Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

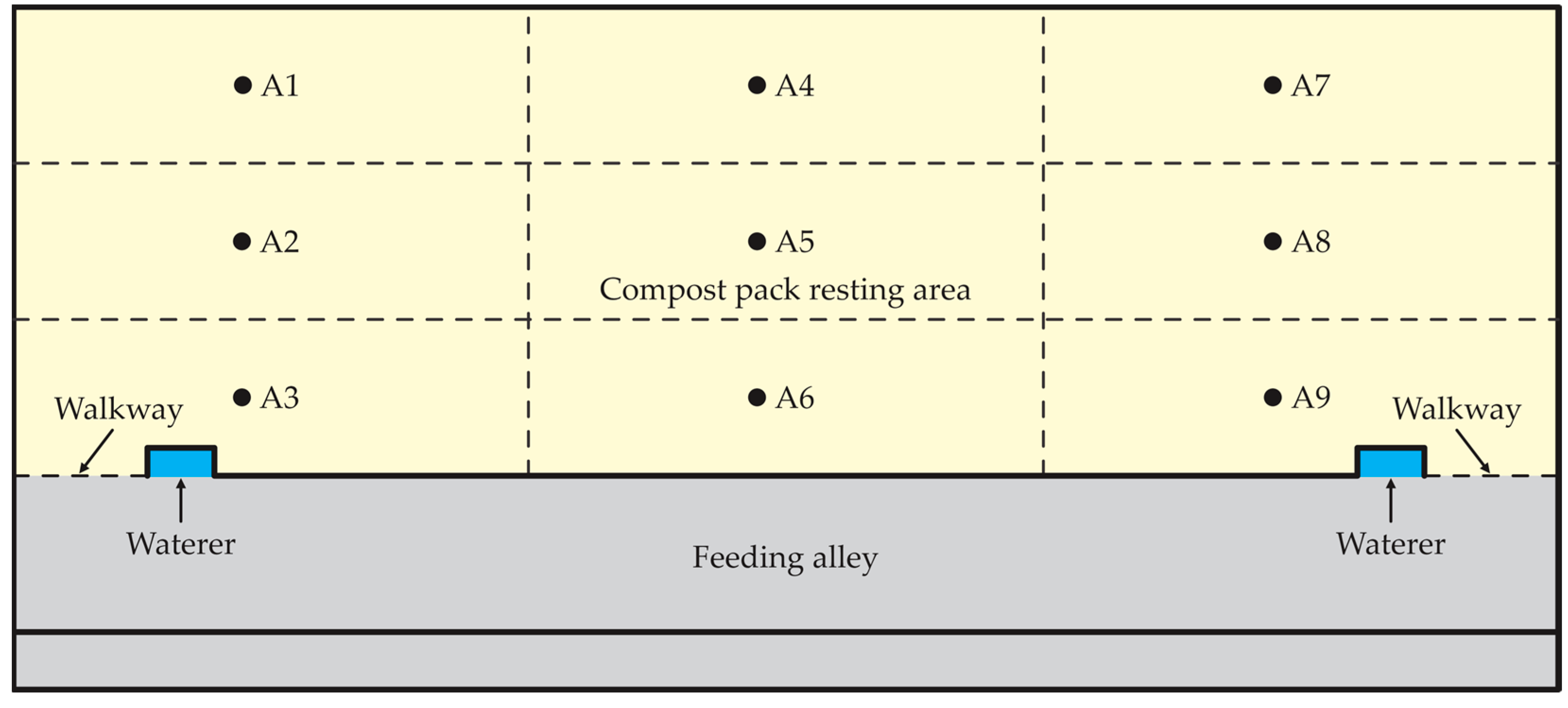

2.1. Sample Collection

2.2. Thermal Properties Measurement

2.3. Chemical Properties Measurement

