Piezoelectric Transformers: An Historical Review

Abstract

:1. Historical Introduction

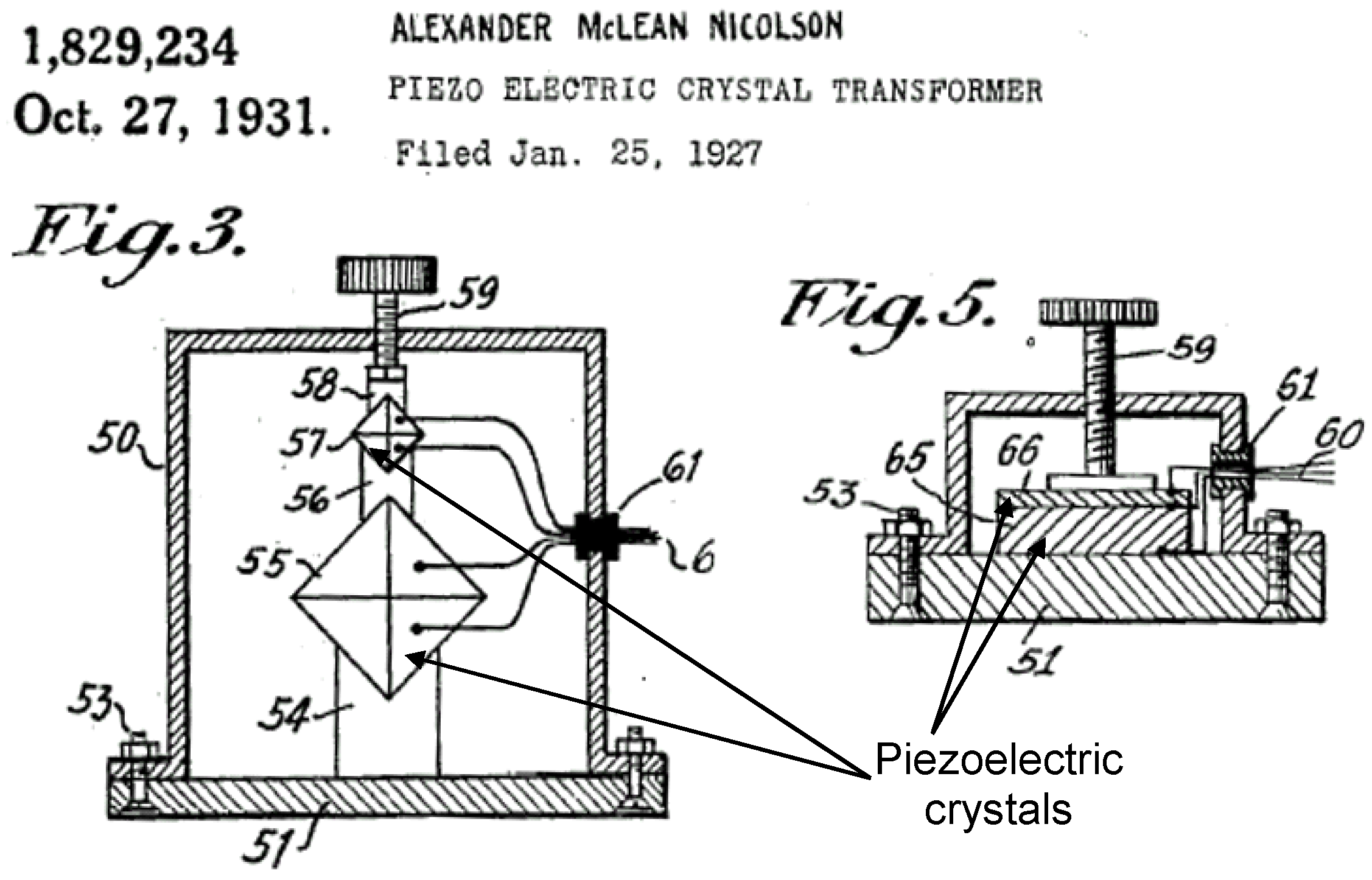

1.1. 1920s–1930s: Early Studies on Piezoelectric Transformers Using Salt Rochelle Single Crystal

