AI-Enhanced Model for Integrated Performance Prediction and Classification of Vibration-Reducing Gloves for Hand-Transmitted Vibration Control

Abstract

1. Introduction

2. Experimental Designs and Methods

2.1. Subjects

2.2. Glove Selection

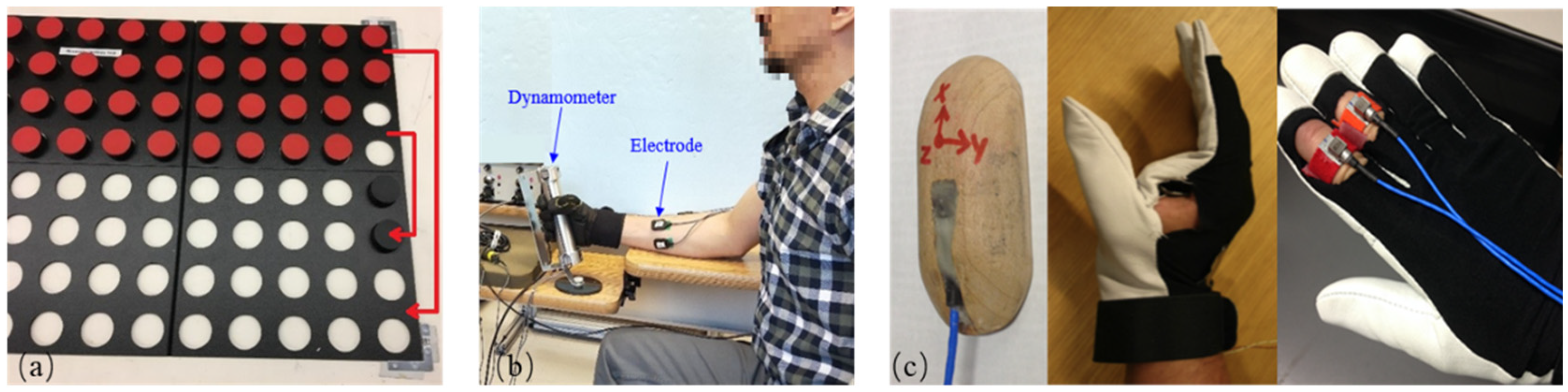

2.3. Experimental Methods of VR Gloves

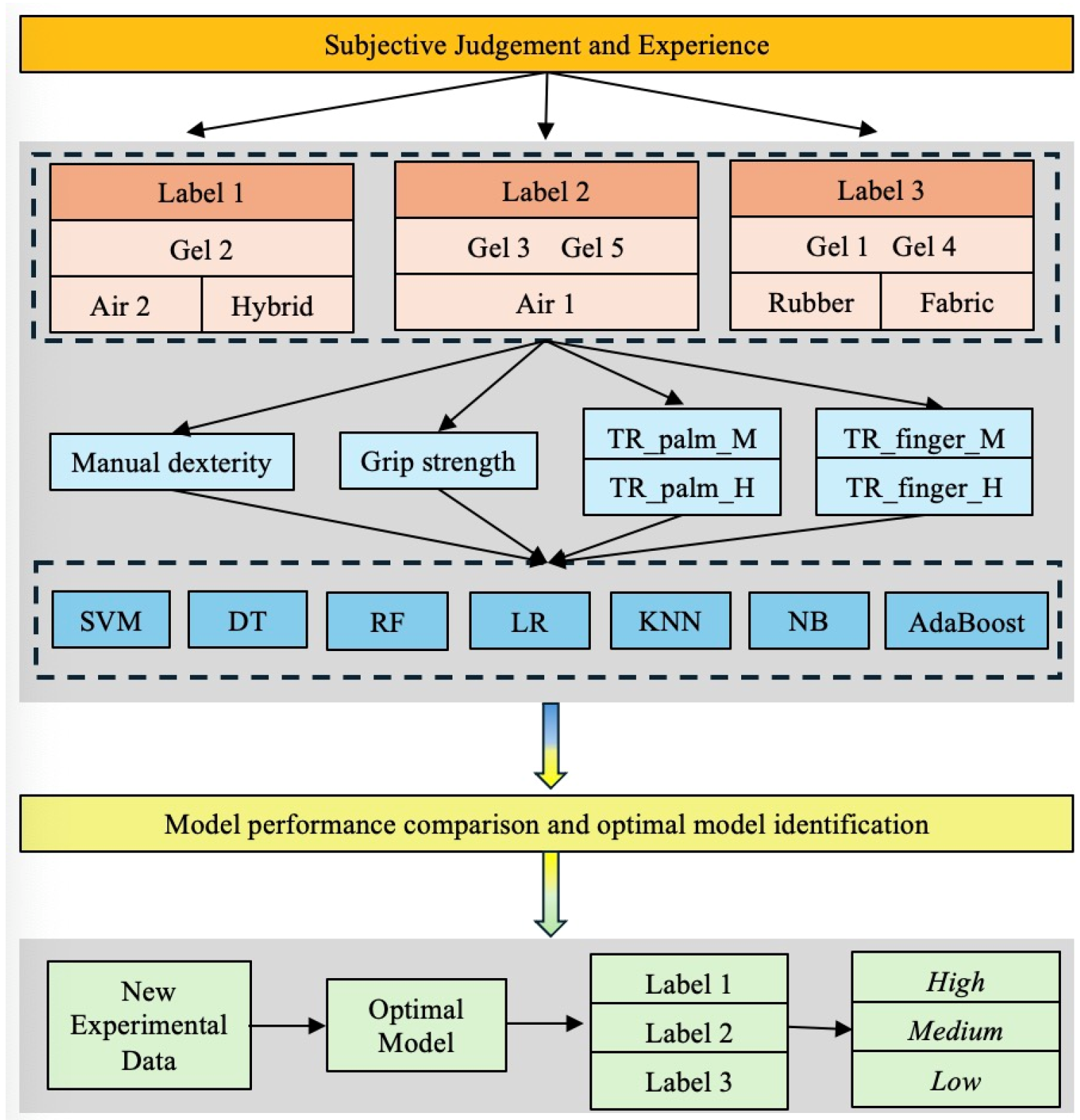

3. Performance Assessment of Data-Driven Models

4. Results and Discussions

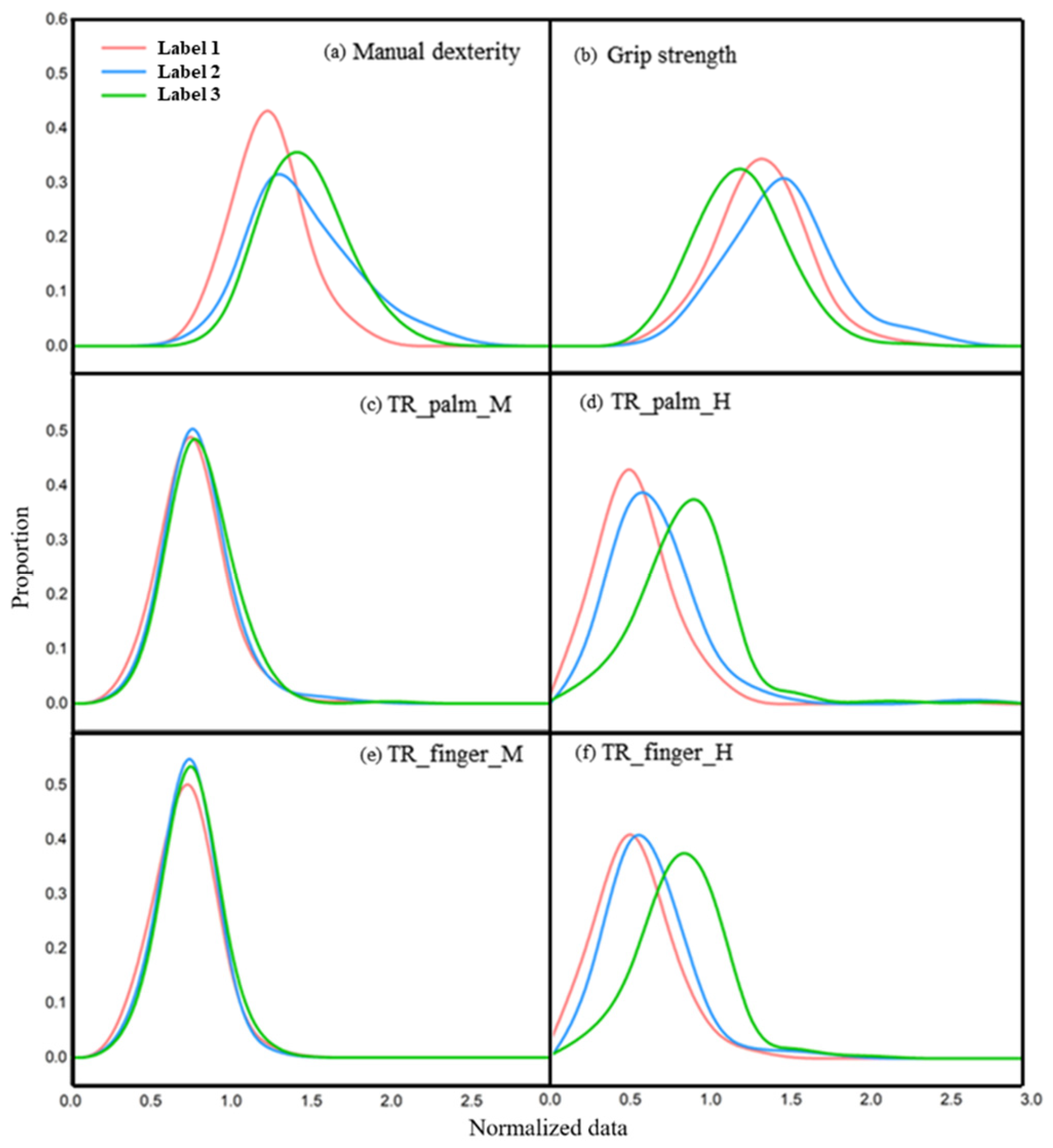

4.1. Features Analysis

4.2. Model Comparison and Verification

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weir, E.; Lander, L. Hand–arm vibration syndrome. Can. Med. Assoc. J. 2005, 172, 1001–1002. [Google Scholar] [CrossRef]

- Yao, Y.; Rakheja, S.; Gauvin, C.; Marcotte, P.; Hamouda, K. Evaluation of effects of anti-vibration gloves on manual dexterity. Ergonomics 2018, 61, 1530–1544. [Google Scholar] [CrossRef]

- Hamouda, K.; Rakheja, S.; Dewangan, K.N.; Marcotte, P. Fingers’ vibration transmission and grip strength preservation performance of vibration reducing gloves. Appl. Ergon. 2018, 66, 121–138. [Google Scholar] [CrossRef]

