Genomic Diversity, Competition, and Toxin Production by Group I and II Clostridium botulinum Strains Used in Food Challenge Studies

Abstract

1. Introduction

2. Materials and Methods

2.1. Biosafety and Ethics

2.2. Bacterial Strains and Growth Conditions

2.3. Whole Genome Sequencing

2.4. Core Genome SNP Analysis and Phylogeny

2.5. Strain Inhibition Testing

2.6. Toxin Production Testing

2.7. Specific Toxin Activity Determination of BoNT/B4 and BoNT/E3

3. Results

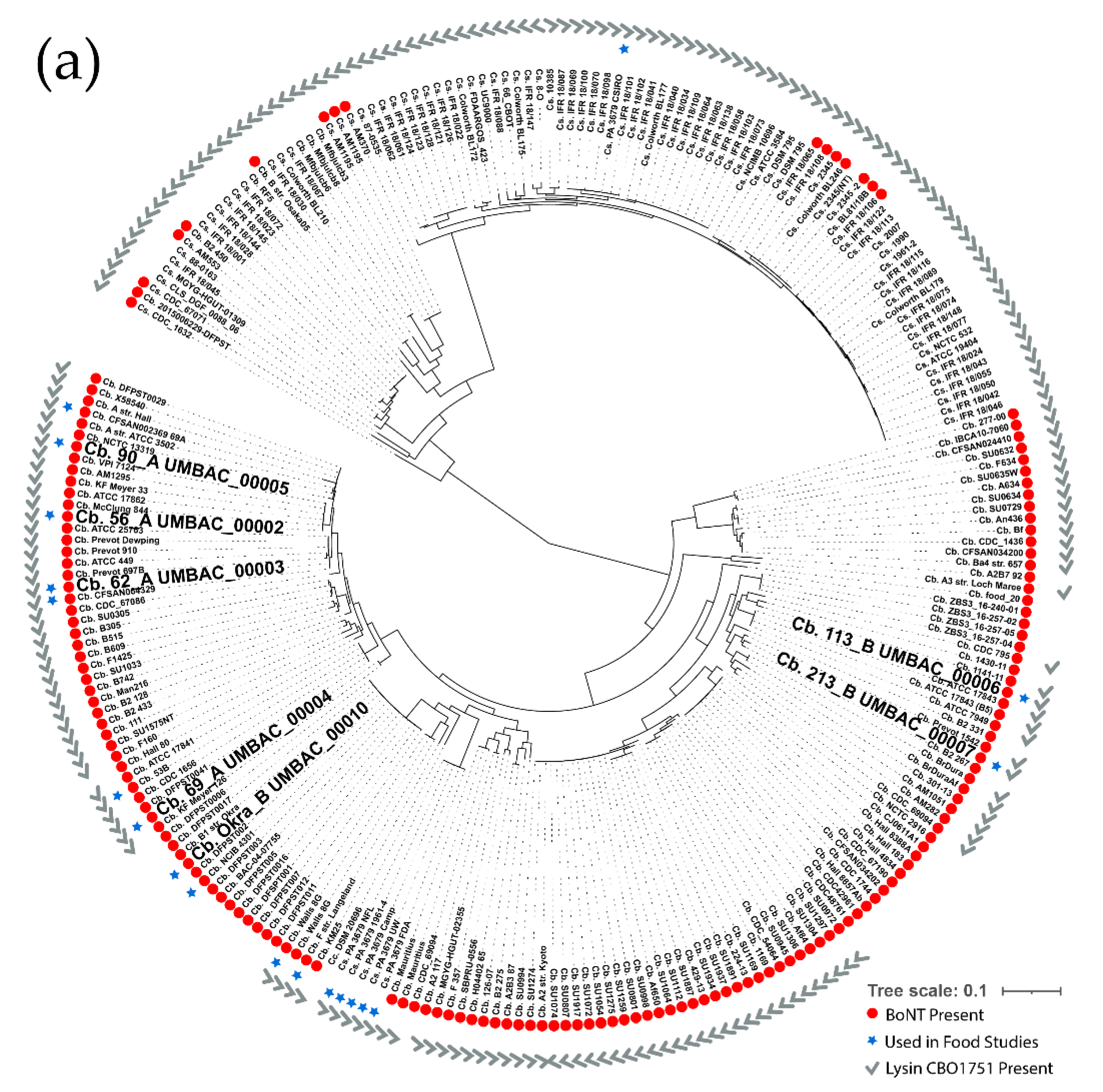

3.1. Phylogenetic Analysis of Cocktail Strains Indicates Some Lineages of Toxigenic Clostridium Are Not Represented

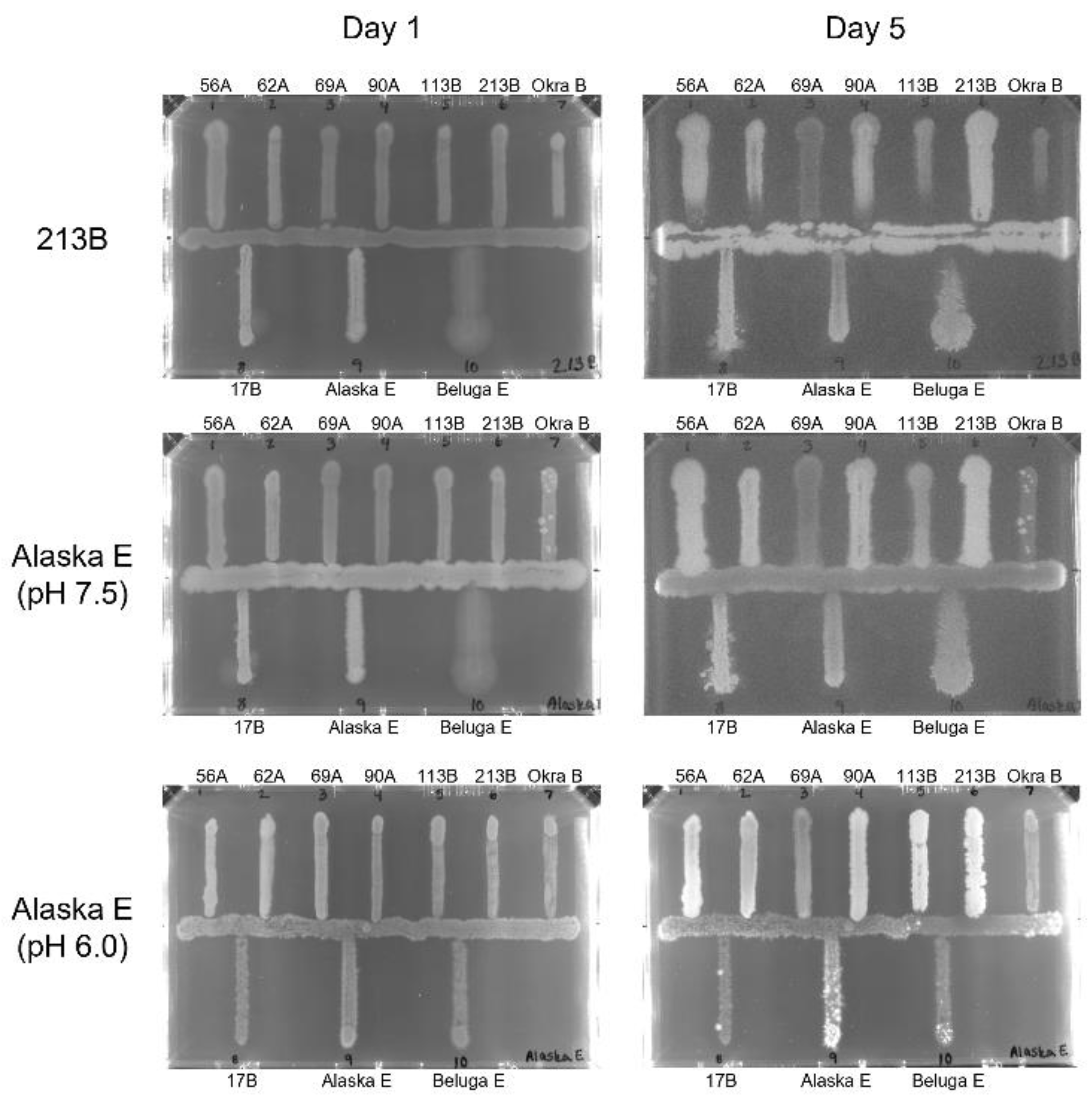

3.2. Several Group I and Group II C. botulinum Strains Display Antagonistic Growth Behavior