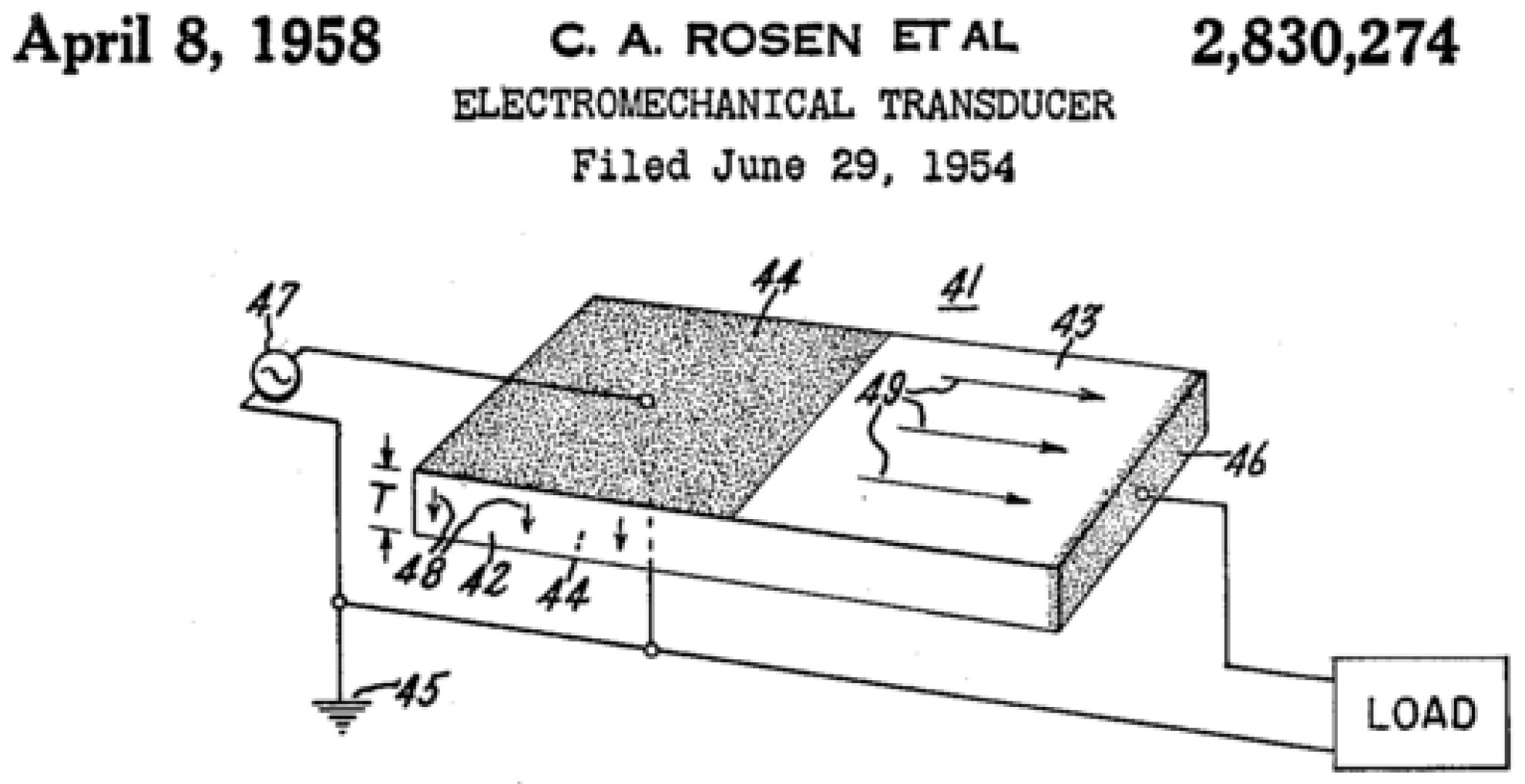

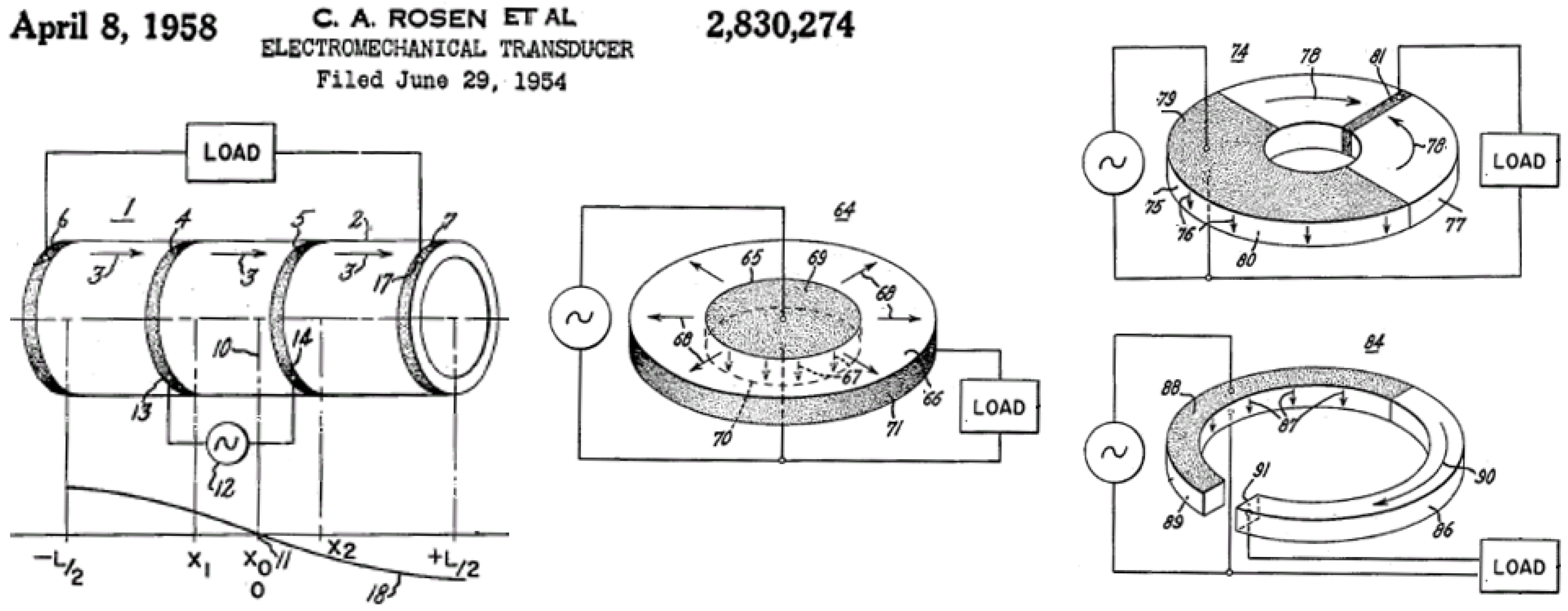

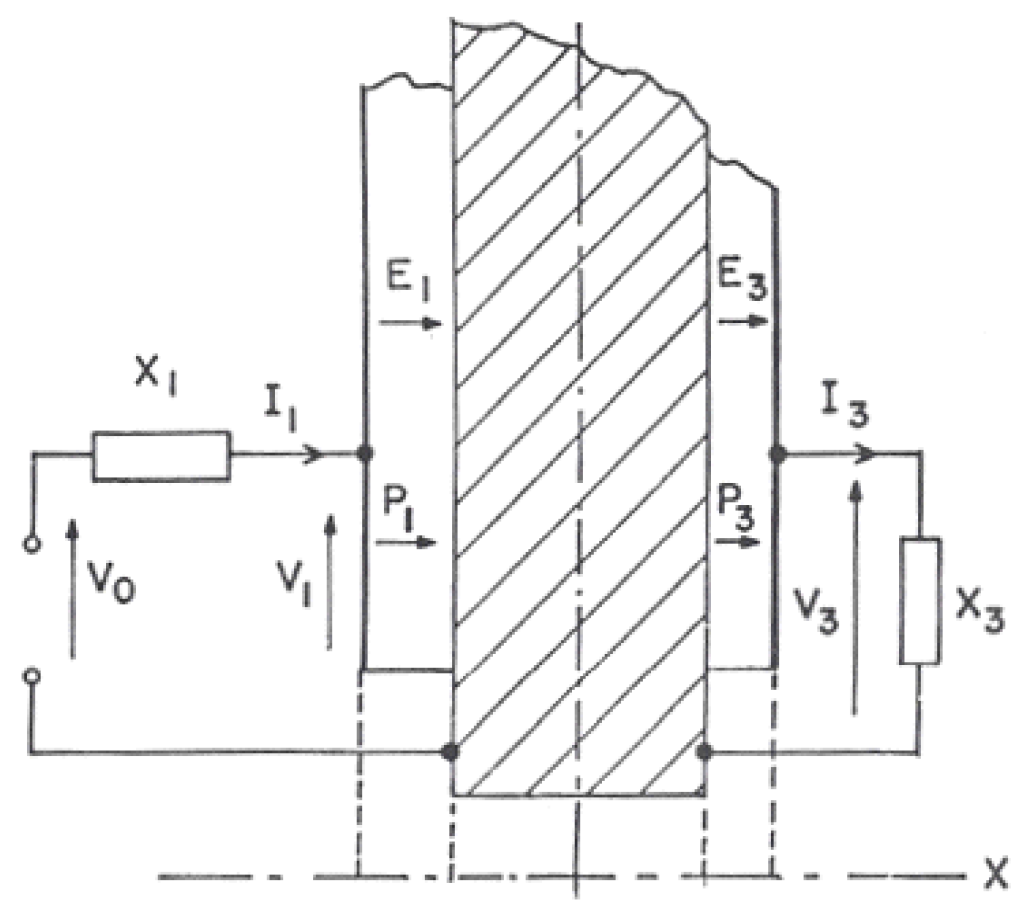

1.2. 1940s to Early 1960s: Charles A. Rosen’s Work at General Electric, Syracuse, NY, with BaTiO3 Ferroelectric Ceramics