- ISO 10819:2013; Mechanical Vibration and Shock-Hand-Arm Vibration—Measurement and Evaluation of the Vibration Transmissibility of Gloves at the Palm of the Hand. International Organization for Standardization (ISO): Geneva, Switzerland, 2013.

- Md Rezali, K.A.; Griffin, M.J. The transmission of vibration through gloves to the hand and to the fingers: Effects of material dynamic stiffness. Appl. Mech. Mater. 2014, 564, 149–154. [Google Scholar] [CrossRef]

- Yao, Y.; Rakheja, S.; Marcotte, P. Distributed vibration isolation and manual dexterity of anti-vibration gloves: Is there a correlation? Ergonomics 2020, 63, 735–755. [Google Scholar] [CrossRef] [PubMed]

- Ervin, C.A. A Standardized Dexterity Test Battery. In Performance of Protective Clothing, Proceedings of the Second International Symposium on Performance of Protective Clothing, Tampa, FL, USA, 19–21 January 1987; ASTM International: West Conshohocken, PA, USA, 1988. [Google Scholar]

- Jurgensen, C.E. Extension of the Minnesota Rate of Manipulation Test. J. Appl. Psychol. 1943, 27, 164. [Google Scholar] [CrossRef]

- Dianat, I.; Haslegrave, C.M.; Stedmon, A.W. Methodology for evaluating gloves in relation to the effects on hand performance capabilities: A literature review. Ergonomics 2012, 55, 1429–1451. [Google Scholar] [CrossRef]

- Dianat, I.; Haslegrave, C.M.; Stedmon, A.W. Short and longer duration effects of protective gloves on hand performance capabilities and subjective assessments in a screw-driving task. Ergonomics 2010, 53, 1468–1483. [Google Scholar] [CrossRef]

- Yao, Y.; Rakheja, S.; Marcotte, P. Relationship among hand forces imparted on a viscoelastic hand-handle interface. Measurement 2019, 145, 525–534. [Google Scholar] [CrossRef]

- Larivière, C.; Plamondon, A.; Lara, J.; Tellier, C.; Boutin, J.; Dagenais, A. Biomechanical assessment of gloves. A study of the sensitivity and reliability of electromyographic parameters used to measure the activation and fatigue of different forearm muscles. Int. J. Ind. Ergon. 2004, 34, 101–116. [Google Scholar] [CrossRef]

- Wimer, B.; Dong, R.G.; Welcome, D.E.; Warren, C.; McDowell, T.W. Development of a new dynamometer for measuring grip strength applied on a cylindrical handle. Med. Eng. Phys. 2009, 31, 695–704. [Google Scholar] [CrossRef]

