Simple Summary

Poor indoor air quality and gaseous emissions are undesirable side effects of livestock and poultry production. Gaseous emissions of odor, odorous volatile organic compounds (VOCs), ammonia (NH3), hydrogen sulfide (H2S), and greenhouse gases (GHGs) have detrimental effects on the quality of life in rural communities, the environment, and climate. Proven mitigation technologies are needed to increase the sustainability of animal agriculture. This study’s objective was to evaluate the ultraviolet (UV) light treatment of odor and common air pollutant emissions from stored swine manure on a pilot-scale. To our knowledge, this is the first study of this scope that was needed for scaling up technologies treating gaseous emissions of odor, odorous VOCs, NH3, H2S, ozone, and GHGs. The study bridged the knowledge gap between lab-scales and simplified treatment of model gases to the treatment of complex gaseous mixtures emitted from swine manure in fast-moving air. The manure emissions were treated in fast-moving air using a mobile lab equipped with UV-A and UV-C lights and photocatalytic surface coating. The percent reduction of targeted gases depended on the UV dose and wavelength. While generally mitigating targeted gases, some UV treatments resulted in CO2 and ozone (O3). The results proved that the UV technology was sufficiently effective in treating odorous gases, and the mobile lab was ready for farm-scale trials. The UV technology can be considered for the scaled-up treatment of emissions and air quality improvement inside livestock barns.

Abstract

It is essential to mitigate gaseous emissions that result from poultry and livestock production to increase industry sustainability. Odorous volatile organic compounds (VOCs), ammonia (NH3), hydrogen sulfide (H2S), and greenhouse gases (GHGs) have detrimental effects on the quality of life in rural communities, the environment, and climate. This study’s objective was to evaluate the photocatalytic UV treatment of gaseous emissions of odor, odorous VOCs, NH3, and other gases (GHGs, O3—sometimes considered as by-products of UV treatment) from stored swine manure on a pilot-scale. The manure emissions were treated in fast-moving air using a mobile lab equipped with UV-A and UV-C lights and TiO2-based photocatalyst. Treated gas airflow (0.25–0.76 m3∙s−1) simulates output from a small ventilation fan in a barn. Through controlling the light intensity and airflow, UV dose was tested for techno-economic analyses. The treatment effectiveness depended on the UV dose and wavelength. Under UV-A (367 nm) photocatalysis, the percent reduction of targeted gases was up to (i) 63% of odor, (ii) 51%, 51%, 53%, 67%, and 32% of acetic acid, propanoic acid, butanoic acid, p-cresol, and indole, respectively, (iii) 14% of nitrous oxide (N2O), (iv) 100% of O3, and 26% generation of CO2. Under UV-C (185 + 254 nm) photocatalysis, the percent reductions of target gases were up to (i) 54% and 47% for p-cresol and indole, respectively, (ii) 25% of N2O, (iii) 71% of CH4, and 46% and 139% generation of CO2 and O3, respectively. The results proved that the UV technology was sufficiently effective in treating odorous gases, and the mobile lab was ready for farm-scale trials. The UV technology can be considered for the scaled-up treatment of emissions and air quality improvement inside livestock barns. Results from this study are needed to inform the experimental design for future on-farm research with UV-A and UV-C.

1. Introduction

Poor indoor air quality and gaseous emissions are undesirable side effects of livestock and poultry production. Gaseous emissions of odor, odorous volatile organic compounds (VOCs), ammonia (NH3), hydrogen sulfide (H2S), and greenhouse gases (GHGs) have detrimental effects on the quality of life in rural communities, the environment, and climate. Proven mitigation technologies are needed to increase the sustainability of animal agriculture. The farm-scale readiness and the effectiveness of technologies for mitigation of gaseous emissions from livestock agriculture are summarized by Maurer et al. [1]. The user-friendly description of technologies and the scientific literature database is provided by the Iowa State University Extension and Outreach website [2].

Photocatalysis with UV (ultraviolet) light has received considerable attention for special applications in indoor air quality. However, the research of UV photocatalysis in livestock agriculture applications is still limited. Costa et al. [3] and Guarino et al. [4] pioneered UV-A photocatalysis in swine weaning and farrowing units reporting mitigation of NH3, GHGs, particulate matter (PM), and increased feed conversion efficiency. However, the previous research’s technical design information, such as light dose and photocatalyst coating thickness required for application to actual farms, was not provided. Our team has been motivated by these early examples of farm-scale applications in Europe to conduct lab-to-farm-scale research to scale up and adapt UV photocatalysis to the swine farming systems prevailing in the American swine industry.

Several lessons were learned from the lab-scale to the pilot-scale progression of research. Zhu et al. [5] showed that a TiO2 based photocatalytic coating (PureTi, Cincinnati, OH, USA) is sufficient to effectively mitigate odorous VOCs. Research showing the reduction of NH3 and odorous VOCs with UV-C followed [6,7,8]. Recently, the application of UV-A photocatalysis for NH3, odorous VOCs, ozone, and nitrous oxide (N2O) was shown [9,10]. Testing UV-A photocatalysis (a safer bandwidth for direct human and animal exposure) showed a mitigation effect on a pilot-scale in the actual livestock farm environment [9,11].

