Optimization of the Production of Vaccine Epitopes from Clostridium novyi Alpha-Toxin Using Strains of Recombinant Escherichia coli

Abstract

1. Introduction

2. Materials and Methods

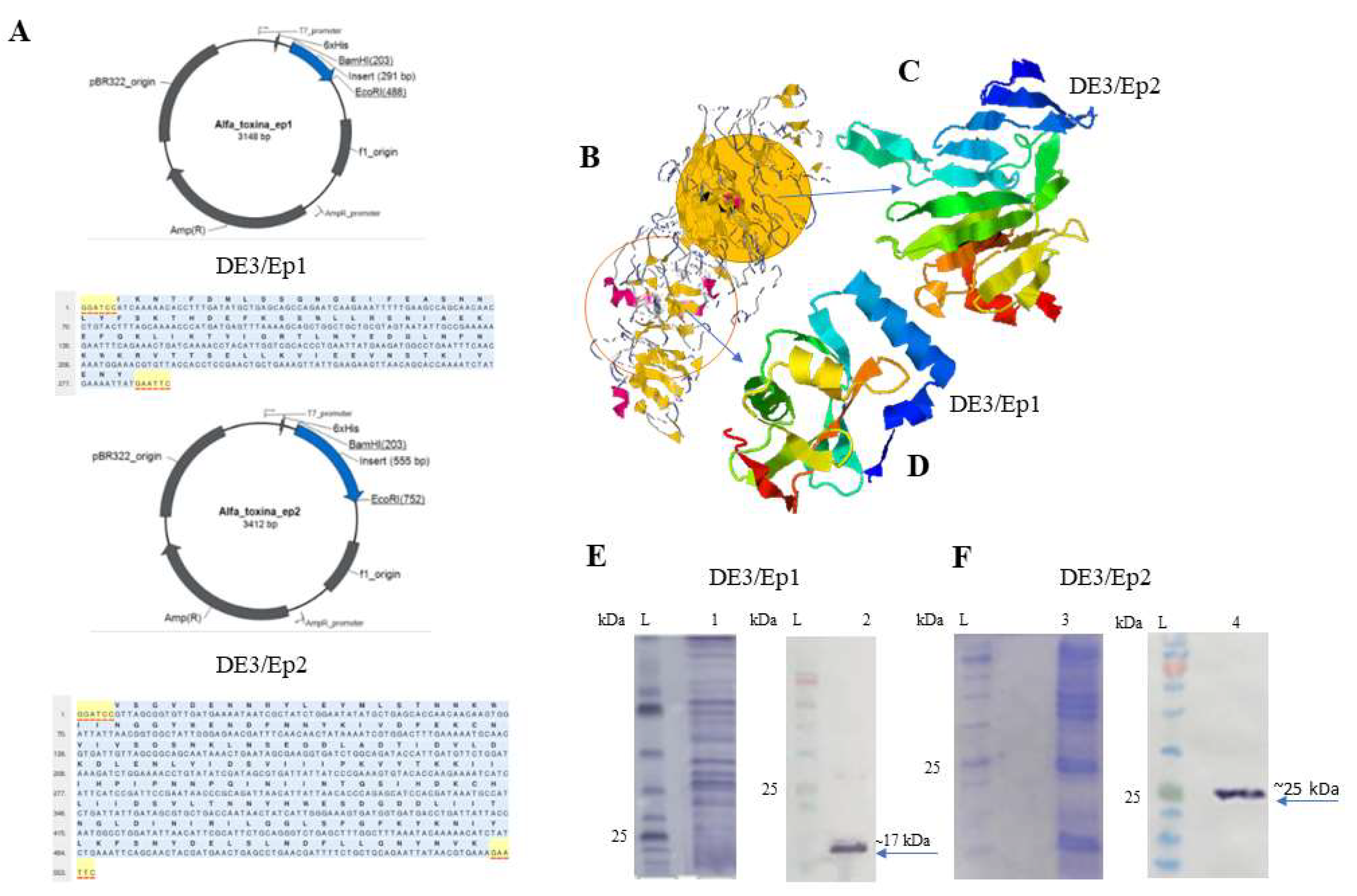

2.1. Bioinformatics Tools and Vaccine Epitope Expression Vector Construction