- Lemerle, P.; Klinger, A.; Cristalli, A.; Geuder, M. Application of pressure mapping techniques to measure push and gripping forces with precision. Ergonomics 2008, 51, 168–191. [Google Scholar] [CrossRef] [PubMed]

- McDowell, T.W.; Dong, R.G.; Welcome, D.E.; Xu, X.S.; Warren, C. Vibration-reducing gloves: Transmissibility at the palm of the hand in three orthogonal directions. Ergonomics 2013, 56, 1823–1840. [Google Scholar] [CrossRef] [PubMed]

- Welcome, D.E.; Dong, R.G.; Xu, X.S.; Warren, C.; McDowell, T.W. The effects of vibration-reducing gloves on finger vibration. Int. J. Ind. Ergon. 2014, 44, 45–59. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.G.; Welcome, D.E.; Wu, J.Z. Frequency weightings based on biodynamics of fingers-hand-arm system. Ind. Health 2005, 43, 516–526. [Google Scholar] [CrossRef]

- Rakheja, S.; Wu, J.Z.; Dong, R.G.; Schopper, A.W.; Boileau, P.-É. A comparison of biodynamic models of the human hand–arm system for applications to hand-held power tools. J. Sound Vib. 2002, 249, 55–82. [Google Scholar] [CrossRef]

- Dong, R.G.; Dong, J.H.; Wu, J.Z.; Rakheja, S. Modeling of biodynamic responses distributed at the fingers and the palm of the human hand–arm system. J. Biomech. 2007, 40, 2335–2340. [Google Scholar] [CrossRef]

- Yao, Y.; Rakheja, S.; Marcotte, P. A methodology for integrated performance analyses of vibration reducing gloves. Int. J. Ind. Ergon. 2021, 85, 103174. [Google Scholar] [CrossRef]

- Ntoutsi, E.; Fafalios, P.; Gadiraju, U.; Iosifidis, V.; Nejdl, W.; Vidal, M.-E.; Ruggieri, S.; Turini, F.; Papadopoulos, S.; Krasanakis, E. Bias in data-driven artificial intelligence systems—An introductory survey. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2020, 10, e1356. [Google Scholar] [CrossRef]

- Baier, L.; Jöhren, F.; Seebacher, S. Challenges in the deployment and operation of machine learning in practice. In Proceedings of the ECIS, Stockholm, Sweden, 8–14 June 2019; pp. 1–15. [Google Scholar]

- Habib, M.K.; Ayankoso, S.A.; Nagata, F. Data-driven modeling: Concept, techniques, challenges and a case study. In Proceedings of the 2021 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 8–11 August 2021; pp. 1000–1007. [Google Scholar]

- Sain, S.R. The Nature of Statistical Learning Theory; Taylor & Francis: Oxfordshire, UK, 1996. [Google Scholar]

- Li, W.; Zhuo, Y.; Bao, J.; Shen, Y. A data-based soft-sensor approach to estimating raceway depth in ironmaking blast furnaces. Powder Technol. 2021, 390, 529–538. [Google Scholar] [CrossRef]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Mousavi, S.Z.; Kavian, A.; Soleimani, K.; Mousavi, S.R.; Shirzadi, A. GIS-based spatial prediction of landslide susceptibility using logistic regression model. Geomat. Nat. Hazards Risk 2011, 2, 33–50. [Google Scholar] [CrossRef]

- Raymer, M.L.; Sanschagrin, P.C.; Punch, W.F.; Venkataraman, S.; Goodman, E.D.; Kuhn, L.A. Predicting conserved water-mediated and polar ligand interactions in proteins using a K-nearest-neighbors genetic algorithm. J. Mol. Biol. 1997, 265, 445–464. [Google Scholar] [CrossRef]

- Rish, I. An empirical study of the naive Bayes classifier. In Proceedings of the IJCAI 2001 Workshop on Empirical Methods in Artificial Intelligence, Seattle, WA, USA, 4–6 August 2001; pp. 41–46. [Google Scholar]

- Zhang, C.; Ma, Y. Ensemble Machine Learning; Springer: Berlin/Heidelberg, Germany, 2012; Volume 144. [Google Scholar]

