Multi-Stage Data Processing for Enhancing Korean Cattle (Hanwoo) Weight Estimations by Automated Weighing Systems

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Acquisition

2.2. Development of Algorithmic Process for Weight Estimation

2.3. Data Pre-Processing

2.4. Weight Estimation for Automatic Weighing System

2.5. Data Post-Processing

2.6. Performance Evaluation

2.7. Statistical Analysis

3. Results

3.1. Comparison of Discrepancies Between AWSs and Static Scale Steer Weight Measurements

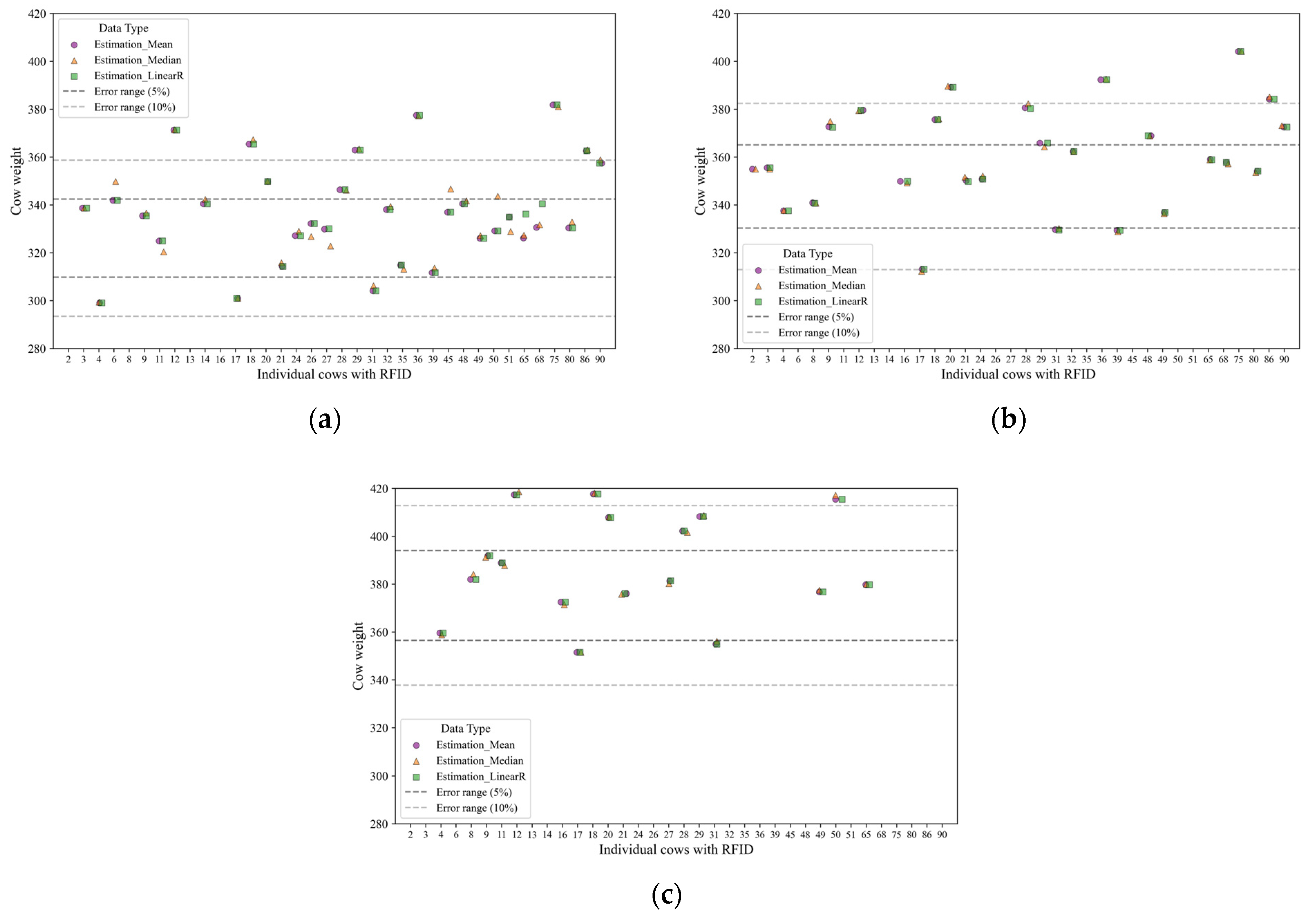

3.2. Comparison of Individual Weight by Using Error Margin

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AWS | Automated weighing system |

