Accuracy of Predictive Equations for Metabolizable Energy Compared to Energy Content of Foods for Dogs and Cats Estimated by In Vivo Methods in Brazil

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

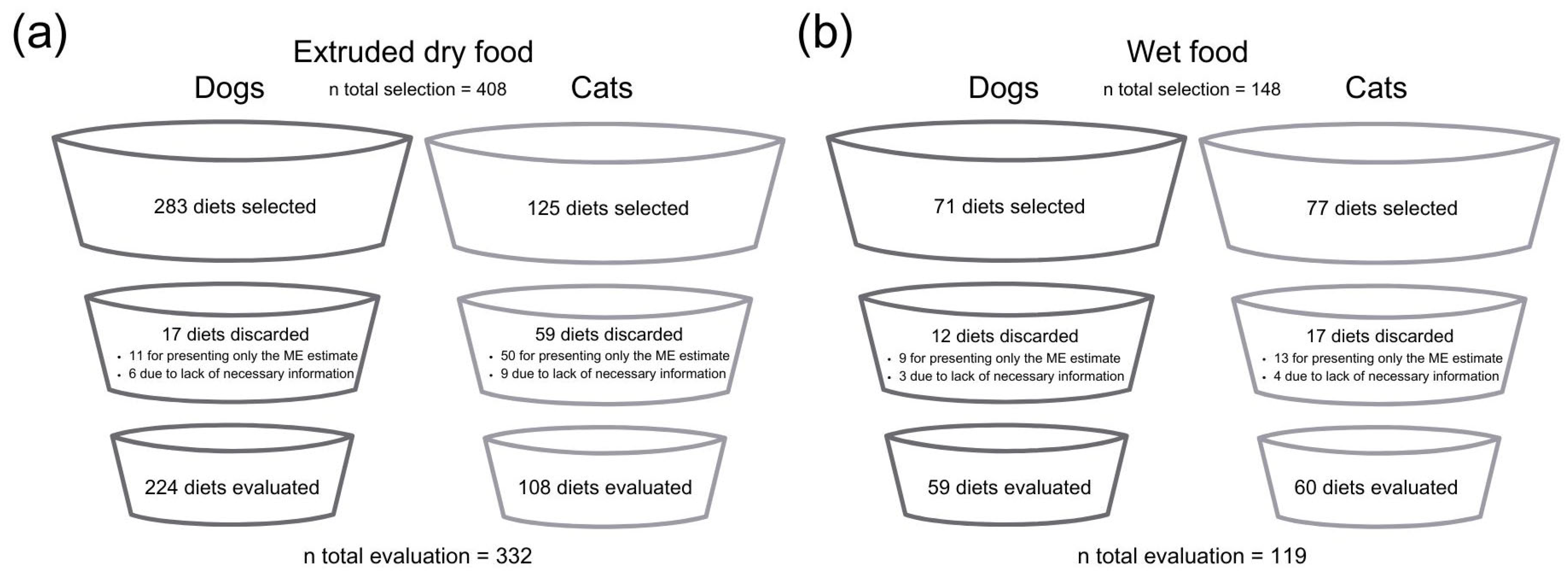

2.1. Commercial Products

2.2. Metabolizable Energy Estimation Equations

- 1.

- Atwater factors [6]:

- 2.

- Modified Atwater factors [7]:

- 3.

- (a)

- Determination of GE:considering the composition of CP, EE, NFE, and CF in natural matter (NM).GE (Kcal/Kg) = (5.7 × g CP/kg) + (9.4 × g EE/kg) + [4.1 × (g NFE/kg + g CF/kg)],

- (b)

- Percentage energy digestibility (PED):PED for cat food = 87.9 − (0.88 × %CF, in DM),PED for dog food = 91.2 − (1.43 × %CF, in DM).

- (c)

- Determination of DE:DE (kcal/kg) = GE × (PED/100).

