Variation in Wool Characteristics across the Body in a Herd of Alpacas Kept in Poland

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Measurements

2.2. Statistical Analyses

3. Results

4. Discussion

| Species | Country | No. of Animals | No. of Sampling Sites | Mean Fiber Diameter (μm) | Fiber Diameter Coefficient of Variation (%) | Incidence of Medullated Fibers (%) | Staple Length (cm) | Reference |

|---|---|---|---|---|---|---|---|---|

| Alpaca | Poland | 36 | 1 | 25.3 | 20.4 | 68.9 | - | Radzik-Rant and Wiercińska [7] |

| Alpaca | Peru | 36 | 1 | 22.1 | - | 67.4 | - | Pinares et al. [27] |

| Alpaca | Australia | 1100 | 1 | 24.0–29.9 | - | 20–50 | 7.5–15 | McGregor [8] |

| Alpaca | Australia | 836 | 1 | 28.8 | 25.4 | - | - | McGregor and Butler [1] |

| Alpaca | USA | 585 | 1 | 27.9 | 23.5 | 17.5 | 11.6 | Lupton et al. [3] |

| Alpaca | Australia | 120 | 4 | 27.5–37.6 | 24.3–30.6 | 24.4–44.5 | - | Aylan-Parker and McGregor [16] |

| Alpaca | Peru | 31 | 24 | 26.6–49.7 | 18–23.9 | - | 4.1–9.2 | McGregor et al. [17] |

| Vicuna | Peru | 30 | 12 | 13.6–14.3 | 19.3–20.7 | - | 2.3–3.3 | Quispe et al. [18] |

| Angora goats | Argentina | 40 | 6 | 31.2–37.5 | 20.4–21.8 | 2.3–3.7 | 11.4–12.4 | Taddeo et al. [13] |

| American bison | Australia | 16 | 5–7 | 17.6–19.4 | 24.0–27.0 | - | 2.7–4.7 | McGregor [33] |

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- McGregor, B.A.; Butler, K. Sources of variation in fibre diameter attributes of Australia alpacas and implications for fleece evaluation and animal selection. Aust. J. Agric. Res. 2004, 55, 433–442. [Google Scholar] [CrossRef]

- Wuliji, T. Production performance, repeatability and heritability estimates for live weight, fleece weight and fiber characteristics of alpacas in New Zealand. Small Rumin. Res. 2000, 37, 189–201. [Google Scholar] [CrossRef]

- Lupton, C.J.; McColl, A.; Stobart, R.H. Fiber characteristics of the Huacaya Alpaca. Small Rumin. Res. 2006, 64, 211–244. [Google Scholar] [CrossRef]

- Krajewska-Wędzina, M.; Raczyńska, A.; Najbar, J.; Turcewicz, P. Alpaki-nowy gatunek hodowlany w Polsce. Część I. Ogólna charakterystyka gatunku. Życie Weterynaryjne 2020, 95, 422–426. [Google Scholar]

- Frank, E.N.; Hick, M.V.H.; Gauna, C.D.; Lamas, H.E.; Renieri, C.; Antonini, M. Phenotypic and genetic description of fiber traits in South American domestic camelids. Small Rumin. Res. 2006, 61, 113–129. [Google Scholar] [CrossRef]

- Czaplicki, Z. Properties and Structure of Polish Alpaca Wool. Fibres Text. East. Eur. 2012, 20, 8–12. [Google Scholar]

- Radzik-Rant, A.; Wiercińska, K. Analysis of the wool thickness and medullation characteristics based on sex and color in a herd of alpacas in Poland. Arch. Anim. Breed. 2021, 64, 157–165. [Google Scholar] [CrossRef]

- McGregor, B.A. Production, attributes and relative value of alpaca fleeces in southern Australia and implications for industry development. Small Rumin. Res. 2006, 61, 93–111. [Google Scholar] [CrossRef]

- Montes, M.; Quicano, I.; Quispe, R.; Quispe, E.; Ruiz, L.A. Quality characteristics of Huacaya alpaca fibre produced on the Peruvian Andean Plateau Region of Huancavelica. Span. J. Agric. Res. 2008, 6, 33–38. [Google Scholar] [CrossRef]

- Wurzingr, M.; Delgado, J.; Nürnberg, M.; Valle Zárate, A.; Stemmer, A.; Ugarte, G.; Skner, J. Genetic and non-genetic factors influencing fibre quality of Bolivian llamas. Small Rumin. Res. 2006, 61, 131–139. [Google Scholar] [CrossRef]

