Design and Implementation of an Autonomous Intelligent Fertigation System for Cross-Regional Applications

Abstract

1. Introduction

2. System Design and Architecture

2.1. Overall Architecture

2.2. Functional Modules

- Fertilizer Delivery Unit—A mechanically adjustable iris mechanism dynamically regulates outlet aperture (0–1894 mm2), ensuring stable fertilizer flow regardless of storage height.

- Fertigation Delivery Unit—A dual-axis motion assembly with fuzzy PID control enables stable irrigation on slopes up to 38°, combining horizontal and rotational movements to achieve flexible canopy-level spraying and root-level fertilization.

- Communication and Data Unit—The ESP8266-based interconnection module provides Wi-Fi communication with <200 ms latency, supporting data synchronization, video streaming, and real-time human–machine interaction through a cloud dashboard.

- Software and Decision-Making Unit—An STM32F1 embedded platform running FreeRTOS executes multi-threaded control (fuzzy PID, water–fertilizer ratio optimization, trajectory control) with ≤50 ms response delay. Decision-making integrates sensor feedback, YOLOv5s-based crop recognition, and environmental data, enabling the adaptive adjustment of water–fertilizer strategies across diverse conditions.

3. Mechanical Structural Design

3.1. Fertilizer Delivery Unit

3.2. Fertigation Delivery Unit

4. Control and Sensing Modules

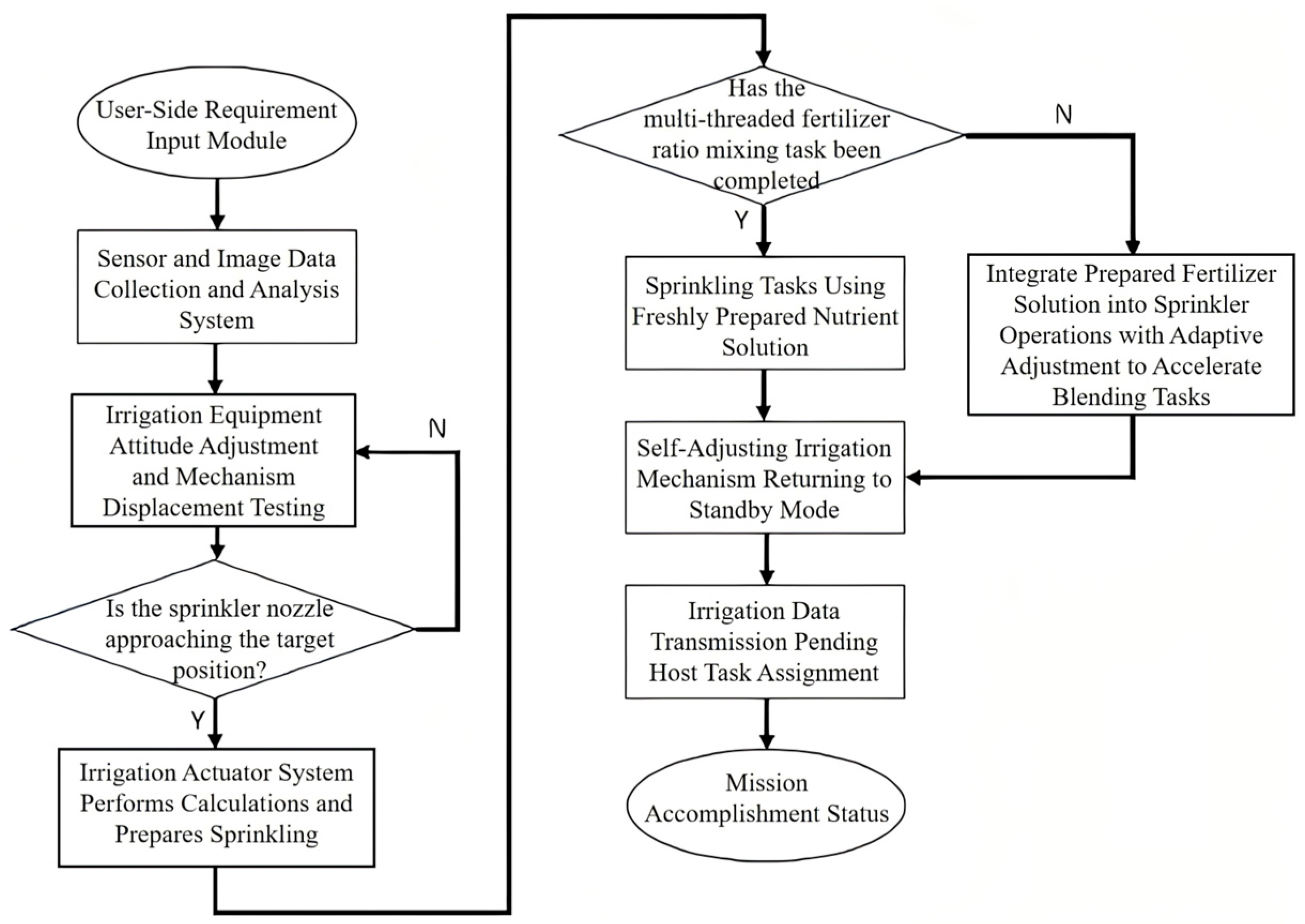

4.1. Software Control Architecture

- Upper-layer Application: User interaction, irrigation logic control, and data visualization;

- Control Algorithm Thread: Runs fuzzy PID and water–fertilizer ratio calculation (priority: 10, scheduling period: 10 ms);

- Sensor Data Acquisition Thread: Collects environmental and equipment status data (priority: 8, scheduling period: 50 ms);

- Wireless Communication Thread: Handles MQTT data transmission/reception (priority: 6, scheduling period: 100 ms);

- Data Storage Thread: Logs operational data to MySQL database (priority: 4, scheduling period: 1 s).