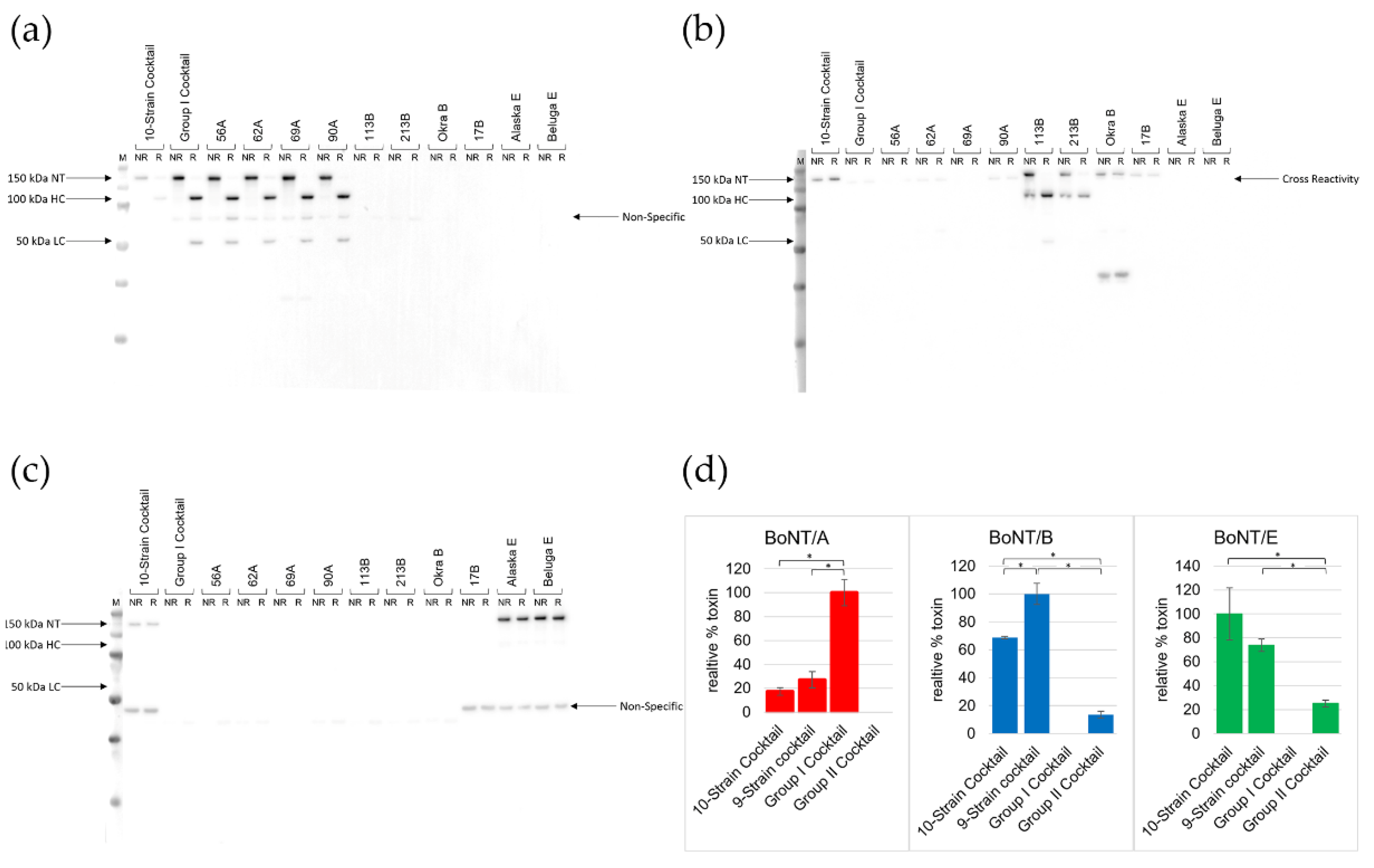

3.3. A 10-Strain Cocktail Combining Group I and Group II Strains Produces High Levels of Toxin in Spite of Competition

3.4. BoNT/E1 and/E3 Have Similar Specific Activities, While BoNT/B4 Has Reduced Activity Compared to BoNT/B1

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peck, M.W.; Smith, T.J.; Anniballi, F.; Austin, J.W.; Bano, L.; Bradshaw, M.; Cuervo, P.; Cheng, L.W.; Derman, Y.; Dorner, B.G.; et al. Historical Perspectives and Guidelines for Botulinum Neurotoxin Subtype Nomenclature. Toxins 2017, 9, 38. [Google Scholar] [CrossRef] [PubMed]

- Schantz, E.J.; Johnson, E.A. Properties and use of botulinum toxin and other microbial neurotoxins in medicine. Microbiol. Rev. 1992, 56, 80–99. [Google Scholar] [CrossRef] [PubMed]

- Carter, A.T.; Peck, M.W. Genomes, neurotoxins and biology of Clostridium botulinum Group I and Group II. Res. Microbiol. 2015, 166, 303–317. [Google Scholar] [CrossRef]

- Inzalaco, H.N.t.; Tepp, W.H.; Fredrick, C.; Bradshaw, M.; Johnson, E.A.; Pellett, S. Posttranslational Regulation of Botulinum Neurotoxin Production in Clostridium botulinum Hall A-hyper. mSphere 2021, 6, e0032821. [Google Scholar] [CrossRef] [PubMed]

- Johnson, E.A.; Montecucco, C. Chapter 11 Botulism. In Handbook of Clinical Neurology; Elsevier: Amsterdam, The Netherlands, 2008; Volume 91, pp. 333–368. [Google Scholar]

- Shapiro, R.L.; Hatheway, C.; Swerdlow, D.L. Botulism in the United States: A Clinical and Epidemiologic Review. Ann. Intern. Med. 1998, 129, 221–228. [Google Scholar] [CrossRef] [PubMed]

