An Equivalent Circuit Analysis and Suspension Characteristics of AC Magnetic Suspension Using Magnetic Resonant Coupling

Abstract

1. Introduction

- Sensorless magnetic suspension without any active feedback control;

- Self-stabilization characteristics even in the presence of disturbance;

- High-efficiency energy transfer to the floator;

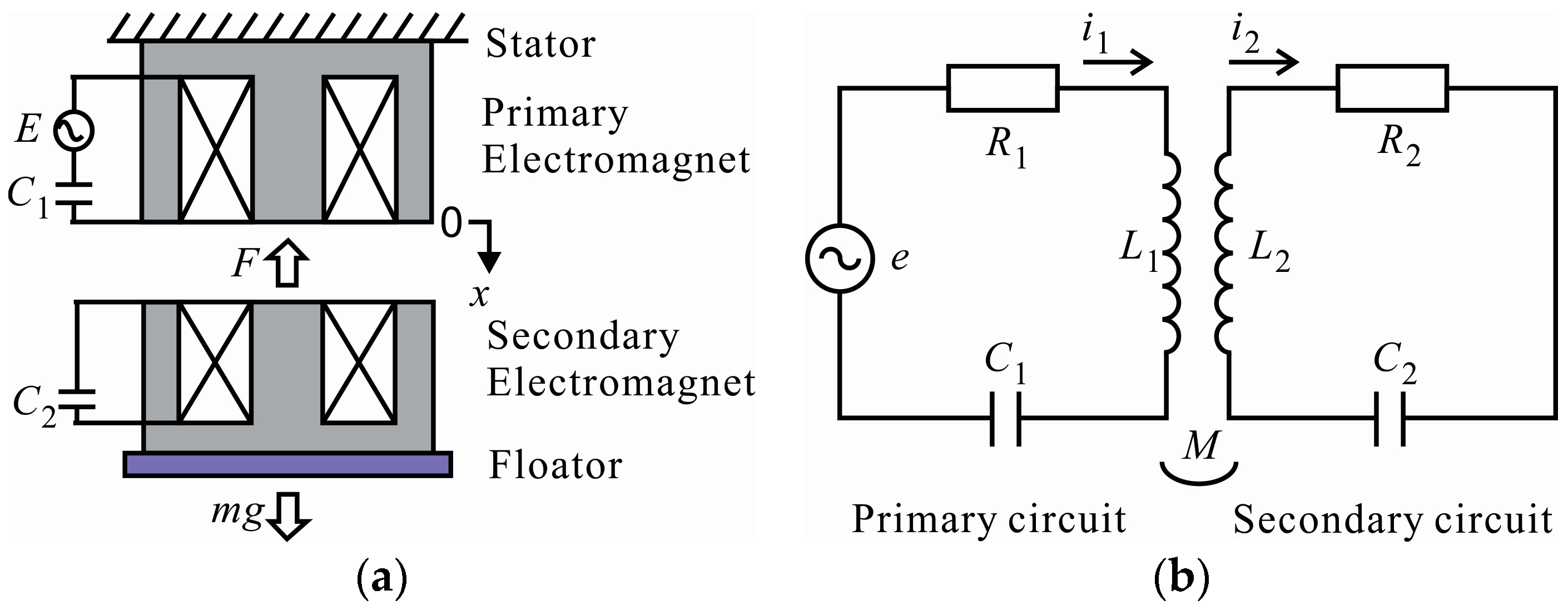

2. Principle of Magnetic Resonant Coupling

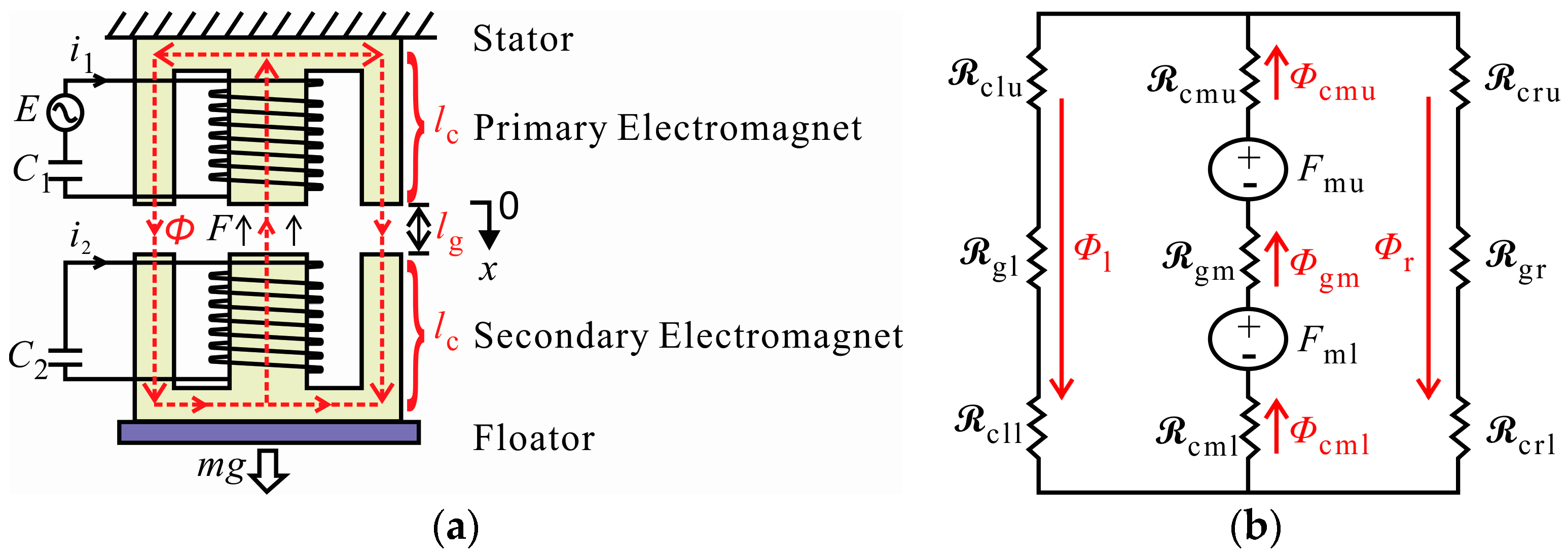

3. Analysis of Magnetic Circuit

3.1. Assumptions

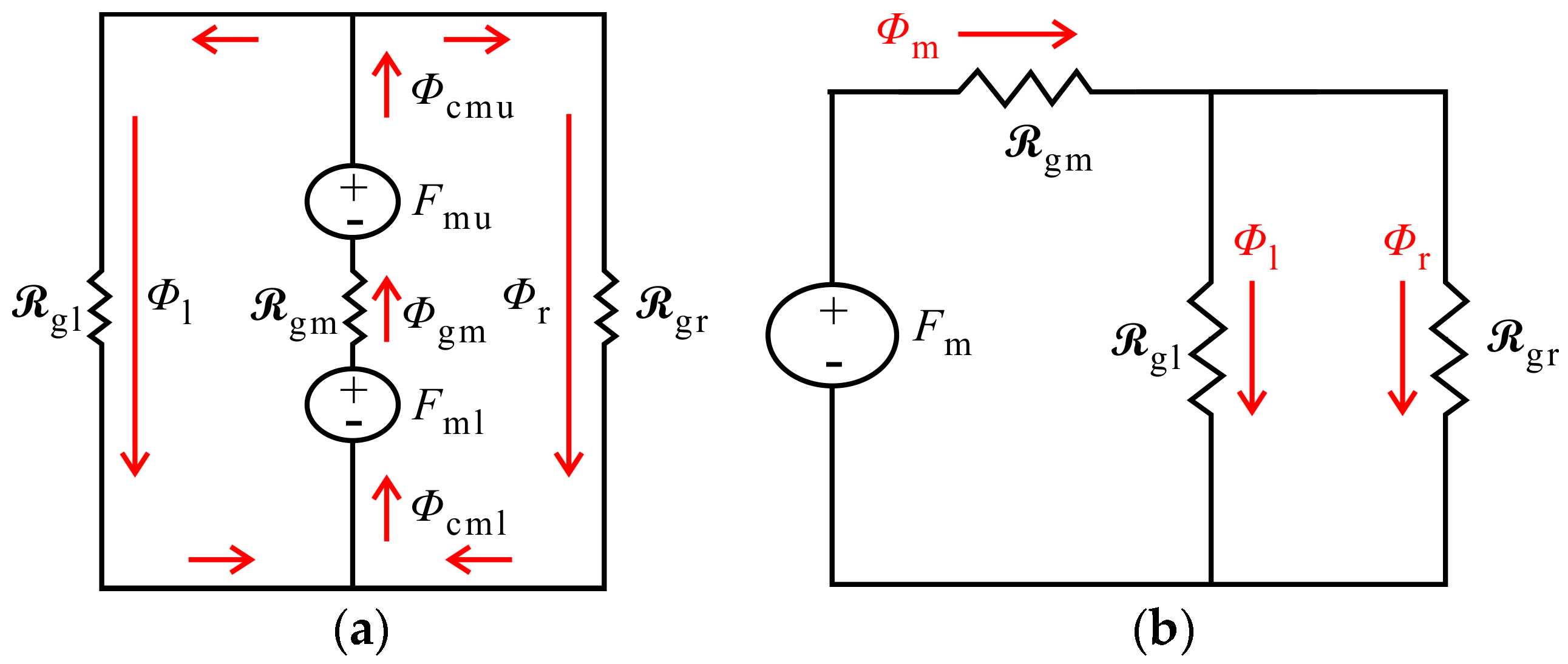

3.2. Equivalent Magnetic Circuit Analysis

4. Analysis of Electrical Circuit

