Evaluation of Water Scarcity Footprint for Taiwanese Dairy Farming

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selected Dairy Farms

2.2. System Boundaries

2.3. Data Collection

2.4. Impact Assessment

2.5. Water Scarcity Productivity (WSP)

3. Results and Discussion

3.1. Water Consumption by In Situ Measurement and Estimation

3.2. Water Stress Index (WSI), Stress-Weighted Water Scarcity Footprint (WSF), and Water Scarcity Productivity (WSP)

3.3. Raw Milk Yield, Quality, and Pricing

3.4. Fresh Water Supply for Efficient Raw Milk Production

3.5. Impact Level Assessment

3.6. Impact Mitigation Options for the Agri-Food Industry

3.7. Limitations of This Study/Monthly Variation of the Water Stress Index (WSI)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, R.T. Current Situation of Taiwan’s Dairy Industry. In Collection of Notes on the Utilization and Planning of Dairy Cattle; Taiwan Provincial Consultation Council: Taichung County, Taiwan, 2005; pp. 8–15. [Google Scholar]

- COA. 2017 Annual Report of the Agricultural Statistics of the Republic of China; Statistical Office of the Council of Agriculture, Executive Yuan: Taipei, Taiwan, 2017; p. 106. (In Chinese)

- Pfister, S.; Boulay, A.M.; Berger, M.; Hadjikakou, M.; Motoshita, M.; Hess, T.; Ridoutt, B.; Weinzettel, J.; Scherer, L.; Döll, P.; et al. Understanding the LCA and ISO water footprint: A response to Hoekstra (2016) “A critique on the water-scarcity weighted water footprint in LCA”. Ecol. Indic. 2017, 72, 352–359. [Google Scholar] [CrossRef] [PubMed]

- Ridoutt, B.G.; Pfister, S. A revised approach to water footprinting to make transparent the impacts of consumption and production on global freshwater scarcity. Glob. Environ. Chang. 2010, 20, 113–120. [Google Scholar] [CrossRef]

- Koehler, A. Water use in LCA: Managing the planet’s freshwater resources. Int. J. Life Cycle Assess. 2008, 13, 451–455. [Google Scholar] [CrossRef]

- Bai, X.; Ren, X.; Khanna, N.Z.; Zhou, N.; Hu, M. Comprehensive water footprint assessment of the dairy industry chain based on ISO 14046: A case study in China. Resour. Conserv. Recycl. 2018, 132, 369–375. [Google Scholar] [CrossRef]

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the Environmental Impacts of Freshwater Consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Xu, C.-C.; Ridoutt, B.G.; Liu, J.-J.; Zhang, H.-L.; Chen, F.; Li, Y. Water availability footprint of milk and milk products from large-scale dairy production systems in Northeast China. J. Clean. Prod. 2014, 79, 91–97. [Google Scholar] [CrossRef]

- De Boer, I.J.M.; Hoving, I.E.; Vellinga, T.V.; Van de Ven, G.W.J.; Leffelaar, P.A.; Gerber, P.J. Assessing environmental impacts associated with freshwater consumption along the life cycle of animal products: The case of Dutch milk production in Noord-Brabant. Int. J. Life Cycle Assess. 2013, 18, 193–203. [Google Scholar] [CrossRef]

- Murphy, E.; de Boer, I.J.M.; van Middelaar, C.E.; Holden, N.M.; Shalloo, L.; Curran, T.P.; Upton, J. Water footprinting of dairy farming in Ireland. J. Clean. Prod. 2017, 140, 547–555. [Google Scholar] [CrossRef]

- Payen, S.; Falconer, S.; Ledgard, S.F. Water scarcity footprint of dairy milk production in New Zealand—A comparison of methods and spatio-temporal resolution. Sci. Total Environ. 2018, 639, 504–515. [Google Scholar] [CrossRef] [PubMed]

- Ridoutt, B.; Hodges, D. From ISO14046 to water footprint labeling: A case study of indicators applied to milk production in south-eastern Australia. Sci. Total Environ. 2017, 599–600, 14–19. [Google Scholar] [CrossRef] [PubMed]