Thus, earlier tests show practical percent reduction efficiencies for several targeted odorous air pollutants using marketed spray-on coatings for indoor building materials. Still, practical research questions must be addressed before the UV-A (or UV-C) technology can be adopted for farm-scale application to barn interiors to improve air quality inside livestock barns. Additionally, there is an interest in scaling up the UV treatment to mitigate emissions from the barn exhaust air. There is also an interest in UV-C applications to mitigate the risk of airborne pathogens from the ambient air, feed, supplies, personnel threatening farm biosecurity, and using UV to lower the pathogen load inside barns [12]. Thus, this research addresses the gap in knowledge to scale up UV-A and UV-C technology from proven performance mitigating two standard gases (NH3, butan-1-ol) at a mobile lab-scale to the treatment of a much more complex mixture of gases released from swine manure. Comprehensive assessment of the mitigation effects for a wide range of gases is needed for scaling up technologies treating gaseous emissions of odor, odorous VOCs, NH3, H2S, ozone, and GHGs. This research aimed to scale up TiO2-based photocatalysis treatment with UV-A and UV-C light to pilot-scale conditions. Specifically, the objective was to evaluate the percent reduction of gaseous emissions and investigate the required UV dose to mitigate the targeted odorous gases generated from swine manure, where the realistic mix of gases and aerosols was treated at fast-moving air and airflows consistent with those on production-scale farms. This study used a mobile UV laboratory designed and commissioned for testing with large (~1 m3/s) airflows [13]. This study data obtained under simulated swine conditions with fast-moving airflows, like a real swine farm, is considered helpful in evaluating UV photocatalysis performance. Results from this study are needed to inform the experimental design for future on-farm research with UV-A and UV-C. Box 1 provides definitions of key acronyms used in this paper.

Box 1. Definitions of key acronyms used in this paper.

CH4: methane

CO2: carbon dioxide

DMDS: dimethyl disulfide

DMTS: dimethyl trisulfide

ECD: electron capture detector

FID: flame ionization detector

GC-MS: gas chromatograph-mass spectrometer

GHGs: greenhouse gases

H2S: hydrogen sulfide

J: Joule (unit of energy)

LED: light-emitting diode

NIST: National Institute of Standards and Technology

NH3: ammonia

N2O: nitrous oxide

OUE: odor unit

O3: ozone

ppb: part per billion

ppm: part per million

SPME: solid-phase microextraction

TiO2: titanium dioxide

UV-A: ultraviolet light (315–400 nm range)

UV-C: ultraviolet light (100–280 nm range)

VOCs: volatile organic compounds

W: watt (unit of power)

2. Materials and Methods

2.1. Materials and Methods

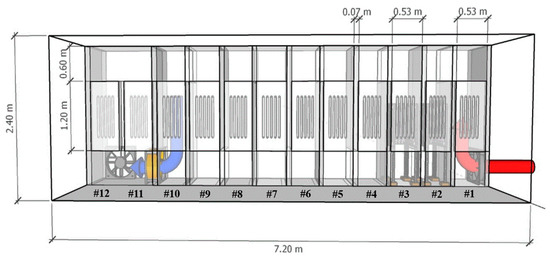

The mobile laboratory (7.2 × 2.4 × 2.4 m) designed and verified in the previous study [13] was used in this study. The mobile laboratory consisted of 12 chambers (7.2 × 0.9 × 2.4 m), and each chamber (0.53 × 0.9 × 2.4 m) was divided into vertical baffles. Chambers #11 and #12 were connected without a vertical baffle. Each chamber was equipped with 11 panels coated with TiO2 (nanostructured TiO2 anatase at 10 μg/cm2 from PureTi, Cincinnati, OH, USA) on all sides. Two fans (I-Fan Type 40, Fancom, Panningen, the Netherlands) were installed on the mobile laboratory to control the airflow inside. The air velocity was measured with the anemometer fan (ATM, Fancom, Panningen, the Netherlands) installed in chamber #10, and the internal airflow can be controlled in real-time using the fan monitoring system (Lumina 20/21, Fancom, Panningen, the Netherlands) by controlling the two fans and the anemometer fan.

2.2. Generation of Odorous Gas Emissions from Swine Manure

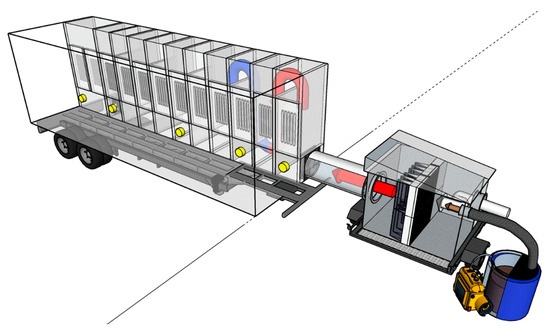

A plastic drum (55 gal, ~200 L) filled with 35–40 gal of swine manure was used to generate a realistic mixture of odorous gases and aerosols and investigate UV photocatalysis performance (Figure 1 and Figure A1). Compressed air was continuously supplied to the bottom of the manure (Figure S1), and the headspace gas was blended with ambient air. A filtration unit prevented the inflow of flies and dust into the UV mobile lab. Detailed information about the mobile laboratory and filter house has been reported in the previous study [13].

Figure 1.

Schematic of mobile laboratory for UV treatment of gaseous emissions. UV dose is controlled by either adjusting treatment time (by controlled airflow rate) or adjusting irradiation (by turning lamps on/off). Brown arrow: untreated gas from the manure drum (blue barrel); white arrow: ambient air for diluting the untreated gas; red arrow: inlet air to UV treatment with reduced particle matter load (due to the filtration unit; pictured on the right); blue arrow: UV-treated air. Yellow: gas sampling ports.