4.1. Current Equations

4.2. Force Equations

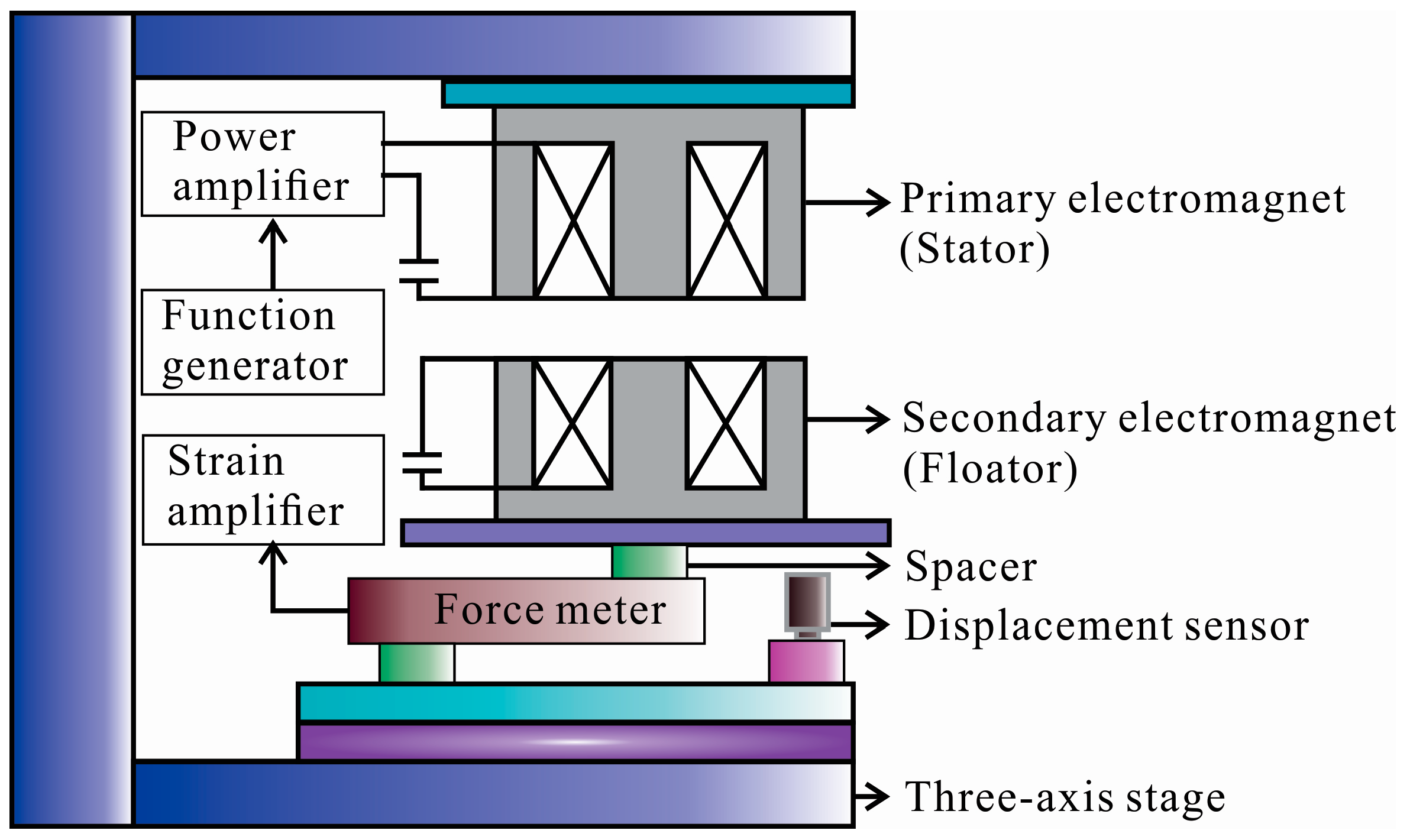

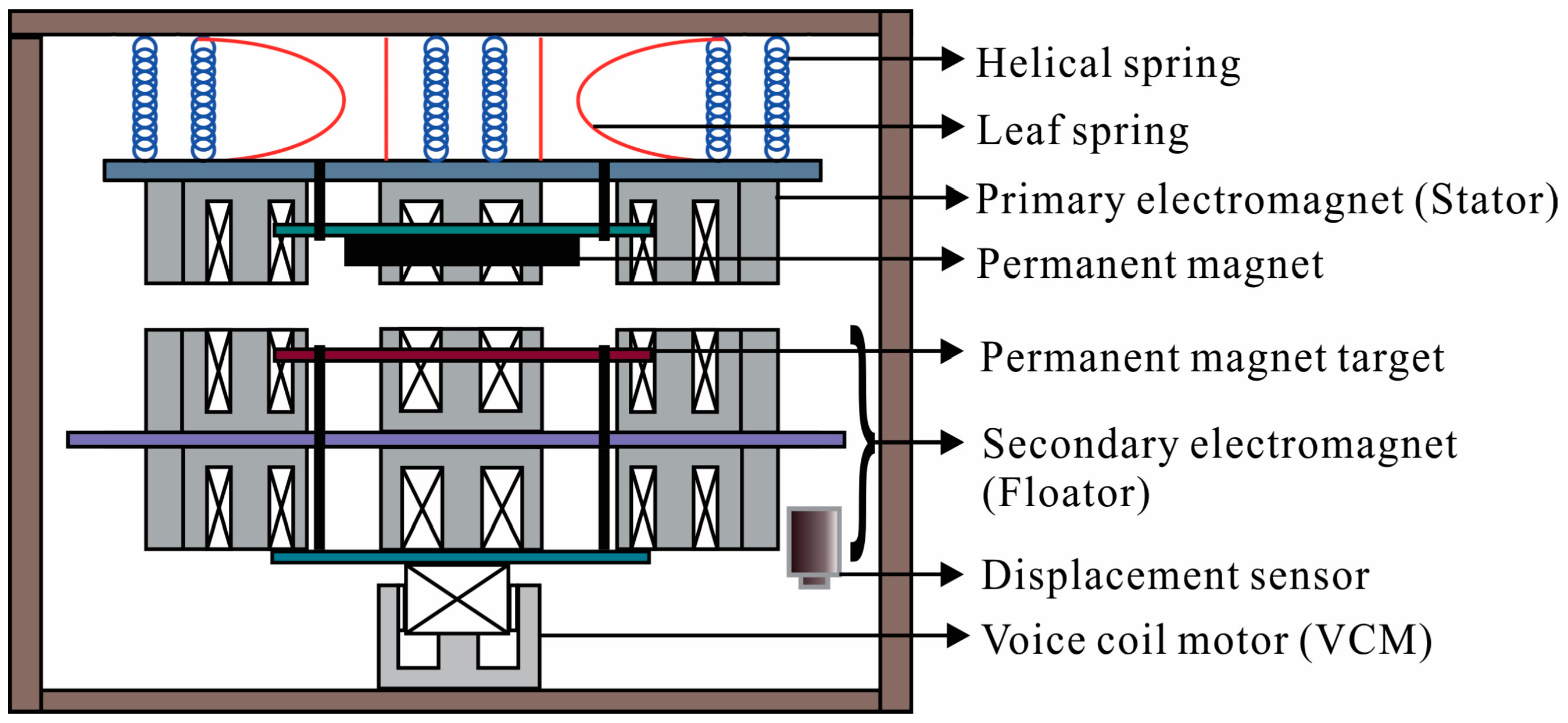

5. Experimental System

6. Investigation of Fundamental Characteristics

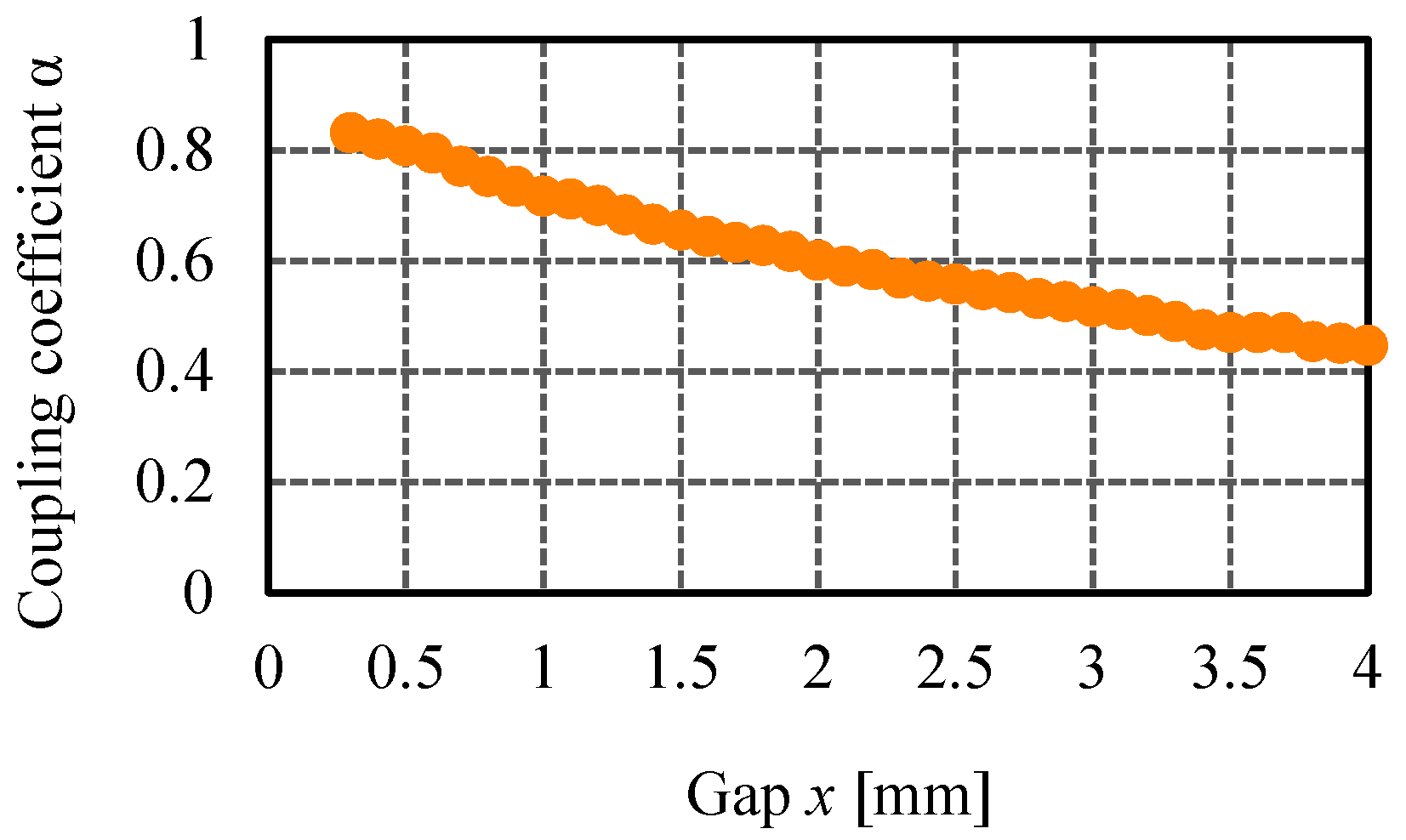

6.1. Characteristics of Self-Inductance and Mutual Inductance

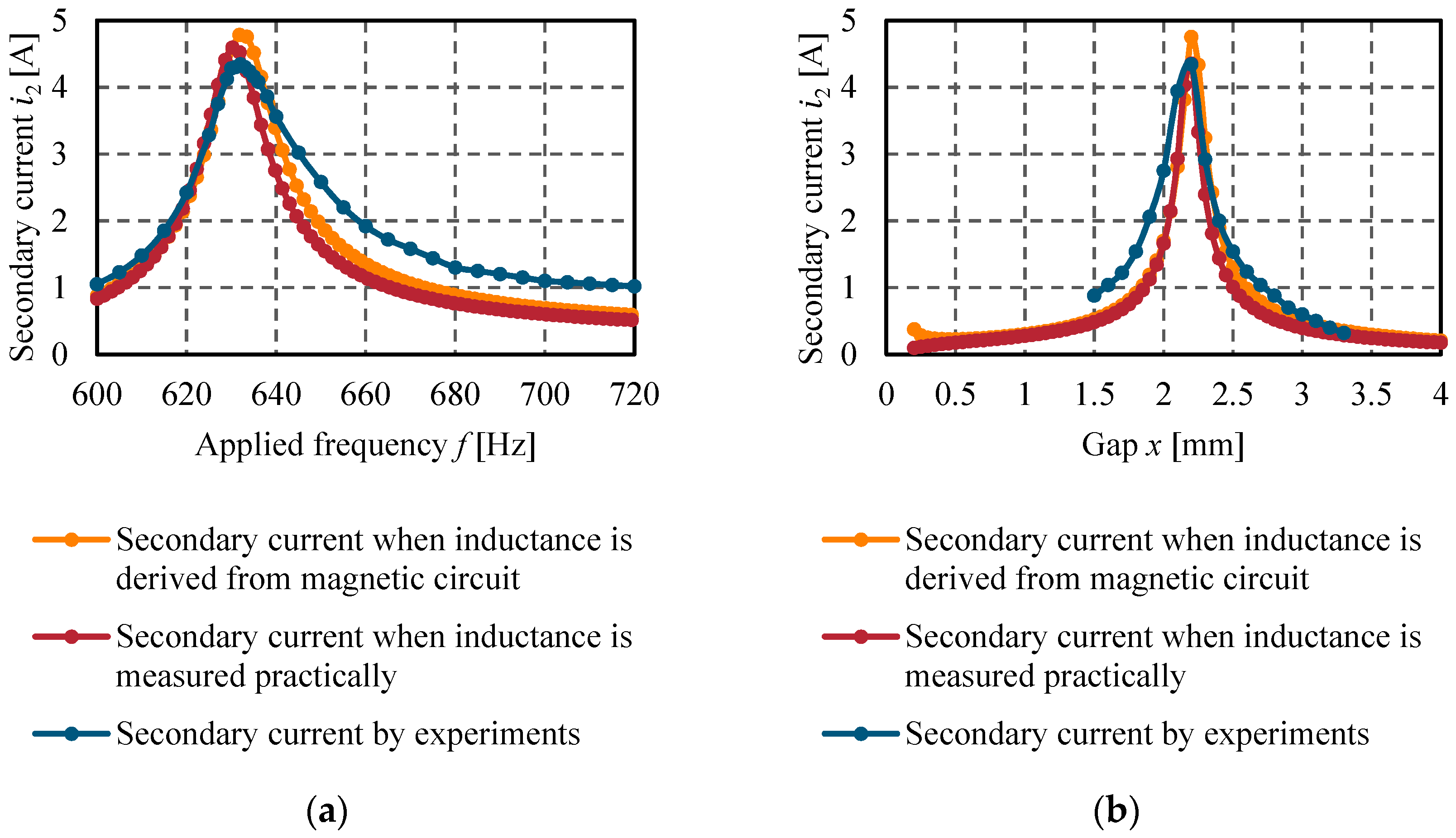

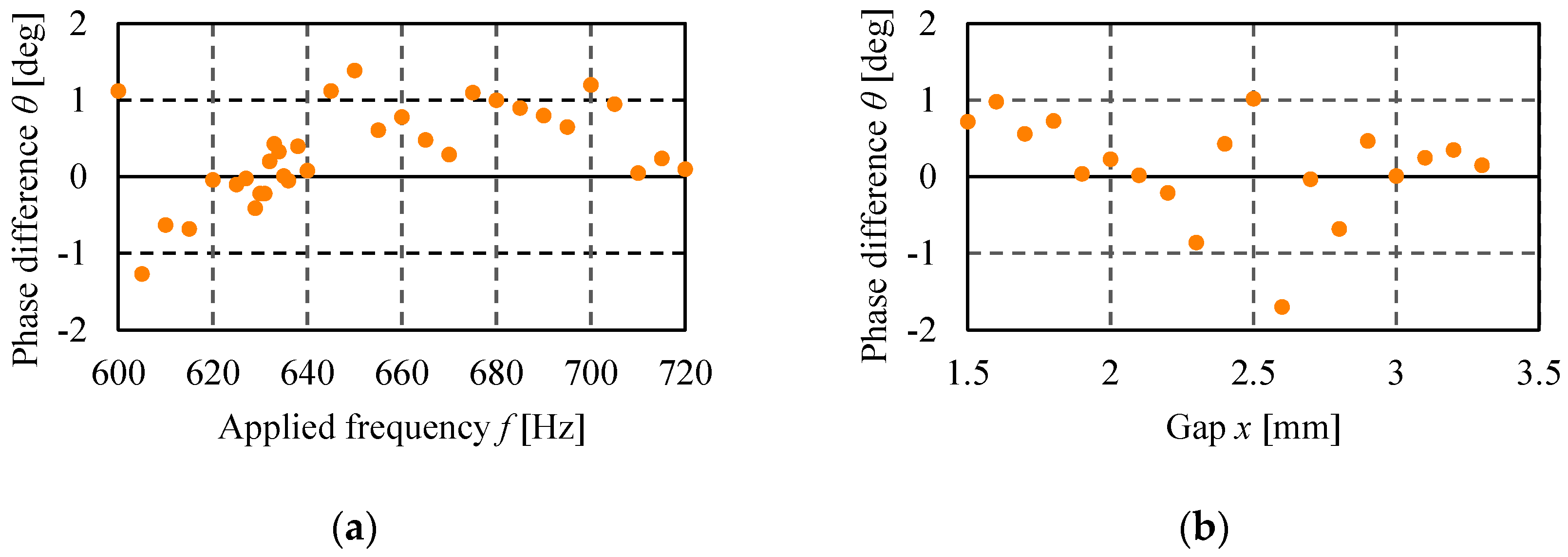

6.2. Characteristics of Currents

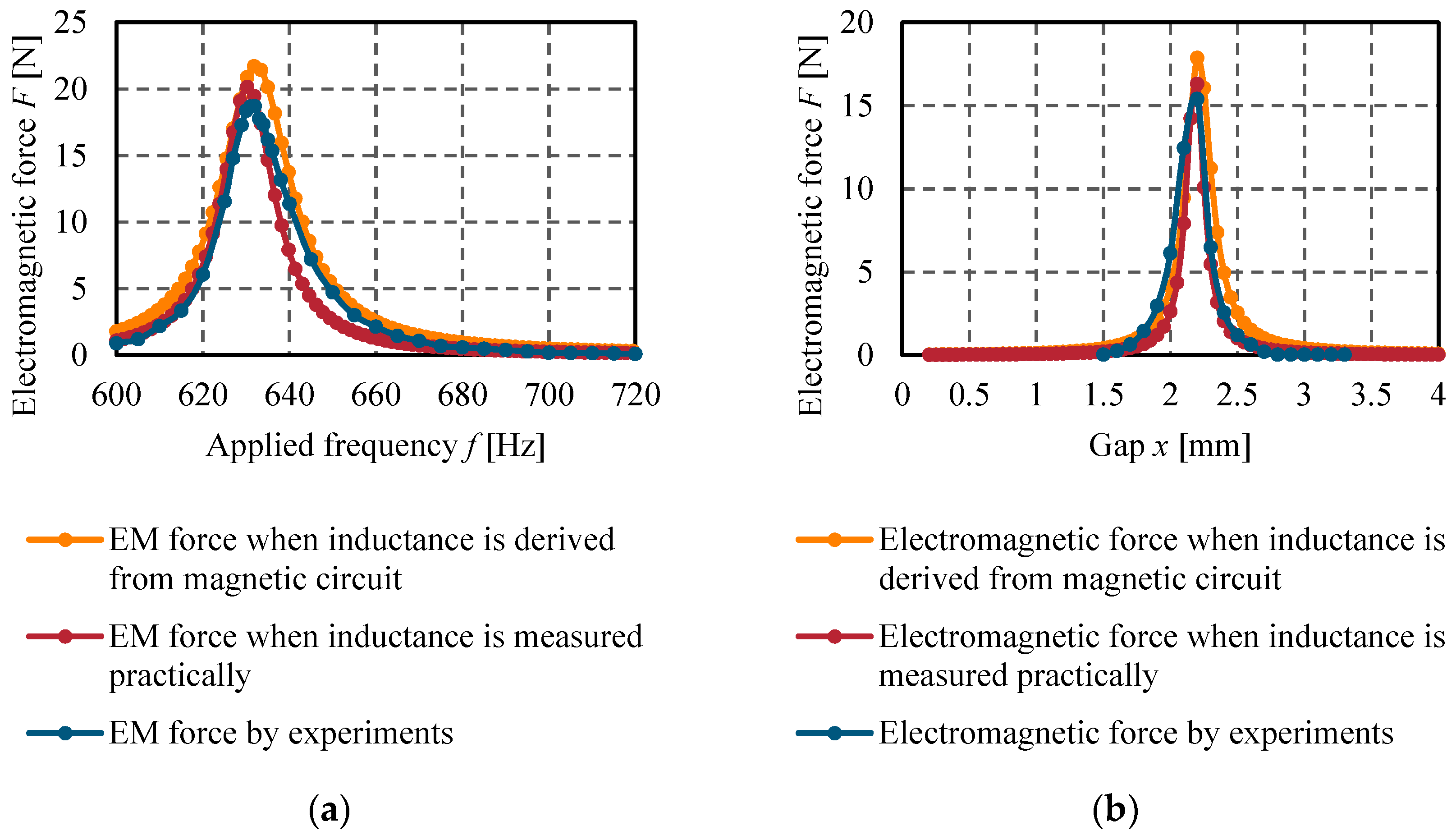

6.3. Characteristics of Attractive Force

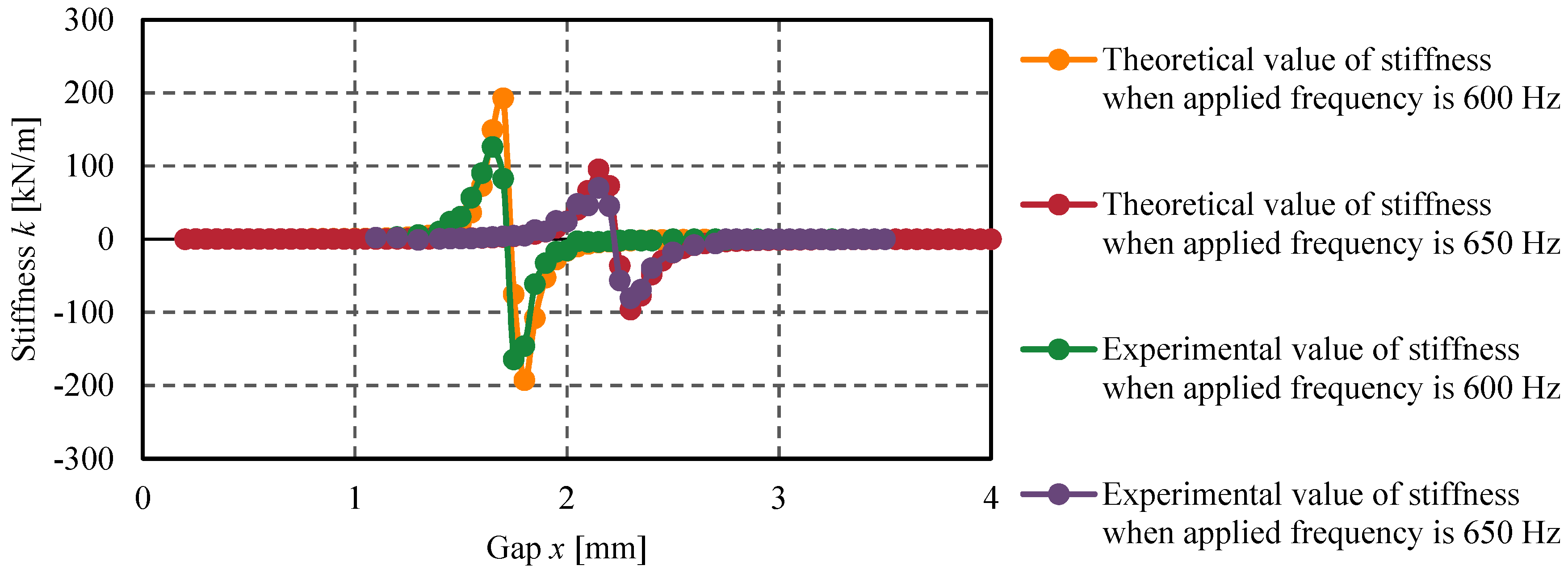

6.4. Characteristics of Stiffness

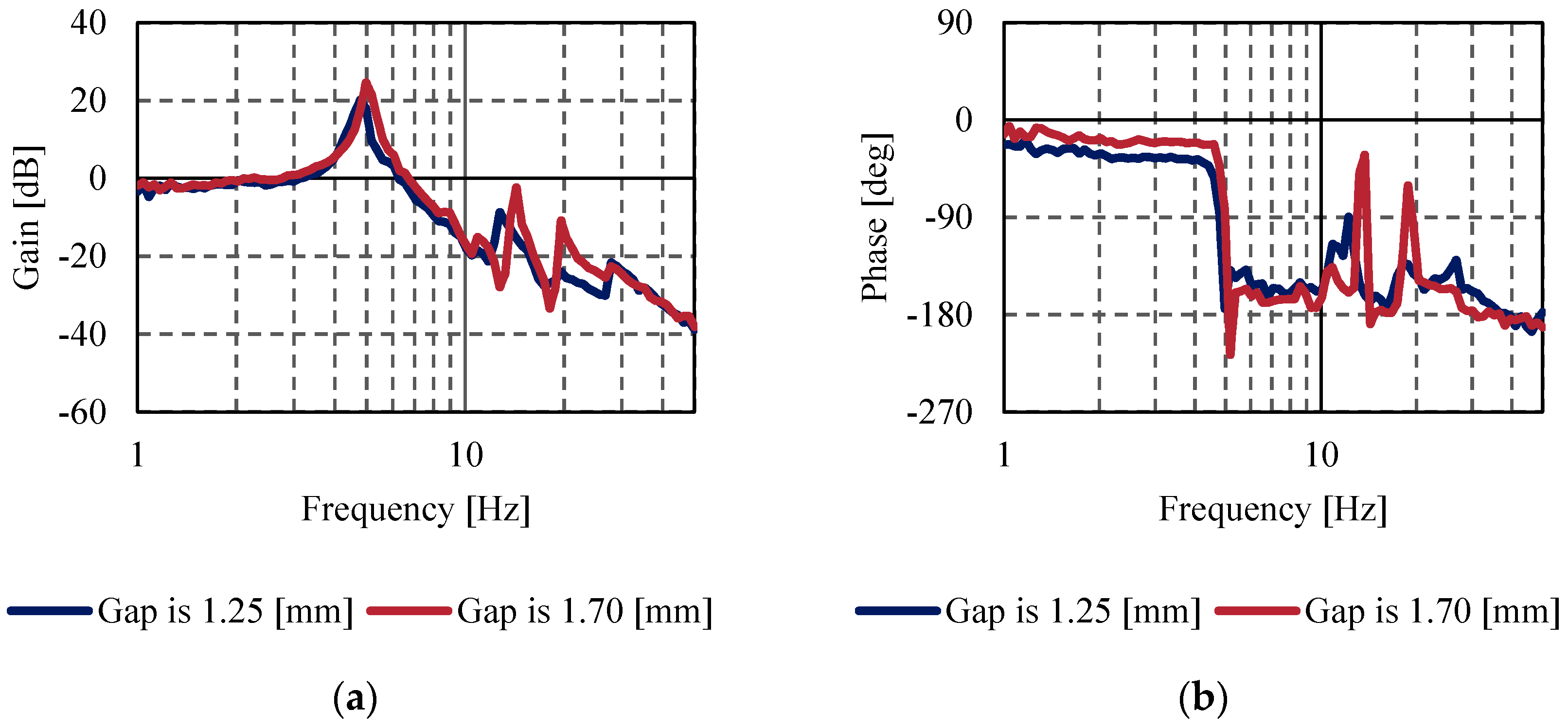

7. Characteristics of Suspension

