1. Introduction

Modular drive joints are now widely used in industrial robots and collaborative robots, integrating high efficiency and high power density permanent magnet synonym motors (PMSMs), harmonic drive, torque sensors, shafts, bearings, dual encoders, and other components [

1,

2,

3]. The PMSM is widely employed in modular drive joints due to its advantages: fast dynamics, high efficiency and reliability, and a favorable torque to inertia ratio [

4,

5,

6]. However, the torque ripple in the PMSM and the stiffness of the modular drive joint influenced by the flexpline of harmonic drive easily induce velocity ripple [

7,

8]. Furthermore, the velocity ripple will result in vibration, noise, and other similar problems, which are major factors affecting the accuracy of the motion control system [

9]. In the last few years, many kinds of research have been done on the accuracy of motion control, where the velocity ripple has been found to be a major issue [

10].

The factors that cause the velocity ripple of modular drive joints can mainly be divided into two categories. The first category is caused by the position measuring errors because the feedback velocity signal is usually calculated from the measured position signal [

11,

12]. Many algorithms were introduced to correct the position measuring error under certain conditions but with no systematic description for measuring the position measuring error on the velocity ripple in the servo system [

13,

14]. The other category is caused by the inevitable parasitic torque ripple in the PMSM, such as cogging and flux harmonics, leading to velocity ripples, vibrations, acoustic noise, and poor response performance in motion control systems [

5,

15].

Aiming to minimize torque ripple and realize velocity ripple elimination, the methods can also mainly be classified in two ways: one way is to optimize the design or improve the body structure of the PMSM [

16,

17,

18,

19], and the other way is to depend on control algorithms. The former mainly involves skewing the slot or magnet, ensuring a fractional number of slots per pole, and improving the winding distribution. These methods are proven to be effective for eliminating the velocity ripple but require complex production processes. Besides, once the designed and optimized body structure is produced, the modular drive joint cannot be modified, which results in a higher production cost [

20,

21]. The control algorithms of the latter way mainly contain sensorless methods and sensor-based methods. The sensorless methods control the current phase indirectly by controlling the voltage–current phase deference based on the V/f control [

22,

23,

24]. However, if the load inertia varies depending on the joint position, such as robot posture changing, the other velocity ripple will occur easily [

25].

On the contrary, the sensor-based methods are the main approaches to eliminating velocity ripple, which mainly include traditional proportion-integral-differential (PID) methods and improved PID methods, intelligent methods, and model-based methods. The traditional methods, such as PI velocity control and cascade control structure (CCS) based on PI controllers, are simple and easily achieve velocity ripple but with limited efficiency [

5]. The intelligent methods include: adaptive fuzzy control methods [

2,

26,

27] and neural network algorithms [

28] with robust performance, iterative learning control (ILC) methods as a model-free control strategy to suppress velocity ripple and that is robust to noise [

29,

30], and a linear parameter varying

velocity control method with robustness against disturbance characteristics [

31]. These methods achieve robustness against velocity ripple and disturbances, but with a large amount of data calculation and poor real-time performance. In recent years, model-based methods have been developed, including model predictive control (MPC) methods, observer-based control methods, sliding mode control methods, and so on. These methods have advantages such as robustness, simple modeling, and the ability to handle control variable constraints to ensure the system’s satisfactory performance [

7].

Among the model-based methods, the methods based on the equivalent rigid-body velocity method [

32] and self-resonance cancellation (SRC) methods [

33,

34] are more popular. The equivalent rigid-body velocity method aims to add system damping to eliminate velocity ripple. The SRC method aims to achieve a rigid-body system by the weighted sum of sensor signals: dual encoders (motor-side encoder and link-side encoder). Base on the dual encoders of the modular drive joint, the rigid-body velocity can be obtained. The conventional method based on equivalent rigid-body velocity added an equivalent damping term after the closed loop to suppress velocity ripple. However, it only can suppress a limited frequency range ripple of velocity. To improve the conventional equivalent rigid-body velocity method, a method based on a state observer to suppress velocity ripple in the full frequency range ripple was proposed in [

35]. As for the SRC methods, there are fewer control parameters but there are high requirements for system model identification accuracy, which is challenging to apply in practical engineering applications with the low accuracy of system identification.

