The Use of the Dynamics of Changes in Table Eggs during Storage to Predict the Age of Eggs Based on Selected Quality Traits

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Eggs

2.2. Egg Quality Analyses

- egg shape index (EI, as a ratio of its width and length, using electronic caliper),

- air cell depth (ACD, by candling, according to scale),

- egg weight (EW, using laboratory balance with 0.01 g accuracy),

- egg specific gravity (SG, based on egg weight measurement in the air and in the water, according to Archimedes principle),

- proportions of particular egg elements (as the ratio of their weight to the weight of whole egg).

- color (SC, as a percentage of reflected light),

- weight (SW, using laboratory balance with 0.01 g accuracy),

- thickness (ST, by micrometer screw, at the “equator”),

- density (SD, calculated based on shell area and volume, according to Shafey [18].

2.3. Statistical Analyses

- —estimated value of egg trait

- —intercept

- —coefficient of the polynomial term

- —estimated value of egg trait

- —intercept

- β1–β6—coefficient of the polynomial term

3. Results

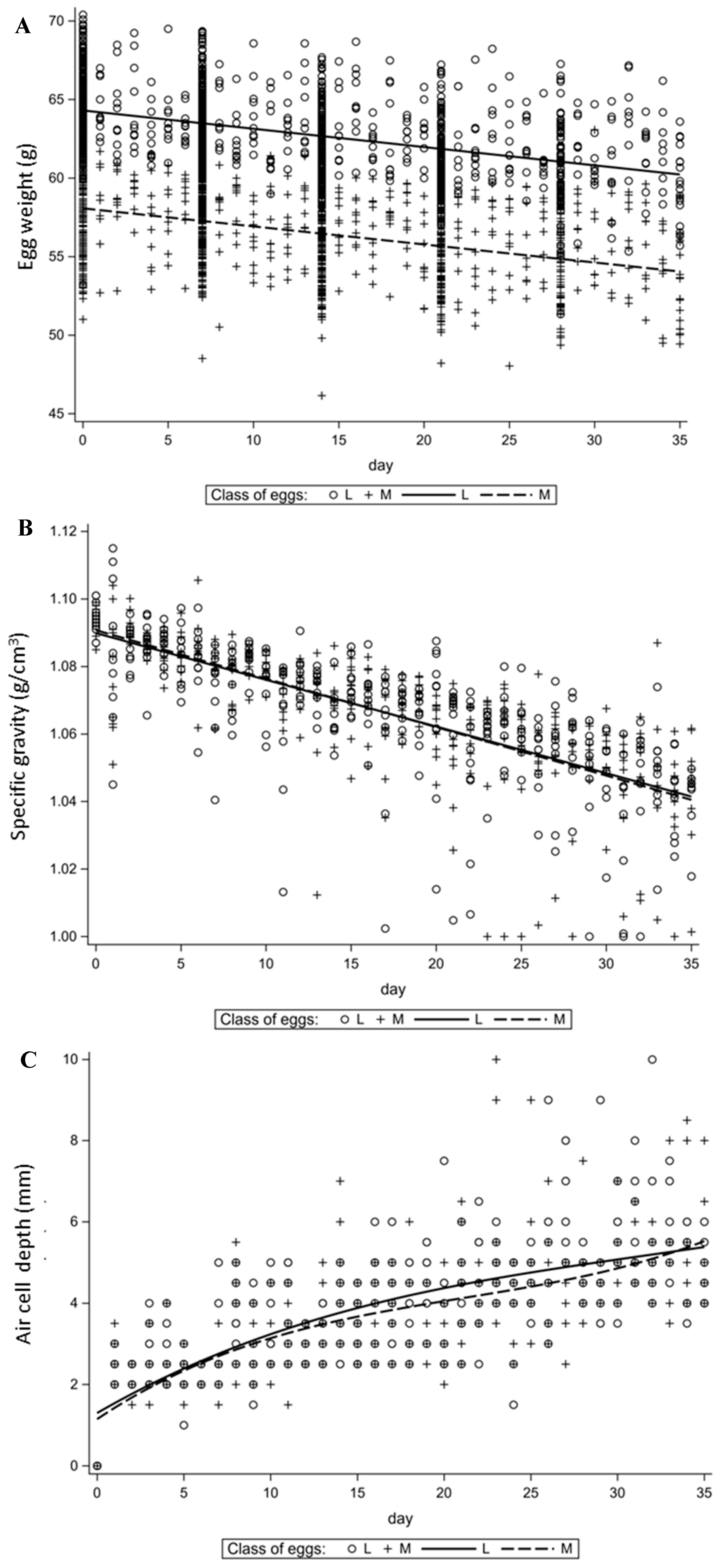

3.1. Dynamics of Egg Quality Changes during Storage

3.2. Prediction of Egg Age based on the Dynamics of Changes in Egg Quality

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Commission Regulation (EC), No. 589/2008 of 23 June 2008 Laying down Detailed Rules for Implementing Council Regulation (EC) No. 1234/2007 as Regards Marketing Standards for Eggs. Off. J. Eur. Union 2008, 163, 6–23.