- Rasetti-Escargueil, C.; Lemichez, E.; Popoff, M.R. Public Health Risk Associated with Botulism as Foodborne Zoonoses. Toxins 2019, 12, 17. [Google Scholar] [CrossRef]

- Lúquez, C.; Edwards, L.; Griffin, C.; Sobel, J. Foodborne Botulism Outbreaks in the United States, 2001–2017. Front. Microbiol. 2021, 12, 1982. [Google Scholar] [CrossRef] [PubMed]

- Peck, M.W.; Stringer, S.C.; Carter, A.T. Clostridium botulinum in the post-genomic era. Food Microbiol. 2011, 28, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Botulism in the United States, 1899–1996; Handbook for Epidemiologists, Clinicians, and Laboratory Workers; U.S. Dept. of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Center for Infectious Diseases, Division of Bacterial and Mycotic Diseases, CDC Stacks: Washington, DC, USA, 1998.

- Collins, M.D.; Lawson, P.A.; Willems, A.; Cordoba, J.J.; Fernandez-Garayzabal, J.; Garcia, P.; Cai, J.; Hippe, H.; Farrow, J.A.E. The Phylogeny of the Genus Clostridium: Proposal of Five New Genera and Eleven New Species Combinations. Int. J. Syst. Evol. Microbiol. 1994, 44, 812–826. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.K.; Xie, G.; Foley, B.T.; Smith, T.J. Genetic diversity within the botulinum neurotoxin-producing bacteria and their neurotoxins. Toxicon 2015, 107, 2–8. [Google Scholar] [CrossRef] [PubMed]

- Brunt, J.; van Vliet, A.H.M.; Stringer, S.C.; Carter, A.T.; Lindström, M.; Peck, M.W. Pan-Genomic Analysis of Clostridium botulinum Group II (Non-Proteolytic C. botulinum) Associated with Foodborne Botulism and Isolated from the Environment. Toxins 2020, 12, 306. [Google Scholar] [CrossRef] [PubMed]

- Brunt, J.; van Vliet, A.H.M.; Carter, A.T.; Stringer, S.C.; Amar, C.; Grant, K.A.; Godbole, G.; Peck, M.W. Diversity of the Genomes and Neurotoxins of Strains of Clostridium botulinum Group I and Clostridium sporogenes Associated with Foodborne, Infant and Wound Botulism. Toxins 2020, 12, 586. [Google Scholar] [CrossRef]

- Williamson, C.H.D.; Sahl, J.W.; Smith, T.J.; Xie, G.; Foley, B.T.; Smith, L.A.; Fernández, R.A.; Lindström, M.; Korkeala, H.; Keim, P.; et al. Comparative genomic analyses reveal broad diversity in botulinum-toxin-producing Clostridia. BMC Genom. 2016, 17, 180. [Google Scholar] [CrossRef] [PubMed]

- Solomon, H.M.; Lilly, T.J. BAM Chapter 17: Clostridium Botulinum; Food and Drug Adminitstration: White Oak, MD, USA, 2001. [Google Scholar]

- Lindström, M.; Korkeala, H. Laboratory diagnostics of botulism. Clin. Microbiol. Rev. 2006, 19, 298–314. [Google Scholar] [CrossRef] [PubMed]

- McClure, P.J.; Cole, M.B.; Smelt, J.P. Effects of water activity and pH on growth of Clostridium botulinum. Soc. Appl. Bacteriol. Symp. Ser. 1994, 23, 105s–114s. [Google Scholar] [CrossRef] [PubMed]

- Peck, M.W. Biology and Genomic Analysis of Clostridium botulinum. In Advances in Microbial Physiology; Poole, R.K., Ed.; Academic Press: Cambridge, MA, USA, 2009; Volume 55, pp. 183–320. [Google Scholar]

- Matthews, K.; Young, M.; Goodburn, K.; Grinyer, L.; Jenson, I.; Peck, M.; Btachford, S.; Kirk, S.; Sims, K.; Wilson, N. Guidelines for Setting Shelf Life of Chilled Foods in Relation to Non-Proteolytic Clostridium Botulinum, 1st ed.; Leatherhead Food Research, Chilled Food Association, Meat & Livestock: Northamptonshire, UK, 2018. [Google Scholar]

- Doyle, M.P. Evaluating the Potential Risk from Extended-Shelf-Life Refrigerated Foods by Clostridium botulinum Inoculation Studies. Food Technol. 1991, 45, 154–156. [Google Scholar]

- Bradshaw, M.; Marshall, K.M.; Heap, J.T.; Tepp, W.H.; Minton, N.P.; Johnson, E.A. Construction of a nontoxigenic Clostridium botulinum strain for food challenge studies. Appl. Environ. Microbiol. 2010, 76, 387–393. [Google Scholar] [CrossRef]