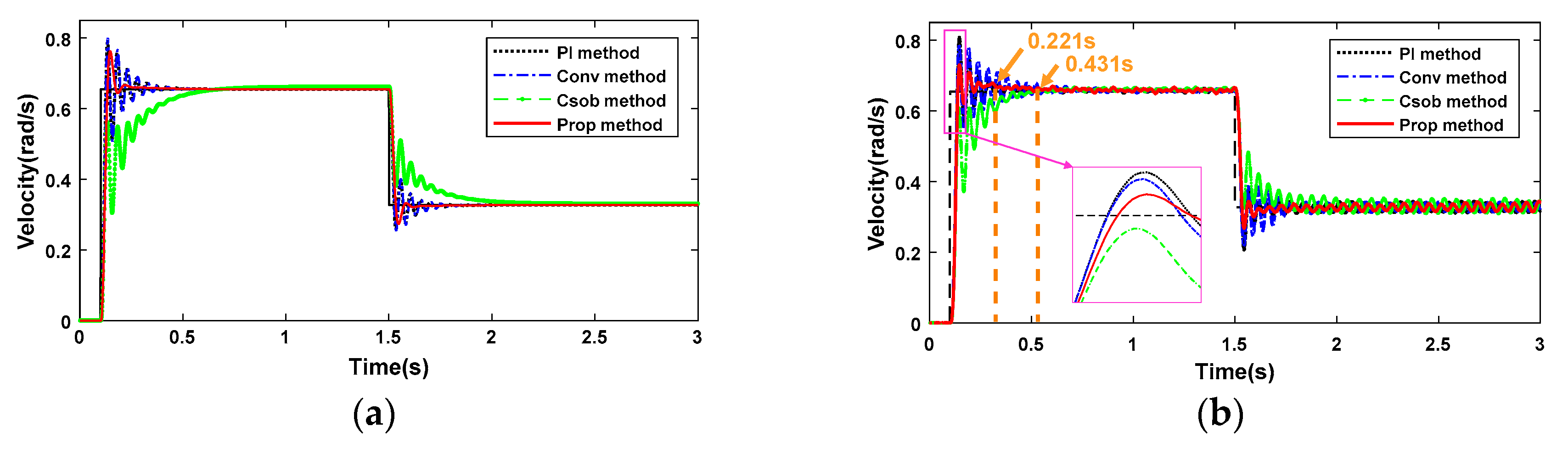

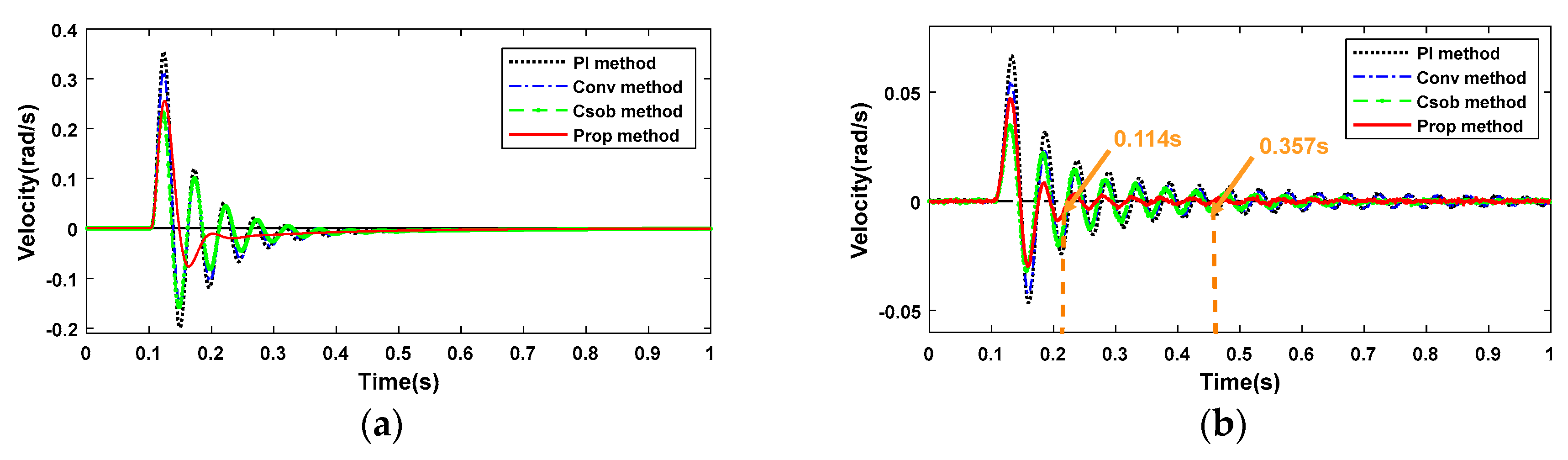

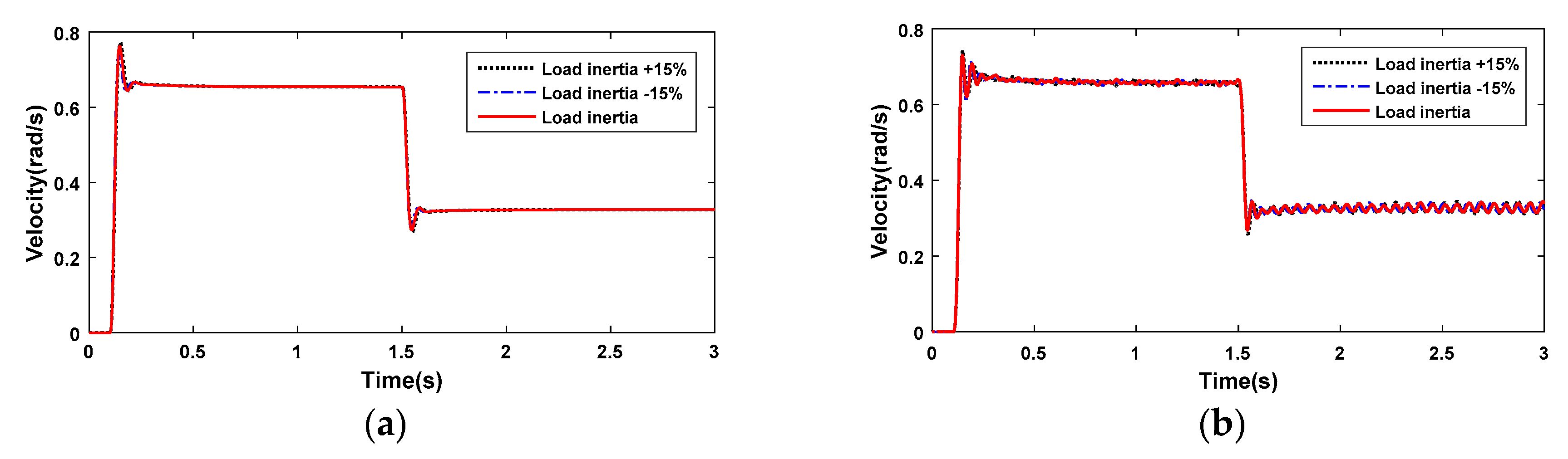

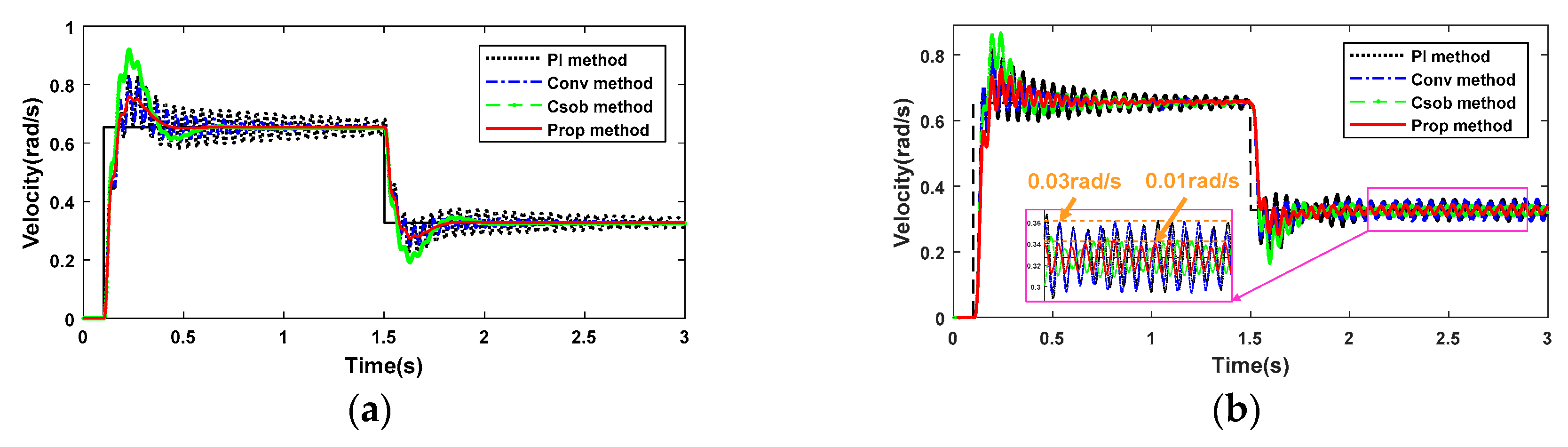

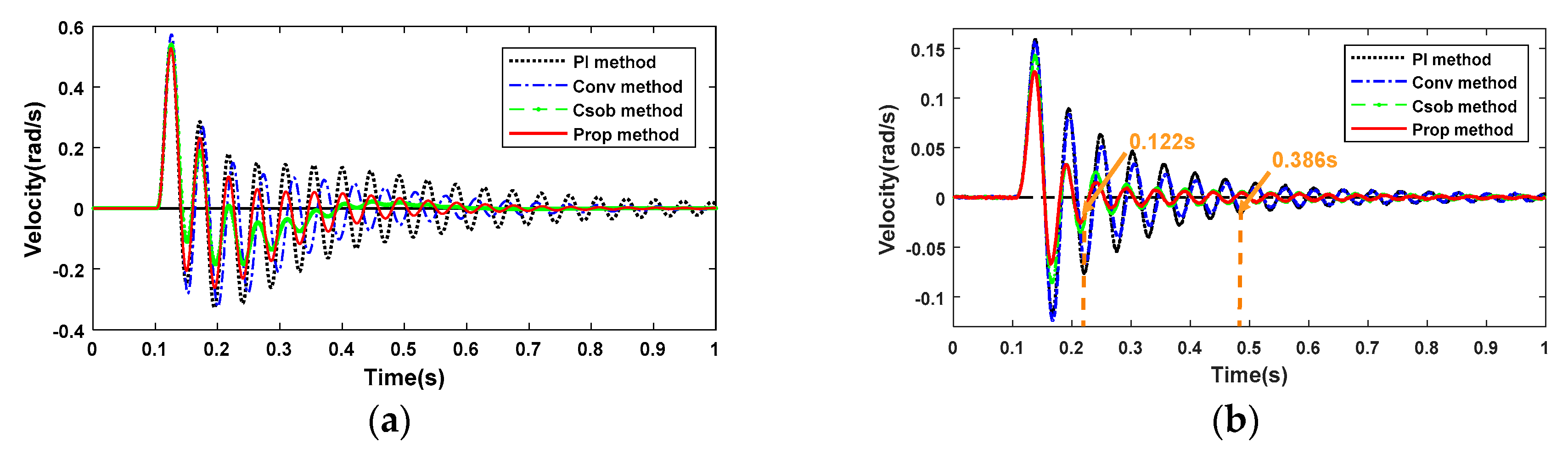

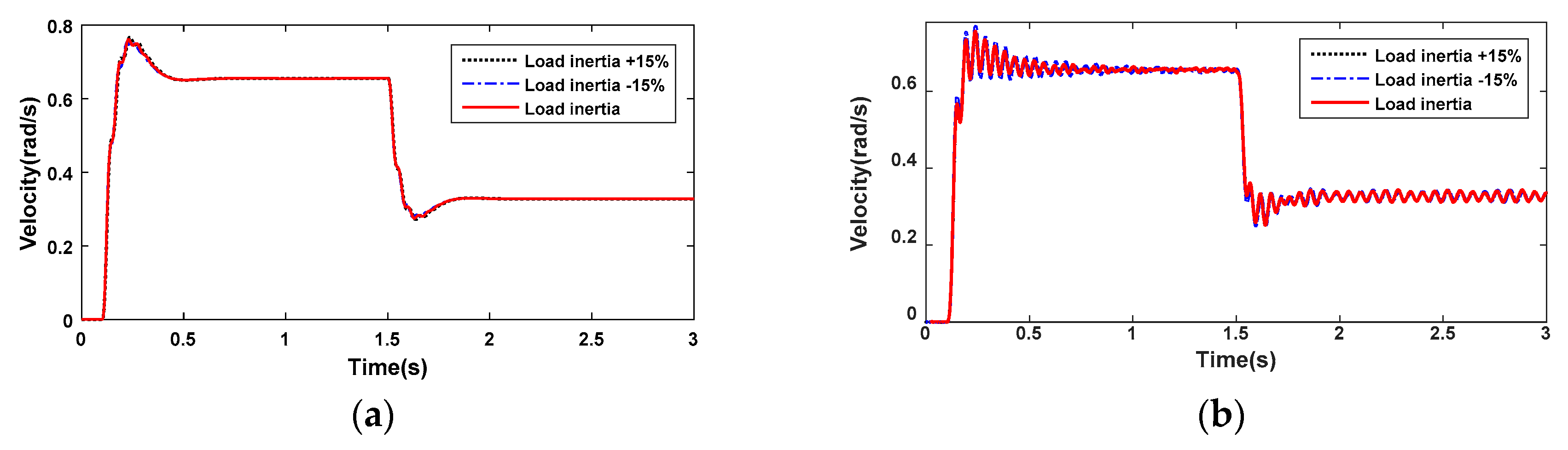

A method combined with the ideas of the equivalent rigid-body velocity method and SRC method is proposed to add system damping with fewer control parameters in this paper. The proposed method contains a rigid-body velocity solver (RBVS), a velocity ripple elimination controller (VREC), and a proportional–integral (PI) controller. As the feedback velocity can be motor velocity or link velocity, the proposed method can be further classed as a motor-side controller and link-side controller. In the proposed method, the RBVS obtains a rigid-body velocity based on the signals of dual encoders (motor velocity measured by the motor-side encoder and link velocity measured by the link-side encoder) without any control parameters. The VREC is based on the RBVS to add an equivalent system damping term and constant term, which eliminates velocity ripple and input disturbance effectively and, meanwhile, increases the robustness to modular drive joint load inertia changes. The added equivalent damping term consists of system parameters and control parameters, which can be increased or decreased with the adjustment of control parameters. In this paper, the velocity ripple suppression effects are confirmed in a modular drive joint with variable velocity tracking in simulations and experiments with a motor-side controller and link-side controller, respectively. Furthermore, the damped input disturbance and robustness to load inertia changes are also verified by simulations and experiments with a motor-side controller and link-side controller, respectively.

This paper is organized as follows. The dynamic model and system identification of a modular drive joint are described in

Section 2. The proposed method is designed and the controller parameters are analyzed in

Section 3.

Section 4 includes simulations and experiments of the motor-side controller and link-side controller to verify the velocity ripple elimination effects, input disturbance suppression effects, and the robust performance to load inertia changes. Finally,

Section 5 concludes this paper.

2. Dynamic Modeling and System Identification

The modular drive joint is widely used in most collaborative robots as the core part, integrating electronic circuits and other mechanical components. The mechanical structure is described in [

35,

36].

