Is the Grass Always Greener? Comparing the Environmental Impact of Conventional, Natural and Grass-Fed Beef Production Systems

Abstract

:Simple Summary

Abstract

1. Introduction

2. Experimental Section

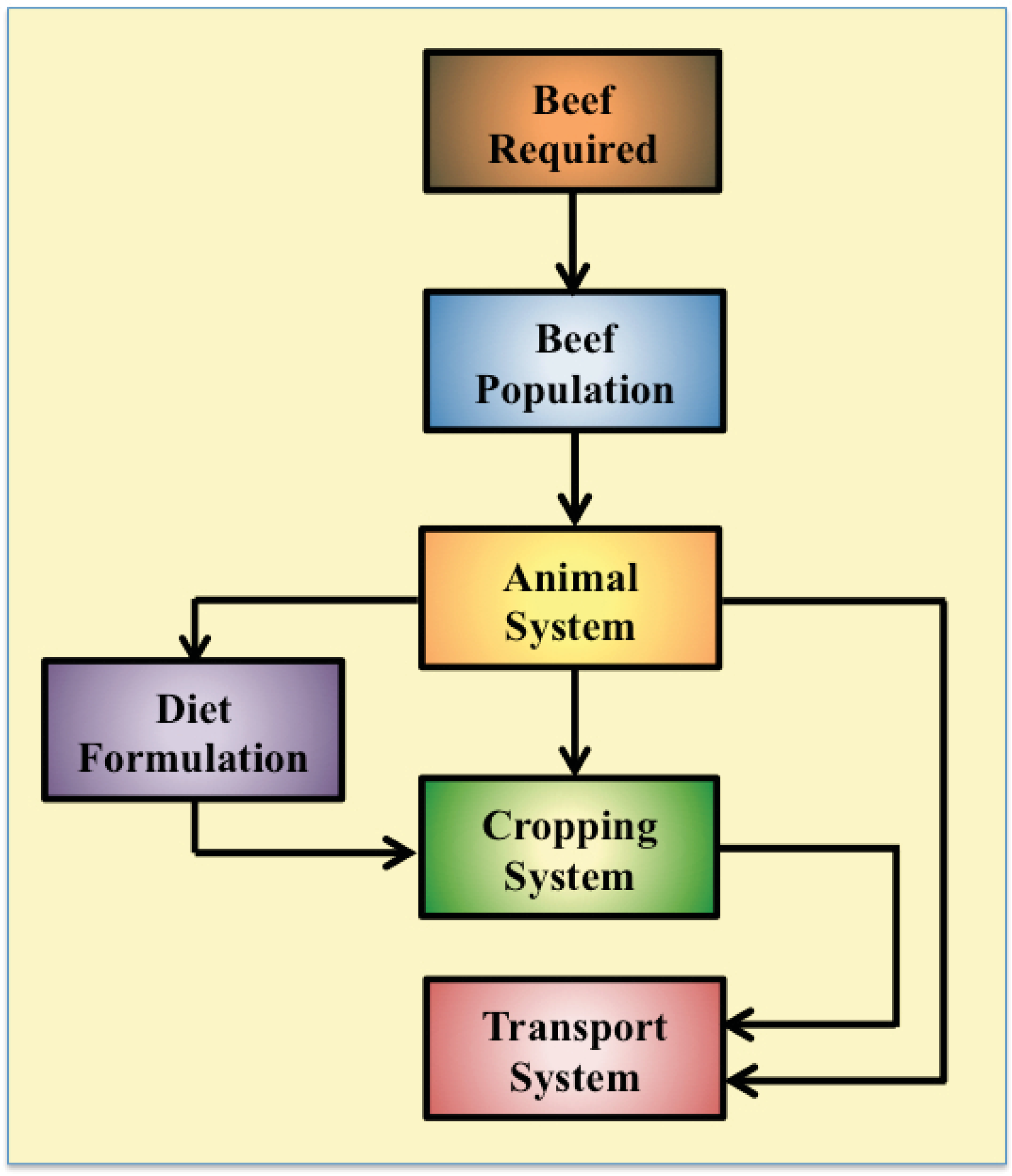

2.1. The Beef Production System Environmental Model

2.1.1. The Beef Population Sub-Model