- Parker, M.D.; Barrett, P.I.; Shepherd, J.; Price, L.J.; Bull, S.D. Characterisation of non-toxigenic Clostridium spp. strains, to use as surrogates for non-proteolytic Clostridium botulinum in chilled food challenge testing. J. Microbiol. Methods 2015, 108, 83–91. [Google Scholar] [CrossRef]

- Peck, M.W.; van Vliet, A.H. Impact of Clostridium botulinum genomic diversity on food safety. Curr. Opin. Food Sci. 2016, 10, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Notermans, S.; Veld, P. Microbiological Challenge Testing. Compr. Rev. Food Sci. Food Saf. 2003, 2, 46–50. [Google Scholar] [CrossRef]

- National Advisory Committee on Microbiological Criteria for Foods. Parameters for determining inoculated pack/challenge study protocols. J. Food Prot. 2010, 73, 140–202. [Google Scholar] [CrossRef]

- Peck, M.W.; Webb, M.D.; Goodburn, K.E. Assessment of the risk of botulism from chilled, vacuum/modified atmosphere packed fresh beef, lamb and pork held at 3 °C–8 °C. Food Microbiol. 2020, 91, 103544. [Google Scholar] [CrossRef]

- Carlin, F.; Peck, M.W. Growth of and toxin production by nonproteolytic Clostridium botulinum in cooked puréed vegetables at refrigeration temperatures. Appl. Environ. Microbiol. 1996, 62, 3069–3072. [Google Scholar] [CrossRef] [PubMed]

- Hospital, X.F.; Hierro, E.; Stringer, S.; Fernández, M. A study on the toxigenesis by Clostridium botulinum in nitrate and nitrite-reduced dry fermented sausages. Int. J. Food Microbiol. 2016, 218, 66–70. [Google Scholar] [CrossRef] [PubMed]

- Glass, K.A.; Mu, M.; LeVine, B.; Rossi, F. Inhibition of Clostridium botulinum in Model Reduced-Sodium Pasteurized Prepared Cheese Products. J. Food Prot. 2017, 80, 1478–1488. [Google Scholar] [CrossRef] [PubMed]

- Hyytiä-Trees, E.; Skyttä, E.; Mokkila, M.; Kinnunen, A.; Lindström, M.; Lähteenmäki, L.; Ahvenainen, R.; Korkeala, H. Safety Evaluation of Sous Vide-Processed Products with Respect to Nonproteolytic Clostridium botulinum by Use of Challenge Studies and Predictive Microbiological Models. Appl. Environ. Microbiol. 2000, 66, 223–229. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Del Torre, M.; Stecchini, M.L.; Braconnier, A.; Peck, M.W. Prevalence of Clostridium species and behaviour of Clostridium botulinum in gnocchi, a REPFED of italian origin. Int. J. Food Microbiol. 2004, 96, 115–131. [Google Scholar] [CrossRef] [PubMed]

- Peterson, M.E.; Paranjpye, R.N.; Poysky, F.T.; Pelroy, G.A.; Eklund, M.W. Control of Nonproteolytic Clostridium botulinum Types B and E in Crab Analogs by Combinations of Heat Pasteurization and Water Phase Salt. J. Food Prot. 2002, 65, 130–139. [Google Scholar] [CrossRef] [PubMed]

- Eklund, M.W.; Peterson, M.E.; Paranjpye, R.; Pelroy, G.A. Feasibility of a Heat-Pasteurization Process for the Inactivation of Nonproteolytic Clostridium botulinum types B and E in Vacuum-Packaged, Hot-Process (Smoked) Fish. J. Food Prot. 1988, 51, 720–726. [Google Scholar] [CrossRef] [PubMed]

- Daifas, D.P.; Smith, J.P.; Blanchfield, B.; Sanders, G.; Austin, J.W.; Koukoutisis, J. Effects of mastic resin and its essential oil on the growth of proteolytic Clostridium botulinum. Int. J. Food Microbiol. 2004, 94, 313–322. [Google Scholar] [CrossRef]

- Food Directorate, Health Products and Food Branch, Health Canada. Clostridium botulinum Challenge Testing of Ready-to-Eat Foods; 2010, Version 1. Available online: https://www.canada.ca/en/health-canada/services/food-nutrition/legislation-guidelines/policies/clostridium-botulinum-challenge-testing-ready-foods-2010.html (accessed on 1 August 2022).

