Modeling and Design Optimization of A Shaft-Coupled Motor and Magnetic Gear

Abstract

:1. Introduction

2. Electromagnetic Modeling

2.1. Harmonic Modeling Method

- The electromagnetic problem can be described in a 2D polar coordinate system ()

- For a given region, the material has linear and homogenous magnetic properties in the r-direction.

- The ferromagnetic material is infinitely permeable. Consequently, no analytical expression of the magnetic flux density can be obtained within the ferromagnetic material.

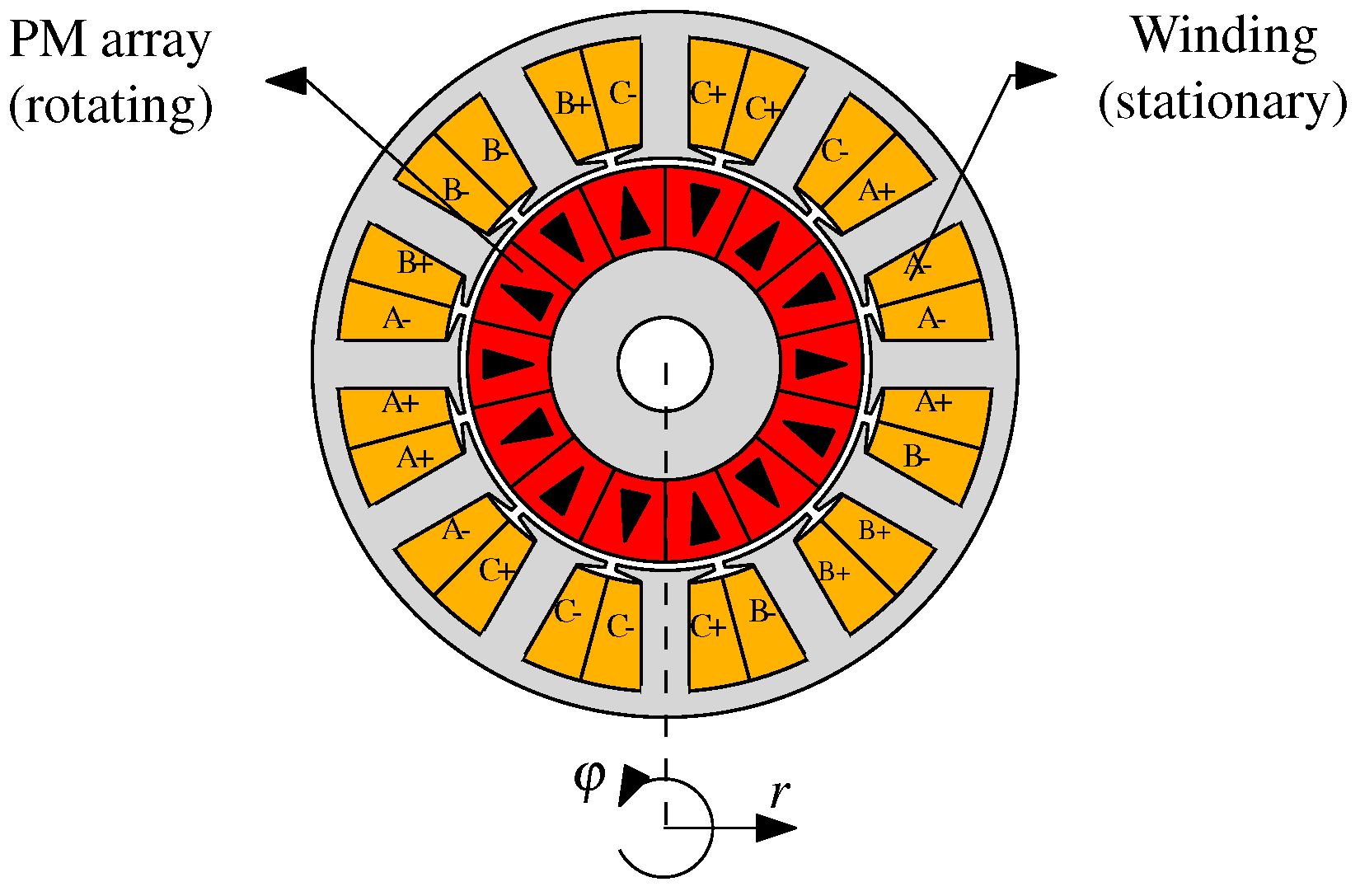

2.2. Harmonic Modeling of an Electrical Motor

- Neumann boundary conditionThis specifies the tangential magnetic field strength to be [8] at the boundary between two regions of which one has , giving

- Between region I and rotor ferromagnetic core ()

- Between region IV and stator ferromagnetic core (), for

- Continuous boundary conditionBy applying Maxwell equations at the interface between different regions [13], the boundary conditions and are obtained, where k and indicate adjacent regions having a finite permeability (). Considering regions with the same tangential width, the following continuous boundary conditions are identified:

- Between regions I and II ()

- Between regions III and IV and stator ferromagnetic core (), for

- Combination of Neumann and continuous boundary conditionsEach slot air region III has different tangential widths with respect to the radially adjacent airgap region II. This gives rise to a combination of both Neumann and continuous boundary conditions which hold at certain intervals between regions II and III, for :The slots introduce tangential Neumann boundary conditions on region III, resulting in at the tangential boundaries and . Consequently, the cosine component of in in region III vanishes, resulting in and . Therefore, the boundary condition Equation (20) can be expressed aswhere M denotes the number of modeled harmonics in region . To simplify Equation (22), a correlation technique is applied [8], resulting inThe boundary condition Equation (21) can be expressed aswhich can be simplified through the correlation technique as follows:where , , , , and are the correlation terms (see [8] for the solutions).