2.4. Physical Properties Measurement

3. Results

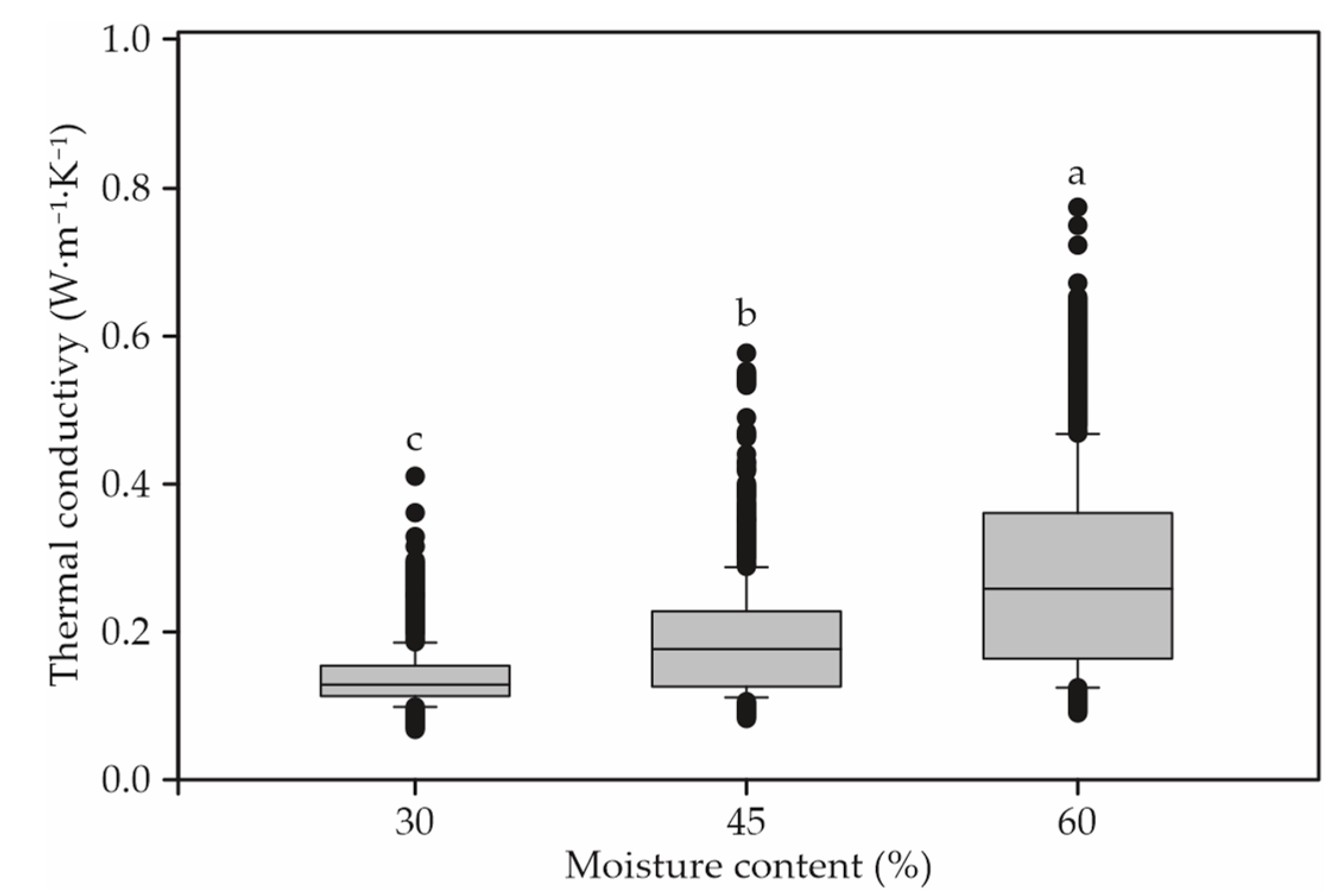

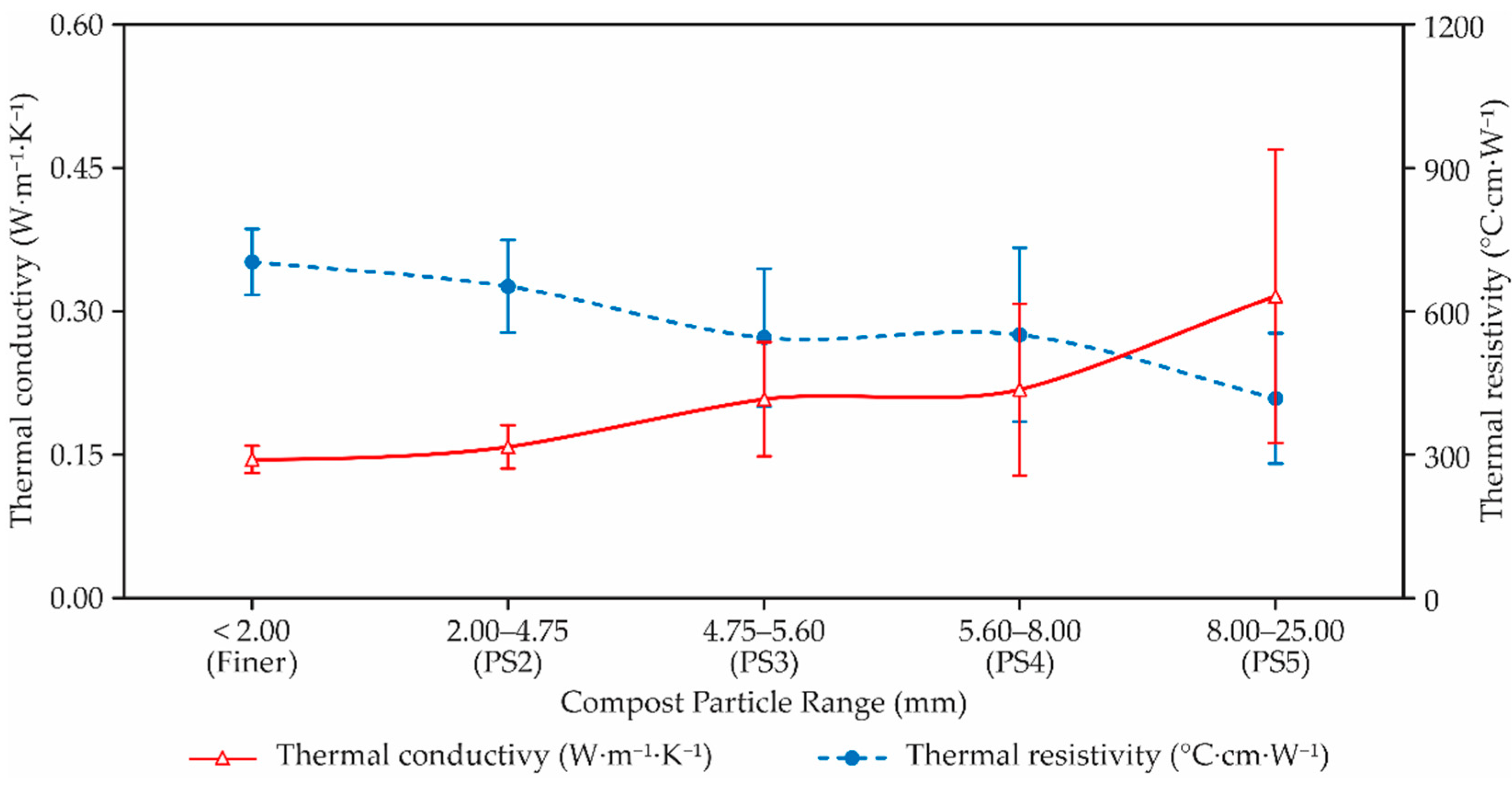

3.1. Thermal Properties of Compost Materials

