Plasma Synthetic Jet Actuators for Active Flow Control

Abstract

1. Introduction

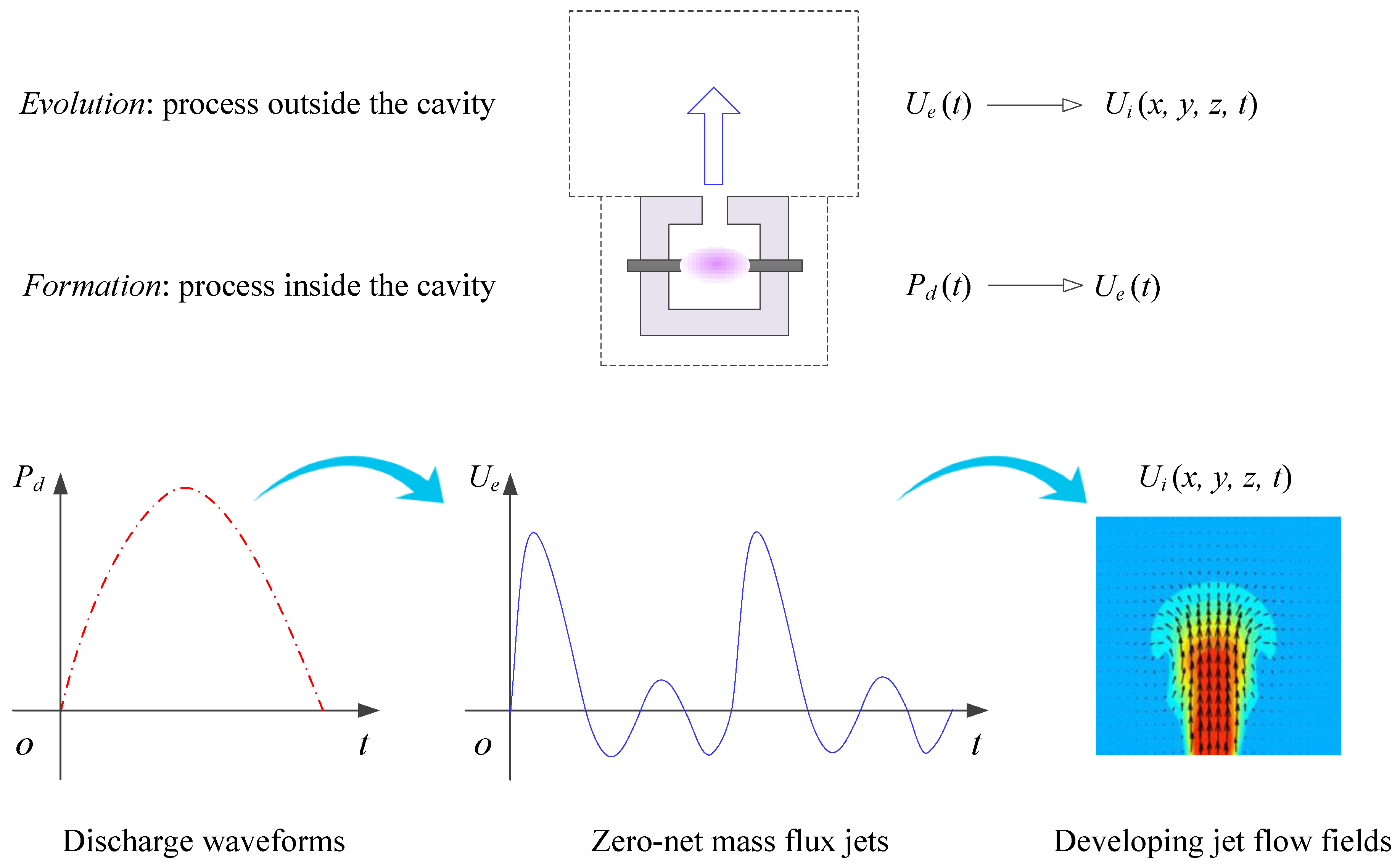

2. Plasma Synthetic Jet Actuator System

2.1. Working Principles

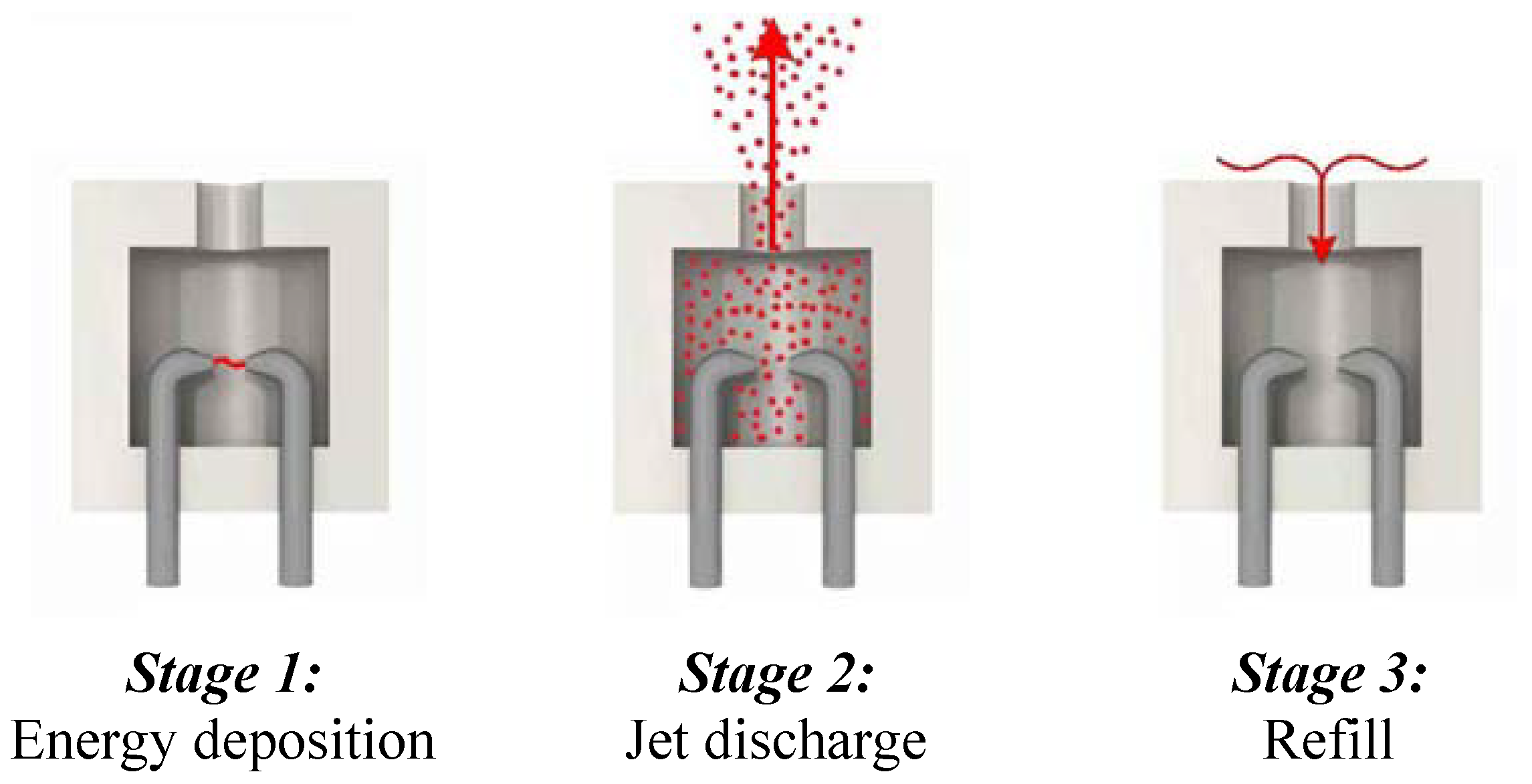

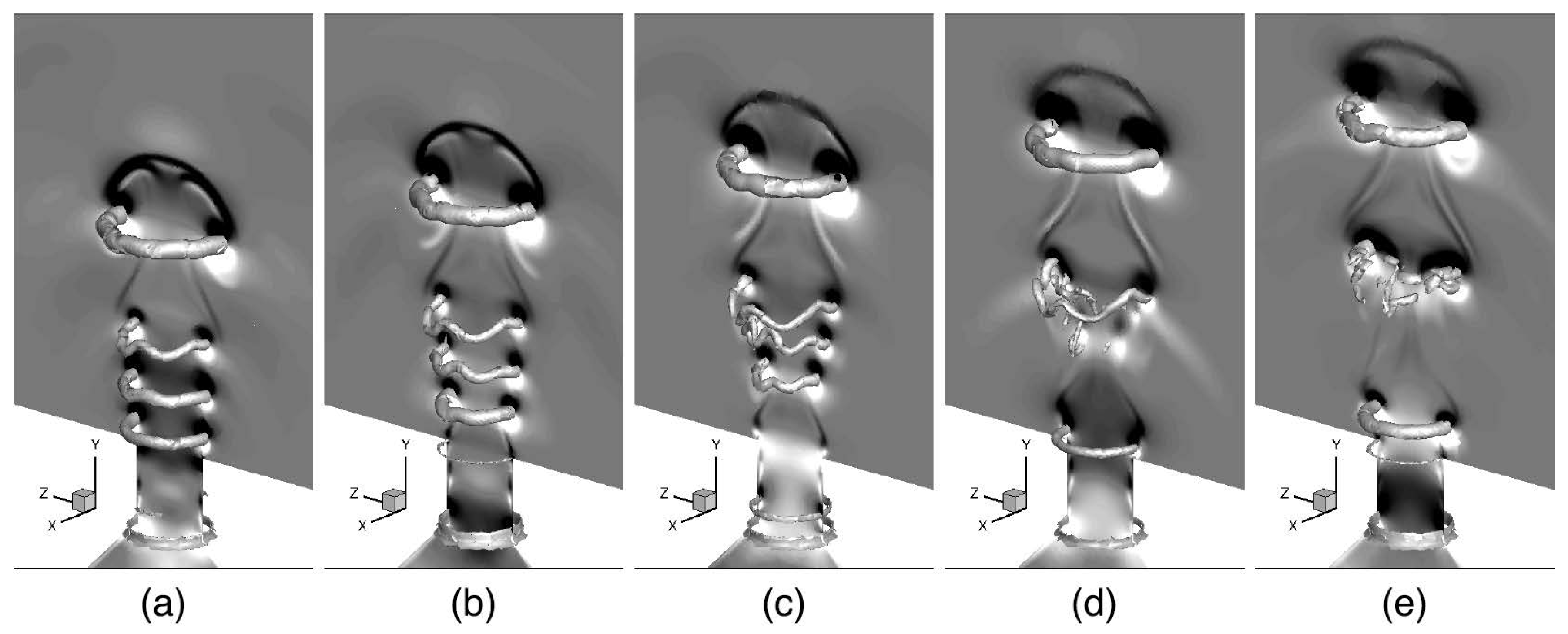

- The cycle begins with the generation of an electrical arc/spark within the cavity which provides energy to the fluid and quickly increases its temperature and pressure. Since the energy discharge is locally confined between the electrode gap, the spatial distributions of temperature and pressure are non-uniform. Several shock waves are produced, moving outwards at supersonic speed [24]. Details on the energy deposition process are reported in Section 2.2.

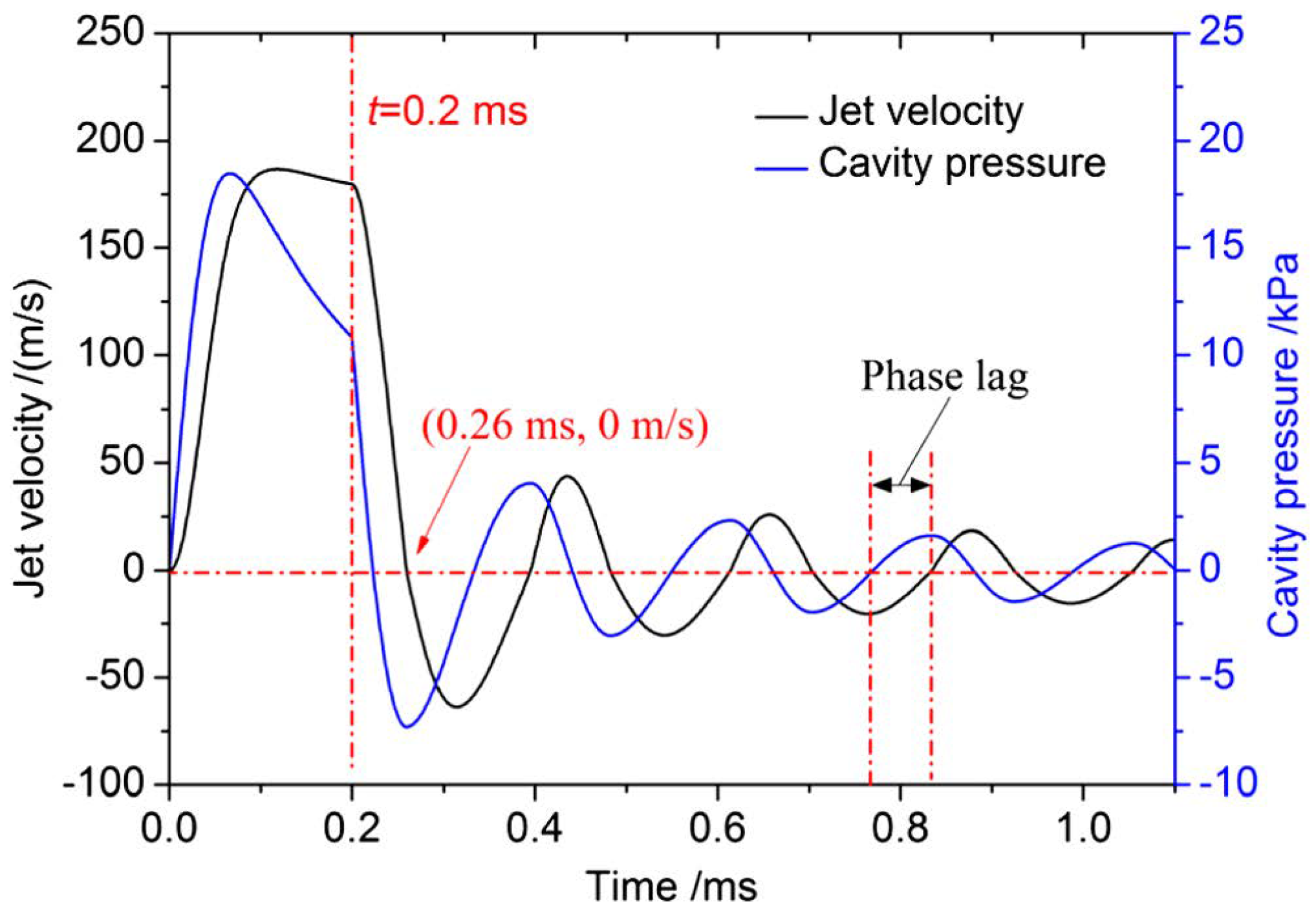

- After the energy deposition, the high-pressure air is exhausted through the orifice/slot, converting the internal energy of the cavity air into jet kinetic energy. During this process, a vortex ring forms near the orifice exit and convects downstream towards the far field under self-induction. The cavity pressure decreases due to the jet expulsion and the heat transfer through the actuator cavity wall. The jet evolution process depends on both the electrical parameters (e.g., the amount of energy transferred to the cavity air, the discharge duration) [25], and the geometric quantities of the actuator (e.g., exit orifice area, throat length, cavity volume, electrode distance and location) [26].

- The jet stage terminates with a negative differential pressure across the exit throat [27], which drives the air into the actuator cavity and initializes the refresh stage. The ingested low-temperature ambient air is subsequently mixed with the high-temperature cavity air, thus resetting the actuator cavity to its original state. Additionally, the convective and radiative heat transfer between the cavity and external environment also benefit the actuator recovery.

2.2. Power Supply Systems

- The trigger circuit is mainly composed of an internal DC power supply, a flyback circuit and a trigger transformer. The DC power supply provides a low adjustable voltage, which, through the flyback converter, is led to values of O(100) V. When switched on, the capacitors inside the circuit begin to discharge across the trigger transformer (with a ratio around 1:30) that quickly (in a few s) raise the voltage between the electrodes.

- The sustain circuit is represented by an external DC power supply, whose discharge time is controlled by a MOSFET (metal-oxide-semiconductor field-effect transistor), a ‘mixer’ consisting of two diodes, and an electrical ballast. The power supply can provide a voltage of up to O(500) V, which by itself is not able to produce a spark between the electrodes. The ‘mixer’ combines the electrical outputs of the trigger and sustain circuits together, while the electrical ballast protects the system.