- (d)

- Determination of ME:ME for cat food (kcal/kg) = DE − (0.77 × g CP/kg),ME for dog food (kcal/kg) = DE − (1.04 × g CP/kg),

2.3. Statistical Analysis

3. Results

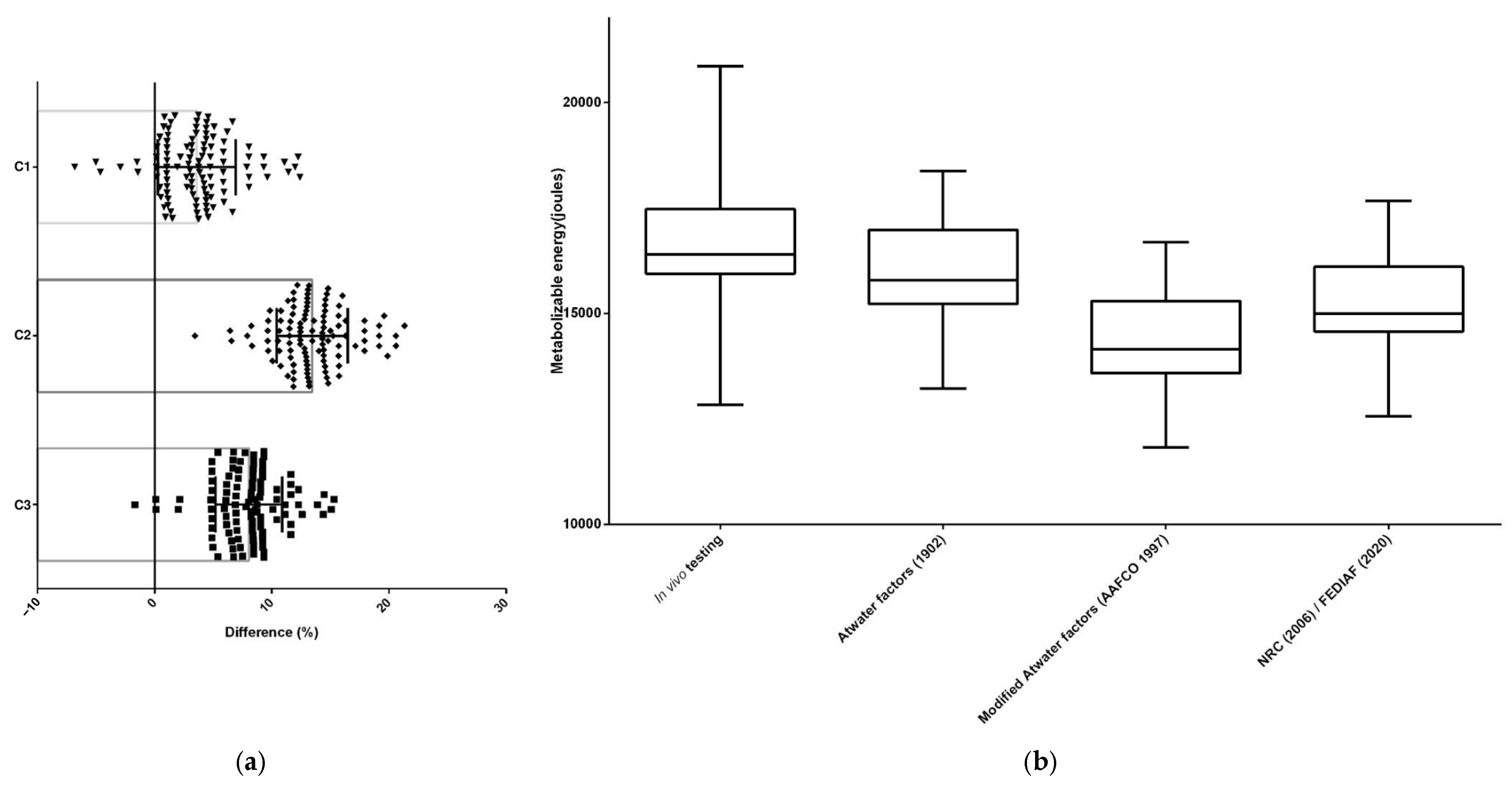

3.1. Dry Extruded Diets

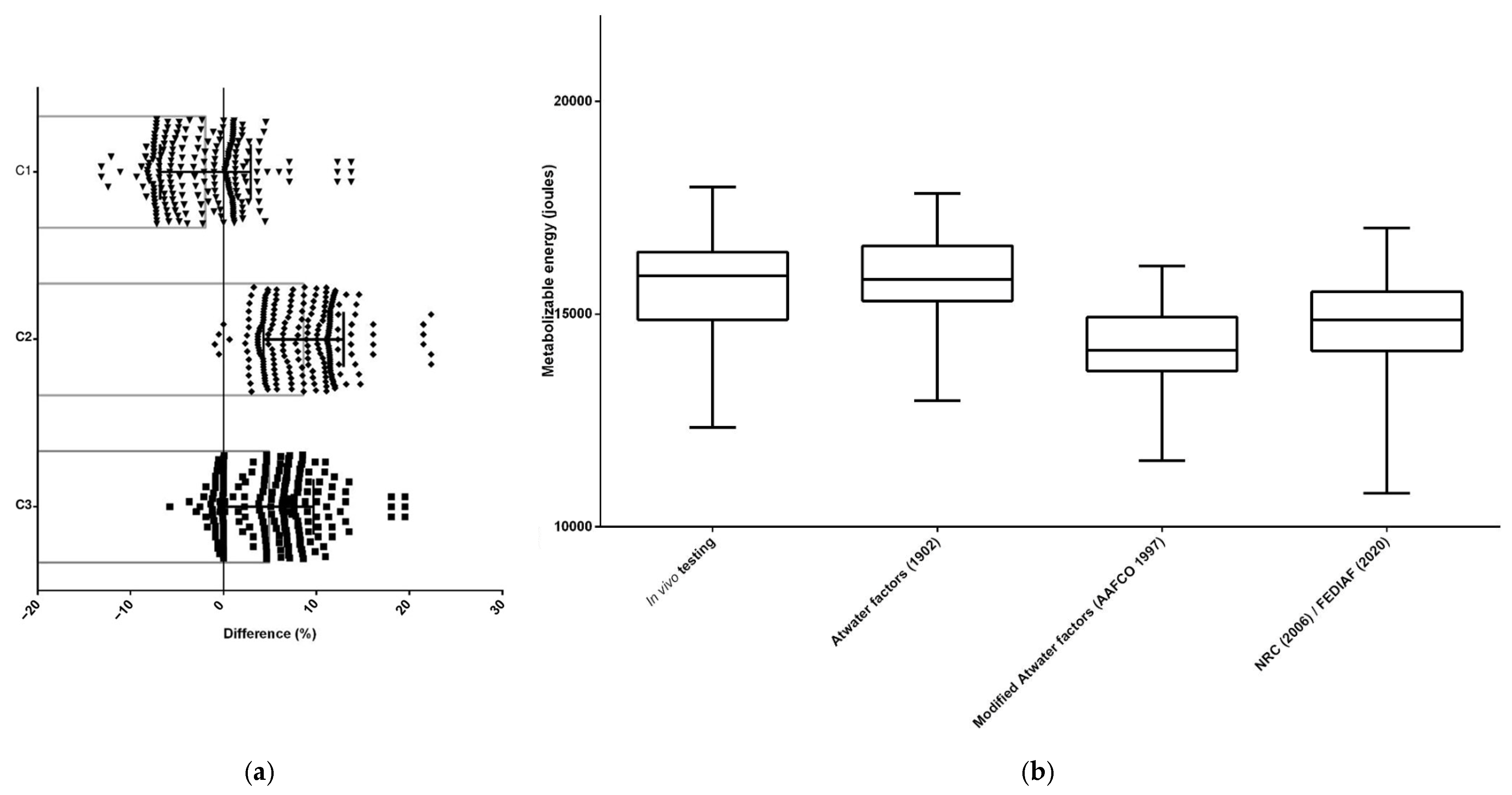

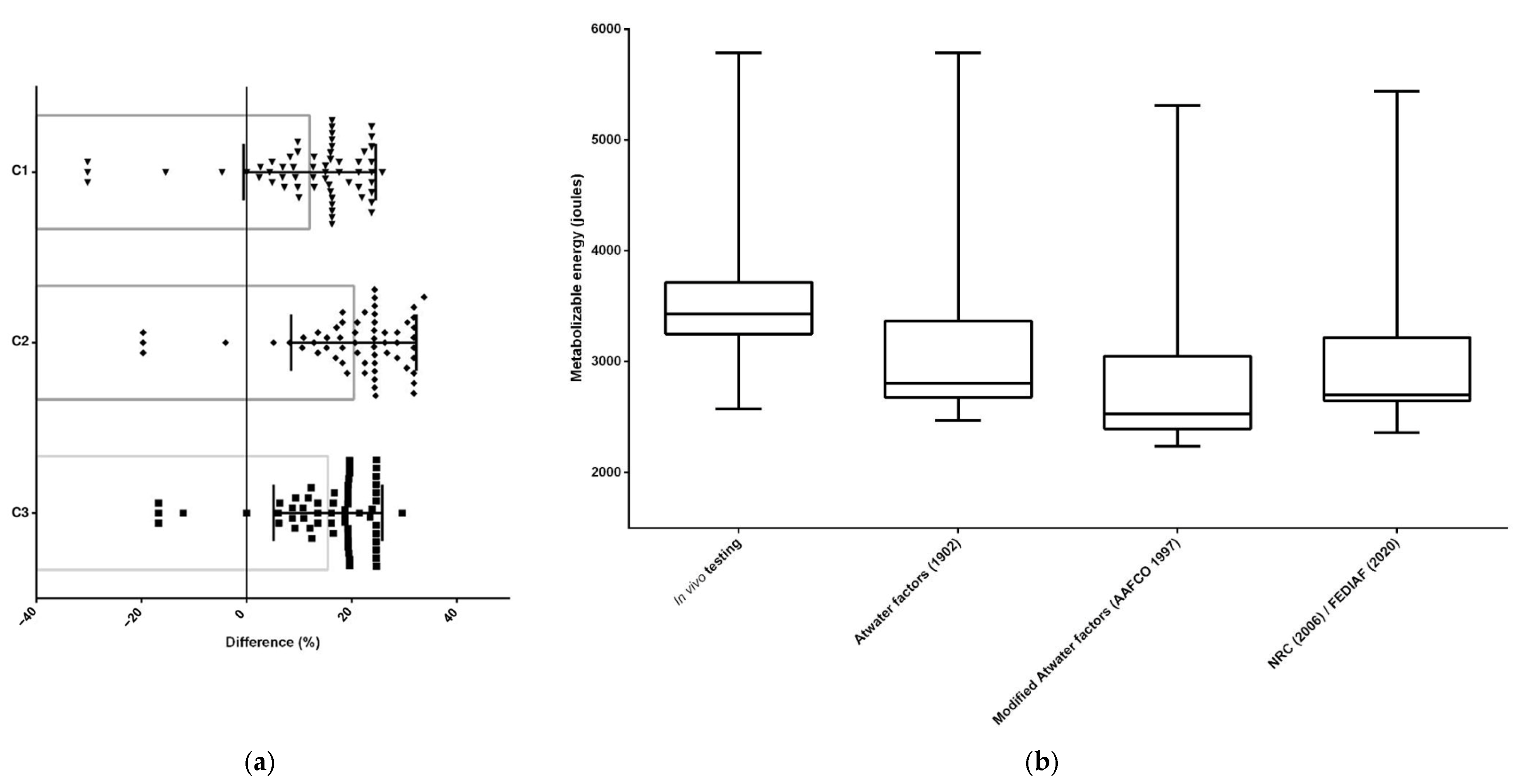

3.2. Wet Foods

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NRC (National Research Council). Nutrient Requirements of Dogs and Cats; National Academy Press: Washington, DC, USA, 2006. [Google Scholar]