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Britcher, C.; Britcher, C. Application of magnetic suspension technology to large scale facilities–Progress, problems and promises. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997. [Google Scholar]

- Mushi, S.E.; Lin, Z.; Allaire, P.E. Design, Construction, and Modeling of a Flexible Rotor Active Magnetic Bearing Test Rig. IEEE/ASME Trans. Mechatron. 2012, 17, 1170–1182. [Google Scholar] [CrossRef]

- MIZUNO, T. Analysis on the Fundamental Properties of Active Magnetic Bearing Control Systems by a Transfer Function Approach. JSME Int. J. Ser. C 2001, 44, 367–373. [Google Scholar] [CrossRef]

- Kimman, M.H.; Langen, H.H.; Munnig Schmidt, R.H. A miniature milling spindle with Active Magnetic Bearings. Mechatronics 2010, 20, 224–235. [Google Scholar] [CrossRef]

- Ahrens, M.; Kucera, L.; Larsonneur, R. Performance of a magnetically suspended flywheel energy storage device. IEEE Trans. Control. Syst. Technol. 1996, 4, 494–502. [Google Scholar] [CrossRef]

- Hijikata, W.; Shinshi, T.; Asama, J.; Li, L.; Hoshi, H.; Takatani, S.; Shimokohbe, A. A Magnetically Levitated Centrifugal Blood Pump With a Simple-structured Disposable Pump Head. Artif. Organs 2008, 32, 531–540. [Google Scholar] [CrossRef] [PubMed]