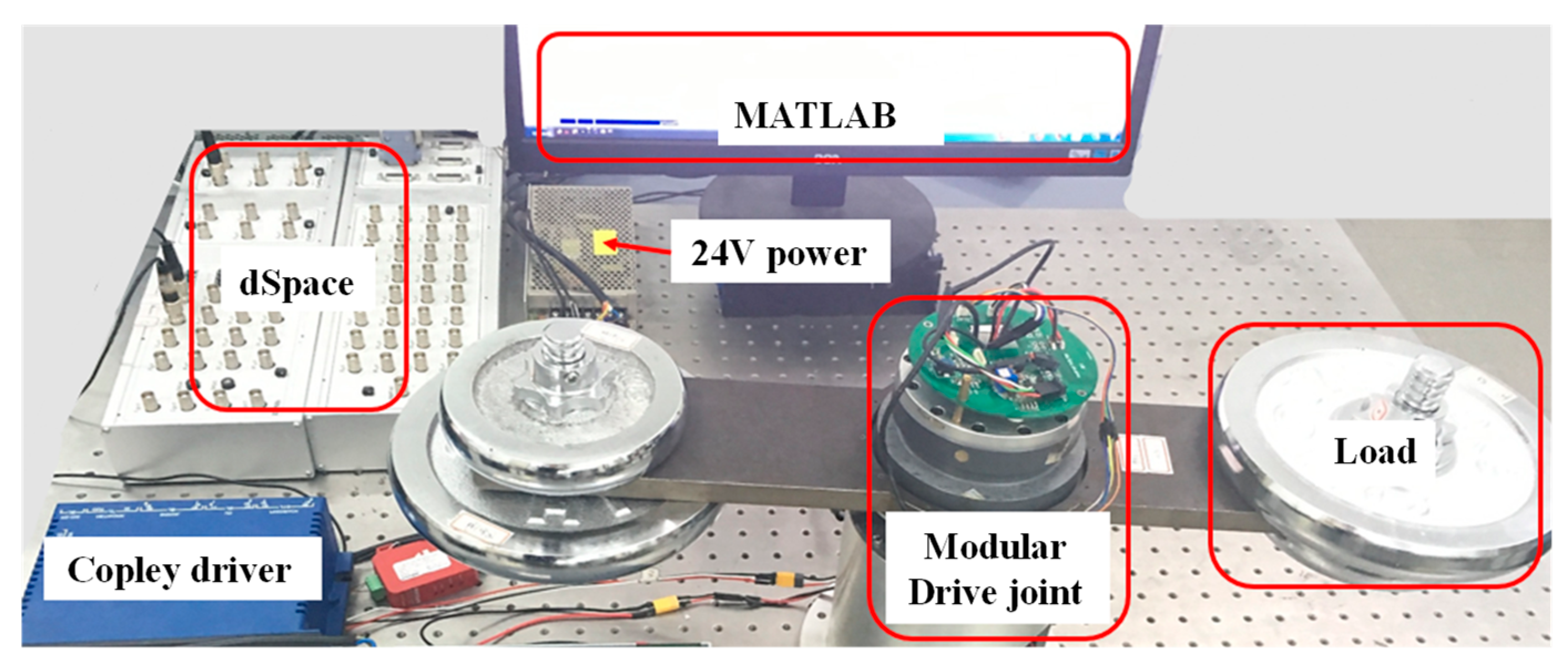

Figure 1 shows the experimental platform based on a modular drive joint together with dSpace hardware in the loop real-time simulation platform and MATLAB real-time workspace. The actuator of the modular drive joint is the Copley driver. This experimental platform’s power is 24 V. The weights installed at both ends of the connecting rod act as the load inertia.

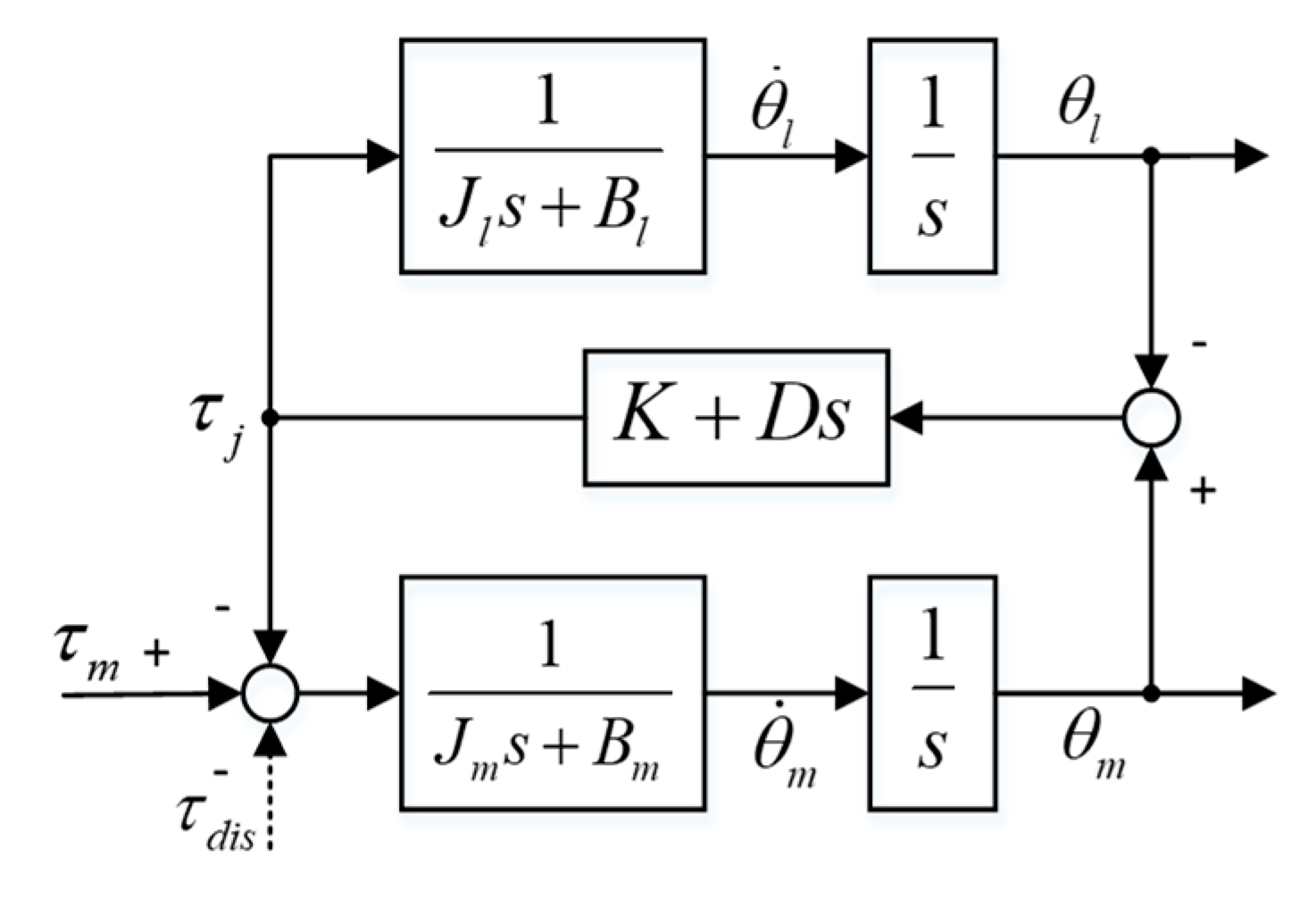

Figure 2 shows that the gear ratio of harmonic drive in the modular drive joint is equivalent to 1 [

35]. Therefore, the dynamic response of this two-inertia system can be simplified as Equation (1).

The physical meanings of

are motor inertia, motor viscous damping, load inertia, load viscous damping, joint stiffness, joint viscous damping, input torque, joint torque, input disturbance, motor position, link position, motor velocity, link velocity, motor acceleration, and link acceleration, respectively. The transfer function from input torque

to motor velocity

and link velocity

in the Laplace domain can be formulated as follows.

where

.

