Multi-Method Combined Screening of Agarase-Secreting Fungi from Sea Cucumber and Preliminary Analyses on Their Agarases and Agar-Oligosaccharide Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Strains and Materials

2.2. Preliminary Screening and Identification of Agarase-Secreting Strains

2.3. Amplification, Sequencing, and Phylogenetic Analysis of the ITS rDNA

2.4. Agarase Activity Assay

2.4.1. DNS Method

2.4.2. Gram’s Iodine Method

2.5. SDS-PAGE and Agarase Zymogram Assay

2.6. Preparation and Identification of Enzymolytic Products

2.6.1. Thin-Layer Chromatography (TLC)

2.6.2. High-Performance Liquid Chromatography (HPLC)

2.7. Characterization of Crude Agarase Enzyme of Strain ACD-11-B

2.8. Statistical Analyses

3. Results

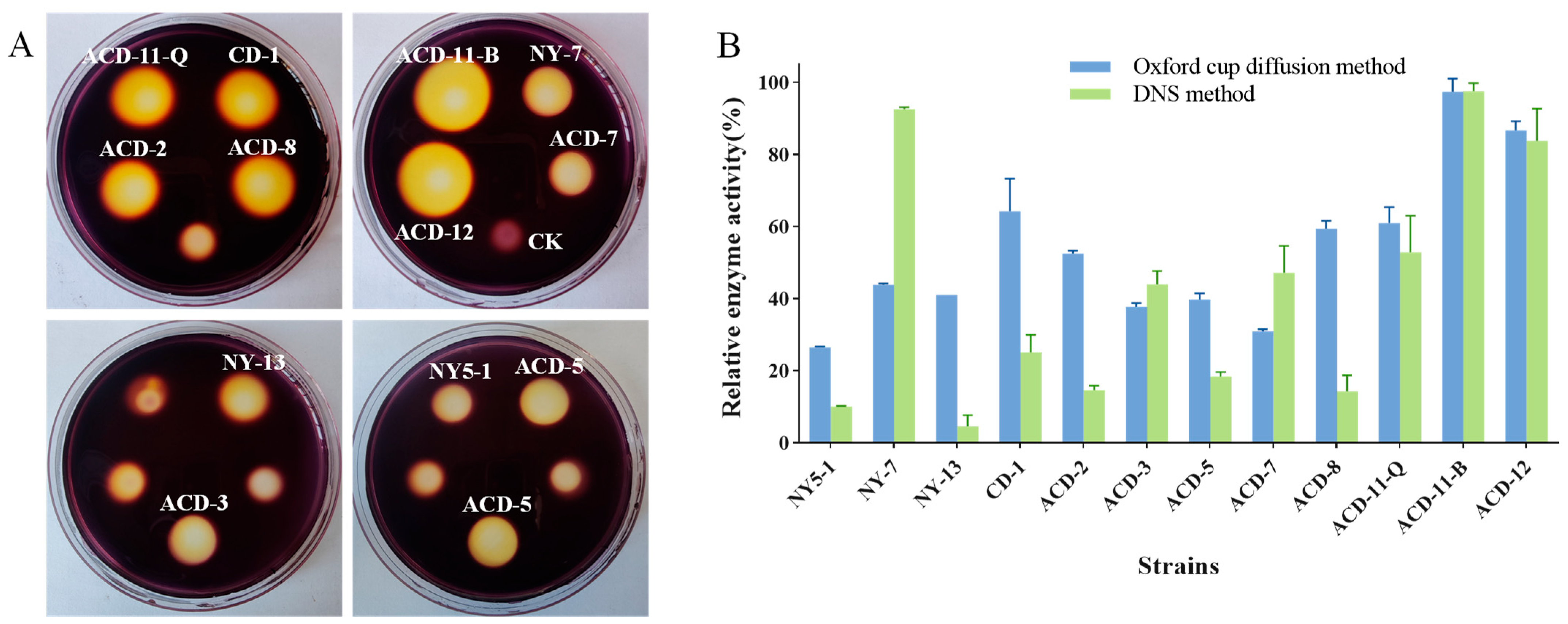

3.1. Screening and Identification of Agarase-Secreting Strains

3.2. Evaluation of Agarase Activities