2.2. DE3 Cultivation on a Rotary Shaker

2.3. DE3 Cultivation in SD Medium in a Stirred-Tank Biological Reactor

2.4. Scaling Up DE3 Cultivation in SD Medium in an Unstirred-Tank Biological Reactor

2.5. System for Induction and Purification of DE3/Ep1 and DE3/Ep2 Recombinant Epitopes

2.6. Western Blotting

2.7. Fermentation Parameters

2.7.1. Determination of Glucose Consumption

2.7.2. Determination of Acetic Acid (Hac) and DMY Production

2.7.3. Yield Coefficients

2.8. Statistical Analysis

3. Results

3.1. Detection of Vaccine Epitopes

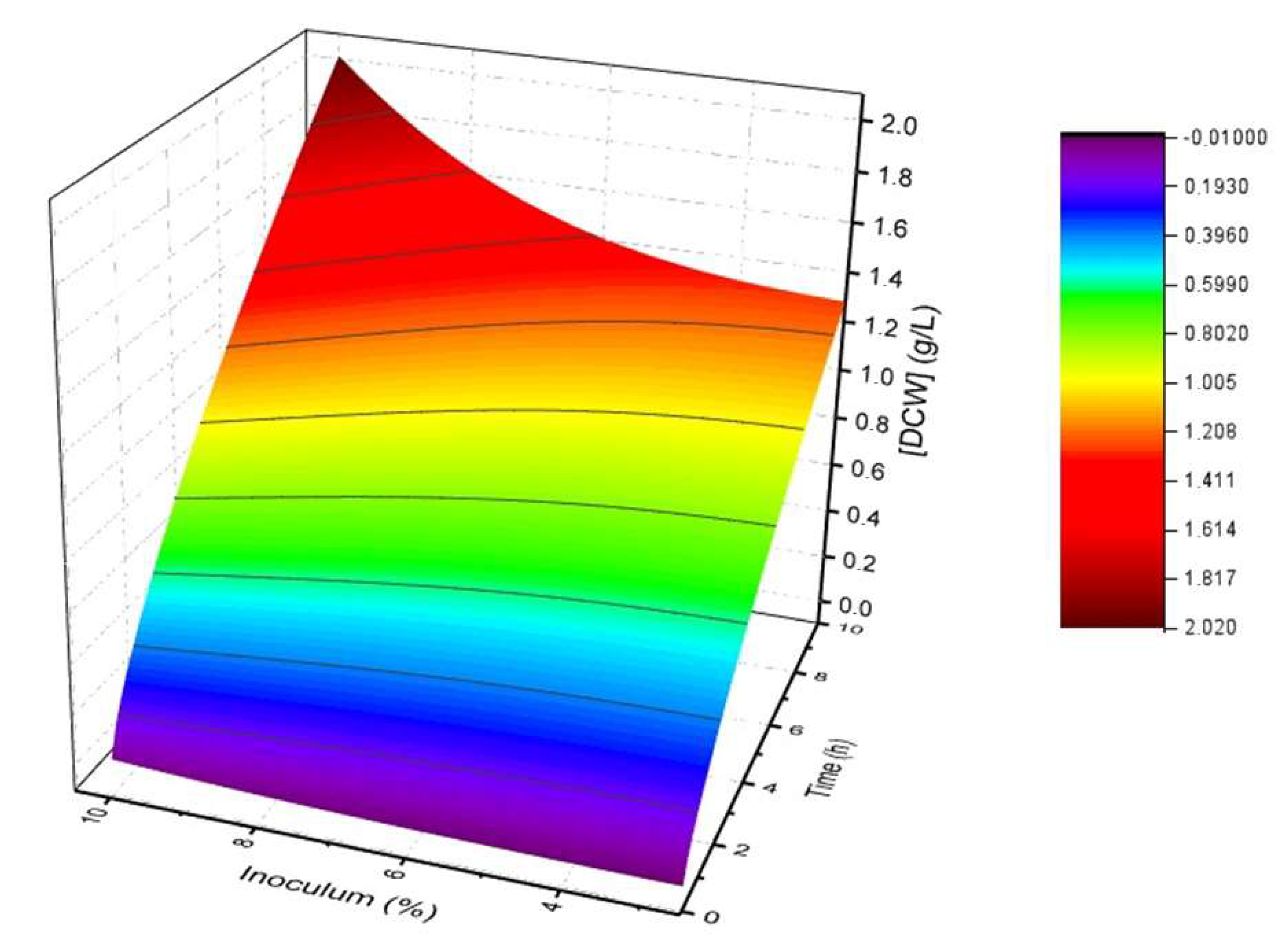

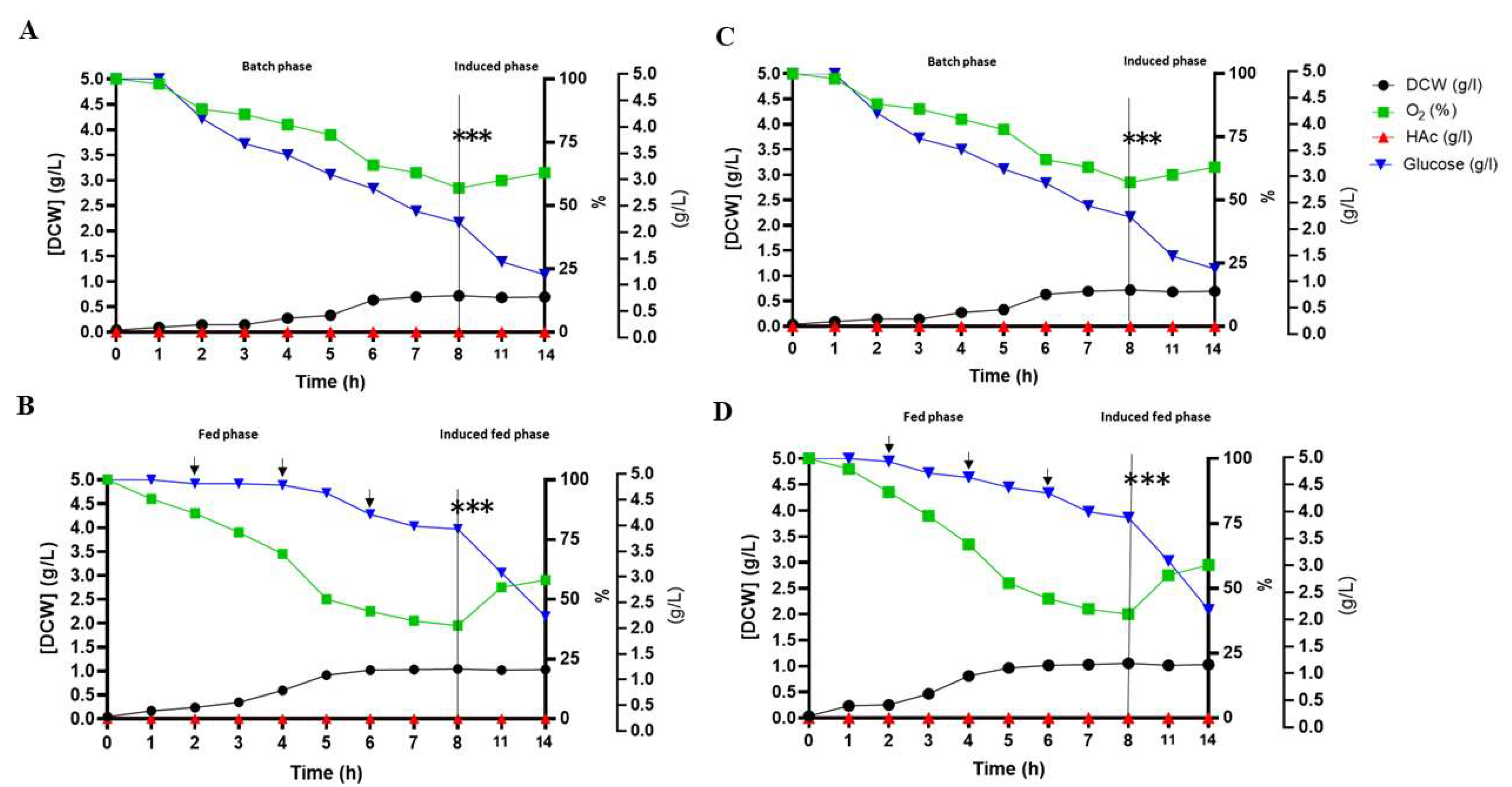

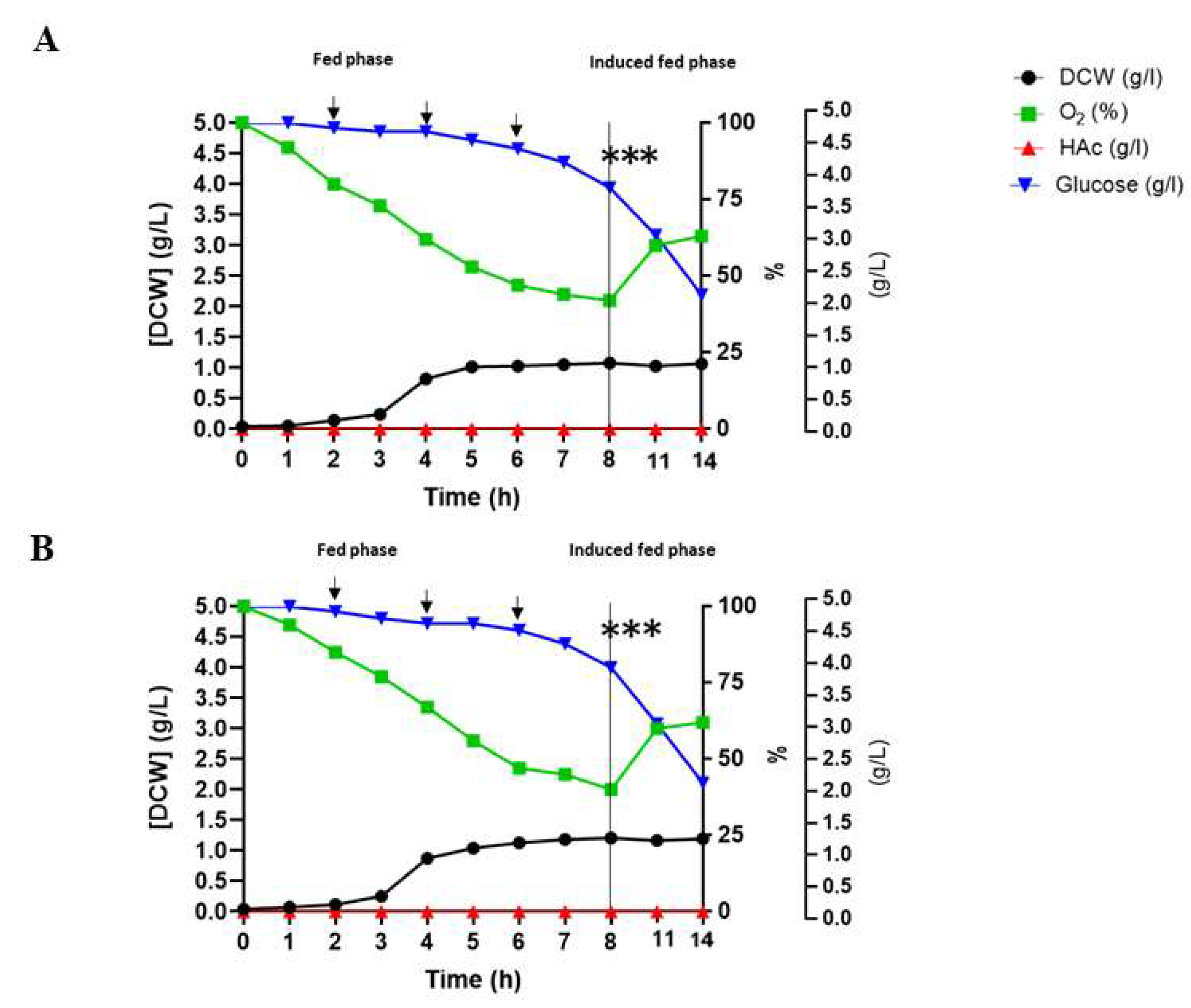