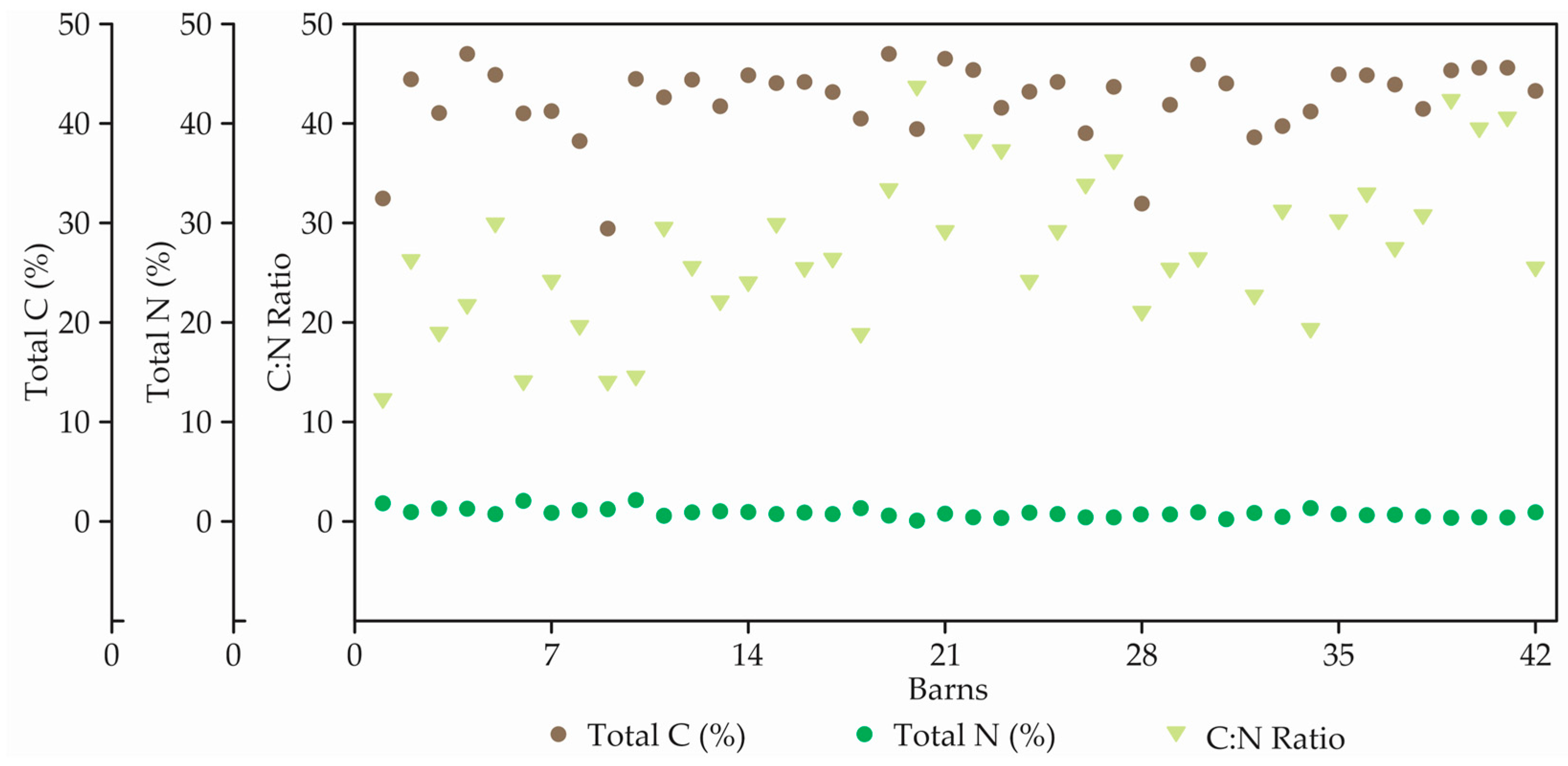

3.2. Chemical Properties of Compost Materials

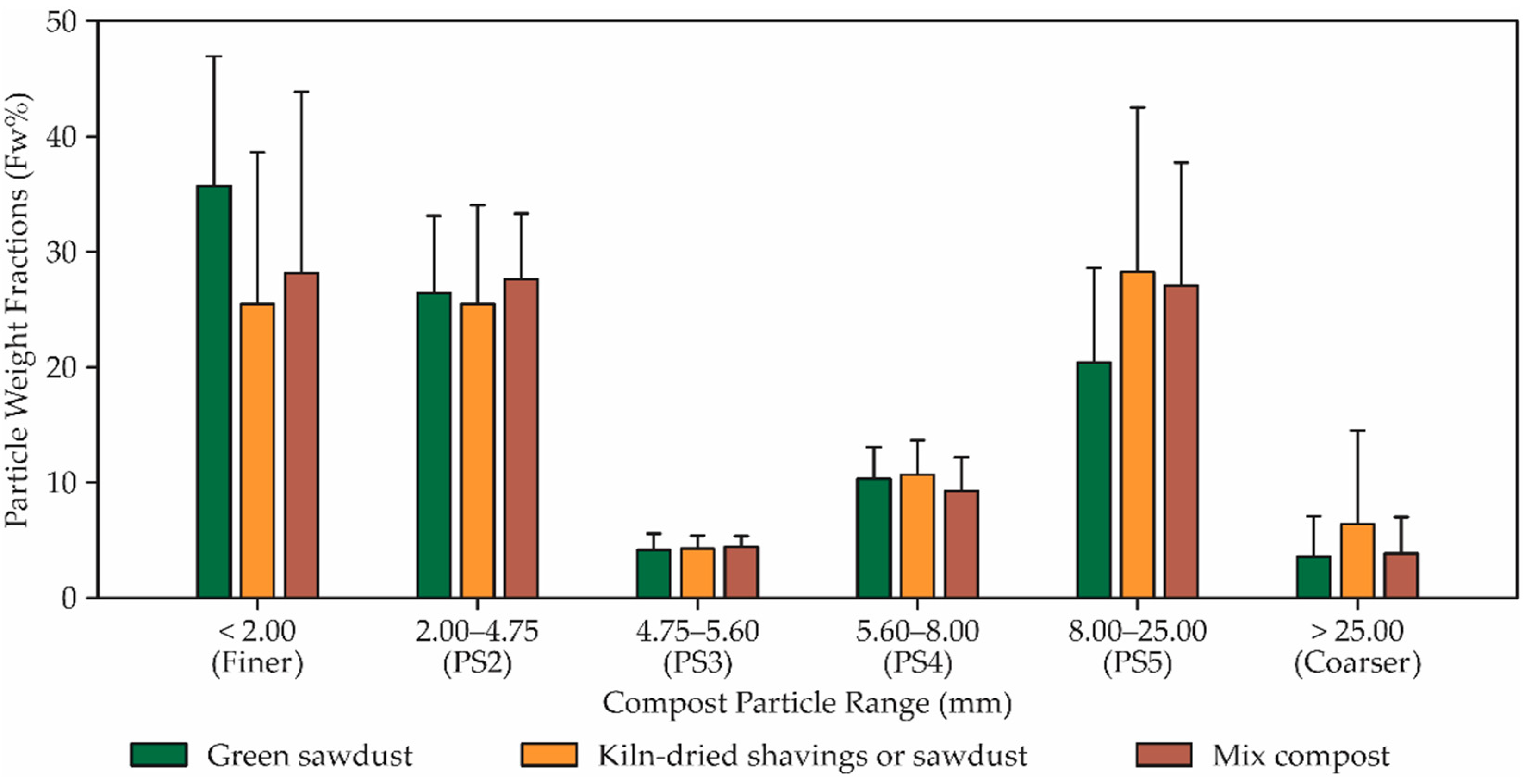

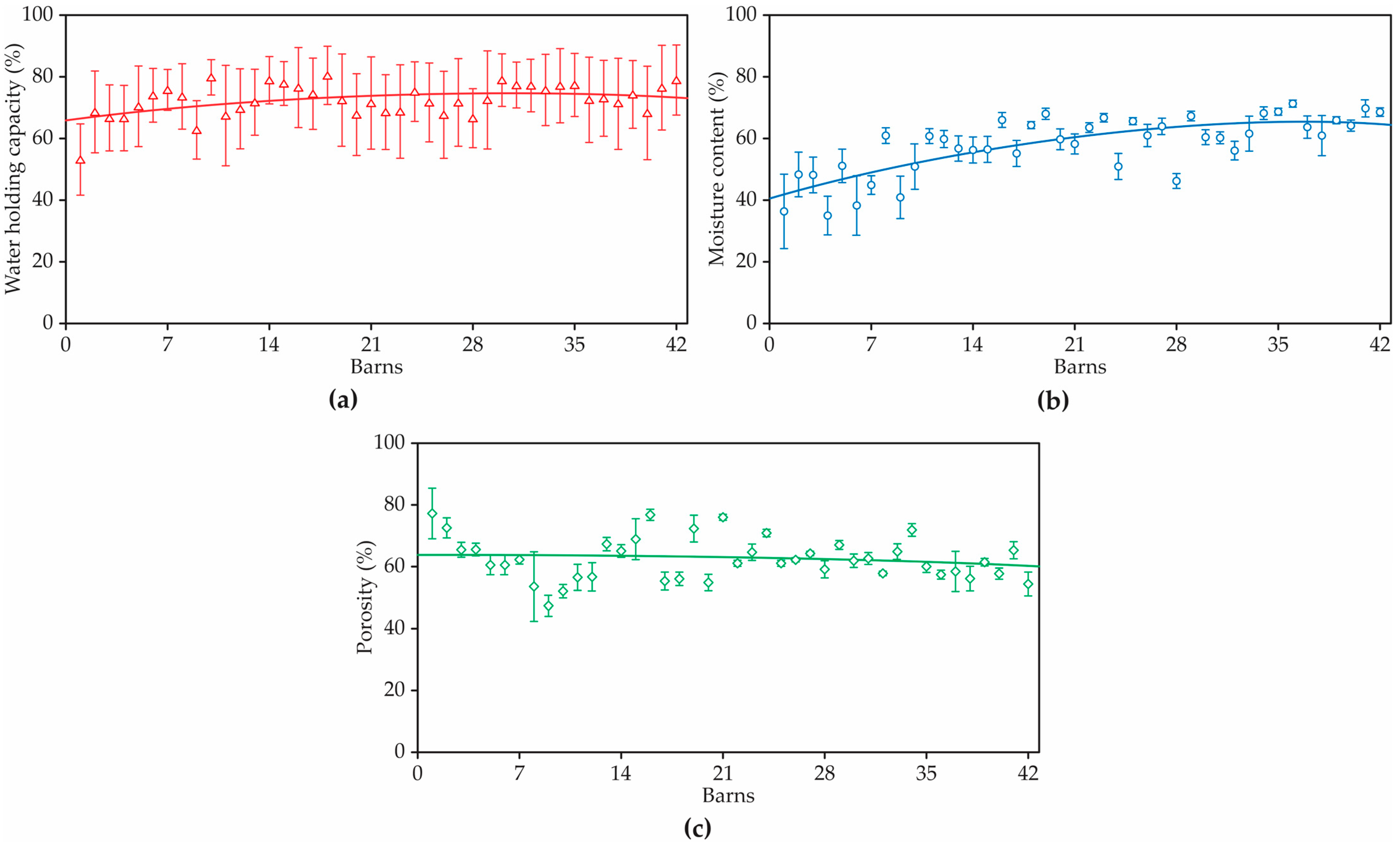

3.3. Physical Properties of Compost Materials

4. Discussion

4.1. Thermal Properties of Compost Materials

4.2. Chemical Properties of Compost Materials

4.3. Physical Properties of Compost Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited Review: Compost-Bedded Pack Barns for Dairy Cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef] [PubMed]