2.3. Actuator Construction

2.4. Electromagnetic Interference

3. Characterization in Quiescent Flow

3.1. Experimental Studies

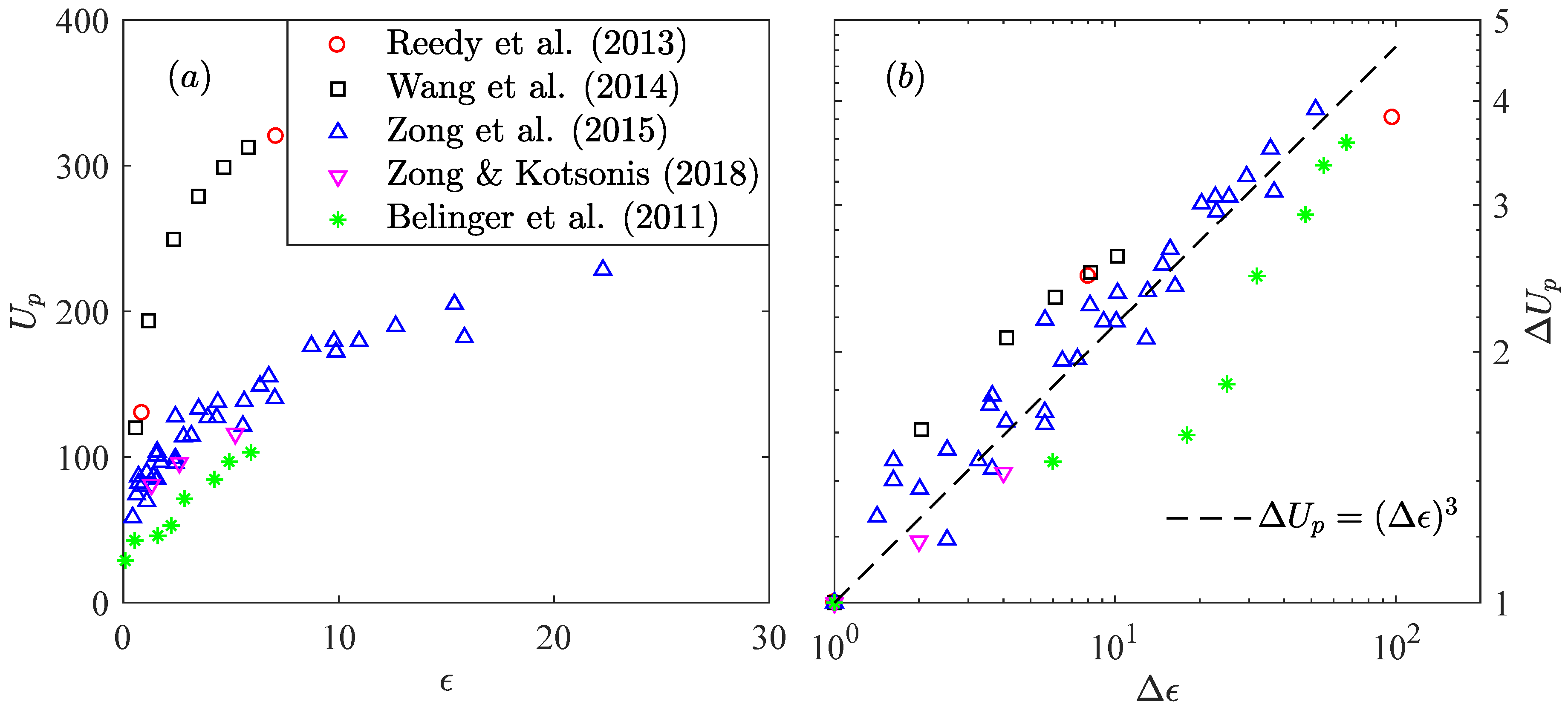

3.1.1. Jet Formation Parameters and Jet Intensity Metrics

3.1.2. Effect of Electrical Parameters on the Formation Process

3.1.3. Effect of Geometrical and Atmospheric Parameters on Formation Process

3.1.4. Evolution Process

3.2. Numerical Studies

3.3. Theoretical Models

3.3.1. Energy Deposition

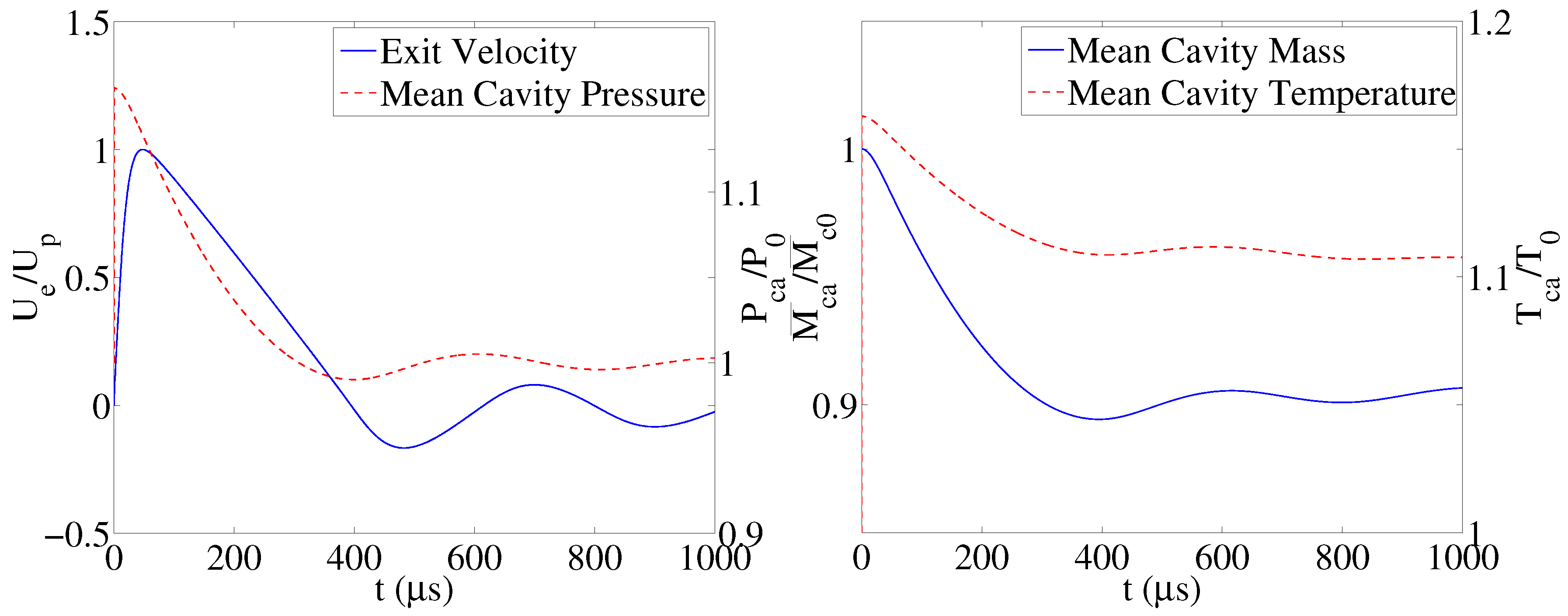

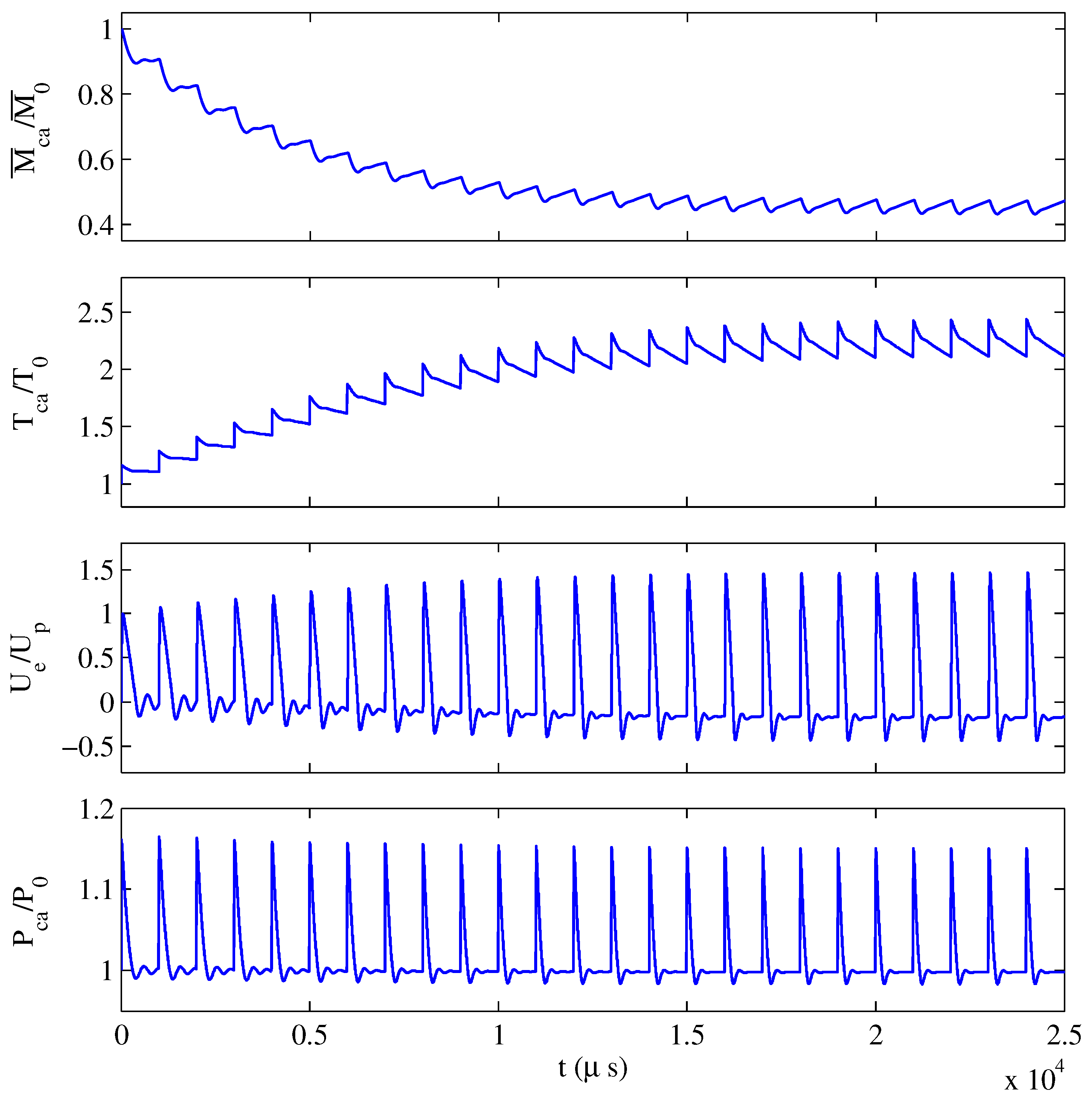

3.3.2. Jet and Refresh Stages

3.3.3. LEM Results

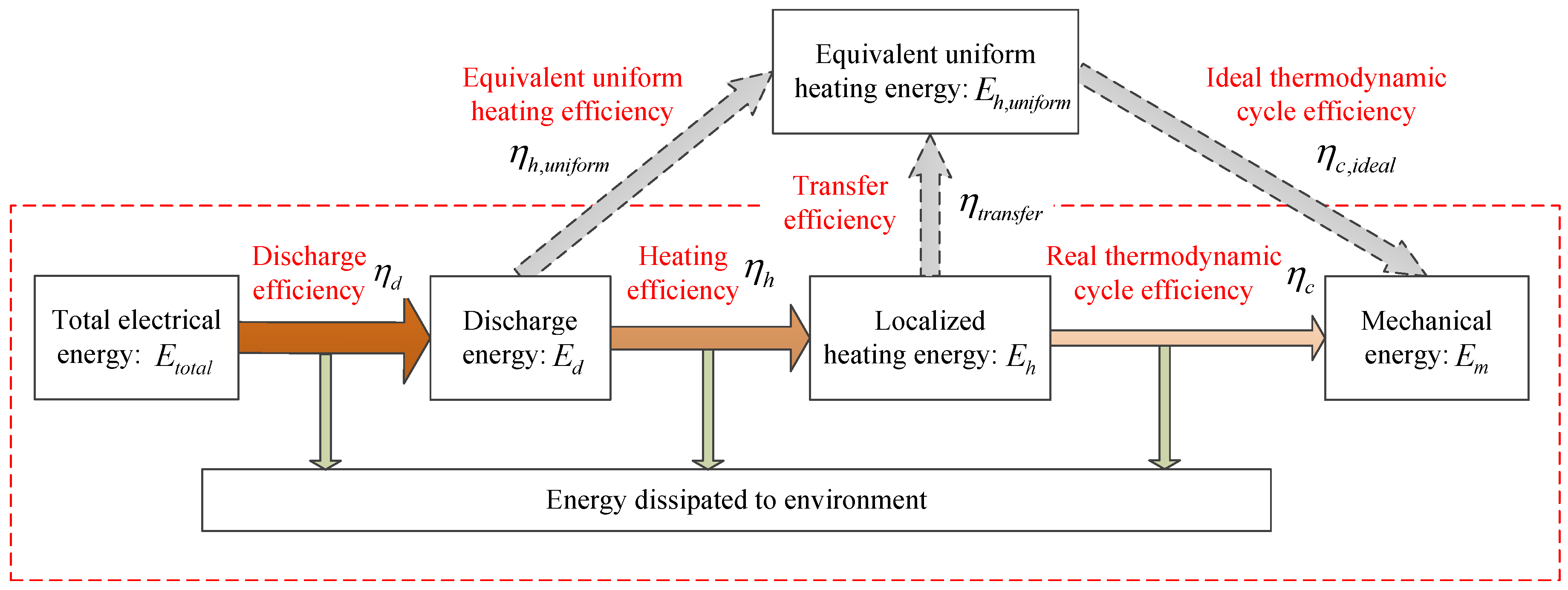

4. Energy Efficiency

5. Flow Control Applications

6. Conclusions and Recommendations

Author Contributions

Conflicts of Interest

References

- Cattafesta, L.N., III; Sheplak, M. Actuators for active flow control. Annu. Rev. Fluid Mech. 2011, 43, 247–272. [Google Scholar] [CrossRef]

- Gad-el Hak, M. Flow Control: Passive, Active, and Reactive Flow Management, 1st ed.; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Joslin, R.D.; Miller, D.N. (Eds.) Fundamentals and Applications of Modern Flow Control; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009. [Google Scholar]

- Glezer, A.; Amitay, M. Synthetic jets. Annu. Rev. Fluid Mech. 2002, 34, 503–529. [Google Scholar] [CrossRef]

- Chiatto, M.; Capuano, F.; Coppola, G.; de Luca, L. LEM characterization of synthetic jet actuators driven by piezoelectric element: A review. Sensors 2017, 17, 1216. [Google Scholar] [CrossRef] [PubMed]