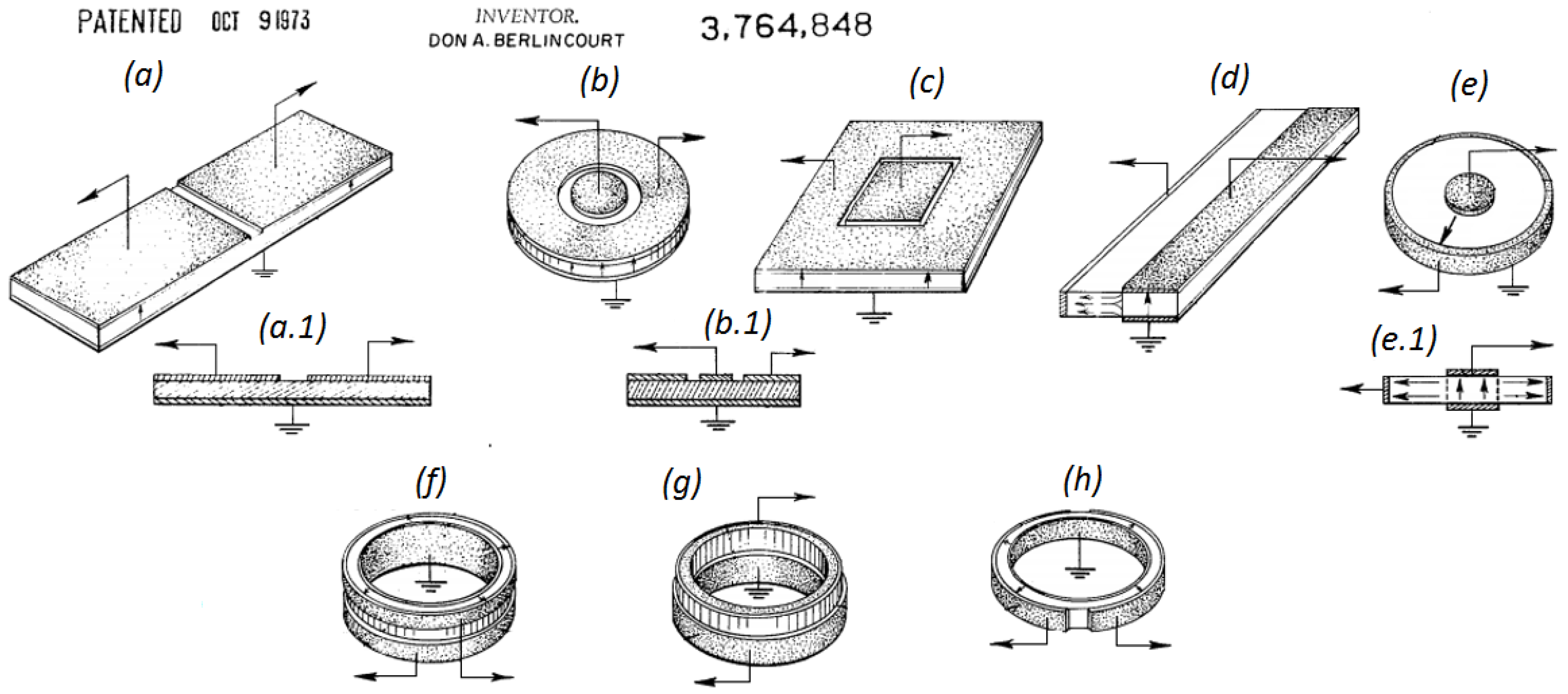

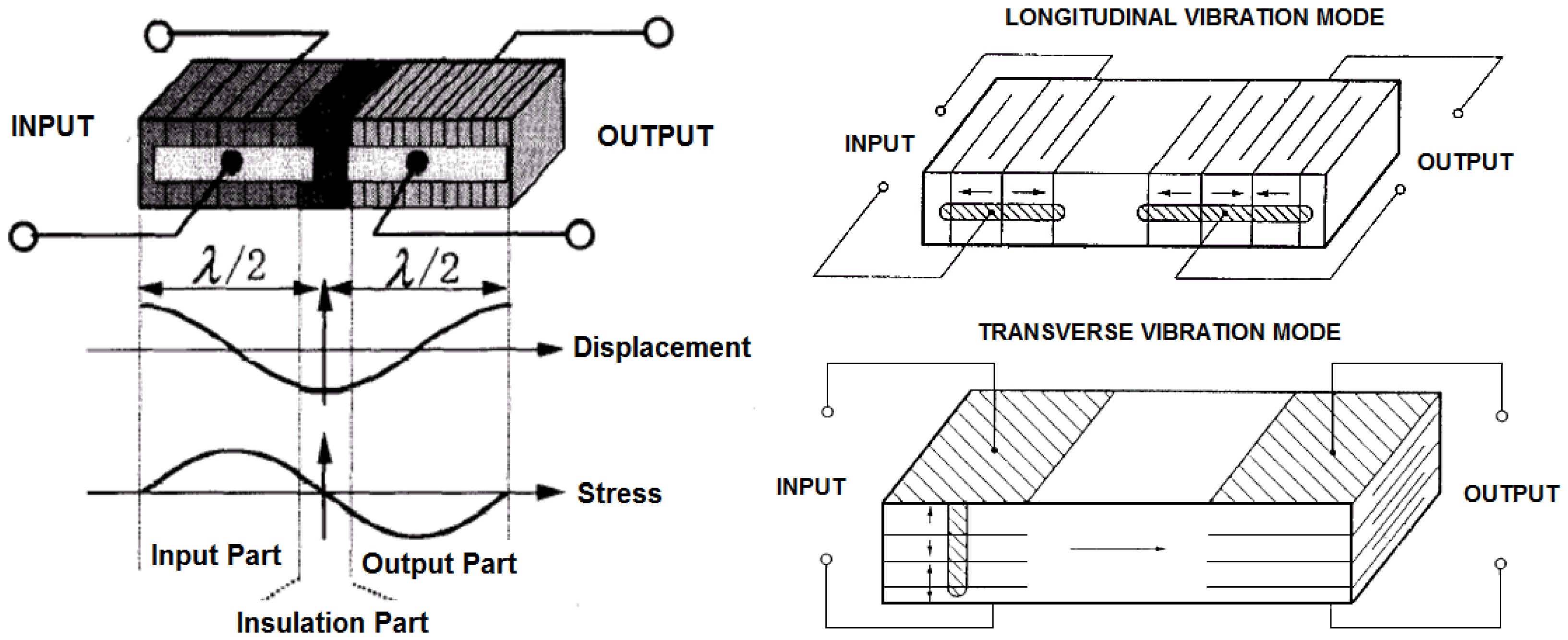

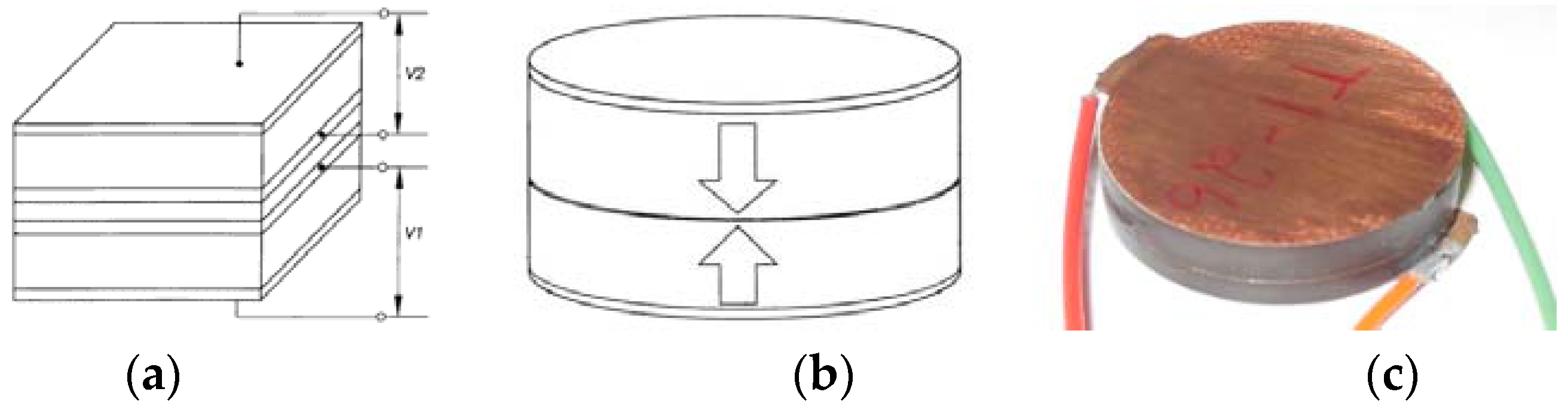

1.3. Late 1950s to Late 1960s: Clevite Corporation—Introduction of PZT to PT Technology

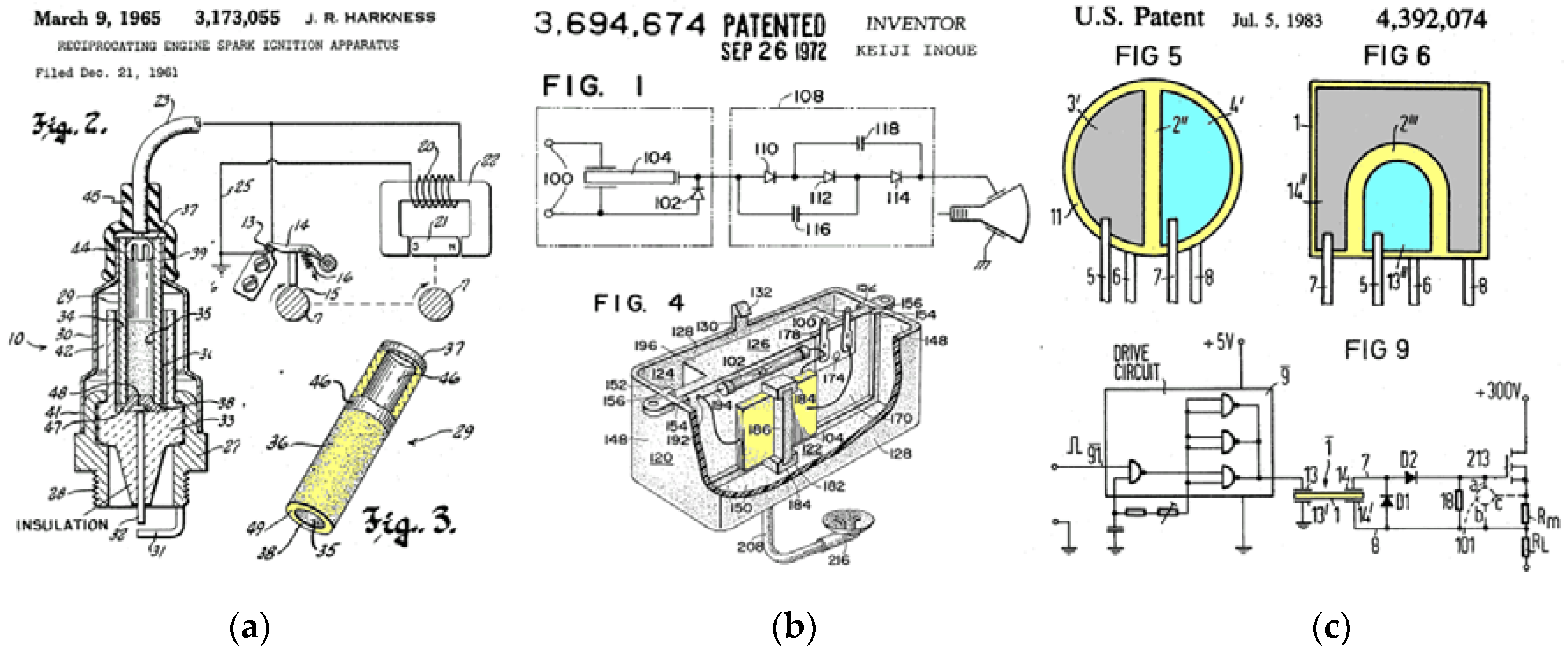

1.4. Late 1960s–1980s: Period of Proliferation

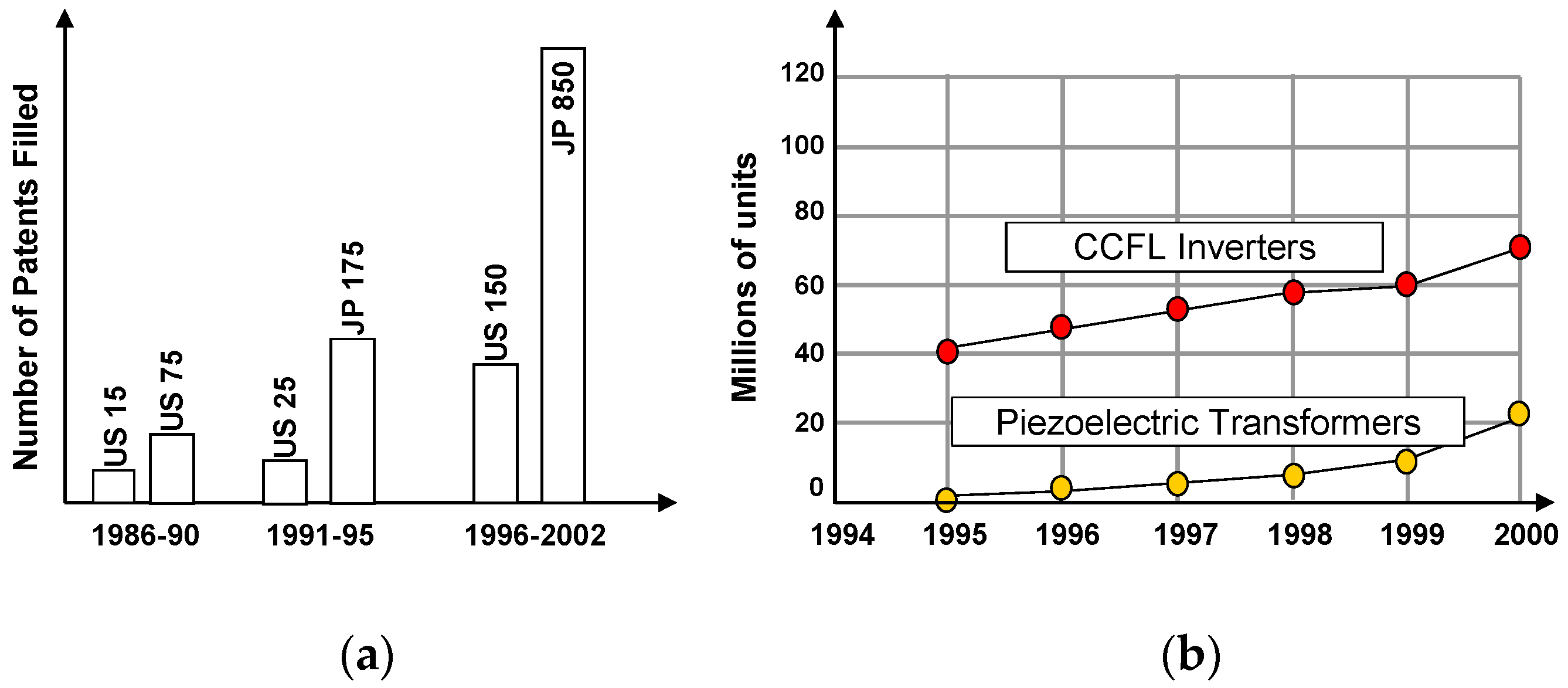

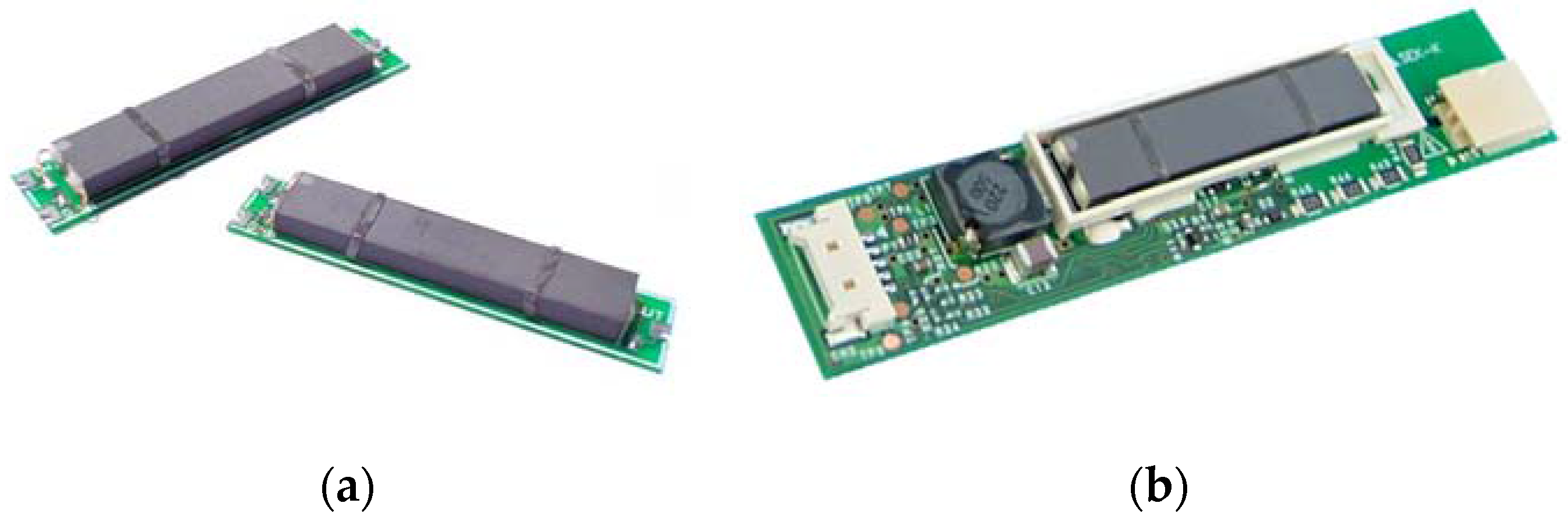