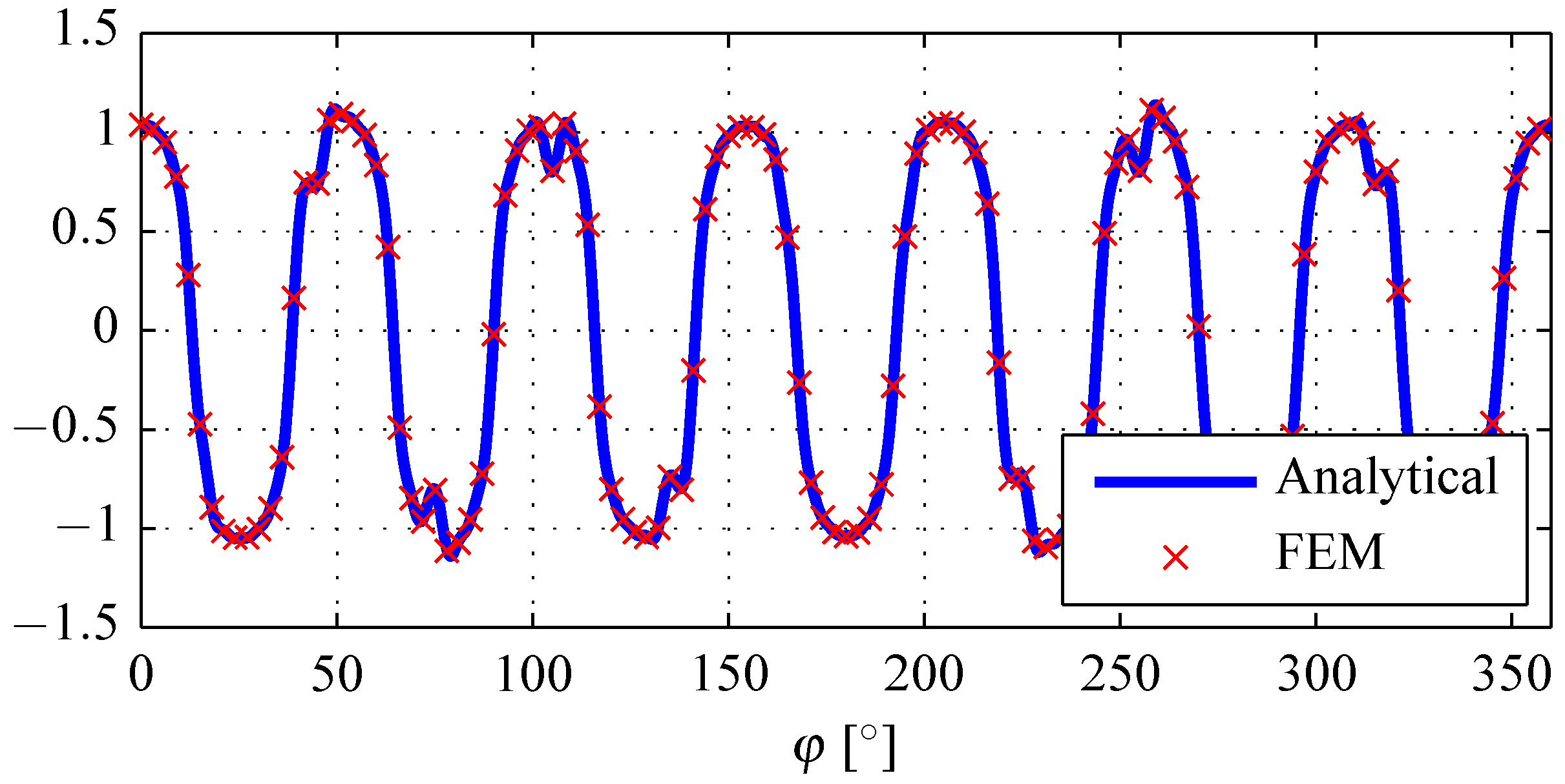

2.2.1. Model Verification

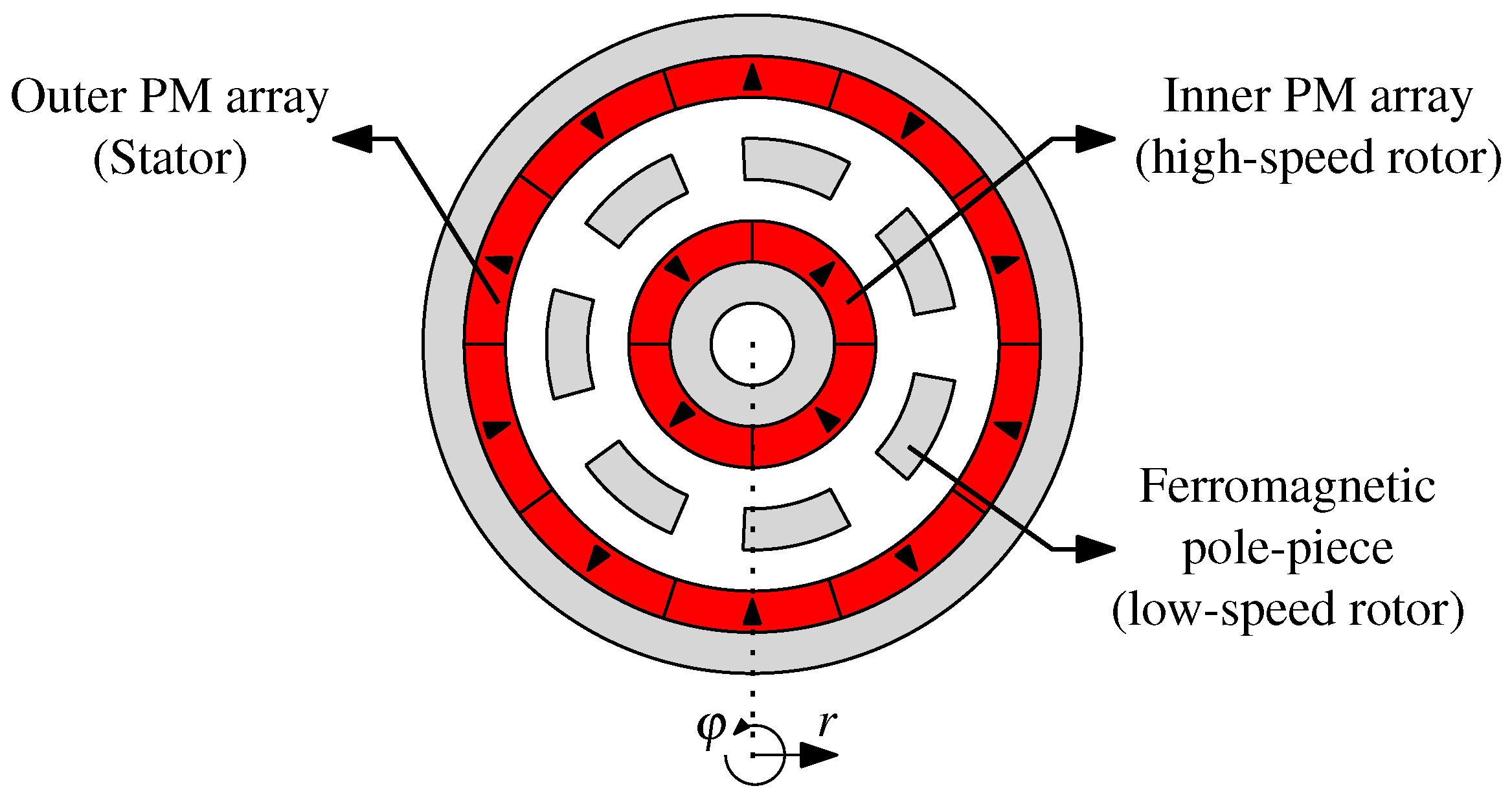

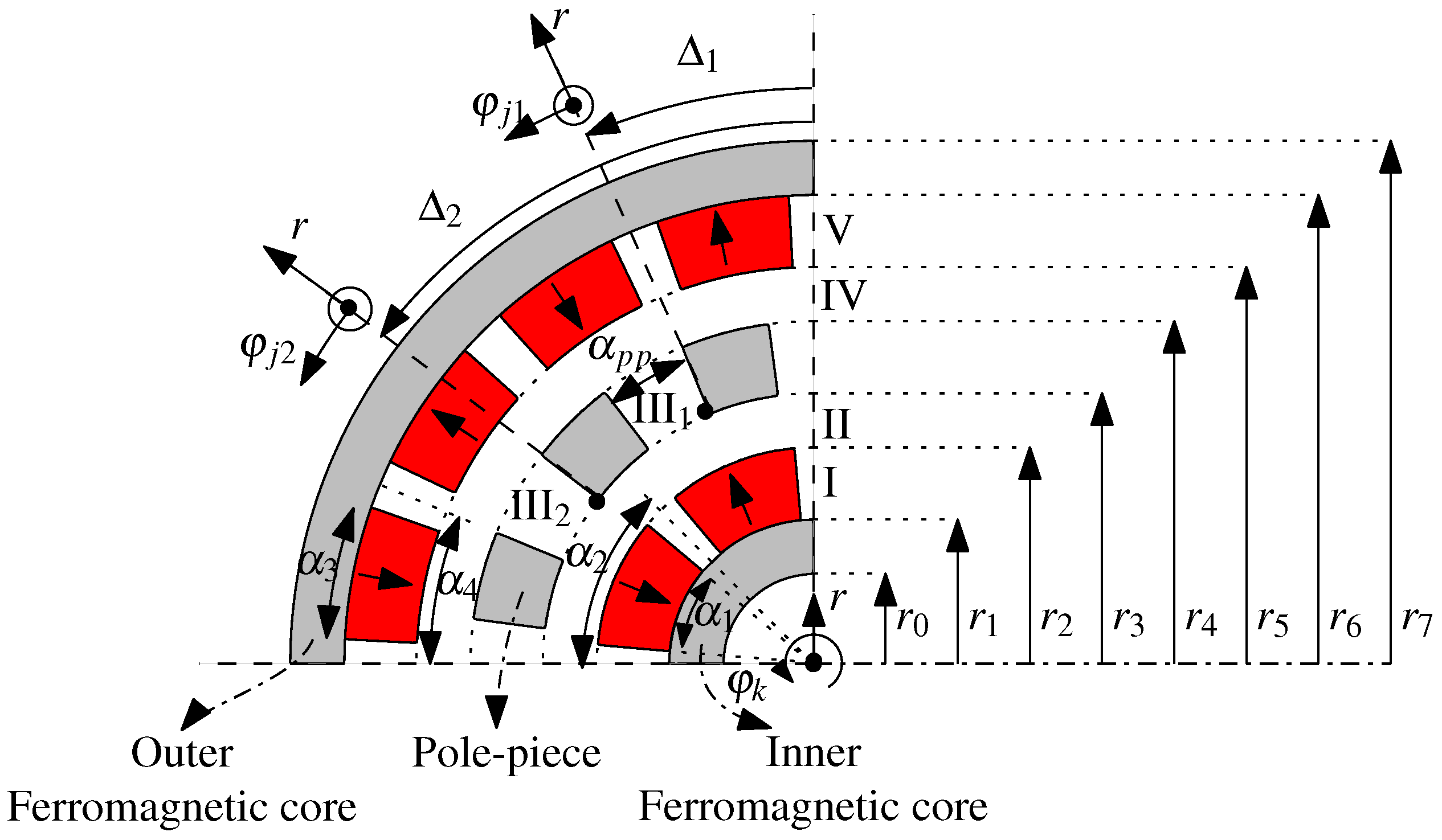

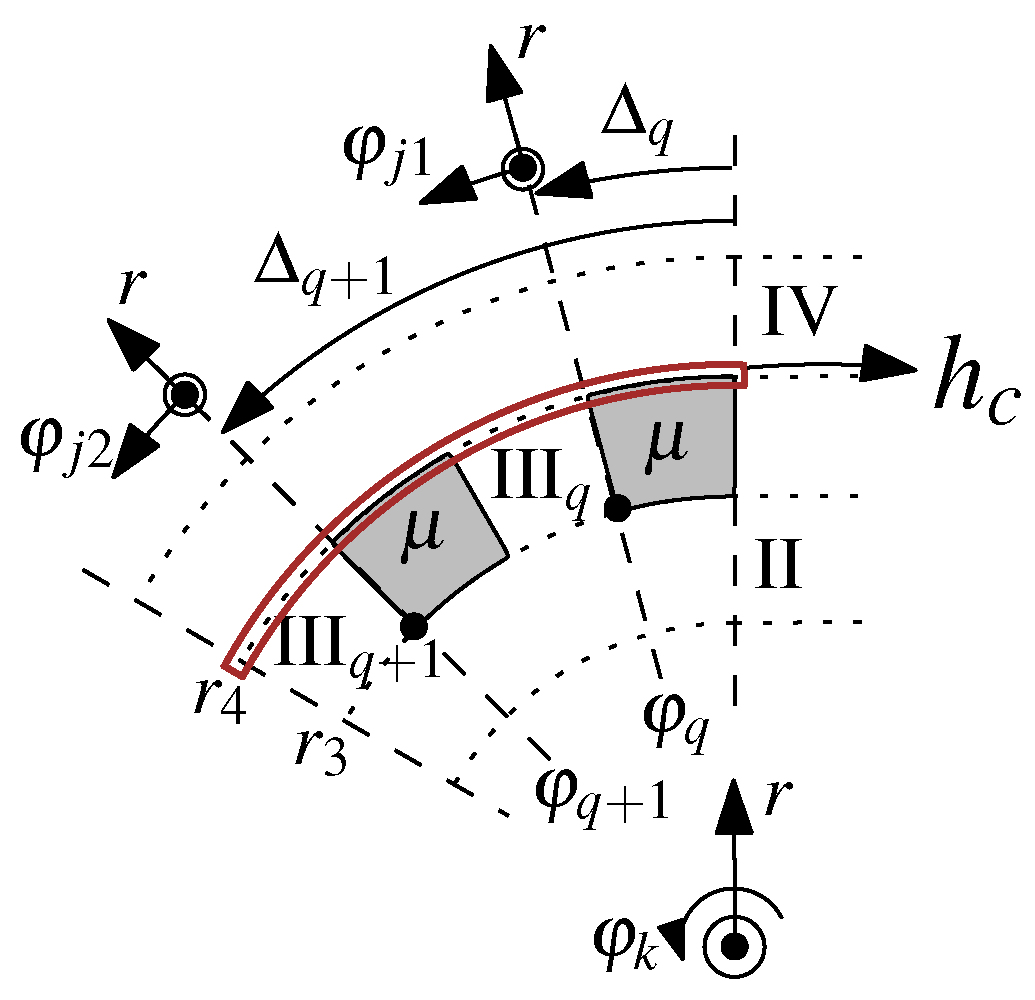

2.3. Harmonic Modeling of a Magnetic Gear

- Neumann boundary condition at and

- Continuous boundary condition at and

- Combination of Neumann and continuous boundary conditions at (between regions II and III) and (between regions IV and III)

- Conservation of the magnetic flux around the pole piecesThis boundary condition concerns Gauss’ law for magnetic field given byBy applying the the above to the pole-piece depicted in Figure 8, the following is obtainedfor which , with being the number of independent equations. An extra equation is required to solve all the unknowns, obtained from the application of Ampere’s law at the pole-pieces radial boundary highlighted in Figure 8, as follows:for which J is zero, resulting inwhere is the infinitesimal height of the boundary between region IV and III. Since , the following is obtained:

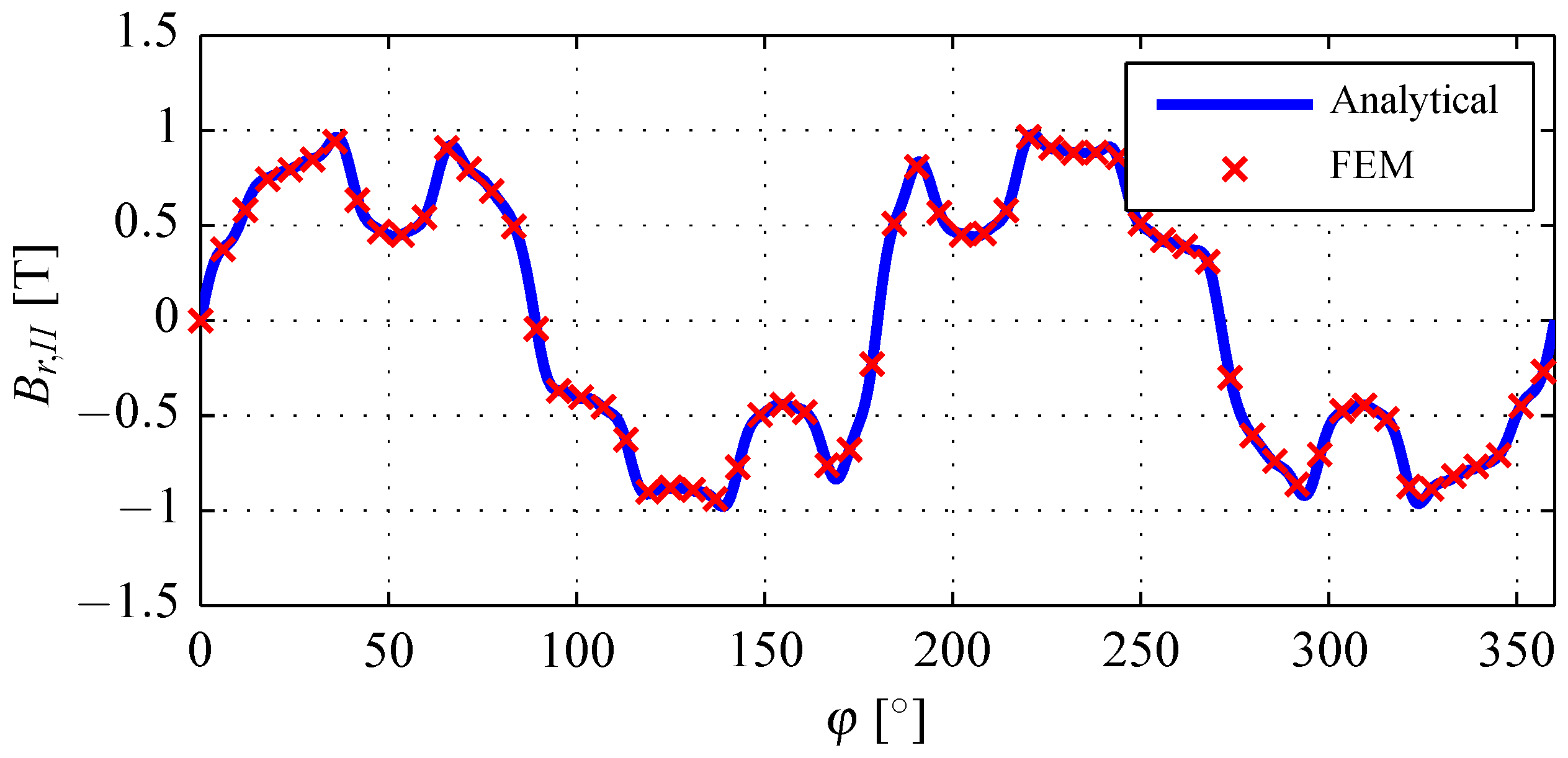

2.3.1. Model Verification

3. Definition of Optimization Problem Statements

3.1. Optimization Problem Statement for the Electrical Motor

- Objective functionThe considered application requires that the motor and magnetic gear are compact and lightweight. An objective function that handles these requirements is the inverse of the mass torque densitywhere is the motor mass and is the motor peak torque, defined as the highest level of torque that can be sustained for a period of time while the winding temperature rise does not exceed its limit. A thermal model is therefore developed, which is used to estimate the motor winding temperature and to derive the respective inequality constraint function (further described in the next part of this paper subsection).The motor torque can be calculated using Maxwell stress tensor as follows:where L is the axial length, is the radius of the middle of airgap region II in Figure 4, and are the radial and tangential magnetic flux densities in region II.