- Grossman, K.; Bohdan, C.; VanWie, D. Sparkjet actuators for flow control. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003; p. 57. [Google Scholar]

- Cybyk, B.; Grossman, K.; Wilkerson, J. Performance characteristics of the sparkjet flow control actuator. In Proceedings of the 2nd AIAA Flow Control Conference, Portland, OR, USA, 28 June–1 July 2004; p. 2131. [Google Scholar]

- Cybyk, B.; Grossman, K.; Wilkerson, J.; Chen, J.; Katz, J. Single-pulse performance of the sparkjet flow control actuator. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; p. 401. [Google Scholar]

- Cybyk, B.; Land, H.; Simon, D.; Chen, J.; Katz, J. Experimental characterization of a supersonic flow control actuator. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 478. [Google Scholar]

- Haack Popkin, S.; Cybyk, B.; Land, B.; Foster, C.; Emerick, T.; Alvi, F. Recent Performance-Based Advances in SparkJet Actuator Design for Supersonic Flow Applications. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013; p. 322. [Google Scholar]

- Caruana, D.; Barricau, P.; Hardy, P. The “Plasma Synthetic Jet” Actuator. Aero-thermodynamic Characterization and First Flow Control Applications. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 1307. [Google Scholar]

- Hardy, P.; Barricau, P.; Caruana, D.; Gleyzes, C.; Belinger, A.; Cambronne, J.P. Plasma synthetic jet for flow control. In Proceedings of the 40th Fluid Dynamics Conference and Exhibit, Chicago, IL, USA, 28 June–1 July 2010; p. 5103. [Google Scholar]