- Brazil. Ministry of Agriculture, Livestock, and Supply. Establishes Criteria and Procedures for the Registration, Labeling, and Advertising of Products for Pet Animal Feed and Exemptions from Mandatory Registration; Instrução Normativa No. 30, de 05 de Agosto de 2009; Ministry of Agriculture, Livestock, and Supply: Brasília, Brazil, 2009. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/insumos-pecuarios/alimentacao-animal/arquivos-alimentacao-animal/legislacao/instrucao-normativa-no-30-de-5-de-agosto-de-2009.pdf (accessed on 25 October 2024).

- Castrillo, C.; Hervera, M.; Baucells, M.D. Methods for predicting the energy value of pet foods. Rev. Bras. Zoot. 2009, 38, 1–14. [Google Scholar] [CrossRef]

- Association of American Feed Control Officials (AAFCO); Official Publication; AAFCO: Washington, DC, USA, 2019.

- Rubner, M. Calorimetrische untersuchungen (Calorimetric Investigations). Z. Fur Biol. 1985, 261, 261–275. [Google Scholar]

- Atwater, W.O. Value of food for supplying energy. In Principles of Nutrition and Nutritive Value of Food; U.S. Department of Agriculture: Washington, DC, USA, 1902; pp. 10–12. [Google Scholar]

- Association of American Feed Control Officials (AAFCO); Official Publication; AAFCO: Washington, DC, USA, 1997.

- Laflamme, D.P. Determining metabolizable energy content in commercial pet foods. J. Anim. Physiol. Anim. Nutr. 2001, 85, 222–230. [Google Scholar] [CrossRef] [PubMed]

- FEDIAF. Nutritional Guidelines for Complete and Complementary Pet Food for Cats and Dogs; The European Pet Food Industry Federation: Brussels, Belgium, 2020. [Google Scholar]

- Calvez, J.; Weber, M.; Ecochard, C.; Kleim, L.; Flanagan, J.; Biourge, V.; German, A.J. Metabolisable energy content in canine and feline foods is best predicted by the NRC 2006 equation. PLoS ONE 2019, 14, e0223099. [Google Scholar] [CrossRef] [PubMed]

- EN 16967:2017; Animal Feeding Stuffs: Methods of Sampling and Analysis—Predictive Equations for Metabolizable Energy in Feed Materials and Compund Feed (Pet Food) for Cats and Dogs Including Dietetic Food. European Commission: Brussels, Belgium, 2017. Available online: https://standards.iteh.ai/catalog/standards/cen/d603d89a-b2c6-4625-b6ef-3144e80f3742/en-16967-2017 (accessed on 25 October 2024).

- Kienzle, E. Further developments in the prediction of metabolizable energy (ME) in pet food. J. Nutr. 2002, 132, 1796–1798. [Google Scholar] [CrossRef] [PubMed]

- Hall, J.A.; Melendez, L.D.; Jewell, D.E. Using gross energy improves metabolizable energy predictive equations for pet foods whereas undigested protein and fiber content predict stool quality. PLoS ONE 2013, 8, e54405. [Google Scholar] [CrossRef] [PubMed]

- Kienzle, E.; Opitz, B.; Earle, K.E.; Smith, P.M.; Maskell, I.E.; Iben, C. An Improved Method for the Estimation of Energy in Pet Foods. J. Nutr. 1998, 128 (Suppl. S12), 2806S–2808S. [Google Scholar] [CrossRef] [PubMed]