- Usva, K.; Virtanen, E.; Hyvärinen, H.; Nousiainen, J.; Sinkko, T.; Kurppa, S. Applying water scarcity footprint methodologies to milk production in Finland. Int. J. Life Cycle Assess. 2019, 24, 351–361. [Google Scholar] [CrossRef]

- Zonderland-Thomassen, M.A.; Ledgard, S.F. Water footprinting—A comparison of methods using New Zealand dairy farming as a case study. Agric. Syst. 2012, 110, 30–40. [Google Scholar] [CrossRef]

- Quinteiro, P.; Ridoutt, B.G.; Arroja, L.; Dias, A.C. Identification of methodological challenges remaining in the assessment of a water scarcity footprint: A review. Int. J. Life Cycle Assess. 2018, 23, 164–180. [Google Scholar] [CrossRef]

- Cai, X.; Rosegrant, M.W. Chapter 10—World Water Productivity: Current Situation and Future Options. In Water Productivity in Agriculture: Limits and Opportunities for Improvement; Kijne, J.W., Barker, R., Molden, D., Eds.; CAB International: Wallingford, UK, 2003; pp. 163–178. [Google Scholar]

- HCG. Final Report of the Hsinchu County Local Climate Change Adjustment Project; Hsinchu County Government (HCG): Hsinchu, Taiwan, 2014. (In Chinese)

- Mekonnen, M.M.; Hoekstra, A.Y. A global assessment of the water footprint of farm animal products. Ecosystems 2012, 15, 401–415. [Google Scholar] [CrossRef]

- IDF. A Common Carbon Footprint Approach for Dairy: The IDF Guide to Standard Lifecycle Assessment Methodology for the Dairy Sector; Bulletin of the International Dairy Federation, International Dairy Federation (IDF): Brussels, Belgium, 2010; Available online: http://www.ukidf.org/ documents/bulletin445.pdf (accessed on 8 November 2019).

- COA. Analysis of Production Cost and Income of Major Livestock and Poultry Products in Taiwan; Council of Agriculture (COA), Executive Yuan, R.O.C.: Taipei, Taiwan, 2017; pp. 85–86. (In Chinese)

- Guinée, J.B.; Heijungs, R.; Huppes, G. Economic allocation: Examples and derived decision tree. Int. J. Life Cycle Assess. 2004, 9, 23–33. [Google Scholar] [CrossRef]

- Vörösmarty, C.J.; Green, P.; Salisbury, J.; Lammers, R.B. Global Water Resources: Vulnerability from Climate Change and Population Growth. Science 2000, 289, 284–288. [Google Scholar] [CrossRef] [PubMed]

- COA. Research and Development Strengthening Water Resources Allocation Measures (Second) Meeting; Council of Agriculture (COA), Executive Yuan, R.O.C.: Taipei, Taiwan, 2017. (In Chinese)

- COA. Application for Agricultural Land for Agricultural Facilities; Council of Agriculture (COA), Executive Yuan, R.O.C.: Taipei, Taiwan, 2019. (In Chinese)

- Beede, D.K. Water: The most important nutrient for dairy cattle. In Proceedings of the 31st Florida Dairy Production Conference, Gainesville, FL, USA, 12–13 April 1994; pp. 83–98. [Google Scholar]

- West, J.W. Effects of Heat-Stress on Production in Dairy Cattle. J. Dairy Sci. 2003, 86, 2131–2144. [Google Scholar] [CrossRef]

- Murry, M.R.; Davis, C.L.; McCoy, G.C. Factors affecting water consumption by Holstein cows in early lactation. J. Dairy Sci. 1983, 66, 35–38. [Google Scholar] [CrossRef]

- Milan, K.Z.; Coppock, C.E.; West, J.W.; Lanham, J.K.; Nave, D.H.; Labore, J.M. Effects of drinking water temperature on production responses in lactating Holstein cows in summer. J. Dairy Sci. 1986, 69, 1013–1019. [Google Scholar] [CrossRef]

