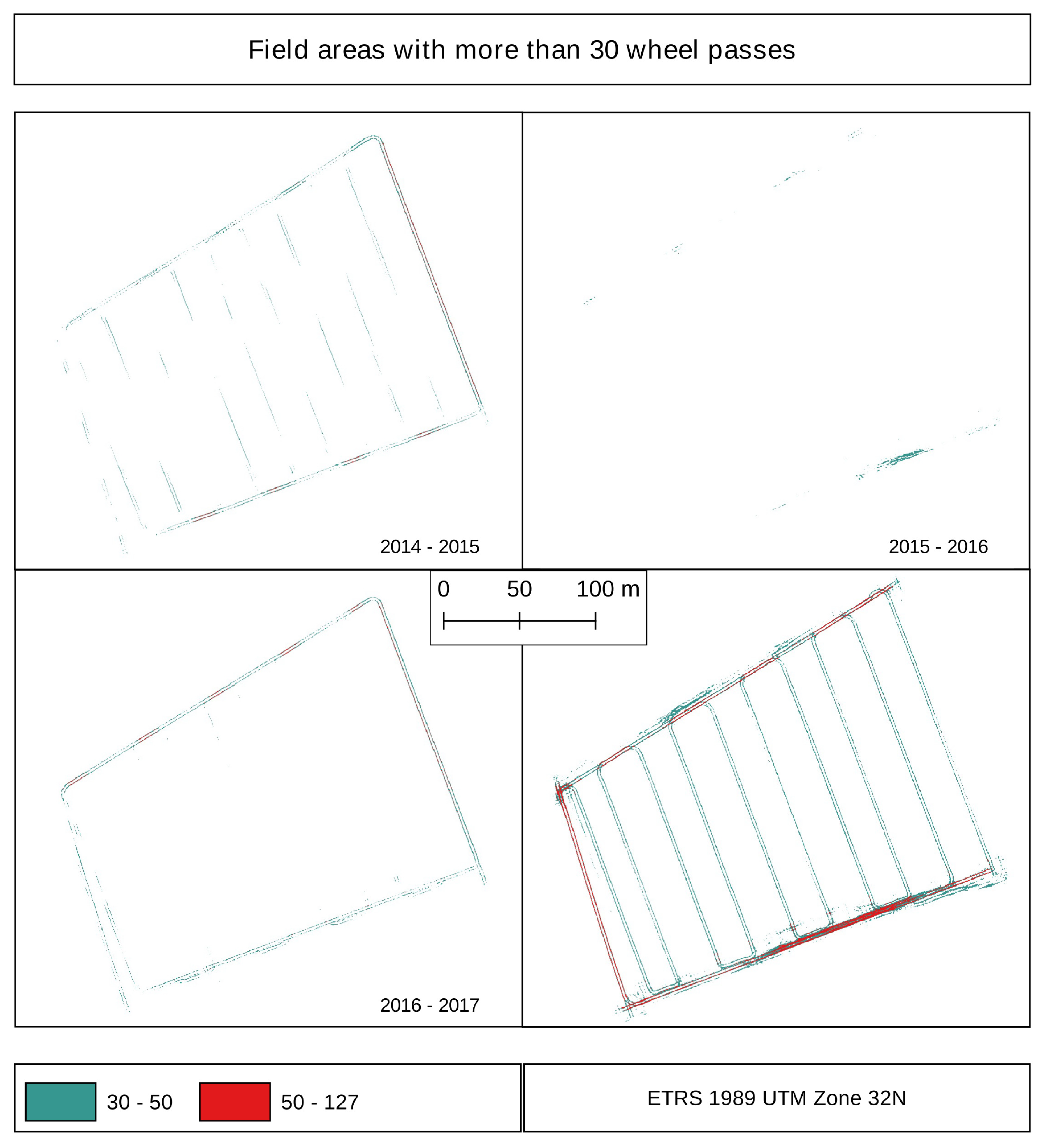

3.1. Analysis of Cumulative Results for Whole Cropping Seasons

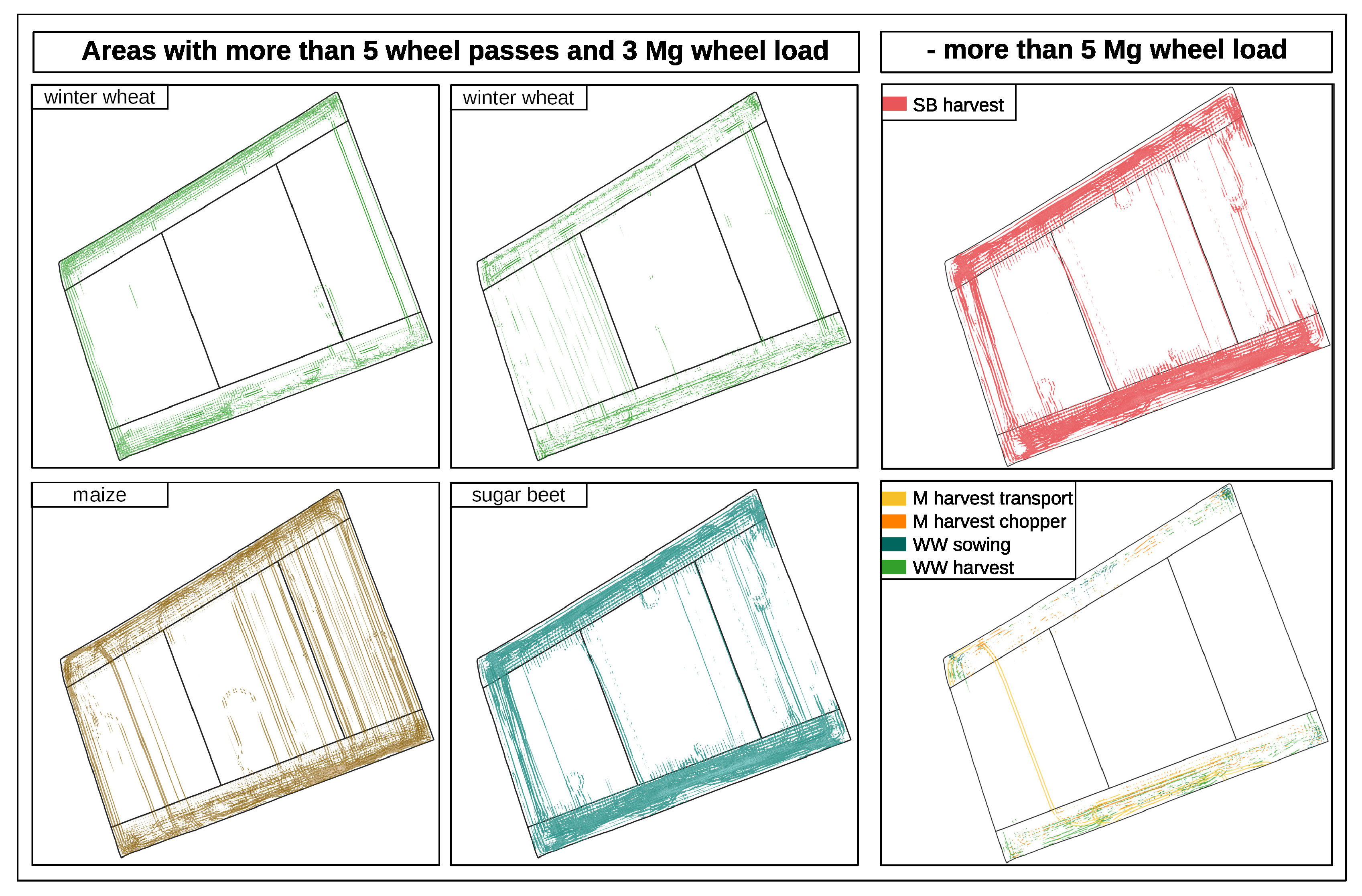

3.2. Analysis of Traffic Intensity for Single Work Processes

3.3. Spatial-Temporal Modeling and Future Perspectives

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| GPS | Global Positioning System |