- Riley, M.A. Molecular mechanisms of bacteriocin evolution. Annu. Rev. Genet. 1998, 32, 255–278. [Google Scholar] [CrossRef] [PubMed]

- Dineen, S.S.; Bradshaw, M.; Johnson, E.A. Cloning, nucleotide sequence, and expression of the gene encoding the bacteriocin boticin B from Clostridium botulinum strain 213B. Appl. Environ. Microbiol. 2000, 66, 5480–5483. [Google Scholar] [CrossRef]

- Morzywolek, A.; Plotka, M.; Kaczorowska, A.K.; Szadkowska, M.; Kozlowski, L.P.; Wyrzykowski, D.; Makowska, J.; Waters, J.J.; Swift, S.M.; Donovan, D.M.; et al. Novel Lytic Enzyme of Prophage Origin from Clostridium botulinum E3 Strain Alaska E43 with Bactericidal Activity against Clostridial Cells. Int. J. Mol. Sci. 2021, 22, 9536. [Google Scholar] [CrossRef] [PubMed]

- Lau, A.H.S.; Hawirko, R.Z.; Chow, C.T. Purification and properties of boticin P produced by Clostridium botulinum. Can. J. Microbiol. 1974, 20, 385–390. [Google Scholar] [CrossRef]

- Sebaihia, M.; Peck, M.W.; Minton, N.P.; Thomson, N.R.; Holden, M.T.G.; Mitchell, W.J.; Carter, A.T.; Bentley, S.D.; Mason, D.R.; Crossman, L.; et al. Genome sequence of a proteolytic (Group I) Clostridium botulinum strain Hall A and comparative analysis of the clostridial genomes. Genome Res. 2007, 17, 1082–1092. [Google Scholar] [CrossRef] [PubMed]

- Smith, T.J.; (Northern Arizona University, Flagstaff, AZ, USA). Personal Communication, 2022.

- Skinner, G.E.; Gendel, S.M.; Fingerhut, G.A.; Solomon, H.A.; Ulaszek, J. Differentiation between types and strains of Clostridium botulinum by riboprinting. J. Food Prot. 2000, 63, 1347–1352. [Google Scholar] [CrossRef] [PubMed]

- Reddy, N.R.; Marshall, K.M.; Morrissey, T.R.; Loeza, V.; Patazca, E.; Skinner, G.E.; Krishnamurthy, K.; Larkin, J.W. Combined high pressure and thermal processing on inactivation of type A and proteolytic type B spores of Clostridium botulinum. J. Food Prot. 2013, 76, 1384–1392. [Google Scholar] [CrossRef]

- Gonzalez-Escalona, N.; Timme, R.; Raphael, B.H.; Zink, D.; Sharma, S.K. Whole-genome single-nucleotide-polymorphism analysis for discrimination of Clostridium botulinum group I strains. Appl. Environ. Microbiol. 2014, 80, 2125–2132. [Google Scholar] [CrossRef] [PubMed]

- Tucker, C.B.; Homer, S. Outbreak of Botulism in Tennessee Due to Type B Cl. botulinum. Public Health Rep. 1939, 54, 1556–1560. [Google Scholar] [CrossRef]

- Weedmark, K.A.; Mabon, P.; Hayden, K.L.; Lambert, D.; Domselaar, G.V.; Austin, J.W.; Corbett, C.R.; Griffiths, M.W. Clostridium botulinum Group II Isolate Phylogenomic Profiling Using Whole-Genome Sequence Data. Appl. Environ. Microbiol. 2015, 81, 5938–5948. [Google Scholar] [CrossRef]

- Dolman, C.E.; Murakami, L. Clostridium botulinum Type F with Recent Observations on Other Types. J. Infect. Dis. 1961, 109, 107–128. [Google Scholar] [CrossRef]

- Ding, W.; Baumdicker, F.; Neher, R.A. panX: Pan-genome analysis and exploration. Nucleic Acids Res. 2018, 46, e5. [Google Scholar] [CrossRef] [PubMed]

- Dong, M.; Tepp, W.H.; Johnson, E.A.; Chapman, E.R. Using fluorescent sensors to detect botulinum neurotoxin activity in vitro and in living cells. Proc. Natl. Acad. Sci. USA 2004, 101, 14701–14706. [Google Scholar] [CrossRef]

- Wentz, T.G.; Tremblay, B.J.M.; Bradshaw, M.; Doxey, A.C.; Sharma, S.K.; Sauer, J.D.; Pellett, S. Endogenous CRISPR-Cas Systems in Group I Clostridium botulinum and Clostridium sporogenes Do Not Directly Target the Botulinum Neurotoxin Gene Cluster. Front. Microbiol. 2021, 12, 787726. [Google Scholar] [CrossRef]

- Altschul, S.F.; Gish, W.; Miller, W.; Myers, E.W.; Lipman, D.J. Basic local alignment search tool. J. Mol. Biol. 1990, 215, 403–410. [Google Scholar] [CrossRef]

- Letunic, I.; Bork, P. Interactive Tree of Life (iTOL) v5: An online tool for phylogenetic tree display and annotation. Nucleic Acids Res. 2021, 49, W293–W296. [Google Scholar] [CrossRef]

- Schantz, E.J.; Kautter, D.A. Standardized Assay for Clostridium botulinum Toxins. J. Assoc. Off. Anal. Chem. 1978, 61, 96–99. [Google Scholar] [CrossRef]