- Hill, R.C. Challenges in measuring energy expenditure in companion animals: A clinician’s perspective. J. Nutr. 2006, 136, 1967–1972. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, K.A.; Cargo-Froom, C.; Verbrugghe, A.; Shoveller, A.K. Equations used to develop commercial dog food feeding guidelines and Canadian owner feeding practices in 2018. Can. Vet. J. 2021, 62, 357–366. [Google Scholar] [PubMed]

- Urrego, M.I.G.; Ernandes, M.C.; Matheus, L.F.d.O.; Santos, K.M.; Oba, P.M.; Silva, C.G.P.; Vendramini, T.H.A.; Pedrinelli, V.; Brunetto, M.A. Nutritional composition and evaluation of different methodologies for fat determination in wet feed for dogs and cats. Braz. J. Vet. Res. An. Sci. 2017, 54, 398–406. [Google Scholar] [CrossRef]

- German, A.J. The growing problem of obesity in dogs and cats. J. Nutr. 2006, 136, 1940–1946. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, E.N.; Thomas, D.G.; Morris, P.J.; Hawthorne, A.J. Energy requirements of adult cats. Br. J. Nutr. 2010, 103, 1083–1093. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, E.N.; Thomas, D.G.; Cave, N.J.; Morris, P.J.; Butterwick, R.F.; German, A.J. Energy requirements of adult dogs: A meta-analysis. PLoS ONE 2014, 9, e109681. [Google Scholar] [CrossRef] [PubMed]

| Nutrient | Extruded | Wet | ||

|---|---|---|---|---|

| Cats (n = 108) | Dogs (n = 224) | Cats (n = 60) | Dogs (n = 59) | |

| Moisture (maximum) | 93.9 ± 9.46 (80.0–120.0) | 99.9 ± 8.39 (90.0–120.0) | 816.2 ± 20.74 (750.0–840.0) | 807.3 ± 38.99 (630.0–860.0) |

| Crude protein (minimum) | 346.8 ± 45.69 (250.0–500.0) | 262.9 ± 31.74 (200.0–355.0) | 92.7 ± 13.94 (70.0–125.0) | 80.3 ± 11.63 (34.0–95.0) |

| Fat (minimum) | 141.4 ± 40.84 (80.0–230.0) | 131.5 ± 32.89 (70.0–211.0) | 35.2 ± 15.68 (20.0–95.0) | 39.2 ± 10.23 (20.0–70.0) |

| Crude fiber (maximum) | 44.2 ± 20.87 (18.0–150.0) | 40.4 ± 20.27 (19.0–150.0) | 17.1 ± 4.56 (6.0–25.0) | 18.5 ± 4.34 (6.0–30.0) |

| Ash (maximum) | 81.2 ± 7.51 (53.0–105.0) | 76.4 ± 15.50 (6.0–110.00) | 26.1 ± 4.84 (13.0–33.0) | 25.1 ± 6.93 (14.3–38.0) |

| Nitrogen-free extract | 292.5 ± 59.56 (145.0–435.0) | 388.9 ± 55.35 (240.0–485.0) | 12.7 ± 13.10 (0.0–56.2) | 29.6 ± 43.17 (0.0–227.0) |

| Variables | Predictive Equations | P 1 | |||||

|---|---|---|---|---|---|---|---|

| In Vivo Testing (Reference) | Atwater Factors [6] | Modified Atwater Factors [7] | NRC and FEDIAF [1,9] | C1 | C2 | C3 | |