- Lee, S.J.; Chan, C.L. Monitoring the quality of drinking and cleaning water on dairy farm. Taiwan Livest. Res. 2012, 45, 1–18. (In Chinese) [Google Scholar]

- COA. The Dairy Processing Plant Acquired the Raw Milk Raw Material Acceptance and Pricing Points of the Dairy Farmers; Council of Agriculture (COA), Executive Yuan, R.O.C.: Taipei, Taiwan, 2013. (In Chinese)

- Huang, S.Y.; Wu, M.X.; Wu, P.X. Nutrition Management of Lactating Cows; Dairy Farmer Association R.O.C.: Tainan City, Taiwan, 1999. (In Chinese) [Google Scholar]

- COA. Reports on the Quantitative Targets and Total Inventory of Agricultural Water Use; Documents of Council of Agriculture (COA), Executive Yuan, R.O.C.: Taipei, Taiwan, 2000. (In Chinese)

- Polsky, L.; von Keyserlingk, M.A.G. Invited review: Effects of heat stress on dairy cattle welfare. J. Dairy Sci. 2017, 100, 8645–8657. [Google Scholar] [CrossRef] [PubMed]

- Van, M.E.; Counotte, G.; Noordhuizen, J. Drinking water for dairy cattle: Always a benefit or a microbiological risk? Tijdschrift voor Diergeneeskunde 2013, 138, 86–97. [Google Scholar]

- MOI. Geographic Information System of Population Statistic Data; Department of Household Affair, Ministry of the Interior (MOI), R.O.C.: Taipei, Taiwan, 2018. (In Chinese)

- Kuoppala, K.; Khalili, H.; Jaakkola, S. Water intake and drinking behaviour of dairy cows offered grass silage. In Proceedings of the 38th International Congress of the ISAE—International Society for Applied Ethology, Helsinki, Finland, 3–7 August 2004; p. 149. [Google Scholar]

- MOEA. The Study Corporate Water Footprint Inventory Mechanism and Related Policy Promotion; Water Resources Agency, Ministry of Economic Affairs (MOEA), R.O.C.: Taipei, Taiwan, 2015; Volume 2/2, ISBN 9789860473643.

- Zhou, C.Y. Current situation of water demand in Taiwan and management strategy tools. Civ. Hydraul. 2015, 42, 19–29. (In Chinese) [Google Scholar]

- Wognum, N.; Bremmers, H.; Trienekens, J.; Van der Vorst, J.; Bloemhof-Ruwaard, J. Systems for sustainability and transparency of food supply chains—Current status and challenges. Adv. Eng. Inform. 2011, 25, 65–76. [Google Scholar] [CrossRef]

- Lin, Y.Y. Discussion on Consumer Green Consumption Concept and Green Consumption Behavior. Master’s Thesis, Institute of International Business Studies, National Taiwan University, Taipei City, Taiwan, June 2019. [Google Scholar]

- Cai, M.F. Ecological label information effect on consumer behavior. Master’s Thesis, Information Management Institute, The National Central University, Taoyuan County, Taiwan, June 2011. [Google Scholar]

- Pfister, S.; Bayer, P. Monthly water stress: Spatially and temporally explicit consumptive water footprint of global crop production. J. Clean. Prod. 2014, 73, 52–62. [Google Scholar] [CrossRef]

| Parameters | Units | Farm Number | Average | Total | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| Livestock | ||||||||