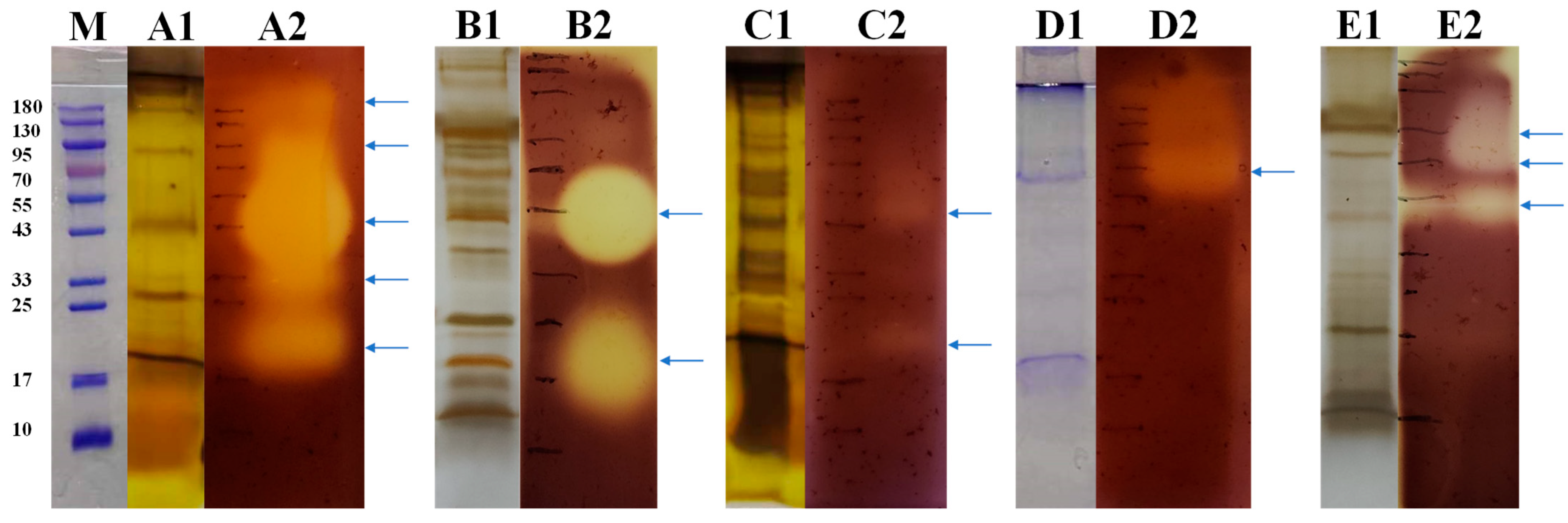

3.3. Profiles of Agarase Produced by the Strains

3.4. Agar Enzymolytic Product Analysis of Agarase-Secreting Strains

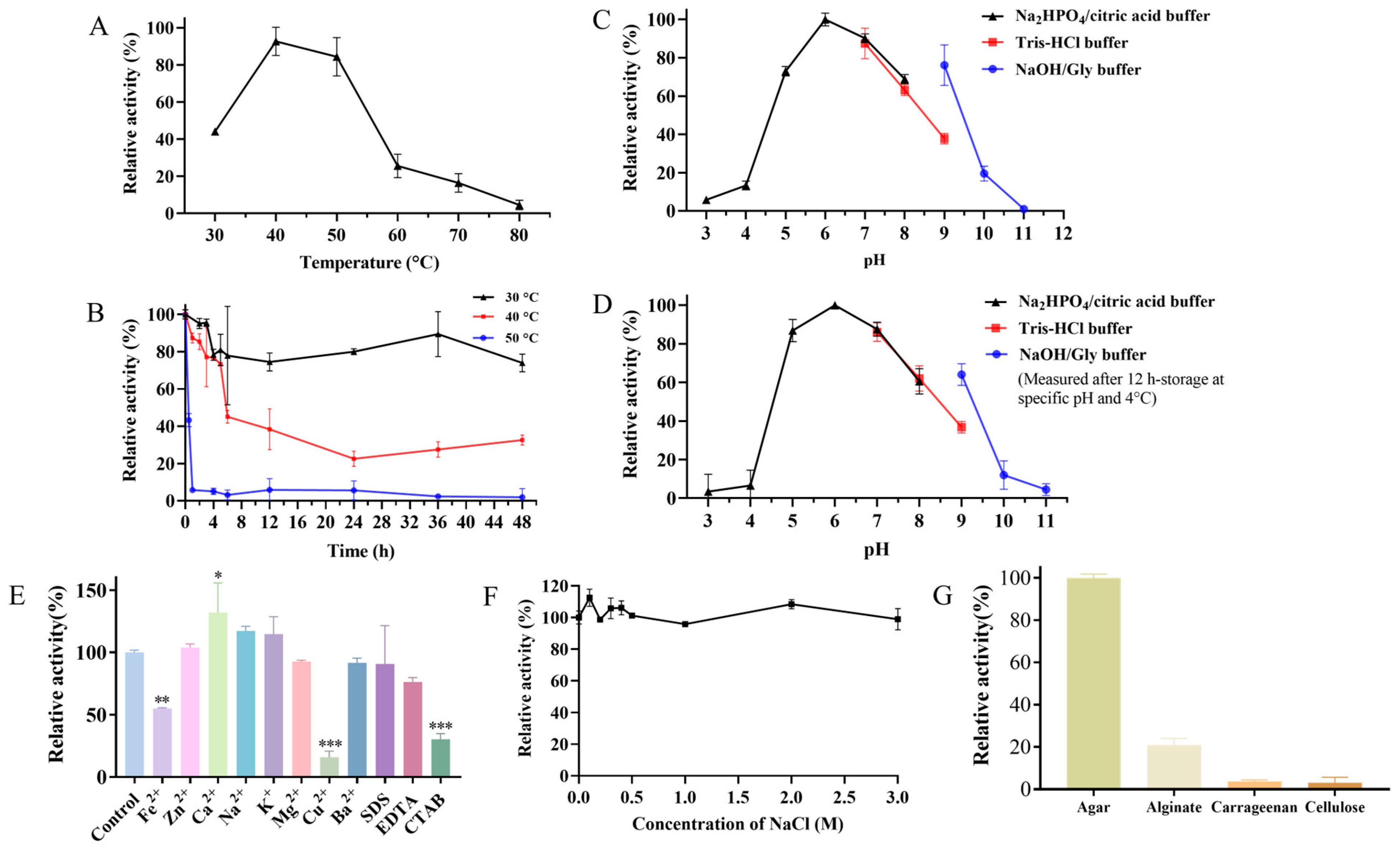

3.5. Characterization of Crude Agarase Enzyme of Strain ACD-11-B

| Source | Protein | Molecular Weight (kDa) | Optimal Temp./pH | Temp./pH Stability a | Metal Ions/ Chemical Agents b | Main Product | Refs. |

|---|---|---|---|---|---|---|---|

| Stenotrophomonas sp. NTa | N.D. c | 89.0 | 40 °C/10.0 | 20 °C/30 °C, 1 h, stable; 40 °C, 1 h, 64%; 50 °C, 1 h, 46%; 60 °C, 30 min, no activity; pH 5.0–11.0, >65%; | K+, Mg2+, Ba2+, Ca2+, Na+ | NA2, NA4, NA6 | [36] |

| Thalassomonas sp. LD5 | AgaD | 180 | 35 °C/7.4 | <30 °C/>45 °C, >50%; | Ca2+ | NA4 | [37] |

| Vibrio Natriegens WPAGA4 | rAga3420 | 100 | 40 °C/7.0 | 10 °C/0 °C, 59.7%/41.2%; 10–30 °C, 50 min, good stability; | Mg2+, Fe2+, Fe3+, Ca2+, Mn2+, Cu2+, K+, DTT | NA2 | [38] |

