An Overview of Novel Actuators for Soft Robotics

Abstract

1. Introduction

2. Systematical Review Method

2.1. Mechanical Compliance

2.2. Optimal Geometry

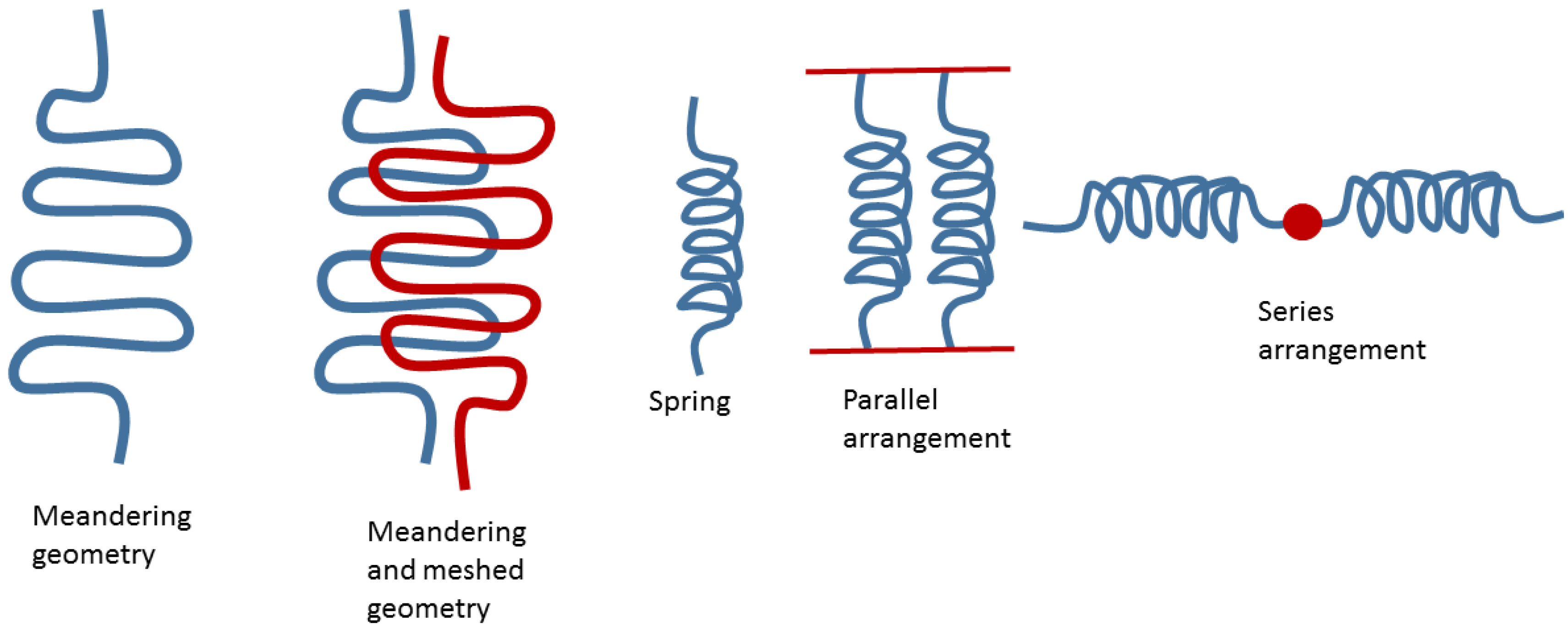

2.2.1. Optimal Geometry in SMA

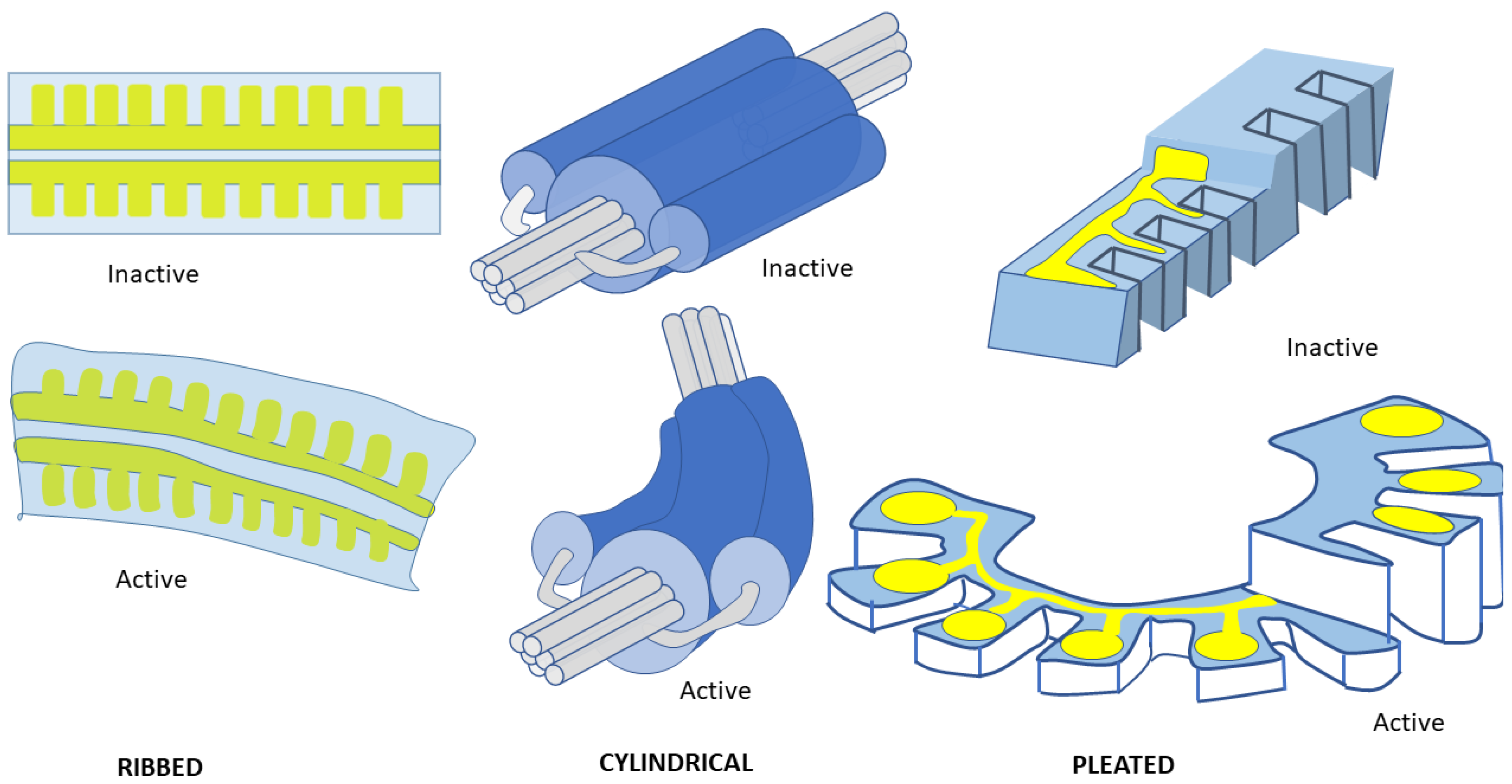

2.2.2. Optimal Geometry in FEA.

2.2.3. Optimal Geometry in SMP

2.2.4. Optimal Geometry in DEAP

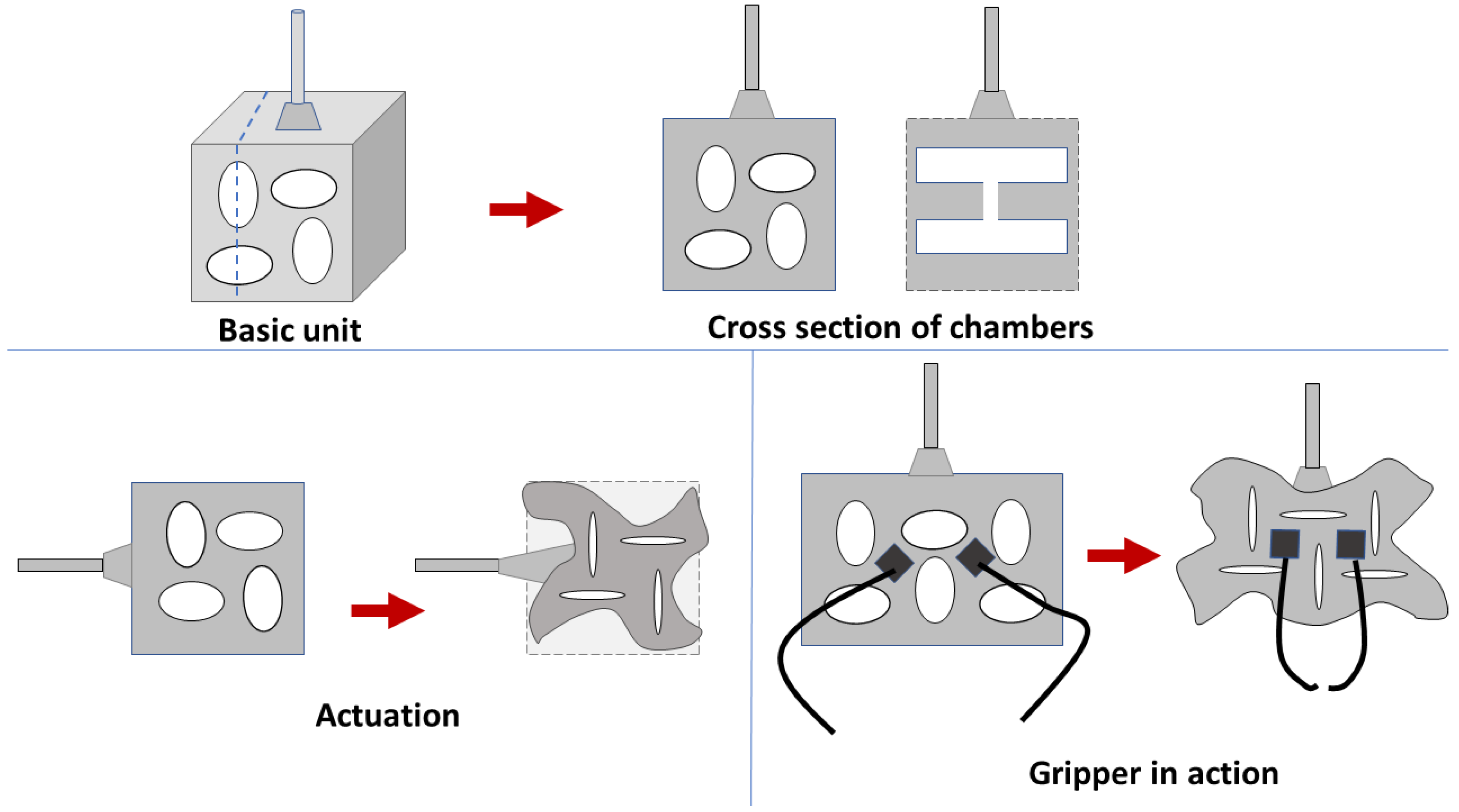

2.2.5. Optimal Geometry in E/MA

2.3. Scalability and Complexity

2.3.1. Scalability of SMAs

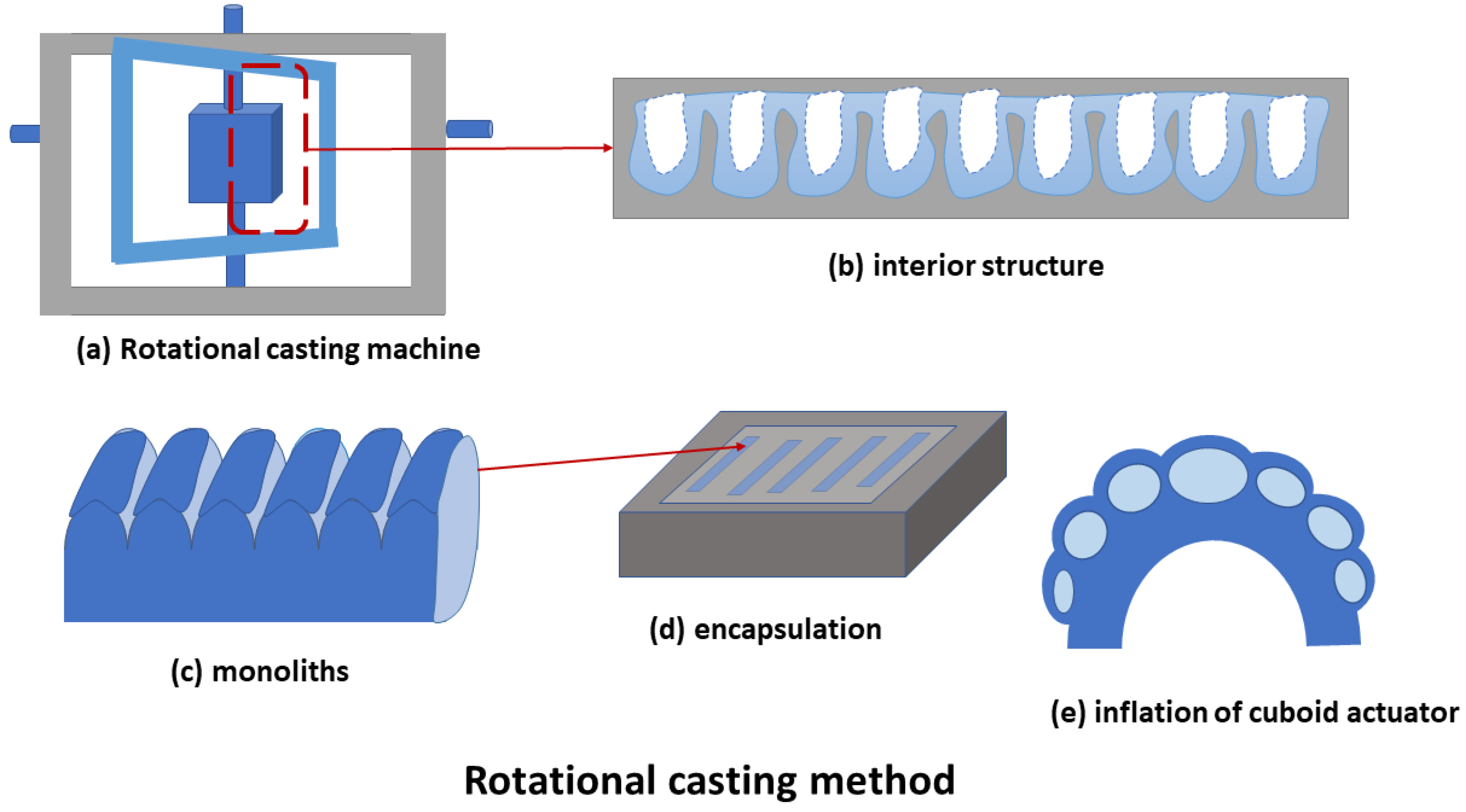

2.3.2. Scalability of FEAs

2.3.3. Scalability of SMP.

2.3.4. Scalability of DEAPs

2.3.5. Scalability of E/MAs

2.4. Energy Efficiency

2.5. Operation Range

2.5.1. Operation Range of SMAs

2.5.2. Operation Range of FEAs

2.5.3. Operation Range of DEAPs

2.5.4. Operation Range of SMPs

2.5.5. Operation Range of E/MAs

2.6. Modality of Operation

2.7. Controllability

2.8. Technology Readiness Level (TRL)

3. Case Studies for Application Matching

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Elango, N.; Faudzi, A.A.M. A review article: Investigations on soft materials for soft robot manipulations. Int. J. Adv. Manuf. Technol. 2015, 80, 1027–1037. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, S.20400–S.20403. [Google Scholar] [CrossRef] [PubMed]

- Gaiser, I.; Wiegand, R.; Ivlev, O.; Andres, A.; Breitwieser, H.; Schulz, S.; Bretthauer, G. Compliant Robotics and Automation with Flexible Fluidic Actuators and Inflatable Structures. In Smart Actuator and Sensing Systems—Recent Advances and Future Challenges; InTech: London, UK, 2012; Chapter 22; pp. 567–608. [Google Scholar]