| Number of heifers < 6 mths old | head | 22 | 69 | 36 | 27 | 64 | 44 | - |

| Number of heifers > 6 mths old | head | 60 | 54 | 73 | 122 | 73 | 76 | - |

| Number of bred heifer | head | 23 | 48 | 19 | 30 | 56 | 35 | - |

| Number of milkers | head | 86 | 178 | 77 | 200 | 160 | 140 | - |

| Number of dry cows | head | 12 | 25 | 6 | 16 | 16 | 15 | - |

| Total dairy cattle | head | 203 | 374 | 211 | 395 | 369 | 310 ± 95 | 1552 |

| Workload | heads/labor | 41 | 47 | 70 | 56 | 53 | 53 ± 11 | - |

| Raw milk fat content | % | 3.81 | 3.87 | 3.86 | 3.74 | 3.94 | 3.85 | - |

| Raw milk protein content | % | 3.33 | 3.24 | 3.17 | 3.27 | 3.37 | 3.27 | - |

| Raw milk production | t | 919 | 1798 | 681 | 1713 | 1683 | 1359 | - |

| FPCM a | t | 316 | 617 | 234 | 588 | 578 | 467 | 2333 |

| Daily raw milk yield | kg | 29.3 | 27.6 | 24.2 | 23.5 | 28.9 | 26.7 | - |

| Daily FPCM yield | kg | 10.1 | 9.5 | 8.3 | 8.0 | 10.0 | 9.2 | - |

| Number of water meters | set | 2 | 4 | 2 | 2 | 2 | ||

| Total water consumption | m3/yr | 11,544 | 19,356 | 4176 | 16,812 | 15,576 | 13,493 ± 5923 | 67,464 |

| Water consumption per head | m3/head/yr | 56.1 | 51.8 | 19.9 | 43.0 | 43.4 | 43 ± 14 | |

| 95% of Water consumption b | L/kg FPCM | 34.9 | 29.9 | 17.0 | 27.3 | 25.7 | 27 ± 7 | - |

| Feed | ||||||||

| Chinese Pennisetum | t | - | - | - | - | 200 | - | 200 |

| Pangola grass | t | 406.5 | - | 72.5 | - | - | - | 479 |

| Parameters | Units | Farm No. | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Available length of the water trough | cm/head | 14.0 | 10.1 | 3.7 | 5.9 | 13.4 |

| Water trough supply | heads/water trough | 16.9 | 31.2 | 26.5 | 43.9 | 21.7 |

| Average water trough depth | cm | 27.5 | 29.2 | 30.75 | 23.3 | 35 |

| Average water trough width | cm | 45 | 54.2 | 71.25 | 39.4 | 30 |

| Item No. | Categories of Water Consumption (m3) | Farm No. | Total (m3)/ Ratio (%) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| Water meter | 962 ± 390 (100%) | 1613 ± 186 (100%) | 348 ± 65 (100%) | 1401 ± 169 (100%) | 1298 ± 473 (100%) | 5622 (100%) | |

| 1 | Water used in the milking room | 146 ± 13 (15%) | 146 ± 73 (9%) | 85 ± 9 (24.4%) | 150 ± 46 (11%) | 155 ± 31 (12%) | 552 (9.8%) |

| 2 | Clean and supplement the water trough | 169 ± 68 (18%) | 105 ± 18 (7%) | 5.5 ± 0.8 (2%) | 27 ± 6 (2%) | 75 ± 29 (6%) | 382 (6.8%) |

| 3 | Cooling water | 108 ± 140 (11%) | 301 ± 278 (19%) | 6 ± 20 (2%) | 102 ± 117 (7%) | 239 ± 250 (18%) | 756 (13.4%) |

| 4 | TMR mixed water | 35 ± 3 (4%) | 61 ± 0 (4%) | 18 ± 2 (5.3%) | 150 ± 8 (11%) | 79 ± 37 (6%) | 343 (6.1%) |

| 5 | Cleaning water | 11 ± 13 (1%) | 179 ± 61 (11%) | 4.4±2.7 (1.3%) | 151 ± 92 (11%) | 35 ± 30 (3%) | 380 (6.8%) |

| 6 | Miscellaneous work including disinfection | 0.4 ± 1.4 (0%) | 5.4 ± 1.4 (0.3%) | 1.0 ± 0 (0.3%) | 80 ± 31 (6%) | 3.8 ± 0.6 (0.3%) | 91 (0.2%) |

| 7 | Drinking meter | 480 ± 175 (50%) | 811 ± 169 (50%) | 222 ± 47 (64%) | 708 ± 93 (51%) | 690 ± 209 (53%) | 2911 (52%) |