- Cruz, A.; Morante, R.; Cervantes, I.; Burgos, A.; Gutiérrez, J.P. Effect of the gestation and lactation on fiber diameter and its variability in Peruvian alpacas. Livest. Sci. 2017, 198, 31–36. [Google Scholar] [CrossRef]

- Fish, V.E.; Mahar, T.J.; Crook, B.J. Sampling variation over a fleece for mean fibre diameter, standard deviation of fibre diameter and mean fibre curvature. Wool Technol. Sheep Breed. 2002, 50, 798–804. [Google Scholar]

- Taddeo, H.R.; Duga, L.; Almeida, D.; Willems, P.; Somlo, R. Variation of mohair quality over the body in Angora goats. Small Rumin. Res. 2000, 36, 285–291. [Google Scholar] [CrossRef]

- McGregor, B.A.; Butler, K.L. Variation of mean fibre diameter across mohair fleeces: Implications for within flock animal selection, genetic selection, fleece classing and objective sale lot building. Small Rumin. Res. 2008, 75, 54–64. [Google Scholar] [CrossRef]

- McGregor, B.A.; Butler, K.L. Variation of staple length across mohair fleeces: Implications for animal selection and fleece evaluation. J. Agric. Sci. Camb. 2009, 147, 493–501. [Google Scholar] [CrossRef]

- Aylan-Parker, J.; McGregor, B. Optimizing sampling techniques and estimating sampling variance of fleece quality attributes in alpacas. Small Rumin. Res. 2002, 44, 53–64. [Google Scholar] [CrossRef]

- McGregor, B.A.; Ramos, H.E.; Quispe Pena, E.C. Variation of fibre characteristics among sampling sites for Huacaya alpaca fleeces from the High Andes. Small Rumin. Res. 2012, 102, 191–196. [Google Scholar] [CrossRef]

- Quispe, E.C.; Fiorella Sánchez, F.; Filella, J.B.; Ruiz, L.A. Variation of commercially important characteristics among sampling sites for vicuña (Vicugna vicugna mensalis) fleeces. J. Camelid Sci. 2014, 7, 1–14. [Google Scholar]

- Knox, I.; Lamb, P. Grower Adoption of Clip Preparation Standards for Australia Alpaca Fibre. A Report for the Rural Industries Research and Development Corporation. 2002. Available online: http://www.agrifutures.com.au/wp-content/uploads/publications/02-016.pdf (accessed on 20 May 2021).

- Hoffman, E. The Complete Alpaca Book; Bonny Doon Press: Santa Cruz, CA, USA, 2006. [Google Scholar]

- Sánchez, A.L.; Urioste, J.I.; Peñagaricano, F.; Neimaur, K.; Sienra, I.; Naya, H.; Kremer, R. Genetic parameters of objectionable fibers and of their association with fleece traits in Corriedale sheep. J. Anim. Sci. 2016, 94, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Frank, E.N.; Hick, M.V.H.; Castillo, M.F.; Prieto, A.; Adot, O. Fiber-based components determining handle and skin comfort in fabrics made from dehaired and non-dehaired llama fiber. Int. J. Appl. Sci. Technol. 2014, 4, 51–66. [Google Scholar]

- Frank, E.N.; Hick, M.H.V.; Riva de Neyra, L.A. The problem of prickling on fabrics of South American camelids fibers: Possible approaches for mechanical solutions. Asian Res. J. Agric. 2017, 5, 1–9. [Google Scholar] [CrossRef][Green Version]

- Gutiérrez, G.A.; Varona, L.; Pun, A.; Morante, R.; Burgos, A.; Cervantes, I.; Pérez-Cabal, M.A. Genetic parameters for growth of fiber diameter in alpacas. J. Anim. Sci. 2011, 89, 2310–2315. [Google Scholar] [CrossRef]

- Gutiérrez, G.A.; Cervantes, I.; Pérez-Cabal, M.A.; Burgos, A.; Morante, R. Weighting fibre and morphological traits in a genetic index for an alpaca breeding programme. Animal 2014, 8, 360–369. [Google Scholar] [CrossRef]

- Cruz, A.; Morante, R.; Gutiérrez, J.P.; Torres, R.; Burgos, A.; Cervantes, I. Genetic parameters for medullated fiber and its relationship with other productive traits in alpacas. Animal 2019, 13, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Pinares, R.; Gutiérrez, G.A.; Cruz, A.; Morante, R.; Cervantes, I.; Burgos, A.; Gutiérrez, J.P. Heritability of individual fiber medullation in Peruvian alpacas. Small Rumin. Res. 2018, 165, 93–100. [Google Scholar] [CrossRef]