- Jones, D.R.; Ward, G.E.; Regmi, P.; Karcher, D.M. Impact of Egg Handling and Conditions during Extended Storage on Egg Quality. Poult. Sci. 2018, 97, 716–723. [Google Scholar] [CrossRef] [PubMed]

- Samli, H.E.; Agma, A.; Senkoylu, N. Effects of Storage Time and Temperature on Egg Quality in Old Laying Hens. J. Appl. Poult. Res. 2005, 14, 548–553. [Google Scholar] [CrossRef]

- Drabik, K.; Chabroszewska, P.; Vasiukov, K.; Adamczuk, A.; Batkowska, J. Glycerin as a Factor for Moderating Quality Changes in Table Eggs during Storage. Arch. Anim. Breed. 2018, 61, 285–292. [Google Scholar] [CrossRef]

- Scott, T.A.; Silversides, F.G. The Effect of Storage and Strain of Hen on Egg Quality1. Poult. Sci. 2000, 79, 1725–1729. [Google Scholar] [CrossRef]

- Vlčková, J.; Tůmová, E.; Míková, K.; Englmaierová, M.; Okrouhlá, M.; Chodová, D. Changes in the Quality of Eggs during Storage Depending on the Housing System and the Age of Hens. Poult. Sci. 2019, 98, 6187–6193. [Google Scholar] [CrossRef]

- Menezes, P.C.; Lima, E.R.; Medeiros, J.P.; Oliveira, W.N.; Evêncio-Neto, J. Egg Quality of Laying Hens in Different Conditions of Storage, Ages and Housing Densities. Rev. Bras. Zootec. 2012, 41, 2064–2069. [Google Scholar] [CrossRef] [Green Version]

- Jin, Y.H.; Lee, K.T.; Lee, W.I.; Han, Y.K. Effects of Storage Temperature and Time on the Quality of Eggs from Laying Hens at Peak Production. Asian-Australas. J. Anim. Sci. 2011, 24, 279–284. [Google Scholar] [CrossRef]

- Brodacki, A.; Batkowska, J.; Drabik, K.; Chabroszewska, P.; Łuczkiewicz, P. Selected Quality Traits of Table Eggs Depending on Storage Time and Temperature. Br. Food J. 2019, 121, 2016–2026. [Google Scholar] [CrossRef]

- Jones, D.R.; Musgrove, M.T. Effects of Extended Storage on Egg Quality Factors. Poult. Sci. 2005, 84, 1774–1777. [Google Scholar] [CrossRef]

- Jia, F.; Yan, W.; Yuan, X.; Dai, R.; Li, X. Modified Atmosphere Packaging of Eggs: Effects on the Functional Properties of Albumen. Food Packag. Shelf Life 2019, 22, 100377. [Google Scholar] [CrossRef]

- Rocculi, P.; Cocci, E.; Sirri, F.; Cevoli, C.; Romani, S.; Rosa, M.D. Modified Atmosphere Packaging of Hen Table Eggs: Effects on Functional Properties of Albumen. Poult. Sci. 2011, 90, 1791–1798. [Google Scholar] [CrossRef] [PubMed]

- Drabik, K.; Batkowska, J.; Próchniak, T.; Horecka, B. Citric Acid as a Factor Limiting Changes in the Quality of Table Eggs during Their Storage. Poult. Sci. 2021, 100, 100995. [Google Scholar] [CrossRef] [PubMed]

- Yüceer, M.; Caner, C. The Effects of Ozone, Ultrasound and Coating with Shellac and Lysozyme–Chitosan on Fresh Egg during Storage at Ambient Temperature – Part 1: Interior Quality Changes. Int. J. Food Sci. Technol. 2020, 55, 259–266. [Google Scholar] [CrossRef]

- Pires, P.G.S.; Machado, G.S.; Franceschi, C.H.; Kindlein, L.; Andretta, I. Rice Protein Coating in Extending the Shelf-Life of Conventional Eggs. Poult. Sci. 2019, 98, 1918–1924. [Google Scholar] [CrossRef]