- Hatheway, C.L. Botulism. In Laboratory Diagnosis of Infectious Diseases: Principles and Practice; Balows, A., Hausler, W.J., Ohashi, M., Turano, A., Lennete, E.H., Eds.; Springer: New York, NY, USA, 1988; pp. 111–133. [Google Scholar]

- Goodnough, M.C.; Hammer, B.; Sugiyama, H.; Johnson, E.A. Colony immunoblot assay of botulinal toxin. Appl. Environ. Microbiol. 1993, 59, 2339–2342. [Google Scholar] [CrossRef]

- Prabakaran, S.; Tepp, W.; DasGupta, B.R. Botulinum neurotoxin types B and E: Purification, limited proteolysis by endoproteinase Glu-C and pepsin, and comparison of their identified cleaved sites relative to the three-dimensional structure of type A neurotoxin. Toxicon 2001, 39, 1515–1531. [Google Scholar] [CrossRef]

- Reed, L.J.; Muench, H. A simple method of estimating fifty per cent endpoints. Am. J. Epidemiol. 1938, 27, 493–497. [Google Scholar] [CrossRef]

- Butler, R.R., 3rd; Schill, K.M.; Wang, Y.; Pombert, J.F. Genetic Characterization of the Exceptionally High Heat Resistance of the Non-toxic Surrogate Clostridium sporogenes PA 3679. Front. Microbiol. 2017, 8, 545. [Google Scholar] [CrossRef]

- Brown, J.L.; Tran-Dinh, N.; Chapman, B. Clostridium sporogenes PA 3679 and Its Uses in the Derivation of Thermal Processing Schedules for Low-Acid Shelf-Stable Foods and as a Research Model for Proteolytic Clostridium botulinum. J. Food Prot. 2012, 75, 779–792. [Google Scholar] [CrossRef]

- Zhang, Z.; Lahti, M.; Douillard, F.P.; Korkeala, H.; Lindström, M. Phage lysin that specifically eliminates Clostridium botulinum Group I cells. Sci. Rep. 2020, 10, 21571. [Google Scholar] [CrossRef]

- Bradshaw, M.; Dineen, S.S.; Maks, N.D.; Johnson, E.A. Regulation of neurotoxin complex expression in Clostridium botulinum strains 62A, Hall A-hyper, and NCTC 2916. Anaerobe 2004, 10, 321–333. [Google Scholar] [CrossRef]

- Kozaki, S.; Kamata, Y.; Nishiki, T.; Kakinuma, H.; Maruyama, H.; Takahashi, H.; Karasawa, T.; Yamakawa, K.; Nakamura, S. Characterization of Clostridium botulinum type B neurotoxin associated with infant botulism in japan. Infect. Immun. 1998, 66, 4811–4816. [Google Scholar] [CrossRef]

- Rossetto, O.; Montecucco, C. Tables of Toxicity of Botulinum and Tetanus Neurotoxins. Toxins 2019, 11, 686. [Google Scholar] [CrossRef]

- Smith, T.J.; Tian, R.; Imanian, B.; Williamson, C.H.D.; Johnson, S.L.; Daligault, H.E.; Schill, K.M. Integration of Complete Plasmids Containing Bont Genes into Chromosomes of Clostridium parabotulinum, Clostridium sporogenes, and Clostridium argentinense. Toxins 2021, 13, 473. [Google Scholar] [CrossRef]

- Giordani, F.; Fillo, S.; Anselmo, A.; Palozzi, A.M.; Fortunato, A.; Gentile, B.; Azarnia Tehran, D.; Ciammaruconi, A.; Spagnolo, F.; Pittiglio, V.; et al. Genomic characterization of Italian Clostridium botulinum group I strains. Infect. Genet. Evol. 2015, 36, 62–71. [Google Scholar] [CrossRef]

- Poortmans, M.; Vanoirbeek, K.; Dorner, M.B.; Michiels, C.W. Selection and Development of Nontoxic Nonproteolytic Clostridium botulinum Surrogate Strains for Food Challenge Testing. Foods 2022, 11, 1577. [Google Scholar] [CrossRef]

- Eklund, M.W.; Poysky, F.T.; Peterson, M.E.; Paranjpye, R.N.; Pelroy, G.A. Competitive inhibition between different Clostridium botulinum types and strains. J. Food Prot. 2004, 67, 2682–2687. [Google Scholar] [CrossRef]

- Zhang, Z.; Douillard, F.P.; Korkeala, H.; Lindström, M. Specific Isolation of Clostridium botulinum Group I Cells by Phage Lysin Cell Wall Binding Domain with the Aid of S-Layer Disruption. Int. J. Mol. Sci. 2022, 23, 8391. [Google Scholar] [CrossRef]

- Whitemarsh, R.C.M.; Tepp, W.H.; Bradshaw, M.; Lin, G.; Pier, C.L.; Scherf, J.M.; Johnson, E.A.; Pellett, S. Characterization of botulinum neurotoxin A subtypes 1 through 5 by investigation of activities in mice, in neuronal cell cultures, and in vitro. Infect. Immun. 2013, 81, 3894–3902. [Google Scholar] [CrossRef]