- Moseley, P.; Florez, J.M.; Sonar, H.A.; Agarwal, G.; Curtin, W.; Paik, J. Modeling, Design, and Development of Soft Pneumatic Actuators with Finite Element Method. Adv. Eng. Mater. 2016, 18, 978–988. [Google Scholar] [CrossRef]

- Gaiser, I.; Schulz, S.; Breitwieser, H.; Bretthauer, G. Enhanced Flexible Fluidic Actuators for Biologically Inspired Lightweight Robots with Inherent Compliance. In Proceedings of the 2010 IEEE International Conference on Robotics and Biomimetics, Tianjin, China, 14–18 December 2010; pp. 1–6. [Google Scholar]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A Recipe for Soft Fluidic Elastomer Robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef] [PubMed]

- Tsagarakis, N.; Caldwell, D. Improved modelling and assessment of pneumatic muscle actuators. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA’00), San Francisco, CA, USA, 24–28 April 2000; Volume 4. [Google Scholar]

- Mutlu, R.; Alici, G.; Xiang, X.; Li, W. Electro-mechanical modelling and identification of electroactive polymer actuators as smart robotic manipulators. Mechatronics 2014, 24, 241–251. [Google Scholar] [CrossRef]

- Lee, K.; Tawfick, S. Fiber Micro-Architected Electro-Elasto-Kinematic Muscles. Extreme Mech. Lett. 2016, 8, 64–69. [Google Scholar] [CrossRef]

- Mirfakhrai, T.; Madden, J.D.W.; Baughman, R.H. Polymer artificial muscles. Mater. Today 2007, 10, 30–38. [Google Scholar] [CrossRef]

- Mathijssen, G.; Schultz, J.; Vanderborght, B.; Bicchi, A. A muscle-like recruitment actuator with modular redundant actuation units for soft robotics. Robot. Auton. Syst. 2015, 74, 40–50. [Google Scholar] [CrossRef]

- Rodriguez, J.N.; Zhu, C.; Duoss, E.B.; Wilson, T.S.; Spadaccini, C.M.; Lewicki, J.P. Shape-morphing composites with designed micro-architectures. Sci. Rep. 2016, 6, 27933. [Google Scholar] [CrossRef] [PubMed]

- Stilli, A.; Wurdemann, H.A.; Althoefer, K. Shrinkable, stiffness-controllable soft manipulator based on a bio-inspired antagonistic actuation principle. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Chicago, IL, USA, 14–18 September 2014. [Google Scholar]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Res. Lett. 2018, 558, 274–291. [Google Scholar] [CrossRef] [PubMed]

- Do, T.N.; Phan, H.; Nguyen, T.-Q.; Visell, Y. Miniature Soft Electromagnetic Actuators for Robotic Applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Hodgson, D.E.; Biermann, R.J. Shape Memory Alloys. In ASM Handbook, Vol 2: Properties and Selection: Non-Ferrous Alloys and Special Purpose Materials; ASM International: Almere, The Netherlands, 1990; pp. 897–902. [Google Scholar]

- Madden, J.D.W. Dielectric Elastomers as High-performance Electroactive Polymers. In Dielectric Elastomers as Electromechanical Transducers; Carpi, F., De Rossi, D., Kornbluh, R., Pelrine, R., Sommer-Larsen, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; Chapter 2. [Google Scholar]

- Johnston, I.D.; McCluskey, D.K.; Tan, C.K.L.; Tracey, M.C. Mechanical Characterization of Bulk Sylgard 184 for microfluidics and micro-engineering. J. Micromech. Microeng. 2014, 24, 1–7. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- An, S.-M.; Ryu, J.; Cho, M.; Cho, K.-J. Engineering design framework for a shape memory alloy coil spring actuator using a static two-state model. Smart Mater. Struct. 2012, 21, 5. [Google Scholar] [CrossRef]

- Sofla, A.Y.N.; Elzey, D.M.; Wadley, H.N.G. Two-way antagonistic shape actuation based on the one-way shape memory effect. J. Intell. Mater. Syst. Struct. 2008, 19, 1017–1027. [Google Scholar] [CrossRef]

- Elsayed, Y.; Lekakou, C.; Geng, T.; Saaj, C.M. Design optimization of soft silicone pneumatic actuators using finite element analysis. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Besancon, France, 8–11 July 2014. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.B.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of Soft Fiber-Reinforced Bending Actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A Resilient, Untethered Soft Robot. Soft Robot. 2014, 1, S.213–S.223. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.; Whitesides, G. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Haines, C.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.W.; Kim, S.H.; Fang, S.; de Andrade, M.J.; Göktepe, F.; et al. Artificial Muscles from Fishing Line and Sewing Thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, A.; Bettinger, C.J. Shape recovery kinetics in vascularized 3D-printed polymeric actuators. Adv. Eng. Mater. 2015, 17, 1287–1293. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Joseph, J. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuations. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Carpi, F.; Salaris, C.; De Rossi, D. Folded dielectric elastomer actuators. Smart Mater. Struct. 2007, 16, 300–305. [Google Scholar] [CrossRef]

- Maas, J.; Tepel, D.; Hoffstadt, T. Actuator design and automated manufacturing process for DEAP-based multilayer stack actuators. Soft Mechatron. 2015, 50, 2839–2854. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Cardoso, V.F.; Ribeiro, C.; Lanceros-Méndez, S. Electroactive Polymers as Actuators, In Advanced Piezoelectric Materials: Science and Technology, 2nd ed.; Woodhead Publishing Limited: Sawston, UK, 2010; Chapter 8. [Google Scholar]

