Economic Feasibility of Implementing Stunning for Farmed Fish in the EU: A Multi-Species Assessment

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Approach

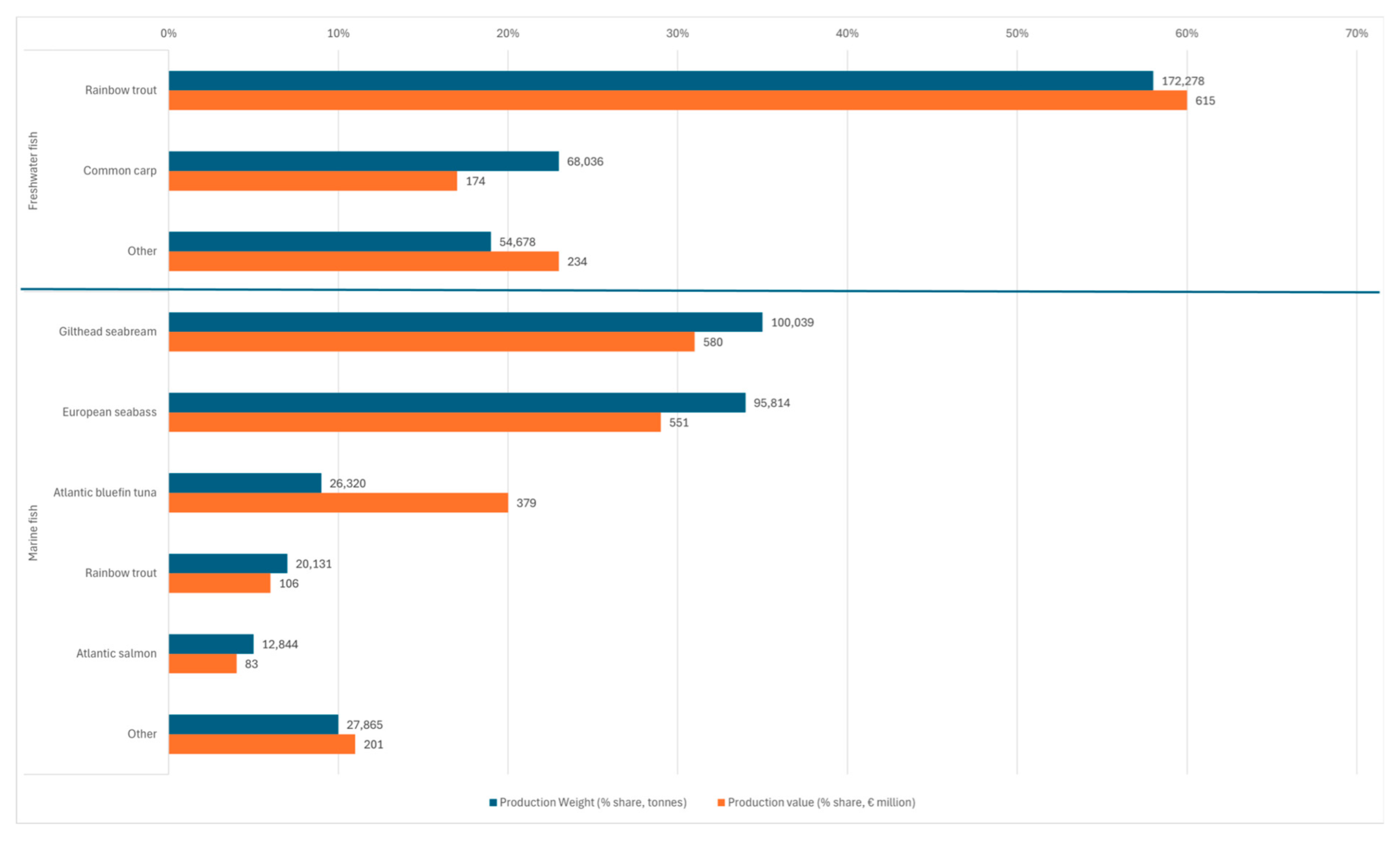

2.2. Study Scope

2.3. Species Scope

2.4. Segment Selection Method

2.5. Cost Estimation

2.6. Assumptions

2.7. Sensitivity Analyses

2.8. Cost Analysis Metrics

2.9. Economic Feasibility Assessment

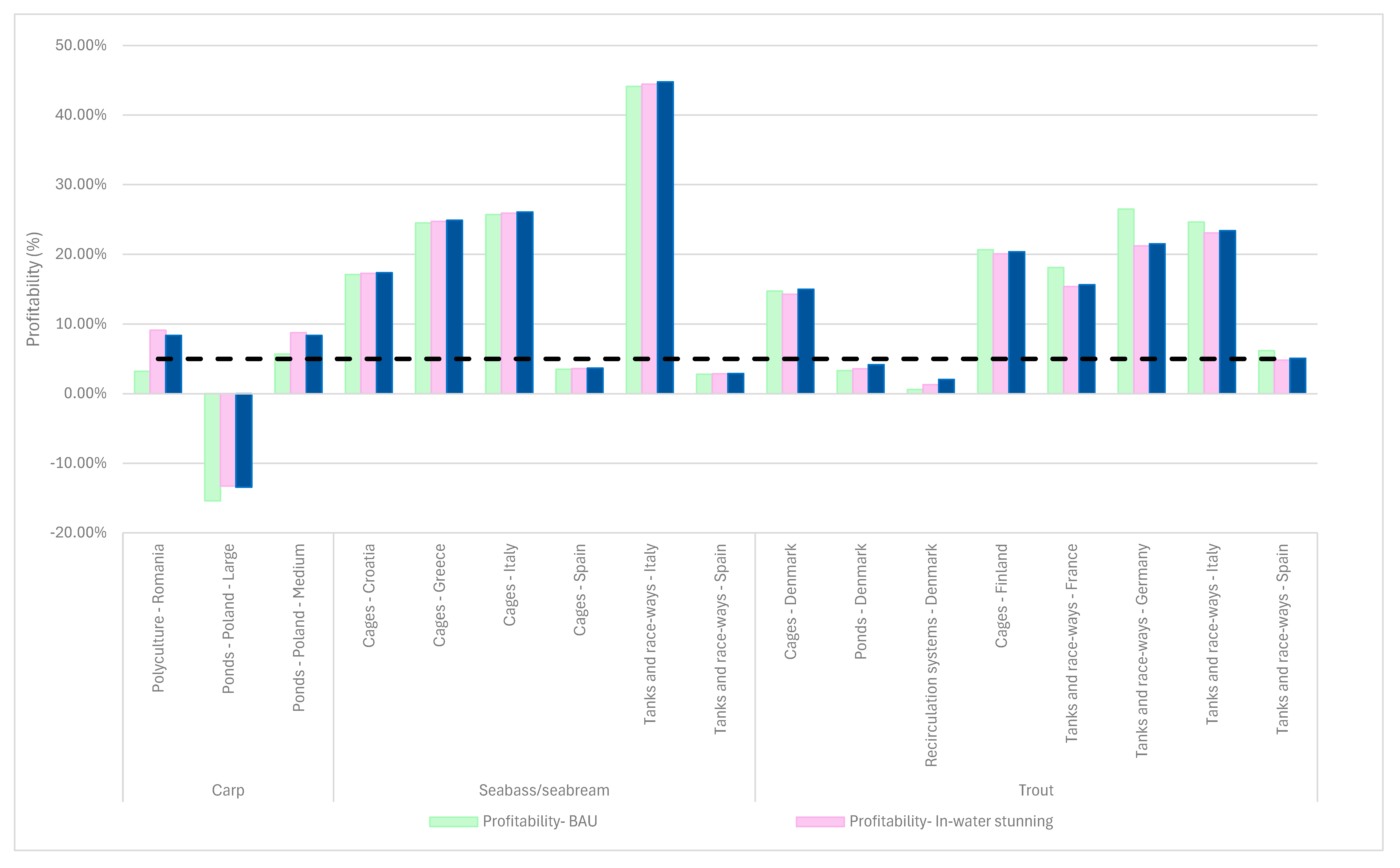

- Net Margin (with stunning) > 5%: Economically robust;

- 0–5%: Slim margins;

- <0%: Economically unfeasible.

3. Results

3.1. Do Stunning Methods Increase Production Costs?

3.1.1. The Total Additional Costs per Enterprise

| Dry Electrical Stunning (EUR) | In-Water Electrical Stunning (EUR) | Overall Average Cost (EUR) | |

|---|---|---|---|

| All species | 18,390 | 1234 | 9812 |

| Carp | 25,601 | 23,551 | 24,576 |

| Trout | −63,816 | −26,559 | −45,188 |

| Seabass and Seabream | 20,183 | 27,133 | 23,658 |

3.1.2. Cost per Unit of Production

3.1.3. Costs as a Percentage of Current Production Costs

3.1.4. Costs as a Share of the Final Product Price

3.1.5. Summary of Stunning Cost Impacts

3.2. How Does Cost Pass-Through Affect Economic Feasibility?

3.2.1. Market-Based Cost Pass-Through

3.2.2. Sensitivity Analyses on Cost Pass-Through

3.2.3. Sensitivity Analyses on Increased Annual Costs