2.1.2. The Animal System Sub-Model

2.1.3. The Cropping System Sub-Model

2.1.4. The Transportation Sub-Model

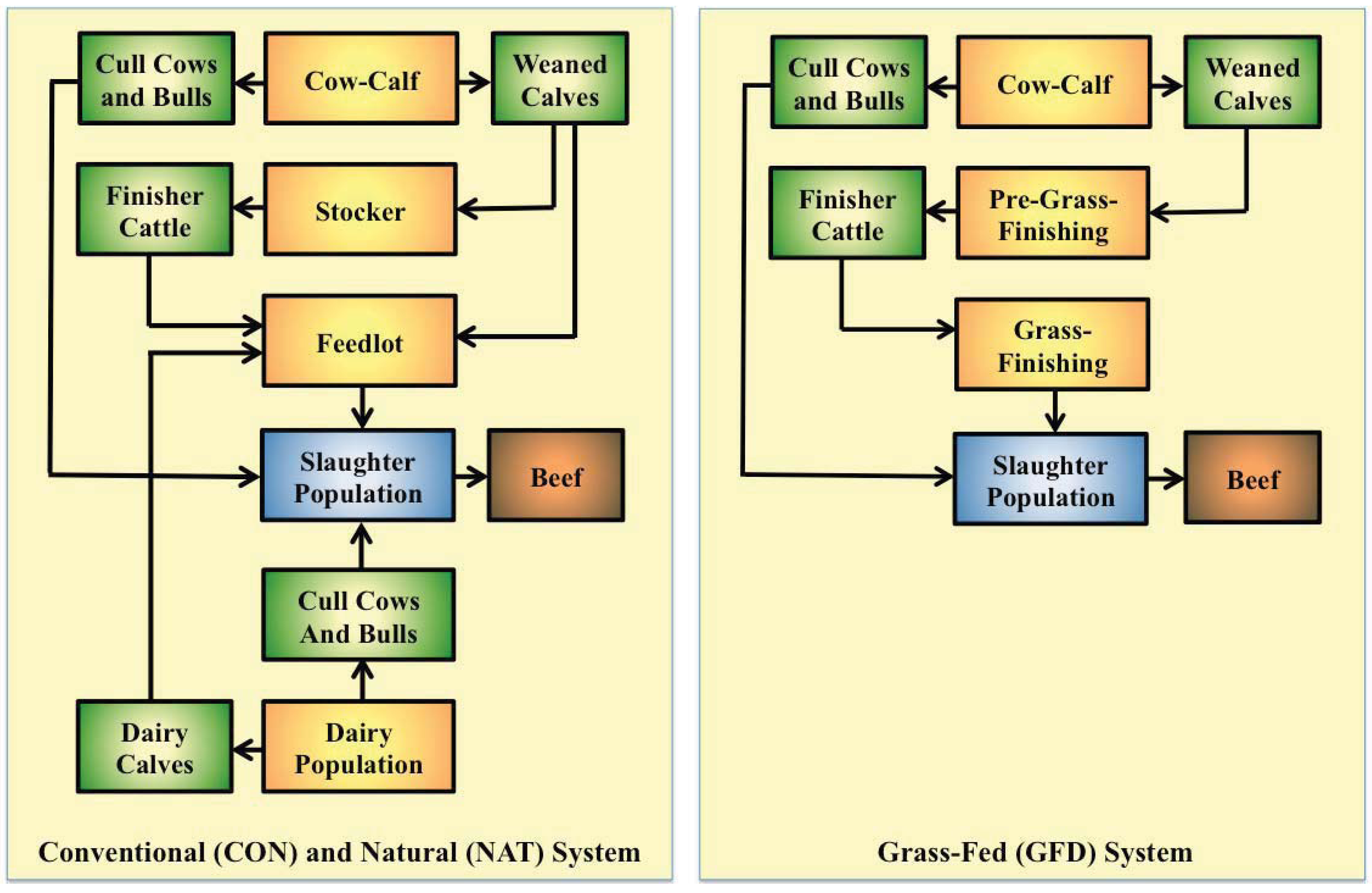

2.2. Conventional and Natural Beef Production System Characteristics

| System | Time in sub-system (d) | Growth rate (kg/d) | Weight change (kg) | End weight (kg) | Slaughter data | ||