| RTK | Real-Time Kinematic |

| WW | Winter Wheat |

| SB | Sugar Beet |

| M | Maize |

References

- Keller, T.; Sandin, M.; Colombi, T.; Horn, R.; Or, D. Historical increase in agricultural machinery weights enhanced soil stress levels and adversely affected soil functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- FAO; ITPS. Status of the World’s Soil Resources (SWSR)—Main Report; Food and Agriculture Organization of the United Nations and Intergovernmental Technical Panel on Soils: Rome, Italy, 2015; 650p. [Google Scholar]

- Horn, R.; Domżżał, H.; Słowińska-Jurkiewicz, A.; van Ouwerkerk, C. Soil compaction processes and their effects on the structure of arable soils and the environment. Soil Tillage Res. 1995, 35, 23–36. [Google Scholar] [CrossRef]

- Lamande, M.; Schjønning, P.; Tøgersen, F.A. Mechanical behaviour of an undisturbed soil subjected to loadings: Effects of load and contact area. Soil Tillage Res. 2007, 97, 91–106. [Google Scholar] [CrossRef]

- Keller, T.; Arvidsson, J. Technical solutions to reduce the risk of subsoil compaction: Effects of dual wheels, tandem wheels and tyre inflation pressure on stress propagation in soil. Soil Tillage Res. 2004, 79, 191–205. [Google Scholar] [CrossRef]

- Horn, R.; Way, T.; Rostek, J. Effect of repeated tractor wheeling on stress/strain properties and consequences on physical properties in structured arable soils. Soil Tillage Res. 2003, 73, 101–106. [Google Scholar] [CrossRef]

- Schjønning, P.; Lamandé, M.; Berisso, F.E.; Simojoki, A.; Alakukku, L.; Andreasen, R.R. Gas Diffusion, Non-Darcy Air Permeability, and Computed Tomography Images of a Clay Subsoil Affected by Compaction. Soil Sci. Soc. Am. J. 2013, 77, 1977–1990. [Google Scholar] [CrossRef]

- Radford, B.J.; Yule, D.F.; McGarry, D.; Playford, C. Amelioration of soil compaction can take 5 years on a Vertisol under no till in the semi-arid subtropics. Soil Tillage Res. 2007, 97, 249–255. [Google Scholar] [CrossRef]

- Berisso, F.E.; Schjønning, P.; Keller, T.; Lamandé, M.; Simojoki, A.; Iversen, B.V.; Alakukku, L.; Forkman, J. Gas transport and subsoil pore characteristics: Anisotropy and long-term effects of compaction. Geoderma 2013, 195–196, 184–191. [Google Scholar] [CrossRef]

- Besson, A.; Séger, M.; Giot, G.; Cousin, I. Identifying the characteristic scales of soil structural recovery after compaction from three in-field methods of monitoring. Geoderma 2013, 204–205, 130–139. [Google Scholar] [CrossRef]

- Arvidsson, J.; Keller, T. Soil stress as affected by wheel load and tyre inflation pressure. Soil Tillage Res. 2007, 96, 284–291. [Google Scholar] [CrossRef]

- Botta, G.F.; Becerra, A.T.; Tourn, F.B. Effect of the number of tractor passes on soil rut depth and compaction in two tillage regimes. Soil Tillage Res. 2009, 103, 381–386. [Google Scholar] [CrossRef]

- Becerra, A.T.; Botta, G.F.; Bravo, X.L.; Tourn, M.; Melcon, F.B.; Vazquez, J.; Rivero, D.; Linares, P.; Nardon, G. Soil compaction distribution under tractor traffic in almond (Prunus amigdalus L.) orchard in Almería España. Soil Tillage Res. 2010, 107, 49–56. [Google Scholar] [CrossRef]