2.3. Tested UV Sources

In this study, the mitigation of target gases was investigated using four different light sources (UV-A: 367 nm and UV-C: 254, 222, 185 + 254 nm, Figure A2). Two different low-pressure mercury sources were used, both of which emit strongly at 254 nm, but one additionally contains a small 185 nm component because the bulb is made from special materials that allow transmission of that line. The emission spectrum of low-pressure mercury lamps is well known, and these sources both also contained small emissions at 365 nm and other wavelengths common to all of these bulbs. Nonetheless, we refer to these as 254 nm or (185 + 254) nm light sources. An excimer source emitting at 222 nm was the third source; these three sources constitute variations on wavelengths between 222 and 365 nm. The fourth source was an LED with emission centered at 367 nm, quite near the 365 nm range that mercury lamps commonly were used for, but without many of the disadvantages of a mercury-based lamp. This is considered within the UV-A region.

Each chamber inside the mobile laboratory was equipped with 5 UV-A LED lamps (T8 LED, Eildon Technology, Shenzhen, China). An additional 100 UV-A lamps (effectively adding 20 times the light intensity, Table S1) were installed on a removable rack in each of the two chambers (#2–#3) to investigate the reduction of targeted gases according to the UV dose (Figure 2). Detailed information on UV-A lamps used in this study was reported previously [13].

Figure 2.

Detailed schematic (side view) of UV treatment inside a flow-through mobile laboratory with UV lamps. The untreated airflow is irradiated while passing through a series of chambers (#1–#12) equipped with TiO2 photocatalytic surfaces and 5 UV-A lamps per chamber. The two chambers (#2 and #3) were equipped with additional 100 portable lamp holders to increase light intensity. Treated air moves in a serpentine pattern from the inlet (right, red) to the outlet (left, blue). UV dose is controlled by either adjusting treatment time (by controlled airflow rate) or adjusting irradiation (by turning lamps on/off).

All UV-C sources were tested inside chamber #2 while all the UV-A lights in other chambers were turned off. For UV-C (254 nm and 185 + 254 nm, American Ultraviolet Co, Lebanon, IN, USA), four lamps of each different wavelength were installed on the door in one chamber (#2). In the case of the 222 nm excimer UV-C (Ushio America Inc., Cypress, CA, USA), one lamp (Care222 Series) and power supply were installed on the door in chamber #2 (Figure A2). The effects of UV wavelength were measured locally in chamber #2 for all lamp types. The targeted gas concentrations in the untreated gas (control) were measured in the #1 chamber’s sampling port. The treated gas concentration after the UV treatment was measured in the #3 chamber’s sampling port (Figure 1 and Figure 2).

2.4. The Light Intensity of Different UV Wavelength Lamps

The light intensity is needed to estimate the UV irradiation (and therefore, the dose when integrated over time). The light intensity was measured by ILT-1700 radiometer (International Light Technologies, Peabody, MA, USA) with wavelength-specific sensors and filters. The UV-C 254 nm, 222 nm, 185 nm, and UV-A 365 nm was measured by the SED240 sensor (w/NS254 filter; 254 ± 5 nm); SED240 sensor (w/NS220 filter, 220 ± 5 nm); SED185 sensor (w/NS185 filter, 185 ± 5 nm); SED033 sensor (w/NS365 filter, 365 ± 5 nm), respectively. The 222 nm sensor only imperfectly excludes light from its intended window, and non-zero artifactual measurements were seen with the two Hg sources. All UV lamps were turned on for 5 min before each measurement or experimental run to ensure stable and consistent UV irradiation. For techno-economic analysis, the electric power consumption was measured using a wattage meter (P3, Lexington, NY, USA). The summary of measured light intensity inside the mobile lab under different UV wavelengths and doses is shown in Tables S1–S7.

2.5. Measurement of Odor

Gas samples for odor analyses were collected from the inlet and outlet gas sampling ports inside the UV mobile lab into 10 L Tedlar bags using a Vac-U-Chamber and sampling pump (both from SKC Inc., Eighty-Four, PA, USA). Tedlar bags were precleaned by flushing with clean air three times before use. Gas samples were analyzed for odor using a dynamic triangular forced-choice olfactometer (St. Croix Sensory Inc., Stillwater, MN, USA). Four trained panelists at two repetitions each were used to analyze each sample, presented from low to increasingly lower dilutions to the point of consistent odor detection.

2.6. Measurement of Odorous Volatile Organic Compounds

Odorous VOCs, such as sulfur-containing VOCs, volatile fatty acids (VFAs), and phenolic compounds, are significant contributors to livestock odor [14]. VOC analysis was conducted in the same way as described in detail in the previous study [15]. Briefly, VOC samples were collected in 1 L gas sampling glass bulbs. An internal standard (hexane) was used to minimize variability in sampling and sample preparation. A 2 cm DVB/Carboxen/PDMS solid-phase microextraction (SPME) fiber (Supelco, Bellefonte, PA, USA) was used to extract VOCs from the glass bulbs for 50 min, then analyzed with a GC-MS within 12 h of sample collection. The NIST mass spectral library (with at least 80% spectral match) was used to confirm the compounds’ identity. A set of 15 standards for targeted odorous VOC were used (acetic acid, propionic acid, isobutyric acid, butyric acid, isovaleric acid, valeric acid, hexanoic acid, dimethyl disulfide, diethyl disulfide, dimethyl trisulfide, guaiacol, phenol, p-cresol, 4-ethyl phenol, indole, and skatole) and calibrated to verify the GC retention time and MS spectral signal.

2.7. Measurement of Ozone Concentrations

Ozone is generated during UV-C irradiation of air, and thus, it was a targeted gas. On the other hand, the generated O3 can react and mitigate odorous VOCs. In this research, the O3 detector was connected to the monitoring system (Series 500 monitor, Aeroqual, New Zealand) and installed at the gas sampling ports when in use. The detector was factory-calibrated (Gas Sensing, Inwood, IA, USA) and certified before use. The detection range was 0–50 ppb.