| RMSE | Root mean square error |

| IQR | Interquartile range |

| LinearR | Linear regression |

| Avg ± SD | Average ± standard deviation |

References

- Davison, C.; Michie, C.; Tachtatzis, C.; Andonovic, I.; Bowen, J.; Duthie, C.-A. Feed conversion ratio (FCR) and performance group estimation based on predicted feed intake for the optimisation of beef production. Sensors 2023, 23, 4621. [Google Scholar] [CrossRef] [PubMed]

- Pezzuolo, A.; Milani, V.; Zhu, D.; Guo, H.; Guercini, S.; Marinello, F. On-barn pig weight estimation based on body measurements by structure-from-motion (SfM). Sensors 2018, 18, 3603. [Google Scholar] [CrossRef]

- González-García, E.; Alhamada, M.; Pradel, J.; Douls, S.; Parisot, S.; Bocquier, F.; Menassol, J.-B.; Llach, I.; González, L.A. A mobile and automated walk-over-weighing system for a close and remote monitoring of liveweight in sheep. Comput. Electron. Agric. 2018, 153, 226–238. [Google Scholar] [CrossRef]

- Cho, H.; Jeon, S.; Lee, M.; Kang, K.; Kang, H.; Park, E.; Kim, M.; Hong, S.; Seo, S. Analysis of the factors influencing body weight variation in Hanwoo Steers using an automated weighing system. Animals 2020, 10, 1270. [Google Scholar] [CrossRef]

- Dickinson, R.; Morton, J.; Beggs, D.; Anderson, G.; Pyman, M.; Mansell, P.; Blackwood, C. An automated walk-over weighing system as a tool for measuring liveweight change in lactating dairy cows. J. Dairy Sci. 2013, 96, 4477–4486. [Google Scholar] [CrossRef]

- Hou, G.; Li, R.; Tian, M.; Ding, J.; Zhang, X.; Yang, B.; Chen, C.; Huang, R.; Yin, Y. Improving Efficiency: Automatic Intelligent Weighing System as a Replacement for Manual Pig Weighing. Animals 2024, 14, 1614. [Google Scholar] [CrossRef]

- Bhoj, S.; Tarafdar, A.; Chauhan, A.; Singh, M.; Gaur, G.K. Image processing strategies for pig liveweight measurement: Updates and challenges. Comput. Electron. Agric. 2022, 193, 106693. [Google Scholar] [CrossRef]

- Liu, H.; Reibman, A.R.; Boerman, J.P. Feature extraction using multi-view video analytics for dairy cattle body weight estimation. Smart Agric. Technol. 2023, 6, 100359. [Google Scholar] [CrossRef]

- Williams, L.R.; Fox, D.R.; Bishop-Hurley, G.J.; Swain, D.L. Use of radio frequency identification (RFID) technology to record grazing beef cattle water point use. Comput. Electron. Agric. 2019, 156, 193–202. [Google Scholar] [CrossRef]

- Ranches, J.; De Oliveira, R.; Vedovatto, M.; Palmer, E.; Moriel, P.; Arthington, J. Use of radio-frequency identification technology to assess the frequency of cattle visits to mineral feeders. Trop. Anim. Health Prod. 2021, 53, 341. [Google Scholar] [CrossRef]

- Stankovski, S.; Ostojic, G.; Senk, I.; Rakic-Skokovic, M.; Trivunovic, S.; Kucevic, D. Dairy cow monitoring by RFID. Sci. Agric. 2012, 69, 75–80. [Google Scholar] [CrossRef]