3.2.4. Summary of Cost Pass-Through Impacts

4. Discussion

4.1. Comparison with Previous Studies

4.2. Evaluation of Modeling Assumptions and Real-World Feasibility

4.3. Implications for Policy and Practice

4.4. Limitations

4.5. Future Research

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Segment | Number of Enterprises | Production per Enterprise (BAU) (kg) | Revenue per Enterprise (BAU) (€) | Costs per Enterprise (BAS) (€) | Profit per Enterprise (BAU) (€) | Profitability (BAU) (%) |

|---|---|---|---|---|---|---|

| Carp Polyculture—Romania | 272 | 53,569 | 156,338 | 127,748 | 28,591 | 18.3% |

| Carp ponds—Poland—Large | 42 | 190,000 | 547,200 | 607,704 | −26,600 | −4.9% |

| Carp ponds—Poland—Medium | 81 | 90,000 | 305,100 | 264,106 | 53,100 | 17.4% |

| Carp (all segments) | 395 | 75,546 | 228,404 | 206,743 | 27,748 | 12.1% |

| Seabass & Seabream Cages—Croatia | 23 | 584,703 | 6,791,923 | 5,600,537 | 1,191,386 | 17.5% |

| Seabass & Seabream Cages—Greece | 300 | 349,799 | 3,291,141 | 2,457,579 | 833,562 | 25.3% |

| Seabass & Seabream Cages—Italy | 23 | 345,398 | 3,196,520 | 2,348,097 | 848,423 | 26.5% |

| Seabass & Seabream Cages—Spain | 25 | 1,283,135 | 9,660,380 | 9,293,618 | 366,762 | 3.8% |

| Seabass & Seabream Tanks and race-ways—Italy | 21 | 179,132 | 1,689,519 | 916,822 | 772,697 | 45.7% |