- Jones, D.R.; Karcher, D.M.; Abdo, Z. Effect of a Commercial Housing System on Egg Quality during Extended Storage1. Poult. Sci. 2014, 93, 1282–1288. [Google Scholar] [CrossRef]

- Marzec, A.; Damaziak, K.; Kowalska, H.; Riedel, J.; Michalczuk, M.; Koczywąs, E.; Cisneros, F.; Lenart, A.; Niemiec, J. Effect of Hens Age and Storage Time on Functional and Physiochemical Properties of Eggs. J. Appl. Poult. Res. 2019, 28, 290–300. [Google Scholar] [CrossRef]

- Shafey, T.M. Effects of Egg Size and Eggshell Conductance on Hatchability Traits of Meat and Layer Breeder Flocks. Asian-Australas. J. Anim. Sci. 2002, 15, 1–6. [Google Scholar] [CrossRef]

- Williams, K.C. Some Factors Affecting Albumen Quality with Particular Reference to Haugh Unit Score. World’s Poult. Sci. J. 1992, 48, 5–16. [Google Scholar] [CrossRef]

- Huang, Q.; Qiu, N.; Ma, M.H.; Jin, Y.G.; Yang, H.; Geng, F.; Sun, S.H. Estimation of Egg Freshness Using S-Ovalbumin as an Indicator. Poult. Sci. 2012, 91, 739–743. [Google Scholar] [CrossRef]

- Abdel-Nour, N.; Ngadi, M.; Prasher, S.; Karimi, Y. Prediction of Egg Freshness and Albumen Quality Using Visible/Near Infrared Spectroscopy. Food Bioprocess Technol. 2011, 4, 731–736. [Google Scholar] [CrossRef]

- Dong, X.; Dong, J.; Peng, Y.; Tang, X. Comparative Study of Albumen PH and Whole Egg PH for the Evaluation of Egg Freshness. Spectrosc. Lett. 2017, 50, 463–469. [Google Scholar] [CrossRef]

- Ragni, L.; Gradari, P.; Berardinelli, A.; Giunchi, A.; Guarnieri, A. Predicting Quality Parameters of Shell Eggs Using a Simple Technique Based on the Dielectric Properties. Biosyst. Eng. 2006, 94, 255–262. [Google Scholar] [CrossRef]

- Soltani, M.; Omid, M.; Alimardani, R. Egg Quality Prediction Using Dielectric and Visual Properties Based on Artificial Neural Network. Food Anal. Methods 2015, 8, 710–717. [Google Scholar] [CrossRef]

- Li, J.; Zhu, S.; Jiang, S.; Wang, J. Prediction of Egg Storage Time and Yolk Index Based on Electronic Nose Combined with Chemometric Methods. LWT-Food Sci. Technol. 2017, 82, 369–376. [Google Scholar] [CrossRef]

- Tan, W.; Zhang, Q.; Yang, L.; Tian, L.; Jia, J.; Lu, M.; Liu, X.; Duan, X. Actual Time Determination of Egg Freshness: A Centroid Rate Based Approach. Food Packag. Shelf Life 2020, 26, 100574. [Google Scholar] [CrossRef]

- Batkowska, J.; Brodacki, A.; Knaga, S. Quality of Laying Hen Eggs During Storage Depending on Egg Weight and Type of Cage System (Conventional vs. Furnished Cages). Ann. Anim. Sci. 2014, 14, 707–719. [Google Scholar] [CrossRef] [Green Version]

- Rondoni, A.; Asioli, D.; Millan, E. Consumer Behaviour, Perceptions, and Preferences towards Eggs: A Review of the Literature and Discussion of Industry Implications. Trends Food Sci. Technol. 2020, 106, 391–401. [Google Scholar] [CrossRef]

- Kralik, Z.; Kralik, G.; Grčević, M.; Galović, D. Effect of Storage Period on the Quality of Table Eggs. AAK 2014, 18, 200–206. [Google Scholar]

- Dennis, J.E.; Xiao, S.-Q.; Agarwal, M.; Fink, D.J.; Heuer, A.H.; Caplan, A.I. Microstructure of Matrix and Mineral Components of Eggshells from White Leghorn Chickens (Gallus Gallus). J. Morphol. 1996, 228, 287–306. [Google Scholar] [CrossRef]