- Chang, A.Z.; Imaz, J.A.; González, L.A. Calf birth weight predicted remotely using automated in-paddock weighing technology. Animals 2021, 11, 1254. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.J.; Savage, D.; Hinch, G. Repeatability and frequency of in-paddock sheep walk-over weights: Implications for individual animal management. Anim. Prod. Sci. 2013, 54, 207–213. [Google Scholar] [CrossRef]

- Qiao, Y.; Kong, H.; Clark, C.; Lomax, S.; Su, D.; Eiffert, S.; Sukkarieh, S. Intelligent perception for cattle monitoring: A review for cattle identification, body condition score evaluation, and weight estimation. Comput. Electron. Agric. 2021, 185, 106143. [Google Scholar] [CrossRef]

- Basu, S.; Meckesheimer, M. Automatic outlier detection for time series: An application to sensor data. Knowl. Inf. Syst. 2007, 11, 137–154. [Google Scholar] [CrossRef]

- Song, J.-W.; Lee, M.; Cho, H.; Lee, D.-H.; Seo, S.; Lee, W.-H. Development of individual models for predicting cow milk production for real-time monitoring. Comput. Electron. Agric. 2025, 228, 109698. [Google Scholar] [CrossRef]

- Jung, J.-M.; Kim, D.-H.; Cho, H.; Lee, M.; Jeong, J.; Lee, D.-H.; Seo, S.; Lee, W.-H. Multi-algorithmic approach for detecting outliers in cattle intake data. J. Agric. Food Res. 2024, 15, 101021. [Google Scholar] [CrossRef]

- Blázquez-García, A.; Conde, A.; Mori, U.; Lozano, J.A. A review on outlier/anomaly detection in time series data. ACM Comput. Surv. (CSUR) 2021, 54, 1–33. [Google Scholar] [CrossRef]

- Mehrang, S.; Helander, E.; Pavel, M.; Chieh, A.; Korhonen, I. Outlier detection in weight time series of connected scales. In Proceedings of the 2015 IEEE International Conference on Bioinformatics and Biomedicine (BIBM), Washington, DC, USA, 9–12 November 2015; pp. 1489–1496. [Google Scholar] [CrossRef]

- Kim, M.-J.; Mo, C.; Kim, H.T.; Cho, B.-K.; Hong, S.-J.; Lee, D.H.; Shin, C.-S.; Jang, K.J.; Kim, Y.-H.; Baek, I. Research and technology trend analysis by big data-based smart livestock technology: A review. J. Biosyst. Eng. 2021, 46, 386–398. [Google Scholar] [CrossRef]

- Tukey, J.W. Exploratory Data Analysis; Addison-Wesley: Reading, MA, USA, 1977. [Google Scholar] [CrossRef]

- MacNeil, M.D.; Berry, D.P.; Clark, S.A.; Crowley, J.J.; Scholtz, M.M. Evaluation of partial body weight for predicting body weight and average daily gain in growing beef cattle. Transl. Anim. Sci. 2021, 5, txab126. [Google Scholar] [CrossRef]

- Hodson, T.O. Root mean square error (RMSE) or mean absolute error (MAE): When to use them or not. Geosci. Model Dev. Discuss. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Kim, T.K. T test as a parametric statistic. Korean J. Anesthesiol. 2015, 68, 540–546. [Google Scholar] [CrossRef] [PubMed]

- Kwak, S.G.; Kim, J.H. Central limit theorem: The cornerstone of modern statistics. Korean J. Anesthesiol. 2017, 70, 144–156. [Google Scholar] [CrossRef] [PubMed]

- Team, R.C. R: A Language and Environment for Statistical Computing; Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Ihaka, R.; Gentleman, R. R: A language for data analysis and graphics. J. Comput. Graph. Stat. 1996, 5, 299–314. [Google Scholar] [CrossRef]

- Yendri, D.; Afif, H. Design of cow cattle weighing system technology and automatic giving feed. In Proceedings of the 2020 International Conference on Information Technology Systems and Innovation (ICITSI), Bandung, Indonesia, 19–23 October 2020; pp. 185–191. [Google Scholar] [CrossRef]