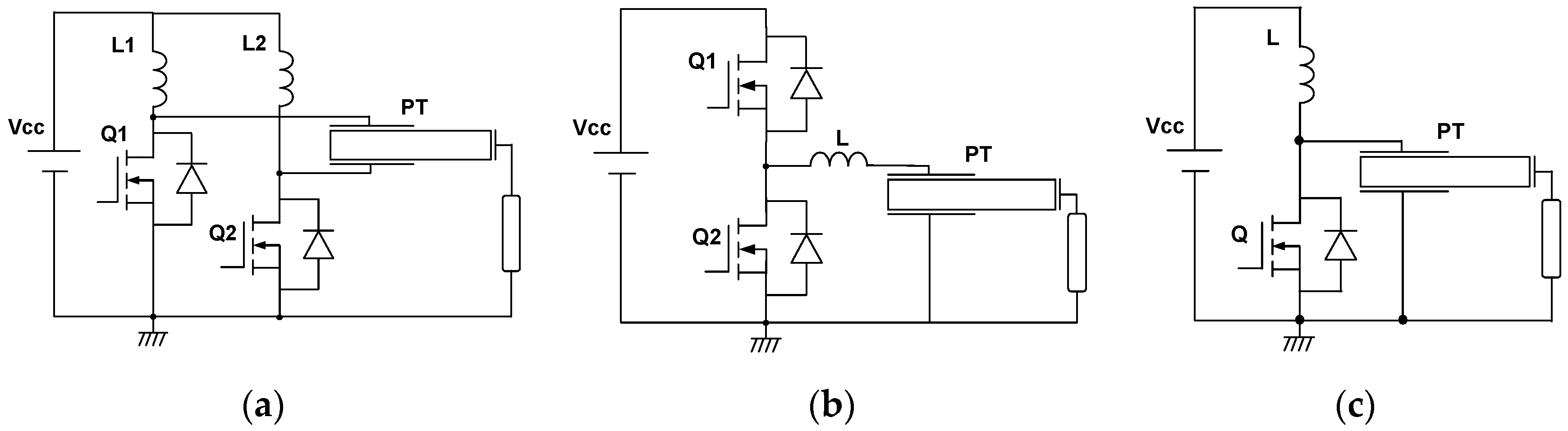

1.5. 1990s–2000s: Commercial Introduction of PTs for CCFL Backlighting

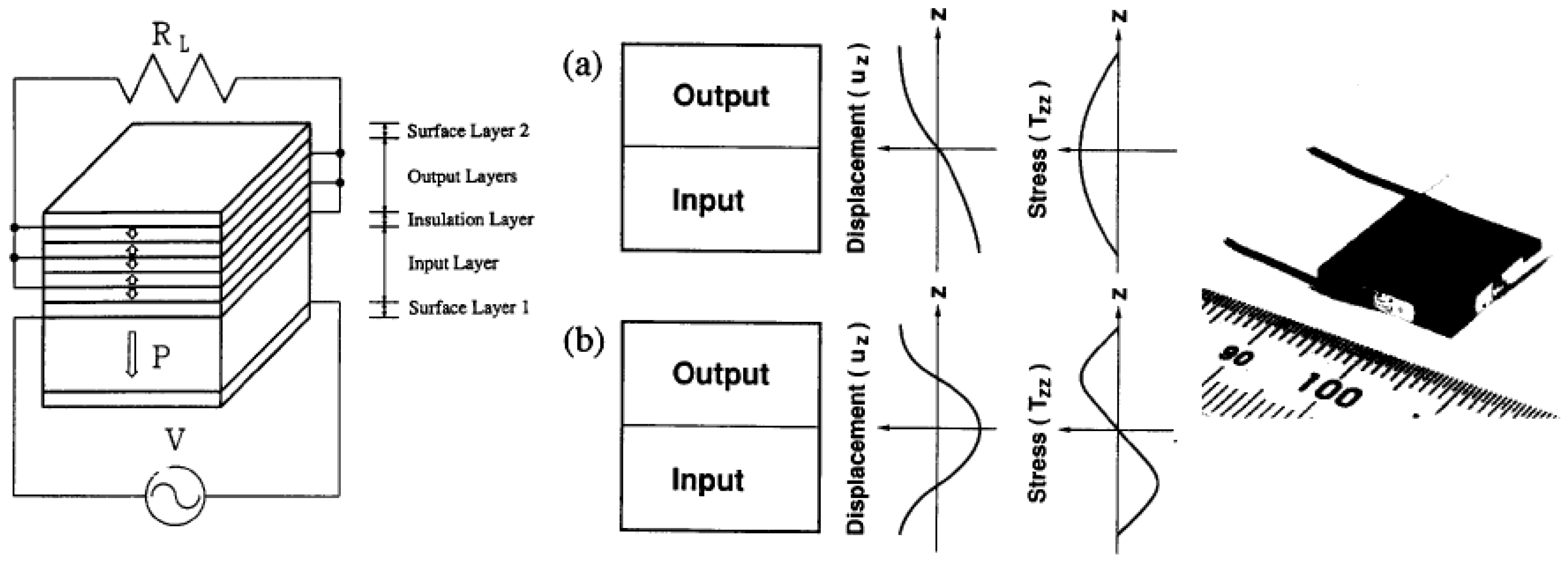

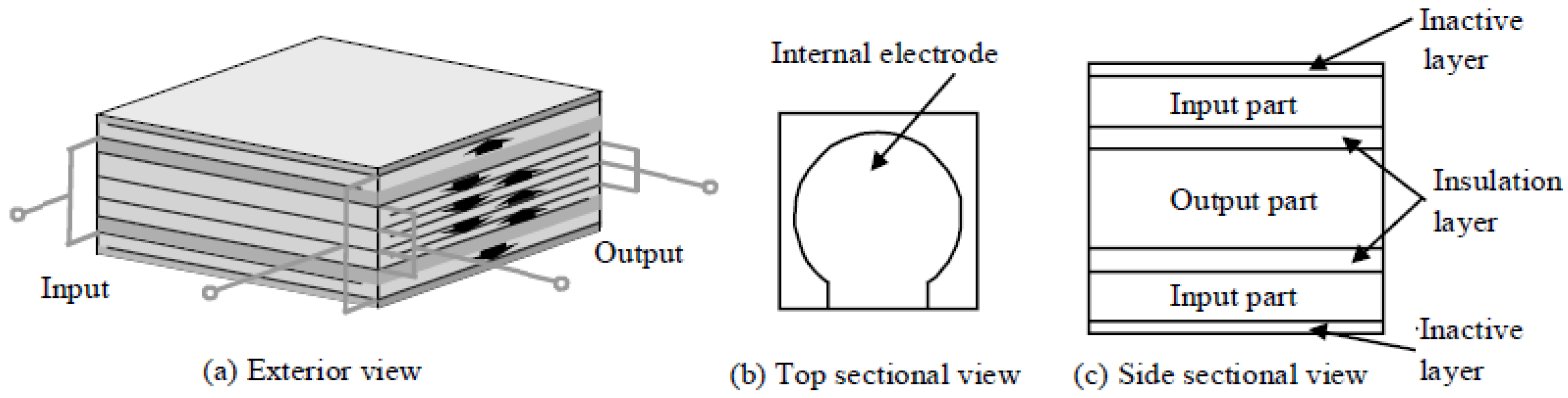

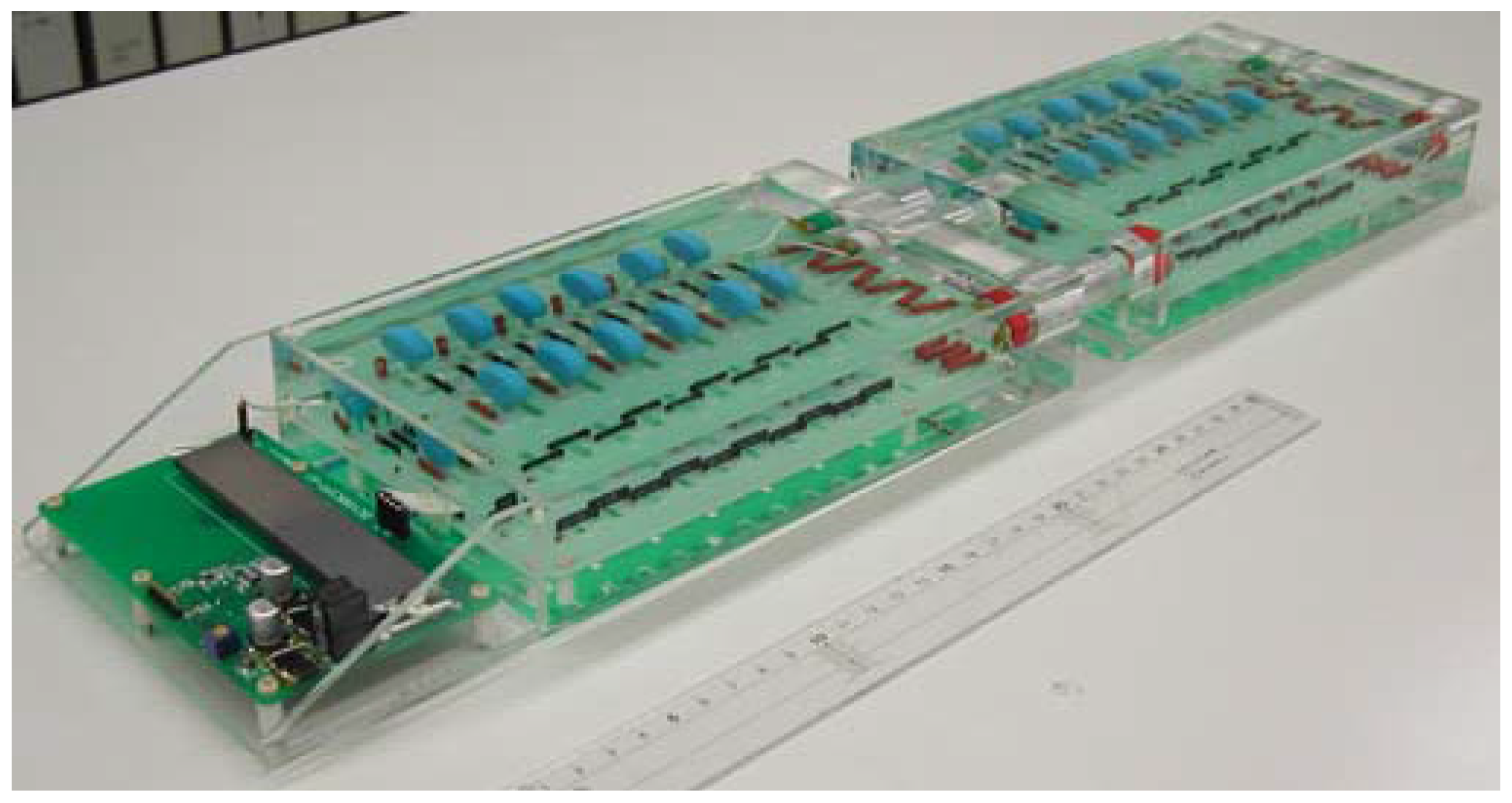

1.6. Beyond the 2000s: Power Piezoelectric Transformers

2. Space, Defense and Security Applications of Piezoelectric Transformers