- Pei, Q.; Rosenthal, M.; Pelrine, R.; Stanford, S.; Kornbluh, R. Multifunctional electroelastomer roll actuators and their application for biomimetic walking robots. Proc. SPIE 2002, 4698. [Google Scholar] [CrossRef]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric elastomer based grippers for soft robotics. Adv. Mater. 2015, 27, 6814–6819. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Res. Lett. 2018, 554, 81–85. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Ferreno, I.; San Juan, J. Micro pulling growth of very thin shape memory alloys single crystals. Funct. Mater. Lett. 2017, 10, 1740003. [Google Scholar] [CrossRef]

- Sheng, J.; Gandhi, D.; Gullapalli, R.; Simard, J.M.; Desai, J.P. Development of a Meso-scale SMA-based Torsion Actuator for Image-Guided Procedures. IEEE Trans. Robot. 2017, 33, 240–248. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Zhao, H.; Li, Y.; Elsamadisi, A.; Shepherd, R. Scalable manufacturing of high force wearable soft actuators. Extreme Mech. Lett. 2015, 3, 89–104. [Google Scholar] [CrossRef]

- Shapiro, Y.; Wolf, A.; Gabor, K. Bi-bellows: Pneumatic bending actuator. Sens. Actuators A Phys. 2011, 167, 484–494. [Google Scholar] [CrossRef]

- Lelieveld, C.; Jansen, K.; Teuffel, P. Mechanical characterization of a shape morphing smart composite with embedded shape memory alloys in a shape memory polymer matrix. J. Intell. Mater. Syst. Struct. 2015, 27, 1–11. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. High-performance robotic muscles from conductive nylon sewing thread. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 2313–2318. [Google Scholar]

- Wissler, M.; Mazza, E. Modeling of a pre-strained circulator actuator made of dielectric elastomers. Sens. Actuators A Phys. 2005, 120, 184–192. [Google Scholar] [CrossRef]

- Spinella, I.; Dragoni, E. Analysis and design of hollow helical springs for shape memory alloys. J. Intell. Mater. Syst. Struct. 2010, 21, 185–199. [Google Scholar] [CrossRef]

- Zong, H.; Ni, Z.; Ding, X.; Lookman, T.; Sun, J. Origin of low thermal hysteresis in shape memory alloy ultrathin films. Acta Mater. 2016, 103, 407–415. [Google Scholar] [CrossRef]

- Belyaev, S.; Resnina, N.; Zhruravlev, R. Work production and variation in shape memory effects during thermal cycling of equiatomic TiNi alloy. J. Mater. Eng. Perform. 2014, 23, 2343–2346. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; MacCrone, R.K.; Schadler, L.S.; Reed, C.W.; Keefe, R. Polymer nanocomposite dielectric-the role of the interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–643. [Google Scholar] [CrossRef]

- Koh, S.J.A.; Zhao, X.; Suo, Z. Maximal energy that can be converted by a dielectric elastomer generator. Appl. Phys. Lett. 2009, 94, 262902. [Google Scholar] [CrossRef]

- Wehner, M.; Tolley, M.T.; Menguc, Y.; Park, Y.-L.; Mozeika, A.; Ding, Y.; Onal, C.; Shepherd, R.F.; Whitesides, G.M.; Wood, R.J. Pneumatic Energy Sources for Autonomous and Wearable Soft Robotics. Soft Robot. 2014, 2, 1–12. [Google Scholar] [CrossRef]

- Coral, W.; Rossi, C.; Colorado, J.; Lemus, D.; Barrientos, A. SMA Based Muscle-Like Actuation in Biologically Inspired-Robots: A Stateof the Art Review. In Smart Actuation and Sensing Systems—Recent Advances and Future Challenges; Berselli, G., Ed.; InTech: London, UK, 2012; p. 5382. [Google Scholar]

- Follador, M.; Cianchetti, M.; Arienti, A.; Laschi, C. A general method for the design and fabrication of shape memory alloy active spring actuators. Smart Mater. Struct. 2012, 21, 115029. [Google Scholar] [CrossRef]

- Sehitoglu, H.; Wu, Y.; Patriarca, L. Shape memory functionality under multi-cycles in NiTiHf. Scr. Mater. 2017, 129, 11–15. [Google Scholar] [CrossRef]

- Niyajama, R.; Sun, X.; Sung, C.; An, B.; Rus, D.; Kim, S. Pouch Motors: Printable Soft Actuators Integrated with Computational Design. Soft Robot. 2015, 2, 59–70. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Li, H.; Poh, M.; Xia, F.; Cheng, Z.Y.; Xu, H.; Huang, C. An all-organic composite actuator material with a high dielectric constant. Nature 2002, 149, 284–287. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, W.R.; Wilson, E.D.; Assaf, T.; Rossiter, J.; Dodd, T.J.; Porrill, J.; Anderson, S.R. Control-focused, nonlinear and time-varying modelling of dielectric elastomer actuators with frequency response analysis. Smart Mater. Struct. 2015, 24, 5. [Google Scholar] [CrossRef]

- Ossmer, H.; Wendler, F.; Gueltig, M.; Lambrecht, F.; Miyazaki, S.; Kohl, M. Energy-efficient minature-scale heat pumping based on shape memory alloys. Smart Mater. Struct. 2016, 25, 8. [Google Scholar] [CrossRef]

- Ignat, M.; Ovezea, D.; Hamciuc, E.; Hamciuc, C.; Dimitrov, L. Study on the electromechanical properties of polyimide composites containing TiO2 nanotubes and carbon nanotubes. J. Polym. Res. 2014, 21, 536. [Google Scholar] [CrossRef]