2.8. Measurement of Greenhouse Gas Concentrations

UV treatment of odorous VOCs and NH3 can result in the generation of GHGs that should be tracked. Methane (CH4), carbon dioxide (CO2), and nitrous oxide (N2O) were measured. GHGs samples were collected using syringes and 5.9 mL Exetainer vials (Labco Limited, UK) and were analyzed for concentrations on a GC equipped with FID and ECD detectors (SRI Instruments, Torrance, CA, USA). Samples were analyzed on the day of collection. Standard calibrations were constructed daily using 10.3 and 20.5 ppm CH4, 1005 and 4010 ppm CO2, and 0.101 and 1.01 ppm N2O. Pure helium was used to calibrate the baseline of 0 ppm (Air Liquide America, Plumsteadville, PA, USA).

2.9. Measurement of Ammonia and Hydrogen Sulfide Concentrations

Ammonia (NH3) is a major contributor to air pollution from livestock operations. Hydrogen sulfide (H2S) is a toxic air pollutant and a significant contributor to odor. NH3 and H2S concentrations were measured with a real-time analyzer (OMS-300, Smart Control & Sensing, Daejeon, Korea) calibrated with high precision standard gases (5-point dilution, R2 = 0.99). The analyzer was equipped with NH3/CR-200 and H2S/C-50 electrochemical gas sensors (Membrapor, Wallisellen, Switzerland), NH3/CR-200 (0 to 100 ppm), and H2S/C-50 (0 to 50 ppm), respectively.

2.10. Evaluation of Treatment Effectiveness and Data Analysis

The overall mean percent reduction for each measured targeted gas was estimated using:

where CCon and CTreat are the mean measured concentrations in control and treated air, respectively. For odor and odorous VOCs, odor units (OUE∙m−3) and MS detector responses (peak area counts, PAC) were used.

% R = (Ccon − CTreat)/Ccon × 100

Emissions were calculated as a product of measured gas concentrations and the total airflow rate through the UV mobile lab, adjusted for standard conditions and dry air using collected environmental data. The overall mean emission of each measured gas was estimated as:

where C = the mean measured target gas concentration in control and treated air (mL/m3, OUE/m3). V = the treated airflow rate (m3/min). MW = the molecular weight of the targeted gas (g/mol). T = the temperature in the control and treated air. The 2.24 × 104 is an ideal gas conversion factor for L to moles at 273.15 K [13].

Emission (g·min−1) = C × V × (273.15 K × MW)/(273.15 K + T) × (2.24 × 104)

The electric energy consumption during UV treatment was estimated using the measured power consumption by lamps:

where EEC = electric energy consumption (kWh). P = measured electric power consumption for the UV lamps turned ‘on’ during treatment (W). ts = treatment time for air irradiated with the UV lamps that were turned ‘on’ inside the mobile lab (s).

EEC = P × ts/(3600 × 1000)

The mass of mitigated gas pollutant (M) with UV during given treatment time (ts) was estimated by comparing gas emission rate (E) in treatment and control:

where M = mass of mitigated gas pollutant (g). Econ = emission rate at the ‘control’ sampling location. Etreat = emission rate at the ‘treatment’ sampling location.

M = (Econ − Etreat) × ts/60

The electric energy of UV treatment (EE, kWh/g) was estimated as using electric energy consumption (EEC) needed to mitigate a gas pollutant mass (M):

EE = EEC/M

Finally, the estimated cost of electric energy (Cost) needed for UV treatment was estimated using the mean cost of rural energy in Iowa (USD 0.13/kWh):

where Cost = estimated cost of electric energy needed for UV treatment to mitigate a unit mass of pollutants in the air (USD/g).

Cost = EE × USD 0.13/kWh

UV dose was estimated using measured light intensity (I) at a specific UV wavelength (mW/cm2) and treatment time (ts). Since the photocatalysis reaction was assumed to be the primary mechanism for the target gas mitigation, the light intensity irradiated on the TiO2 surface was used. For lamps emitting light at multiple UV wavelengths, the UV dose was calculated using the light intensity of the primary wavelength suggested by the lamp manufacturer.

where UV Dose = energy of the UV light on the surface of photocatalyst (mJ/cm2).

UV dose = I × ts

2.11. Statistical Analysis

The overall mean percent reduction for each measured targeted gas was estimated using the following: R studio (version 3.6.2; Boston, MA, USA) was used to analyze the target standard gases’ mitigation under UV photocatalysis treatment. The UV dose and treatment time parameters between control concentration and treatment concentration were statistically analyzed using one-way ANOVA. The statistical difference was confirmed by obtaining the p-value through the Tukey test. A significant difference was defined for a p-value < 0.05 in this study.

3. Results

3.1. Mitigation of Targeted Gases as a Function of UV-A Dose Controlled by Light Intensity and Airflow Rate

3.1.1. Odor—Effects of UV-A Dose

The UV-A photocatalysis showed a significant percent odor reduction. The UV dose of 2.5 mJ/cm2 was required for statistically significant odor reduction (Table 1). As the UV dose was increased, the odor reduction increased up to 63%.

Table 1.

Mitigation of odor with the different UV-A doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance.

3.1.2. Volatile Organic Compounds—Effects of UV-A Dose

UV-A photocatalysis significantly mitigated selected targeted odorous VOCs while also generating a small subset of other VOCs. This is an important observation as the complex and compound-specific photocatalytic reactions can affect the overall percent reduction of odor. UV-A dose ≥ 2.5 mJ/cm2 was required to mitigate phenolic compounds (Table 2), similarly to the findings for odor where the same UV dose resulted in significant mitigation (Table 1). As the UV dose increased up to ~3.9 mJ/cm2, the percent reduction of VOCs and the number of mitigated (targeted) VOCs increased. The highest percent reductions were measured for acetic acid (49%), butanoic acid (53%), p-cresol (67%), and indole (32%). The highest dose (5.8 mJ/cm2) did not improve the mitigation effect, suggesting that there is merit to optimizing the UV dose, especially from the techno-economic standpoint.