- European Parliament and the Council of the European Union. Directive 2010/63/EU of the European Parliament and of the Council of 22 September 2010 on the Protection of Animals Used for Scientific Purpose. Off. J. Eur. Union 2010, 276, 33–79. [Google Scholar]

- IWTO. Fiber Diameter Distribution Parameters and Percentage of Medullated Fibres and Wool and Other Animal Fibres by the Projection Microscope; IWTO-8-2011; International Wool Textile Organization: Belgium, Brussel, 2011. [Google Scholar]

- SPSS Base, Version 23.0; SPSS Inc.: Chicago, IL, USA, 2016.

- Valbonesi, A.; Cristofanelli, S.; Pierdominici, F.; Gonzales, M.; Antonioni, M. Comparison of fiber and cuticular attributes of alpaca and llama fleeces. Text. Res. J. 2010, 80, 344–353. [Google Scholar] [CrossRef]

- McGregor, B. Comparative productivity and grazing behaviour of Huacaya alpacas and Pepin Merino sheep Grazen on annual pastures. Small Rumin. Res. 2002, 44, 219–232. [Google Scholar] [CrossRef]

- McGregor, B.A. Production, properties and processing of American bison (Bison bison) wool grown in southern Australia. Anim. Prod. Sci. 2012, 52, 431–435. [Google Scholar] [CrossRef][Green Version]

- Preston, J.W.V.; Hatcher, S.; McGregor, B.A. Effects of site of assessment and variation in wool quality traits on the tactile assessment of textural greasy wool handle. Anim. Prod. Sci. 2014, 54, 1665–1670. [Google Scholar] [CrossRef]

| Item | Total Fibers | Non-Medullated Fibers | Discontinuous Medullated Fibers | Continuous Medullated Fibers |