| Seabass & Seabream Tanks and race-ways—Spain | 4 | 1,001,831 | 11,719,845 | 11,368,532 | 351,312 | 3.0% |

| Seabass and Seabream (all segments) | 396 | 418,215 | 3,879,762 | 3,061,918 | 817,844 | 21.1% |

| Trout Cages—Denmark | 4 | 3,339,710 | 19,757,767 | 17,138,911 | 2,618,856 | 13.3% |

| Trout Ponds—Denmark | 55 | 309,080 | 1,429,840 | 1,373,988 | 55,851 | 3.9% |

| Trout Recirculation systems—Denmark | 17 | 962,905 | 3,769,300 | 3,746,336 | 22,964 | 0.6% |

| Trout Cages—Finland | 30 | 289,281 | 1,932,769 | 1,534,046 | 398,724 | 20.6% |

| Trout Tanks and race-ways—France | 322 | 119,412 | 623,869 | 510,980 | 112,889 | 18.1% |

| Trout Tanks and race-ways—Germany | 151 | 47,198 | 350,980 | 258,056 | 92,923 | 26.5% |

| Trout Tanks and race-ways—Italy | 143 | 259,533 | 998,385 | 752,380 | 246,005 | 24.6% |

| Trout Tanks and race-ways—Spain | 81 | 220,050 | 1,031,533 | 967,863 | 63,670 | 6.2% |

| Trout (all segments) | 802 | 194,089 | 945,858 | 800,733 | 145,125 | 15.3% |

References

- Sinclair, M.; Hötzel, M.J.; Lee, N.Y.P.; de Luna, M.C.T.; Sharma, A.; Idris, M.; Islam, M.A.; Iyasere, O.S.; Navarro, G.; Ahmed, A.A.; et al. Animal Welfare at Slaughter: Perceptions and Knowledge across Cultures. Front. Anim. Sci. 2023, 4, 1141789. [Google Scholar] [CrossRef]

- European Commission. Welfare of Farmed Fish: Common Practices during Transport and at Slaughter; European Commission, Directorate-General for Health and Food Safety: Brussels, Belgium, 2017; pp. 1–186. [Google Scholar]

- Clemente, G.A.; Tolini, C.; Boscarino, A.; Lorenzi, V.; Dal Lago, T.L.; Benedetti, D.; Bellucci, F.; Manfrin, A.; Trocino, A.; Rota Nodari, S. Farmed Fish Welfare during Slaughter in Italy: Survey on Stunning and Killing Methods and Indicators of Unconsciousness. Front. Vet. Sci. 2023, 10, 1253151. [Google Scholar] [CrossRef]

- Giménez-Candela, M.; Saraiva, J.L.; Bauer, H. The Legal Protection of Farmed Fish in Europe—Analysing the Range of EU Legislation and the Impact of International Animal Welfare Standards for the Fishes in European Aquaculture. Derecho Anim. 2020, 11, 65–119. [Google Scholar] [CrossRef]

- Lines, J.A.; Spence, J. Safeguarding the Welfare of Farmed Fish at Harvest. Fish Physiol. Biochem. 2012, 38, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Robb, D.H.F.; Kestin, S.C. Methods Used to Kill Fish: Field Observations and Literature Reviewed. Anim. Welf. 2002, 11, 269–282. [Google Scholar] [CrossRef]

- Van De Vis, H.; Kolarevic, J.; Stien, L.H.; Kristiansen, T.S.; Gerritzen, M.; Van De Braak, K.; Abbink, W.; Sæther, B.-S.; Noble, C. Welfare of Farmed Fish in Different Production Systems and Operations. In The Welfare of Fish; Kristiansen, T.S., Fernö, A., Pavlidis, M.A., Van De Vis, H., Eds.; Animal Welfare; Springer International Publishing: Cham, Switzerland, 2020; Volume 20, pp. 323–361. ISBN 978-3-030-41674-4. [Google Scholar]

- Dehcheshmeh, A.M.; Khosravizadeh, M.; Khosravizadeh, S.M.; Babadi, S.; Shiry, N. Electro-Immobilisation and Fish Welfare: An Investigation into Stress, Consciousness, and Physiological Aspects During Slaughter. J. Appl. Anim. Welf. Sci. 2025, 28, 243–258. [Google Scholar] [CrossRef] [PubMed]

- Acerete, L.; Reig, L.; Alvarez, D.; Flos, R.; Tort, L. Comparison of Two Stunning/Slaughtering Methods on Stress Response and Quality Indicators of European Sea Bass (Dicentrarchus labrax). Aquaculture 2009, 287, 139–144. [Google Scholar] [CrossRef]

- Schuck-Paim, C.; Alonso, W.J.; Pereira, P.A.; Saraiva, J.L.; Cerqueira, M.; Chiang, C.; Sneddon, L.U. Quantifying the Welfare Impact of Air Asphyxia in Rainbow Trout Slaughter for Policy and Practice. Sci. Rep. 2025, 15, 19850. [Google Scholar] [CrossRef]

- EFSA. Welfare Aspects of the Main Systems of Stunning and Killing the Main Commercial Species of Animals. EFSA J. 2004, 45, 122. [Google Scholar] [CrossRef]

- Gräns, A.; Niklasson, L.; Sandblom, E.; Sundell, K.; Algers, B.; Berg, C.; Lundh, T.; Axelsson, M.; Sundh, H.; Kiessling, A. Stunning Fish with CO2 or Electricity: Contradictory Results on Behavioural and Physiological Stress Responses. Animal 2016, 10, 294–301. [Google Scholar] [CrossRef]

