Seasonal and Diurnal Ammonia Emissions from Swine-Finishing Barn with Ground Channel Ventilation

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Swine Barn Design and Ventilation System Description

2.2. Ammonia, Ventilation Rate, and Temperature

- CE = Ammonia concentration of exhausted air (mL m−3);

- V = Room ventilation rate (m3 min−1);

- MW = Molecular weight of ammonia gas (g mol−1);

- TE = Exhaust air temperature (°C);

- CA = Ammonia concentration of ambient air (mL m−3);

- TA = Ambient air temperature (°C);

- Number of animal units = Number of pigs × Average body weight (kg) ÷ 500 kg.

2.3. Statistical Analysis

3. Results and Discussion

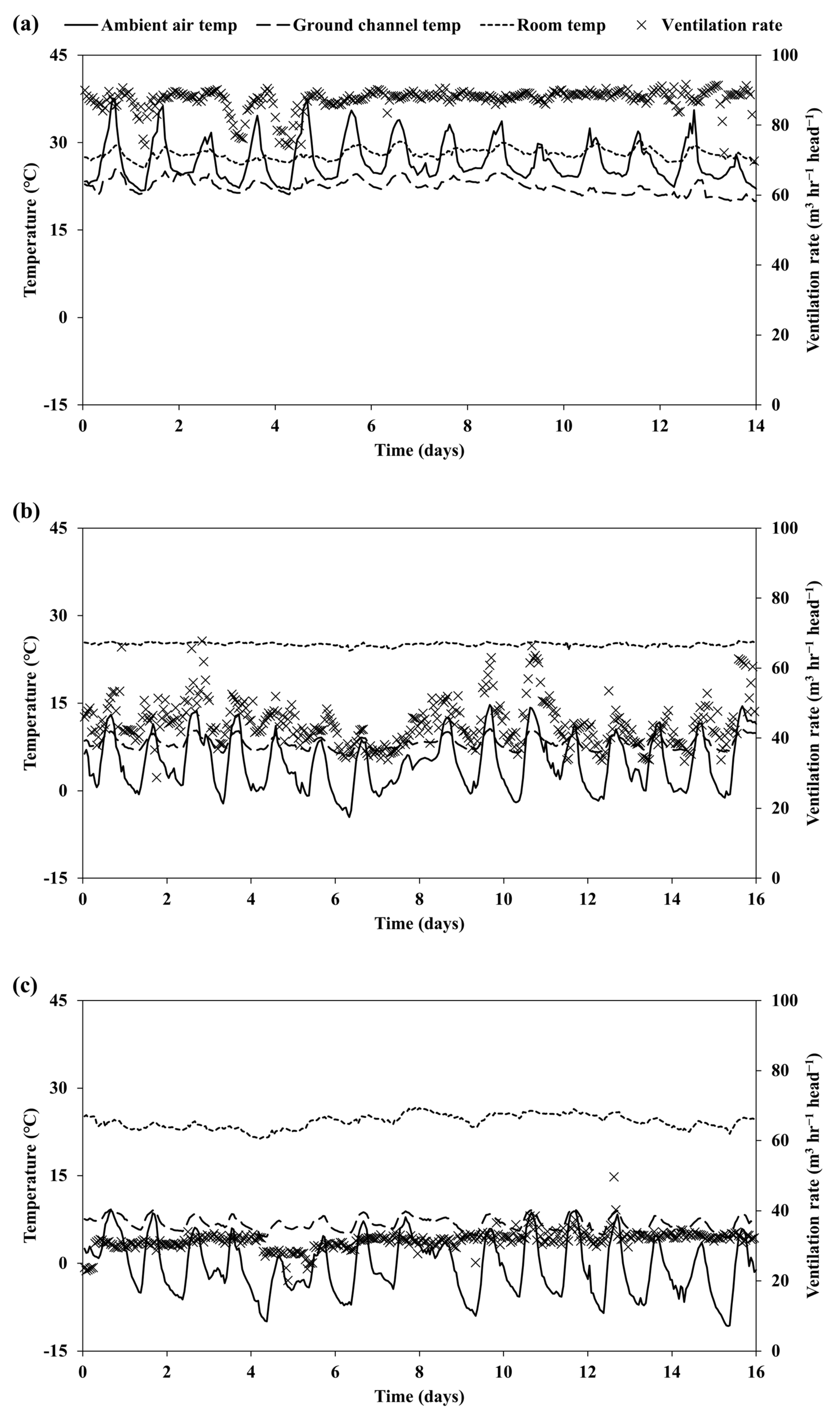

3.1. Seasonal Characteristics of Temperature and Ventilation Rate

| Growth Stage | Stocking Density (m2 head−1) | Ambient Temperature (°C) | Ventilation Rate (m3 h−1 head−1) | Ventilation Rate | ||