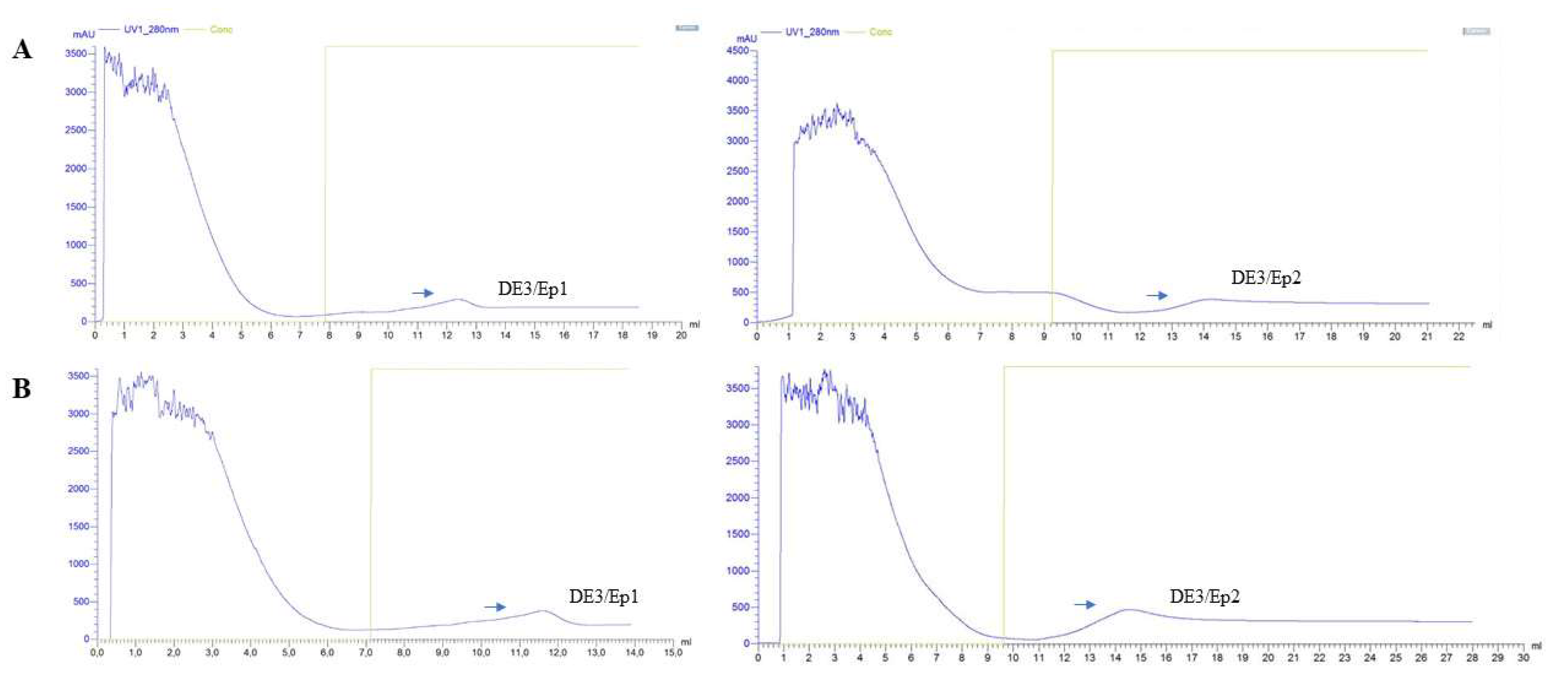

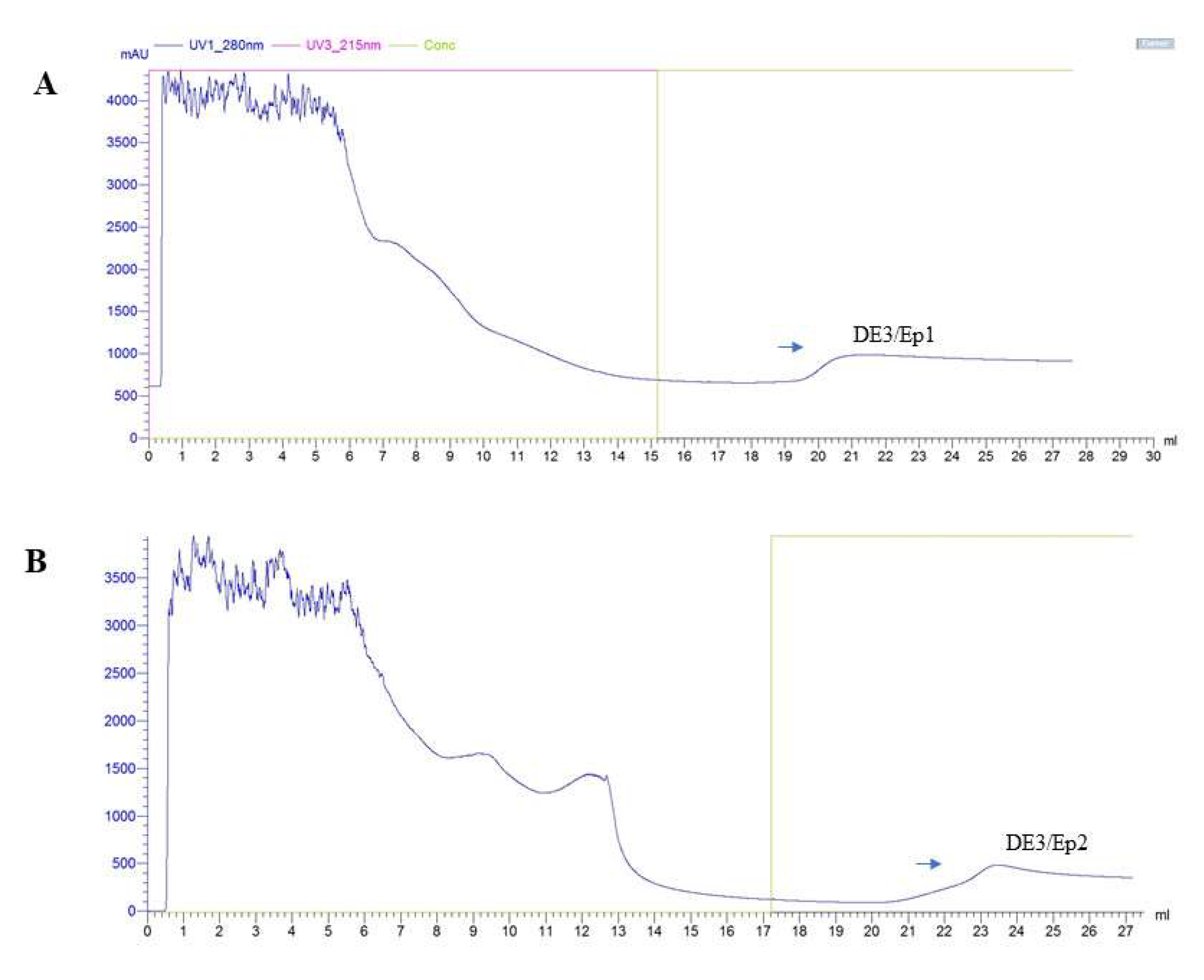

3.2. Optimization and Scaling of Vaccine Epitope Production

3.3. DE3 Induction Strategy and Vaccine Epitope Purification

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| C. novyi | Clostridium novyi type B |