- Lotz, P.; Matysek, M.; Schlaak, H.F. Fabrication and Application of Miniaturized Dielectric Elastomer Stack Actuators. IEEE/ASME Trans. Mechatron. 2011, 16, 58–66. [Google Scholar] [CrossRef]

- Schmidt, A.; Bergamini, A.E.; Kovacs, G.; Mazza, E. Experimental characterization and modeling of circular actuators made of interpenetrating polymer network-reinforced acrylic elastomer. J. Intell. Mater. Syst. Struct. 2013, 24, 1257–1265. [Google Scholar] [CrossRef]

- Keplinger, C.; Li, T.; Baumgartner, R.; Suo, Z.; Bauer, S. Harnessing snap-through instability in soft dielectrics to achieve giant voltage-triggered deformation. Soft Matter 2012, 8, 285–288. [Google Scholar] [CrossRef]

- McCoul, D.; Pei, Q. Tubular dielectric actuator for active fluidic control. Smart Mater. Struct. 2015, 24, 105016. [Google Scholar] [CrossRef]

- Zainal, M.A.; Sahlan, S.; Ali, M.S.M. Micromachined Shape-Memory-Alloy Microactuators and Their Application in Biomedical Devices. Micromachines 2015, 6, 879–901. [Google Scholar] [CrossRef]

- Behl, M.; Kratz, K.; Nöchel, U.; Sauter, T.; Lendlein, A. Temperature-Memory Polymer Actuators. Proc. Natl. Acad. Sci. USA 2013, 110, 12555–12559. [Google Scholar] [CrossRef] [PubMed]

- Karagiannis, D.; Stamatelos, D.; Kappatos, V.; Spathopoulos, T. An investigation of shape memory alloys as actuating elements in aerospace morphing applications. Mech. Adv. Mater. Struct. 2017, 24, 647–657. [Google Scholar] [CrossRef]

- Ameduri, S.; Concilio, A.; Favaloro, N.; Pellone, L. A shape memory alloy application for compact unmanned aerial vehicles. Aerospace 2016, 3, 1–18. [Google Scholar] [CrossRef]

- Chang, W.-S.; Araki, Y. Use of shape-memory alloys in construction: A critical interview. Proc. Inst. Civ. Eng. 2016, 169, 87–95. [Google Scholar]

- Small, W., IV; Singhal, P.; Wilson, T.S.; Maitland, D.J. Biomedical Applications of Thermally Activated Shape Memory Polymers. J. Mater. Chem. 2010, 20, 3356–3366. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Mosadegh, B.; Ainla, A.; Lee, B.; Khashai, F.; Suo, Z.; Bertoldi, K.; Whitesides, G.M. Buckling of elastomeric beams enables actuation of soft machines. Adv. Mater. 2016, 27, 6323–6327. [Google Scholar] [CrossRef] [PubMed]

- Godaba, H.; Li, J.; Wang, Y.; Zhu, J. A soft jellyfish robot driven by a dielectric elastomer actuator. IEEE Robot. Autom. Lett. 2016, 1, 624–631. [Google Scholar] [CrossRef]

- Rosset, S.; Shea, H.R. Flexible and stretchable electrodes for dielectric elastomer actuators. Appl. Phys. A 2013, 110, 281–307. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Lohse, N.; Jackson, M. Data-driven Bending Angle Prediction of Soft Pneumatic Actuators with Embedded Flex Sensors. IFAC-PapersOnLine 2016, 49, 513–520. [Google Scholar] [CrossRef]

- Helps, T.; Rossiter, J. Proprioceptive Flexible Fluidic Actuators Using Conductive Working Fluids. Soft Robot. 2018, 5, 175–189. [Google Scholar] [CrossRef] [PubMed]

- Tarvainen, T.V.J.; Yu, W. Pneumatic Multi-Pocket Elastomer Actuators for Metacarpophalangeal Joint Flexion and Abduction-Adduction. Actuators 2017, 6, 27. [Google Scholar] [CrossRef]

- Choi, I.; Corson, N.; Peiros, L.; Hawkes, E.W.; Keller, S.; Follmer, S. A Soft, Controllable, High Force Density Linear Brake Utilizing Layer Jamming. IEEE Robot. Autom. Lett. 2018, 3, 450–457. [Google Scholar] [CrossRef]

- Jani, J.M.; Huang, S.; Leary, M.; Subic, A. Numerical modeling of shape memory alloy linear actuator. Comput. Mech. 2015, 56, 443–461. [Google Scholar] [CrossRef]

- Feng, Y.P.; Blanquer, A.; Fornell, J.; Zhang, H.; Solsona, P.; Baro, M.D.; Surinach, S.; Ibanez, E.; Garcia-Lecina, E.; Wei, X.; et al. Novel Fe-Mn-Si-Pd alloys: Insights into mechanical, magnetic, corrosion resistance and biocompatibility performances. J. Mater. Chem. B 2016, 4, 6402–6412. [Google Scholar] [CrossRef]

- Westbrook, K.K.; Mather, P.T.; Parakh, V.; Dunn, M.L.; Ge, Q.; Lee, B.M.; Qi, H.J. Two-way reversible shape memory effects in a free-standing polymer composite. Smart Mater. Struct. 2011, 20, 6. [Google Scholar] [CrossRef]