Table 2.

Mitigation of odorous VOCs with the different doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance.

3.1.3. Ozone—Effects of UV-A Dose

Compared with a baseline (ambient air) amount of O3 detected without UV irradiation, the concentration of O3 was effectively mitigated (up to 100%) by UV-A irradiation (Table 3). This observation was consistent with our earlier UV-A research in lab-scale and pilot-scale (poultry farm) conditions [9,10]. Therefore, the treatment of the lowest UV dose (1.3 mJ·cm−2) is the most economical condition if O3 is the targeted gas. It is also important to mention that the mean O3 concentration in the UV mobile lab outlet was 4.7 ppb. This concentration is relatively low and likely of low concern for scaling up to farm environments, where abundant VOCs are present to react with O3 and further reduce the risk of its release to the atmosphere outside the barn.

Table 3.

Mitigation of O3 with the different UV doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance.

3.1.4. Greenhouse Gases—Effects of UV-A Dose

The N2O concentrations were significantly reduced (by 4–14%) with UV-A photocatalysis for 2.5 mJ/cm2 or higher doses (Table 4). However, there was no statistically significant change in CH4 concentrations (Table S8), and there was a significant generation of CO2 (up to −26%) (Table S9) that increased with the UV dose.

Table 4.

Mitigation of N2O with the different UV doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance.

3.1.5. Ammonia and Hydrogen Sulfide—Effects of UV-A Dose

Significant percent reduction of NH3 concentrations was measured only for the maximum UV-A dose (5.8 mJ/cm2; Table 5). The treatment efficiency was low (6%), similar to the previous reports [4,9,10,13]. The mean NH3 concentration in control was 5.4 ppm. No steady concentration of H2S was measured in control (likely due to the limited supply of it in manure). The H2S was typically detectable at the start of the experiment, but its concentration in control was rapidly diminishing, preventing reproducible measurements after UV-A treatment. This limitation will be addressed in farm-scale trials, where H2S in barn air or barn exhaust is continuously present, the mitigation of H2S can be objectively tested.

Table 5.

Mitigation of NH3 with the different UV doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance.

3.2. Comparison of the Mitigation of Targeted Gases as a Function of UV Wavelength

The comparison of UV-A and UV-C photocatalysis treatment was conducted in only one chamber (#2) due to the limited number of available UV-C lamps that are more costly than UV-A. The results are summarized below. Testing conditions were the same for all lamps to enable a fair side-by-side comparison.

3.2.1. Odor—Effects of UV Wavelength

The short UV-C wavelength (185 + 254 nm) resulted in a 44% reduction of overall detected odor. This was a remarkable mitigation effect, considering that the UV dose was the lowest among all tested (Table 6). However, odor reduction was not significant for all treatments (0.09 < p-value < 0.94). This was likely due to the variability of control used for just one treatment chamber tested (Table 6). Odor measurements via dilution olfactometry and human panelists are inherently more variable than chemical analyses. This limitation could be addressed by refurbishing the entire UV mobile laboratory with one type of lamp, effectively allowing a more extensive range of doses to be tested (e.g., lower variability reported for UV treatment using an entire mobile lab with 12 chambers facilitating treatment, Table 1).

Table 6.

Mitigation of odor with different UV wavelengths irradiating gaseous emissions inside the #2 chamber.

3.2.2. Volatile Organic Compounds—Effects of UV Wavelength

The phenolic compounds of p-cresol and indole were effectively treated with UV-C (185 + 254 nm) with a statistically significant percent reduction at 47 and 54%, respectively (Table 7). p-Cresol and indole are often referred to as the ‘signature’ barnyard odors and potent odorants; thus, their mitigation is consistent with the results for overall odor reduction (Table 6). The UV-C (185 + 254 nm) dose was the lowest tested, yet the percent reductions for other targeted VOCs were notable and ranged from 10 to 59%. The 185 + 254 nm light source is essentially identical to the 254 nm light source, save that the ‘glass’ of the lamp itself additionally transmits a small amount of very high energy 185 nm photons. The additional 185 nm irradiation (when part of 185 + 254 nm treatment) results in effective reduction of targeted VOCs. The UV-C (254 and 222 nm) sources also effectively mitigated much targeted VOCs (from 15 to 70%), although there is no significant statistical mitigation. The use of longer-wavelength UV-A (367 nm) and the highest dose resulted in a statistically significant reduction for acetic acid (57%) and butanoic acid (33%).

Table 7.

Mitigation of odorous VOCs with different UV wavelength irradiating gaseous emissions inside the #2 chamber. Bold signifies statistical significance.

3.2.3. Ozone—Effects of UV Wavelength

O3 was reduced at all wavelengths except for 185 + 254 nm. Specifically, complete mitigation (below detection limits) was measured for 222 and 254 nm treatments. The percent reduction increased from 30 to 97% as the UV dose increased for the 367 nm wavelength. O3 increased by ~140% (Table 8) for the 185 + 254 nm treatment. This is due to the direct photolysis of O2 in the air, which leads to O3 formation.

Table 8.

Mitigation of O3 concentration with different UV wavelength irradiating gaseous emissions inside the #2 chamber. Bold signifies statistical significance.