- Inequality constraint functions

- –

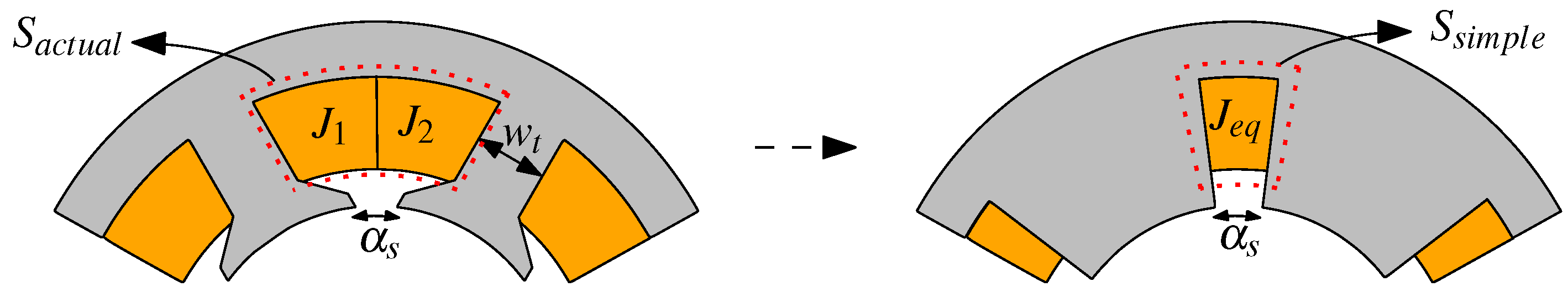

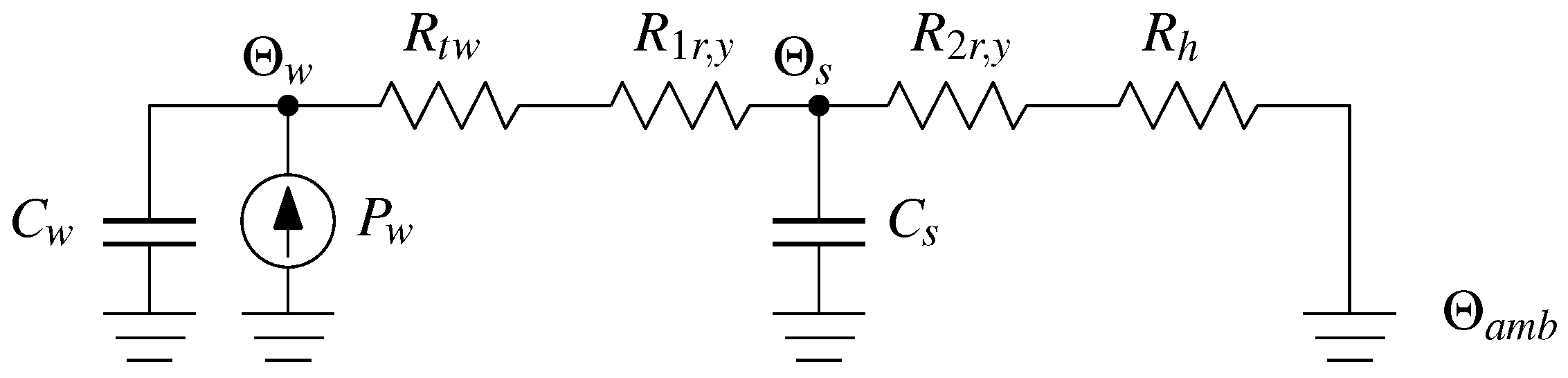

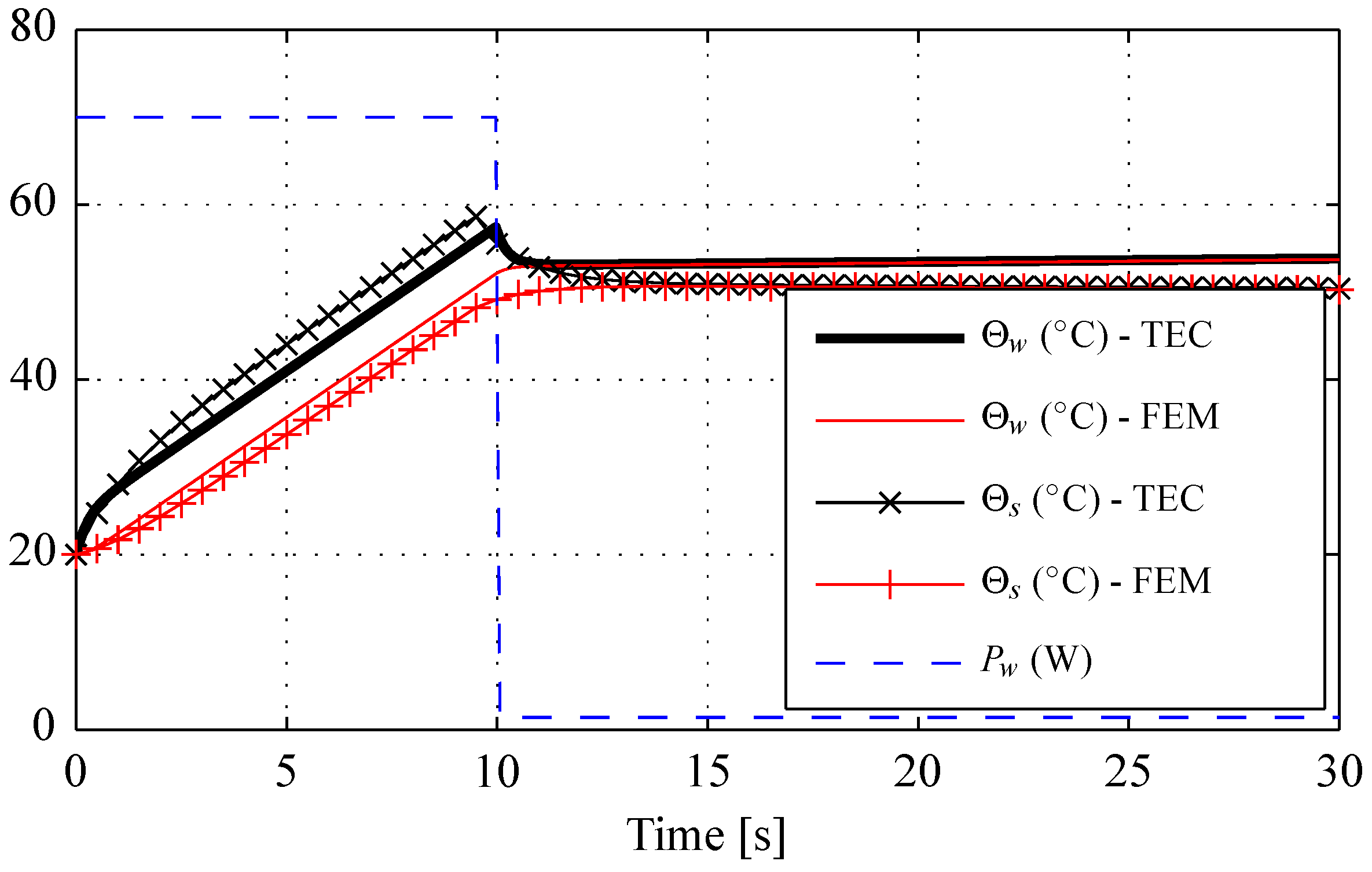

- Winding temperatureBased on Equation (36), the following constraint on the peak torque is definedwhere is the winding temperature that can be sustained for 10 s (given that its initial temperature at time = 0 s is the same as the ambient temperature), while the peak winding copper loss is maintained. Note that core (iron) losses also contribute to the temperature increase, although this is neglected in the considered application since the motor maximum speed is 3000 rpm, which is relatively low for the investigated topology and this occurs only in a transient task. Ultimately, constraint function Equation (38) imposes a limit on the winding current density when the motor peak torque is applied. A simple transient thermal equivalent circuit (TEC) in Figure 10 is developed to estimate the temperatures in the winding () and stator () as functions of time, which are obtained by solvingwhere , , are the radial conductive thermal resistances of the winding, stator yoke (inner and outer part), respectively, and is the convective thermal resistance (natural cooling is assumed). and are the thermal capacitances of the winding and stator, respectively. The calculation of thermal resistances and capacitances are based on the method described in [17]. The winding copper loss is calculated aswhere J is the current density, is the single-turn length of a winding coil loop, is the coil cross-section area and is the slot fill-factor. Figure 11 illustrated the temperatures of the motor winding and stator dynamically respond to the changes in copper loss, at ambient temperature of 20 C. A good agreement between TEC and FEM is apparent.

- –

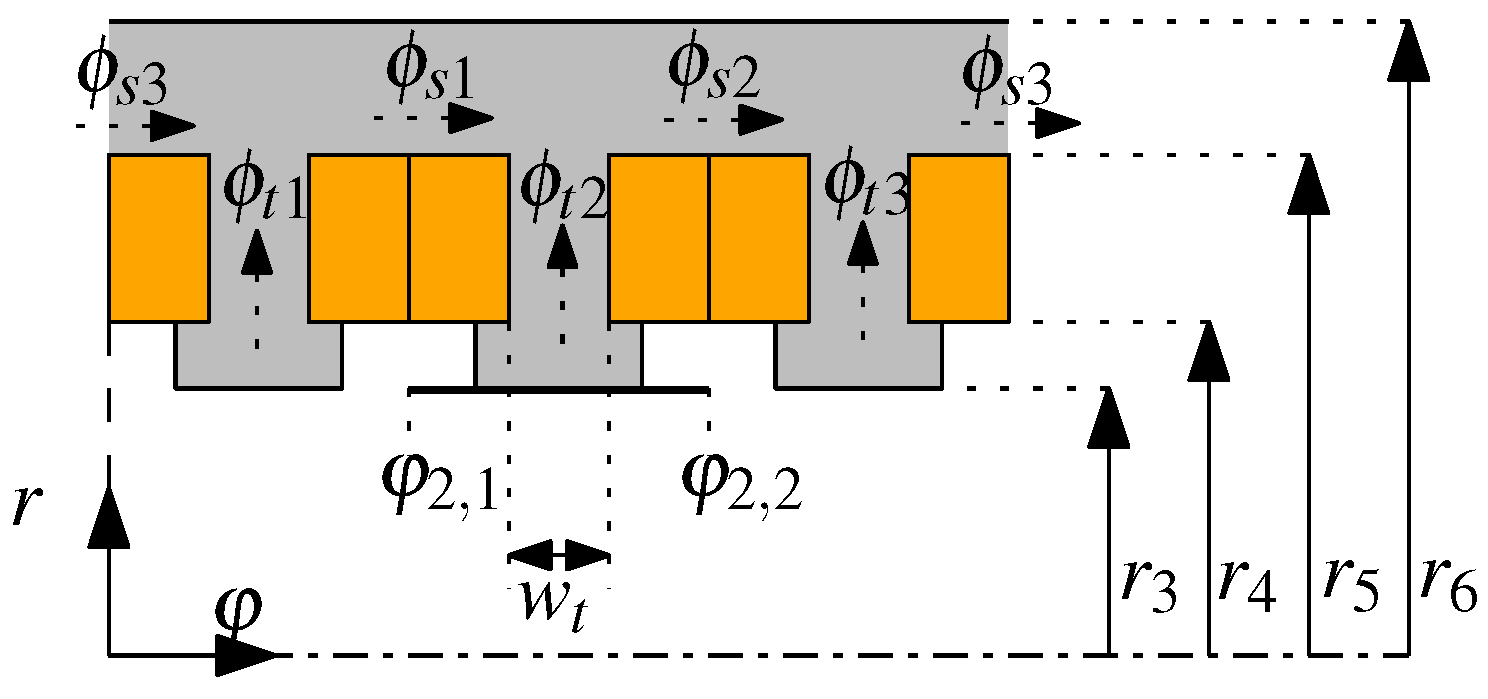

- Magnetic flux density in the ferromagnetic coresThe used ferromagnetic core material has a typical saturation point at B = 1.5 T in its characteristic. Thus, to maintain a linear current-torque relation in the motor, the following constraint functions are definedwhere and are the magnetic flux density in the stator tooth and stator yoke, respectively, given bywhere is the tooth width, and are the flux that goes through the i-th tooth and j-th yoke part (see Figure 12), respectively, estimated aswhere mod() in (46) is a modulo operation, giving the remainder after division between and Q, while the integration limits and are depicted in Figure 12.