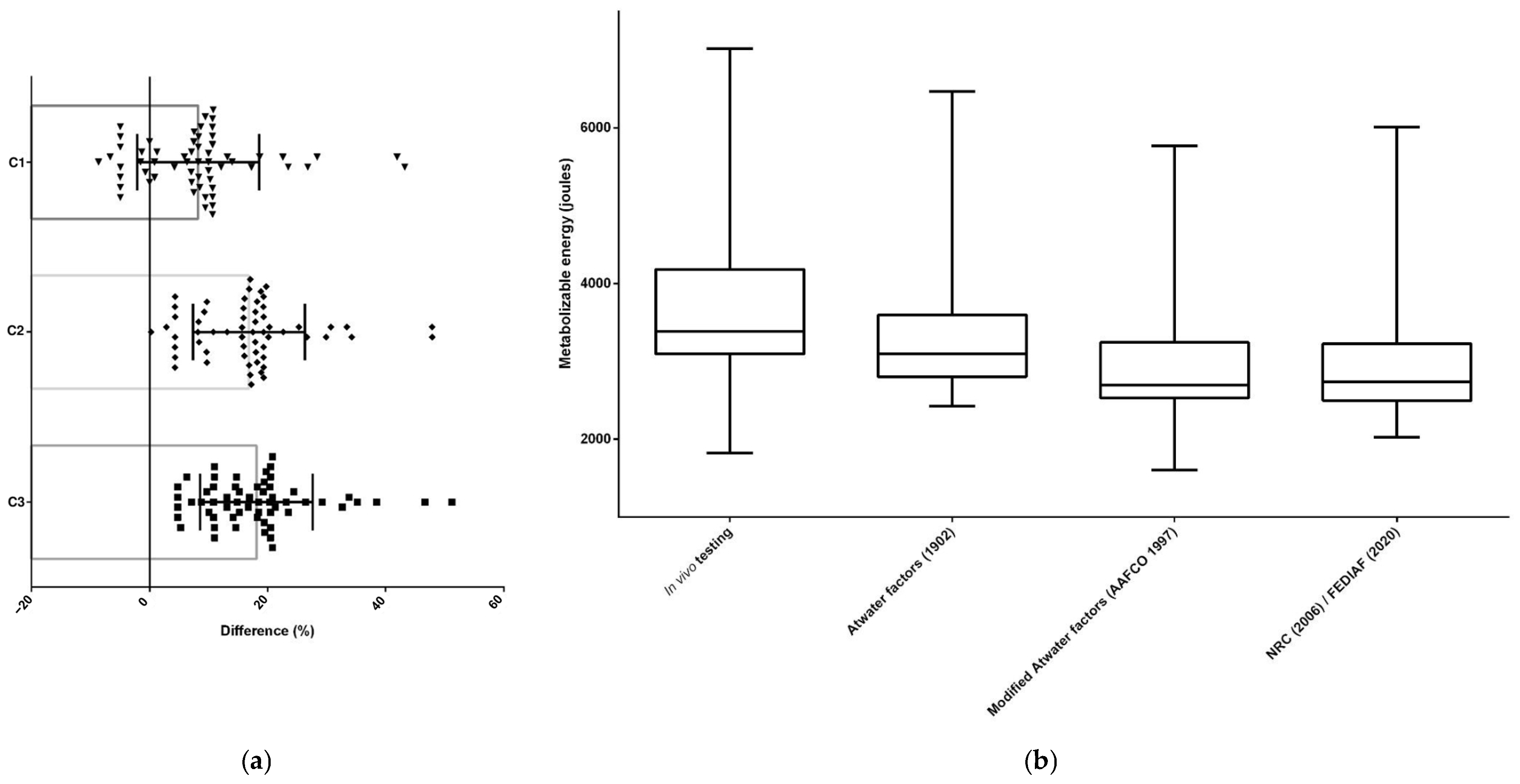

| Metabolizable energy (MJ/kg) | 1.66 ± 0.13 | 1.60 ± 0.11 | 1.44 ± 0.11 | 1.53 ± 0.10 | <0.0001 | <0.0001 | <0.0001 |

| Difference 2 (%) | — | 3.59 ± 3.32 | 13.45 ± 3.05 | 8.05 ± 2.84 | — | — | — |

| Variables | Predictive Equations | P 1 | |||||

|---|---|---|---|---|---|---|---|

| In Vivo Testing (Reference) | Atwater Factors [6] | Modified Atwater Factors [7] | NRC and FEDIAF [1,9] | C1 | C2 | C3 | |