| Catenovulum sp. X3 | AgaXa | 52 | 52 °C/7.4 | <42 °C, >95%; pH 5.0–9.0, 12 h, 85%; | DDT, β-met, Mg2+ | DP4, DP6, DP8 | [39] |

| Shewanella sp. WPAGA9 | AgaW1540 | 50 | 35 °C/7.0 | 20 °C, 1 h, 94.7%; 25 °C, 1 h, 97.9%; | Ba2+, Mn2+, Ni2+, K+, Ga2+, Sr2+, Ag+, Cr2+, Fe2+, EDTA | NA4, NA6 | [40] |

| Alteromonas sp. SY37-12 | N.D. | 39.5 | 35 °C/7.0 | 50 °C, 15 min, no activity; 70 °C, 1 min, no activity; | Na+ | NA4, NA6 | [41] |

| Thalassomonas sp. LD5 | AgaE | 97 | 35 °C/7.0 | 50 °C, 10 min, no activity; | Na+ | NA4, NA6 | [42] |

| D. arenaria Nicot | N.D. | N.D. | 40 °C/7.0 | 40 °C/50 °C; 30 min; >75%; 40 °C/50 °C,1 h, 65.74%/55.46%; pH 4–10, >75%; | N.D. | N.D. | [26] |

| Agarivorans albus YKW-34 | AgaA34 | 50 | 40 °C/8.0 | pH 6.0–11.0, 1 h, >80%;50 °C, 1 h, >95%; | β-Me, DTT | NA2, NA4 | [43] |