- Ferraz, P.F.P.; Ferraz, G.A.S.; Leso, L.; Klopčič, M.; Barbari, M.; Rossi, G. Properties of Conventional and Alternative Bedding Materials for Dairy Cattle. J. Dairy Sci. 2020, 103, 8661–8674. [Google Scholar] [CrossRef] [PubMed]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost Bedded Pack Dairy Barn Management, Performance, and Producer Satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Lee, S.S.; Jeon, B.T.; Kang, C.W. Evaluation of Optimum Moisture Content for Composting of Beef Manure and Bedding Material Mixtures Using Oxygen Uptake Measurement. Asian Australas. J. Anim. Sci. 2015, 13, 962–966. [Google Scholar] [CrossRef]

- Lorenzo, L.; Ferraz, P.F.P.; Ferraz, G.A.S.; Rossi, G.; Barbari, M. Factors Affecting Evaporation of Water from Cattle Bedding Materials. Biosyst. Eng. 2021, 205, 164–173. [Google Scholar] [CrossRef]

- Kheravii, S.K.; Swick, R.A.; Choct, M.; Wu, S.B. Potential of Pelleted Wheat Straw as an Alternative Bedding Material for Broilers. Poult. Sci. 2017, 96, 1641–1647. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H. Thermal Properties of Soils as Affected by Density and Water Content. Biosyst. Eng. 2003, 86, 97–102. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Z. Review of Soil Thermal Conductivity and Predictive Models. Int. J. Therm. Sci. 2017, 117, 172–183. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, X.; Pradhan, A.; Puppala, A.J. Thermal Conductivity of Quartz Sands by Thermo-Time Domain Reflectometry Probe and Model Prediction. J. Mater. Civ. Eng. 2015, 27, 04015059. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, X.; Pradhan, A.; Puppala, A.J. A New Generalized Soil Thermal Conductivity Model for Sand–Kaolin Clay Mixtures Using Thermo-Time Domain Reflectometry Probe Test. Acta Geotech. 2017, 12, 739–752. [Google Scholar] [CrossRef]

- Ahn, H.K.; Sauer, T.J.; Richard, T.L.; Glanville, T.D. Determination of Thermal Properties of Compost Bulking Materials by Using Various Methods. In Proceedings of the 2006 ASAE Annual Meeting, Boston, MA, USA, 19–22 August 2006. [Google Scholar] [CrossRef]

- Ahn, H.K.; Sauer, T.J.; Richard, T.L.; Glanville, T.D. Determination of Thermal Properties of Composting Bulking Materials. Bioresour. Technol. 2009, 100, 3974–3981. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, V.C.; Damasceno, F.A.; Oliveira, C.E.A.; Ferraz, P.F.P.; Ferraz, G.A.S.; Saraz, J.A.O. Compost-Bedded Pack Barns in the State of Minas Gerais: Architectural and Technological Characterization. Agron. Res. 2019, 17, 2016–2028. [Google Scholar] [CrossRef]

- Fávero, S.; Portilho, F.V.R.; Oliveira, A.C.R.; Langoni, H.; Pantoja, J.C.F. Factors Associated with Mastitis Epidemiologic Indexes, Animal Hygiene, and Bulk Milk Bacterial Concentrations in Dairy Herds Housed on Compost Bedding. Livest. Sci. 2015, 181, 220–230. [Google Scholar] [CrossRef]

- Zoes, V.; Dinel, H.; Paré, T.; Jaouich, A. Growth Substrates Made from Duck Excreta Enriched Wood Shavings and Source-Separated Municipal Solid Waste Compost and Separates: Physical and Chemical Characteristics. Bioresour. Technol. 2001, 78, 21–30. [Google Scholar] [CrossRef]

- Liberty, K.R. Yard-Waste Compost Biofilters for Ammonia Adsorption and Biotransformation. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2002. [Google Scholar]

- Maia, G.D.N.; Sales, G.T.; Gates, R.S.; Taraba, J.L. Characterizing physical properties of gas-phase biofilter media. Trans. ASABE 2012, 55, 1939–1950. [Google Scholar] [CrossRef]

- Chandrakanthi, M.; Mehrotra, A.K.; Hettiaratchi, J.P.A. Thermal Conductivity of Leaf Compost Used in Biofilters: An Experimental and Theoretical Investigation. Environ. Pollut. 2005, 136, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Yun, T.S.; Santamarina, J.C. Fundamental Study of Thermal Conduction in Dry Soils. Granul. Matter 2008, 10, 197–207. [Google Scholar] [CrossRef]

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Newman, M.C.; Akers, K.A.; Wood, C.L.; McQuerry, K.J.; Bewley, J.M. The Relationship between Compost Bedded Pack Performance, Management, and Bacterial Counts. J. Dairy Sci. 2014, 97, 2669–2679. [Google Scholar] [CrossRef]

- Shane, E.M.; Endres, M.I.; Janni, K.A. Alternative Bedding Materials for Compost Bedded Pack Barns in Minnesota: A Descriptive Study. Appl. Eng. Agric. 2010, 26, 465–473. [Google Scholar] [CrossRef]