- –

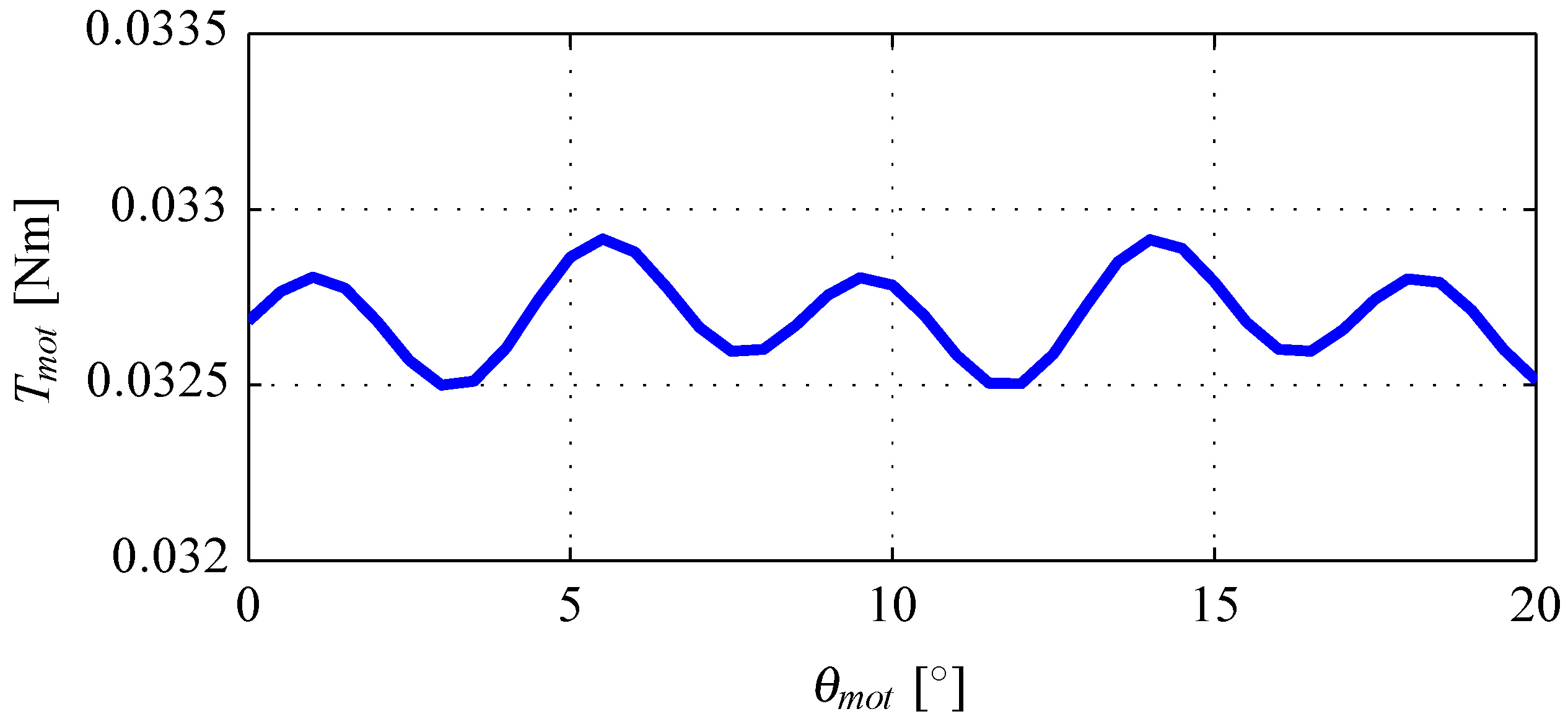

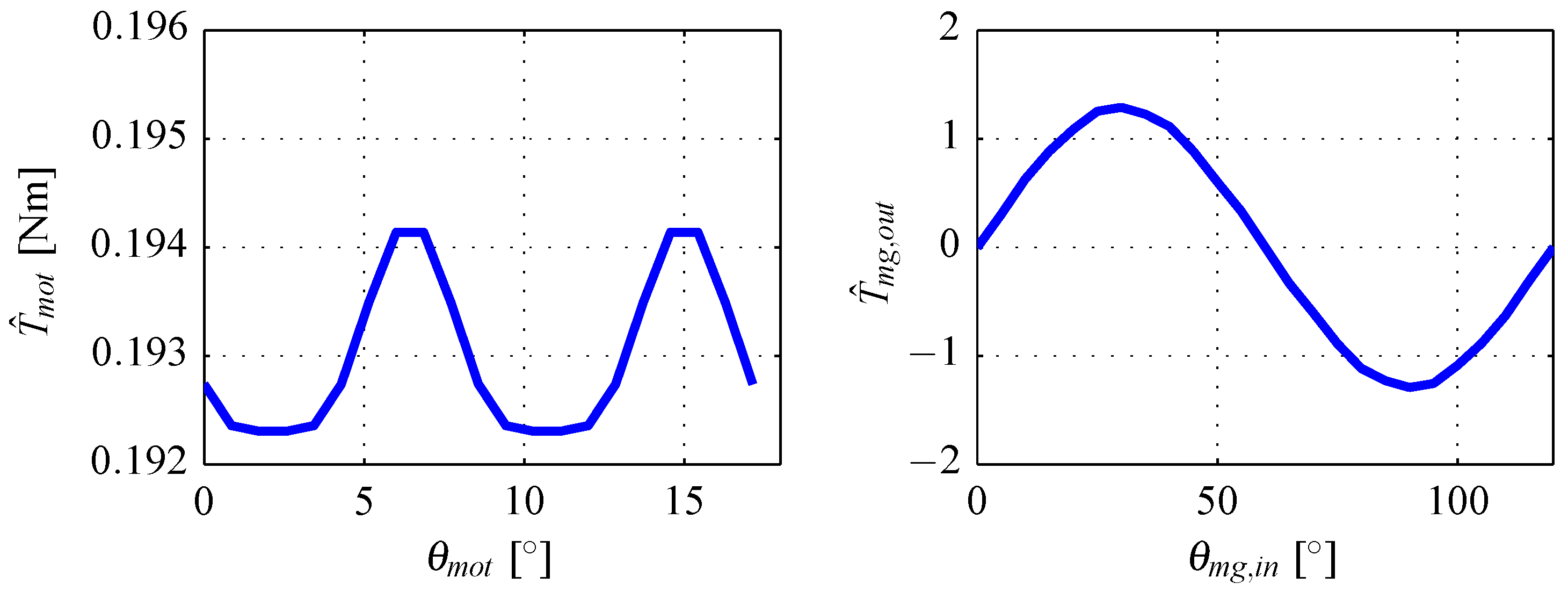

- Torque rippleA smooth torque characteristic is required in the considered application. For that reason, the ripple in the motor torque shown Figure 13 is constrained by the following functionwhere is the motor peak torque and is the average value of motor peak torque.

- Equality constraint functionsA series of optimization tasks will be performed on the motor. For a given optimization task, fixed values of motor outer dimensions are assigned. Therefore, the following equality constraint on outer diameter is introducedMeanwhile, the motor axial length is assigned as a design parameter.

- Design variables and bound constraintsThe design variable vector consists of motor geometric parameters (see Figure 4) and current densityfor which each variable adheres to the following lower and upper bound vectors ( and , respectively),

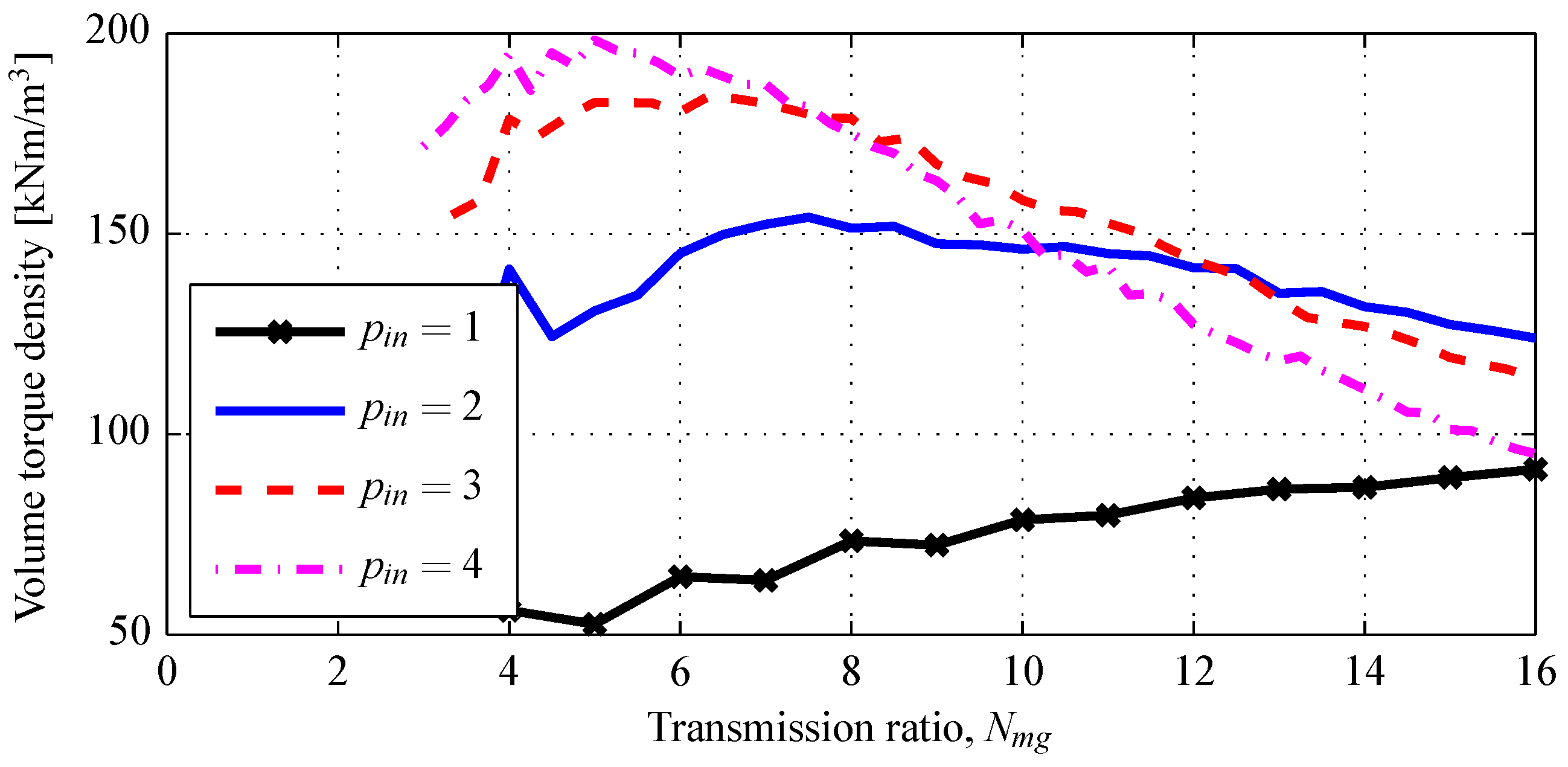

3.2. Optimization Problem Statement for the Magnetic Gear

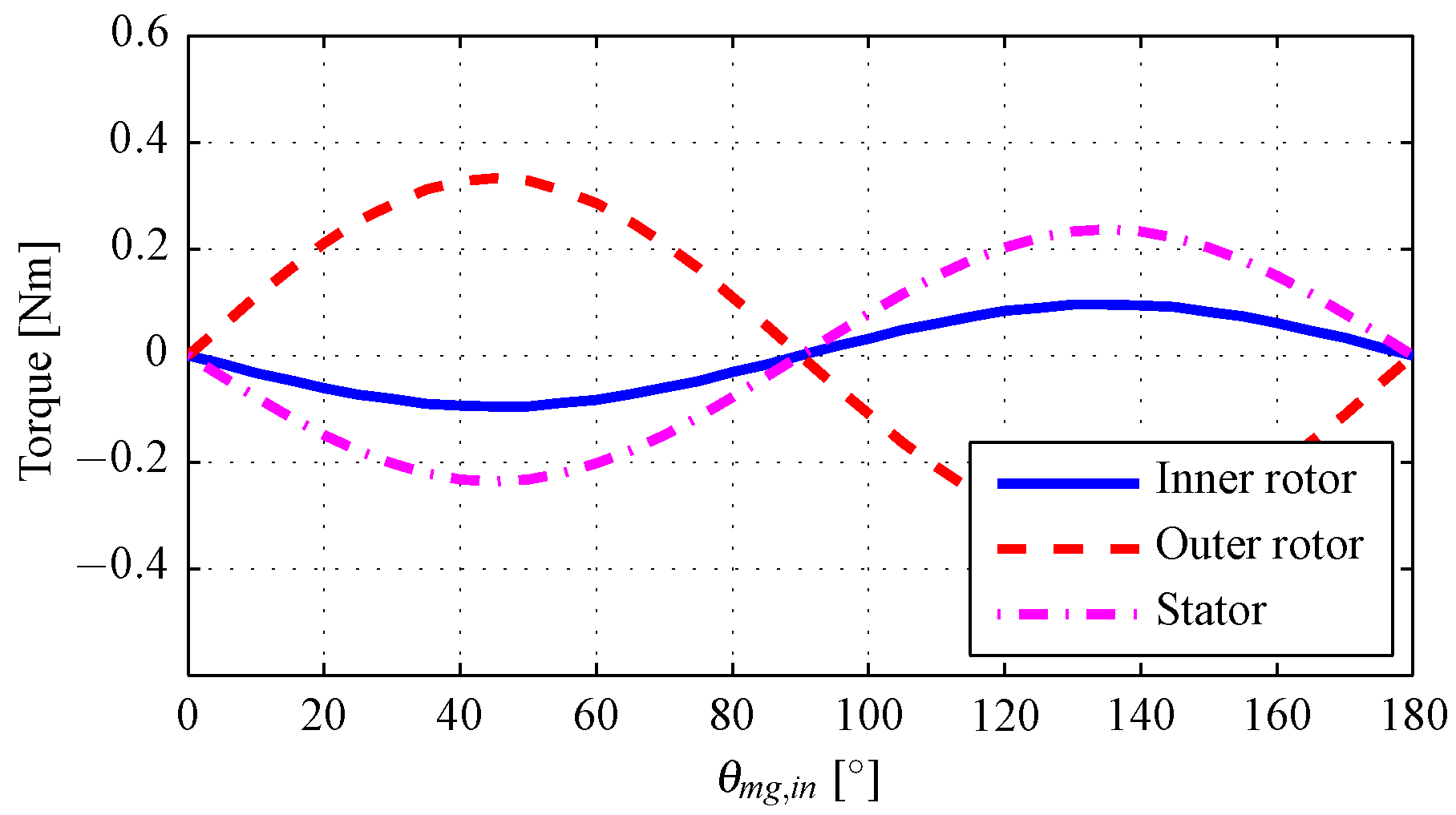

- Objective functionSimilar to the electrical motor optimization, the defined objective function of the magnetic gear is the inverse of mass torque densitywhere is the magnetic gear mass and is the peak value of the outer rotor torque, which has a sinusoidal torque-position characteristic. This is shown in Figure 14 together with the torque characteristics of the inner rotor and stator. The outer rotor torque is calculated as follows:where and are the magnetic gear stator and inner rotor torque, respectively.