|---|---|---|---|---|---|---|

| Autumn (Compared to Winter) | Summer (Compared to Winter) | |||||

| This study | Finisher | 1.09 | 26.9 ± 1.0 | 87.1 ± 1.9 | 1.4 times | 2.8 times |

| 1.16 | 4.7 ± 4.5 | 44.3 ± 3.8 | ||||

| 1.06 | −0.7 ± 4.8 | 31.5 ± 1.7 | ||||

| MWPS [16] | Finisher | 0.83 | Hot weather | 203.9 | 3.4 times | 12.0 times |

| 0.74 | Mild weather | 59.5 | ||||

| Cold weather | 17.0 | |||||

| ASHRAE [17] | Finisher | 0.74 | Hot weather | 216.0 | - | 12.0 times |

| Cold weather | 18.0 | |||||

| Sun et al. [39] * | Fattening | 1.02 | 19.4 ± 6.4 | 161.0 | - | 4.4–7.2 times |

| 1.04 | −1.6 ± 3.4 | 36.0 | ||||

| 0.97 | −9.7 ± 3.6 | 22.4 | ||||

| Blunden et al. [40] * | Finisher | 0.83 | 22.3 ± 4.9 | 68.6 | 3 times | - |

| 0.87 | 5.5 ± 4.8 | 23.1 | ||||

| Costa and Guarino [38] * | Gestation | 2.02 | 24.39 | 116.2 | 2.7 times | 6.0 times |

| 2.29 | 8 | 43.6 | ||||

| 2.02 | 3.13 | 19.4 | ||||

| Fattening | 0.86 | 24.4 | 81.4 | 3.6 times | - | |

| 0.86 | 7.1 | 22.9 | ||||

| Rumsey et al. [41] * | Fattening | Not available | 26.0 ± 4.1 | 119.6 | 3.6 times | - |