- Veerkamp, R. Selection for economic efficiency of dairy cattle using information on live weight and feed intake: A review. J. Dairy Sci. 1998, 81, 1109–1119. [Google Scholar] [CrossRef]

- Byrne, H.J.; Knief, P.; Keating, M.E.; Bonnier, F. Spectral pre and post processing for infrared and Raman spectroscopy of biological tissues and cells. Chem. Soc. Rev. 2016, 45, 1865–1878. [Google Scholar] [CrossRef]

- Salvi, M.; Acharya, U.R.; Molinari, F.; Meiburger, K.M. The impact of pre-and post-image processing techniques on deep learning frameworks: A comprehensive review for digital pathology image analysis. Comput. Biol. Med. 2021, 128, 104129. [Google Scholar] [CrossRef]

- Lyle, G.; Bryan, B.; Ostendorf, B. Post-processing methods to eliminate erroneous grain yield measurements: Review and directions for future development. Precis. Agric. 2014, 15, 377–402. [Google Scholar] [CrossRef]

- Niloofar, P.; Francis, D.P.; Lazarova-Molnar, S.; Vulpe, A.; Vochin, M.-C.; Suciu, G.; Balanescu, M.; Anestis, V.; Bartzanas, T. Data-driven decision support in livestock farming for improved animal health, welfare and greenhouse gas emissions: Overview and challenges. Comput. Electron. Agric. 2021, 190, 106406. [Google Scholar] [CrossRef]

| Pre- Processing | Estimation Methods 1 | Feb (228 2) | Mar (190) | ||||

|---|---|---|---|---|---|---|---|

| Predicted 3 | Reference | RMSE 4 | Predicted | Reference | RMSE | ||

| Tukey | Mean | 337.01 a | 326.08 a (19.9) | 12.35 | 360.31 c | 347.68 c (21.52) | 14.39 |

| (21.14) | (21.68) | ||||||

| Median | 337.92 a | 12.85 | 360.42 c | 14.64 | |||

| (21.44) | (21.98) | ||||||

| LinearR | 337.64 a | 12.95 | 360.46 c | 14.44 | |||

| (21.01) | (22.11) | ||||||

| Average ± standard deviation | Mean | 337.48 b | 326.08 b (19.9) | 13.01 | 360.31 d | 347.68 d (21.52) | 14.39 |

| (20.95) | (21.68) | ||||||

| Median | 337.49 b | 12.34 | 360.42 d | 14.64 | |||

| (21.51) | (21.98) | ||||||

| LinearR | 337.91 b | 13.56 | 360.46 d | 14.44 | |||

| (21.15) | (22.11) | ||||||

| Apr (144) | Total (562) | ||||||

| Predicted | Reference | RMSE | Predicted | Reference | RMSE | ||

| Tukey | Mean | 389.56 e | 375.26 e (19.48) | 17.95 | 357.43 g | 349.28 g (28.53) | 14.54 |

| (22.95) | (29.82) | ||||||

| Median | 389.73 e | 18.23 | 357.89 g | 14.88 | |||

| (23.25) | (29.82) | ||||||

| LinearR | 389.57 e | 17.95 | 357.71 g | 14.78 | |||

| (22.95) | (29.8) | ||||||

| Average ± standard deviation | Mean | 389.85 f | 375.26 f (19.48) | 18.35 | 357.69 h | 349.28 h (28.53) | 14.89 |