| Microbulbifer sp. BN3 | N3-1 | 34.3 | 50 °C/6.0 | pH 4.0–9.0, >70%; 30–60 °C, 30 min, >40%; | K+, Na+, Mg2+ | NA2, NA4 | [44] |

| Aspergillus Sydowii ACD-11-B | Crude enzyme | N.D. | 40 °C/6.0 | 30 °C, 48 h, >70%; pH 5.9–9.0, 12 h, >60% | K+, Ca2+, Na+ | NA2 | This study |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chi, W.J.; Chang, Y.K.; Hong, S.K. Agar degradation by microorganisms and agar-degrading enzymes. Appl. Microbiol. Biotechnol. 2012, 94, 917–930. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.T.; Kim, S.M. Agarase: Review of major sources, categories, purification method, enzyme characteristics and applications. Mar. Drugs 2010, 8, 200–218. [Google Scholar] [CrossRef] [PubMed]

- Torres, M.D.; Flórez-Fernández, N.; Domínguez, H. Integral utilization of red seaweed for bioactive production. Mar. Drugs 2019, 17, 314. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.R.; Hong, S.K. Implications of agar and agarase in industrial applications of sustainable marine biomass. Appl. Microbiol. Biotechnol. 2020, 104, 2815–2832. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Jiang, C.; Mao, X. Biochemical characterization and substrate degradation mode of a novel α-agarase from Catenovulum agarivorans. J. Agric. Food Chem. 2019, 67, 10373–10379. [Google Scholar] [CrossRef]

- Cheong, K.-L.; Qiu, H.-M.; Du, H.; Liu, Y.; Khan, B. Oligosaccharides derived from red seaweed: Production, properties, and potential health and cosmetic applications. Molecules 2018, 23, 2451. [Google Scholar] [CrossRef] [PubMed]

- Yun, E.J.; Yu, S.; Kim, Y.A.; Liu, J.J.; Kang, N.J.; Jin, Y.S.; Kim, K.H. In vitro prebiotic and anti-colon cancer activities of agar-derived sugars from red seaweeds. Mar. Drugs 2021, 19, 213. [Google Scholar] [CrossRef]

- Kang, O.L.; Ghani, M.; Hassan, O.; Rahmati, S.; Ramli, N. Novel agaro-oligosaccharide production through enzymatic hydrolysis: Physicochemical properties and antioxidant activities. Food Hydrocoll. 2014, 42, 304–308. [Google Scholar] [CrossRef]

- Gu, X.; Zhao, L.; Tan, J.; Zhang, Q.; Fu, L.; Li, J. Characterization of a novel β-agarase from Antarctic macroalgae-associated bacteria metagenomic library and anti-inflammatory activity of the enzymatic hydrolysates. Front. Microbiol. 2022, 13, 972272. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, W.; Hao, C.; Mao, X. Agaropentaose protects SH-SY5Y cells against 6-hydroxydopamine-induced neurotoxicity through modulating NF-κB and p38MAPK signaling pathways. J. Funct. Foods 2019, 57, 222–232. [Google Scholar] [CrossRef]

- Qu, W.; Wang, D.; Wu, J.; Chan, Z.; Di, W.; Wang, J.; Zeng, R. Production of neoagaro-oligosaccharides with various degrees of polymerization by using a truncated marine agarase. Front. Microbiol. 2020, 11, 574771. [Google Scholar] [CrossRef] [PubMed]

- Rhee, Y.J.; Han, C.R.; Kim, W.C.; Jun, D.Y.; Rhee, I.K.; Kim, Y.H. Isolation of a novel freshwater agarolytic Cellvibrio sp. KY-YJ-3 and characterization of its extracellular beta-agarase. J. Microbiol. Biotechnol. 2010, 20, 1378–1385. [Google Scholar] [CrossRef]

- Jung, S.; Jeong, B.C.; Hong, S.K.; Lee, C.R. Cloning, expression, and biochemical characterization of a novel acidic GH16 β-Agarase, AgaJ11, from Gayadomonas joobiniege G7. Appl. Biochem. Biotechnol. 2017, 181, 961–971. [Google Scholar] [CrossRef]