|---|---|---|---|---|---|---|---|

| Age (d) | Weight (kg) | ||||||

| Pre-weaned beef calf | CON | 207 | 0.98 | 203 | 245 | N/A | N/A |

| NAT | 207 | 0.98 | 203 | 245 | N/A | N/A | |

| GFD | 207 | 0.88 | 183 | 226 | N/A | N/A | |

| Pre-weaned dairy calf b | CON | 56 | 0.92 | 51 | 92 | N/A | N/A |

| NAT | 56 | 0.92 | 51 | 92 | N/A | N/A | |

| Stocker | CON | 123 | 0.99 | 122 | 367 | N/A | N/A |

| NAT | 159 | 0.77 | 122 | 367 | N/A | N/A | |

| Pre-grass finishing | GFD | 159 | 0.42 | 67 | 293 | N/A | N/A |

| Calf-fed beef in feedlot | CON | 203 | 1.61 | 326 | 571 | 410 | 571 |

| NAT | 203 | 1.20 | 244 | 489 | 435 | 489 | |

| Calf-fed dairy in feedlot | CON | 259 | 1.74 | 449 | 541 | 315 | 541 |

| NAT | 259 | 1.48 | 383 | 476 | 315 | 476 | |

| Yearling-fed beef in feedlot | CON | 110 | 1.86 | 204 | 571 | 440 | 571 |

| NAT | 110 | 1.48 | 163 | 530 | 440 | 530 | |

| Grass-finished | GFD | 313 | 0.61 | 192 | 486 | 679 | 486 |

2.3. Grass-Fed Beef Production System Characteristics

3. Results and Discussion

| System | CON | NAT | GFD |

|---|---|---|---|

| Animals | |||

| Supporting population b (×103) | 5,539 | 6,265 | 8,482 |

| Stockers/Pre-finishing (×103) | 628 | 920 | 1,378 |

| Finishing animals (×103) | 2,334 | 2,640 | 3,045 |

| Total animals slaughtered c (×103) | 2,756 | 3,117 | 3,580 |

| Total population d (×103) | 7,046 | 8,257 | 12,510 |

| Nutrition resources | |||

| Population energy requirement e (MJ × 106) | 228,651 | 254,841 | 353,484 |

| Feedstuffs (t × 103) | 54,476 | 67,263 | 106,166 |

| Land (ha × 103) | 5,457 | 6,678 | 9,868 |

| Water (liters × 106) | 485,698 | 572,477 | 1,957,224 |

| Fossil fuel energy (MJ × 106) | 8,773 | 10,304 | 12,290 |

| Waste output | |||

| Manure (t × 103) | 36,976 | 45,431 | 74,392 |

| Nitrogen excretion (t) | 399,789 | 486,683 | 807,759 |

| Phosphorus excretion (t) | 37,190 | 46,897 | 76,567 |

| Greenhouse gas emissions | |||

| Methane f (t) | 501,593 | 586,729 | 854,561 |

| Nitrous oxide g (t) | 7,532 | 9,078 | 13,833 |

| Carbon footprint h (t CO2-eq × 103) | 15,989 | 18,772 | 26,785 |

4. Conclusions

Conflict of Interest

References and Notes

- What is Sustainability? Available online: http://www.epa.gov/Sustainability/basicinfo.htm (accessed on 15 March 2010).

- How to Feed the World in 2050; FAO: Rome, Italy, 2009.