| Estimated total (Item 1–7) | 950 | 1608 | 342 | 1368 | 1277 | 5415 | |

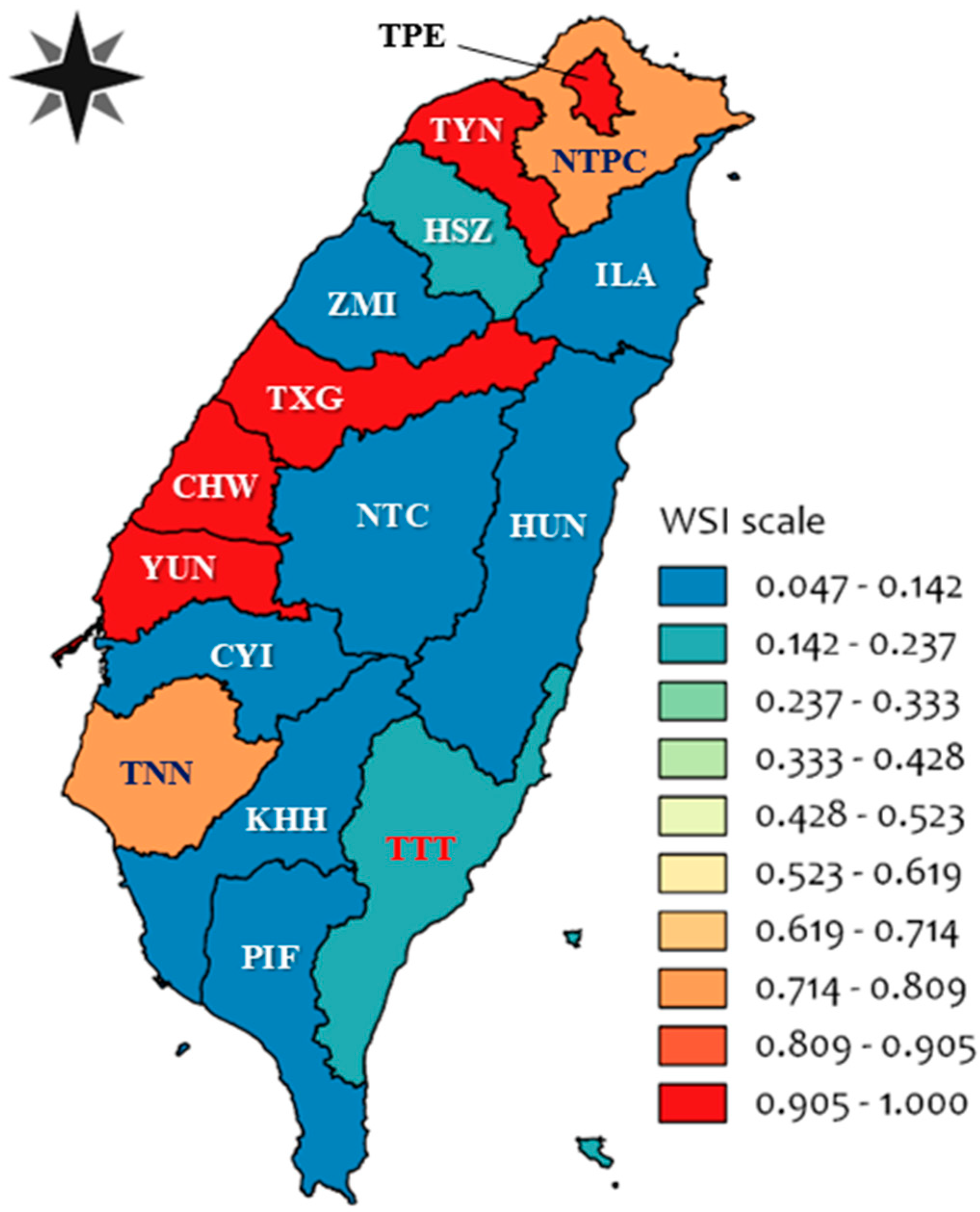

| Regions | County/City | Water Stress Index (WSI) | Stress-Weighted Water Scarcity Footprint (WSF) | Water Scarcity Productivity (WSP) |