3.2.4. Greenhouse Gases—Effects of UV Wavelength

Significant mitigation was measured for CH4, with the (185 + 254) nm lamps. However, other wavelength lamps did not show statistically significant reduction (Table 9). CO2 concentrations increased for all UV wavelengths tested (Table S10) and were statistically significant for 185 + 254 nm and 367 nm (high UV dose). N2O was mitigated at statistically significant levels (from 8 to 25%) for all treatments except for the low 367 nm dose (Table 10). The highest percent reduction for CH4 and N2O resulted from the 185 + 254 nm treatment.

Table 9.

Mitigation of CH4 concentration with different UV wavelength irradiating gaseous emissions inside the #2 chamber. Bold signifies statistical significance.

Table 10.

Mitigation of N2O concentration with different UV wavelength irradiating gaseous emissions inside the #2 chamber. Bold signifies statistical significance.

3.2.5. Ammonia and Hydrogen Sulfide—Effects of UV Wavelength

There was no statistically significant reduction for all UV wavelengths tested, and the percent reduction ranged from 0.3 to 2.1% (Table 11). The average concentration of the control group was 3.1 ppm (Table 11). H2S concentrations in control were not stable enough to warrant reporting the effect.

Table 11.

Mitigation of NH3 concentration with different UV wavelength irradiating gaseous emissions inside the #2 chamber.

4. Discussion

4.1. Summary of the UV-A Photocatalysis—Comparison with Previous Research

UV photocatalysis can be considered a potential technology to reduce odorous gases and improve air quality. This research provides mitigation data for a more extensive set of odorants and air pollutants compared with the state-of-the-art. UV-A photocatalysis reduced several of the targeted odorous gases (Table 12) with statistical significance. The reproducibility of mitigation with UV-A photocatalysis warrants further scaling up into larger volumetric flowrates common for farm applications.

Table 12.

Summary and comparison of the % reduction of targeted gases with UV-A photocatalysis. Bold signifies statistical significance.

This research provided data that can be considered for early assessment and extrapolating the techno-economic analysis of the UV-A treatment to practical scales (Table 13).

Table 13.

Techno-economic analysis of mitigating target gases with UV-A photocatalysis.

Caution needs to be exercised when extrapolating pilot-scale data. However, several major recommendations can be made. The UV-A treatment does not appear to be effective for farm-scale mitigation of NH3, considering that the mitigation effect was rather small (Table 5 and Table 11). Thus, effective reduction of kg/day quantities of NH3 from typical swine farms with UV-A appears to be too costly.

On the other hand, mitigation of several targeted air pollutants is worth considering. For example, mitigation of N2O (the most potent GHG, Table 4 and Table 10) might be further exploited for farm income generation that uses subsidies and programs focused on reducing GHGs emissions and mitigating climate change. Direct emissions of O3 from farms have not been a concern, as opposed to the secondary pollutant generation of O3 as a by-product of emitted VOCs and their atmospheric chemistry. Thus, the incentivization and credit taking for the at-source mitigation of O3 might be considered (Table 3 and Table 8). Finally, the significant reduction of odor and odorous VOCs is encouraging at this scale (Table 1, Table 2, Table 6 and Table 7). Of course, planned farm-scale trials can provide a more realistic techno-economic assessment of UV-A cost. Farm-scale trials with the UV-A photocatalysis installed inside barns to mitigate indoor air quality and the pathogen load are warranted.

4.2. Summary of the UV-C Photocatalysis

The effects of UV wavelength were only tested in one chamber inside the UV mobile lab due to increasing UV-C dose limitation. Thus, the comparison is somewhat limited (Table 14). Therefore, the results show the UV-C’s future potential that still needs to be tested on a larger scale. The UV-C can efficiently reduce odorous VOCs with a lower dose (compared to UV-A). One caveat to UV-C use is risks associated with direct skin and eye tissue exposure and O3 generation.

Table 14.

Summary of the % reduction of targeted gases with UV-C photocatalysis. Bold signifies statistical significance.

4.3. Evaluation of UV Photocatalysis Based on TiO2 in the Livestock Environment

We summarized the percent mitigation of targeted gases in the previous studies and this mobile lab research series to show the UV photocatalysis performance (Lee et al., 2021; Table 14) [16]. The mitigation of selected target gases via photocatalysis with UV-A and UV-C in livestock-relevant environmental conditions can be considered as an effective method to mitigate the odorous gases.

The TiO2 based photocatalysis with UV-A yields significant reductions of NH3 (~31%), H2S (~40%), CH4 (~27%), N2O (~14%), O3 (~100%), Odorous VOCs (~100%), and odor (~63%) [16]. In the case of CO2, generation has been reported after UV-A photocatalysis in previous studies. CO2 is the oxidative endpoint for photocatalytic oxidation of virtually all carbon-containing compounds, and thus its mitigation would not derive from its chemical removal. The percent reduction for the targeted gas showed a difference depending on the coating thickness and UV dose.

The UV-C photocatalyst showed a higher mitigation effect at a lower dose than UV-A photocatalysis. In particular, it showed a significant reduction in H2S (~100%), CH4 (~40%) and VOCs (~100%) even after irradiation for a relatively short time (1 s) [6,17,18]. Additionally, it is encouraging that it can effectively reduce H2S, which is harmful to farms, among the compounds generated in swine barns. In previous research results, it was reported that UV photocatalysis showed high efficiency compared to other mitigation technologies in economic analysis (estimated average electricity cost of UV treatment per pig was USD 0.15–0.23) [6,18].