| Metabolizable energy (MJ/kg) | 1.56 ± 0.12 | 1.59 ± 0.09 | 1.42 ± 0.09 | 1.48 ± 0.10 | 0.0070 | <0.0001 | <0.0001 |

| Difference 2 (%) | — | −1.94 ± 4.87 | 8.62 ± 4.29 | 4.90 ± 4.79 | — | — | — |

| Variables | Predictive Equations | P 1 | |||||

|---|---|---|---|---|---|---|---|

| In Vivo Testing (Reference) | Atwater Factors [6] | Modified Atwater Factors [7] | NRC and FEDIAF [1,9] | C1 | C2 | C3 | |

| Metabolizable energy (MJ/kg) | 0.36 ± 0.06 | 0.31 ± 0.06 | 0.28 ± 0.06 | 0.29 ± 0.06 | <0.0001 | <0.0001 | <0.0001 |

| Difference 2 (%) | — | 11.99 ± 12.56 | 20.41 ± 11.90 | 15.45 ± 10.34 | — | — | — |

| Variables | Predictive Equations | P 1 | |||||

|---|---|---|---|---|---|---|---|

| In Vivo Testing (Reference) | Atwater Factors [6] | Modified Atwater Factors [7] | NRC and FEDIAF [1,9] | C1 | C2 | C3 | |

| Metabolizable energy (MJ/kg) | 0.36 ± 0.09 | 0.33 ± 0.08 | 0.30 ± 0.07 | 0.29 ± 0.07 | 0.0370 | <0.0001 | <0.0001 |

| Difference 2 (%) | — | 8.25 ± 10.34 | 16.85 ± 9.48 | 18.12 ± 9.55 | — | — | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, P.H.; Amaral, A.R.; Príncipe, L.d.A.; Risolia, L.W.; Rentas, M.F.; Fasolai, A.B.; Zafalon, R.V.A.; Finardi, G.L.F.; Jeremias, J.T.; Pedreira, R.S.; et al. Accuracy of Predictive Equations for Metabolizable Energy Compared to Energy Content of Foods for Dogs and Cats Estimated by In Vivo Methods in Brazil. Animals 2025, 15, 1477. https://doi.org/10.3390/ani15101477

Marchi PH, Amaral AR, Príncipe LdA, Risolia LW, Rentas MF, Fasolai AB, Zafalon RVA, Finardi GLF, Jeremias JT, Pedreira RS, et al. Accuracy of Predictive Equations for Metabolizable Energy Compared to Energy Content of Foods for Dogs and Cats Estimated by In Vivo Methods in Brazil. Animals. 2025; 15(10):1477. https://doi.org/10.3390/ani15101477

Chicago/Turabian StyleMarchi, Pedro Henrique, Andressa Rodrigues Amaral, Leonardo de Andrade Príncipe, Larissa Wünsche Risolia, Mariana Fragoso Rentas, Ana Beatriz Fasolai, Rafael Vessecchi Amorim Zafalon, Gabriela Luiza Fagundes Finardi, Juliana Toloi Jeremias, Raquel Silveira Pedreira, and et al. 2025. "Accuracy of Predictive Equations for Metabolizable Energy Compared to Energy Content of Foods for Dogs and Cats Estimated by In Vivo Methods in Brazil" Animals 15, no. 10: 1477. https://doi.org/10.3390/ani15101477

APA StyleMarchi, P. H., Amaral, A. R., Príncipe, L. d. A., Risolia, L. W., Rentas, M. F., Fasolai, A. B., Zafalon, R. V. A., Finardi, G. L. F., Jeremias, J. T., Pedreira, R. S., Balieiro, J. C. d. C., & Vendramini, T. H. A. (2025). Accuracy of Predictive Equations for Metabolizable Energy Compared to Energy Content of Foods for Dogs and Cats Estimated by In Vivo Methods in Brazil. Animals, 15(10), 1477. https://doi.org/10.3390/ani15101477