- Jayawant, B.V. Review Lecture–Electromagnetic suspension and levitation techniques. Proc. R. Soc. Lond. A. Math. Phys. Sci. 1988, 416, 245–320. [Google Scholar]

- Eisaka, T.; Hanajima, N.; Yanagita, Y.; Tagawa, R. Control of a Magnetic Levitation System by Robust Model Matching. IFAC Proc. Vol. 1993, 26, 173–176. [Google Scholar] [CrossRef]

- Yadav, S.; Verma, S.K.; Nagar, S.K. Optimized PID controller for magnetic levitation system. Ifac-PapersOnLine 2016, 49, 778–782. [Google Scholar] [CrossRef]

- Golob, M.; Tovornik, B. Modeling and control of the magnetic suspension system. ISA Trans. 2003, 42, 89–100. [Google Scholar] [CrossRef]

- Atherton, D. Maglev using permanent magnets. IEEE Trans. Magn. 1980, 16, 146–148. [Google Scholar] [CrossRef]

- Bassani, R. Earnshaw (1805–1888) and Passive Magnetic Levitation. Meccanica 2006, 41, 375–389. [Google Scholar] [CrossRef]

- Jayawant, B.V.; Sinha, P.K.; Wheeler, A.R.; Whorlow, R.J.; Willsher, J. Development of 1-ton magnetically suspended vehicle using controlled d.c. electromagnets. Proc. Inst. Electr. Eng. 1976, 123, 941. [Google Scholar] [CrossRef]

- Lindon, P.; Henn, J.W. Linear perturbation models for a.c. magnetic suspension systems. Int. J. Control. 1979, 30, 427–446. [Google Scholar] [CrossRef]

- Henn, J.W. Linear perturbation models for a.c. magnetic suspension systems: Experimental and theoretical results. Control. Theory Appl. IEE Proc. D 1980, 127, 64–74. [Google Scholar] [CrossRef]

- Moriyama, S.I. AC Magnetic Suspension Using a Differential Feedback Power Amplifier. IEEJ Trans. Ind. Appl. 1998, 118, 916–921. [Google Scholar] [CrossRef][Green Version]

- Kaplan, B.-Z.; Regev, D. Dynamic stabilization of tuned-circuit levitators. IEEE Trans. Magn. 1976, 12, 556–559. [Google Scholar] [CrossRef]

- Hagihara, S. Performance and stability of a magnetic suspension device using a tuned LCR circuit. Proc. Inst. Electr. Eng. 1978, 125, 153. [Google Scholar] [CrossRef]