- Feddern, V.; Prá, M.C.; Mores, R.; Nicoloso, R.D.; Coldebella, A.; Abreu, P.G. Egg Quality Assessment at Different Storage Conditions, Seasons and Laying Hen Strains. Ciência E Agrotecnologia 2017, 41, 322–333. [Google Scholar] [CrossRef] [Green Version]

- Wellman-Labadie, O.; Picman, J.; Hincke, M.T. Antimicrobial Activity of the Anseriform Outer Eggshell and Cuticle. Comp. Biochem. Physiol. Part B Biochem. Mol. Biol. 2008, 149, 640–649. [Google Scholar] [CrossRef]

- Rodríguez-Navarro, A.B.; Domínguez-Gasca, N.; Muñoz, A.; Ortega-Huertas, M. Change in the Chicken Eggshell Cuticle with Hen Age and Egg Freshness. Poult. Sci. 2013, 92, 3026–3035. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-C.; Chen, T.-H.; Wu, Y.-C.; Lee, Y.-C.; Tan, F.-J. Effects of Egg Washing and Storage Temperature on the Quality of Eggshell Cuticle and Eggs. Food Chem. 2016, 211, 687–693. [Google Scholar] [CrossRef] [PubMed]

- Aygun, A.; Sert, D. Effects of Vacuum Packing on Eggshell Microbial Activity and Egg Quality in Table Eggs under Different Storage Temperatures. J. Sci. Food Agric. 2013, 93, 1626–1632. [Google Scholar] [CrossRef] [PubMed]

- Heath, J.L. Chemical and Related Osmotic Changes in Egg Albumen During Storage1. Poult. Sci. 1977, 56, 822–828. [Google Scholar] [CrossRef]

- Liu, M.; Yu, W.; Ren, F.; Wu, J. Formation and Characterization of Peptides in Egg White during Storage at Ambient Temperature. Food Chem. 2018, 263, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Cotterill, O.J.; Winter, A.R. Egg White Lysozyme: 3. The Effect of PH on the Lysozyme-Ovomucin Interaction. Poult. Sci. 1955, 34, 679–686. [Google Scholar] [CrossRef]

- Monira, K.N.; Salahuddin, M.; Miah, G. Effect of Breed and Holding Period on Egg Quality Characteristics of Chicken. Int. J. Poult. Sci. 2003, 2, 261–263. [Google Scholar]

- Eke, M.O.; Olaitan, N.I.; Ochefu, J.H. Effect of Storage Conditions on the Quality Attributes of Shell (Table) Eggs. Niger. Food J. 2013, 31, 18–24. [Google Scholar] [CrossRef] [Green Version]

| Class | M | L | ||

|---|---|---|---|---|

| Trait | ρ | p-Value | ρ | p-Value |

| EW | −0.20287 | 0.0001 | −0.20407 | 0.0001 |

| SG | −0.82275 | <0.0001 | −0.79993 | <0.0001 |

| ACD | 0.76409 | <0.0001 | 0.75573 | <0.0001 |

| HU | −0.62356 | <0.0001 | −0.69372 | <0.0001 |

| AW | −0.35078 | <0.0001 | −0.32698 | <0.0001 |

| ApH | 0.73197 | <0.0001 | 0.77513 | <0.0001 |

| YI | −0.59984 | <0.0001 | −0.50617 | <0.0001 |

| YpH | 0.38091 | <0.0001 | 0.38466 | <0.0001 |

| Trait | EWC | Model | Pr > F | R2 | MD (Observed – Expected) | SD | Pr > T | Model Type |

|---|---|---|---|---|---|---|---|---|

| EW | M | EW = 58.06968 − 0.11497 ∗ day | <0.0001 | 0.17 | −0.00001 | 2.496 | 0.9999 | linear |

| L | EW = 64.30016 − 0.11649 ∗ day | <0.0001 | 0.20 | −0.00002 | 2.285 | 0.9997 | ||

| SG | M | SG = 1.09072 − 0.00144 ∗ day | <0.0001 | 0.53 | 0.000082 | 0.014 | 0.9124 | linear |

| L | SG = 1.08987 − 0.00138 ∗ day | <0.0001 | 0.53 | −0.00006 | 0.014 | 0.9353 | ||

| ACD | M | ACD = 1.14811 + 0.28495 ∗ day − 0.01024 ∗ day2 + 0.00016181 ∗ day3 | <0.0001 | 0.54 | 0.00179 | 1.072 | 0.9749 | polynominal |

| L | ACD = 1.29760 + 0.24602 ∗ day − 0.00586 ∗ day2 + 0.00006181 ∗ day3 | <0.0001 | 0.56 | −0.00103 | 1.062 | 0.9854 | ||