- Belinger, A.; Hardy, P.; Barricau, P.; Cambronne, J.; Caruana, D. Influence of the energy dissipation rate in the discharge of a plasma synthetic jet actuator. J. Phys. D Appl. Phys. 2011, 44, 365201. [Google Scholar] [CrossRef]

- Belinger, A.; Naudé, N.; Cambronne, J.; Caruana, D. Plasma synthetic jet actuator: Electrical and optical analysis of the discharge. J. Phys. D Appl. Phys. 2014, 47, 345202. [Google Scholar] [CrossRef]

- Dufour, G.; Hardy, P.; Quint, G.; Rogier, F. Physics and models for plasma synthetic jets. Int. J. Aerodyn. 2013, 3, 47–70. [Google Scholar] [CrossRef]

- Sary, G.; Dufour, G.; Rogier, F.; Kourtzanidis, K. Modeling and parametric study of a plasma synthetic jet for flow control. AIAA J. 2014, 52, 1591–1603. [Google Scholar] [CrossRef]

- Narayanaswamy, V.; Shin, J.; Clemens, N.; Raja, L. Investigation of plasma-generated jets for supersonic flow control. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; p. 285. [Google Scholar]

- Narayanaswamy, V.; Raja, L.L.; Clemens, N.T. Control of a shock/boundary-layer interaction by using a pulsed-plasma jet actuator. AIAA J. 2012, 50, 246–249. [Google Scholar] [CrossRef]

- Reedy, T.M.; Kale, N.V.; Dutton, J.C.; Elliott, G.S. Experimental characterization of a pulsed plasma jet. AIAA J. 2013, 51, 2027–2031. [Google Scholar] [CrossRef]

- Anderson, K.V.; Knight, D.D. Plasma jet for flight control. AIAA J. 2012, 50, 1855–1872. [Google Scholar] [CrossRef]

- Zong, H.; Wu, Y.; Jia, M.; Song, H.; Liang, H.; Li, Y.; Zhang, Z. Influence of geometrical parameters on performance of plasma synthetic jet actuator. J. Phys. D Appl. Phys. 2015, 49, 025504. [Google Scholar] [CrossRef]

- Zong, H.; Kotsonis, M. Characterisation of plasma synthetic jet actuators in quiescent flow. J. Phys. D Appl. Phys. 2016, 49, 335202. [Google Scholar] [CrossRef]

- Chiatto, M.; de Luca, L. Numerical and Experimental Frequency Response of Plasma Synthetic Jet Actuators. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January2017. [Google Scholar] [CrossRef]

- Zong, H.; Kotsonis, M. Electro-mechanical efficiency of plasma synthetic jet actuator driven by capacitive discharge. J. Phys. D Appl. Phys. 2016, 49, 455201. [Google Scholar] [CrossRef]

- Zong, H.; Cui, W.; Wu, Y.; Zhang, Z.; Liang, H.; Jia, M.; Li, Y. Influence of capacitor energy on performance of a three-electrode plasma synthetic jet actuator. Sens. Actuators A Phys. 2015, 222, 114–121. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Y.; Jia, M.; Zong, H.; Cui, W.; Liang, H.; Li, Y. Influence of the discharge location on the performance of a three-electrode plasma synthetic jet actuator. Sens. Actuators A Phys. 2015, 235, 71–79. [Google Scholar] [CrossRef]

- Popkin, S.H.; Cybyk, B.Z.; Foster, C.H.; Alvi, F.S. Experimental estimation of SparkJet efficiency. AIAA J. 2016, 54, 1831–1845. [Google Scholar] [CrossRef]

- Zong, H.; Wu, Y.; Song, H.; Jia, M. Efficiency characteristic of plasma synthetic jet actuator driven by pulsed direct-current discharge. AIAA J. 2016, 54, 3409–3420. [Google Scholar] [CrossRef]

- Roth, J. Industrial Plasma Engineering. Volume 1: Principles; Institute of Physics Publishing: Bristol, UK; Philadelphia, PA, USA, 1995. [Google Scholar]

- Popkin, S.H.; Taylor, T.M.; Cybyk, B.Z. Development and application of the sparkjet actuator for high-speed flow control. Johns Hopkins APL Tech. Dig. 2013, 32, 404–418. [Google Scholar]

- Chiatto, M.; Palumbo, A.; de Luca, L. A Calibrated Lumped Element Model for the Prediction of PSJ Actuator Efficiency Performance. Actuators 2018, 7, 10. [Google Scholar] [CrossRef]

- Haack, S.; Land, H.; Cybyk, B.; Ko, H.; Katz, J. Characterization of a high-speed flow control actuator using digital speckle tomography and PIV. In Proceedings of the 4th AIAA Flow Control Conference, Seattle, WA, USA, 23–26 June 2008. [Google Scholar]

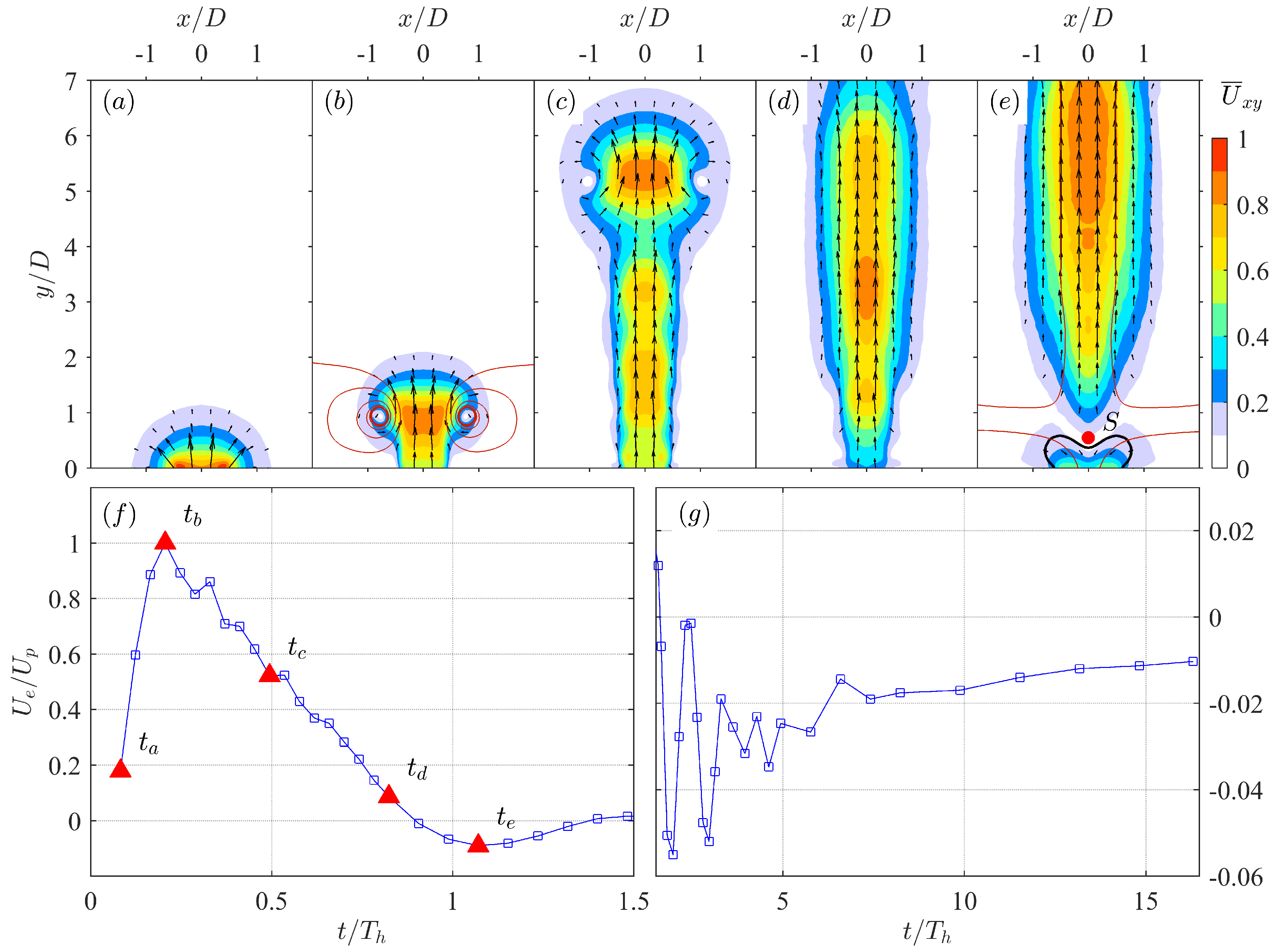

- Zong, H.; Kotsonis, M. Formation, evolution and scaling of plasma synthetic jets. J. Fluid Mech. 2018, 837, 147–181. [Google Scholar] [CrossRef]