- Hu, Z.; Lin, B.K.; Xu, Y.; Zhong, M.Q.; Liu, G.M. Production and purification of agarase from a marine agarolytic bacterium Agarivorans sp. HZ105. J. Appl. Microbiol. 2009, 106, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Di, W.; Qu, W.; Zeng, R. Cloning, expression, and characterization of thermal-stable and pH-stable agarase from mangrove sediments. J. Basic Microbiol. 2018, 58, 302–309. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Rui, J.; Du, Z.; Xue, C.; Li, X.; Mao, X. Complete genome sequence of Agarivorans gilvus WH0801T, an agarase-producing bacterium isolated from seaweed. J. Biotechnol. 2016, 219, 22–23. [Google Scholar] [CrossRef]

- Lee, Y.; Jo, E.; Lee, Y.J.; Eom, T.Y.; Gang, Y.; Kang, Y.H.; Marasinghe, S.D.; Hettiarachchi, S.A.; Kang, D.H.; Oh, C. A novel agarase, Gaa16B, isolated from the marine bacterium Gilvimarinus agarilyticus JEA5, and the moisturizing effect of its partial hydrolysis products. Mar. Drugs 2021, 20, 2. [Google Scholar] [CrossRef]

- Cui, X.; Jiang, Y.; Chang, L.; Meng, L.; Yu, J.; Wang, C.; Jiang, X. Heterologous expression of an agarase gene in Bacillus subtilis, and characterization of the agarase. Int. J. Biol. Macromol. 2018, 120, 657–664. [Google Scholar] [CrossRef]

- Jiang, C.; Liu, Z.; Cheng, D.; Mao, X. Agarose degradation for utilization: Enzymes, pathways, metabolic engineering methods and products. Biotechnol. Adv. 2020, 45, 107641. [Google Scholar] [CrossRef]

- Sun, H.; Gao, L.; Xue, C.; Mao, X. Marine-polysaccharide degrading enzymes: Status and prospects. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2767–2796. [Google Scholar] [CrossRef]

- Pathiraja, D.; Christiansen, L.; Park, B.; Schultz-Johansen, M.; Bang, G.; Stougaard, P.; Choi, I.G. A novel auxiliary agarolytic pathway expands metabolic versatility in the agar-degrading marine bacterium Colwellia echini A3T. Appl. Environ. Microbiol. 2021, 87, e0023021. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Ye, Z.; Li, X.; Tian, Y.; Bai, Y.; Chen, L.; Qiu, C.; Xie, Z.; Jin, Z.; Svensson, B. Enzymatic preparation and potential applications of agar oligosaccharides: A review. Crit. Rev. Food Sci. Nutr. 2022, 64, 5818–5834. [Google Scholar] [CrossRef] [PubMed]

- Lu, T. Metabolomic-Genomic Mining of Metabolites Produced by Marine Symbiotic Fungi from Holothuria scabra. Master’s Thesis, Guangdong Ocean University, Zhanjiang, China, 2023. [Google Scholar]

- Wang, M.; Chen, L.; Zhang, Z.; Wang, X.; Qin, S.; Yan, P. Screening of alginate lyase-excreting microorganisms from the surface of brown algae. AMB Express 2017, 7, 74. [Google Scholar] [CrossRef]

- Lu, T.; Liu, Y.; Zhou, L.; Liao, Q.; Nie, Y.; Wang, X.; Lei, X.; Hong, P.; Feng, Y.; Hu, X.; et al. The screening for marine fungal strains with high potential in alkaloids production by in situ colony assay and LC-MS/MS based secondary metabolic profiling. Front. Microbiol. 2023, 14, 1144328. [Google Scholar] [CrossRef]

- Gomaa, M.; Hifney, A.F.; Fawzy, M.A.; Abdel-Gawad, K.M. Statistical optimization of culture variables for enhancing agarase production by Dendryphiella arenaria utilizing Palisada perforata (Rhodophyta) and enzymatic saccharification of the macroalgal biomass. Mar. Biotechnol. 2017, 19, 592–600. [Google Scholar] [CrossRef]

- Lee, Y.R.; Jung, S.; Chi, W.J.; Bae, C.H.; Jeong, B.C.; Hong, S.K.; Lee, C.R. Biochemical characterization of a novel GH86 β-agarase producing neoagarohexaose from Gayadomonas joobiniege G7. J. Microbiol. Biotechnol. 2018, 28, 284–292. [Google Scholar] [CrossRef]