- Inequality constraint functions

- –

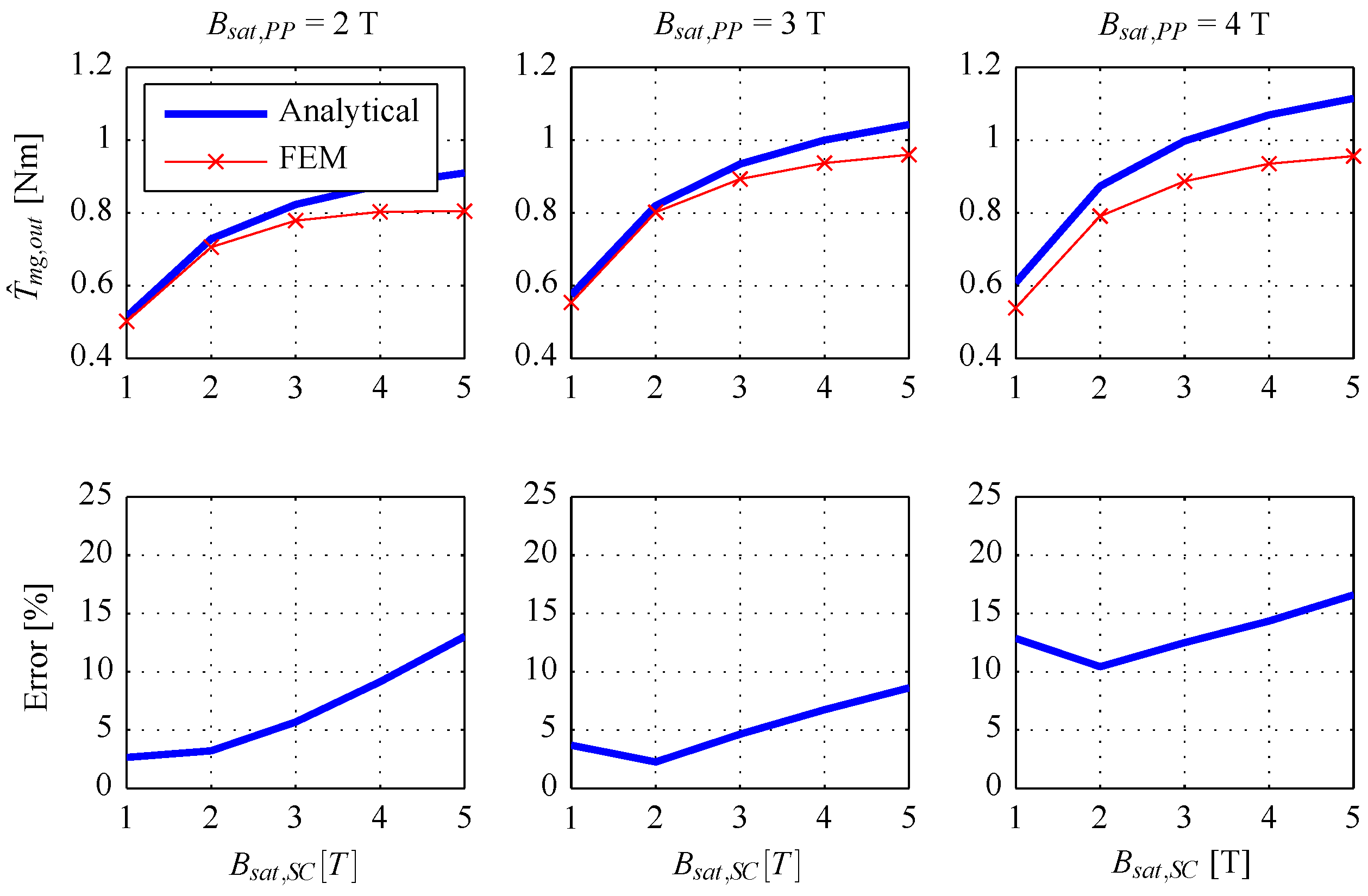

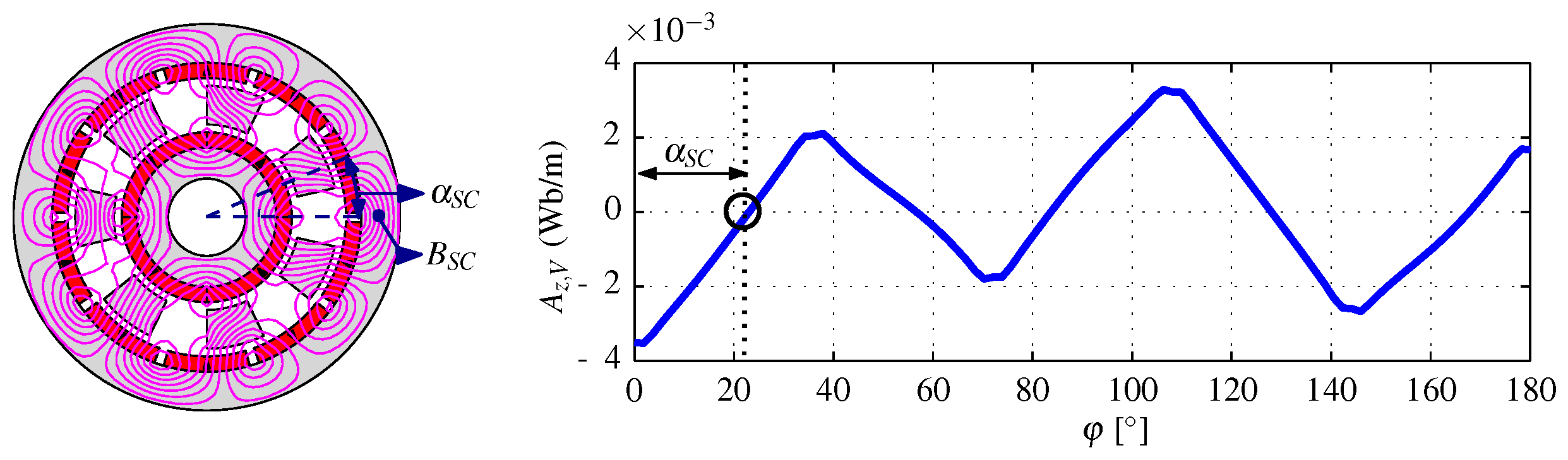

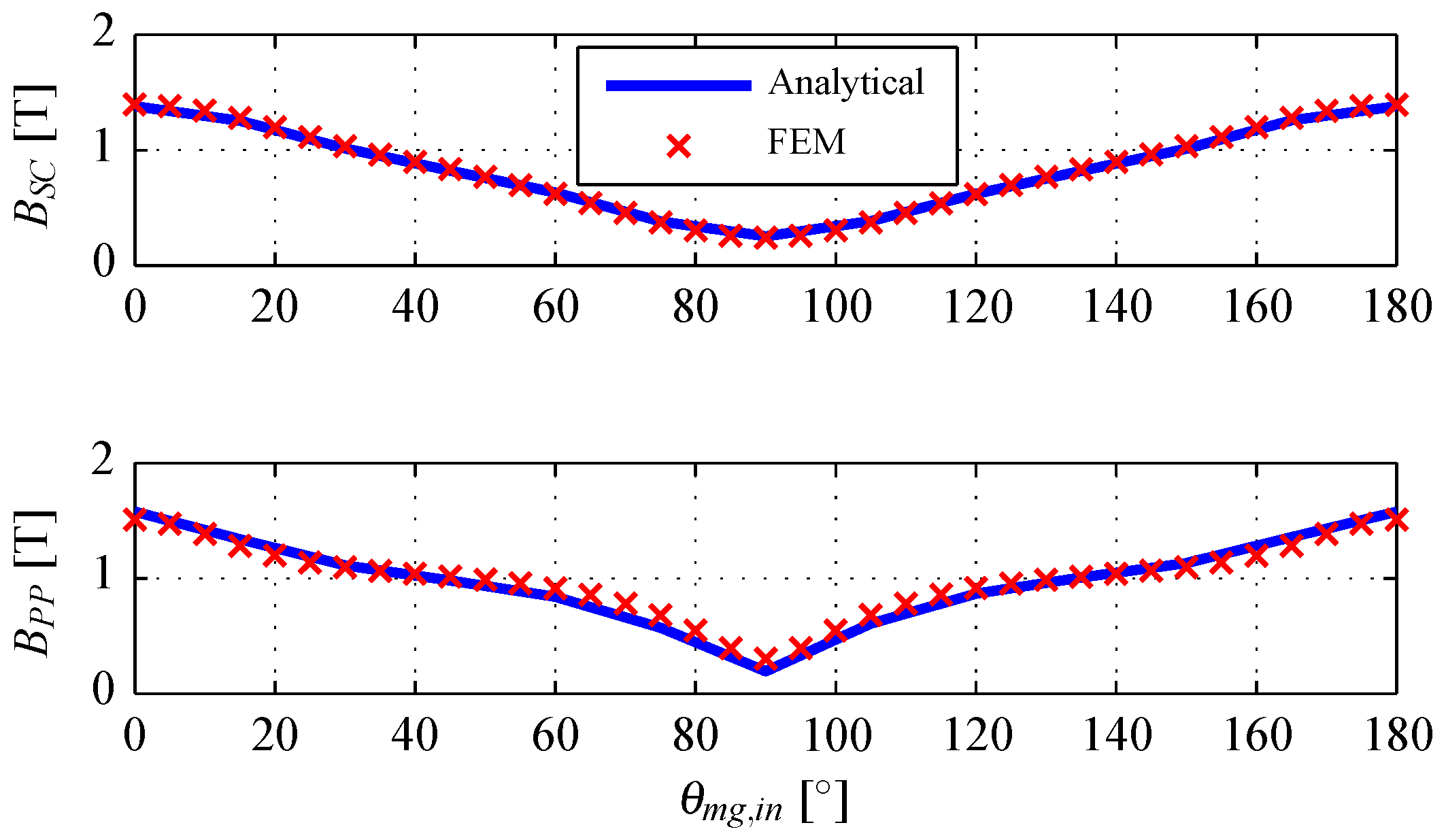

- Magnetic flux density in the ferromagnetic coresConstraints on the magnetic flux density in the pole-pieces and stator core of the magnetic gear are introduced to avoid saturation in the ferromagnetic cores, which leads to the inaccuracy of the analytical model with respect to the FEM model that accounts for nonlinear curve of the ferromagnetic steel 1010. The constraint values are selected such that the resulting torque is maximized while the analytical model accuracy is not significantly sacrificed. Figure 15 shows the variations of torque and discrepancy between analytical and FEM models for different values of the constraints and , belonging to the pole-pieces and stator core, respectively. The constraints T and T as calculated by the analytical model are selected based on the previous consideration on torque and model accuracy; thus, the following constraint functions are defined:where is the magnetic flux density in the stator core, estimated throughwhere is flux that enters the stator core over a range, from to as illustrated in Figure 16, for which the angle is determined from the zero crossing of the vector potential spatial distribution in region V. Meanwhile, is the magnetic flux density in the pole-piecewhere is the vector potential distribution throughout regions III,...,III and the pole pieces, obtained through the the following linear interpolationwhere and are the inner and outer airgap vector potential distributions, respectively, while (see Figure 7 for and ). As can be seen from Figure 17, there is a good agreement between the analytical and FEM estimated values of and .