5. Conclusions

This study evaluated the photocatalytic UV-A and UV-C treatment of gaseous emissions of odor, odorous VOCs, NH3, and other gases (GHGs, O3) from stored swine manure on a pilot-scale. To our knowledge, this is the first study of this scope that was needed for scaling up technologies treating gaseous emissions of odor, odorous VOCs, NH3, H2S, ozone, and GHGs. The study bridged the knowledge gap between lab-scales and simplified treatment of model gases to the treatment of complex gaseous mixtures emitted from swine manure in fast-moving air. The results showed that the proposed UV technology is ready for the next stage of testing and mitigation of emissions from swine farms. The treatment effectiveness depended on the UV dose and wavelength. Specific findings are summarized below.

Under UV-A (367 nm) photocatalysis, the percent reduction of targeted gases was up to:

- 63% of odor,

- 51%, 51%, 53%, 67%, and 32% of acetic acid, propanoic acid, butanoic acid, p-cresol, and indole, respectively,

- 14% of nitrous oxide (N2O),

- 100% of O3, 6% of NH3, and

- 26% generation of CO2.

Under UV-C (185 + 254 nm) photocatalysis, the percent reduction of target gases was up to:

- 54% and 47% for p-cresol and indole, respectively,

- 25% of N2O,

- 71% of CH4, and

- 46% and 139% generation of CO2 and O3, respectively.

UV-C (222 nm) photocatalysis showed a reduction of 8% for N2O, 100% for O3. Lastly, UV-C (254 nm) photocatalysis showed a reduction of 14% for N2O, 100% for O3. The UV-A photocatalysis (367 nm) was not economical to reduce NH3; while it appeared to be economical and effective in mitigating odor and VOC. The 2.5 mJ/cm2 dose is required to significantly reduce odor. UV-C photocatalysis (185 + 254 nm) was shown to be more efficient than UV-A photocatalysis by significantly reducing several target gases with a low dose, but additional research is needed because there was a limit to the dose control of UV-C in this study. The results proved that the UV technology was sufficiently effective in treating odorous gases in a simulated swine emissions environment, and the mobile lab was ready for farm-scale trials. The UV technology can be considered for the scaled-up treatment of emissions and air quality improvement inside livestock barns.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/ani11051289/s1, Figure S1: Generation of gaseous emissions from swine manure. Compressed air is fed into the bottom of the swine manure storage vessel. Gaseous emissions from the vessel’s headspace are then blended with clean air, Table S1: Measurement of UV-A light intensity according to the number of lamps in the chamber of the mobile laboratory, Table S2: The measured light intensity (µW/cm2) with 254 nm lamp irradiation in chamber #2, Table S3: The measured light intensity (µW/cm2) of photolysis with UV-C excimer (222 nm) irradiation in chamber #2, Table S4: The measured light intensity (µW/cm2) with UV-C fluorescent (185+254 nm) irradiation in chamber #2, Table S5: UV-C fluorescent (254 nm) light intensity (µW/cm2) at 11 panels in #2 chamber (Top, Bottom, Front Top, Front Bottom, Left Top, Left Bottom, Right Top, Right Bottom, Back Top, Back Middle, and Back Bottom), Table S6: UV-C excimer (222 nm) light intensity (µW/cm2) at 11 panels in #2 chamber (Top, Bottom, Front Top, Front Bottom, Left Top, Left Bottom, Right Top, Right Bottom, Back Top, Back Middle, and Back Bottom), Table S7: UV-C fluorescent (185 + 254 nm) light intensity (µW/cm2) at 11 panels in #2 chamber (Top, Bottom, Front Top, Front Bottom, Left Top, Left Bottom, Right Top, Right Bottom, Back Top, Back Middle, and Back Bottom), Table S8: Mitigation of CH4 with the different UV doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure, Table S9: Mitigation of CO2 with the different UV doses (1.3, 2.0, 2.5, 3.9, and 5.8 mJ/cm2) irradiating gaseous emissions from swine manure. Bold signifies statistical significance, Table S10: Mitigation of CO2 concentration with different UV wavelength irradiating gaseous emissions inside the #2 chamber. Bold signifies statistical significance.

Author Contributions

Conceptualization, J.A.K., W.S.J.; methodology, J.A.K.; validation, M.L., W.M., and J.A.K.; formal analysis, M.L.; investigation, M.L., W.M., B.C., P.L. and C.B.; resources, M.L., W.M., B.C., P.L., C.B. and J.A.K.; data curation, M.L., W.M. and J.A.K.; writing—original draft preparation, M.L.; writing—review and editing, M.L., J.A.K. and W.S.J.; visualization, M.L.; supervision, J.A.K.; project administration, J.A.K., W.S.J.; funding acquisition, J.A.K., W.S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Iowa Pork Producers Association Project #18-089 “Employing environmental mitigation technology and/or practices: Treating swine odor and improving air quality with black light.” In addition, this research was partially supported by the Iowa Agriculture and Home Economics Experiment Station, Ames, Iowa. Project no. IOW05556 (Future Challenges in Animal Production Systems: Seeking Solutions through Focused Facilitation) sponsored by Hatch Act and State of Iowa funds.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Materials; further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge Woosang Lee (Smart Control & Sensing Inc.) for his help with the NH3 and H2S monitoring system.

Conflicts of Interest

The author does not declare a conflict of interest. The funders did not play any role in the study design, data collection, analysis, interpretation, and decision to write a manuscript or present results.

Appendix A

Figure A1.

Picture of UV mobile laboratory (back) and filter house mounted on a trailer (front) with manure drum and gaseous emission generation system.

Figure A2.

Picture of UV-C lamps installed inside Chamber #2. Caution—colors should be interpreted as actual UV output.