- Chen, X.; Lin, H.; Jin, M.; Zeng, R.; Lin, M. Characterization of a novel alkaline β-agarase and its hydrolysates of agar. Food Chem. 2019, 295, 311–319. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Song, X.N.; Lin, Y.; Xiao, Q.; Du, X.P.; Chen, Y.H.; Xiao, A.F. Antioxidant capacity and prebiotic effects of Gracilaria neoagaro oligosaccharides prepared by agarase hydrolysis. Int. J. Biol. Macromol. 2019, 137, 177–186. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Chen, P.; Zeng, Y.; Yang, J.; Men, Y.; Zhu, Y.; Sun, Y. Production of neoagarobiose from agar through a dual-enzyme and two-stage hydrolysis strategy. Int. J. Biol. Macromol. 2020, 160, 288–295. [Google Scholar] [CrossRef]

- Li, J. Screening of Agar-Degrading Bacteria and Characterization of Agarase. Master’s Thesis, Jiangnan University, Wuxi, China, 2020. [Google Scholar]

- Pu, J.; Zhao, X.; Wang, Q.; Wang, Y.; Zhou, H. Development and validation of a HPLC method for determination of degree of polymerization of xylo-oligosaccharides. Food Chem. 2016, 213, 654–659. [Google Scholar] [CrossRef]

- Yoon, S.Y.; Chae, G.H.; Jang, S.W.; Suh, J.Y.; Kong, K.H. A quantitative assay for agarase activity determination using agarose-iodine complex. Anal. Biochem. 2022, 641, 114560. [Google Scholar] [CrossRef] [PubMed]

- Sawant, S.S.; Salunke, B.K.; Kim, B.S. A rapid, sensitive, simple plate assay for detection of microbial alginate lyase activity. Enzyme Microb. Technol. 2015, 77, 813. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.P.; Cao, M.; Li, B.; Ji, X.F.; Zhang, X.Y.; Zhang, Y.Q.; Wang, H.Y. Cloning, secretory expression and characterization of a unique pH-stable and cold-adapted alginate lyase. Mar. Drugs 2020, 18, 189. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, R.; Xiao, A.; Li, L.; Jiang, Z.; Chen, F.; Ni, H. Characterization of an alkaline β-agarase from Stenotrophomonas sp. NTa and the enzymatic hydrolysates. Int. J. Biol. Macromol. 2016, 86, 525–534. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J.; Liu, D.; Liu, H.; Lu, X.; Yu, W. Characterization of an α-agarase from Thalassomonas sp. LD5 and its hydrolysate. Appl. Microbiol. Biotechnol. 2018, 102, 2203–2212. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Wang, J.; Zeng, R.; Wang, D.; Wang, W.; Tong, X.; Qu, W. Agarose-degrading characteristics of a deep-sea bacterium Vibrio Natriegens WPAGA4 and its cold-adapted GH50 agarase Aga3420. Mar. Drugs 2022, 20, 692. [Google Scholar] [CrossRef]

- Xie, W.; Lin, B.; Zhou, Z.; Lu, G.; Lun, J.; Xia, C.; Li, S.; Hu, Z. Characterization of a novel β-agarase from an agar-degrading bacterium Catenovulum sp. X3. Appl. Microbiol. Biotechnol. 2013, 97, 4907–4915. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Yan, R.; Zeng, R.; Zuo, Y.; Wang, D.; Qu, W. Expression and characterization of a novel cold-adapted and stable β-agarase gene agaW1540 from the deep-sea bacterium Shewanella sp. WPAGA9. Mar. Drugs 2021, 19, 431. [Google Scholar] [CrossRef]

- Wang, J.; Mou, H.; Jiang, X.; Guan, H. Characterization of a novel beta-agarase from marine Alteromonas sp. SY37-12 and its degrading products. Appl. Microbiol. Biotechnol. 2006, 71, 833–839. [Google Scholar] [CrossRef]

- Xu, J.; Cui, Z.; Zhang, W.; Lu, J.; Lu, X.; Yu, W. Characterizing of a new α-agarase AgaE from Thalassomonas sp. LD5 and probing its catalytically essential residues. Int. J. Biol. Macromol. 2022, 194, 50–57. [Google Scholar] [CrossRef]

- Fu, X.T.; Lin, H.; Kim, S.M. Purification and characterization of a novel beta-agarase, AgaA34, from Agarivorans albus YKW-34. Appl. Microbiol. Biotechnol. 2008, 78, 265–273. [Google Scholar] [CrossRef] [PubMed]

- Li, R.K.; Chen, Z.; Ying, X.J.; Ng, T.B.; Ye, X.Y. A novel GH16 beta-agarase isolated from a marine bacterium, Microbulbifer sp. BN3 and its characterization and high-level expression in Pichia pastoris. Int. J. Biol. Macromol. 2018, 119, 1164–1170. [Google Scholar] [CrossRef]