|---|---|---|---|---|

| LSM ± SD | LSM ± SD | LSM ± SD | LSM ± SD | |

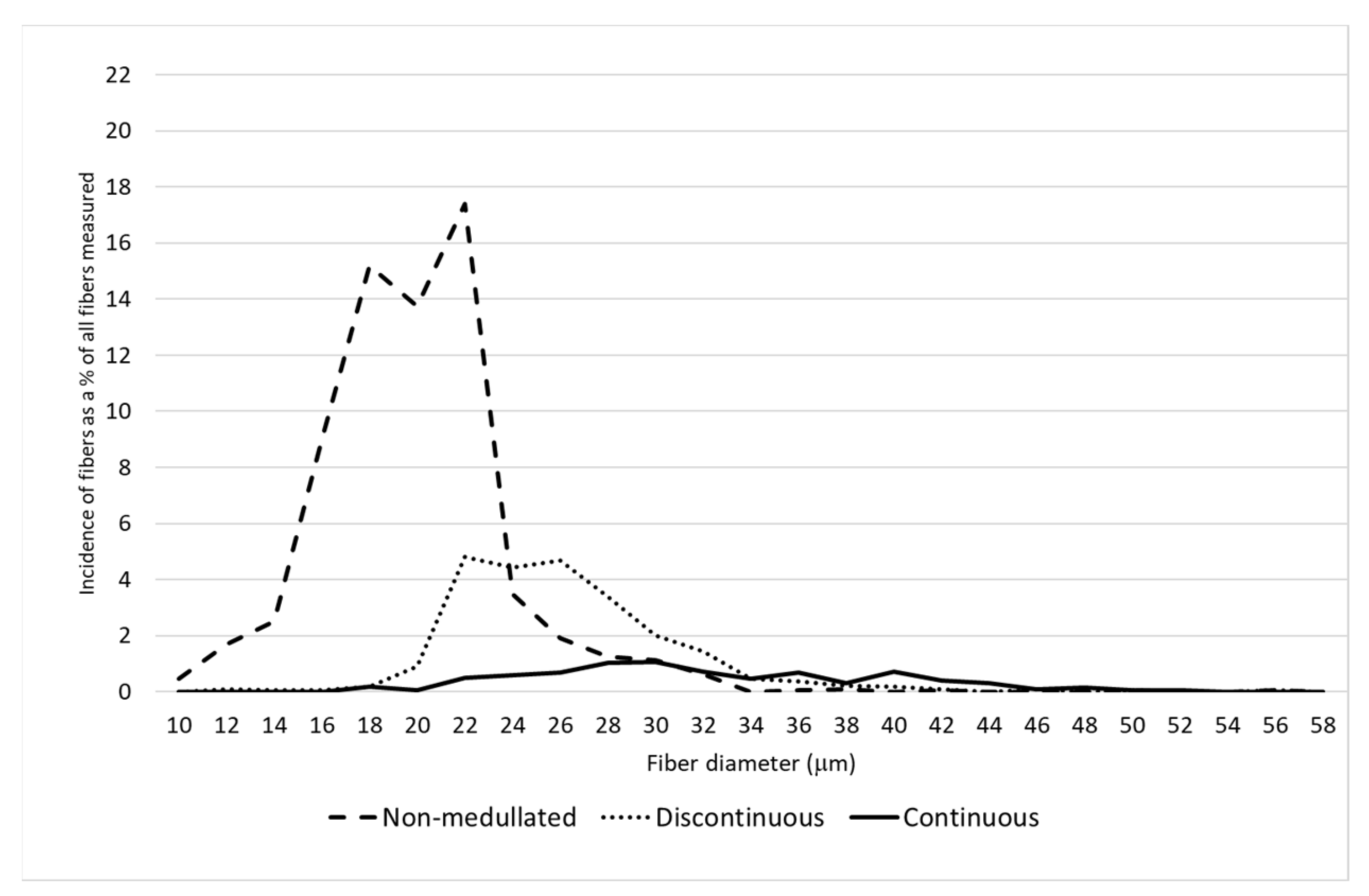

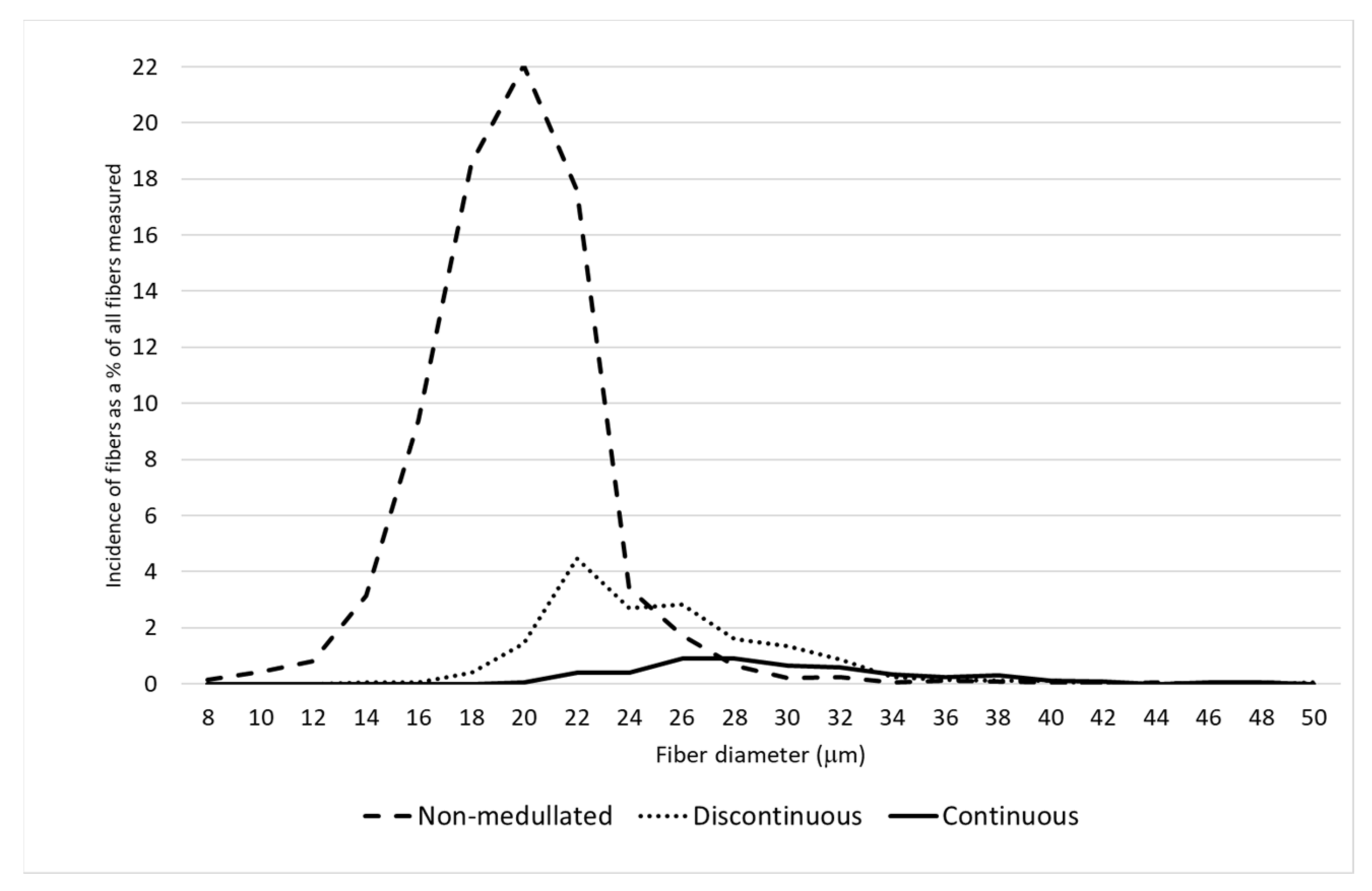

| Mean fiber diameter (MFD) (μm) | 22.0 ± 4.1 | 19.6 ± 3.1 | 24.3± 3.5 | 29.4 ± 4.0 |

| Fiber diameter standard deviation (FD SD) | 5.1 ± 2.1 | 3.9 ± 1.9 | 3.9 ± 2.2 | 4.7 ± 2.4 |

| Fiber diameter coefficient of variation (FD CV) (%) | 22.4 ± 4.6 | 19.2 ± 5.3 | 15.4 ± 5.4 | 15.7 ± 6.1 |

| Fiber share (%) | 65.1 ± 18.2 | 23.7 ± 14.1 | 11.3 ± 9.4 | |

| Incidence of medullated fibers (%) | 35.0 ± 18.1 | |||

| Staple length (cm) | 12.8 ± 3.5 |

| Item | Midside (MS) | Saddle (S) | Neck (N) | Pieces (P) | p Value |

|---|---|---|---|---|---|

| LSM ± SD | LSM ± SD | LSM ± SD | LSM ± SD | ||

| Mean fiber diameter (MFD) (μm) | 20.8 a ± 2.4 | 19.7 a ±1.8 | 21.9 a ±2.3 | 25.5 b ± 5.9 | 0.000 |

| Fiber diameter standard deviation (FD SD) | 4.9 ± 1.3 | 4.1 a ± 0.6 | 4.7 a ± 0.56 | 6.4 b ± 3.6 | 0.005 |

| Fiber diameter coefficient of variation (FD CV) (%) | 23.3 ± 4.5 | 20.9 ± 2.4 | 21.7 ±1.3 | 23.8 ± 7.5 | 0.206 |