|---|---|---|---|---|

| H2Oeq/kg FPCM | Fat and Protein Corrected Milk (FPCM)-kg/m3-Water | |||

| Northern Taiwan | New Taipei City (NTPC) | 0.73 | 32.7 | 0.051 |

| Taipei City (TPE) | 1 | 44.8 | 0.037 | |

| Taoyuan City (TYN) | 1 | 44.8 | 0.037 | |

| Hsinchu Country (HSZ) | 0.21 | 9.4 | 0.178 | |

| Ilan Country (ILA) | 0.08 | 3.6 | 0.468 | |

| Central Taiwan | Miaoli Country (ZMI) | 0.1 | 4.5 | 0.375 |

| Taichung Country (TXG) | 1 | 44.8 | 0.037 | |

| Changhua Country (CHW) | 1 | 44.8 | 0.037 | |

| Nantou Country (NTC) | 0.05 | 2.2 | 0.749 | |

| Yunlin Country (YUN) | 0.99 | 44.3 | 0.038 | |

| Southern Taiwan | Chiayi Country (CYI) | 0.05 | 2.2 | 0.749 |

| Tainan City (TNN) | 0.77 | 34.5 | 0.049 | |

| Kaohsiung City (KHH) | 0.14 | 6.3 | 0.268 | |

| Pingtung Country (PIF) | 0.12 | 5.4 | 0.312 | |

| Eastern Taiwan | Taitung Country (TTT) | 0.15 | 6.7 | 0.250 |

| Hualien Country (HUN) | 0.09 | 4.0 | 0.416 |

| Solids-Not-Fat (%) | 8.00–8.16 | 8.17–8.32 | 8.33–8.48 | 8.49–8.64 | 8.65–8.80 | 8.81–8.99 | 9.00–9.17 | Above 9.18 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seasons | C | T | W | C | T | W | C | T | W | C | T | W | C | T | W | C | T | W | C | T | W | C | T | W | |

| Milk Fat (%) | |||||||||||||||||||||||||

| 2.8 | 0.54 | 0.70 | 0.77 | 0.55 | 0.71 | 0.77 | 0.55 | 0.71 | 0.78 | 0.55 | 0.72 | 0.78 | 0.56 | 0.72 | 0.79 | 0.56 | 0.72 | 0.79 | 0.56 | 0.73 | 0.79 | 0.57 | 0.73 | 0.80 | |

| 2.9 | 0.60 | 0.77 | 0.84 | 0.61 | 0.77 | 0.84 | 0.61 | 0.78 | 0.85 | 0.61 | 0.78 | 0.85 | 0.62 | 0.79 | 0.85 | 0.62 | 0.79 | 0.86 | 0.62 | 0.79 | 0.86 | 0.63 | 0.80 | 0.86 | |

| 3.0 | 0.66 | 0.84 | 0.90 | 0.67 | 0.84 | 0.91 | 0.67 | 0.85 | 0.91 | 0.67 | 0.85 | 0.92 | 0.68 | 0.85 | 0.92 | 0.68 | 0.86 | 0.92 | 0.68 | 0.86 | 0.93 | 0.69 | 0.86 | 0.93 | |

| 3.1 | 0.67 | 0.85 | 0.92 | 0.68 | 0.85 | 0.92 | 0.68 | 0.86 | 0.93 | 0.68 | 0.86 | 0.93 | 0.69 | 0.87 | 0.93 | 0.69 | 0.87 | 0.94 | 0.69 | 0.87 | 0.94 | 0.70 | 0.88 | 0.94 | |

| 3.2 | 0.70 | 0.88 | 0.94 | 0.70 | 0.88 | 0.95 | 0.70 | 0.89 | 0.95 | 0.71 | 0.89 | 0.96 | 0.71 | 0.89 | 0.96 | 0.71 | 0.90 | 0.96 | 0.72 | 0.90 | 0.97 | 0.72 | 0.90 | 0.97 | |