- Wang, Q. Screening of Strains Producing Alginate Lyase, Optimization of Enzyme Production Conditions and Preliminary Study on Fermenting Sargassum horneri. Master’s Thesis, Yantai University, Yantai, China, 2021. [Google Scholar]

- Dutta, T.; Sahoo, R.; Sengupta, R.; Ray, S.S.; Bhattacharjee, A.; Ghosh, S. Novel cellulases from an extremophilic filamentous fungi Penicillium citrinum: Production and characterization. J. Ind. Microbiol. Biotechnol. 2008, 35, 275–282. [Google Scholar] [CrossRef] [PubMed]

- Miranda, O.A.; Salgueiro, A.A.; Pimentel, M.C.B.; Lima Filho, J.L.; Melo, E.H.M.; Durán, N. Lipase production by a Brazilian strain of Penicillium citrinum using an industrial residue. Bioresour. Technol. 1999, 69, 145–147. [Google Scholar] [CrossRef]

- Ren, J.; Lai, B.; Niu, D.; Wang, Z.; Hardie, W.J.; Zhi, J.; Wang, C.; Yu, Y.; Taoli, H.; Li, Z.; et al. Characterization of erythromycin-degrading strain Aspergillus sydowii W1 revealed by transcriptome analyses. Int. Biodeterior. Biodegrad. 2023, 178, 105545. [Google Scholar] [CrossRef]

- Ghosh, M.; Das, A.; Mishra, A.K.; Nanda, G. Aspergillus sydowii MG 49 is a strong producer of thermostable xylanolytic enzymes. Enzyme Microb. Technol. 1993, 15, 703–709. [Google Scholar] [CrossRef]

- Tulsani, N.J.; Jakhesara, S.J.; Hinsu, A.T.; Jyotsana, B.; Dafale, N.A.; Patil, N.V.; Purohit, H.J.; Joshi, C.G. Genome analysis and CAZy repertoire of a novel fungus Aspergillus sydowii C6d with lignocellulolytic ability isolated from camel rumen. Electron. J. Biotechnol. 2022, 59, 36–45. [Google Scholar] [CrossRef]

- Alwakeel, S.S.; Ameen, F.; Al Gwaiz, H.; Sonbol, H.; Alghamdi, S.; Moharram, A.M.; Al-Bedak, O.A. Keratinases produced by Aspergillus stelliformis, Aspergillus sydowii, and Fusarium brachygibbosum isolated from human hair: Yield and activity. J. Fungi 2021, 7, 471. [Google Scholar] [CrossRef]

- Takenaka, S.; Kato, M.; Oribe, Y.; Kimura, Y.; Tanaka, S.; Matsumoto, J.-i.; Doi, M. Exploring the potential of katsuobushi grounds as a source of bioactive peptides through fermentation with Aspergillus sydowii. Process Biochem. 2023, 130, 534–544. [Google Scholar] [CrossRef]

- Kurakake, M.; Okumura, T.; Morimoto, Y. Synthesis of galactosyl glycerol from guar gum by transglycosylation of α-galactosidase from Aspergillus sp. MK14. Food Chem. 2015, 172, 150–154. [Google Scholar] [CrossRef]

- Saravanan, P.; Chatterjee, A.; Kiran, K.J.; Bhowmick, G.D.; Sappati, P.K.; Nagarajan, V. Exploring seaweed-associated marine microbes: Growth impacts and enzymatic potential for sustainable resource utilization. Indian J. Microbiol. 2024, 64, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Yun, E.J.; Kim, D.H.; Park, S.Y.; Kim, K.H. Anticariogenic activity of agarobiose and agarooligosaccharides derived from red macroalgae. J. Agric. Food Chem. 2019, 67, 7297–7303. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liu, P.; Hao, C.; Wu, L.; Wan, W.; Mao, X. Neoagaro-oligosaccharide monomers inhibit inflammation in LPS-stimulated macrophages through suppression of MAPK and NF-κB pathways. Sci. Rep. 2017, 7, 44252. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Yang, S.; Liu, X.; Li, Y.; Gu, Z.; Jiang, Z. Dietary neoagarotetraose extends lifespan and impedes brain aging in mice via regulation of microbiota-gut-brain axis. J. Adv. Res. 2023, 52, 119–134. [Google Scholar] [CrossRef]

- Hong, S.J.; Lee, J.-H.; Kim, E.J.; Yang, H.J.; Chang, Y.-K.; Park, J.-S.; Hong, S.-K. In vitro and in vivo investigation for biological activities of neoagarooligosaccharides prepared by hydrolyzing agar with β-agarase. Biotechnol. Bioprocess Eng. 2017, 22, 489–496. [Google Scholar] [CrossRef]