- De Boer, H.C.; Wiersma, M. Thermophilic Composting of the Pack Can Reduce Nitrogen Loss from Compost-Bedded Dairy Barns. Biosyst. Eng. 2021, 210, 20–32. [Google Scholar] [CrossRef]

- Barberg, A.E.; Endres, M.I.; Salfer, J.A.; Reneau, J.K. Performance and Welfare of Dairy Cows in an Alternative Housing System in Minnesota. J. Dairy Sci. 2007, 90, 1575–1583. [Google Scholar] [CrossRef]

- Russelle, M.P.; Blanchet, K.M.; Randall, G.W.; Everett, L.A. Characteristics and Nitrogen Value of Stratified Bedded Pack Dairy Manure. Crop Manag. 2009, 8, 1–10. [Google Scholar] [CrossRef]

- Janni, K.A.; Endres, M.I.; Reneau, J.K.; Schoper, W.W. Compost Dairy Barn Layout and Management Recommendations. Appl. Eng. Agric. 2007, 23, 97–102. [Google Scholar] [CrossRef]

- Radavelli, W.M.; Danieli, B.; Zotti, M.L.A.N.; Gomes, F.J.; Endres, M.I.; Schogor, A.L.B. Compost Barns in Brazilian Subtropical Region (Part 1): Facility, Barn Management and Herd Characteristics Compost. Res. Soc. Dev. 2020, 2020, 5–24. [Google Scholar] [CrossRef]

- Barberg, A.E.; Endres, M.I.; Janni, K.A. Compost Dairy Barns in Minnesota: A Descriptive Study. Appl. Eng. Agric. 2007, 23, 231–238. [Google Scholar] [CrossRef]

- Misra, R.V.; Roy, R.N.; Hiraoka, H. On-Farm Composting Methods. In Land and Water Discussion Paper; UN-FAO: Rome, Italy, 2003; Volume 2, p. 51. [Google Scholar]

- Rosen, C.J.; Halbach, T.R.; Mugaas, R. A Guide to Managing Organic Yard Wastes; University of Minnesota Extension Publication: St. Paul, MN, USA, 2000. [Google Scholar]

- Leonard, J. Composting: An Alternative Approach to Manure Management. Adv. Dairy Technol. 2001, 13, 431–441. [Google Scholar]

- Tham, K.W.; Zuraimi, M.S. Size Relationship between Airborne Viable Bacteria and Particles in a Controlled Indoor Environment Study. Indoor Air 2005, 15, 48–57. [Google Scholar] [CrossRef]

- Nazaroff, W.W. Indoor Particle Dynamics. Indoor Air 2004, 14, 175–183. [Google Scholar] [CrossRef]

- Rynk, R.; Van de Kamp, M.; Willson, G.B.; Singley, M.E.; Richard, T.L.; Kolega, J.J.; Brinton, W.F. On-Farm Composting Handbook (NRAES 54); Northeast Regional Agricultural Engineering Service (NRAES): Ithaca, NY, USA, 1992. [Google Scholar]

- Damasceno, F.A. Compost Bedded Pack Barns System and Computational Simulation of Airflow through Naturally Ventilated Reduced Model. Ph.D. Thesis, Universidade Federal de Viçosa, Viçosa, MG, Brazil, 2012. [Google Scholar]