- Schjønning, P.; Lamandé, M.; Munkholm, L.J.; Lyngvig, H.S.; Nielsen, J.A. Soil precompression stress, penetration resistance and crop yields in relation to differently-trafficked, temperate-region sandy loam soils. Soil Tillage Res. 2016, 163, 298–308. [Google Scholar] [CrossRef]

- Naderi-Boldaji, M.; Kazemzadeh, A.; Hemmat, A.; Rostami, S.; Keller, T. Changes in soil stress during repeated wheeling: A comparison of measured and simulated values. Soil Res. 2018, 56, 204–214. [Google Scholar] [CrossRef]

- Pulido-Moncada, M.; Munkholm, L.J.; Schjønning, P. Wheel load, repeated wheeling, and traction effects on subsoil compaction in northern Europe. Soil Tillage Res. 2019, 186, 300–309. [Google Scholar] [CrossRef]

- Seehusen, T.; Riggert, R.; Fleige, H.; Horn, R.; Riley, H. Soil compaction and stress propagation after different wheeling intensities on a silt soil in South-East Norway. Acta Agric. Scand. Sect. B—-Soil Plant Sci. 2019, 69, 343–355. [Google Scholar] [CrossRef]

- Horn, R.; Fleige, H. Risk assessment of subsoil compaction for arable soils in Northwest Germany at farm scale. Soil Tillage Res. 2009, 102, 201–208. [Google Scholar] [CrossRef]

- Schjønning, P.; Lamandé, M.; Keller, T.; Pedersen, J.; Stettler, M. Rules of thumb for minimizing subsoil compaction. Soil Use Manag. 2012, 28, 378–393. [Google Scholar] [CrossRef]

- Håkansson, I.; Reeder, R.C. Subsoil compaction by vehicles with high axle load—Extent, persistence and crop response. Soil Tillage Res. 1994, 29, 277–304. [Google Scholar] [CrossRef]

- Kroulík, M.; Kumhála, F.; Hůla, J.; Honzík, I. The evaluation of agricultural machines field trafficking intensity for different soil tillage technologies. Soil Tillage Res. 2009, 105, 171–175. [Google Scholar] [CrossRef]

- Kroulík, M.; Kvíz, Z.; Kumhála, F.; Hůla, J.; Loch, T. Procedures of soil farming allowing reduction of compaction. Precis. Agric. 2011, 12, 317–333. [Google Scholar] [CrossRef]

- Duttmann, R.; Brunotte, J.; Bach, M. Spatial analyses of field traffic intensity and modeling of changes in wheel load and ground contact pressure in individual fields during a silage maize harvest. Soil Tillage Res. 2013, 126, 100–111. [Google Scholar] [CrossRef]

- Duttmann, R.; Schwanebeck, M.; Nolde, M.; Horn, R. Predicting soil compaction risks related to field traffic during silage maize harvest. Soil Sci. Soc. Am. J. 2014, 78, 408–421. [Google Scholar] [CrossRef]

- Håkansson, I. Machinery-induced compaction of arable soils: Incidence–consequences–counter measures. In Reports from the Division of Soil Management; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2005; Volume 109. [Google Scholar]

- Augustin, K.; Kuhwald, M.; Brunotte, J.; Duttmann, R. FiTraM: A model for automated spatial analyses of wheel load, soil stress and wheel pass frequency at field scale. Biosyst. Eng. 2019, 180, 108–120. [Google Scholar] [CrossRef]

- FAO. World Reference Base for Soil Resources 2014, Update 2015: International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; FAO: Rome, Italy, 2015. [Google Scholar]

- Goetze, P.; Rucknagel, J.; Jacobs, A.; Marlander, B.; Koch, H.J.; Christen, O. Environmental impacts of different crop rotations in terms of soil compaction. J. Environ. Manag. 2016, 181, 54–63. [Google Scholar] [CrossRef]