- Yao, Y.; Rakheja, S.; Larivière, C.; Marcotte, P. Assessing increased activities of the forearm muscles due to anti-vibration gloves: Construct validity of a refined methodology. Hum. Factors 2022, 64, 466–481. [Google Scholar] [CrossRef]

| Parameter | Maximum | Minimum | Mean | Standard Deviation |

|---|---|---|---|---|

| Age (years) | 35 | 22 | 27.54 | 3.71 |

| Height (cm) | 181 | 169 | 174.81 | 5.51 |

| Body weight (kg) | 79 | 60 | 70.27 | 6.33 |

| Hand length (mm) | 205 | 180 | 188.73 | 7.24 |

| Palm circumference (mm) | 220 | 185 | 197.67 | 10.59 |

| Labels | Values | Features | |||||

|---|---|---|---|---|---|---|---|

| Manual Dexterity | TR_palm_M | TR_palm_H | TR_finger_M | TR_finger_H | Grip Strength | ||

| 1 | Min | 0.89 | 0.55 | 0.18 | 0.59 | 0.05 | 0.92 |

| Max | 1.98 | 1.90 | 2.53 | 1.32 | 1.62 | 2.69 | |

| Mean | 1.58 | 0.88 | 0.67 | 0.83 | 0.65 | 1.47 | |

| 2 | Min | 0.96 | 0.57 | 0.31 | 0.62 | 0.28 | 0.86 |

| Max | 2.64 | 1.83 | 2.89 | 1.38 | 1.76 | 2.59 | |

| Mean | 1.37 | 0.93 | 0.79 | 0.86 | 0.75 | 1.59 | |

| 3 | Min | 0.85 | 0.60 | 0.29 | 0.59 | 0.23 | 0.87 |

| Max | 2.32 | 2.01 | 2.29 | 1.26 | 1.73 | 2.38 | |

| Mean | 1.50 | 0.96 | 0.95 | 0.89 | 0.90 | 1.39 | |

| Prediction Models | ACC | SN | PPV | F-Score | AUC | Average Performance |

|---|---|---|---|---|---|---|

| SVM | 0.81 | 0.88 | 0.71 | 0.79 | 0.82 | 0.80 |

| KNN | 0.83 | 0.81 | 0.78 | 0.79 | 0.83 | 0.81 |

| LR | 0.79 | 0.85 | 0.71 | 0.77 | 0.80 | 0.78 |

| NB | 0.79 | 0.81 | 0.72 | 0.76 | 0.80 | 0.78 |

| RF | 0.84 | 0.69 | 0.90 | 0.78 | 0.82 | 0.81 |

| DT | 0.78 | 0.69 | 0.75 | 0.72 | 0.77 | 0.74 |

| AdaBoost | 0.90 | 0.92 | 0.86 | 0.89 | 0.91 | 0.90 |

| Prediction Models | ACC | SN | PPV | F-Score | AUC | Average Performance |

|---|---|---|---|---|---|---|

| SVM | 0.83 | 0.80 | 0.81 | 0.81 | 0.82 | 0.83 |

| KNN | 0.78 | 0.73 | 0.75 | 0.74 | 0.76 | 0.78 |

| LR | 0.81 | 0.83 | 0.76 | 0.79 | 0.80 | 0.81 |

| NB | 0.81 | 0.82 | 0.77 | 0.79 | 0.80 | 0.81 |

| RF | 0.82 | 0.77 | 0.81 | 0.79 | 0.80 | 0.82 |

| DT | 0.85 | 0.85 | 0.80 | 0.83 | 0.83 | 0.85 |

| AdaBoost | 0.92 | 0.90 | 0.92 | 0.91 | 0.91 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, Y.; Xiao, W.; Moezi, A.; Tarabini, M.; Saccomandi, P.; Rakheja, S. AI-Enhanced Model for Integrated Performance Prediction and Classification of Vibration-Reducing Gloves for Hand-Transmitted Vibration Control. Actuators 2025, 14, 436. https://doi.org/10.3390/act14090436

Yao Y, Xiao W, Moezi A, Tarabini M, Saccomandi P, Rakheja S. AI-Enhanced Model for Integrated Performance Prediction and Classification of Vibration-Reducing Gloves for Hand-Transmitted Vibration Control. Actuators. 2025; 14(9):436. https://doi.org/10.3390/act14090436

Chicago/Turabian StyleYao, Yumeng, Wei Xiao, Alireza Moezi, Marco Tarabini, Paola Saccomandi, and Subhash Rakheja. 2025. "AI-Enhanced Model for Integrated Performance Prediction and Classification of Vibration-Reducing Gloves for Hand-Transmitted Vibration Control" Actuators 14, no. 9: 436. https://doi.org/10.3390/act14090436

APA StyleYao, Y., Xiao, W., Moezi, A., Tarabini, M., Saccomandi, P., & Rakheja, S. (2025). AI-Enhanced Model for Integrated Performance Prediction and Classification of Vibration-Reducing Gloves for Hand-Transmitted Vibration Control. Actuators, 14(9), 436. https://doi.org/10.3390/act14090436