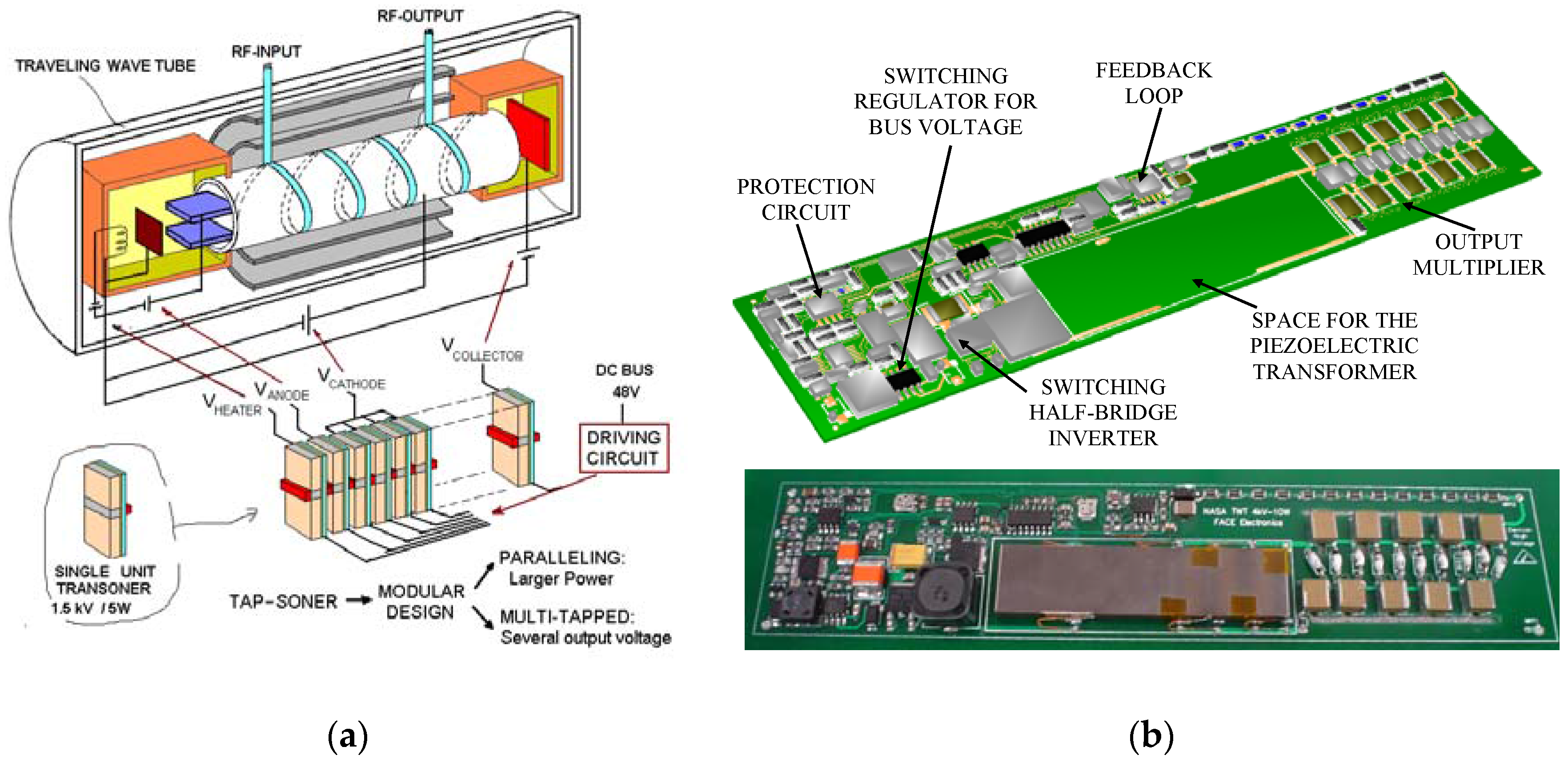

2.1. High Voltage Piezoelectric-Based Power Supply to Drive the Main Payload of Satellite Communication Systems: The Traveling Wave Tube

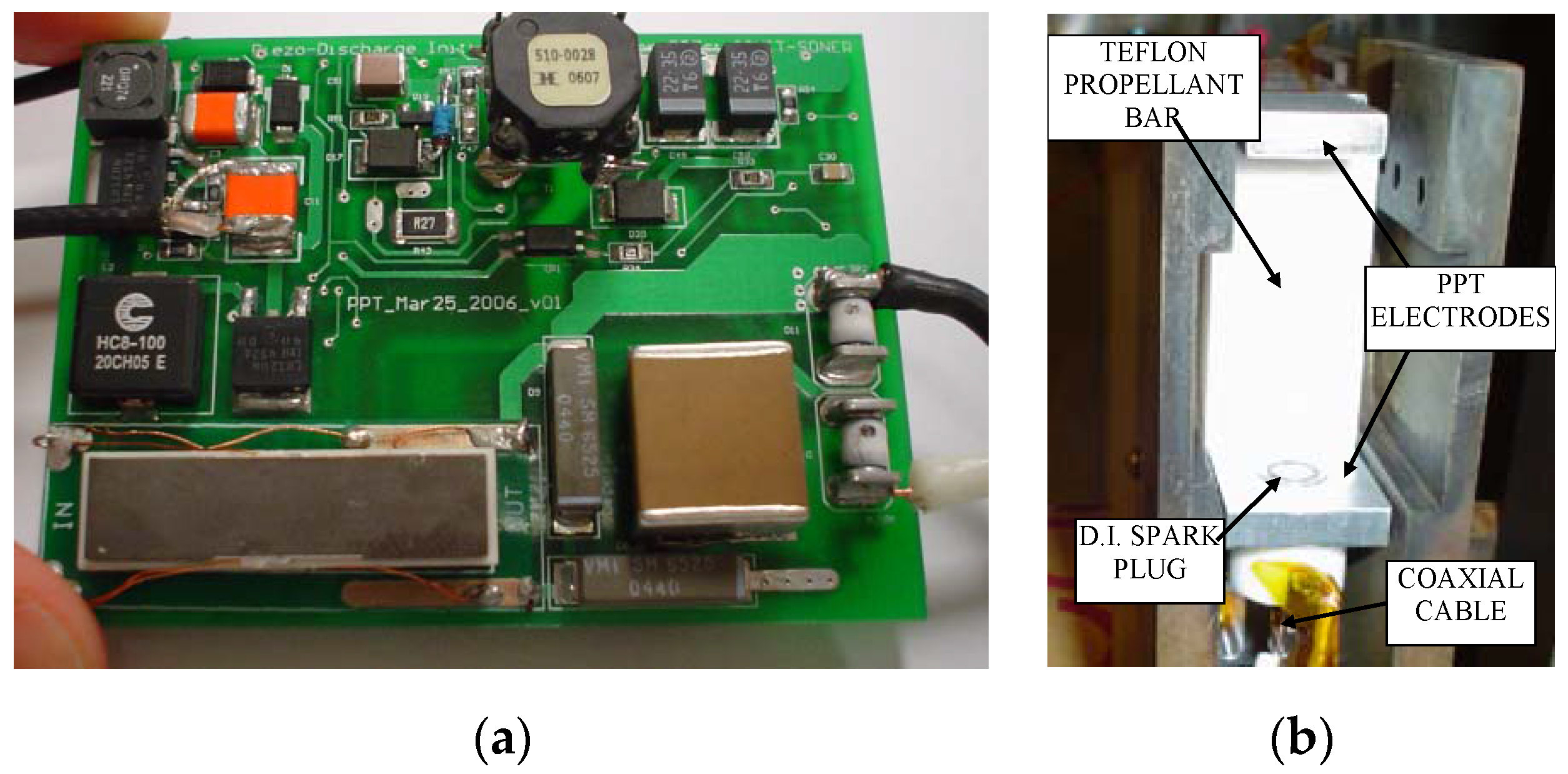

2.2. Development of New Integrated Ignition Systems for Small Satellite Thruster by Using Piezoelectric Transformer Technology