- Tilman, D.; Cassman, K.G.; Matson, P.A.; Naylor, R.; Polasky, S. Agricultural sustainability and intensive production practices. Nature 2002, 418, 671–677. [Google Scholar] [CrossRef]

- Xue, H.; Mainville, D.; You, W.; Nayga, R.M. Consumer preferences and willingness to pay for grass-fed beef: Empirical evidence from in-store experiments. Food Quality Preference 2010, 21, 857–866. [Google Scholar] [CrossRef]

- Capper, J.L. The environmental impact of United States beef production: 1977 compared with 2007. J. Anim. Sci. 2011, 89, 4249–4261. [Google Scholar] [CrossRef]

- Lawrence, J.D.; Ibarburu, M. Economic Analysis of Pharmaceutical Technologies in Modern Beef Production in a Bioeconomy Era; Iowa State University: Ames, IA, USA, 2007. [Google Scholar]

- Capper, J.L.; Hayes, D.J. The environmental and economic impact of removing growth-enhancing technologies from United States beef production. J. Anim. Sci. 2012. submitted. [Google Scholar]

- MacArthur Clark, J.A.; Pottera, M.; Hardinga, E. The welfare implications of animal breeding and breeding technologies in commercial agriculture. Livest. Sci. 2006, 103, 270–281. [Google Scholar] [CrossRef]

- Fraser, D. Toward a global perspective on farm animal welfare. Appl. Anim. Behav. Sci. 2008, 113, 330–339. [Google Scholar] [CrossRef]

- Anderson, S.A.; Yeaton Woo, R.W.; Crawford, L.M. Risk assessment of the impact on human health of resistant Campylobacter jejuni from fluoroquinolone use in beef cattle. Food Control 2001, 12, 13–25. [Google Scholar] [CrossRef]

- Harrington, L.M.B.; Lu, M. Beef feedlots in southwestern Kansas: Local change, perceptions, and the global change contex. Global Environ. Change 2002, 12, 273–282. [Google Scholar] [CrossRef]

- Niche beef products comprise small share of total retail beef sales. Available online: http://www.beef.org/uDocs/nichebeefproducts.pdf (accessed on 16 January 2012).

- USDA/AMS, United States Standards for Livestock and Meat Marketing Claims, Grass (Forage) Fed Claim for Ruminant Livestock and the Meat Products Derived From Such Livestock—Docket No. AMS–LS–07–0113; LS–05–09; USDA: Washington, DC, USA, 2007.

- Agricultural Modeling and Training Systems (AMTS). In Cattle Pro; Cornell Research Foundation: Ithaca, NY, USA, 2006.

- Beckett, J.L.; Oltjen, J.W. Estimation of the water requirement for beef production in the United States. J. Anim. Sci. 1993, 71, 818–826. [Google Scholar]

- Meyer, U.; Stahl, W.; Flachowsky, G. Investigations on the water intake of growing bulls. Livest. Sci. 2006, 103, 186–191. [Google Scholar] [CrossRef]

- Moe, P.W.; Tyrrell, H.F. Methane production in dairy cows. J. Dairy Sci. 1979, 62, 1583–1586. [Google Scholar] [CrossRef]

- Kaspar, H.F.; Tiedje, J.M. Dissimilatory reduction of nitrate and nitrite in the bovine rumen: Nitrous oxide production and effect of acetylene. Appl. Environ. Microbiol. 1981, 41, 705–709. [Google Scholar]

- Kirchgessner, M.; Windisch, W.; Muller, H.L.; M, K. Release of methane and of carbon dioxide by dairy cattle. Agribiol. Res. 1991, 44, 2–9. [Google Scholar]

- U.S. EPA, Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2008; U.S. EPA: Washington, DC, USA, 2010.

- IPCC, IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies (IGES) for the IPCC: Kanagawa, Japan, 2006.

- USDA/NASS, 2007 Census of Agriculture: Farm and Ranch Irrigation Survey; USDA: Washington, DC, USA, 2007.

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United State. Agr. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- U.S. EPA, Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends: 1975 Through 2009; US EPA: Washington, DC, USA, 2009.

- USDA, Part I: Baseline Reference of Feedlot Management Practices, 1999; USDA:APHIS:VS, CEAH, National Animal Health Monitoring System: Fort Collins, CO, USA, 2000.