| 11.3 ± 6.2 | 33.0 | |||||

3.2. Seasonal Ammonia Concentration and Emission

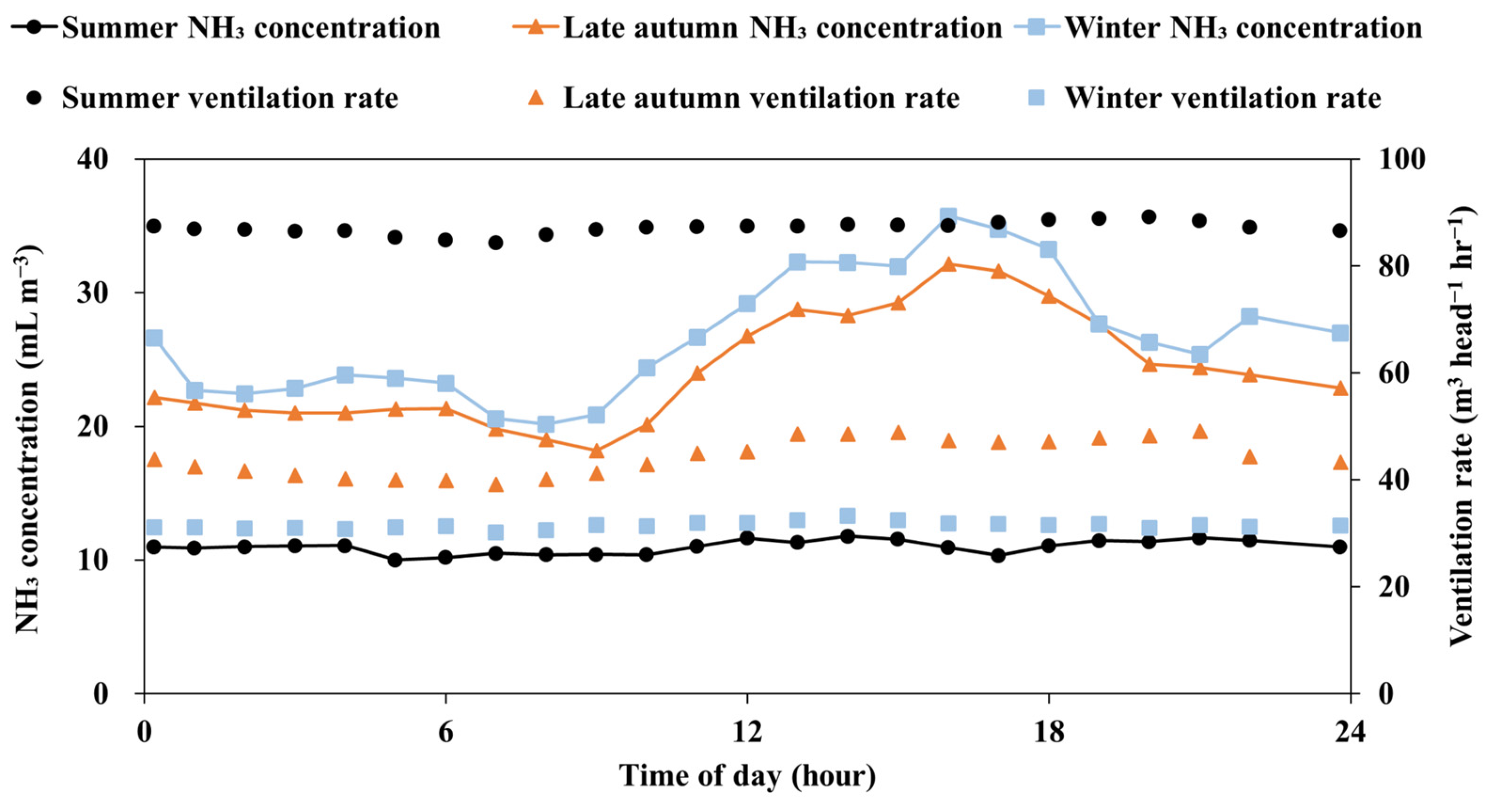

3.3. Variation in Diurnal Ammonia Concentration and Emission

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krupa, S. Effects of atmospheric ammonia (NH3) on terrestrial vegetation: A review. Environ. Pollut. 2003, 124, 179–221. [Google Scholar] [CrossRef] [PubMed]

- Fenn, M.E.; Poth, M.A.; Aber, J.D.; Baron, J.S.; Bormann, B.T.; Johnson, D.W.; Lemly, A.D.; McNulty, S.G.; Ryan, D.F.; Stottlemyer, R. Nitrogen excess in North American ecosystems: Predisposing factors, ecosystem responses, and management strategies. Ecol. Appl. 1998, 8, 706–733. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. National emission inventory-Ammonia emissions from animal husbandry operations. Draft Report, 30 January 2004. [Google Scholar]

- Denmead, O.; Chen, D.; Griffith, D.; Loh, Z.; Bai, M.; Naylor, T. Emissions of the indirect greenhouse gases NH3 and NOx from Australian beef cattle feedlots. Aust. J. Exp. Agric. 2008, 48, 213–218. [Google Scholar] [CrossRef]

- McCubbin, D.R.; Apelberg, B.J.; Roe, S.; Divita, F. Livestock ammonia management and particulate-related health benefits. Environ. Sci. Technol. 2002, 36, 1141–1146. [Google Scholar] [CrossRef]

- Hristov, A.N. Contribution of ammonia emitted from livestock to atmospheric fine particulate matter (PM2. 5) in the United States. J. Dairy Sci. 2011, 94, 3130–3136. [Google Scholar] [CrossRef]

- Ma, R.; Li, K.; Guo, Y.; Zhang, B.; Zhao, X.; Linder, S.; Guan, C.; Chen, G.; Gan, Y.; Meng, J. Mitigation potential of global ammonia emissions and related health impacts in the trade network. Nat. Commun. 2021, 12, 6308. [Google Scholar] [CrossRef]

- Ministry of Environment (Republic of Korea). Air Pollutant Emissions 2024. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=106&tblId=DT_106N_03_0100007&conn_path=I2&language=en (accessed on 13 February 2025).