- Caggiano, M. Quality in Harvesting and Post-Harvesting Procedures—Influence on Quality. Fish Freshness and Quality Assessment for Sea Bass and Sea Bream. Cah. Options Méditerranéennes 2000, 51, 55–61. [Google Scholar]

- Vargas Baldi, S.C.; Parisi, G.; Bonelli, A.; Balieiro, J.C.C.; Lapa Guimarães, J.; Macedo Viegas, E.M. Effects of Different Stunning/Slaughter Methods on Frozen Fillets Quality of Cobia (Rachycentron Canadum). Aquaculture 2018, 486, 107–113. [Google Scholar] [CrossRef]

- Rucinque, D.S.; van de Vis, H.; Reimert, H.; Roth, B.; Foss, A.; Taconeli, C.A.; Gerritzen, M. Pre-Slaughter Stunning of Farmed Atlantic Halibut in CO2-Saturated Seawater: Assessment of Unconsciousness by Electroencephalography (EEG). Animals 2023, 13, 1993. [Google Scholar] [CrossRef] [PubMed]

- Oliveira Filho, P.R.C.; Oliveira, P.J.M.G.; Viegas, E.M.M.; Melo, M.P.; Natori, M.M.; Baldi, S.C.V. Physiological Stress and Meat Quality of Pacu (Piaractus Mesopotamicus) Submitted to CO2 Narcosis, Hypothermia and Electrical Stunning. Aquac. Res. 2021, 52, 5034–5043. [Google Scholar] [CrossRef]

- Bowman, J.; van Nuland, N.; Hjelmstedt, P.; Berg, C.; Gräns, A. Evaluation of the Reliability of Indicators of Consciousness during CO2 Stunning of Rainbow Trout and the Effects of Temperature. Aquac. Res. 2020, 51, 5194–5202. [Google Scholar] [CrossRef]

- Camargo-dos-Santos, B.; Carlos, C.L.; Favero-Neto, J.; Alves, N.P.C.; Gonçalves, B.B.; Giaquinto, P.C. Welfare in Nile Tilapia Production: Dorsal Fin Erection as a Visual Indicator for Insensibility. Animals 2021, 11, 3007. [Google Scholar] [CrossRef]

- EFSA. Species-Specific Welfare Aspects of the Main Systems of Stunning and Killing of Farmed Turbot. EFSA J. 2009, 7, 1073. [Google Scholar] [CrossRef]

- EFSA. SCIENTIFIC OPINION Species-Specific Welfare Aspects of the Main Systems of Stunning and Killing of Farmed Carp Scientific Opinion of the Panel on Animal Health and Welfare (Question N° EFSA-Q-2008-439). EFSA J. 2009, 1013, 1–37. [Google Scholar]

- FAO. Fishery and Aquaculture Statistics. Global Aquaculture Production 1950–2021; FAO: Rome, Italy, 2023. [Google Scholar]

- FishCount. Towards More Humane Commercial Fishing. Available online: https://fishcount.org.uk/ (accessed on 20 March 2025).

- Mood, A.; Brooke, A. Estimating the Number of Fish Caught in Global Fishing Each Year; Fishcount: San Diego, CA, USA, 2010; p. 18. [Google Scholar]

- FAO. The State of World Fisheries and Aquaculture 2024 Blue Transformation in Action; The State of World Fisheries and Aquaculture (SOFIA); FAO: Rome, Italy, 2024; p. 264. [Google Scholar]

- FAO Fishery and Aquaculture Statistics. Global Fish Trade. All Partners Aggregated 1976–2020. Available online: www.fao.org/fishery/statistics/software/fishstatj/en%0A (accessed on 2 September 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Farm to Fork Strategy for a Fair, Healthy and Environmentally-Friendly Food System; European Commission: Brussels, Belgium, 2020; pp. 1–20. [Google Scholar]

- European Commission. Revision of the Animal Welfare Legislation. Available online: https://food.ec.europa.eu/animals/animal-welfare/evaluations-and-impact-assessment/revision-animal-welfare-legislation_en (accessed on 2 April 2025).

- European Commission. Inception Impact Assessment: Revision of the EU Legislation on Animal Welfare; European Commission, Directorate-General for Health and Food Safety: Brussels, Belgium, 2023. [Google Scholar]

- Mood, A.; Lara, E.; Boyland, N.K.; Brooke, P. Estimating Global Numbers of Farmed Fishes Killed for Food Annually from 1990 to 2019. Anim. Welf. 2023, 32, e12. [Google Scholar] [CrossRef]

- EUMOFA. The EU Market Overview. Available online: https://eumofa.eu/supply-balance? (accessed on 27 March 2025).

- de la Rosa, I.; Castro, P.L.; Ginés, R. Twenty Years of Research in Seabass and Seabream Welfare during Slaughter. Animals 2021, 11, 2164. [Google Scholar] [CrossRef]

- Espmark, Å.M.; Grimsbø, E.; Patel, S.; Rimstad, E.; Seljetun, O.; Vindas, M.A.; Granquist, E.G.; Helen, G.; Jørgensen, M.; Nordgreen, J.; et al. Assessment of Welfare Aspects of Stunning and Killing of Farmed Fish in Norway; VKM: Oslo, Norway, 2025; pp. 1–85. [Google Scholar]

- Brijs, J.; Hjelmstedt, P.; Sundell, E.; Berg, C.; Sandblom, E.; Gräns, A. Effects of Electrical and Percussive Stunning on Neural, Ventilatory and Cardiac Responses of Rainbow Trout. Aquaculture 2025, 594, 741387. [Google Scholar] [CrossRef]