- Chen, S.; Hu, J.; Zhuo, H.; Zhu, Y. Two-way shape memory effect in polymer laminates. Mater. Lett. 2008, 62, 4088–4090. [Google Scholar] [CrossRef]

- Sadeghzadeh, A.; Asua, E.; Feuchtwanger, J.; Etxebarria, V.; Garcia-Arribas, A. Ferromagnetic shape memory alloy actuator enabled for nanometric position control using hysteresis compensation. Sens. Actuators A Phys. 2012, 182, 122–129. [Google Scholar] [CrossRef]

- McCoul, D.; Rosset, S.; Besse, N.; Shea, H. Multifunctional shape memory electrodes for dielectric elastomer actuators enabling high holding force and low-voltage multisegment addressing. Smart Mater. Struct. 2017, 26, 1–10. [Google Scholar] [CrossRef]

- Schmidt, A.M. Electromagnetic Activation of Shape Memory Polymer Networks Containing Magnetic Nanoparticles. Macromol. Rapid Commun. 2006, 27, 1168–1172. [Google Scholar] [CrossRef]

- Said, M.M.; Yunas, J.; Bais, B.; Hamzah, A.A.; Majlis, B.Y. The Design, Fabrication, and Testing of an Electromagnetic Micropump with a Matrix-Patterned Magnetic Polymer Composite Actuator Membrane. Micromachines 2018, 9, 1–10. [Google Scholar]

- Tone, T.; Suzuki, K. An Automated Liquid Manipulation by Using a Ferrofluid-Based Robotic Sheet. IEEE Robot. Autom. Lett. 2018, 3, 2814–2821. [Google Scholar] [CrossRef]

| Criteria | Qualitative Evaluation | Quantitative Information |

|---|---|---|

| Mechanical compliance | Inherently compliant, variable stiffness is possible | 0.5 Nm/degree @10 Bar, 0.016 Nm/degree @ 5 Bar [6], (Figure 22, Actuator with 18 mm Diameter) |

| Optimal geometry | Determined by fluidic chamber size and fluidic-network topology | For Tip Force/Energy: Ribbed Segment (0.58 N/J), Cylindrical (0.83 N/J), Pleated (0.4 N/J) [7], (Figure 10d) |

| Scalability | Scalable, easy to manufacture | Casting (80%), Layering (20%) |

| Energy efficiency | Amplification through structural parameters and snap-through property | Watt/Weight: 1 W/g [8] |

| Operation range | Wide (from micro- to macro-scale) | Force: up to 10 N, Stroke: up to 10 cm, Pressure: up to 0.5 MPa [8] |

| Modality | Pneumatics/hydraulics | --- |

| Controllability | Poor for SPA, good for FFA | |

| TRL | Utilizes existing hydraulic, pneumatic structures and polymer designs | TRL 6–8 |

| Actuator Type | Qualitative Evaluation (Section 2.1) | Quantitative Info (Section 2.1) |

|---|---|---|

| SMA (Shape Memory Alloys) | SMA has almost no inherent compliancy. It is not compliant in martensite phase and the austenitic phase lasts only when it is heated. However, when used in spring form or meandering profiles, it can obtain certain compliant features due to form. SMA enables light-weight construction when the circuits are left outside of the robotic structure. | For Ti-Ni type SMA, 80–85 GPa (for austenite) 28–60 GPa (for martensite) [17] 20–80 GPa [18] |

| FEA (Fluidic Elastomeric Actuators) | FEA platforms are inherently compliant due to the structural elements mostly comprising elastomeric polymers. The fluid also contributes to the compliance, however it can be varied by changing the internal pressure of fluidic chambers. FEA is essentially a light-weight structure if compressors and the pneumatic circuit elements are left outside of the robot. | 0.5 Nm/degree @10 Bar, 0.016 Nm/degree @ 5 Bar [6] (Same with the chamber material compliance when deflated: 1.32–2.97 MPa for PDMS) [19] |

| SMP (Shape Morphing Polymers) | SMPs are also inherently compliant because of the polymers used in the structure. However, the thermal actuation can largely affect the state of the polymer and in some states the polymer is more rigid. | 0.01–3 GPa [20] |

| DEAP (Dielectric-Electrically Actuated Polymers) | DEAP uses a hyper-elastic polymer membrane and compliant/stretchable electrodes, therefore it is inherently compliant. However, the pre-stretching rings or any rigid structure around it may cause the increased stiffness. DEAP supports light-weight structures however the high-voltage circuit should be placed away from the robotic platform. | 0.1–3 MPa [18] |

| E/MA (Magnetic/Electro-Magnetic Actuators) | E/MA can be produced as soft actuators using ferromagnetic particles in a polymeric substrate or embedding a stretchable/flexible coil in a softer substrate. In all cases, while the particles and coils limits the compliance, the polymeric substrates are the main compliance provider. | 0.001–0.05 GPa (Generic silicone rubbers, depending on mixture proportions) |

| Actuator | Force | Strain/Stroke |

|---|---|---|

| SMA | F × 10−1 | 5–8% |

| FEA | F × 102 | <28% |

| SMP | F × 10 | 10% |

| DEAP | F × 100 | 40% (as single membrane) |

| E/MA | F × 10−4 | 15–25% |

| Actuator | Control Challenge |

|---|---|

| SMA | Hysteresis, slow response time. |

| FEA | Non-linear behavior of pneumatic modality due to compressibility and dependencies on temperature. |

| SMP | Non-linear and often unidentified behavior, non-linear dependencies on temperature. |

| DEAP | Electrical break-down limits, mechanical strain limits, durability, extra need for signal conditioning and amplification. |