2.3. High Voltage Power Supplies for Compact Neutron Generators

3. Other Applications of Piezoelectric Transformers

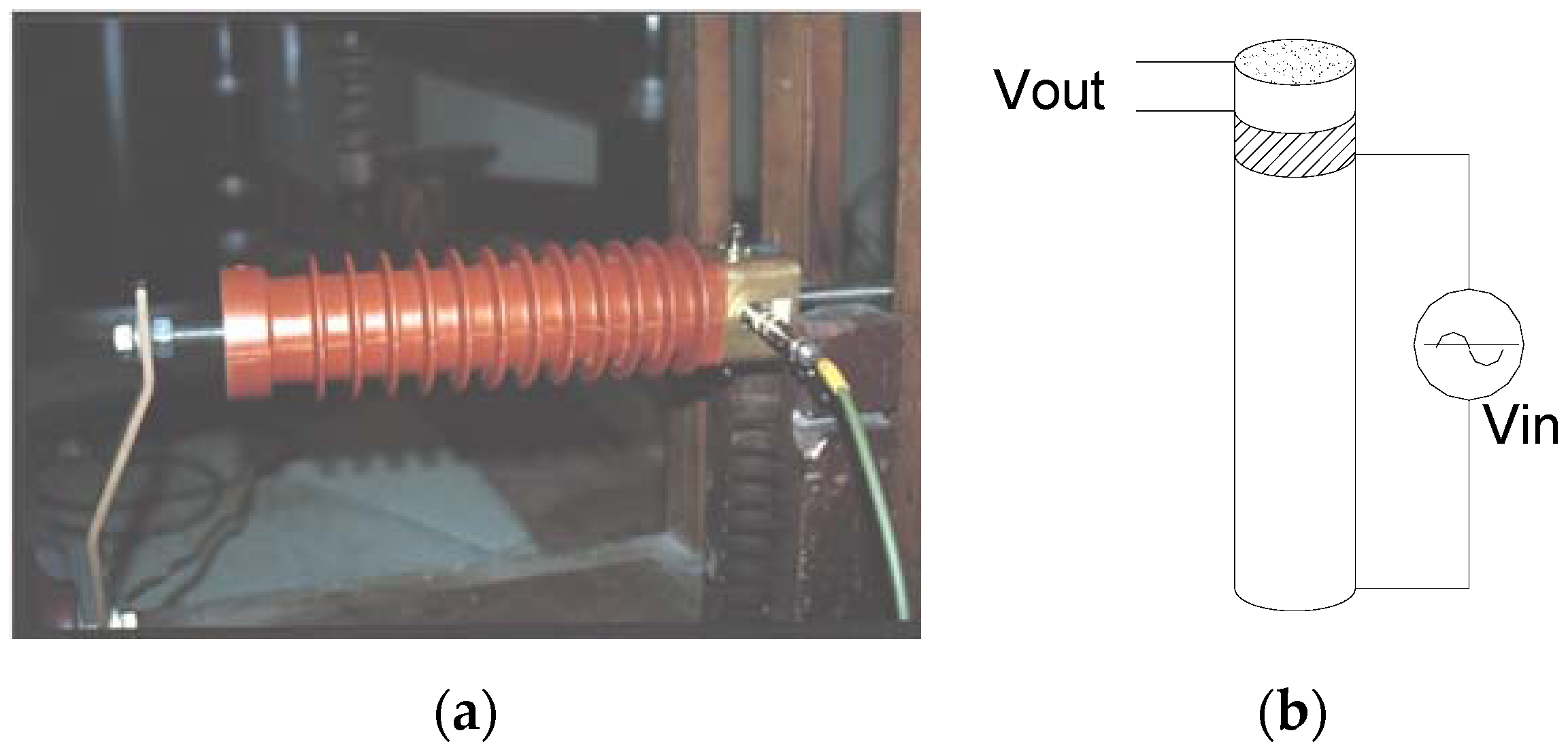

3.1. High Voltage Non-Resonant Piezoelectric Transformer for Monitoring High Voltage Networks

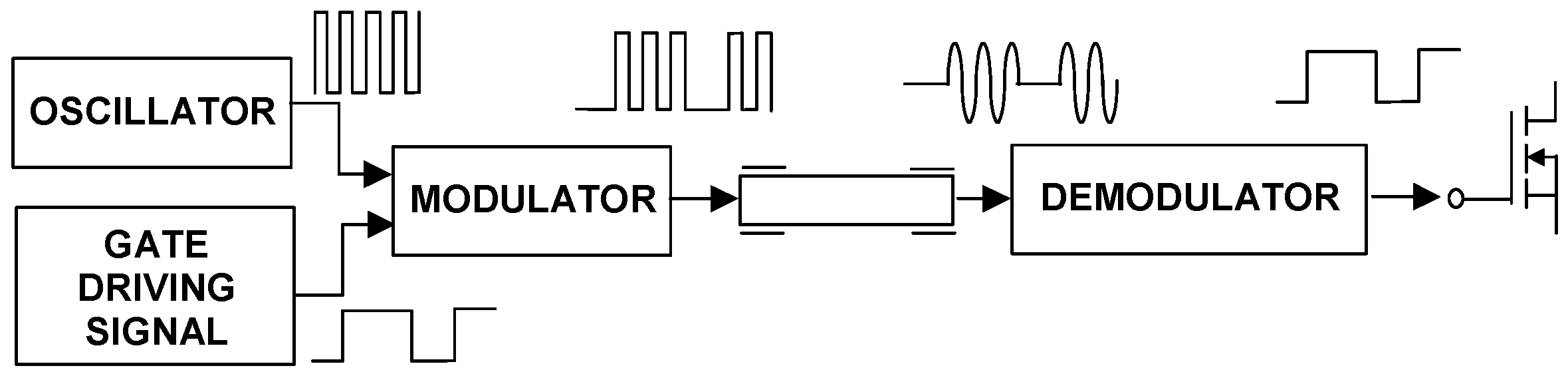

3.2. Piezoelectric Transformers for Isolation Feedback and Gate Driver Applications

4. Conclusions

Conflicts of Interest

References

- Nicolson, A.M. Piezo-Electric Crystal Transformer. U.S. Patent No. 1,829,234, 25 January 1927. [Google Scholar]

- Nicolson, A.M. Multiple Piezo-Electric Transformer. U.S. Patent No. 1,863,345, 11 March 1927. [Google Scholar]

- Nicolson, A.M. Piezoelectric Crystal Converter-Generator. U.S. Patent No. 1,975,517, 2 May 1931. [Google Scholar]

- Jaffe, B.; Cook, W.R., Jr.; Jaffe, H. Piezoelectric Ceramics, 1st ed.; Academic Press: New York, NY, USA, 1971; pp. 1–5. [Google Scholar]

- Wainer, E.; Salomon, A.N. Electrical Reports of the Titanium Alloy Manufacturing Division, Report 10; National Lead Co.: Winchester, MA, USA, 1943. [Google Scholar]

- Gray, R.B. Transducer and Method of Making the Same. U.S. Patent No. 2,486,560, 20 September 1946. [Google Scholar]

- Roberts, S. Dielectric and piezoelectric properties of barium titanate. Phys. Rev. 1947, 71, 890–895. [Google Scholar] [CrossRef]

- Mason, W.P. Electrostrictive effect in barium titanate ceramics. Phys. Rev. 1948, 74, 1134–1147. [Google Scholar] [CrossRef]

- Jaffe, H. Properties of electromechanical ceramics. Electronics 1948, 21, 128–130. [Google Scholar]

- Hart, P.E.; Nilsson, N.J.; Perrault, R.; Mitchell, T.; Kulikowski, C.A. In Memoriam: Charles Rosen, Norman Nielsen and Saul Amarel. AI Mag. 2003, 24, 6–12. [Google Scholar]

- Softky, M. Charles Rosen, Robotics Pioneer, Dies at 85; The Almanac: San Mateo, CA, USA, 2002. [Google Scholar]

- Rosen, C.A. Principles of Transistor Circuits; Shea, R.F., Ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1953. [Google Scholar]

- Rosen, C.A.; Fish, K.A.; Rothenberg, H.C. Electromechanical Transducer. U.S. Patent No. 2,830,274, 29 January 1954. [Google Scholar]

- Rosen, C.A. Electromechanical Transducer. U.S. Patent No. 2,974,296, 26 May 1959. [Google Scholar]

- Rosen, C.A. Electrical Conversion Apparatus. U.S. Patent No. 2,975,354, 30 November 1956. [Google Scholar]

- Rosen, C.A. Analysis and Design of Ceramic Transformers and Filters. Ph.D. Thesis, Syracuse University, Syracuse, NY, USA, 1956. [Google Scholar]

- Rosen, C.A. Ceramic transformers and filters. In Proceedings of the 7th Electronic Components Symposium, Washington, DC, USA, 1–3 May 1956; pp. 205–211.

- Tehon, S.W. Piezoelectric and Magnetostrictive Transducers. Ph.D. Thesis, University of Illinois, Urbana, IL, USA, 1958. [Google Scholar]

- Tehon, S.W. Final Report for Ceramic Power Transformers, General Electric Company to Navy Department, BuShips Contract NObsr-81369, June 1960–January 1962; General Electric Company: Syracuse, NY, USA, 1962. [Google Scholar]

- Rosen, C.A.; Tehon, S.W. Solid State Magnetic and Dielectric Devices; Katz, H.W., Ed.; John Wiley & Sons, Inc.: London, UK, 1959; pp. 170–197. [Google Scholar]

- Jaffee, B.; Roth, R.S.; Marzullo, S. Piezoelectric properties of lead zirconate-lead titanate solid-solution ceramic ware. J. Appl. Phys. 1954, 25, 809–810. [Google Scholar] [CrossRef]

- Jaffe, B. Piezoelectric Transducers Using Lead Titanate and Lead Zirconate. U.S. Patent No. 2,708,244, 24 March 1954. [Google Scholar]

- Jaffee, B.; Roth, R.S.; Marzullo, S. Morphotropic Piezoelectric Ceramics. U.S. Patent No. 2,849,404, 13 April 1956. [Google Scholar]

- Cross, L.E.; Newnham, R.E. Remembering Bernard Jaffe. Ferroelectrics 1984, 51, 157–158. [Google Scholar] [CrossRef]

- Cross, L.E.; Newnham, R.E. History of ferroelectric. In Ceramics and Civilization, Volume III. High-Technology Ceramics-Past, Present, and Future; The American Ceramic Society: Westerville, OH, USA, 1987; pp. 289–305. [Google Scholar]

- Fujishima, S. The history of ceramic filters. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Jaffe, H.; Berlincourt, D.A. Piezoelectric Ceramic Resonators. U.S. Patent No. 2,969,512, 17 February 1960. [Google Scholar]

- Munk, E.C. The equivalent electrical circuit for radial modes of a piezoelectric ceramic disc with concentric electrodes. Philips Res. Rep. 1965, 20, 170–189. [Google Scholar]

- Berlincourt, D.A. Piezoelectric Starter and Ballast for Gaseous Discharge Lamps. U.S. Patent No. 3,764,848, 15 March 1972. [Google Scholar]

- Schafft, H.W. Piezoelectric Voltage Transforming Device. U.S. Patent No. 3,281,726, 10 October 1963. [Google Scholar]

- Schafft, H.W. Voltage Generation Utilizing Piezoelectric Effects. U.S. Patent No. 3,397,328, 14 June 1966. [Google Scholar]

- Kramer, D.A. Power Supply Circuit Employing Piezoelectric Voltage Transforming Device. U.S. Patent No. 3,657,579, 16 April 1971. [Google Scholar]

- Mccusker, J.H.; Perlman, S.S. Ferro-Electric Transformers with Means to Suppress or Limit Resonant Vibrations. U.S. Patent No. 3,683,211, 1 April 1971. [Google Scholar]

- Lim, C.C. Piezoelectric Ultra-Voltage Generator for a Television Receiver. U.S. Patent No. 4,459,505, 28 May 1982. [Google Scholar]

- Inoue, K. Self-Exciting Type High Voltage Generating Apparatus Utilizing Piezoelectric Voltage Transforming Elements. U.S. Patent No. 3,679,918, 19 June 1970. [Google Scholar]

- Inoue, K. High Voltage Generating Apparatus. U.S. Patent No. 3,694,674, 25 September 1970. [Google Scholar]

- Kawada, T. Apparatus for Driving Piezoelectric Transformers. U.S. Patent No. 3,708,701, 18 March 1971. [Google Scholar]

- Kawada, T. Driving Apparatus for Piezoelectric Ceramic Elements. U.S. Patent No. 3,743,868, 12 October 1971. [Google Scholar]

- Kawada, T. Piezoelectric Transformers. U.S. Patent No. 3,778,648, 28 June 1972. [Google Scholar]

- Kawada, T. High Voltage Generating Device Having an Operating Monitoring Device. U.S. Patent No. 3,790,826, 19 December 1972. [Google Scholar]

- Kawada, T. Corona Discharge Apparatus for Particle Collection. U.S. Patent No. 3,900,766, 2 November 1973. [Google Scholar]

- Sasaki, R.; Kitani, T. A High-Voltage Generator Circuit Configuration Utilizing a Ceramic Transformer. U.S. Patent No. 3,598,909, 25 July 1968. [Google Scholar]

- Ansai, Y.; Mifune, H.; Tani, K. Gas Ignition Device. U.S. Patent No. 4,054,936, 16 March 1976. [Google Scholar]

- Harkness, J.R. Reciprocating Engine Spark Ignition Apparatus. U.S. Patent No. 3,173,055, 21 December 1961. [Google Scholar]

- Tanaka, T.; Yorita, H.; Tomita, M.; Igashira, T. High Voltage Generating Device. U.S. Patent No. 4,767,967, 4 June 1985. [Google Scholar]

- Kleinschmidt, P.; Magori, V. Trigger Device and Piezo-Ignition Coupler with Galvanic Decoupling. U.S. Patent No. 4,392,074, 9 April 1981. [Google Scholar]

- Leskovec, R.A.; Davenport, J.M.; Burman, O.B. Autoresonant Piezoelectric Transformer Signal Coupler. U.S. Patent No. 4,584,499, 12 April 1985. [Google Scholar]

- Tsuchiya, H. Ceramic transformers made from titanates. J. Inst. Electr. Eng. Jpn. 1961, 81, 603–609. (In Japanese) [Google Scholar]

- Kaname, Y.; Ise, Y. A study of transducer design of piezoelectric ceramic transformers. J. Acoust. Soc. Jpn. 1976, 32, 470–479. (In Japanese) [Google Scholar]

- Kawashima, S.; Ohnishi, O.; Hakamata, H.; Tagami, S.; Fukuoka, A.; Inoue, T.; Hirose, S. Third order longitudinal mode piezoelectric ceramic transformer and its application to high-voltage power inverter. In Proceedings of the 1994 IEEE Ultrasonics Symposium, Cannes, France, 31 October–3 November 1994; pp. 525–530.