- Guo, Q.; Dan, M.; Zheng, Y.; Shen, J.; Zhao, G.; Wang, D. Improving the thermostability of a novel PL-6 family alginate lyase by rational design engineering for industrial preparation of alginate oligosaccharides. Int. J. Biol. Macromol. 2023, 249, 125998. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, J.; Zhang, L.; Sun, J.; Li, Y.; Wu, L.; Zhou, J.; Xue, C.; Mao, X. Structure-based design of agarase AgWH50C from Agarivorans gilvus WH0801 to enhance thermostability. Appl. Microbiol. Biotechnol. 2019, 103, 1289–1298. [Google Scholar] [CrossRef]

- Alkotaini, B.; Han, N.S.; Kim, B.S. Enhanced catalytic efficiency of endo-β-agarase I by fusion of carbohydrate-binding modules for agar prehydrolysis. Enzyme Microb. Technol. 2016, 93–94, 142–149. [Google Scholar] [CrossRef]

| Strain ID | Isolation Position in Sea Cucumber | Accession Numbers of ITS rDNA Sequences | Closest Fungal Strain | Sequence Identity (%) | Diameter Ratio of Clearance Zone/ Colony |

|---|---|---|---|---|---|

| NY5-1 | Mucus | OM349543 | Cladosporium colombiae | 99.64% | 1.35 ± 0.01 |

| NY-7 | Mucus | OM349544 | Cladosporium halotolerans | 100.00% | 1.50 ± 0.03 |

| NY-13 | Mucus | ON384773 | Aspergillus sydowii | 99.81% | 1.57 ± 0.05 |

| CD-1 | Intestinal | PV573377 | Penicillium citrinum | 99.14% | 1.85 ± 0.03 |

| ACD-2 | Intestinal | OM349547 | Penicillium citrinum | 100.00% | 1.83 ± 0.07 |

| ACD-3 | Intestinal | ON380857 | Cladosporium tenuissimum | 100.00% | 1.64 ± 0.06 |

| ACD-5 | Intestinal | OM368350 | Penicillium mallochii | 100.00% | 1.41 ± 0.04 |

| ACD-7 | Intestinal | OM349549 | Cladosporium halotolerans | 100.00% | 1.30 ± 0.03 |

| ACD-8 | Intestinal | OM349550 | Penicillium citrinum | 100.00% | 1.66 ± 0.07 |

| ACD-11-B | Intestinal | PV573475 | Aspergillus sydowii | 99.79% | 1.98 ± 0.06 |

| ACD-11-Q | Intestinal | PV573478 | Penicillium citrinum | 100.00% | 1.83 ± 0.04 |

| ACD-12 | Intestinal | OM349552 | Aspergillus sydowii | 100.00% | 1.81 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Lu, T.; Sun, X.; Ban, F.; Zhou, L.; Liu, Y.; Feng, Y.; Zhang, Y. Multi-Method Combined Screening of Agarase-Secreting Fungi from Sea Cucumber and Preliminary Analyses on Their Agarases and Agar-Oligosaccharide Products. Microorganisms 2025, 13, 1235. https://doi.org/10.3390/microorganisms13061235

He S, Lu T, Sun X, Ban F, Zhou L, Liu Y, Feng Y, Zhang Y. Multi-Method Combined Screening of Agarase-Secreting Fungi from Sea Cucumber and Preliminary Analyses on Their Agarases and Agar-Oligosaccharide Products. Microorganisms. 2025; 13(6):1235. https://doi.org/10.3390/microorganisms13061235

Chicago/Turabian StyleHe, Shuting, Tiantian Lu, Xiaoyu Sun, Fangfang Ban, Longjian Zhou, Yayue Liu, Yan Feng, and Yi Zhang. 2025. "Multi-Method Combined Screening of Agarase-Secreting Fungi from Sea Cucumber and Preliminary Analyses on Their Agarases and Agar-Oligosaccharide Products" Microorganisms 13, no. 6: 1235. https://doi.org/10.3390/microorganisms13061235

APA StyleHe, S., Lu, T., Sun, X., Ban, F., Zhou, L., Liu, Y., Feng, Y., & Zhang, Y. (2025). Multi-Method Combined Screening of Agarase-Secreting Fungi from Sea Cucumber and Preliminary Analyses on Their Agarases and Agar-Oligosaccharide Products. Microorganisms, 13(6), 1235. https://doi.org/10.3390/microorganisms13061235