References

- Maurer, D.L.; Koziel, J.A.; Harmon, J.D.; Hoff, S.J.; Rieck-Hinz, A.M.; Andersen, D.S. Summary of performance data for technologies to control gaseous, odor, and particulate emissions from livestock operations: Air management practices assessment tool (AMPAT). Data Brief 2016, 7, 1413–1429. [Google Scholar] [CrossRef] [PubMed]

- Air Management Practices Assessment Tool. Available online: https://www.extension.iastate.edu/ampat/animal-housing (accessed on 24 February 2021).

- Costa, A.; Chiarello, G.L.; Selli, E.; Guarino, M. Effects of TiO2 based photocatalytic paint on concentrations and emissions of pollutants and on animal performance in a swine weaning unit. J. Environ. Manag. 2012, 96, 86–90. [Google Scholar] [CrossRef] [PubMed]

- Guarino, M.; Costa, A.; Porro, M. Photocatalytic TiO2 coating—To reduce ammonia and greenhouse gases concentration and emission from animal husbandries. Bioresour. Technol. 2008, 99, 2650–2658. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Koziel, J.A.; Maurer, D.L. Mitigation of livestock odors using black light and a new titanium dioxide-based catalyst: Proof-of-concept. Atmosphere 2017, 8, 103. [Google Scholar] [CrossRef]

- Koziel, J.A.; Yang, X.; Cutler, T.; Zhang, S.; Zimmerman, J.J.; Hoff, S.J.; Jenks, W.S.; Laor, Y.; Ravid, U.; Armon, R. Mitigation of odor and pathogens from CAFOs with UV/TiO2: Exploring the cost effectiveness. In Proceedings of the Mitigating Air Emissions from Animal Feeding Operations Conference, Des Moines, IA, USA, 19–21 May 2008; pp. 169–173. [Google Scholar]

- Rockafellow, E.M.; Koziel, J.A.; Jenks, W.S. Laboratory-Scale Investigation of UV Treatment of Ammonia for Livestock and Poultry Barn Exhaust Applications. J. Environ. Qual. 2012, 41, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Koziel, J.A.; Laor, Y.; Zhu, W.; van Leeuwen, J.H.; Jenks, W.S.; Hoff, S.J.; Zimmerman, J.; Zhang, S.; Ravid, U. VOC Removal from Manure Gaseous Emissions with UV Photolysis and UV-TiO2 Photocatalysis. Catalysts 2020, 10, 607. [Google Scholar] [CrossRef]

- Lee, M.; Li, P.; Koziel, J.A.; Ahn, H.; Wi, J.; Chen, B.; Meiirkhanuly, Z.; Banik, C.; Jenks, W.S. Pilot-scale testing of UV-A light treatment for mitigation of NH3, H2S, GHGs, VOCs, odor, and O3 inside the poultry barn. Front. Chem. 2020, 8, 613. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Wi, J.; Koziel, J.A.; Ahn, H.; Li, P.; Chen, B.; Meiirkhanuly, Z.; Banik, C.; Jenks, W. Effects of UV-A Light Treatment on Ammonia, Hydrogen Sulfide, Greenhouse Gases, and Ozone in Simulated Poultry Barn Conditions. Atmosphere 2020, 11, 283. [Google Scholar] [CrossRef]

- Maurer, D.L.; Koziel, J.A. On-farm pilot-scale testing of black ultraviolet light and photocatalytic coating for mitigation of odor, odorous VOCs, and greenhouse gases. Chemosphere 2019, 221, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Koziel, J.A.; Zimmerman, J.J.; Zhang, J.; Cheng, T.Y.; Yim-Im, W.; Hoff, S.J. Mitigation of Airborne PRRSV Transmission with UV Light Treatment: Proof-of-Concept. Agriculture 2021, 11, 259. [Google Scholar] [CrossRef]

- Lee, M.; Koziel, J.A.; Murphy, W.; Jenks, W.S.; Fonken, B.; Storjohann, R.; Chen, B.; Li, P.; Banik, C.; Wahe, L. Design and testing of mobile laboratory for mitigation of gaseous emissions from livestock agriculture with photocatalysis. Int. J. Environ. Res. Public Health 2021, 18, 1523. [Google Scholar] [CrossRef] [PubMed]

- Lo, Y.C.M.; Koziel, J.A.; Cai, L.; Hoff, S.J.; Jenks, W.S.; Xin, H. Simultaneous Chemical and Sensory Characterization of Volatile Organic Compounds and Semi-Volatile Organic Compounds Emitted from Swine Manure using Solid Phase Microextraction and Multidimensional Gas Chromatography–Mass Spectrometry–Olfactometry. J. Environ. Qual. 2008, 37, 521–534. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Koziel, J.A.; Banik, C.; Ma, H.; Lee, M.; Wi, J.; Meiirkhanuly, Z.; Andersen, D.S.; Białowiec, A.; Parker, D.B. Emissions from swine manure treated with current products for mitigation of odors and reduction of NH3, H2S, VOC, and GHG emissions. Data 2020, 5, 54. [Google Scholar] [CrossRef]

- Lee, M.; Koziel, J.A.; Murphy, W.; Jenks, W.S.; Chen, B.; Li, P.; Banik, C. Mitigation of Odor and Gaseous Emissions from Swine Barn with UV-A and UV-C Photocatalysis. Preprints 2021, 2021030629. [Google Scholar] [CrossRef]

- Yao, H.; Feilberg, A. Characterisation of photocatalytic degradation of odorous compounds associated with livestock facilities by means of PTR-MS. Chem. Eng. J. 2015, 277, 341–351. [Google Scholar] [CrossRef]

- Liu, Z.; Murphy, P.; Maghirang, R.; DeRouchey, J. Mitigation of air emissions from swine buildings through the photocatalytic technology using UV/TiO2. In Proceedings of the 2015 ASABE Annual International Meeting, New Orleans, LA, USA, 26–29 July 2015. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).