- Tagami, S.; Shimada, Y.; Kawashima, S.; Isobe, K.; Ohnishi, O.; Inoue, T.; Hirose, S. Color-LCD backlight inverter utilizing piezoelectric ceramic transformer. SID Symp. Dig. Tech. Pap. 1995, 26, 382–385. [Google Scholar]

- Sugimoto, M.; Shimada, Y.; Furuhashi, N.; Taihaku, N. Very compact inverter for color LCD backlight utilizing a packaged piezoelectric ceramic transformer. SID Symp. Dig. Tech. Pap. 1996, 27, 757–760. [Google Scholar]

- Shoyama, M.; Horikoshi, K.; Ninomiya, T.; Zaitsu, T.; Sasaki, Y. Operation analysis of the push-pull piezoelectric inverter. In Proceedings of the APEC Conference, Atlanta, GA, USA, 23–27 February 1997; Volume 2, pp. 573–578.

- Piezoelectric Transformers. Application Note Philips Magnetic Products; Philips Components: Eindhoven, The Netherlands, 1997.

- Sasaki, Y.; Yamamoto, M.; Ochi, A.; Inoue, T.; Takahashi, S. Small multilayer piezoelectric transformers with high power density—Characteristics of second and third-mode Rosen-type transformers. Jpn. J. Appl. Phys. 1999, 38, 5598–5602. [Google Scholar] [CrossRef]

- Mohan, N.; Undeland, T.M.; Robbins, W.P. Power Electronics: Converters, Applications, and Design; John Wiley & Sons, Inc.: New York, NY, USA, 1989. [Google Scholar]

- Ninomiya, T.; Shoyama, M.; Zaitsu, T.; Inoue, T. Zero-voltage techniques and their application to high-frequency converter with piezoelectric transformer. In Proceedings of the 20th International Conference on Industrial Electronics, Control and Instrumentation, Bologna, Italy, 5–9 September 1994; Volume 3, pp. 1665–1669.

- Data Sheet BA9825FV Piezo-Electric Transformer Inverter Control IC; Rohm Co., Ltd.: Tokyo, Japan, 2004.

- Data Sheet UCC3975, UCC3976, UCC3977, Multi-Topology Piezoelectric Transformer Controller, SLUS499A; Texas Instruments Inc.: Dallas, TX, USA, 2001.

- Stuetzer, O.M. Linear Theory of Piezoelectric Transformers; Sandia Laboratory Report No. SC-RR-66-414; Sandia Laboratories: Albuquerque, NM, USA, 1966.

- Inoue, T.; Ohnishi, O.; Ohde, N. Thickness Mode Vibration Piezoelectric Transformer. U.S. Patent No. 5,118,982, 30 May 1990. [Google Scholar]

- Sasaki, Y.; Uehara, K.; Inoue, T. Piezoelectric Ceramic Transformer Being Driven with Thickness Extensional Vibration. U.S. Patent No. 5,241,236, 1 April 1992. [Google Scholar]

- Ohnishi, O.; Kishie, H.; Iwamoto, A.; Sasaki, Y.; Zaitsu, T.; Inoue, T. Piezoelectric ceramic transformer operating in thickness extensional vibration mode for power supply. In Proceedings of the 1992 IEEE Ultrasonics Symposium, Tucson, AZ, USA, 20–23 October 1992; pp. 483–488.

- Zaitsu, T.; Inoue, T.; Ohnishi, O.; Iwamoto, A. 2 MHz power converter with piezoelectric ceramic transformer. In Proceedings of the 14th International Telecommunications Energy Conference, Washington, DC, USA, 4–8 October 1992; pp. 430–437.

- Zaitsu, T.; Ohnishi, O.; Inoue, T.; Shoyama, M.; Ninomiya, T.; Lee, F.C.; Hua, G.C. Piezoelectric transformer operating in thickness extensional vibration and its application to switching converter. In Proceedings of the 25th Annual IEEE Power Electronics Specialists Conference and Exposition, Taipei, Taiwan, 20–25 June 1994; pp. 585–589.

- Zaitsu, T.; Shigehisa, T.; Inoue, T.; Shoyama, M.; Ninomiya, T. Piezoelectric transformer converter with frequency control. In Proceedings of the 17th International Telecommunications Energy Conference, The Hague, The Netherlands, 29 October–1 November 1995; pp. 175–180.

- Zaitsu, T.; Shigehisa, T.; Shoyama, M.; Ninomiya, T. Piezoelectric transformer converter with PWM control. In Proceedings of the Eleventh Annual Applied Power Electronics Conference and Exposition, San Jose, CA, USA, 3–7 March 1996; pp. 279–283.

- Lin, C.Y.; Lee, F.C. Development of a piezoelectric transformer converter. In Proceedings of the Virginia Power Electron. Center (VPEC) Sem., Blacksburg, VA, USA, 19–21 September 1993; pp. 79–85.

- Lin, C.Y.; Lee, F.C. Design of a piezoelectric transformer converter and its matching networks. In Proceedings of the 25th Annual IEEE Power Electronics Specialists Conference and Exposition, Taipei, Taiwan, 20–25 June 1994; pp. 607–612.

- Lin, C.Y. Design and Analysis of Piezoelectric Transformer Converters. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 1997. [Google Scholar]

- Zaitsu, T.; Fuda, Y.; Okabe, Y.; Ninomiya, T.; Hamamura, S.; Katsuno, M. New piezoelectric converter for AC-adapter. In Proceedings of the Twelfth Annual Applied Power Electronics Conference and Exposition, Atlanta, GA, USA, 23–27 February 1997; Volume 2, pp. 568–572.

- Zaitsu, T. AC/DC Converter with a Piezoelectric Transformer. U.S. Patent No. 5,969,954, 15 January 1998. [Google Scholar]

- Zaitsu, T. Power Conversion Using Piezoelectric Transformers. Ph.D. Thesis, Kyushu University, Fukuoka, Japan, 1997. [Google Scholar]

- Katsuno, M.; Fuda, Y. Piezoelectric transformers using inter-digital internal electrodes. In Proceedings of the 1998 IEEE Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; Volume 1, pp. 897–900.

- Yamane, T.; Hamamura, S.; Zaitsu, T.; Ninomiya, T.; Shoyama, M.; Fuda, Y. Efficiency improvement of piezoelectric transformer DC-DC converter. In Proceedings of the 29th Annual IEEE Power Electronics Specialists Conference, Fukuoka, Japan, 17–22 May 1998; Volume 2, pp. 1255–1261.

- Hamamura, S.; Zaitsu, T.; Ninomiya, T.; Shoyama, M. Noise characteristics of piezoelectric-transformer DC-DC converter. In Proceedings of the 29th Annual IEEE Power Electronics Specialists Conference, Fukuoka, Japan, 17–22 May 1998; Volume 2, pp. 1262–1267.

- Hu, J.; Fuda, Y.; Katsuno, M.; Yoshida, T. A study on the rectangular-bar-shaped multilayer piezoelectric transformer using length extensional vibration mode. Jpn. J. Appl. Phys. 1999, 38, 3208–3212. [Google Scholar] [CrossRef]

- Bishop, R.P. Multi-Layer Piezoelectric Transformer. U.S. Patent No. 5,834,882, 27 May 1997. [Google Scholar]

- Carazo, A.V. Multilayer Piezoelectric Transformer. U.S. Patent No. 6,614,144, 4 October 2001. [Google Scholar]

- CIT Challenge Award (ELC-99-007). Transoner Characterization; Virginia Tech: Blacksburg, VA, USA, 1999. [Google Scholar]

- CIT Challenge Award (ELC-00-006). Linear Ballast Development; Virginia Tech: Blacksburg, VA, USA, 2000. [Google Scholar]

- Lin, R.L.; Baker, E.; Lee, F. Characterization of piezoelectric transformers. In Proceedings of the Power Electronics Seminars at Virginia Tech, Blacksburg, VA, USA, 19–21 September 1999; pp. 219–225.

- Lin, R.L. Piezoelectric Transformer Characterization and Application of Electronic Ballast. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2001. [Google Scholar]

- Lin, R.L.; Lee, F.C.; Baker, E.M.; Chen, D.Y. Inductor-less piezoelectric transformer electronic ballast for linear fluorescent lamp. In Proceedings of the 16th Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 4–8 March 2001; Volume 2, pp. 664–669.

- Hamamura, S.; Kurose, D.; Ninomiya, T.; Yamamoto, M. New control method of piezoelectric transformer converter by PWM and PFM for wide range of input voltage. In Proceedings of the IEEE CIEP, Acapulco, Mexico, 15–19 October 2000; pp. 3–8.

- Yamamoto, M.; Sasaki, Y.; Ochi, A.; Inoue, T.; Hamamura, S. Step-down piezoelectric transformer for AC-DC converters. Jpn. J. Appl. Phys. 2001, 40, 3637–3642. [Google Scholar] [CrossRef]

- Ivensky, G.; Zafrany, I.; Ben-Yaakov, S. Generic operational characteristics of piezoelectric transformers. In Proceedings of the 31st Annual IEEE Power Electronics Specialists Conference, Galway, Ireland, 18–23 June 2000; Volume 3, pp. 1657–1662.

- Bronstein, S.; Ben-Yaakov, S. Design considerations for achieving ZVS in a half bridge inverter that drives a piezo transformer with no series inductor. In Proceedings of the 33rd Annual IEEE Power Electronics Specialists Conference, Cairns, Queensland, Australia, 23–27 June 2002; Volume 2, pp. 585–590.

- Ben-Yaakov, S.; Lineykin, S. Frequency tracking to maximum power of piezoelectric transformer HV converters under load variations. In Proceedings of the 33rd Annual IEEE Power Electronics Specialists Conference, Cairns, Queensland, Australia, 23–27 June 2002; Volume 2, pp. 657–662.