- USDA, Beef 2007–08 Part I: Reference of Beef Cow-Calf Management Practices in the United States, 2007–08; USDA:APHIS:VS, CEAH, National Animal Health Monitoring System: Fort Collins, CO, USA, 2009.

- USDA, Beef 2007–08 Part II: Reference of Beef Cow-calf Management Practices in the United States, 2007–08; USDA:APHIS:VS, CEAH, National Animal Health Monitoring System: Fort Collins, CO, USA, 2009.

- USDA, Part II: Baseline Reference of Feedlot Health and Health Management, 1999; USDA:APHIS:VS, CEAH, National Animal Health Monitoring System: Fort Collins, CO, USA, 2000.

- Cederberg, C.; Stadig, M. System expansion and allocation in life cycle assessment of milk and beef production. Int. J. LCA. 2003, 8, 350–356. [Google Scholar] [CrossRef]

- Capper, J.L.; Cady, R.A.; Bauman, D.E. The environmental impact of dairy production: 1944 compared with 2007. J. Anim. Sci. 2009, 87, 2160–2167. [Google Scholar] [CrossRef]

- Sprott, L.R.; Goehring, T.B.; Beverly, J.R.; Corah, L.R. Effects of ionophores on cow herd production: A review. J. Anim. Sci. 1988, 66, 1340–1346. [Google Scholar]

- Perrett, T.; Wildman, B.K.; Jim, G.K.; Vogstad, A.R.; Fenton, R.K.; Hannon, S.L.; Schunicht, O.C.; Abutarbush, S.M.; Booker, C.W. Evaluation of the efficacy and cost-effectiveness of Melengestrol Acetate in feedlot heifer calves in Western Canada. Vet. Ther. 2008, 9, 223–240. [Google Scholar]

- Sides, G.E.; Swingle, R.S.; Vasconcelos, J.T.; Borg, R.C.; Moseley, W.M. Effect of feeding Melengestrol Acetate, Monensin, and Tylosin on performance, carcass measurements, and liver abscesses of feedlot heifers. Profess. Anim. Scient. 2009, 25, 459–464. [Google Scholar]

- Scramlin, S.M.; Platter, W.J.; Gomez, R.J.; Choat, W.T.; McKeith, F.T.; Killefer, J. Comparative effects of ractopamine hydrochloride and zilpaterol hydrochloride on growth performance, carcass traits, and longissimus tenderness of finishing steers. J. Anim. Sci. 2010, 88, 1823–1829. [Google Scholar] [CrossRef]

- Montgomery, J.L.; Krehbiel, C.R.; Cranston, J.J.; Yates, D.A.; Hutcheson, J.P.; Nichols, W.T.; Streeter, M.N.; Bechtol, D.T.; Johnson, E.; TerHune, T.; Montgomery, T.H. Dietary zilpaterol hydrochloride. I. Feedlot performance and carcass traits of steers and heifers. J. Anim. Sci. 2009, 87, 1374–1383. [Google Scholar]

- Montgomery, J.L.; Krehbiel, C.R.; Cranston, J.J.; Yates, D.A.; Hutchseon, J.P.; Nichols, W.T.; Streeter, M.N.; Swingle, R.S.; Montgomery, T.H. Effects of dietary zilpaterol hydrochloride on feedlot performance and carcass characteristics of beef steers fed with and without monensin and tylosin. J. Anim. Sci. 2009, 87, 1013–1023. [Google Scholar]

- Elam, N.A.; Vasconcelos, J.T.; Hilton, G.G.; VanOverbeke, D.L.; Lawrence, T.E.; Montgomery, T.H.; Nichols, W.T.; Streeter, M.N.; Hutcheson, J.P.; Yates, D.A.; Galyean, M.L. Effect of zilpaterol hydrochloride duration of feeding on performance and carcass characteristics of feedlot cattle. J. Anim. Sci. 2009, 87, 2133–2141. [Google Scholar]

- Laudert, S.; Vogel, G.; Schroeder, A.; Platter, W.; Van Koevering, M. Effects of ractopamine fed to finishing steers. II. Summary of six studies—Carcass traits. J. Anim. Sci. 2005, 83 (Suppl. 1), 112. [Google Scholar]

- Schroeder, A.L.; Polser, D.M.; Laudert, S.B.; Vogel, G.J.; Ripberger, T.; Van Koevering, M.T. The Effect of Optaflexx on Growth Performance and Carcass Traits of Steers and Heifers. In Proceedings of the 19th Annual Southwest Nutrition and Management Conference, Tempe, AZ, USA, 24–25 February 2004; pp. 65–81.