- Aarnink, A.J.A.; Keen, A.; Metz, J.H.M.; Speelman, L.; Verstegen, M.W.A. Ammonia emission patterns during the growing periods of pigs housed on partially slatted floors. J. Agric. Eng. Res. 1995, 62, 105–116. [Google Scholar] [CrossRef]

- Canh, T.; Aarnink, A.; Schutte, J.; Sutton, A.; Langhout, D.; Verstegen, M. Dietary protein affects nitrogen excretion and ammonia emission from slurry of growing–finishing pigs. Livest. Prod. Sci. 1998, 56, 181–191. [Google Scholar] [CrossRef]

- Philippe, F.-X.; Laitat, M.; Canart, B.; Vandenheede, M.; Nicks, B. Comparison of ammonia and greenhouse gas emissions during the fattening of pigs, kept either on fully slatted floor or on deep litter. Livest. Sci. 2007, 111, 144–152. [Google Scholar] [CrossRef]

- Ivanova-Peneva, S.G.; Aarnink, A.J.; Verstegen, M.W. Ammonia emissions from organic housing systems with fattening pigs. Biosyst. Eng. 2008, 99, 412–422. [Google Scholar] [CrossRef]

- Ni, J.-Q.; Heber, A.J.; Diehl, C.A.; Lim, T.T. Ammonia, Hydrogen Sulphide and Carbon Dioxide Release from Pig Manure in Under-foor Deep Pits. J. Agric. Eng. Res. 2000, 77, 53–66. [Google Scholar] [CrossRef]

- Saha, C.K.; Zhang, G.; Kai, P.; Bjerg, B. Effects of a partial pit ventilation system on indoor air quality and ammonia emission from a fattening pig room. Biosyst. Eng. 2010, 105, 279–287. [Google Scholar] [CrossRef]

- Hinz, T.; Linke, S. A comprehensive experimental study of aerial pollutants in and emissions from livestock buildings. Part 2: Results. J. Agric. Eng. Res. 1998, 70, 119–129. [Google Scholar] [CrossRef]

- MWPS. Mechanical Ventilating Systems for Livestock Housing; Midwest Plan Service: Ames, IA, USA, 1990. [Google Scholar]

- ASHRAE. Chapter 25. Environmental Control for Animals and Plants. In 2023 ASHRAE Handbook—HVAC Applications (SI); ASHRAE Inc.: Atlanta, GA, USA, 2023. [Google Scholar]

- Heber, A.J.; Ni, J.Q.; Lim, T.T.; Diehl, C.A.; Sutton, A.L.; Duggirala, R.K.; Haymore, B.L.; Kelly, D.T.; Adamchuk, V.I. Effect of a manure additive on ammonia emission from swine finishing buildings. Trans. ASAE 2000, 43, 1895–1902. [Google Scholar] [CrossRef]

- National Research Council; Division on Earth; Life Studies; Board on Environmental Studies; Committee on Animal Nutrition; Ad Hoc Committee on Air Emissions from Animal Feeding Operations. The Scientific Basis for Estimating Air Emissions from Animal Feeding Operations: Interim Report; National Academies Press: Washington, DC, USA, 2002. [Google Scholar]

- Dong, H.; Kang, G.; Zhu, Z.; Tao, X.; Chen, Y.; Xin, H.; Harmon, J.D. Ammonia, methane, and carbon dioxide concentrations and emissions of a hoop grower-finisher swine barn. Trans. ASABE 2009, 52, 1741–1747. [Google Scholar] [CrossRef]

- Wi, J.; Lee, S.; Kim, E.; Lee, M.; Koziel, J.A.; Ahn, H. Effects of treated manure conditions on ammonia and hydrogen sulfide emissions from a swine finishing barn equipped with semicontinuous pit recharge system in summer. Atmosphere 2020, 11, 713. [Google Scholar] [CrossRef]

- Ma, C.; Guldberg, L.B.; Hansen, M.J.; Feng, L.; Petersen, S.O. Frequent export of pig slurry for outside storage reduced methane but not ammonia emissions in cold and warm seasons. Waste Manag. 2023, 169, 223–231. [Google Scholar] [CrossRef]

- Philippe, F.-X.; Laitat, M.; Wavreille, J.; Nicks, B.; Cabaraux, J.-F. Effects of a high-fibre diet on ammonia and greenhouse gas emissions from gestating sows and fattening pigs. Atmos. Environ. 2015, 109, 197–204. [Google Scholar] [CrossRef]

- Stinn, J. Environmental Assessment and Control Towards Improved Swine Breeding-Gestation-Farrowing Operation in the Midwestern United States. Doctoral Dissertation, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Cao, Y.; Bai, Z.; Misselbrook, T.; Wang, X.; Ma, L. Ammonia emissions from different pig production scales and their temporal variations in the North China Plain. J. Air Waste Manag. Assoc. 2021, 71, 23–33. [Google Scholar] [CrossRef]