| (23.25) | (29.76) | ||||||

| Median | 389.53 f | 18.09 | 357.66 h | 14.66 | |||

| (23.56) | (29.97) | ||||||

| LinearR | 389.50 f | 18.20 | 357.81 h | 15.08 | |||

| (23) | (29.75) | ||||||

| Before post-processing (702 1) | |||||||

|---|---|---|---|---|---|---|---|

| Processing | Range | Feb | Mar | ||||

| Mean | Median | LinearR | Mean | Median | LinearR | ||

| Tukey | 5% | 81.8 | 81.8 | 78.8 | 61.1 | 55.6 | 60 |

| 10% | 97 | 97 | 97 | 72.2 | 72.2 | 71.4 | |

| Avg ± SD | 5% | 73.5 | 82.4 | 72.7 | 61.1 | 55.6 | 60 |

| 10% | 94.1 | 94.1 | 97 | 72.2 | 72.2 | 71.4 | |

| Difference | 8.3 | −0.6 | 6.1 | 0 | 0 | 0 | |

| 2.9 | 2.9 | 0 | 0 | 0 | 0 | ||

| Apr | Total | ||||||

| Tukey | 5% | 50 | 42.3 | 54.2 | 64.3 | 59.9 | 64.3 |

| 10% | 88.5 | 88.5 | 95.8 | 85.9 | 85.9 | 88.1 | |

| Avg ± SD | 5% | 40 | 31.4 | 41.2 | 58.2 | 56.5 | 58 |

| 10% | 65.7 | 65.7 | 67.6 | 77.3 | 77.3 | 78.7 | |

| Difference | 10 | 10.9 | 13 | 6.1 | 3.4 | 6.3 | |

| 22.8 | 22.8 | 28.2 | 8.6 | 8.6 | 9.4 | ||

| After post-processing (562 1) | |||||||

| Processing | Range | Feb | Mar | ||||

| Mean | Median | LinearR | Mean | Median | LinearR | ||

| Tukey | 5% | 84.4 | 84.4 | 81.3 | 84.6 | 76.9 | 84 |

| 10% | 100 | 100 | 100 | 100 | 100 | 100 | |

| Avg ± SD | 5% | 78.1 | 87.5 | 75 | 84.6 | 76.9 | 84 |

| 10% | 100 | 100 | 100 | 100 | 100 | 100 | |

| Difference | 6.3 | −3.1 | 6.3 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0 | 0 | ||

| Apr | Total | ||||||

| Tukey | 5% | 72.2 | 61.1 | 72.2 | 80.4 | 74.1 | 79.2 |

| 10% | 100 | 100 | 100 | 100 | 100 | 100 | |

| Avg ± SD | 5% | 77.8 | 61.1 | 77.8 | 80.2 | 75.2 | 78.9 |

| 10% | 100 | 100 | 100 | 100 | 100 | 100 | |

| Difference | −5.6 | 0 | −5.6 | 0.2 | −1.1 | 0.3 | |

| 0 | 0 | 0 | 0 | 0 | 0 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-H.; Song, J.-W.; Cho, H.; Lee, M.; Lee, D.-H.; Seo, S.; Lee, W.-H. Multi-Stage Data Processing for Enhancing Korean Cattle (Hanwoo) Weight Estimations by Automated Weighing Systems. Animals 2025, 15, 1785. https://doi.org/10.3390/ani15121785

Kim D-H, Song J-W, Cho H, Lee M, Lee D-H, Seo S, Lee W-H. Multi-Stage Data Processing for Enhancing Korean Cattle (Hanwoo) Weight Estimations by Automated Weighing Systems. Animals. 2025; 15(12):1785. https://doi.org/10.3390/ani15121785

Chicago/Turabian StyleKim, Dong-Hyeon, Jae-Woo Song, Hyunjin Cho, Mingyung Lee, Dae-Hyun Lee, Seongwon Seo, and Wang-Hee Lee. 2025. "Multi-Stage Data Processing for Enhancing Korean Cattle (Hanwoo) Weight Estimations by Automated Weighing Systems" Animals 15, no. 12: 1785. https://doi.org/10.3390/ani15121785

APA StyleKim, D.-H., Song, J.-W., Cho, H., Lee, M., Lee, D.-H., Seo, S., & Lee, W.-H. (2025). Multi-Stage Data Processing for Enhancing Korean Cattle (Hanwoo) Weight Estimations by Automated Weighing Systems. Animals, 15(12), 1785. https://doi.org/10.3390/ani15121785