- Laudert, S.; Vogel, G.; Schroeder, A.; Platter, W.; Van Koevering, M. Effects of ractopamine fed to finishing steers. I. Summary of six studies—Growth performance. J. Anim. Sci. 2005, 83 (Suppl. 1), 112. [Google Scholar]

- Abney, C.S.; Vasconcelos, J.T.; McMeniman, J.P.; Keyser, S.A.; Wilson, K.R.; Vogel, G.J.; Galyean, M.L. Effects of ractopamine hydrochloride on performance, rate and variation in feed intake, and acid-base balance in feedlot cattle. J. Anim. Sci. 2007, 85, 3090–3098. [Google Scholar] [CrossRef]

- Gruber, S.L.; Tatum, J.D.; Engle, T.E.; Mitchell, M.A.; Laudert, S.B.; Schroeder, A.L.; Platter, W.J. Effects of ractopamine supplementation on growth performance and carcass characteristics of feedlot steers differing in biological type. J. Anim. Sci. 2007, 85, 1809–1815. [Google Scholar]

- Vogel, G.J.; Duff, G.C.; Lehmkuhler, J.; Beckett, J.L.; Drouilliard, J.S.; Schroeder, A.L.; Platter, W.J.; Van Koevering, M.T.; Laudert, S.B. Effect of ractopamine hydrochloride on growth performance and carcass traits in calf-fed and yearling Holstein steers fed to slaughter. Profess. Anim. Sci. 2009, 25, 26–32. [Google Scholar]

- Anderson, D.B.; Moody, D.E.; Hancock, D.L. Beta-Adrenergic Agonists. In Encyclopedia of Animal Science; Pond, W.G., Bell, A.W., Eds.; Marcel-Dekker Inc.: New York, NY, USA, 2005. [Google Scholar]

- Baxa, T.J.; Hutcheson, J.P.; Miller, M.F.; Brooks, J.C.; Nichols, W.T.; Streeter, M.N.; Yates, D.A.; Johnson, B.J. Additive effects of a steroidal implant and zilpaterol hydrochloride on feedlot performance, carcass characteristics, and skeletal muscle messenger ribonucleic acid abundance in finishing steers. J. Anim. Sci. 2010, 88, 330–337. [Google Scholar]

- Avery, A.; Avery, D. The Environmental Safety and Benefits of Pharmaceutical Technologies in Beef Production; Hudson Institute, Center for Global Food Issues: Washington, DC, USA, 2007. [Google Scholar]

- Pelletier, N.; Pirog, R.; Rasmussen, R. Comparative life cycle environmental impacts of three beef production strategies in the Upper Midwestern United States. Agr. Syst. 2010, 103, 380–389. [Google Scholar] [CrossRef]

- Bauman, D.E.; Capper, J.L. Future Challenges and Opportunities in Animal Nutrition. In Proceedings of 26th Southwest Nutrition & Management Conference, Tempe, AZ, USA, 24 February 2011.

- Global Agriculture Towards 2050; FAO: Rome, Italy, 2009.

- Garnett, T. Livestock-related greenhouse gas emissions: Impacts and options for policy makers. Environ. Sci. Policy 2009, 12, 491–503. [Google Scholar] [CrossRef]

- Pimentel, D.; Pimentel, M. Sustainability of meat-based and plant-based diets and the environment. Am. J. Clin. Nutr. 2003, 78, 660S–663S. [Google Scholar]

- We can feed 10 billion of us, study finds—But it won’t be easy. Available online: http://www.grist.org/population/2011-10-13-we-can-feed-10-billion-of-us-study-finds-but-it-wont-be-easy (accessed on 6 January 2012).