| DE3 | Escherichia coli BL21 pLysS (DE3) |

| DMY | Dry mass yield (g/L) |

| HAc | Acetic acid (g/L) |

| O2 | Dissolved oxygen (%) |

| µ | Specific growth rate (h−1) |

| YX/S | Biomass yield coefficient |

| YP/S | Product yield coefficient |

| QP | Product volumetric productivity |

| QX | Volumetric productivity of biomass |

| IEDB-AR | Immune Epitope Database Analysis Resource |

| DE3/Ep1 | Epitope 1 of alpha-toxin transformed into DE3 |

| DE3/Ep2 | Epitope 2 of alpha-toxin transformed into DE3 |

| de3/ep1 | Alpha-toxin genetic sequence encoding DE 3/Ep1 |

| de3/ep2 | Alpha-toxin genetic sequence encoding DE 3/Ep2 |

| pRSET | Expression plasmid |

| IPTG | Isopropyl-β-D-thiogalactopyranoside |

| SD | Semi-defined culture medium with zinc and manganese chelate |

| EDTA-Zn | Zinc chelate |

| EDTA-Mn | Manganese chelate |

| TFA | Trifluoroacetic acid |

| GOD | Glucose oxidase |

| POD | Peroxidase |

| H3PO4 | Phosphoric acid |

| RSA | Response surface analysis |

References

- Ma, M.; Boyd, J.T.; Trinh, H.T.; Coombs, J.W.; Fermann, G.J. Fatal myocarditis due to Clostridium novyi type B in a previously healthy woman: Case report and literature review. Scand. J. Infect. Dis. 2007, 39, 77–80. [Google Scholar] [CrossRef]

- Lobato, F.C.F.; Salvarani, F.M.; Gonçalves, L.A.; Pires, P.S.; Otávio, R.; Silva, R.O.S.; Alves, G.G.; Neves, M.; Oliveira Júnior, C.A.; Lúcio, P.; et al. Clostridioses dos animais de produção. Vet. Zootec. 2013, 20, 29–48. [Google Scholar]

- Walker, D.J.F.; Heap, J.T.; Winzer, K.; Minton, N.P. A genetic assay for gene essentiality in Clostridium. Anaerobe 2016, 42, 40–43. [Google Scholar] [CrossRef]

- Carvalho, T.B.; Zen, S. A cadeia de Pecuária de Corte no Brasil: Evolução e tendências. Rev. IPecege 2017, 3, 85–99. [Google Scholar] [CrossRef]

- Uzal, F.A.; Vidal, J.E.; McClane, B.A.; Gurjar, A.A. Clostridium perfringens Toxins Involved in Mammalian Veterinary Diseases. Open. Toxinol. J. 2010, 2, 24–42. [Google Scholar] [CrossRef]

- Brandi, I.V.; Mozzer, O.D.; Jorge, E.V.; Passos, F.J.V.; Passos, F.M.L.; Cangussu, A.S.R.; Sobrinho, E.M. Growth conditions of Clostridium perfringens type B for production of toxins used to obtain veterinary vaccines. Bioprocess Biosyst. Eng. 2014, 37, 1737–1742. [Google Scholar] [CrossRef]

- Brandi, I.V.; Santos, E.M.S.; Carvalho, B.M.A.; Durães, C.A.F.; Farias, P.K.S.; Sari, R.S.; Cangussu, A.S.R.; Pessoa, A. Total combining power: Technique for the evaluation of the quality control process of clostridiosis vaccines. J. Microbiol. Methods 2016, 130, 164–168. [Google Scholar] [CrossRef]

- Fouad, E.A.; Toaleb, N.I.; Hassan, S.E.; El Shanawany, E.E.; Keshta, H.G.; Abdel-Rahman, E.H.; Hegazi, A.G. Evaluation of the therapeutic effect of propolis on Fasciola gigantica and Clostridium novyi type B infections in sheep. Trop. Biomed. 2021, 38, 102–110. [Google Scholar] [CrossRef]

- Brito, H.S.; Alencar, F.C.; Albuquerque, B.; Silva, M.G.; Félix, M.K.; Mulholland, D.S.; Oliveira, E.E.; Mariúba, L.A.M.; Sobrinho, E.M.; Brandi, I.V.; et al. Pathologic findings on ruminant enteric clostridial diseases reveal specificities and differences among iota and iota-like toxins. Rev. Cienc. Agric. 2021, 38, 157–174. [Google Scholar] [CrossRef]

- Navarro, M.A.; Dutra, F.; Briano, C.; Romero, A.; Persiani, M.; Freedman, J.C.; Morrell, E.; Beingesser, J.; Uzal, F.A. Pathology of Naturally Occurring Bacillary Hemoglobinuria in Cattle. Vet. Pathol. 2017, 54, 457–466. [Google Scholar] [CrossRef]

- Le Gratiet, T.; Le Marechal, C.; Devaere, M.; Chemaly, M.; Woudstra, C. Exploration of the Diversity of Clustered Regularly Interspaced Short Palindromic Repeats-Cas Systems in Clostridium novyi sensu lato. Front. Microbiol. 2021, 12, 711413. [Google Scholar] [CrossRef]

- Zeng, J.; Deng, G.; Wang, J.; Zhou, J.; Liu, X.; Xie, Q.; Wang, Y. Potential protective immunogenicity of recombinant Clostridium perfringens α–β2–β1 fusion toxin in mice, sows and cows. Vaccine 2011, 29, 5459–5466. [Google Scholar] [CrossRef] [PubMed]

- Aquino, P.L.M.; Fonseca, F.S.; Mozzer, O.D.; Giordano, R.C.; Sousa, R. Optimization of the Production of Inactivated Clostridium novyi Type B Vaccine Using Computational Intelligence Techniques. Appl. Biochem. Biotechnol. 2016, 179, 895–909. [Google Scholar] [CrossRef] [PubMed]

- Sookhoo, J.R.; Schiffman, Z.; Ambagala, A.; Kobasa, D.; Pardee, K.; Babiuk, S. Protein Expression Platforms and the Challenges of Viral Antigen Production. Vaccines 2024, 12, 1344. [Google Scholar] [CrossRef] [PubMed]