- Kaplan, B.Z. A new analysis of tuned circuit levitators. Int. J. Non. Linear. Mech. 1974, 9, 75–87. [Google Scholar] [CrossRef]

- Jin, J.; Higuchi, T. Dynamics and Stability of Magnetic Suspension Systems Using Tuned LC Circuit. JSME Int. J. Ser. CDyn. Control. Robot. Des. Manuf. 1994, 37, 494–498. [Google Scholar] [CrossRef]

- Tsukamoto, O.; Yasuda, K.; Chen, J.Z. A new magnetic levitation system with AC magnets. IEEE Trans. Magn. 1988, 24, 1497–1500. [Google Scholar] [CrossRef]

- Imura, T.; Hori, Y. Maximizing Air Gap and Efficiency of Magnetic Resonant Coupling for Wireless Power Transfer Using Equivalent Circuit and Neumann Formula. IEEE Trans. Ind. Electron. 2011, 58, 4746–4752. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Wei, Y.; Song, Y. Study on electromagnetic characteristics of the magnetic coupling resonant coil for the wireless power transmission system. J. Appl. Biomater. Funct. Mater. 2018, 16, 140–149. [Google Scholar] [CrossRef] [PubMed]

- Barman, S.D.; Reza, A.W.; Kumar, N.; Karim, M.E.; Munir, A.B. Wireless powering by magnetic resonant coupling: Recent trends in wireless power transfer system and its applications. Renew. Sustain. Energy Rev. 2015, 51, 1525–1552. [Google Scholar] [CrossRef]

- Fareq, M.; Fitra, M.; Irwanto, M.; Syafruddin, H.S.; Gomesh, N.; Irwan, Y.M.; Halim, M.A.; Suwarno; Herman, A.; Hussain, T. 50 cm Air Gap Wireless Power Transfer by Magnetic Resonance Coupling. Appl. Mech. Mater. 2015, 785, 205–209. [Google Scholar] [CrossRef]

- Mizuno, T.; Takahashi, K.; Ishino, Y.; Takasaki, M. Novel AC magnetic suspension using magnetic resonant coupling. Mech. Eng. J. 2016, 3, 1–12. [Google Scholar] [CrossRef][Green Version]

- Rahman, A.; Mizuno, T.; Ishino, Y.; Takasaki, M.; Yamaguchi, D. Performance study on newly developed AC magnetic suspension system using magnetic resonance coupling. Int. J. Appl. Electromagn. Mech. 2020. accepted. [Google Scholar]

- Mizuno, T.; Takahashi, K.; Ishino, Y.; Takasaki, M. Proposal of AC Magnetic Suspension Using Magnetic Resonant Coupling. In Proceedings of the 14th International Symposium on Magnetic Bearings (ISMB14), Linz, Austria, 11−14 August 2014; pp. 491–494. [Google Scholar]

- Akiyama, T.; Mizuno, T.; Takasaki, M.; Ishino, Y.; Obara, K. Development of a totally active magnetically suspended gyro. Mechatronics 2014, 24, 1059–1070. [Google Scholar] [CrossRef]

- Cassell, W.L. Determining the equivalent circuit of a transformer by matrix methods. Electr. Eng. 1957, 76, 913–915. [Google Scholar] [CrossRef]

- Lord, H.W. An equivalent circuit for transformers in which nonlinear effects are present. Trans. Am. Inst. Electr. Eng. Part. I Commun. Electron. 1959, 78, 580–586. [Google Scholar] [CrossRef]

- Bhowmick, D.; Manna, M.; Chowdhury, S.K. Estimation of Equivalent Circuit Parameters of Transformer and Induction Motor from Load Data. IEEE Trans. Ind. Appl. 2018, 54, 2784–2791. [Google Scholar] [CrossRef]

- Guillod, T.; Krismer, F.; Kolar, J.W. Magnetic equivalent circuit of MF transformers: Modeling and parameter uncertainties. Electr. Eng. 2018, 100, 2261–2275. [Google Scholar] [CrossRef]

- Radun, A.V. Development of Dynamic Magnetic Circuit Models Including Iron Saturation and Losses. IEEE Trans. Magn. 2014, 50, 1–10. [Google Scholar] [CrossRef]

- Han, D.K.; Chang, J.H. Design of Electromagnetic Linear Actuator Using the Equivalent Magnetic Circuit Method. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Luo, M.; Dujic, D.; Allmeling, J. Leakage flux modelling of multi-winding transformer using permeance magnetic circuit. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; IEEE: Los Alamitos, CA, USA, 2016; pp. 1108–1114. [Google Scholar]

- Roters, H.C. Electromagnetic Devices, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1941. [Google Scholar]

- Kecik, K.; Mitura, A.; Lenci, S.; Warminski, J. Energy harvesting from a magnetic levitation system. Int. J. Non. Linear. Mech. 2017, 94, 200–206. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, A.; Mizuno, T.; Takasaki, M.; Ishino, Y. An Equivalent Circuit Analysis and Suspension Characteristics of AC Magnetic Suspension Using Magnetic Resonant Coupling. Actuators 2020, 9, 52. https://doi.org/10.3390/act9030052

Rahman A, Mizuno T, Takasaki M, Ishino Y. An Equivalent Circuit Analysis and Suspension Characteristics of AC Magnetic Suspension Using Magnetic Resonant Coupling. Actuators. 2020; 9(3):52. https://doi.org/10.3390/act9030052

Chicago/Turabian StyleRahman, Arifur, Takeshi Mizuno, Masaya Takasaki, and Yuji Ishino. 2020. "An Equivalent Circuit Analysis and Suspension Characteristics of AC Magnetic Suspension Using Magnetic Resonant Coupling" Actuators 9, no. 3: 52. https://doi.org/10.3390/act9030052

APA StyleRahman, A., Mizuno, T., Takasaki, M., & Ishino, Y. (2020). An Equivalent Circuit Analysis and Suspension Characteristics of AC Magnetic Suspension Using Magnetic Resonant Coupling. Actuators, 9(3), 52. https://doi.org/10.3390/act9030052