- Wilkinson, J.M. Re-defining efficiency of feed use by livestock. Animal 2011, 5, 1014–1022. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food security: The challenge of feeding 9 billion people. Science 2010, 327, 812–818. [Google Scholar]

- Harta, M.R.; Quin, B.F.; Nguyen, M.L. Phosphorus runoff from agricultural land and direct fertilizer effects: A review. J. Environ. Qual. 2004, 33, 1954–1972. [Google Scholar] [CrossRef]

- Arogo, J.; Westerman, P.W.; Heber, A.J.; Robarge, W.P.; Classen, J.J. Ammonia Emissions from Animal Feeding Operations. In Animal Agriculture and the Environment: National Center for Manure and Animal Waste Management White Papers; Rice, J.M., Caldwell, D.F., Humenik, F.J., Eds.; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Beauchemin, K.A.; Janzen, H.H.; Little, S.M.; McAllister, T.A.; McGinn, S.M. Mitigation of greenhouse gas emissions from beef production in western Canada—Evaluation using farm-based life cycle assessment. An. Feed. Sci. Tech. 2011, 166-167, 663–677. [Google Scholar] [CrossRef]

- Cederberg, C.; Meyer, D.; Flysjo, A. Life Cycle Inventory of Greenhouse Gas Emissions and Use of Land and Energy in Brazilian Beef Production; The Swedish Institute for Food and Biotechnology: Gothenburg, Sweden, 2009. [Google Scholar]

- Peters, G.M.; Rowley, H.V.; Wiedemann, S.; Tucker, R.; Short, M.D.; Schultz, M.S. Red meat production in Australia: Life cycle assessment and comparison with overseas studies. Environ. Sci. Technol. 2010, 44, 1327–1332. [Google Scholar]

- Ridoutt, B.G.; Sanguansri, P.; Harper, G.S. Comparing carbon and water footprints for beef cattle production in Southern Australia. Sustainability 2011, 3, 2443–2455. [Google Scholar] [CrossRef]

- Meat Eater's Guide to Climate Change and Health; Environmental Working Group: Washington, DC, USA, 2011.

- Johnson, K.A.; Johnson, D.E. Methane emissions from cattle. J. Anim. Sci. 1995, 73, 2483–2492. [Google Scholar]

- Pinares-Patiño, C.S.; Waghorn, G.C.; Hegarty, R.S.; Hoskin, S.O. Effects of intensification of pastoral farming on greenhouse gas emissions in New Zealand. N. Z. Vet. J. 2009, 57, 252–261. [Google Scholar] [CrossRef]

- Bruce, J.P.; Frome, M.; Haites, E.; Janzen, H.; Lal, R.; Pawtian, K. Carbon sequestration in soils. J. Soil Water Conserv. 1999, 54, 382–389. [Google Scholar]

- Conant, R.T.; Paustian, K.; Elliott, E.T. Grassland management and conversion into grassland: Effects on soil carbon. Ecol. Appl. 2001, 11, 343–355. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Capper, J.L. Is the Grass Always Greener? Comparing the Environmental Impact of Conventional, Natural and Grass-Fed Beef Production Systems. Animals 2012, 2, 127-143. https://doi.org/10.3390/ani2020127

Capper JL. Is the Grass Always Greener? Comparing the Environmental Impact of Conventional, Natural and Grass-Fed Beef Production Systems. Animals. 2012; 2(2):127-143. https://doi.org/10.3390/ani2020127

Chicago/Turabian StyleCapper, Judith L. 2012. "Is the Grass Always Greener? Comparing the Environmental Impact of Conventional, Natural and Grass-Fed Beef Production Systems" Animals 2, no. 2: 127-143. https://doi.org/10.3390/ani2020127

APA StyleCapper, J. L. (2012). Is the Grass Always Greener? Comparing the Environmental Impact of Conventional, Natural and Grass-Fed Beef Production Systems. Animals, 2(2), 127-143. https://doi.org/10.3390/ani2020127