| Barn | Particle Density (g·cm−3) | Bulk Density (g·cm−3) | POROSITY (%) |

|---|---|---|---|

| 1 | 0.95 ± 0.06 | 0.50 ± 0.06 | 77.12 ± 8.23 |

| 2 | 0.98 ± 0.06 | 0.47 ± 0.01 | 72.30 ± 3.30 |

| 3 | 0.92 ± 0.04 | 0.38 ± 0.02 | 65.41 ± 2.25 |

| 4 | 0.86 ± 0.04 | 0.31 ± 0.01 | 65.40 ± 1.84 |

| 5 | 0.93 ± 0.07 | 0.47 ± 0.03 | 60.53 ± 3.26 |

| 6 | 0.91 ± 0.05 | 0.45 ± 0.01 | 60.50 ± 3.40 |

| 7 | 0.97 ± 0.06 | 0.37 ± 0.01 | 62.07 ± 1.65 |

| 8 | 0.99 ± 0.05 | 0.47 ± 0.13 | 53.63 ± 11.28 |

| 9 | 1.04 ± 0.05 | 0.54 ± 0.02 | 47.43 ± 3.61 |

| 10 | 0.94 ± 0.06 | 0.45 ± 0.01 | 51.92 ± 2.30 |

| 11 | 1.01 ± 0.03 | 0.44 ± 0.04 | 56.52 ± 4.34 |

| 12 | 1.05 ± 0.07 | 0.45 ± 0.02 | 56.70 ± 4.75 |

| 13 | 1.00 ± 0.01 | 0.35 ± 0.03 | 67.37 ± 2.18 |

| 14 | 0.99 ± 0.03 | 0.32 ± 0.01 | 65.21 ± 2.01 |

| 15 | 0.92 ± 0.03 | 0.28 ± 0.05 | 68.64 ± 6.60 |

| 16 | 1.01 ± 0.02 | 0.24 ± 0.01 | 76.72 ± 1.57 |

| 17 | 0.98 ± 0.04 | 0.44 ± 0.01 | 55.31 ± 2.83 |

| 18 | 0.90 ± 0.02 | 0.40 ± 0.02 | 56.00 ± 2.18 |

| 19 | 0.92 ±0.11 | 0.27 ± 0.01 | 71.99 ± 4.26 |

| 20 | 1.06 ± 0.01 | 0.48 ± 0.03 | 54.81 ± 2.62 |

| 21 | 1.01 ± 0.02 | 0.24 ± 0.01 | 75.90 ± 1.02 |

| 22 | 1.00 ± 0.01 | 0.39 ± 0.01 | 60.94 ± 0.96 |

| 23 | 1.02 ± 0.06 | 0.36 ± 0.00 | 64.73 ± 2.43 |

| 24 | 0.97 ± 0.01 | 0.28 ± 0.01 | 70.80 ± 1.10 |

| 25 | 1.00 ± 0.03 | 0.39 ± 0.01 | 61.11 ± 0.41 |

| 26 | 1.11 ± 0.01 | 0.42 ± 0.01 | 62.29 ± 0.75 |

| 27 | 0.94 ± 0.05 | 0.34 ± 0.02 | 64.10 ± 0.94 |

| 28 | 1.04 ± 0.05 | 0.43 ± 0.01 | 58.88 ± 2.64 |

| 29 | 1.06 ± 0.04 | 0.35 ± 0.02 | 66.83 ± 1.20 |

| 30 | 0.97 ± 0.04 | 0.37 ± 0.00 | 61.68 ± 2.11 |

| 31 | 1.04 ± 0.02 | 0.39 ± 0.01 | 62.58 ± 1.81 |

| 32 | 1.00 ± 0.00 | 0.42 ± 0.01 | 57.80 ± 0.65 |

| 33 | 0.93 ± 0.02 | 0.33 ± 0.02 | 64.66 ± 2.52 |

| 34 | 0.97 ± 0.02 | 0.27 ± 0.02 | 71.80 ± 2.12 |

| 35 | 1.01 ± 0.01 | 0.40 ± 0.02 | 59.73 ± 1.78 |

| 36 | 0.95 ± 0.00 | 0.41 ± 0.01 | 57.26 ± 1.44 |

| 37 | 0.91 ± 0.01 | 0.38 ± 0.06 | 58.34 ± 6.60 |

| 38 | 0.87 ± 0.04 | 0.38 ± 0.02 | 56.11 ± 4.06 |

| 39 | 1.03 ± 0.02 | 0.40 ± 0.02 | 61.39 ± 0.78 |

| 40 | 1.06 ± 0.03 | 0.34 ± 0.03 | 57.50 ± 1.87 |

| 41 | 1.05 ± 0.00 | 0.20 ± 0.03 | 77.32 ± 2.67 |

| 42 | 1.05 ± 0.01 | 0.32 ± 0.04 | 54.20 ± 3.78 |

| Average | 0.98 ± 0.02 | 0.38 ± 0.02 | 62.65 ± 2.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damasceno, F.A.; Day, G.B.; Taraba, J.L.; Barbari, M.; Oliveira, C.E.A.; Frigeri, K.D.M.; Vieira, F.M.C.; Bambi, G. Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns. Animals 2022, 12, 2450. https://doi.org/10.3390/ani12182450

Damasceno FA, Day GB, Taraba JL, Barbari M, Oliveira CEA, Frigeri KDM, Vieira FMC, Bambi G. Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns. Animals. 2022; 12(18):2450. https://doi.org/10.3390/ani12182450

Chicago/Turabian StyleDamasceno, Flávio Alves, George B. Day, Joseph L. Taraba, Matteo Barbari, Carlos Eduardo Alves Oliveira, Karen Dal Magro Frigeri, Frederico Márcio Corrêa Vieira, and Gianluca Bambi. 2022. "Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns" Animals 12, no. 18: 2450. https://doi.org/10.3390/ani12182450

APA StyleDamasceno, F. A., Day, G. B., Taraba, J. L., Barbari, M., Oliveira, C. E. A., Frigeri, K. D. M., Vieira, F. M. C., & Bambi, G. (2022). Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns. Animals, 12(18), 2450. https://doi.org/10.3390/ani12182450