- Lima, C.G.R.D.; Lobato, Z.I.P.; Pires, P.S.; Silva, R.O.S.; Salvarani, F.M.; Assis, R.A.; Lobato, F.C.F. Padronização de teste de Potência in vitro Para vacinas que contenham toxoide alfa de Clostridium novyi tipo B. Arq. Inst. Biol. 2011, 78, 507–512. [Google Scholar] [CrossRef]

- Santos, P.S.; Nascimento, R.; Rodrigues, L.P.; Santos, F.A.A.; Faria, P.C.B.; Martins, J.R.S.; Brito-Madurro, A.G.; Madurro, J.M.; Goulart, L.R. Functional Epitope Core Motif of the Anaplasma marginale Major Surface Protein 1a and Its Incorporation onto Bioelectrodes for Antibody Detection. PLoS ONE 2012, 7, e33045. [Google Scholar] [CrossRef]

- Sari, R.S.; Almeida, A.C.; Cangussu, A.S.R.; Jorge, E.V.; Mozzer, O.D.; Santos, H.O.; Quintilio, W.; Brandi, I.V.; Andrade, V.A.; Miguel, A.S.M.; et al. Anti-botulism single-shot vaccine using chitosan for protein encapsulation by simple coacervation. Anaerobe 2016, 42, 182–187. [Google Scholar] [CrossRef]

- Martinelli, D.D. In silico vaccine design: A tutorial in immunoinformatics. Healthc. Anal. 2022, 2, 100044. [Google Scholar] [CrossRef]

- Silvestre, B.T.; Rabelo, É.M.L.; Versiani, A.F.; da Fonseca, F.G.; Silveira, J.A.G.; Bueno, L.L.; Fujiwara, R.T.; Ribeiro, M.F.B. Evaluation of humoral and cellular immune response of BALB/c mice immunized with a recombinant fragment of MSP1a from Anaplasma marginale using carbon nanotubes as a carrier molecule. Vaccine 2014, 32, 2160–2166. [Google Scholar] [CrossRef]

- Moreira, G.M.S.G.; Salvarani, F.M.; da Cunha, C.E.P.; Mendonça, M.; Moreira, Â.N.; Gonçalves, L.A.; Pires, P.S.; Lobato, F.C.F.; Conceição, F.R. Immunogenicity of a Trivalent Recombinant Vaccine Against Clostridium perfringens Alpha, Beta, and Epsilon Toxins in Farm Ruminants. Sci. Rep. 2016, 6, 22816. [Google Scholar] [CrossRef]

- Cangussu, A.S.R.; Mariúba, L.A.M.; Lalwani, P.; Pereira, K.D.E.S.; Astolphi-Filho, S.; Orlandi, P.P.; Epiphanio, S.; Viana, K.F.; Ribeiro, M.F.B.; Silva, H.M.; et al. A hybrid protein containing MSP1a repeats and Omp7, Omp8 and Omp9 epitopes protect immunized BALB/c mice against anaplasmosis. Vet. Res. 2018, 49, 6. [Google Scholar] [CrossRef] [PubMed]

- Félix, M.K.C.; Deusdará, T.T.; Santos, L.S.S.; Aguiar, R.W.S.; Corrêa, R.F.T.; Brandi, I.V.; Sobrinho, E.M.; Ribeiro, B.M.; Mariúba, L.A.M.; Nogueira, P.A.; et al. Inactivated alpha toxin from Clostridium novyi type B in nano-emulsion protect partially protects Swiss mice from lethal alpha toxin challenge. Sci. Rep. 2019, 9, 14082. [Google Scholar] [CrossRef]

- Félix, M.K.C.; Leite, E.R.T.; Dutra, L.R.; Ribeiro, M.A.; Moura, W.S.; Ferreira, T.P.S.; Santos, G.R.; Chapla, V.M.; Vieira, W.A.S.; Câmara, M.P.S.; et al. Secondary metabolites produced by solid-state fermentation of a neotropical Aspergillus flavus strain confer anti-mosquito activity with long shelf-life. Ind. Crops Prod. 2022, 180, 114743. [Google Scholar] [CrossRef]

- Field, J.K.; Euerby, M.R.; Haselmann, K.F.; Petersson, P. Investigation into reversed-phase chromatography peptide separation systems Part IV: Characterisation of mobile phase selectivity differences. J. Chromatogr. A 2021, 1641, 461986. [Google Scholar] [CrossRef]

- Bergmeyer, H.U.; Herder, M.; Rej, R. International federation of clinical chemistry (IFCC). J. Clin. Chem. Clin. Biochem. 1986, 24, 497–510. [Google Scholar] [CrossRef]

- Wu, C.H.; Dong, C.D.; Patel, A.K.; Singhania, R.R.; Yang, M.J.; Guo, H.R.; Kuo, J.M. Characterization of waste cell biomass derived glutamate decarboxylase for in vitro γ-aminobutyric acid production and value-addition. Bioresour. Technol. 2021, 337, 125423. [Google Scholar] [CrossRef]

- Zhang, Y. I-TASSER server for protein 3D structure prediction. BMC Bioinform. 2008, 9, 40. [Google Scholar] [CrossRef] [PubMed]

- Cernat, R.C.; Scott, K.P. Evaluation of novel assays to assess the influence of different iron sources on the growth of Clostridium difficile. Anaerobe 2012, 18, 298–304. [Google Scholar] [CrossRef]

- Raganati, F.; Olivieri, G.; Götz, P.; Marzocchella, A.; Salatino, P. Butanol production from hexoses and pentoses by fermentation of Clostridium acetobutylicum. Anaerobe 2015, 34, 146–155. [Google Scholar] [CrossRef]

- Yamamoto, T.; Ugai, H.; Nakayama-Imaohji, H.; Tada, A.; Elahi, M.; Houchi, H.; Kuwahara, T. Characterization of a recombinant Bacteroides fragilis sialidase expressed in Escherichia coli. Anaerobe 2018, 50, 69–75. [Google Scholar] [CrossRef]