| HU | M | HU = 83.17175 − 1.99460 ∗ day + 0.05648 ∗ day2 − 0.00061806 ∗ day3 | <0.0001 | 0.37 | 0.00126 | 10.460 | 0.9982 | polynominal |

| L | HU = 87.84322 − 3.00134 ∗ day + 0.12044 ∗ day2 − 0.00185 ∗ day3 | <0.0001 | 0.46 | −0.00045 | 10.330 | 0.9993 | ||

| AW | M | AW = 35.27816 − 0.19537 ∗ day + 0.00798 ∗ day2 −0.00014972 ∗ day3 | <0.0001 | 0.11 | −0.00067 | 2.516 | 0.9961 | polynominal |

| L | AW = 39.94734 − 0.27154 ∗ day + 0.01282 ∗ day2 − 0.0002307 ∗ day3 | <0.0001 | 0.10 | −0.00161 | 2.669 | 0.9911 | ||

| ApH | M | ApH= 8.55088 + 0.08458 ∗ day − 0.00407 ∗ day2 + 0.00006202 ∗ day3 | <0.0001 | 0.64 | 0.00112 | 0.115 | 0.8581 | polynominal |

| L | ApH= 8.47459 + 0.09553 ∗ day − 0.00457 ∗ day2 + 0.00006905 ∗ day3 | <0.0001 | 0.71 | 0.00156 | 0.110 | 0.7922 | ||

| YI | M | YI = 44.44111 − 0.50472 ∗ day + 0.01726 ∗ day2 − 0.00030335 ∗ day3 | <0.0001 | 0.32 | −0.0007 | 3.768 | 0.9975 | polynominal |

| L | YI= 43.08972 − 0.55522 ∗ day + 0.02352 ∗ day2 − 0.00041845 ∗ day3 | <0.0001 | 0.25 | 0.000812 | 3.674 | 0.997 | ||

| YpH | M | YpH= 6.37524 − 0.00472 ∗ day + 0.00064422 ∗ day2 − 0.00000850 ∗ day3 | <0.0001 | 0.27 | −0.00000718 | 0.145 | 0.9993 | polynominal |

| L | YpH= 6.32879 + 0.00106 ∗ day + 0.00032864 ∗ day2 − 0.00000350 ∗ day3 | <0.0001 | 0.31 | −0.00003 | 0.135 | 0.9962 |

| Step | Variable Entered | Partial R2 | Model R2 | C(p) | Parameter Estimate | Pr > |t| |

|---|---|---|---|---|---|---|

| Intercept | 17.90251 | 0.5232 | ||||

| 1 | SG | 0.5176 | 0.5176 | 382.072 | −152.426 | <0.0001 |

| 2 | ApH | 0.1096 | 0.6272 | 175.732 | 10.63105 | <0.0001 |

| 3 | YpH | 0.0447 | 0.6719 | 92.7676 | 12.82286 | <0.0001 |

| 4 | YI | 0.0206 | 0.6926 | 55.5100 | −0.33684 | <0.0001 |

| 5 | HU | 0.0182 | 0.7108 | 22.8532 | −0.12071 | <0.0001 |

| 6 | ACD | 0.0094 | 0.7202 | 5.87 | 1.11087 | <0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drabik, K.; Próchniak, T.; Kasperek, K.; Batkowska, J. The Use of the Dynamics of Changes in Table Eggs during Storage to Predict the Age of Eggs Based on Selected Quality Traits. Animals 2021, 11, 3192. https://doi.org/10.3390/ani11113192

Drabik K, Próchniak T, Kasperek K, Batkowska J. The Use of the Dynamics of Changes in Table Eggs during Storage to Predict the Age of Eggs Based on Selected Quality Traits. Animals. 2021; 11(11):3192. https://doi.org/10.3390/ani11113192

Chicago/Turabian StyleDrabik, Kamil, Tomasz Próchniak, Kornel Kasperek, and Justyna Batkowska. 2021. "The Use of the Dynamics of Changes in Table Eggs during Storage to Predict the Age of Eggs Based on Selected Quality Traits" Animals 11, no. 11: 3192. https://doi.org/10.3390/ani11113192

APA StyleDrabik, K., Próchniak, T., Kasperek, K., & Batkowska, J. (2021). The Use of the Dynamics of Changes in Table Eggs during Storage to Predict the Age of Eggs Based on Selected Quality Traits. Animals, 11(11), 3192. https://doi.org/10.3390/ani11113192