| E/MA | mm-scale dimensions, magnetic interference. |

| Actuator | TRL | Explanation |

|---|---|---|

| SMA | 6–8 | Adequate research background, some applications in robotics, still needs to be developed into full products. The problems with hysteresis and limited work-range needs attention. |

| FEA | 6–8 | Built on pneumatics and hydraulics, closer to be produced for large amounts in an automated manner. Limited range of work. |

| SMP | 5–7 | Very few examples outside of laboratory, complex manufacturing and control systems, one-way actuation, limited mechanical recovery. |

| DEAP | 5–7 | Very few examples outside of laboratory, still needs improvement on raw materials, control and electro-mechanical design improvements. Limited due to high voltage requirements and low energy density. |

| E/MA | 4–5 | Novel mm-scale actuators based on strictly controlled laboratory experiments such as in References [16,35]. |

| Domain | Criteria to be taken |

|---|---|

| Medical | Compliance, controllability, scalability, topology, operation range |

| Industrial | Energy efficiency, operation range, compliance, TRL |

| Haptic-Interface | Compliance, scalability, topology, controllability |

| Active Safety in Automotive | Compliance, modality, scalability, energy efficiency, controllability |

| Domain | SMA | FEA | SMP | DEAP | E/MA |

|---|---|---|---|---|---|

| Medical | 2,2,3,2,3 | 5,2,5,4,4 | 5,2,5,4,2 | 5,3,3,2,2 | 5,2,2,2,2 |

| Industrial | 2,3,2,4 | 3,4,5,4 | 1,2,5,3 | 4,2,5,3 | 4,2,5,1 |

| Haptic-Interface | 2,3,2,2 | 5,5,4,2 | 5,5,4,2 | 5,3,2,3 | 5,2,2,2 |

| Active Safety in Automotive | 2,1,3,2,2 | 5,1,5,3,2 | 5,1,5,1,2 | 5,1,3,4,3 | 5,1,2,4,2 |

| Actuator | Medical | Industrial | Haptic-Interface | Active Safety in Automotive |

|---|---|---|---|---|

| SMA | * | * | * | * |

| FEA | *** | *** | *** | *** |

| SMP | ** | * | *** | ** |

| DEAP | ** | ** | ** | *** |

| E/MA | * | ** | * | ** |

| Combination | Improvement/Leverage | Application Domain |

|---|---|---|

| SMA + SMP | Wider bandwidth, removal of the need for external force for SMP, wider cooling window for SMA | Active construction solutions, adaptive and self-healing structures, soft robotics solutions in construction |

| SMA + FEA | Antagonistic principle can be used, wider time window for SMA to cool down, fast responses with FEA action, increase in compliancy, light-weight, shape morphing and stiffness variation is possible | Spine-like or worm-like structures in surgical robotics |

| SMA + DEAP | Antagonistic working principle can be supported. However, the device will be very complicated and inefficient in terms of energy use. | Soft-robotics in mini-scale |

| SMA + E/MA | Faster response due to magnetic actuation, contactless actuation. Disadvantages may involve non-reproducible movement characteristics due to hysteresis but this could be eliminated using feedback control. | Precise positioning systems in nanometer scale [79] |

| SMP + FEA | Superb-shape morphing property via thermal or pneumatic actuation, low-weight | Soft surgical robots and exe-skeletons for augmenting human posture and physio-therapy, soft and adaptable prosthesis structures |

| SMP + DEAP | DEA using flexible electrodes made of conductive SMP, allowing DEA to be rigid on the cold state, resulting a greater holding force | Micro-grippers with minimum-energy principle, tunable optics, haptic displays, microfluidics [80] |

| SMP + E/MA | Using surface modified super-paramagnetic nanoparticles in SMP substrate, remote actuation of complex shapes is possible. Magnetic particles serve as nano-antennas for magnetic heating, rendering the combined system as untethered. | Life sciences, minimally invasive surgery and novel sensor-actuator system for compact volumes [81] |

| FEA + DEAP | Snap-through property can be used to increase overall stroke or force capability, increased electro-mechanical durability of DEAP, removal of constant need to pressurize a particular system | Active touch-boards, haptic displays, and human-machine interfaces |

| FEA + E/MA | Using ferro-magnetic fluids or magnetic particles in polymer substrates untethered actuation of fluids is achieved. The actuator form can be unusual such as a large surface sheet. | Life sciences and micro-fluidic devices: Electromagnetic micro-pump using magnetic polymer [82], liquid manipulation using ferro-fluid based robotic sheet [83] |

| DEAP + E/MA | This is not reported yet and an obvious leverage might be reduction in the high-voltage requirement of DEA structure. | Low-voltage applications of DEAP using magnetic field for better response. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boyraz, P.; Runge, G.; Raatz, A. An Overview of Novel Actuators for Soft Robotics. Actuators 2018, 7, 48. https://doi.org/10.3390/act7030048

Boyraz P, Runge G, Raatz A. An Overview of Novel Actuators for Soft Robotics. Actuators. 2018; 7(3):48. https://doi.org/10.3390/act7030048

Chicago/Turabian StyleBoyraz, Pinar, Gundula Runge, and Annika Raatz. 2018. "An Overview of Novel Actuators for Soft Robotics" Actuators 7, no. 3: 48. https://doi.org/10.3390/act7030048

APA StyleBoyraz, P., Runge, G., & Raatz, A. (2018). An Overview of Novel Actuators for Soft Robotics. Actuators, 7(3), 48. https://doi.org/10.3390/act7030048