- Arcidiacono, C. Engineered Solutions for Animal Heat Stress Abatement in Livestock Buildings. Agric. Eng. Int. CIGR J. 2018, 20. [Google Scholar]

- Jeppsson, K.-H.; Botermans, J. Dust levels depending on ventilation system in buildings for growing finishing pigs. In Proceedings of the Proceedings International Conference of Agricultural Engineering, Zurich, Switzerland, 6–10 July 2014; European Society for Agricultural Engineers: Brussels, Belgium, 2014; pp. 1–6. [Google Scholar]

- Rubayet Bostami, A.; Hong, S.; Islam, M.; Chul-Ju, Y. Potential of geothermal and ground channel system house on reduction of energy consumption and CO2 emissions with maintenance of performance of growing pigs. Int. J. Recent Sci. Res. 2016, 8974–8979. [Google Scholar]

- van Wagenberg, A.V. Measurement, Evaluation and Control of the Microclimate in Rooms for Weaned Piglets; Wageningen University and Research: Wageningen, The Netherlands, 2005. [Google Scholar]

- Liddament, M.W. A Guide to Energy Efficient Ventilation; Air Infiltration and Ventilation Centre: Ghent, Belgium, 1996. [Google Scholar]

- Ministry of Agriculture, F.a.R.A.; Republic of Korea. Enforcement Decree of Livestock Industry Act. 2023. Available online: https://elaw.klri.re.kr/kor_service/lawView.do?hseq=68169&lang=KOR (accessed on 13 February 2025).

- Ministry of Agriculture, F.a.R.A.; Republic of Korea. ANIMAL PROTECTION ACT. 2024. Available online: https://elaw.klri.re.kr/kor_service/lawView.do?hseq=64508&lang=KOR (accessed on 13 February 2025).

- DeVoe, K.R.; Hoff, S.J.; Gao, Y.; Ramirez, B.C. Commissioning of a Segmented Wand for Evaluating Airflow Performance of Fans in Livestock and Poultry Housing. In Proceedings of the 2016 ASABE Annual International Meeting, Orlando, FL, USA, 17–20 July 2016; p. 1. [Google Scholar]

- Wi, J.; Lee, S.; Kim, E.; Lee, M.; Koziel, J.A.; Ahn, H. Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn. Atmosphere 2019, 10, 170. [Google Scholar] [CrossRef]

- Xie, Q.; Ni, J.-Q.; Bao, J.; Su, Z. A thermal environmental model for indoor air temperature prediction and energy consumption in pig building. Build. Environ. 2019, 161, 106238. [Google Scholar] [CrossRef]

- Qi, F.; Li, H.; Zhao, X.; Huang, J.; Shi, Z. Investigation on minimum ventilation, heating, and energy consumption of pig buildings in China during winter. Agriculture 2023, 13, 319. [Google Scholar] [CrossRef]

- Korea Meteorological Administration, Republic of Korea. Seasonal Average Temperature in South Korea from 2014 to 2023. 2024. Available online: https://www.index.go.kr/unity/potal/main/EachDtlPageDetail.do?idx_cd=1400# (accessed on 25 February 2025).

- Costa, A.; Guarino, M. Definition of yearly emission factor of dust and greenhouse gases through continuous measurements in swine husbandry. Atmos. Environ. 2009, 43, 1548–1556. [Google Scholar] [CrossRef]

- Sun, G.; Guo, H.; Peterson, J.; Predicala, B.; Laguë, C. Diurnal odor, ammonia, hydrogen sulfide, and carbon dioxide emission profiles of confined swine grower/finisher rooms. J. Air Waste Manag. Assoc. 2008, 58, 1434–1448. [Google Scholar] [CrossRef]

- Blunden, J.; Aneja, V.P.; Westerman, P.W. Measurement and analysis of ammonia and hydrogen sulfide emissions from a mechanically ventilated swine confinement building in North Carolina. Atmos. Environ. 2008, 42, 3315–3331. [Google Scholar] [CrossRef]

- Rumsey, I.C.; Aneja, V.P.; Lonneman, W.A. Characterizing reduced sulfur compounds emissions from a swine concentrated animal feeding operation. Atmos. Environ. 2014, 94, 458–466. [Google Scholar] [CrossRef]