- Kuhwald, M.; Dörnhöfer, K.; Oppelt, N.; Duttmann, R. Spatially Explicit Soil Compaction Risk Assessment of Arable Soils at Regional Scale: The SaSCiA-Model. Sustainability 2018, 10, 1618. [Google Scholar] [CrossRef]

- van den Akker, J.J.; Hoogland, T. Comparison of risk assessment methods to determine the subsoil compaction risk of agricultural soils in The Netherlands. Soil Tillage Res. 2011, 114, 146–154. [Google Scholar] [CrossRef]

- Söhne, W. Fundamentals of pressure distribution and soil compaction under tractor tires. Agric. Eng. 1958, 39, 276–290. [Google Scholar]

- Gut, S.; Chervet, A.; Stettler, M.; Weisskopf, P.; Sturny, W.G.; Lamandé, M.; Schjønning, P.; Keller, T. Seasonal dynamics in wheel load-carrying capacity of a loam soil in the Swiss Plateau. Soil Use Manag. 2015, 31, 132–141. [Google Scholar] [CrossRef]

- Lamandé, M.; Greve, M.H.; Schjønning, P. Risk assessment of soil compaction in Europe —Rubber tracks or wheels on machinery. CATENA 2018, 167, 353–362. [Google Scholar] [CrossRef]

| Season | Work Process | Machine ID a | Consumption [kg/L] | Harvest [t] | Inflation Pressure [kPa] | |

|---|---|---|---|---|---|---|

| 2014–2015 | soil tillage | PLOW002 | 90 100 | |||

| sowing | SOW002 | 190 | 100 100 | |||

| 4× | fertilizing | FER003 | 45/50/50/75 b | 120 100 | ||

| 2× | spraying | SP005 | 200 | 250 180 150 | ||

| 4× | SP006 | 200 | 250 180 300 | |||

| harvest | HAR003 | 10.8 | 100 100 | |||

| 2015–2016 | soil tillage | CULT002 | 90 90 t | |||

| HARR001 | 90 90 | |||||

| PLOW003 | 90 110 | |||||

| SECT001 | 70 70 130 | |||||

| sowing | SOW001 | 185 | 170 170 70 | |||

| spraying | SP006 | 200 | 250 180 300 | |||

| harvest | HAR001 | 51.4 | 170 140 | |||

| HTRAC001 | 90 100 220 220 | |||||

| 2016–2017 | soil tillage | CULT001 | 90 110 | |||

| HARR002 | 90 90 180 | |||||

| MULCH001 | 120 110 | |||||

| PLOW003 | 90–110 | |||||

| sowing | SOW002 | 190 | 90–110 | |||

| 2× | fertilizing | FER003 | 15 | 100 120 | ||

| 3× | spraying | SP005 | 200 | 250 180 150 | ||

| 3× | SP006 | 200 | 250 180 300 | |||

| harvest | HAR003 | 10.2 | 110 100 | |||

| 2017–2018 | soil tillage | CULT001 | 90 110 | |||

| CULT002 | 90–100 | |||||

| HARR001 | 90–100 | |||||

| MULCH001 | 100 100 | |||||

| PLOW001 | 90 110 | |||||

| SECT001 | 80 80 130 | |||||

| sowing | SOW003 | 5 | 90 110–180 180 | |||

| spraying | SP001 | 200 | 100 100 100 | |||

| fertilizing | FER003 | 100/150 | 100 120 | |||

| 7× | FER002 | 175 | 100 100 | |||

| FER001 | 750 | 100 100 220 | ||||

| FER001 | 500 | 100 100 220 | ||||

| 2× | spraying | SP003 | 200 | 100 100 100 | ||

| harvest | HAR002 | 96.5 | 200 210 210 |

| %—Area | ||||||||

|---|---|---|---|---|---|---|---|---|

| Headland | Crop Zone | Complete | ||||||

| Crop | Work Process | <5 Passes | ≥5 Passes | <5 Passes | ≥5 Passes | <5 Passes | ≥5 Passes | Total |