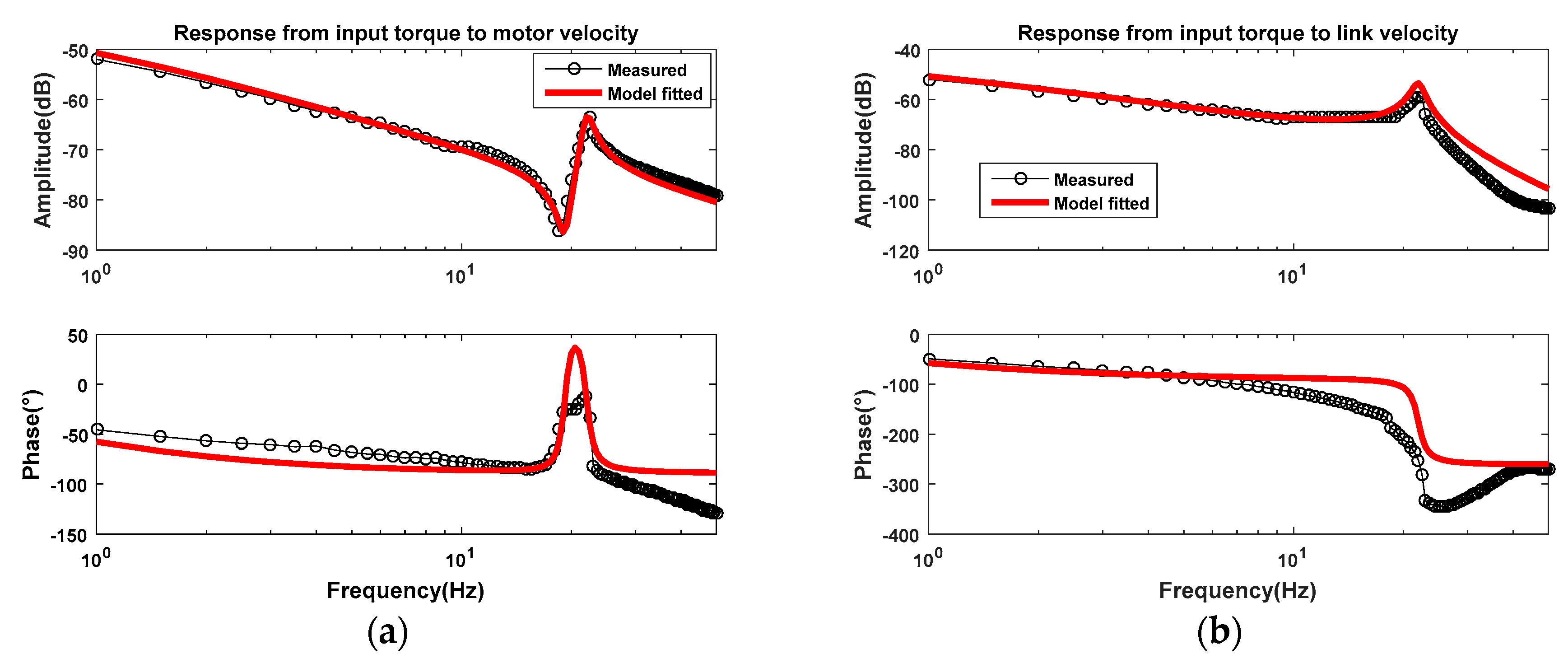

In order to verify that this two-inertia model can fit the actual modular drive joint well, a swept sine current signal is utilized to estimate the joint frequency response, with a load inertia of

kg·m

2. In experiments, the sampling frequency is 1 kHz. As for the modular drive joint, the current torque constant is tested to be 0.17 N·m/A. The input saturation current is set to 10 A. The maximum velocity of the motor side is 2500 rpm. Moreover, the gear ratio of the harmonic drive is 160. After the identification experiment, the joint frequency response from input torque

to motor velocity

and link velocity

can be obtained as shown in

Figure 3a,b, respectively.

In

Figure 3, the black lines are acquired by actual measurement data of the experiment. The red lines are fitted frequency response curves of the two-inertia model. The motor-side velocity response has a clear anti-resonance and resonance behavior from the identified results, whereas the link-side velocity only has a resonance behavior. In fact, the actual joint dynamic model is subjected to several nonlinear and time-varying factors, such as the nonlinear torques, frictions, and damping effects in the motor side and transmission, and the varying efficiency of harmonic drive (60–75% depending on ratio, velocity, and lubricant). In particular, the stiffness and damping of harmonic drive are related to the motion velocity. Therefore, the two-inertia model cannot fit the phase of actual system characteristics well [

37]. However, the amplitude–frequency fitting accuracy can accurately fit the system’s anti-resonance and resonance characteristics, proving that the two-inertia model can reflect the joint’s dynamic characteristics well. The anti-resonance frequency

and resonance frequency

are located at 19 Hz and 21 Hz, respectively. Next, the identified parameters of this modular drive joint are summarized in

Table 1.