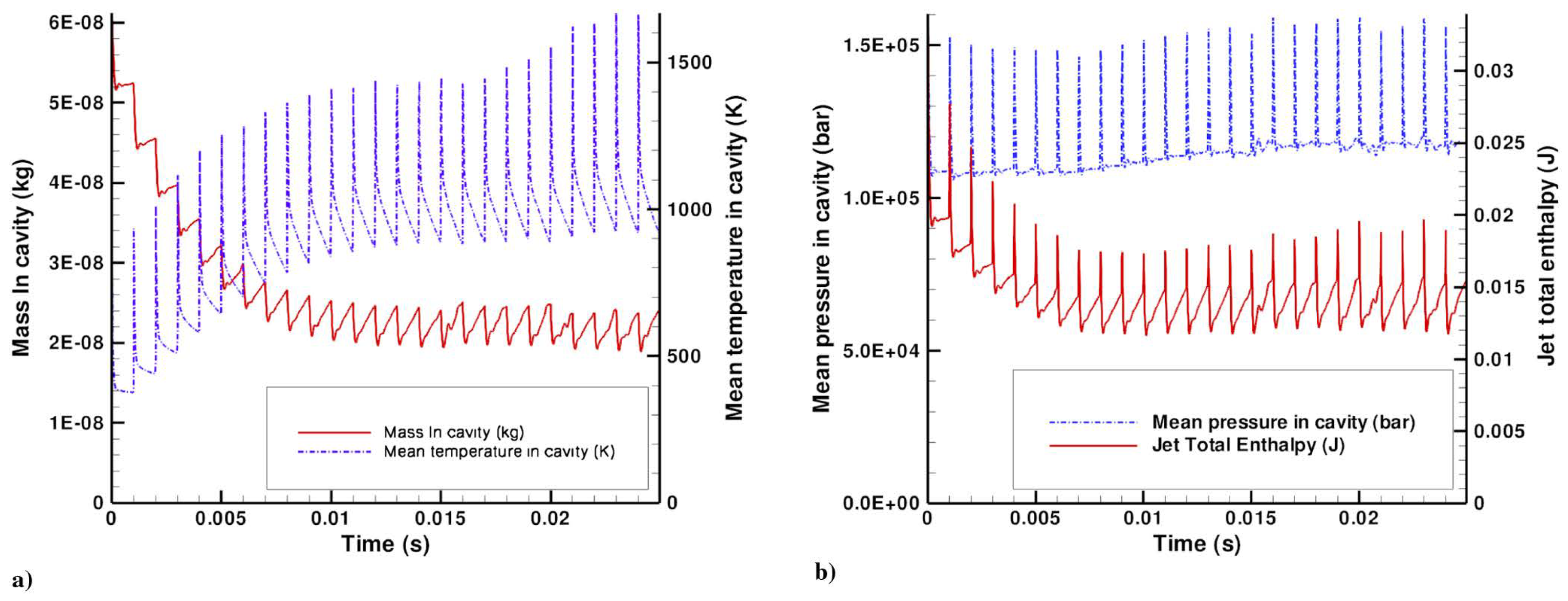

- Zong, H.; Wu, Y.; Li, Y.; Song, H.; Zhang, Z.; Jia, M. Analytic model and frequency characteristics of plasma synthetic jet actuator. Phys. Fluids 2015, 27, 027105. [Google Scholar] [CrossRef]

- Arena, M.; Chiatto, M.; Amoroso, F.; Pecora, R.; de Luca, L. Feasibility studies for the installation of Plasma Synthetic Jet Actuators on the skin of a morphing wing flap. Proc. SPIE 2018, 10595, 105950M. [Google Scholar] [CrossRef]

- Tang, M.; Wu, Y.; Wang, H.; Jin, D.; Guo, S.; Gan, T. Effects of Capacitance on a Plasma Synthetic jet Actuator with a conical cavity. Sens. Actuators A Phys. 2018, 276, 284–295. [Google Scholar] [CrossRef]

- Haack, S.; Taylor, T.; Emhoff, J.; Cybyk, B. Development of an analytical SparkJet model. In Proceedings of the 5th Flow Control Conference, Chicago, IL, USA, 28 June–1 July 2010; p. 4979. [Google Scholar]

- Haack, S.; Taylor, T.; Cybyk, B.; Foster, C.; Alvi, F. Experimental estimation of sparkjet efficiency. In Proceedings of the 42nd AIAA Plasmadynamics and Lasers Conference in Conjunction with the 18th International Conference on MHD Energy Conversion (ICMHD), Honolulu, HI, USA, 27–30 June 2011; p. 3997. [Google Scholar]

- Wang, L.; Xia, Z.x.; Luo, Z.b.; Chen, J. Three-electrode plasma synthetic jet actuator for high-speed flow control. AIAA J. 2013, 52, 879–882. [Google Scholar] [CrossRef]

- Golbabaei-Asl, M.; Knight, D.; Wilkinson, S. Novel technique to determine sparkjet efficiency. AIAA J. 2014, 53, 501–504. [Google Scholar] [CrossRef]

- Jin, D.; Cui, W.; Li, Y.; Li, F.; Jia, M.; Sun, Q.; Zhang, B. Characteristics of pulsed plasma synthetic jet and its control effect on supersonic flow. Chin. J. Aeronaut. 2015, 28, 66–76. [Google Scholar] [CrossRef]

- Narayanaswamy, V.; Raja, L.L.; Clemens, N.T. Characterization of a high-frequency pulsed-plasma jet actuator for supersonic flow control. AIAA J. 2010, 48, 297–305. [Google Scholar] [CrossRef]

- Emerick, T.; Ali, M.; Foster, C.; Alvi, F.; Haack Popkin, S.; Cybyk, B. Sparkjet actuator characterization in supersonic crossflow. In Proceedings of the 6th AIAA Flow Control Conference, New Orleans, LA, USA, 25–28 June 2012; p. 2814. [Google Scholar]

- Jin, D.; Li, Y.; Jia, M.; Song, H.; Cui, W.; Sun, Q.; Li, F. Experimental characterization of the plasma synthetic jet actuator. Plasma Sci. Technol. 2013, 15, 1034–1040. [Google Scholar] [CrossRef]

- Wang, L.; Xia, Z.; Luo, Z.; Zhang, Y. Effect of pressure on the performance of plasma synthetic jet actuator. Sci. China Phys. Mech. Astron. 2014, 57, 2309–2315. [Google Scholar] [CrossRef]