| WW | soil tillage | 47.6 | 18.7 | 42.5 | 1.2 | 43.3 | 5.7 | 49.0 |

| sowing | 59.5 | 6.1 | 47.0 | 50.0 | 1.6 | 51.5 | ||

| 6 × spraying | 8.4 | 0.5 | 4.8 | 0.3 | 5.7 | 0.4 | 6.1 | |

| 4 × fertilizer | 8.5 | 4.9 | 5.7 | 5.7 | ||||

| harvest | 51.9 | 1.3 | 33.6 | 37.4 | 0.3 | 37.7 | ||

| M | soil tillage | 61.5 | 12.9 | 51.7 | 3.2 | 53.6 | 5.7 | 59.2 |

| secondary tillage | 56.4 | 5.4 | 36.0 | 0.1 | 40.6 | 1.5 | 42.1 | |

| secondary tillage | 32.6 | 1.0 | 5.1 | 12.1 | 0.3 | 12.4 | ||

| sowing | 50.9 | 2.7 | 31.3 | 0.1 | 36.0 | 0.8 | 36.8 | |

| spraying | 7.4 | 0.7 | 4.8 | 0.3 | 5.4 | 0.4 | 5.8 | |

| harvest transport | 37.8 | 32.0 | 24.9 | 8.0 | 28.0 | 14.2 | 42.1 | |

| harvest chopper | 54.3 | 3.3 | 29.1 | 35.3 | 0.9 | 36.1 | ||

| WW | soil tillage | 52.5 | 2.1 | 46.8 | 1.2 | 47.4 | 1.4 | 48.8 |

| mulching | 48.9 | 4.8 | 29.4 | 0.4 | 34.1 | 1.5 | 35.6 | |

| sowing | 57.5 | 4.6 | 40.1 | 0.1 | 44.0 | 1.2 | 45.3 | |

| 6 × spraying | 8.0 | 0.6 | 4.8 | 0.3 | 5.6 | 0.4 | 6.0 | |

| 2 × fertilizer | 6.6 | 4.0 | 4.6 | 4.6 | ||||

| harvest | 56.9 | 4.0 | 34.6 | 39.6 | 1.0 | 40.7 | ||

| SB | soil tillage | 39.4 | 56.1 | 62.8 | 18.4 | 56.2 | 28.0 | 84.1 |

| mulching | 47.1 | 1.2 | 26.7 | 31.7 | 0.3 | 32.0 | ||

| secondary tillage | 54.0 | 3.2 | 25.7 | 32.6 | 0.9 | 33.5 | ||

| sowing | 47.1 | 1.5 | 32.5 | 0.3 | 36.0 | 0.6 | 36.5 | |

| kali | 15.7 | 1.5 | 10.1 | 11.4 | 0.4 | 11.8 | ||

| lime | 22.7 | 2.4 | 15.3 | 0.8 | 17.1 | 1.2 | 18.3 | |

| 8 × spraying | 9.4 | 1.3 | 5.0 | 0.3 | 6.1 | 0.5 | 6.7 | |

| 3 × fertilizer | 8.1 | 0.2 | 4.4 | 5.3 | 0.1 | 5.4 | ||

| harvest | 32.6 | 61.0 | 88.2 | 5.5 | 73.1 | 19.6 | 92.7 | |

| %—Area | ||||||||

|---|---|---|---|---|---|---|---|---|

| Headland | Crop Zone | Complete | ||||||

| Crop | Work Process | <5 Mg | ≥5 Mg | <5 Mg | ≥5 Mg | <5 Mg | ≥5 Mg | Total |

| WW | sowing | 63.7 | 1.9 | 47.0 | 51.1 | 0.5 | 51.5 | |

| harvest | 4.5 | 48.7 | 0.3 | 33.3 | 1.4 | 36.3 | 37.7 | |

| M | harvest transport | 64.1 | 5.7 | 32.4 | 0.5 | 40.3 | 1.8 | 42.1 |

| harvest chopper | 3.7 | 53.8 | 0.4 | 28.7 | 1.2 | 34.9 | 36.1 | |

| WW | harvest | 4.6 | 56.4 | 0.6 | 34.0 | 1.6 | 39.1 | 40.7 |

| sowing | 59.3 | 2.9 | 40.1 | 44.5 | 0.7 | 45.3 | ||