3. Controller Design

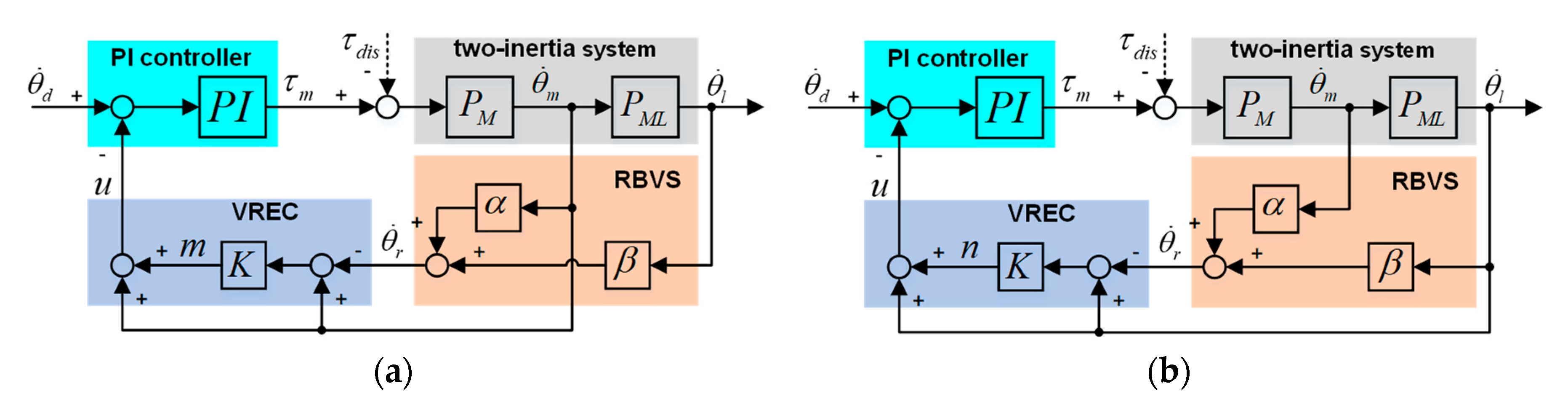

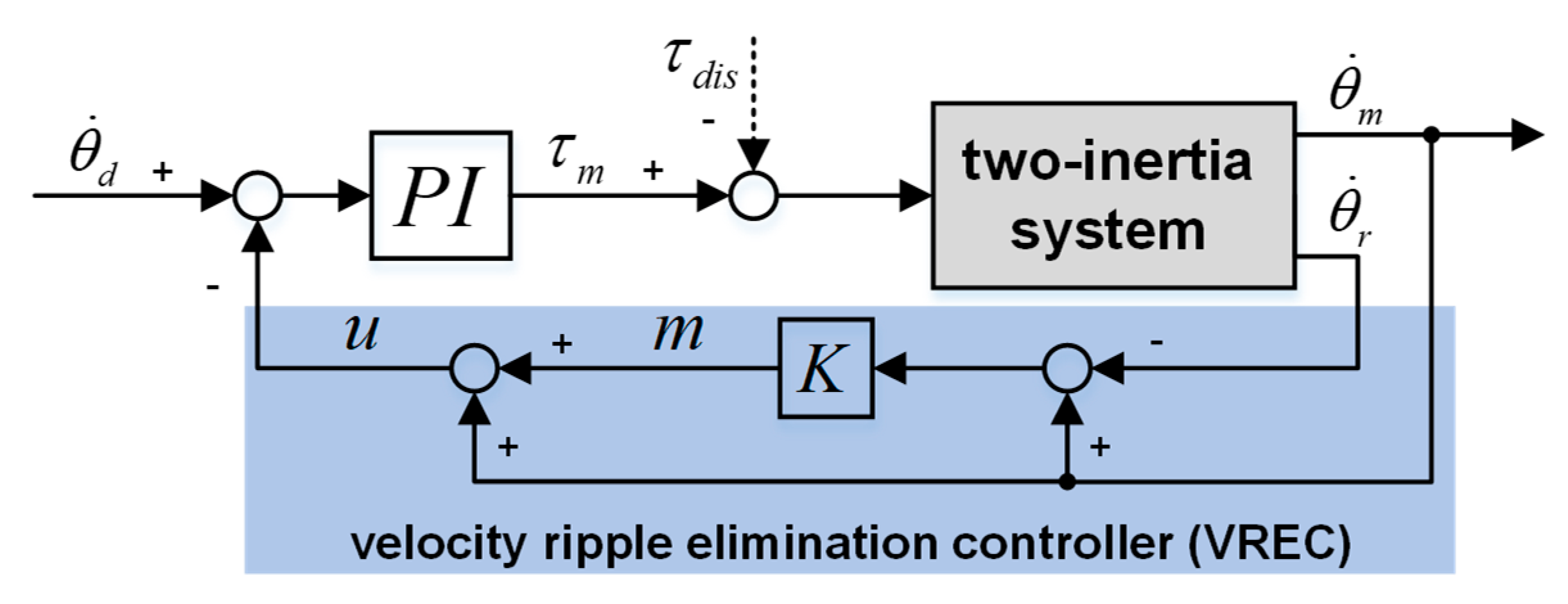

The proposed method in this paper contains an RBVS, a VREC, and a PI controller, as shown in

Figure 4, and aims to eliminate velocity ripple by adding equivalent system damping. The added equivalent damping term is developed by feeding back the velocity

of VREC output to the PI controller. As for the RBVS, rigid-body velocity

can be obtained by the weighted sum of motor velocity

and link velocity

. The PI controller is a proportional and integral controller for the error between the desired velocity

and output velocity

. The VREC comprises pure ripple (

or

) and joint velocity (motor velocity or link velocity). The pure ripple

is the error between motor velocity and rigid-body velocity. As well as the pure ripple,

is the error between link velocity and rigid-body velocity. Therefore, according to the joint velocity, the proposed method can be classed as the motor-side controller and link-side controller, as shown in

Figure 4a,b, respectively.

In

Figure 4, the model

defines transfer function from input torque

to motor velocity

. Meanwhile, the model

defines transfer function from motor velocity

to link velocity

, as shown in Equation (3).

Besides, the PI controller and coefficients

and

of the RBVS are defined as follows, which will be discussed in the next section:

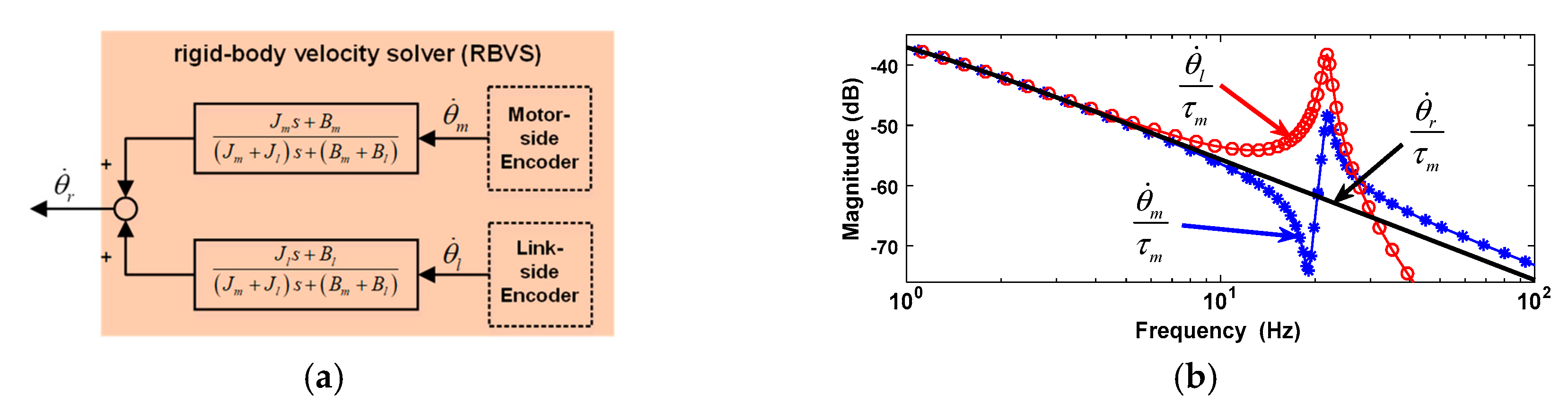

3.1. Rigid-Body Velocity Solver Design

The rigid-body velocity

is obtained based on the weighted sum of motor velocity and link velocity in the rigid-body velocity solver. Combined with the two-inertia model that has been given in Equation (1), rigid-body velocity

can be derived from Equation (5). The input disturbance

is not discussed at this time and is set to zero for simplicity. Among them, motor velocity is measured by the motor-side encoder. Link velocity is measured by the link-side encoder, as shown in

Figure 5a.

The transfer function from input torque

to rigid-body velocity

can be obtained by:

From Equations (2) and (6), the Bode diagram shows the transfer function from input torque

to motor velocity

, link velocity

and rigid-body velocity

in

Figure 5b, as the blue line, red line, and thick black line, respectively. As the modular drive joint identified results listed in

Table 1, the motor viscous damping is higher than link viscous damping, which leads to the magnitude of motor velocity frequency response being lower than the link velocity frequency response.

As stated by the Bode diagram from input torque to rigid-body velocity , there are no anti-resonance and resonance behaviors. Consequently, the system from input torque to rigid-body velocity is an ideal rigid-body system without any velocity ripple. The velocity obtained from the weighted sum of motor velocity and link velocity is an ideal rigid-body velocity.