- Brijs, J.; Sundell, E.; Hjelmstedt, P.; Berg, C.; Senčić, I.; Sandblom, E.; Axelsson, M.; Lines, J.; Bouwsema, J.; Ellis, M.; et al. Humane Slaughter of African Sharptooth Catfish (Clarias gariepinus): Effects of Various Stunning Methods on Brain Function. Aquaculture 2021, 531, 735887. [Google Scholar] [CrossRef]

- Hjelmstedt, P.; Sundell, E.; Brijs, J.; Berg, C.; Sandblom, E.; Lines, J.; Axelsson, M.; Gräns, A. Assessing the Effectiveness of Percussive and Electrical Stunning in Rainbow Trout: Does an Epileptic-like Seizure Imply Brain Failure? Aquaculture 2022, 552, 738012. [Google Scholar] [CrossRef]

- Hjelmstedt, P.; To, F.; Allen, P.J.; Gräns, A. Assessment of Brain Function during Stunning and Killing of Channel Catfish (Ictalurus punctatus). Aquaculture 2025, 596, 741825. [Google Scholar] [CrossRef]

- Sundell, E.; Brijs, J.; Gräns, A. The Quest for a Humane Protocol for Stunning and Killing Nile Tilapia (Oreochromis niloticus). Aquaculture 2024, 593, 741317. [Google Scholar] [CrossRef]

- Hjelmstedt, P.; To, F.; Gräns, A.; Allen, P. Use of Electroencephalogram (EEG) to Optimize Stunning Efficiency and Animal Welfare in Commercial Catfish Production. Aquaculture 2024, 592, 741200. [Google Scholar] [CrossRef]

- Wicke, M.; Murn, N.; Hochman, A. Barriers to Adopting Pre-Slaughter Electrical Stunning of Sea Bream and Sea Bass in Mediterranean Aquaculture: A Gap Analysis. Open Sci. Framew. 2024. [Google Scholar] [CrossRef]

- Springlea, R. Economic Evaluation of Humane Slaughter Methods for Farmed Fish in Italy; Essere Animali: Milan, Italy, 2022; pp. 1–15. [Google Scholar]

- Springlea, R. Economic Evaluation of Humane Slaughter Methods for Farmed Fish in Greece; Essere Animali: Milan, Italy, 2022; pp. 1–15. [Google Scholar]

- Jerlström, J.; Huang, W.; Ehlorsson, C.-J.; Eriksson, I.; Reneby, A.; Comin, A. Stochastic Partial Budget Analysis of Strategies to Reduce the Prevalence of Lung Lesions in Finishing Pigs at Slaughter. Front. Vet. Sci. 2022, 9, 957975. [Google Scholar] [CrossRef] [PubMed]

- Alimi, T. Partial Budget Analysis for On-Farm Research; IITA: Ibadan, Nigeria, 2000; ISBN 978-978-131-043-0. [Google Scholar]

- van de Vis, H.; Reimert, H.; Grimsbø, E.; Roth, B. Electrical Stunning and Killing of Atlantic Salmon; Nofima, Norwegian Seafood Research Fund (FHF): Tromsø, Norway, 2023; pp. 1–14. [Google Scholar]

- Santurtun, E.; Broom, D.M.; Phillips, C.J.C. A Review of Factors Affecting the Welfare of Atlantic Salmon (Salmo salar). Anim. Welf. 2018, 27, 193–204. [Google Scholar] [CrossRef]

- JRC. Scientific, Technical and Economic Committee for Fisheries (STECF), Economic Report on the EU Aquaculture (STECF22-17); Publications Office of the European Union: Luxembourg, 2023; pp. 1–324. [Google Scholar]

- JRC. Scientific, Technical and Economic Committee for Fisheries (STECF)—The EU Aquaculture Sector—Economic Report 2020 (STECF-20-12); Publications Office of the European Union: Luxembourg, 2021; pp. 1–389. [Google Scholar]

- Lasner, T.; Mytlewski, A.; Nourry, M.; Rakowski, M.; Oberle, M. Carp Land: Economics of Fish Farms and the Impact of Region-Marketing in the Aischgrund (DEU) and Barycz Valley (POL). Aquaculture 2020, 519, 734731. [Google Scholar] [CrossRef]

- FAO. Poland—National Aquaculture Sector Overview. Available online: https://www.fao.org/fishery/en/countrysector/naso_poland (accessed on 8 April 2025).

- Eurostat HICP. Annual Data (Average Index and Rate of Change); Eurostat HICP: Luxembourg, 2025. [Google Scholar]

- Bujas, T.; Koričan, M.; Vukić, M.; Soldo, V.; Vladimir, N.; Fan, A. Review of Energy Consumption by the Fish Farming and Processing Industry in Croatia and the Potential for Zero-Emissions Aquaculture. Energies 2022, 15, 8197. [Google Scholar] [CrossRef]

- Vo, T.T.E.; Ko, H.; Huh, J.-H.; Park, N. Overview of Solar Energy for Aquaculture: The Potential and Future Trends. Energies 2021, 14, 6923. [Google Scholar] [CrossRef]

- Solgaard, H.S.; Yang, Y.; Nguyen, T.T. An Investigation of Consumers’ Preference and Willingness to Pay for Fish Welfare in Denmark: A Discrete Choice Modeling Approach. Aquaculture 2023, 574, 739652. [Google Scholar] [CrossRef]

- Brown, C.; Dorey, C. Pain and Emotion in Fishes—Fish Welfare Implications for Fisheries and Aquaculture. ASJ 2019, 8, 175–201. [Google Scholar] [CrossRef]