- Equality constraint functionsFollowing Equation (48), the following constraint on the magnetic gear outer diameter is introducedAdditionally, the magnetic gear axial length is fixed as a design parameter.

- Design variables and bound constraintsThe design variable vector consists of the magnetic gear geometric parameters (see Figure 7)Each of the design variables has lower and upper bounds defined in the vectors and , respectively, as follows:

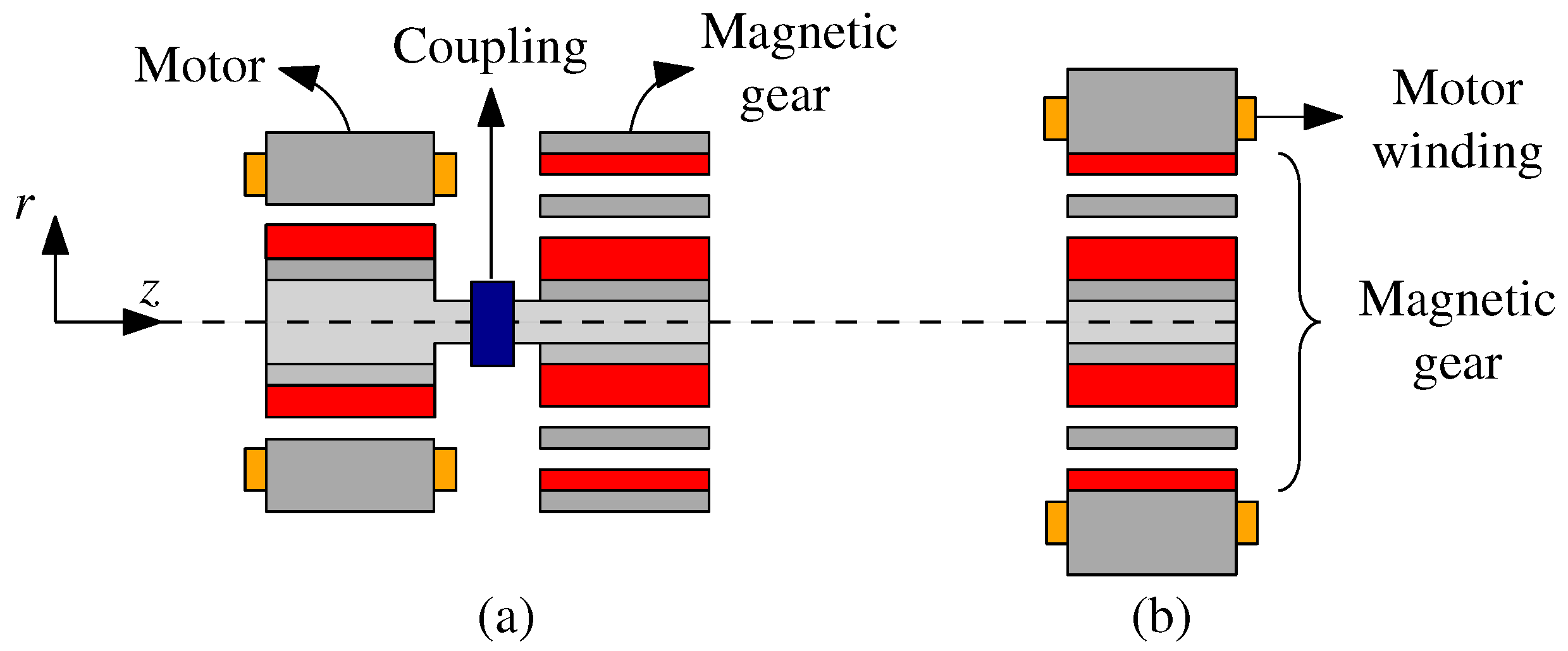

4. Optimization of the Shaft-Coupled Electrical Motor and Magnetic Gear

4.1. Modeling

4.2. Design Requirements

- The diameter of motor is equal to that of magnetic gear.

- The maximum axial length of the actuator is twice its diameter.

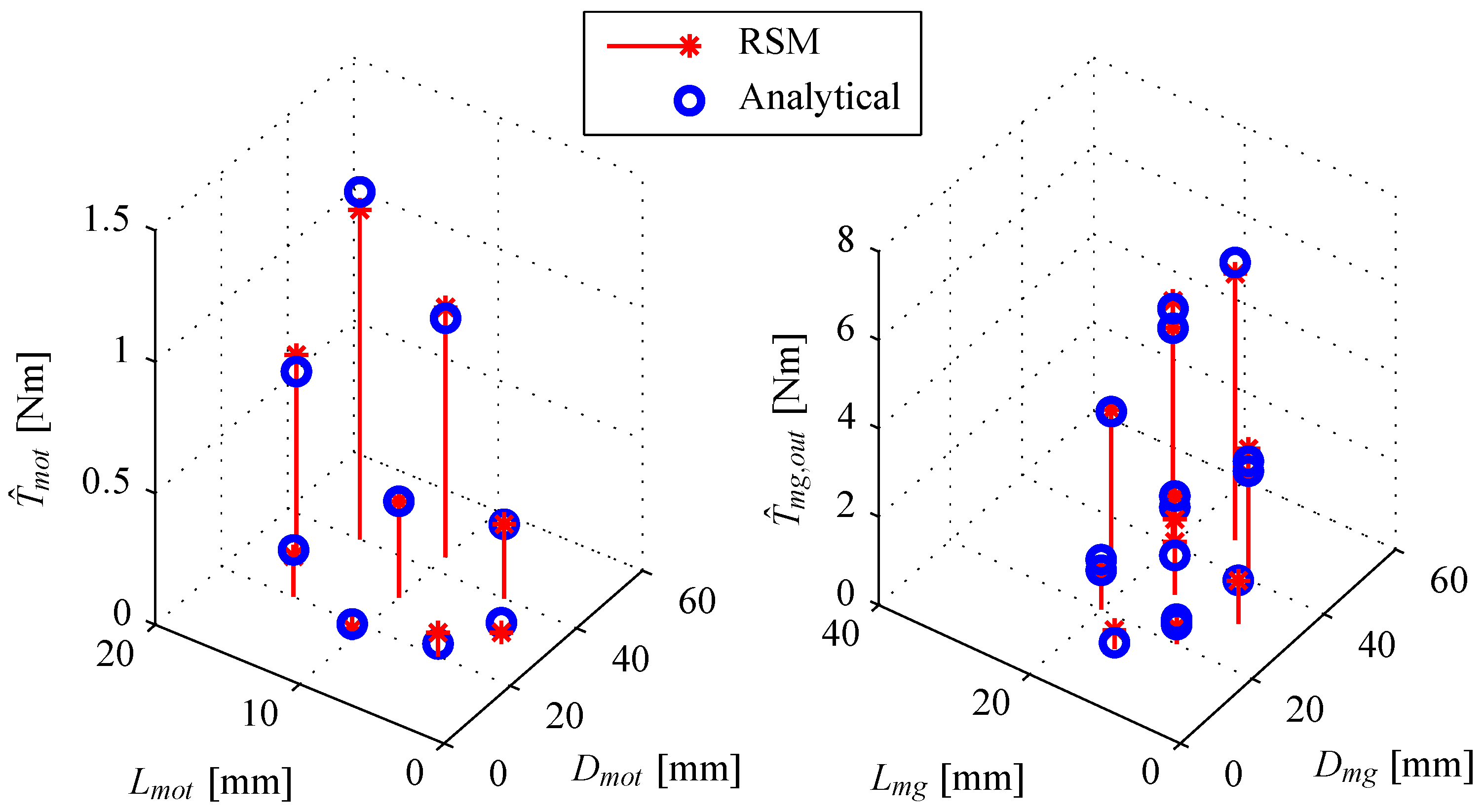

4.3. Response Surface Methodology

- 20 mm 40 mm, 5 mm 15 mm

- 20 mm 40 mm, 10 mm 20 mm, 3.33 9.67.