3.2. Velocity Ripple Elimination Controller Design

3.2.1. Motor-Side Controller Design

Based on the rigid-body velocity discussed in

Section 3.1, the motor-side controller can be simplified as a PI controller and a VREC. The VREC feeds back the velocity

to the desired velocity

input to the PI controller. The pure ripple

is obtained from the error between motor velocity and rigid-body velocity after the proportional gain

tuning, as shown in

Figure 6.

In

Figure 6, the signal

is pure the ripple of motor velocity after being controlled by

. The symbol

is the sum of motor velocity and pure ripple

. The input disturbance

is not discussed for simplicity. Then the open-loop transfer function

from the desired velocity

to motor velocity

can be given in Equation (7).

The closed-loop transfer function

from the desired velocity

to motor velocity

can be derived from the following equations.

In order to analyze the closed-loop transfer function performance of the motor-side controller, the viscous damping terms

are set to zero for simplicity. Then the closed-loop transfer function

can be simplified, as in Equation (10).

Based on the modular drive joint identified results, the resonance frequency is always larger than the anti-resonance frequency , which leads to being more than 1 and being positive permanently. Compared with the open-loop transfer function given in Equation (7), the closed-loop transfer function has an added equivalent damping term and an equivalent natural resonance term , which increase system damping and system response performance, respectively. With the control parameter being positive, the velocity ripple can be eliminated by the increased equivalent damping.

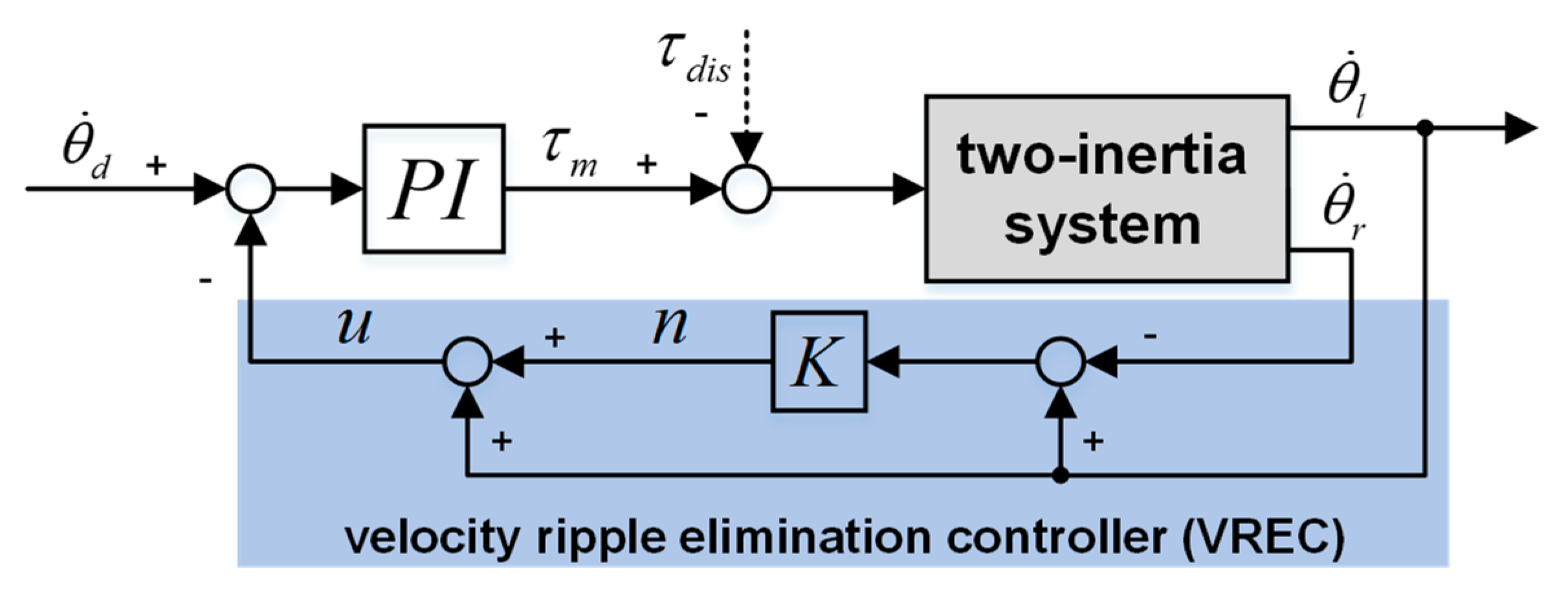

3.2.2. Link-Side Controller Design

Similarly, when the pure ripple

is obtained from the error between link velocity and rigid-body velocity, there could be a link-side controller to eliminate the velocity ripple by feeding back this error and link velocity to the PI controller, as shown in

Figure 7.

In

Figure 7, the signal

is the pure ripple of link velocity after being controlled by

. The symbol

is the sum of link velocity and pure ripple

. The input disturbance

is not discussed for simplicity. The open-loop transfer function

from the desired velocity

to link velocity

can be given by Equation (11).

The closed-loop transfer function

from the desired velocity

to link velocity

can be derived from the following.

Correspondingly, the viscous damping terms

are ignored for simplicity to analyze the closed-loop transfer function performance of the link-side controller. Therefore, the closed-loop transfer function

can be simplified, as shown in Equation (14).

Compared to the open-loop transfer function given in Equation (11), the closed-loop transfer function adds an equivalent damping term and an equivalent natural resonance term . When the is negative, the added equivalent damping term becomes positive, and then the system damping can be increased. With the control parameter and tuning, the velocity ripple can be eliminated by the increased equivalent damping.

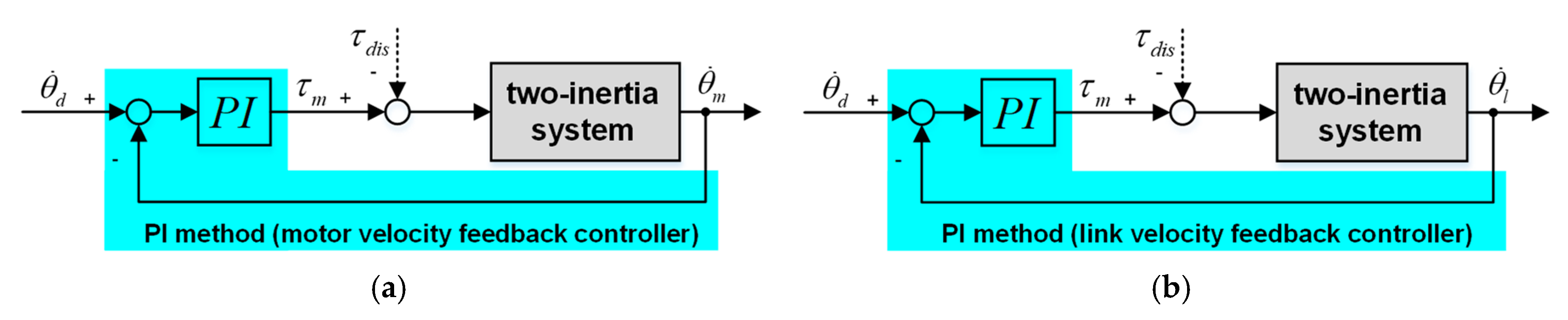

3.3. Controller Parameter Analysis

In the proposed method, as discussed above, the motor-side controller and link-side controller have only one more control parameter

than a PI method. The PI method can also include two kinds of feedback (motor velocity feedback and link velocity feedback), as shown in

Figure 8a,b, respectively.