- Bove, T.; Wolny, W.; Ringgaard, E.; Breboel, K. New type of piezoelectric transformer with very high power density. In Proceedings of the 12th IEEE International Symposium on Applications of Ferroelectrics, Honolulu, HI, USA, 21 July–2 August 2000; pp. 321–324.

- Brebol, K. Piezoelectric Transformer. U.S. Patent No. 6,707,235, 9 September 2000. [Google Scholar]

- Alou, P.; Cobos, J.A.; Sanz, M.; Prieto, R.; Uceda, J.; Rivas, M.; Navas, J. Subharmonic driving: A new concept to drive piezoelectric transformers in power converters. In Proceedings of the 16th Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 4–8 March 2001; Volume 1, pp. 487–491.

- Navas, J.; Bove, T.; Cobos, J.A.; Nuño, F.; Brebol, K. Miniaturised battery charger using piezoelectric transformer. In Proceedings of the 16th Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 4–8 March 2001; Volume 1, pp. 492–496.

- Diaz, J.; Prieto, M.J.; Nuño, F.; Martin, J.A. A new control strategy for and AC/DC converter based on a piezoelectric transformer. IEEE Trans. Ind. Electron. 2004, 51, 850–856. [Google Scholar] [CrossRef]

- Prieto, R.; Sanz, M.; Cobos, J.A.; Alou, P.; García, O.; Uceda, J. Design considerations of multi-layer piezoelectric transformers. In Proceedings of the 16th Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 4–8 March 2001; Volume 2, pp. 1258–1266.

- Prieto, M.J.; Diaz, J.; Martin, J.A.; Nuño, F. A very simple DC/DC converter using piezoelectric transformer. In Proceedings of the 32nd Annual IEEE Power Electronics Specialists Conference, Vancouver, BC, Canada, 17–21 June 2001; Volume 4, pp. 1755–1760.

- Martin, J.A.; Prieto, M.J.; Nuño, F.; Diaz, J. A new full-protected control mode to drive piezoelectric transformers in DC-DC converters. In Proceedings of the 32nd Annual IEEE Power Electronics Specialists Conference, Vancouver, BC, Canada, 17–21 June 2001; Volume 1, pp. 378–383.

- Sanz, M.; Alou, P.; Prieto, R.; Cobos, J.A.; Uceda, J. Comparison of different alternatives to drive piezo transformers. In Proceedings of the 17th Annual IEEE Applied Power Electronics Conference and Exposition, Dallas, TX, USA, 10–14 March 2002; Volume 1, pp. 358–364.

- Nuño, F.; Martín, J.A.; Diaz, J.; Prieto, M.J.; Fernández-Linera, F.M. Quantum mode control for piezoelectric transformers in ac/dc applications. In Proceedings of the VIII IEEE International Power Electronics Congress, Guadalajara, Mexico, 20–24 October 2002; pp. 202–207.

- Diaz, J.; Martin-Ramos, J.A.; Prieto, M.J.; Nuño, F. A double-closed loop DC/DC converter based on a piezoelectric transformer. In Proceedings of the 35th Annual IEEE Power Electronics Specialists Conference, Anaheim, CA, USA, 22–26 February 2004; Volume 3, pp. 1423–1428.

- Bisogno, F.E.; Radecker, M.; Knoll, A.; Carazo, A.V.; Riedlhammer, A.; Deboy, G.; Norvez, N.; Pacas, J.M. Comparison of resonant topologies for step-down applications using piezoelectric transformers. In Proceedings of the 35th Annual IEEE Power Electronics Specialists Conference, Anaheim, CA, USA, 22–26 February 2004; Volume 2, pp. 2662–2667.

- Radecker, M.; Bisogno, F.; Knoll, A.; Lohmann, G.; Carazo, A.V.; Deboy, G. A low-size multi-power-level single-transistor ballast for low pressure fluorescent lamps, using a piezoelectric transformer. In Proceedings of the IEEE IAS 2004, Seattle, WA, USA, 3–7 October 2004; Volume 1, pp. 307–311.

- Carazo, A.V. Piezoelectric converters for DC/DC and AC/DC applications. In Proceedings of the Portable Power Developer’s Conference, San Jose, CA, USA, 18–20 April 2005.

- Nittayarumphong, S.; Bisogno, F.; Radecker, M.; Knoll, A.; Carazo, A.V. Dynamic behavior of PI controlled class-E resonant converter for step-down applications using piezoelectric transformers. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005.

- Nittayarumphong, S.; Bisogno, F.; Radecker, M.; Carazo, A.V.; Riedlhammer, A.; Guldner, H. High efficiency control methods for class-E resonant converter for step-down applications using piezoelectric transformers (PT). In Proceedings of the 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007.

- Radecker, M. Control Circuit for a Switch Unit of a Clocked Power Supply Circuit, and Resonance Converter. U.S. Patent No. 7,969,754, 14 October 2009. [Google Scholar]

- Horsley, E.L.; Carazo, A.V.; Foster, M.P.; Stone, D.A. A lumped equivalent circuit model for the radial mode piezoelectric transformer. In Proceedings of the 24th Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 1747–1753.

- Horsley, E.L.; Carazo, A.V.; Quang, N.N.; Foster, M.P.; Stone, D.A. Analysis of inductor-less zero-voltage-switching piezoelectric transformer-based converters. IEEE Trans. Power Electron. 2012, 27, 2471–2483. [Google Scholar] [CrossRef]

- Horsley, E.L. Modelling and Analysis of Radial Mode Piezoelectric Transformer and Inductor-Less Resonant Converters. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2011. [Google Scholar]

- Meyer, K.S.; Andersen, M.A.; Jensen, F. Parameterized analysis of zero voltage switching in resonant converters for optimal electrode layout of piezoelectric transformers. In Proceedings of the 39th Annual IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 2543–2548.

- Rodgaard, M.S.; Andersen, T.; Andersen, M.A. Empiric analysis of zero voltage switching in piezoelectric transformer based resonant converters. In Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012), Bristol, UK, 27–29 March 2012; pp. 1–6.

- Andersen, T. Piezoelectric Transformer Based Power Supply for Dielectric Electro Active Polymers. Ph.D. Thesis, Department of Electrical Engineering, Technical University of Denmark, Lyngby, Denmark, 2012. [Google Scholar]

- Rodgaard, M.S. Piezoelectric Transformer Based Power Converters; Design and Control. Ph.D. Thesis, Department of Electrical Engineering, Technical University of Denmark, Lyngby, Denmark, 2012. [Google Scholar]

- Ekhtiari, M.; Zhang, Z.; Andersen, M. State-of-the-art piezoelectric transformer-based switch mode power supplies. In Proceedings of the IECON 2014—40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 5072–5078.

- Carazo, A.V. Piezoelectric transformers for space applications. In MRS Proceedings; Materials Research Society: Warrendale, PA, USA, 2003; Volume 785, pp. D6–D8. [Google Scholar]

- Carazo, A.V. Transoner Power Transfer for TWT Power Systems. NASA SBIR 2001 Phase II. Available online: https://www.sbir.gov/sbirsearch/detail/164409 (accessed on 22 April 2016).

- Carazo, A.V. Novel High-Voltage, High-Power Piezoelectric Transformer Developed and Demonstrated for Space Communications Applications; Research & Technology NASA Glenn Research Center: Cleveland, OH, USA, 2003; pp. 123–124.

- Carazo, A.V. Piezoelectric Transformer and Modular Connections for High Power and High Voltage Power Supplies. U.S. Patent No. 7,019,993, 12 May 2004. [Google Scholar]

- Carazo, A.V. Pulsed Plasma Thruster Piezo-Igniter for Small Satellite. NASA SBIR 2002 Phase II. Available online: https://www.sbir.gov/sbirsearch/detail/164415 (accessed on 22 April 2016).

- Pencil, E.R.; Kamhawi, H.; Arrington, L.A. Overview of NASA’s pulsed plasma thruster development program. In Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Fort Lauderdale, FL, USA, 11–14 July 2004.

- Kamhawi, H. Piezoelectric Ignition Systems Demonstrated for Spacecraft Propulsion Applications; Research & Technology NASA Glenn Research Center: Cleveland, OH, USA, 2005; pp. 65–66.

- Carazo, A.V. Laminated Piezoelectric Transformer. U.S. Patent No. 7,075,217, 9 April 2003. [Google Scholar]

- Sampayan, S.; Caporaso, G.; Chen, Y.-J.; Carazo, A.V.; Falabella, S.; Guethlein, G.; Guse, S.; Harris, J.R.; Hawkins, S.; Holmes, C.; et al. Ultra-compact accelerator technologies for application in nuclear techniques. In Proceedings of the 10th International Conference on Applications of Nuclear Techniques, Crete, Greece, 14–20 June 2009.

- Tang, V.; Sampayan, S.; Falabella, S.; Guethlein, G.; Meyers, G.; Morse, J.; Sanders, D.; Carazo, A.V.; Wang, L. Development and testing of a compact piezotransformer driven pulsed neutron source. In Proceedings of the 20th International Conference on the Application of Accelerators in Research and Industry, Fort Worth, TX, USA, 10–15 August 2008.

- Carazo, A.V. Novel Piezoelectric Transducers for High Voltage Measurements. Ph.D. Thesis, Universitat Politecnica de Catalunya, Barcelona, Spain, 2000. [Google Scholar]

- Lineykin, S.; Ben-Yaakov, S. Feedback isolation by piezoelectric transformers: A feasibility study. In Proceedings of the PCIM 2000, Nuremberg, Germany, 6–8 June 2000; pp. 175–181.

- Xu, Y.; Lorenz, R.D.; Carazo, A.V. Using compact piezoelectric transformers to isolate integrated phase leg shunt current sensors. In Proceedings of the CPES Annual Seminar, Blacksburg, VA, USA, 27–29 April 2003; pp. 462–467.

- Vasic, D.; Costa, F.; Sarraute, E. A new Mosfet & IGBT gate drive insulated by a piezoelectric transformer. In Proceedings of the 32nd Annual IEEE Power Electronics Specialists Conference, Vancouver, BC, Canada, 17–21 June 2001; Volume 3, pp. 1479–1484.

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vazquez Carazo, A. Piezoelectric Transformers: An Historical Review. Actuators 2016, 5, 12. https://doi.org/10.3390/act5020012

Vazquez Carazo A. Piezoelectric Transformers: An Historical Review. Actuators. 2016; 5(2):12. https://doi.org/10.3390/act5020012

Chicago/Turabian StyleVazquez Carazo, Alfredo. 2016. "Piezoelectric Transformers: An Historical Review" Actuators 5, no. 2: 12. https://doi.org/10.3390/act5020012

APA StyleVazquez Carazo, A. (2016). Piezoelectric Transformers: An Historical Review. Actuators, 5(2), 12. https://doi.org/10.3390/act5020012