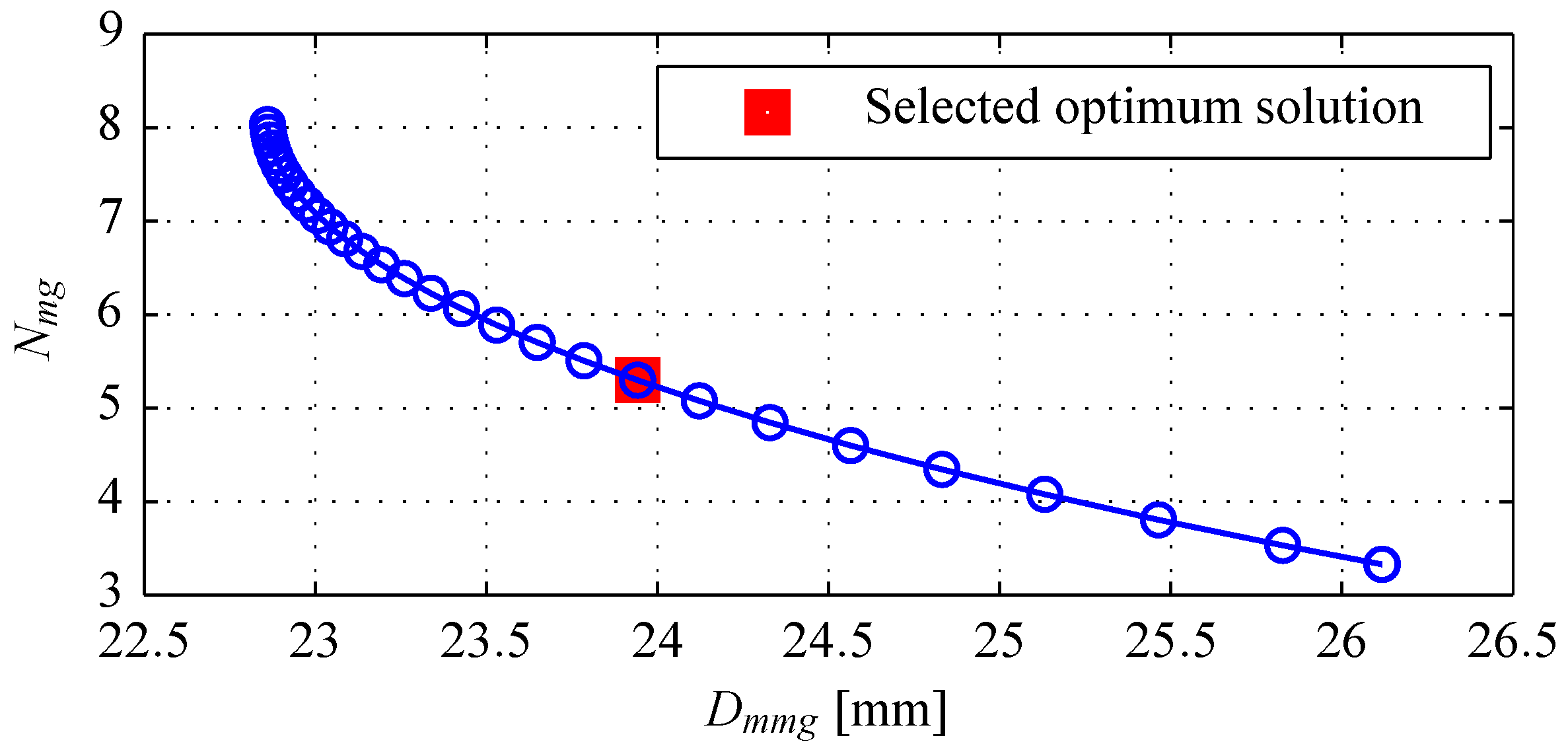

4.4. Definition of Optimization Problem Statement

4.5. Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Albu-Schaffer, A.; Eiberger, O.; Grebenstein, M.; Haddadin, S.; Ott, C.; Wimbock, T.; Wolf, S.; Hirzinger, G. Soft robotics. IEEE Robot. Autom. Mag. 2008, 15, 20–30. [Google Scholar] [CrossRef]

- Zanis, R.; Motoasca, E.; Lomonova, E. Trade-offs in the implementation of rigid and intrinsically compliant actuators in biorobotic applications. In Proceedings of the 2012 4th IEEE RAS EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. 100–105.

- Atallah, K.; Calverley, S.D.; Howe, D. Design, analysis and realisation of a high-performance magnetic gear. IEE Proc. Electr. Power Appl. 2004, 151, 135–143. [Google Scholar] [CrossRef]

- Atallah, K.; Rens, J.; Mezani, S.; Howe, D. A Novel Pseudo Direct-Drive Brushless Permanent Magnet Machine. IEEE Trans. Magn. 2008, 44, 4349–4352. [Google Scholar] [CrossRef]

- Roos, F.; Johansson, H.; Wikander, J. Optimal selection of motor and gearhead in mechatronic applications. Mechatronics 2006, 16, 63–72. [Google Scholar] [CrossRef]

- Van de Straete, H.; Degezelle, P.; De Schutter, J.; Belmans, R. Servo motor selection criterion for mechatronic applications. IEEE/ASME Trans. Mechatron. 1998, 3, 43–50. [Google Scholar] [CrossRef]

- Cusimano, G. Optimization of the choice of the system electric drive-device-transmission for mechatronic applications. Mech. Mach. Theory 2007, 42, 48–65. [Google Scholar] [CrossRef]

- Gysen, B.; Meessen, K.; Paulides, J.; Lomonova, E. General Formulation of the Electromagnetic Field Distribution in Machines and Devices Using Fourier Analysis. IEEE Trans. Magn. 2010, 46, 39–52. [Google Scholar] [CrossRef]

- Gysen, B.L.J. Generalized Harmonic Modeling Technique for 2D Electromagnetic Problesm: Applied to the Design of a Direct-Drive Active Suspension Systems. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2011. [Google Scholar]

- Khuri, A.I.; Mukhopadhyay, S. Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 128–149. [Google Scholar] [CrossRef]

- EL-Refaie, A. Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines: Opportunities and Challenges. IEEE Trans. Ind. Electron. 2010, 57, 107–121. [Google Scholar] [CrossRef]

- Zhu, Z.Q. Fractional slot permanent magnet brushless machines and drives for electric and hybrid propulsion systems. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2011, 30, 9–31. [Google Scholar]

- Furlani, E.P. Permanent Magnet and Electromechanical Devices; Academic Press: San Diego, CA, USA, 2001. [Google Scholar]

- Vanderplaats, G. Numerical Optimization Techniques for Engineering Design; Vanderplaats Research and Development, Inc.: Colorado Springs, CO, USA, 1999. [Google Scholar]

- Coleman, T.F.; Zhang, Y. Optimization Toolbox: User’s Guide (r2015b); MathWorks: Natick, MA, USA, 2015. [Google Scholar]

- Rokke, A. Gradient based optimization of Permanent Magnet generator design for a tidal turbine. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 1199–1205.

- Mellor, P.; Roberts, D.; Turner, D. Lumped parameter thermal model for electrical machines of TEFC design. IEE Proc. B Electr. Power Appl. 1991, 138, 205–218. [Google Scholar] [CrossRef]

- Jolly, L.; Jabbar, M.; Qinghua, L. Design optimization of permanent magnet motors using response surface methodology and genetic algorithms. IEEE Trans. Magn. 2005, 41, 3928–3930. [Google Scholar] [CrossRef]

- Hasanien, H.; Abd-Rabou, A.; Sakr, S. Design Optimization of Transverse Flux Linear Motor for Weight Reduction and Performance Improvement Using Response Surface Methodology and Genetic Algorithms. IEEE Trans. Energy Convers. 2010, 25, 598–605. [Google Scholar] [CrossRef]

- Miettinen, K.; Makela, M.M. On scalarizing functions in multiobjective optimization. OR Spectr. 2002, 24, 193–213. [Google Scholar] [CrossRef]

- Zhu, Z.; Howe, D. Influence of design parameters on cogging torque in permanent magnet machines. IEEE Trans. Energy Convers. 2000, 15, 407–412. [Google Scholar] [CrossRef]

| Region | Description | Parameters |

|---|---|---|

| I | PM array | - Number of PM pole pairs, p |

| - Pole-arc to pole-pitch ratio, | ||

| - Remanence, | ||

| - Relative permeability, | ||

| II | Airgap | N/A |

| III | Slot air | - Number of slots, Q |

| - Slot opening, | ||

| IV | Slot winding | - Number of slots, Q |

| - Slot opening, | ||

| - Current density, J |

| Parameter | Value |

|---|---|

| No. of PM pole pairs, p | 7 |

| No. of slots, Q | 12 |

| Inner shaft radius, | 2.7 mm |

| Inner ferromagnetic core outer radius, | 3.7 mm |

| Inner PM outer radius, | 5.7 mm |

| Inner airgap outer radius, | 6 mm |

| Slot air outer radius, | 6.5 mm |

| Slot winding outer radius, | 10.5 mm |

| Outer stator radius, | 12.5 mm |

| Axial length, L | 18 mm |

| Slot opening, | 5 |

| Tooth width, | 2 mm |

| PM pole-arc to pole-pitch ratio, | 1 |

| PM remanence, | 1.39 |

| PM relative permeability, | 1.05 |

| Ferromagnetic core material (for FEM) | M330-35A |

| Current density, J | 5 A/mm |

| Duration | ||

|---|---|---|

| Analytical (Linear) | FEM (Linear) | FEM (Nonlinear) |

| 0.05 s | 1 s | 6 s |

| Region | Description | Parameters |

|---|---|---|

| I | Inner PM array | - Number of inner PM pole pairs, |

| - Pole-arc to pole-pitch ratio, | ||

| - Remanence, | ||

| - Relative permeability, | ||

| II | Inner airgap | N/A |

| III | Air between pole-pieces | - Number of pole-pieces, Q |

| - Tangential width, | ||

| - Pole-piece arc-to-pitch ratio, | ||

| IV | Outer airgap | N/A |

| V | Outer PM array | - Number of outer PM pole pairs, |

| - Pole-arc to pole-pitch ratio, | ||

| - Remanence, | ||

| - Relative permeability, |

| Parameter | Value |

|---|---|

| No. of inner PM pole pairs, | 2 |

| No. of outer PM pole pairs, | 5 |

| No. of pole-pieces, | 7 |

| Transmission ratio, | 3.5 |

| Inner shaft radius, | 2.5 mm |

| Inner ferromagnetic core outer radius, | 4.5 mm |

| Inner PM outer radius, | 5.5 mm |

| Inner airgap outer radius, | 6 mm |

| Pole-piece outer radius, | 8.5 mm |

| Outer airgap outer radius, | 9 mm |

| Outer PM outer radius, | 10 mm |

| Stator outer radius, | 12.5 mm |

| Inner PM pole-arc to pole-pitch ratio, | 1 |

| Outer PM pole-arc to pole-pitch ratio, | 0.9 |

| Pole-piece arc to pitch ratio, | 0.5 |

| PM remanence, | 1.39 |

| PM relative permeability, | 1.05 |

| Ferromagnetic core material (for FEM) | Steel 1010 |

| Parameter | Shaft-Coupled Motor and Magnetic Gear | Electrical Motor Only |

|---|---|---|

| Diameter | 24 mm | 30 mm |

| Axial length (incl. housing) | 48 mm | 45 mm |

| Volume | 2.2 mm | 3.2 mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanis, R.; Jansen, J.W.; Lomonova, E.A. Modeling and Design Optimization of A Shaft-Coupled Motor and Magnetic Gear. Actuators 2016, 5, 10. https://doi.org/10.3390/act5010010

Zanis R, Jansen JW, Lomonova EA. Modeling and Design Optimization of A Shaft-Coupled Motor and Magnetic Gear. Actuators. 2016; 5(1):10. https://doi.org/10.3390/act5010010

Chicago/Turabian StyleZanis, R., J.W. Jansen, and E.A. Lomonova. 2016. "Modeling and Design Optimization of A Shaft-Coupled Motor and Magnetic Gear" Actuators 5, no. 1: 10. https://doi.org/10.3390/act5010010

APA StyleZanis, R., Jansen, J. W., & Lomonova, E. A. (2016). Modeling and Design Optimization of A Shaft-Coupled Motor and Magnetic Gear. Actuators, 5(1), 10. https://doi.org/10.3390/act5010010