| Non-medullated fibers (%) | 72.5 a ± 14.8 | 78.7 a ± 11.9 | 53.9 b ± 15.9 | 55.1 b ± 16.4 | 0.000 |

| Incidence of medullated fibers (%) | 27.5 a ± 14.8 | 21.3 a ± 11.9 | 46.1 b ± 15.9 | 44.9 b ± 16.4 | 0.000 |

| Discontinuous medullated fibers (%) | 20.1 ± 12.8 | 15.6 a ± 10.6 | 29.1 b ± 16.0 | 30.0 b ± 11.9 | 0.003 |

| Continuous medullated fibers (%) | 7.5 a ± 3.5 | 5.7 a ± 2.6 | 17.0 b ± 9.8 | 15.0 b ± 12.4 | 0.000 |

| Staple length (cm) | 14.9 a ± 3.5 | 13.8 ± 3.5 | 10.9 b ± 3.0 | 11.7 b ± 2.8 | 0.001 |

| Item | Midside (MS) | Saddle (S) | Neck (N) | Pieces (P) | p Value |

|---|---|---|---|---|---|

| LSM ± SD | LSM ± SD | LSM ± SD | LSM ± SD | ||

| MFD of non-medullated fibers (μm) | 19.0 a ± 1.7 | 18.0 a ± 0.9 | 18.9 a ± 1.4 | 22.6 b ± 4.6 | 0.000 |

| FD SD of non-medullated fibers | 3.6 ± 0.8 | 3.5 ± 1.3 | 3.5 a ± 0.6 | 5.0 b ± 3.2 | 0.040 |

| FD CV of non-medullated fibers (%) | 18.6 ± 3.0 | 19.1 ± 6.4 | 18.3 ± 2.5 | 21.0 ± 7.524.0 | 0.420 |