- Ferreira, M.R.A.; Moreira, G.M.S.; Cunha, C.E.P.D.; Mendonça, M.; Salvarani, F.M.; Moreira, Â.N.; Conceição, F.R. Recombinant alpha, beta, and epsilon toxins of Clostridium perfringens: Production strategies and applications as veterinary vaccines. Toxins 2016, 8, 340. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.; Song, F.; Yang, Y.; Ma, C.; Deng, G.; Li, Y.; Wang, Y.; Liu, X. The Generation and Characterization of Recombinant Protein and Antibodies of Clostridium perfringens Beta2 Toxin. J. Immunol. Res. 2016, 2016, 5708468. [Google Scholar] [CrossRef]

- Cangussu, A.S.R.; Cruz, P.A.; Aguiar, R.W.A.; Santos, G.R.; Campos, F.S.; Sobrinho, E.M.; Passos, F.M.L. Prediction of fermentative parameters from mathematical modeling using thermotolerant probiotic yeast. Bioresour. Technol. Rep. 2020, 11, 100522. [Google Scholar] [CrossRef]

- Ramakrishnan, V.; Goveas, L.C.; Prakash, M.; Halami, P.M.; Narayan, B. Optimization of conditions for probiotic curd formulation by Enterococcus faecium MTCC 5695 with probiotic properties using response surface methodology. J. Food Sci. Technol. 2014, 51, 3050–3060. [Google Scholar] [CrossRef][Green Version]

- Zhang, L.; Fang, Q.; Huang, D.; Liu, Y.; Zeng, Y.; Xie, Y.; Luo, J. Anaerobic fermentation of peanut meal to produce even-chain volatile fatty acids using Saccharomyces cerevisiae inoculum. Environ. Technol. 2021, 42, 3820–3831. [Google Scholar] [CrossRef]

- Zheng, Z.; Ali, A.; Su, J.; Huang, T.; Wang, Y.; Zhang, S. Fungal pellets immobilized bacterial bioreactor for efficient nitrate removal at low C/N wastewater. Bioresour. Technol. 2021, 332, 125113. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Zhao, J.; Chu, J.; Wang, Y.; Zhuang, Y. Statistical Optimizing of Medium for Clavulanic Acid Production by Streptomyces clavuligerus Using Response Surface Methodology. Appl. Biochem. Biotechnol. 2021, 193, 3936–3948. [Google Scholar] [CrossRef]

- Shimada, T.; Nakazawa, K.; Tachikawa, T.; Saito, N.; Niwa, T.; Taguchi, H.; Tanaka, K. Acetate overflow metabolism regulates a major metabolic shift after glucose depletion in Escherichia coli. FEBS Lett. 2021, 595, 2047–2056. [Google Scholar] [CrossRef]

- Duarte, L.S.; Matte, C.R.; Dall Cortivo, P.R.; Nunes, J.E.S.; Barsé, L.Q.; Bizarro, C.V.; Ayub, M.A.Z. Expression of Bacillus amyloliquefaciens transglutaminase in recombinant E. coli under the control of a bicistronic plasmid system in DO-stat fed-batch bioreactor cultivations. Braz. J. Microbiol. 2021, 52, 1225–1233. [Google Scholar] [CrossRef]

- Millard, P.; Enjalbert, B.; Uttenweiler-Joseph, S.; Portais, J.C.; Létisse, F. Control and regulation of acetate overflow in Escherichia coli. Elife 2021, 10, e63661. [Google Scholar] [CrossRef]

- Renilla, S.; Bernal, V.; Fuhrer, T.; Castaño-Cerezo, S.; Pastor, J.M.; Iborra, J.L.; Sauer, U.; Cánovas, M. Acetate scavenging activity in Escherichia coli: Interplay of acetyl–CoA synthetase and the PEP–glyoxylate cycle in chemostat cultures. Appl. Microbiol. Biotechnol. 2012, 93, 2109–2124. [Google Scholar] [CrossRef] [PubMed]

- Kilikian, B.V.; Suárez, I.D.; Liria, C.W.; Gombert, A.K. Process strategies to improve heterologous protein production in Escherichia coli under lactose or IPTG induction. Process. Biochem. 2000, 35, 1019–1025. [Google Scholar] [CrossRef]

- Suárez, D.C.; Kilikian, B.V. Acetic acid accumulation in aerobic growth of recombinant Escherichia coli. Process. Biochem. 2000, 35, 1051–1055. [Google Scholar] [CrossRef]

- Tian, H.; Tang, L.; Wang, Y.; Wang, X.; Guan, L.; Zhang, J.; Wu, X.; Li, X. Lactose Induction Increases Production of Recombinant Keratinocyte Growth Factor-2 in Escherichia coli. Int. J. Pept. Res. Ther. 2011, 17, 123–129. [Google Scholar] [CrossRef]

- Bashir, H.; Ahmed, N.; Khan, M.A.; Zafar, A.U.; Tahir, S.; Khan, M.I.; Khan, F.; Husnain, T. Simple procedure applying lactose induction and one-step purification for high-yield production of rhCIFN. Biotechnol. Appl. Biochem. 2016, 63, 708–714. [Google Scholar] [CrossRef]

- Barros, T.; Brumano, L.; Freitas, M.; Pessoa, A.; Parachin, N.; Magalhães, P.O. Development of Processes for Recombinant L-Asparaginase II Production by Escherichia coli Bl21 (De3): From Shaker to Bioreactors. Pharmaceutics 2020, 13, 14. [Google Scholar] [CrossRef] [PubMed]

- Von Den Eichen, N.; Bromig, L.; Sidarava, V.; Marienberg, H.; Weuster-Botz, D. Automated multi-scale cascade of parallel stirred-tank bioreactors for fast protein expression studies. J. Biotechnol. 2021, 332, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Chua, L.H.; Tan, S.C.; Liew, M.W.O. Process intensification of core streptavidin production through high-cell-density cultivation of recombinant E. coli and a temperature-based refolding method. J. Biotechnol. 2018, 276–277, 34–41. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, X.; Shen, Z.; Su, E.; Zhao, L.; Pei, J. Efficient production of aggregation prone 4-α-glucanotransferase by combined use of molecular chaperones and chemical chaperones in Escherichia coli. J. Biotechnol. 2019, 292, 68–75. [Google Scholar] [CrossRef]