- Saraiva, J.; Brijs, J.; Cabrera-Álvarez, M.J.; Arechavala-Lopez, P.; Gräns, A. Blueprint for Research to Detect Loss of Consciousness and/or Sensibility of Fish at Slaughter; Zenodo: Geneva, Switzerland, 2024. [Google Scholar]

| Aspect | European Commission (EC) Study [28] | Essere Animali and Animals Ask [40,41] | Current Study and Rationale |

|---|---|---|---|

| Data set year(s) | 2013 only | 2016–2018 | 2018–2020 |

| Years of data used | One year | Three years | Three years used to improve representativeness and reliability |

| Granularity of production data | Country–species | Largest segment for each country and species | Country–species–system. All countries and species above EUR 20 million in annual sales (17 segments) (e.g., trout; tank vs. recirculation) |

| Wages (used to calculate labor costs) | Estimated averages (EUR 25 k, EUR 50 k, or EUR 75 k/FTE) | Estimated based on the literature | Based on actual wages for each segment |

| Cost–distribution assessment | Assessed as production costs only | Assumed full pass-through to consumers | Evaluates multiple distribution scenarios |

| Feasibility assessment | Not assessed | Not assessed | Economic feasibility was assessed to ensure producers maintain profitability |

| Research Question | Considerations Included in the Study Scope | Considerations Outside of the Scope of This Study |

|---|---|---|

| Economic costs (financing, depreciation, maintenance | Available subsidies |

| Economic savings (labour) | Cost sharing of equipment | |

| Modelling profitability under different cost pass-through scenarios | Price premium for stunning |

| Enterprise profitability | |

| Outcome: Determination of economic feasibility | ||

| Country | Species | Production System | Covered in Previous Studies and Level of Granularity? |

|---|---|---|---|

| Croatia | Seabass and Seabream | Cages | No |

| Denmark | Trout | Cages | In the EC study as trout production in Denmark (system not specified). |

| Denmark | Trout | Ponds | In the EC study as trout production in Denmark (system not specified). |

| Denmark | Trout | Recirculation systems (RAS) | In the EC study as trout production in Denmark (system not specified). |

| Finland | Trout | Cages | No |

| France | Trout | Tanks and raceways | In the EC study as trout production in France (system not specified). |

| Germany | Trout | Tanks and raceways | No |

| Greece | Seabass and Seabream | Cages | In the EC study as seabass and seabream production in Greece (system not specified). Included in the EA/AA study as a segment. |

| Italy | Seabass and Seabream | Cages | In the EC study as seabass and seabream production in Italy (system not specified). Included in the EA/AA study as a segment. |

| Italy | Seabass and Seabream | Tanks and raceways | In the EC study as seabass and seabream production in Italy (system not specified). Excluded from the EA/AA study, in favor of the cages segment. |

| Italy | Trout | Tanks and raceways | In the EC study as trout production in Italy (system not specified). Included in the EA/AA study as a segment. |

| Poland | Carp | Large carp ponds | In the EC study as carp production in Poland (system not specified). |

| Poland | Medium carp ponds | In the EC study as carp production in Poland (system not specified). | |

| Romania | Carp | Carp polyculture | In the EC study as carp production in Romania (system not specified). |

| Spain | Seabass and Seabream | Cages | In the EC study as seabass and seabream production in Spain (system not specified). |

| Spain | Seabass and Seabream | Tanks and raceways | In the EC study as seabass and seabream production in Spain (system not specified). |

| Spain | Trout | Tanks and raceways | No |

| Equipment | Purchase Cost (EUR) | Annual Loan Repayments (EUR) | Depreciation Rate | Maintenance Rate | Labor Saving (Hours /Tonne) | Source |

|---|---|---|---|---|---|---|

| Pump (2–3 tonnes/h) | 30,000 | 10% | 2% | - | EA/AA based on quotes from FAIVRE and VAKI | |

| Pump (20–30 tonnes/h) | 55,000 | 10% | 2% | - | EA/AA based on quote from FAIVRE | |

| Dewater and singulation unit before stunning | 50,000 | 10% | 2% | - | EC based on equipment manufacturers | |

| Dewater unit after stunning | 5000 | 10% | 2% | - | EC based on equipment manufacturers | |

| Electro stunner after dewatering (1–20 tonnes/h) | 56,000 | 5% | 4% | −2.5 (for trout) | Response received from Optimar (current study) | |

| Electro stunner in water in an abattoir (5–10 tonnes/h) | 70,000 | 10% | 1% | - | EC based on equipment manufacturers | |

| Electro stunner in water in an abattoir (20 tonnes/h) | 100,000 | 10% | 1% | −1.5 (for trout) | EA/AA based on quote from Ace Aquatec | |

| Electro stunner in water on harvest boat (5 tonnes/h) | 120,000 | 10% | 1% | - | EA/AA based on quote from Ace Aquatec |

| Methodological Assumptions | Rationale |

|---|---|

| Price transmission is assumed to be 0.5* EU production share of the EU market | EU consumption of the four species is primarily supplied by EU production, meaning that EU enterprises will likely pass on some of the increased cost through higher prices. Sensitivity analyses were performed on the cost pass-through. |

| The average enterprise is characteristic of the industry | Such an assumption is standard practice for widespread analyses, and was also assumed in previous studies [2,40,41]. |

| Enterprises have not implemented stunning equipment and practices | For the species selected, it is recognized that stunning is not widely used [2]. Stunning is, however, more common for Atlantic salmon [2,44,45], and so this species was excluded from the study. |