| SB | harvest | 0.0 | 93.7 | 0.0 | 93.6 | 0.0 | 92.8 | 92.8 |

| %—Area | ||||

|---|---|---|---|---|

| ≥3 Mg and ≥5 Wheel Passes | ||||

| Crop | Work Process | Headland | Crop Zone | Complete |

| WW | sowing | 6.1 | - | 1.6 |

| harvest | 1.3 | <0.1 | 0.3 | |

| soil tillage | 18.7 | 1.2 | 5.7 | |

| spraying | 0.6 | 0.3 | 0.4 | |

| M | sowing | 2.7 | 0.1 | 0.8 |

| soil tillage | 12.8 | 3.2 | 5.7 | |

| harvest transport | 31.9 | 8.0 | 14.2 | |

| harvest | 3.3 | <0.1 | 0.9 | |

| secondary tillage | 6.2 | 0.1 | 1.7 | |

| spraying | 0.7 | 0.3 | 0.4 | |

| WW | sowing | 4.6 | 0.1 | 1.2 |

| soil tillage | 2.1 | 1.2 | 1.4 | |

| harvest | 4.0 | <0.1 | 1.0 | |

| mulching | 4.7 | 0.4 | 1.5 | |

| spraying | 0.8 | 0.4 | 0.5 | |

| SB | sowing | 1.5 | 0.3 | 0.6 |

| fertilizer | 0.4 | 0.0 | 0.1 | |

| harvest | 60.8 | 5.3 | 19.6 | |

| kali | 1.5 | - | 0.4 | |

| lime | 2.4 | 0.8 | 1.2 | |

| mulching | 1.2 | <0.1 | 0.3 | |

| secondary tillage | 3.2 | <0.1 | 0.9 | |

| spraying | 1.4 | 0.3 | 0.6 | |

| sowing | 7.9 | <0.1 | 2.1 | |

| ≥5 Mg and ≥5 Wheel Passes | ||||

| WW | sowing | 0.6 | - | 0.2 |

| harvest | 1.3 | <0.1 | 0.3 | |

| M | harvest transport | 4.5 | 0.5 | 1.5 |

| harvest | 3.2 | <0.1 | 0.9 | |

| WW | sowing | 0.6 | <0.1 | 0.2 |

| harvest | 4.0 | <0.1 | 1.0 | |

| SB | harvest | 60.8 | 5.3 | 19.6 |

| sowing | 1.5 | <0.1 | 0.4 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Augustin, K.; Kuhwald, M.; Brunotte, J.; Duttmann, R. Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale. Geosciences 2020, 10, 292. https://doi.org/10.3390/geosciences10080292

Augustin K, Kuhwald M, Brunotte J, Duttmann R. Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale. Geosciences. 2020; 10(8):292. https://doi.org/10.3390/geosciences10080292

Chicago/Turabian StyleAugustin, Katja, Michael Kuhwald, Joachim Brunotte, and Rainer Duttmann. 2020. "Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale" Geosciences 10, no. 8: 292. https://doi.org/10.3390/geosciences10080292

APA StyleAugustin, K., Kuhwald, M., Brunotte, J., & Duttmann, R. (2020). Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale. Geosciences, 10(8), 292. https://doi.org/10.3390/geosciences10080292