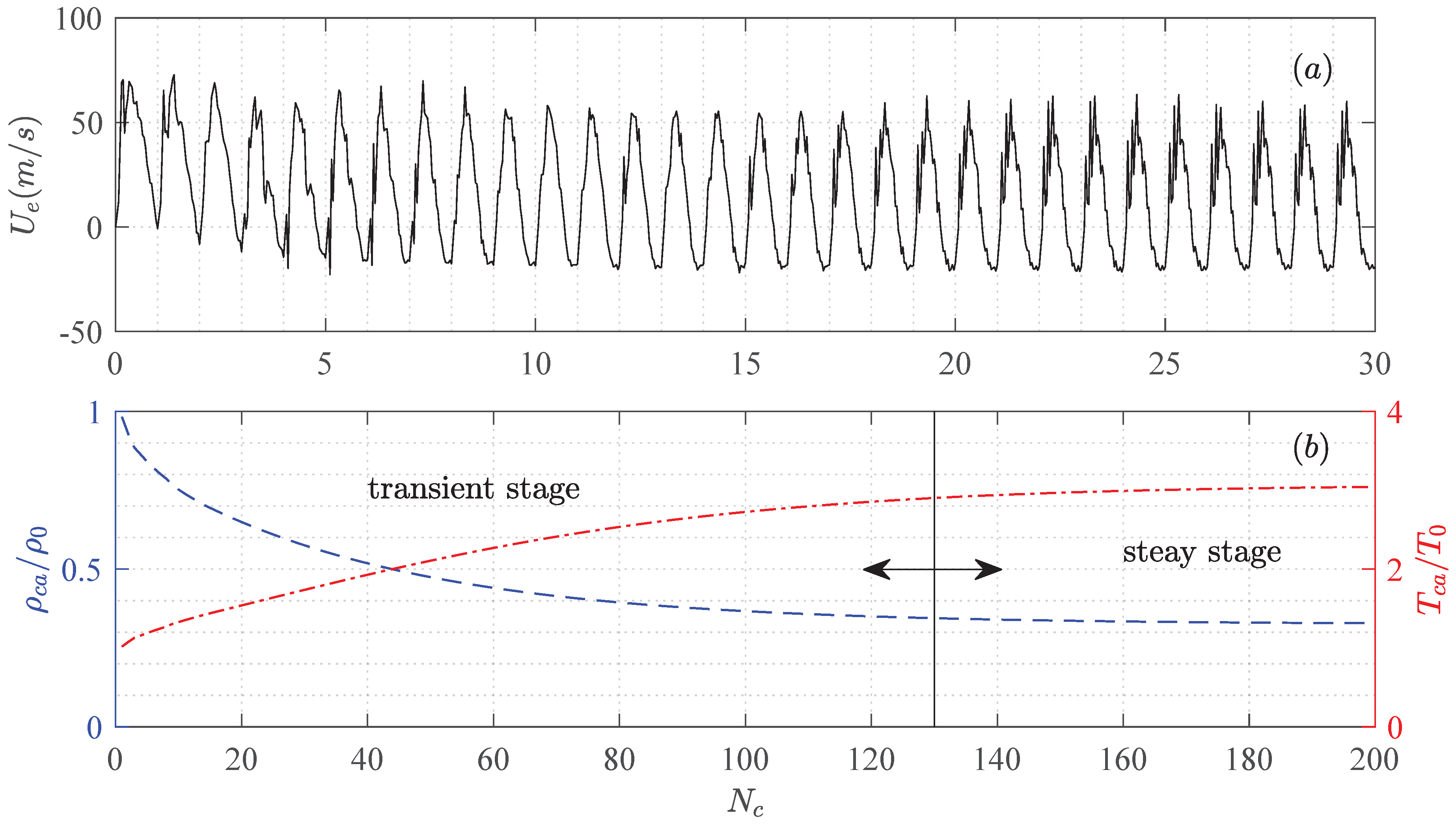

- Zong, H.; Kotsonis, M. Experimental investigation on frequency characteristics of plasma synthetic jets. Phys. Fluids 2017, 29, 115107. [Google Scholar] [CrossRef]

- Grossman, K.; Cybyk, B.; VanWie, D.; Rigling, M. Characterization of sparkjet actuators for flow control. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 5–8 January 2004; p. 89. [Google Scholar]

- Wang, L.; Xia, Z.; Luo, Z.; Zhou, Y.; Zhang, Y. Experimental study on the characteristics of a two-electrode plasma synthetic jet actuator. Acta Phys. Sin. 2014, 63, 194702. [Google Scholar]

- Zong, H. Influence of Nondimensional Heating Volume on Efficiency of Plasma Synthetic Jet Actuators. AIAA J. 2017, 56, 1–4. [Google Scholar] [CrossRef]

- Emerick, T.; Ali, M.; Foster, C.; Alvi, F.; Popkin, S. SparkJet characterizations in quiescent and supersonic flowfields. Exp. Fluids 2014, 55, 1858. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Y.; Jia, M.; Song, H.; Sun, Z.; Zong, H.; Li, Y. The multichannel discharge plasma synthetic jet actuator. Sens. Actuators A Phys. 2017, 253, 112–117. [Google Scholar] [CrossRef]

- Zong, H.; Kotsonis, M. Effect of slotted exit orifice on performance of plasma synthetic jet actuator. Exp. Fluids 2017, 58, 17. [Google Scholar] [CrossRef]

- Li, Y.; Jia, M.; Wu, Y.; Li, Y.H.; Zong, H.H.; Song, H.M.; Liang, H. Influence of air pressure on the performance of plasma synthetic jet actuator. Chin. Phys. B 2016, 25, 095205. [Google Scholar] [CrossRef]

- Zong, H.; Wu, Y.; Song, H.; Jia, M.; Liang, H.; Li, Y.; Zhang, Z. Investigation of the performance characteristics of a plasma synthetic jet actuator based on a quantitative Schlieren method. Meas. Sci. Technol. 2016, 27, 055301. [Google Scholar] [CrossRef]

- Ko, H.; Haack, S.; Land, H.; Cybyk, B.; Katz, J.; Kim, H. Analysis of flow distribution from high-speed flow actuator using particle image velocimetry and digital speckle tomography. Flow Meas. Instrum. 2010, 21, 443–453. [Google Scholar] [CrossRef]

- Gil, P.; Strzelczyk, P. Performance and efficiency of loudspeaker driven synthetic jet actuator. Exp. Therm. Fluid Sci. 2016, 76, 163–174. [Google Scholar] [CrossRef]

- Trávníček, Z.; Kordík, J. Energetic efficiencies of synthetic jet actuators: Commentary on the article by Gil and Strzelczyk. Exp. Therm. Fluid Sci. 2018, 98, 121–123. [Google Scholar] [CrossRef]

- Cybyk, B.; Grossman, K.; Van Wie, D. Computational assessment of the sparkjet flow control actuator. In Proceedings of the 33rd AIAA Fluid Dynamics Conference and Exhibit, Orlando, FL, USA, 23–26 June 2003; p. 3711. [Google Scholar]

- Zhang, Z.; Wu, Y.; Jia, M.; Song, H.; Sun, Z.; Li, Y. MHD-RLC discharge model and the efficiency characteristics of plasma synthetic jet actuator. Sens. Actuators A Phys. 2017, 261, 75–84. [Google Scholar] [CrossRef]

- Smy, P.; Clements, R.; Dale, J.; Simeoni, D.; Topham, D. Efficiency and erosion characteristics of plasma jet igniters. J. Phys. D Appl. Phys. 1983, 16, 783. [Google Scholar] [CrossRef]

- Shin, J. Characteristics of high speed electro-thermal jet activated by pulsed DC discharge. Chin. J. Aeronaut. 2010, 23, 518–522. [Google Scholar] [CrossRef]

- Gharib, M.; Rambod, E.; Shariff, K. A universal time scale for vortex ring formation. J. Fluid Mech. 1998, 360, 121–140. [Google Scholar] [CrossRef]

- Laurendeau, F.; Chedevergne, F.; Casalis, G. Transient ejection phase modeling of a plasma synthetic jet actuator. Phys. Fluids 2014, 26, 125101. [Google Scholar] [CrossRef]

- Gutmark, E.; Grinstein, F. Flow control with noncircular jets. Annu. Rev. Fluid Mech. 1999, 31, 239–272. [Google Scholar] [CrossRef]

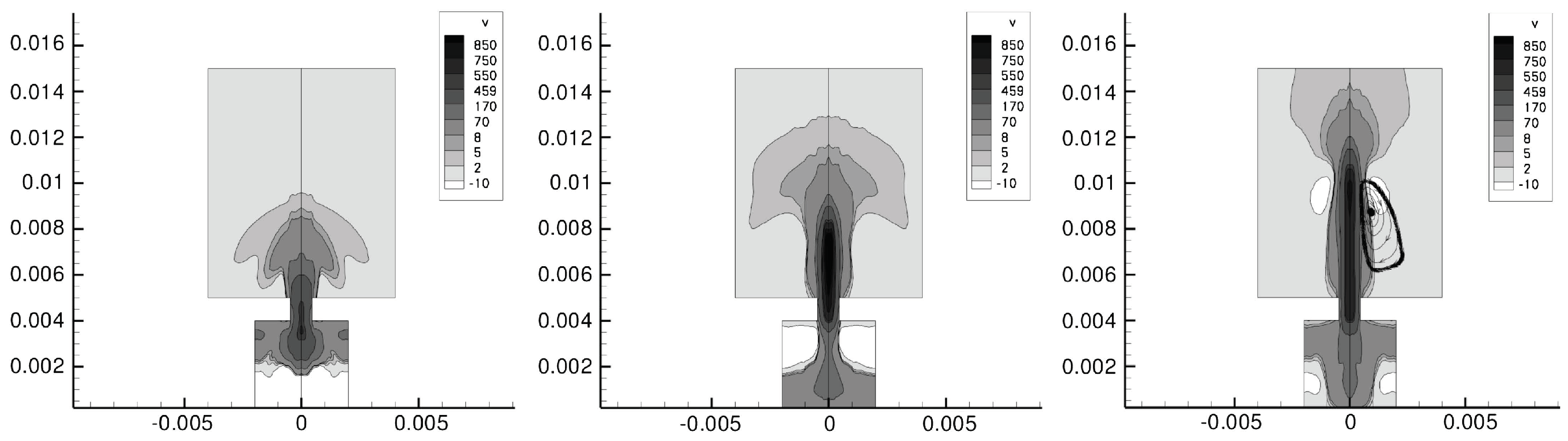

- Quint, G.; Rogier, F.; Dufour, G. Numerical modelling of the electrical arc created inside the cavity of the PSJ actuator. In Proceedings of the 20th AIAA Computational Fluid Dynamics Conference, Honolulu, HI, USA, 27–30 June 2011. [Google Scholar]