- Harper, L.A.; Sharpe, R.R.; Simmons, J.D. Ammonia emissions from swine houses in the southeastern United States. J. Environ. Qual. 2004, 33, 449–457. [Google Scholar] [CrossRef]

- Aarnink, A.; Van Den Berg, A.; Keen, A.; Hoeksma, P.; Verstegen, M. Effect of slatted floor area on ammonia emission and on the excretory and lying behaviour of growing pigs. J. Agric. Eng. Res. 1996, 64, 299–310. [Google Scholar] [CrossRef]

- National Research Council; Division on Earth; Life Studies; Committee on Nutrient Requirements of Swine. Nutrient Requirements of Swine., 11th ed.; National Academies Press: Washington, DC, USA, 2012. [Google Scholar]

- Niyazov, N.; Ostrenko, K. Effect of low-protein diets on the nitrogen balance and productivity of pigs. J. Livest. Sci. 2020, 11, 106–109. [Google Scholar] [CrossRef]

- Sajeev, E.P.M.; Amon, B.; Ammon, C.; Zollitsch, W.; Winiwarter, W. Evaluating the potential of dietary crude protein manipulation in reducing ammonia emissions from cattle and pig manure: A meta-analysis. Nutr. Cycl. Agroecosystems 2018, 110, 161–175. [Google Scholar] [CrossRef]

- Demmers, T.G.M.; Burgess, L.R.; Short, J.L.; Phillips, V.R.; Clark, J.A.; Wathes, C.M. Ammonia emissions from two mechanically ventilated UK livestock buildings. Atmos. Environ. 1999, 33, 217–227. [Google Scholar] [CrossRef]

- Ni, J.Q.; Heber, A.J.; Lim, T.T. Ammonia and hydrogen sulfide in swine production. In Air quality and Livestock Farming; CRC Press: Boca Raton, FL, USA, 2018; pp. 29–47. [Google Scholar]

- Blanes-Vidal, V.; Hansen, M.N.; Pedersen, S.; Rom, H.B. Emissions of ammonia, methane and nitrous oxide from pig houses and slurry: Effects of rooting material, animal activity and ventilation flow. Agric. Ecosyst. Environ. 2008, 124, 237–244. [Google Scholar] [CrossRef]

- Groenestein, C.M.; Hendriks, M.M.W.B.; Den Hartog, L.A. Effect of feeding schedule on ammonia emission from individual and group-housing systems for sows. Biosyst. Eng. 2003, 85, 79–85. [Google Scholar] [CrossRef]

- Guo, Y.; Lian, X.; Yan, P. Diurnal rhythms, locations and behavioural sequences associated with eliminative behaviours in fattening pigs. Appl. Anim. Behav. Sci. 2015, 168, 18–23. [Google Scholar] [CrossRef]

- Guo, H.; Dehod, W.; Agnew, J.; Feddes, J.R.; Lague, C.; Pang, S. Daytime odor emission variations from various swine barns. Trans. ASABE 2007, 50, 1365–1372. [Google Scholar] [CrossRef]

- Choi, L.-Y.; Lee, S.-Y.; Jeong, H.; Park, J.; Hong, S.-W.; Kwon, K.-S.; Song, M. Ammonia and particulate matter emissions at a korean commercial pig farm and influencing factors. Animals 2023, 13, 3347. [Google Scholar] [CrossRef]

- Jerez, S.B.; Zhang, Y.; Wang, X. Spatial and temporal distributions of dust and ammonia concentrations in a swine building. Trans. ASABE 2011, 54, 1873–1891. [Google Scholar] [CrossRef]

- Van Ransbeeck, N.; Van Langenhove, H.; Demeyer, P. Indoor concentrations and emissions factors of particulate matter, ammonia and greenhouse gases for pig fattening facilities. Biosyst. Eng. 2013, 116, 518–528. [Google Scholar] [CrossRef]