| Enterprises purchase and use stunning equipment individually | As there are long periods during which stunning equipment is not needed, it is highly unlikely that enterprises will purchase and use the equipment individually. Instead, it is highly probable that such equipment is shared among enterprises. However, this assumption was made for methodological simplicity, as the impact of this assumption being violated would only increase economic feasibility and lower costs, rather than increase them. |

| Product quality, and therefore product price, are unchanged | Whilst electrical stunning can lead to carcass damage, according to the European Commission, this can be avoided or minimized with increasing understanding of required stunning specifications [2]. |

| Equipment is financed at a 5% interest rate rather than purchased outright or with a low-cost financing option | The European Maritime, Fisheries and Aquaculture Fund (EMFAF) provides low-cost financing for improvements to aquaculture enterprises, and so enterprises may have access to a zero-interest loan for stunning equipment. This would lower the costs of implementing stunning by approximately one-third (varied across segments). Similarly, purchasing the equipment outright would also remove the additional interest rate costs. |

| Changes to energy costs are insignificant | Changes to energy costs are insignificant as they were not reported by manufacturers in previous studies [2,40,41], and are reported to be marginal elsewhere [39], especially in comparison with the average energy consumption of aquaculture in general [51,52]. Sensitivity analyses were performed to test the impact of increased costs. |

| Dry Electrical Stunning (EUR) | In-Water Electrical Stunning (EUR) | Overall Average Cost (EUR) | |

|---|---|---|---|

| All species | 0.11 | 0.12 | 0.12 |

| Carp | 0.30 | 0.28 | 0.29 |

| Trout | 0.11 | 0.15 | 0.13 |

| Seabass and Seabream | 0.01 | 0.03 | 0.02 |

| Dry Electrical Stunning (%) | In-Water Electrical Stunning (%) | Overall Average Cost (EUR) | |

|---|---|---|---|

| All species | 2.90 | 3.20 | 3.05 |

| Carp | 11.31 | 10.41 | 10.86 |

| Trout | 1.33 | 2.12 | 1.73 |

| Seabass and Seabream | 0.77 | 1.04 | 0.91 |

| Dry Electrical Stunning (%) | In-Water Electrical Stunning (%) | Overall Average (%) | |

|---|---|---|---|

| All species | 2.54 | 2.83 | 2.69 |

| Carp | 9.66 | 8.88 | 9.27 |

| Trout | 0.61 | 0.84 | 0.73 |

| Seabass and Seabream | 1.32 | 2.05 | 1.69 |

| BAU | In-Water Electrical Stunning | Change From BAU—In-Water | Dry Electrical Stunning | Change from BAU—Dry | |

|---|---|---|---|---|---|

| Profit per enterprise (EUR) | |||||

| Mean | 472,419 | 468,680 | −3739 | 480,676 | 8257 |

| SD | 661,737 | 700,782 | - | 727,095 | - |

| Median | 246,005 | 232,361 | −13,644 | 235,092 | −10,913 |

| IQR | 716,845 | 705,006 | - | 700,069 | - |

| Range | −26,600 to 2,618,856 | −73,928 to 2,796,509 | - | −75,096 to 2,926,773 | - |

| Profitability (%) | |||||

| Mean | 15.68 | 13.35 | −2.33 | 13.53 | −2.15 |

| SD | 12.60 | 13.09 | 13.16 | ||

| Median | 17.54 | 14.24 | −3.30 | 14.97 | −2.57 |

| IQR | 20.73 | 17.57 | 17.31 | ||

| Range | −4.86 to 45.73 | −13.26 to 44.44 | −13.54 to 44.77 | ||

| BAU (%) | 0% Cost Pass-Through (%) | 100% Cost Pass-Through (%) | Market-Based Pass-Through (%) | |||||

|---|---|---|---|---|---|---|---|---|

| In-Water | Dry | In-Water | Dry | In-Water | Dry | |||

| Carp | Polyculture—Romania | 18.30 | 3.20 | 1.91 | 15.89 | 15.71 | 9.11 | 8.36 |

| Carp | Ponds—Poland—Large | −4.86 | −15.40 | −15.74 | −10.60 | −10.56 | −13.26 | −13.45 |

| Carp | Ponds—Poland—Medium | 17.40 | 5.70 | 5.05 | 12.47 | 12.40 | 8.75 | 8.35 |

| Seabass/seabream | Cages—Croatia | 17.54 | 17.10 | 17.24 | 17.47 | 17.49 | 17.26 | 17.33 |

| Seabass/seabream | Cages—Greece | 25.33 | 24.50 | 24.71 | 25.12 | 25.17 | 24.72 | 24.88 |

| Seabass/seabream | Cages—Italy | 26.54 | 25.70 | 25.91 | 26.32 | 26.38 | 25.91 | 26.07 |

| Seabass/seabream | Cages—Spain | 3.80 | 3.50 | 3.59 | 3.79 | 3.79 | 3.61 | 3.66 |

| Seabass/seabream | Tanks and race-ways—Italy | 45.73 | 44.10 | 44.54 | 45.01 | 45.19 | 44.44 | 44.77 |

| Seabass/seabream | Tanks and race-ways—Spain | 3.00 | 2.80 | 2.83 | 2.99 | 2.99 | 2.84 | 2.88 |

| Trout | Cages—Denmark | 13.25 | 14.70 | 15.83 | 13.45 | 13.61 | 14.24 | 14.97 |

| Trout | Ponds—Denmark | 3.91 | 3.30 | 4.33 | 3.88 | 3.92 | 3.56 | 4.17 |

| Trout | Recirculation systems—Denmark | 0.61 | 1.70 | 2.94 | 0.62 | 0.62 | 1.27 | 2.04 |