| 3.3 | 0.71 | 0.89 | 0.95 | 0.71 | 0.89 | 0.96 | 0.72 | 0.90 | 0.97 | 0.72 | 0.90 | 0.97 | 0.73 | 0.91 | 0.98 | 0.73 | 0.92 | 0.98 | 0.74 | 0.92 | 0.99 | 0.74 | 0.93 | 0.99 | |

| 3.4 | 0.71 | 0.90 | 0.96 | 0.72 | 0.90 | 0.97 | 0.73 | 0.91 | 0.98 | 0.74 | 0.92 | 0.99 | 0.74 | 0.93 | 0.99 | 0.75 | 0.93 | 1.00 | 0.76 | 0.94 | 1.01 | 0.76 | 0.95 | 1.01 | |

| 3.5 | 0.72 | 0.90 | 0.97 | 0.73 | 0.91 | 0.98 | 0.73 | 0.92 | 0.98 | 0.74 | 0.93 | 0.99 | 0.75 | 0.93 | 1.00 | 0.75 | 0.94 | 1.01 | 0.76 | 0.95 | 1.01 | 0.77 | 0.95 | 1.02 | |

| 3.6 | 0.73 | 0.91 | 0.98 | 0.73 | 0.92 | 0.98 | 0.74 | 0.92 | 0.99 | 0.75 | 0.93 | 1.00 | 0.75 | 0.94 | 1.01 | 0.76 | 0.95 | 1.01 | 0.77 | 0.95 | 1.02 | 0.77 | 0.96 | 1.03 | |

| 3.7 | 0.73 | 0.92 | 0.98 | 0.74 | 0.92 | 0.99 | 0.75 | 0.93 | 1.00 | 0.75 | 0.94 | 1.00 | 0.76 | 0.94 | 1.01 | 0.77 | 0.95 | 1.02 | 0.77 | 0.96 | 1.03 | 0.78 | 0.97 | 1.03 | |

| 3.8 | 0.74 | 0.92 | 0.99 | 0.75 | 0.93 | 1.00 | 0.75 | 0.94 | 1.00 | 0.76 | 0.94 | 1.01 | 0.77 | 0.95 | 1.02 | 0.77 | 0.96 | 1.03 | 0.78 | 0.97 | 1.03 | 0.79 | 0.97 | 1.04 | |

| 3.9 | 0.74 | 0.93 | 1.00 | 0.75 | 0.94 | 1.00 | 0.76 | 0.94 | 1.01 | 0.77 | 0.95 | 1.02 | 0.77 | 0.96 | 1.02 | 0.78 | 0.96 | 1.03 | 0.79 | 0.97 | 1.04 | 0.79 | 0.98 | 1.05 | |

| 4.0 | 0.75 | 0.93 | 1.00 | 0.76 | 0.94 | 1.01 | 0.76 | 0.95 | 1.02 | 0.77 | 0.96 | 1.02 | 0.78 | 0.96 | 1.03 | 0.78 | 0.97 | 1.04 | 0.79 | 0.98 | 1.04 | 0.80 | 0.99 | 1.05 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, W.-T.; Su, J.-J. Evaluation of Water Scarcity Footprint for Taiwanese Dairy Farming. Animals 2019, 9, 956. https://doi.org/10.3390/ani9110956

Liao W-T, Su J-J. Evaluation of Water Scarcity Footprint for Taiwanese Dairy Farming. Animals. 2019; 9(11):956. https://doi.org/10.3390/ani9110956

Chicago/Turabian StyleLiao, Wei-Tse, and Jung-Jeng Su. 2019. "Evaluation of Water Scarcity Footprint for Taiwanese Dairy Farming" Animals 9, no. 11: 956. https://doi.org/10.3390/ani9110956

APA StyleLiao, W.-T., & Su, J.-J. (2019). Evaluation of Water Scarcity Footprint for Taiwanese Dairy Farming. Animals, 9(11), 956. https://doi.org/10.3390/ani9110956