- Pellett, S.; Tepp, W.H.; Whitemarsh, R.C.M.; Bradshaw, M.; Johnson, E.A. In vivo onset and duration of action varies for botulinum neurotoxin A subtypes 1-5. Toxicon 2015, 107, 37–42. [Google Scholar] [CrossRef]

- Moritz, M.S.; Tepp, W.H.; Inzalaco, H.N.t.; Johnson, E.A.; Pellett, S. Comparative functional analysis of mice after local injection with botulinum neurotoxin A1, A2, A6, and B1 by catwalk analysis. Toxicon 2019, 167, 20–28. [Google Scholar] [CrossRef]

- Kaji, R. Clinical differences between A1 and A2 botulinum toxin subtypes. Toxicon 2015, 107, 85–88. [Google Scholar] [CrossRef]

- Kohda, T.; Nakamura, K.; Hosomi, K.; Torii, Y.; Kozaki, S.; Mukamoto, M. Characterization of the functional activity of botulinum neurotoxin subtype B6. Microbiol. Immunol. 2017, 61, 482–489. [Google Scholar] [CrossRef]

| Group | Strain | Toxin Subtype | Source | Connection to Foodborne Botulism Outbreak | Citation |

|---|---|---|---|---|---|

| Group I | 56A | A | Canned Olives | Yes | [42] |

| 62A | A | Cow Liver Infarct | Unknown | [43,44] | |

| 69A | A | Canned Spinach | Yes | [43,45] | |

| 90A | A | Olives | Yes | [42] | |

| 113B | B | Soil (Blue Ridge, KY, USA) | No | [42] | |

| 213B | B | Canned Shallots | Yes | [44] | |

| Okra B | B | Home-Canned Okra Beans | Yes | [46] | |

| Group II | Eklund 17B | B | Marine Sediments (Pacific Northwest, USA) | No | [43,47] |

| Alaska E | E | Salmon Eggs | Yes | [47,48] | |

| Beluga E | E | Fermented Whale Flipper | Yes | [47] |

| Test Strain | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Indicator Strain | 56A | 62A | 69A | 90A | 113B | 213B | Okra B | Eklund 17B | Alaska E | Beluga E |

| 56A | + | + | +++ | |||||||

| 62A | + | +++ | +++ | |||||||

| 69A | ++ | ++ | ++ | ++ | ||||||

| 90A | ++ | ++ | ||||||||

| 113B | + | + | + | +++ | ||||||

| 213B | ++ | + | + | + | ||||||

| Okra B | + | + | + | +++ | ||||||

| Eklund 17B | ||||||||||

| Alaska E | + | |||||||||

| Beluga E | ||||||||||

| 10-Strain Cocktail | 9-Strain Cocktail | Group I Cocktail | Group II Cocktail | 62A | |

|---|---|---|---|---|---|

| mLD50 (− trypsin) | 4.3 × 104 | 4.3 × 104 | 1.1 × 106 | <8 × 103 1 | 1.1 × 106 |

| mLD50 (+ trypsin) | 3.8 × 105 | 1.1 × 106 | ND 2 | 1.2 × 105 | ND |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bowe, B.K.; Wentz, T.G.; Gregg, B.M.; Tepp, W.H.; Schill, K.M.; Sharma, S.; Pellett, S. Genomic Diversity, Competition, and Toxin Production by Group I and II Clostridium botulinum Strains Used in Food Challenge Studies. Microorganisms 2022, 10, 1895. https://doi.org/10.3390/microorganisms10101895

Bowe BK, Wentz TG, Gregg BM, Tepp WH, Schill KM, Sharma S, Pellett S. Genomic Diversity, Competition, and Toxin Production by Group I and II Clostridium botulinum Strains Used in Food Challenge Studies. Microorganisms. 2022; 10(10):1895. https://doi.org/10.3390/microorganisms10101895

Chicago/Turabian StyleBowe, Brooke Kathryn, Travis Gwynn Wentz, Brieana Marie Gregg, William Howard Tepp, Kristin Marie Schill, Shashi Sharma, and Sabine Pellett. 2022. "Genomic Diversity, Competition, and Toxin Production by Group I and II Clostridium botulinum Strains Used in Food Challenge Studies" Microorganisms 10, no. 10: 1895. https://doi.org/10.3390/microorganisms10101895

APA StyleBowe, B. K., Wentz, T. G., Gregg, B. M., Tepp, W. H., Schill, K. M., Sharma, S., & Pellett, S. (2022). Genomic Diversity, Competition, and Toxin Production by Group I and II Clostridium botulinum Strains Used in Food Challenge Studies. Microorganisms, 10(10), 1895. https://doi.org/10.3390/microorganisms10101895