Firstly, the PI parameters need to be designed before the proposed method application. Based on the integral of squared error (ISE) criterion [

38], the proportional and integral gain of the motor velocity feedback PI controller are designed as

and

. The proportional and integral gain of the link velocity feedback PI controller are designed as

and

.

3.3.1. Parameters of Motor-Side Controller

For a modular drive joint, the elimination of velocity ripple is mainly to suppress velocity ripple occurring on the link side. This is based on the closed-loop transfer function from the desired velocity to motor velocity with the motor-side controller, as expressed in Equation (10) and

Figure 6. Naturally, the transfer function from the desired velocity to link velocity can be given by Equation (15).

The closed-loop transfer function from the desired velocity to link velocity has an added equivalent damping term

and an equivalent natural resonance term

compared to the open-loop transfer function. The parameter

can be expressed by Equation (16).

When the damping ratio

of the closed-loop transfer function is under damping, critical damping, and over damping, such as

,

,

, as well as the special damping ratio

, the parameter

can be obtained from Equation (16) based on the identified parameters listed in

Table 1 and the above parameters

and

, as shown in

Table 2.

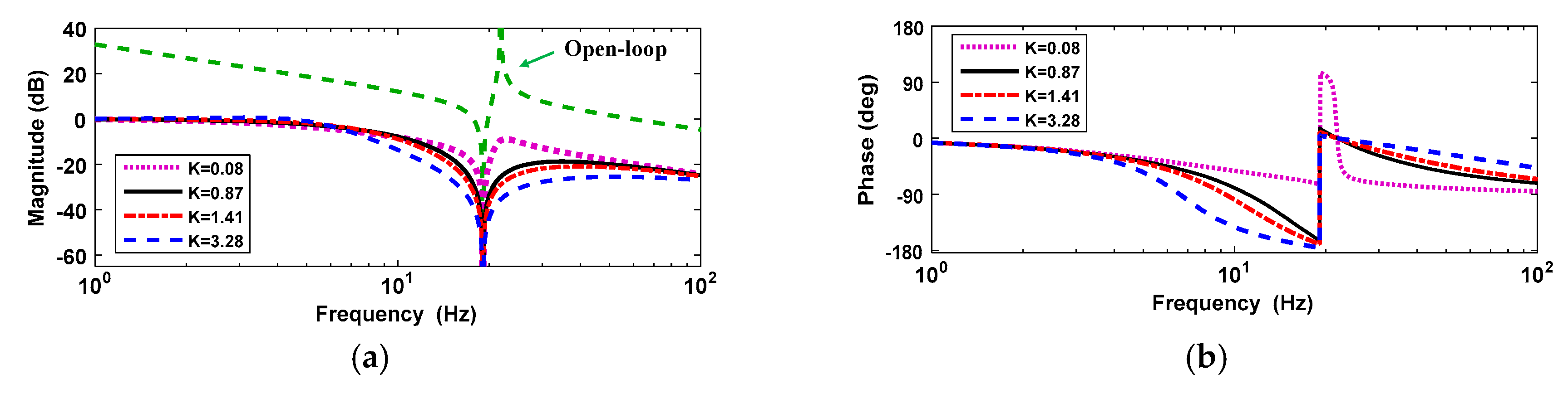

The closed-loop Bode diagrams of motor-side controller from the desired velocity to motor velocity with different parameters

are shown in

Figure 9.

As the parameter

increases (the damping ratio increases), the system damping gradually increases, which leads to the velocity ripple being damped, however, this decreases the closed-loop control bandwidth. The parameter

as well as the proportional and integral gain

and

are designed to be those in

Table 3. Under the current parameters, the amplitude margin and phase margin of the closed-loop frequency response are sufficient. The amplitude margin and phase margin are 22.9 dB and 58.7 deg, respectively, which proves the system is stable after closed-loop control.

3.3.2. Parameters of Link-Side Controller

The link-side controller, shown in

Figure 7, shows that the closed-loop transfer function from the desired velocity to link velocity is expressed in Equation (14). Based on the foregone proportional and integral gain of

and

, the parameter

of the link-side controller can be obtained by Equation (17).

Similarly, when the damping ratio

of the closed-loop transfer function represents under damping, critical damping, and over damping, such as

,

,

, as well as the special damping ratio

, the different parameters

can be summarized in

Table 4, based on the identified parameters listed in

Table 1 and the above parameters

and

.

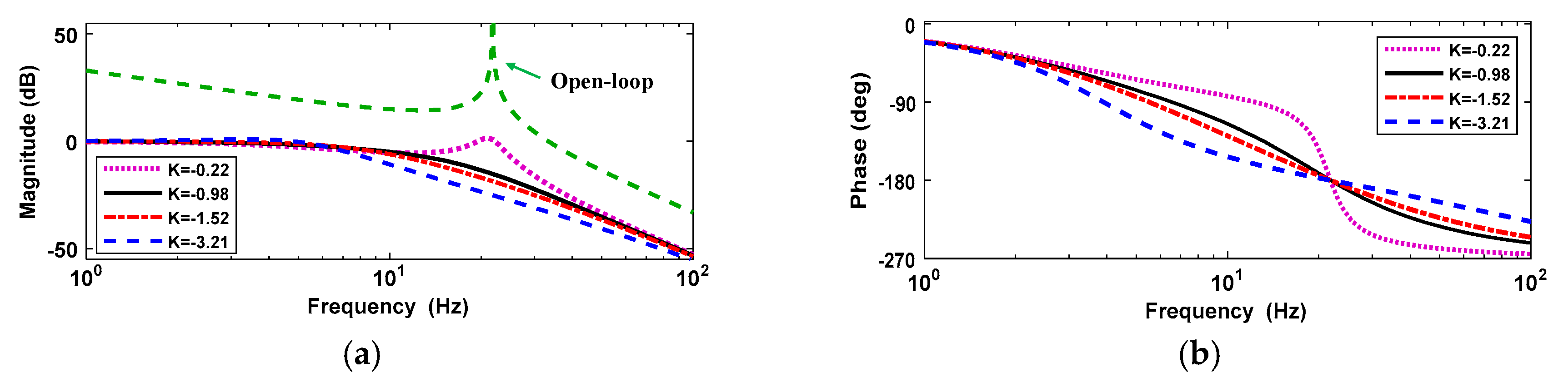

The closed-loop Bode diagram of the link-side controller from the desired velocity to link velocity with different parameters

are shown in

Figure 10.

In a similar way, with parameter

increasing (damping ratio increasing), the system damping gradually increases, which lets the velocity ripple eliminate but decreases the closed-loop control bandwidth. Since there is no anti-resonance point in the transfer function from the desired velocity to link velocity, the phase will drop quickly, and the system is easy to diverge [

39]. Therefore, the control parameters of the link-side controller should be very conservative. The parameter

as well as the proportional–integral gain

and

are set in

Table 5.