- Cardoso, V.M.; Paredes, S.A.H.; Campani, G.; Gonçalves, V.M.; Zangirolami, T.C. ClearColi as a platform for untagged pneumococcal surface protein A production: Cultivation strategy, bioreactor culture, and purification. Appl. Microbiol. Biotechnol. 2022, 106, 1011–1029. [Google Scholar] [CrossRef]

- Peng, S.; Song, J.; Zeng, W.; Wang, H.; Zhang, Y.; Xin, J.; Suo, H. A broad-spectrum novel bacteriocin produced by Lactobacillus plantarum SHY 21–2 from yak yogurt: Purification, antimicrobial characteristics and antibacterial mechanism. LWT 2021, 142, 110955. [Google Scholar] [CrossRef]

- Kojima, K.; Sudo, Y. Expression of microbial rhodopsins in Escherichia coli and their extraction and purification using styrene-maleic acid copolymers. STAR Protoc. 2022, 3, 101046. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Wang, X.; Zhang, T.; Jiang, B.; Mu, W. Characterization of a thermostable inulin fructotransferase from Clostridium clostridioforme AGR2157 that produces difructose dianhydride I from inulin. J. Mol. Catal. B Enzym. 2015, 120, 16–22. [Google Scholar] [CrossRef]

- Cheng, J.; Randall, A.Z.; Sweredoski, M.J.; Baldi, P. SCRATCH: A protein structure and structural feature prediction server. Nucleic Acids Res. 2005, 33, W72–W76. [Google Scholar] [CrossRef]

- Yang, J.; Yan, R.; Roy, A.; Xu, D.; Poisson, J.; Zhang, Y. The I-TASSER Suite: Protein structure and function prediction. Nat. Methods 2015, 12, 7–8. [Google Scholar] [CrossRef]

| Gene Name | Sequence Type | Express Cloning Vector | System | Cell | Bioreactor | Induction | Yield Coefficient | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| µ (h−1) | P (mmol/mL) | YX/S (g/mmol·mL) | YP/S ((mmol/mL)(mmol/mL)−1) | QP (mmol/mL·h) | QX (g/mL·h) | |||||||

| Alpha-toxin (de3/Ep1) | Protein | pRSET A | batch | DE3 | Lab-scale 1 L | Lactose | 0.24 | 0.56 | 30.46 | 0.26 | 0.03 | 8.49 |

| fed-batch | DE3 | Lab-scale 1 L | Lactose | 0.28 | 0.56 | 62.07 | 0.35 | 0.03 | 12.49 | |||

| Alpha-toxin (de3/Ep2) | Protein | pRSET A | batch | DE3 | Lab-scale 1 L | Lactose | 0.25 | 0.61 | 34.35 | 0.29 | 0.03 | 9.15 |

| fed-batch | DE3 | Lab-scale 1 L | Lactose | 0.29 | 0.61 | 61.28 | 0.37 | 0.04 | 12.73 | |||

| Gene Name | Sequence Type | Express Cloning Vector | System | Cell | Bioreactor | Induction | Yield Coefficient | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| µ (h−1) | P (mmol/mL) | YX/S (g/mmol·mL) | YP/S ((mmol/mL)(mmol/mL)−1) | QP (mmol/mL·h) | QX (g/mL·h) | |||||||

| Alpha-toxin (de3/Ep1) | Protein | pRSET A | fed-batch | DE3 | Scale-up 20 L | Lactose/IPTG | 0.30 | 0.56 | 65.76 | 0.36 | 0.04 | 12.97 |

| Alpha-toxin (de3/Ep2) | Protein | pRSET A | fed-batch | DE3 | Scale-up 20 L | Lactose/IPTG | 0.31 | 0.61 | 71.85 | 0.38 | 0.04 | 14.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Félix, M.K.C.; Deusdará, T.T.; Brito, H.S.; Santos, G.R.; Leite, E.R.T.; Chapla, V.M.; Viana, K.F.; Brandi, I.V.; de Almeida, M.E.M.; Mariúba, L.A.M.; et al. Optimization of the Production of Vaccine Epitopes from Clostridium novyi Alpha-Toxin Using Strains of Recombinant Escherichia coli. Microorganisms 2025, 13, 1481. https://doi.org/10.3390/microorganisms13071481

Félix MKC, Deusdará TT, Brito HS, Santos GR, Leite ERT, Chapla VM, Viana KF, Brandi IV, de Almeida MEM, Mariúba LAM, et al. Optimization of the Production of Vaccine Epitopes from Clostridium novyi Alpha-Toxin Using Strains of Recombinant Escherichia coli. Microorganisms. 2025; 13(7):1481. https://doi.org/10.3390/microorganisms13071481

Chicago/Turabian StyleFélix, Mellanie K. C., Tullio T. Deusdará, Hélio S. Brito, Gil R. Santos, Eduardo R. T. Leite, Vanessa M. Chapla, Kelvinson F. Viana, Igor V. Brandi, Maria Edilene M. de Almeida, Luis André M. Mariúba, and et al. 2025. "Optimization of the Production of Vaccine Epitopes from Clostridium novyi Alpha-Toxin Using Strains of Recombinant Escherichia coli" Microorganisms 13, no. 7: 1481. https://doi.org/10.3390/microorganisms13071481

APA StyleFélix, M. K. C., Deusdará, T. T., Brito, H. S., Santos, G. R., Leite, E. R. T., Chapla, V. M., Viana, K. F., Brandi, I. V., de Almeida, M. E. M., Mariúba, L. A. M., Nogueira, P. A., da Silva, E. F., Glória, J. C., da Silva, R. S. R., Braga, D. d. S., de Lima, A. M., Soares, A. M., & Cangussu, A. S. R. (2025). Optimization of the Production of Vaccine Epitopes from Clostridium novyi Alpha-Toxin Using Strains of Recombinant Escherichia coli. Microorganisms, 13(7), 1481. https://doi.org/10.3390/microorganisms13071481