| MFD of discontinuous medullated fibers (μm) | 24.0 ± 1.8 | 23.2 a ± 1.3 | 23.5 a ± 2.5 | 26.6 b ± 5.6 | 0.009 |

| FD SD of discontinuous fibers | 3.6 a ± 1.2 | 3.4 a ± 0.9 | 3.2 a ± 0.8 | 5.5 b ± 3.8 | 0.006 |

| FD CV of discontinuous medullated fibers (%) | 14.8 ± 4.2 | 14.7 ± 3.4 | 13.6 a ± 2.1 | 18.5 b ± 8.6 | 0.038 |

| MFD of continuous medullated fibers (μm) | 29.4 ± 3.8 | 28.3 ± 2.5 | 28.6 ± 3.5 | 31.5 ± 5.1 | 0.062 |

| FD SD of continuous medullated fibers | 5.1 ± 1.6 | 4.2 ± 1.4 | 3.8 a ± 1.1 | 5.8 b ± 3.8 | 0.049 |

| FD CV of continuous medullated fibers (%) | 17.5 ± 4.9 | 15.1 ± 5.7 | 13.1 ± 2.7 | 17.2 ± 9.0 | 0.104 |

| Item | Midside | Total Fleece | Fleece Without Pieces | p Value |

|---|---|---|---|---|

| LSM ± SD | LSM ± SD | LSM ± SD | ||

| Mean fiber diameter (MFD) (μm) | 20.8 ± 2.4 | 22.0 ±2.9 | 20.8 ± 2.0 | 0.282 |

| Fiber diameter standard deviation (FD SD) | 4.9 ± 1.3 | 5.1 ± 1.4 | 4.6 ± 0.8 | 0.495 |

| Fiber diameter coefficient of variation (FD CV) (%) | 23.3 ± 4.5 | 22.4 ± 3.4 | 22.0 ± 2.5 | 0.532 |

| Non-medullated fibers (%) | 72.5 ± 14.8 | 65.1 ± 13.1 | 68.4 ± 13.4 | 0.275 |

| Incidence of medullated fibers (%) | 27.5 ± 14.8 | 35.0 ± 13.0 | 31.6 ± 13.4 | 0.275 |

| Discontinuous medullated fibers (%) | 20.1 ± 12.8 | 23.7 ± 12.1 | 21.6 ± 12.6 | 0.683 |

| Continuous medullated fibers (%) | 7.5 a ± 3.5 | 11.3 b ± 5.3 | 10.0 ± 4.7 | 0.047 |

| Item | Midside (MS) | Saddle (S) | Neck (N) |

|---|---|---|---|

| Mean fiber diameter (MFD) (μm) | 0.927 * | 0.901 * | 0.914 * |

| Fiber diameter standard deviation (FD SD) | 0.956 * | 0.961 * | 0.864 * |

| Fiber diameter coefficient of variation (FD CV) (%) | 0.964 * | 0.921 * | 0.709 * |

| Non-medullated fibers (%) | 0.943 * | 0.939 * | 0.949 * |

| Incidence of medullated fibers (%) | 0.943 * | 0.939 * | 0.949 * |

| Discontinuous medullated fibers (%) | 0.960 * | 0.949 * | 0.955 * |

| Continuous medullated fibers (%) | 0.824 * | 0.663 * | 0.964 * |

| Staple length (cm) | 0.973 * | 0.978 * | 0.935 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radzik-Rant, A.; Wielechowska, M.; Rant, W. Variation in Wool Characteristics across the Body in a Herd of Alpacas Kept in Poland. Animals 2021, 11, 2939. https://doi.org/10.3390/ani11102939

Radzik-Rant A, Wielechowska M, Rant W. Variation in Wool Characteristics across the Body in a Herd of Alpacas Kept in Poland. Animals. 2021; 11(10):2939. https://doi.org/10.3390/ani11102939

Chicago/Turabian StyleRadzik-Rant, Aurelia, Małgorzata Wielechowska, and Witold Rant. 2021. "Variation in Wool Characteristics across the Body in a Herd of Alpacas Kept in Poland" Animals 11, no. 10: 2939. https://doi.org/10.3390/ani11102939

APA StyleRadzik-Rant, A., Wielechowska, M., & Rant, W. (2021). Variation in Wool Characteristics across the Body in a Herd of Alpacas Kept in Poland. Animals, 11(10), 2939. https://doi.org/10.3390/ani11102939