- Laurendeau, F.; Léon, O.; Chedevergne, F.; Senoner, J.M.; Casalis, G. Particle image velocimetry experiment analysis using large-eddy simulation: Application to plasma actuators. AIAA J. 2017, 55, 3767–3780. [Google Scholar] [CrossRef]

- Capitelli, M.; Colonna, G.; Gorse, C.; D’Angola, A. Transport properties of high temperature air in local thermodynamic equilibrium. Eur. Phys. J. D 2010, 11, 279–289. [Google Scholar] [CrossRef]

- De Luca, L.; Girfoglio, M.; Chiatto, M.; Coppola, G. Scaling properties of resonant cavities driven by piezo-electric actuators. Sens. Actuators A Phys. 2016, 247, 465–474. [Google Scholar] [CrossRef]

- Wang, L.; Luo, Z.B.; Xia, Z.X.; Liu, B. Energy efficiency and performance characteristics of plasma synthetic jet. Acta Phys. Sin. 2013, 62, 125207. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, Y.; Jia, M.; Liang, H.; Li, J.; Li, Y. Influence of positive slopes on ultrafast heating in an atmospheric nanosecond-pulsed plasma synthetic jet. Plasma Sources Sci. Technol. 2014, 24, 015007. [Google Scholar] [CrossRef]

- Zong, H.; Kotsonis, M. Realisation of plasma synthetic jet array with a novel sequential discharge. Sens. Actuators A Phys. 2017, 266, 314–317. [Google Scholar] [CrossRef]

- Caruana, D.; Rogier, F.; Dufour, G.; Gleyzes, C. The plasma synthetic jet actuator, physics, modeling and flow control application on separation. AerospaceLab 2013, 6, 1. [Google Scholar]

- Liu, R.; Niu, Z.; Wang, M.; Hao, M.; Lin, Q. Aerodynamic control of NACA 0021 airfoil model with spark discharge plasma synthetic jets. Sci. China Technol. Sci. 2015, 58, 1949–1955. [Google Scholar] [CrossRef]

- Léon, O.; Caruana, D.; Castelain, T. Increase and decrease of the noise radiated by high-Reynolds-number subsonic jets through plasma synthetic jet actuation. In Proceedings of the International Conference on Acoustic Climate Inside and Outside Buildings, Vilnius, Lithuania, 23–26 September 2014. [Google Scholar]

- Chedevergne, F.; Léon, O.; Bodoc, V.; Caruana, D. Experimental and numerical response of a high-Reynolds-number M = 0.6 jet to a Plasma Synthetic Jet actuator. Int. J. Heat Fluid Flow 2015, 56, 1–15. [Google Scholar] [CrossRef]

- Narayanaswamy, V. Investigation of a Pulsed-Plasma Jet for Separation Shock/boundary Layer Interaction Control. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2010. [Google Scholar]

- Narayanaswamy, V.; Raja, L.L.; Clemens, N.T. Control of unsteadiness of a shock wave/turbulent boundary layer interaction by using a pulsed-plasma-jet actuator. Phys. Fluids 2012, 24, 076101. [Google Scholar] [CrossRef]

- Greene, B.; Clemens, N.; Magari, P.; Micka, D. Control of mean separation in shock boundary layer interaction using pulsed plasma jets. Shock Waves 2015, 25, 495–505. [Google Scholar] [CrossRef]

- Jin, D.; Jia, M.; Song, H.; Wu, Y.; Li, F. Control Effect of Arc-driven Plasma Synthetic Jet on Supersonic Shockwave. In Proceedings of the 21st AIAA International Space Planes and Hypersonics Technologies Conference, Xiamen, China, 6–9 March 2017; p. 2228. [Google Scholar]

- Wang, H.; Li, J.; Jin, D.; Dai, H.; Gan, T.; Wu, Y. Effect of a transverse plasma jet on a shock wave induced by a ramp. Chin. J. Aeronaut. 2017, 30, 1854–1865. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Jin, D.; Zhang, Z.; Tang, M.; Wu, Y. Manipulation of ramp-induced shock wave/boundary layer interaction using a transverse plasma jet array. Int. J. Heat Fluid Flow 2017, 67, 133–137. [Google Scholar]

- Wang, H.; Li, J.; Jin, D.; Tang, M.; Wu, Y.; Xiao, L. High-frequency counter-flow plasma synthetic jet actuator and its application in suppression of supersonic flow separation. Acta Astronaut. 2018, 142, 45–56. [Google Scholar] [CrossRef]

- Zhou, Y.; Xia, Z.; Luo, Z.; Wang, L. Effect of three-electrode plasma synthetic jet actuator on shock wave control. Sci. China Technol. Sci. 2017, 60, 146–152. [Google Scholar] [CrossRef]

- Zong, H.; Kotsonis, M. Interaction between plasma synthetic jet and subsonic turbulent boundary layer. Phys. Fluids 2017, 29, 045104. [Google Scholar] [CrossRef]

- Babinsky, H.; Harvey, J.K. Shock Wave-Boundary-Layer Interactions; Cambridge University Press: Cambridge, UK, 2011; Volume 32. [Google Scholar]

- Narayanaswamy, V.; Clemens, N.T.; Raja, L.L. Method for acquiring pressure measurements in presence of plasma-induced interference for supersonic flow control applications. Meas. Sci. Technol. 2011, 22, 125107. [Google Scholar] [CrossRef]

- Yang, G.; Yao, Y.; Fang, J.; Gan, T.; Lu, L. Large-eddy simulation of shock-induced flow separation control using SparkJet concept. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 0045. [Google Scholar]

| Category | Parameters | Referenced Studies | Measurement Techniques |

|---|---|---|---|

| Electrical | Discharge energy, | [9,13,14,19,24,25,36,37,38,39,40,41] | MTTB, DPT, SI, TPP, PIV, PA |

| Repetition rate, | [23,34,41,42,43,44,45,46] | TPP, SI, PIV | |

| Discharge duration, | [13,28] | TPP | |

| Geometrical | Cavity volume, | [27,28,42,47,48,49] | SI, PIV, TPP |

| Exit diameter, D | [21,22,47,50] | SI, TPP, PIV | |

| Throat length, | [21] | TPP | |

| Electrode configuration | [21,26,49,51] | TPP, SI, PIV | |

| Orifice configuration | [50,52] | PIV, SI | |

| Atmospheric | Ambient pressure, | [38,43,45,53] | DPT, SI |

| Ambient temperature, | – | – | |

| Humidity, | – | – |

| Category | Institutions | Representative Literatures |

|---|---|---|

| Separation control at moderate-Reynolds number | ONERA; Xiamen University; UNINA | [35,72,73] |

| Jet noise control | ONERA | [12,74,75] |

| Shock wave/boundary layer interaction control | UT Austin; AFEU; NUDT | [18,76,77,78,79,80,81,82,83] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, H.; Chiatto, M.; Kotsonis, M.; De Luca, L. Plasma Synthetic Jet Actuators for Active Flow Control. Actuators 2018, 7, 77. https://doi.org/10.3390/act7040077

Zong H, Chiatto M, Kotsonis M, De Luca L. Plasma Synthetic Jet Actuators for Active Flow Control. Actuators. 2018; 7(4):77. https://doi.org/10.3390/act7040077

Chicago/Turabian StyleZong, Haohua, Matteo Chiatto, Marios Kotsonis, and Luigi De Luca. 2018. "Plasma Synthetic Jet Actuators for Active Flow Control" Actuators 7, no. 4: 77. https://doi.org/10.3390/act7040077

APA StyleZong, H., Chiatto, M., Kotsonis, M., & De Luca, L. (2018). Plasma Synthetic Jet Actuators for Active Flow Control. Actuators, 7(4), 77. https://doi.org/10.3390/act7040077