- Ni, J.Q.; Heber, A.J.; Lim, T.T.; Diehl, C.A.; Duggirala, R.K.; Haymore, B.L.; Sutton, A.L. Ammonia Emission from a Large Mechanically-Ventilated Swine Building During Warm Weather; 0047-2425; Wiley Online Library: Hoboken, NJ, USA, 2000. [Google Scholar]

| Summer (n = 14) | Late Autumn (n = 16) | Winter (n = 16) | |

|---|---|---|---|

| Ambient temperature (°C) | 26.9 ± 1.0 a | 4.7 ± 1.6 b | −0.7 ± 2.1 c |

| Ground channel temperature (°C) | 22.5 ± 1.0 a | 8.1 ± 0.4 b | 6.8 ± 0.5 c |

| Room temperature (°C) | 28.0 ± 0.6 a | 25.1 ± 0.2 b | 24.3 ± 1.0 c |

| Ventilation rate (m3 h−1 head−1) | 87.1 ± 1.9 a | 44.3 ± 3.8 b | 31.5 ± 1.7 c |

| Summer (n = 14) | Late autumn (n = 16) | Winter (n = 16) | |

|---|---|---|---|

| Ventilation rate (m3 h−1 head−1) | 87.1 ± 1.9 a | 44.3 ± 3.8 b | 31.5 ± 1.7 c |

| NH3 concentration (mL m−3) | 11.0 ± 2.1 a | 24.2 ± 6.0 b | 26.8 ± 4.5 b |

| NH3 emission (g day−1 AU *−1) | 111.0 ± 23.6 a | 125.0 ± 37.3 a | 107.1 ± 20.5 a |

| Summer (n = 14) | Late Autumn (n = 16) | Winter (n = 16) | ||||

|---|---|---|---|---|---|---|

| Day | Night | Day | Night | Day | Night | |

| Ambient temperature (°C) | 29.4 ± 1.7 a | 24.3 ± 0.8 b | 7.0 ± 1.7 a | 2.4 ± 1.8 b | 1.6 ± 2.0 a | −2.9 ± 2.3 b |

| Ground channel temperature (°C) | 22.8 ± 1.2 a | 22.2 ± 0.8 a | 8.7 ± 0.4 a | 7.6 ± 0.4 b | 7.4 ± 0.5 a | 6.3 ± 0.6 b |

| Room temperature (°C) | 28.4 ± 0.7 a | 27.7 ± 0.6 b | 25.1 ± 0.2 a | 25.0 ± 0.2 a | 24.4 ± 1.0 a | 24.2 ± 1.1 a |

| Ventilation rate (m3 h−1 head−1) | 87.2 ± 1.4 a | 87.1 ± 2.6 a | 45.1 ± 4.9 a | 43.5 ± 3.3 a | 31.8 ± 1.9 a | 31.2 ± 1.7 a |

| Summer (n = 14) | Late autumn (n = 16) | Winter (n = 16) | ||||

|---|---|---|---|---|---|---|

| Day | Night | Day | Night | Day | Night | |

| Ventilation rate (m3 h−1 head−1) | 87.2 ± 1.4 a | 87.1 ± 2.6 a | 45.1 ± 4.9 a | 43.5 ± 3.3 a | 31.8 ± 1.9 a | 31.2 ± 1.7 a |

| NH3 concentration (mL m−3) | 11.0 ± 2.1 a | 11.0 ± 2.3 a | 25.6 ± 6.7 a | 22.8 ± 5.6 a | 28.5 ± 5.3 a | 25.0 ± 4.1 b |

| NH3 emission (g h−1 AU *−1) | 4.5 ± 1.0 a | 4.7 ± 1.0 a | 5.6 ± 1.8 a | 4.8 ± 1.4 a | 4.8 ± 1.1 a | 4.1 ± 0.7 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.; Roh, H.; Kim, D.; Wi, J.; Lee, S.; Ahn, H. Seasonal and Diurnal Ammonia Emissions from Swine-Finishing Barn with Ground Channel Ventilation. Animals 2025, 15, 1892. https://doi.org/10.3390/ani15131892

Shin J, Roh H, Kim D, Wi J, Lee S, Ahn H. Seasonal and Diurnal Ammonia Emissions from Swine-Finishing Barn with Ground Channel Ventilation. Animals. 2025; 15(13):1892. https://doi.org/10.3390/ani15131892

Chicago/Turabian StyleShin, Jinho, Heecheol Roh, Daehun Kim, Jisoo Wi, Seunghun Lee, and Heekwon Ahn. 2025. "Seasonal and Diurnal Ammonia Emissions from Swine-Finishing Barn with Ground Channel Ventilation" Animals 15, no. 13: 1892. https://doi.org/10.3390/ani15131892

APA StyleShin, J., Roh, H., Kim, D., Wi, J., Lee, S., & Ahn, H. (2025). Seasonal and Diurnal Ammonia Emissions from Swine-Finishing Barn with Ground Channel Ventilation. Animals, 15(13), 1892. https://doi.org/10.3390/ani15131892