| Trout | Cages—Finland | 20.63 | 19.80 | 20.23 | 20.46 | 20.55 | 20.05 | 20.35 |

| Trout | Tanks and race-ways—France | 18.10 | 14.00 | 14.36 | 17.38 | 17.44 | 15.35 | 15.61 |

| Trout | Tanks and race-ways—Germany | 26.48 | 18.80 | 19.23 | 24.59 | 24.69 | 21.18 | 21.48 |

| Trout | Tanks and race-ways—Italy | 24.64 | 22.40 | 22.83 | 24.10 | 24.20 | 23.07 | 23.38 |

| Trout | Tanks and race-ways—Spain | 6.17 | 4.00 | 4.43 | 6.04 | 6.07 | 4.81 | 5.08 |

| BAU (%) | Stunning (Base Scenario at Market-Based Cost Pass-through) (%) | Stunning (+10% Annual Cost) (%) | Stunning (+20% Annual Cost) (%) | |||||

|---|---|---|---|---|---|---|---|---|

| In-Water | Dry | In-Water | Dry | In-Water | Dry | |||

| Carp | Polyculture—Romania | 18.30 | 9.11 | 8.36 | 8.25 | 7.44 | 7.41 | 6.53 |

| Carp | Ponds—Poland—Large | −4.86 | −13.26 | −13.45 | −13.48 | −13.69 | −13.70 | −13.92 |

| Carp | Ponds—Poland—Medium | 17.40 | 8.75 | 8.35 | 8.29 | 7.86 | 7.84 | 7.38 |

| Seabass/seabream | Cages—Croatia | 17.54 | 17.26 | 17.33 | 17.2 | 17.31 | 17.20 | 17.29 |

| Seabass/seabream | Cages—Greece | 25.33 | 24.72 | 24.88 | 24.66 | 24.83 | 24.60 | 24.79 |

| Seabass/seabream | Cages—Italy | 26.54 | 25.91 | 26.07 | 25.85 | 26.03 | 25.79 | 25.98 |

| Seabass/seabream | Cages—Spain | 3.80 | 3.61 | 3.66 | 3.59 | 3.64 | 3.57 | 3.63 |

| Seabass/seabream | Tanks and race-ways—Italy | 45.73 | 44.44 | 44.77 | 44.31 | 44.68 | 44.18 | 44.58 |

| Seabass/seabream | Tanks and race-ways—Spain | 3.00 | 2.84 | 2.88 | 2.83 | 2.87 | 2.81 | 2.86 |

| Trout | Cages—Denmark | 13.25 | 14.24 | 14.97 | 14.34 | 15.14 | 14.44 | 15.31 |

| Trout | Ponds—Denmark | 3.91 | 3.56 | 4.17 | 3.52 | 4.20 | 3.49 | 4.22 |

| Trout | Recirculation systems—Denmark | 0.61 | 1.27 | 2.04 | 1.34 | 2.19 | 1.41 | 2.33 |

| Trout | Cages—Finland | 20.63 | 20.05 | 20.35 | 19.99 | 20.32 | 19.93 | 20.30 |

| Trout | Tanks and race-ways—France | 18.10 | 15.35 | 15.61 | 15.08 | 15.36 | 14.81 | 15.12 |

| Trout | Tanks and race-ways—Germany | 26.48 | 21.18 | 21.48 | 20.67 | 21.00 | 20.16 | 20.51 |

| Trout | Tanks and race-ways—Italy | 24.64 | 23.07 | 23.38 | 22.91 | 23.26 | 22.76 | 23.13 |

| Trout | Tanks and race-ways—Spain | 6.17 | 4.81 | 5.08 | 4.68 | 4.98 | 4.54 | 4.87 |

| Species | Measure | EC Study | EA/AA Study | This Study |

|---|---|---|---|---|

| Carp | Cost per unit (EUR) | 0.06 to 0.67 | - | 0.12 to 0.48 |

| Share of current price (%) | 3 to 28 | - | 4 to 20 | |

| Seabass and Seabream | Cost per unit (EUR) | 0.04 to 0.13 | 0.06 to 0.07 | −0.15 to 0.08 |

| Share of current price (%) | 0 to 2 | 1 | 0 to 3 | |

| Rainbow trout | Cost per unit (EUR) | −0.06 to 0.24 | 0.06 to 0.07 | −0.09 to 0.57 |

| Share of current price (%) | −2 to 8 | 2 | −3 to 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carpenter, G.; Vanderzwalmen, M.; Lambert, H. Economic Feasibility of Implementing Stunning for Farmed Fish in the EU: A Multi-Species Assessment. Animals 2025, 15, 2812. https://doi.org/10.3390/ani15192812

Carpenter G, Vanderzwalmen M, Lambert H. Economic Feasibility of Implementing Stunning for Farmed Fish in the EU: A Multi-Species Assessment. Animals. 2025; 15(19):2812. https://doi.org/10.3390/ani15192812

Chicago/Turabian StyleCarpenter, Griffin, Myriam Vanderzwalmen, and Helen Lambert. 2025. "Economic Feasibility of Implementing Stunning for Farmed Fish in the EU: A Multi-Species Assessment" Animals 15, no. 19: 2812. https://doi.org/10.3390/ani15192812

APA StyleCarpenter, G., Vanderzwalmen, M., & Lambert, H. (2025). Economic Feasibility of Implementing Stunning for Farmed Fish in the EU: A Multi-Species Assessment. Animals, 15(19), 2812. https://doi.org/10.3390/ani15192812