4.2. Communication and IoT Integration

4.3. Fertilizer Weighing and Mixing Unit

4.4. Fertilizer Delivery Motion Control

4.5. Fertigation Motion Control

5. Experimental Setup and Results

5.1. Prototype and Testbed

- A sliding iris switch mechanism for fertilizer delivery (validated in Section 5.2);

- Dynamic water–fertilizer adjustment based on environmental parameters (validated in Section 5.5);

- An integrated STM32F4-based real-time scheduling architecture using RTOS.

5.2. Fertilizer Delivery Tests

5.3. Motion Control Tests

5.4. Terrain Adaptability Tests

- Body Tilt Deviation: Measured using an MPU6050 tilt sensor (±45° range, ±0.1° accuracy, TDK InvenSense, San Jose, CA, USA) mounted at the system’s center of gravity; data were sampled at 10 Hz and averaged over 5 s.

- Vibration Acceleration: Recorded with an ADXL345 accelerometer (±2 g range, ±0.01 g accuracy, Analog Devices, Inc., Norwood, MA, USA) installed on the drive wheel axle. Spectral analysis indicated that terrain-induced oscillations (5–8 Hz) were effectively suppressed, accounting for <5% of total vibration energy.

- Average Power Consumption: Monitored with a YHDC AC current sensor (±0.5% accuracy) over 3 min of continuous operation. Power consumption exhibited a positive correlation with slope, increasing by 8.3% on average for every 5° increment.

- Test results (averaged across repetitions) are summarized in Table 6.

5.5. Irrigation/Fertilization Performance

5.6. Visual Recognition Performanc

5.7. Human–Machine Interface Usability

- Data monitoring visualizes real-time environmental parameters (soil/air temperature, humidity, and light intensity) via integrated dashboards, highlighting microclimatic variations across regions. This real-time feedback mechanism allows operators to fine-tune water–fertilizer strategies (Equations (1)–(5)) based on local conditions and to intervene promptly in response to unexpected events, ensuring that resource allocation aligns with environmental heterogeneity and effectively addressing challenges in adaptive resource allocation under environmental variability.

- Remote control enables irrigation path planning by converting user-drawn trajectories into Bézier curve waypoints, transmitted via UART with a latency of <200 ms. For slopes up to 38°, operators can refine trajectories based on real-time crop position data from the YOLOv5s system, ensuring alignment with target crops. This manual optimization complements the fuzzy PID controller’s automatic torque and speed adjustments: the controller suppresses 5–8 Hz slope-induced vibrations and maintains body tilt deviation within ±1.5°, whereas manual refinement compensates for terrain undulations or uneven crop distribution beyond the algorithm’s adaptive capacity. The integration of both mechanisms ensures responsive fertigation under heterogeneous conditions and improves overall terrain adaptability.

- System configuration manages region-specific parameters such as autonomous navigation thresholds (e.g., slope limits), communication protocols (MQTT/UART), and data logging strategies. Recorded operational data continuously refine water–fertilizer decision models and aperture control curves, minimizing fertigation deviations. Tailored parameter settings can further enhance stability across varied terrains, thereby strengthening the system’s cross-region adaptability.

6. Discussion

6.1. Mechanistic Innovation Addressing Core Limitations

6.1.1. Dynamic Fertilizer Delivery Control: Rethinking Flow Stability

6.1.2. Terrain-Adaptive Actuation: Overcoming Slope-Induced Instability

6.1.3. Data-Driven Water–Fertilizer Synergy: Enabling Environment-Responsive Allocation

6.1.4. Cross-Regional Autonomy: Balancing Edge Control and Cloud Coordination

6.2. Comparative Advantages

6.3. Limitations and Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Charania, I.; Li, X. Smart farming: Agriculture’s shift from a labor intensive to technology native industry. Internet Things 2020, 9, 100142. [Google Scholar] [CrossRef]

- Pawlak, K.; Kołodziejczak, M. The Role of Agriculture in Ensuring Food Security in Developing Countries: Considerations in the Context of the Problem of Sustainable Food Production. Sustainability 2020, 12, 5488. [Google Scholar] [CrossRef]

- Wei, X. Intelligent agricultural mechanization: A new era engine for agricultural development. Appl. Comput. Eng. 2024, 102, 55–60. [Google Scholar] [CrossRef]

- Shi, L.; Shi, G.; Qiu, H. General review of intelligent agriculture development in China. Chin. Agric. Econ. Rev. 2019, 11, 39–51. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Murase, H.; Morimoto, T.; Torii, T. Intelligent systems for agriculture in Japan. IEEE Control Syst. Mag. 2001, 21, 71–85. [Google Scholar]

- Adli, H.K.; Remli, M.A.; Wan Salihin Wong, K.N.S.; Ismail, N.A.; González-Briones, A.; Corchado, J.M.; Mohamad, M.S. Recent Advancements and Challenges of AIoT Application in Smart Agriculture: A Review. Sensors 2023, 23, 3752. [Google Scholar] [CrossRef]

- Chen, J.; Yang, A. Intelligent agriculture and its key technologies based on internet of things architecture. IEEE Access 2019, 7, 77134–77141. [Google Scholar] [CrossRef]

- Assimakopoulos, F.; Vassilakis, C.; Margaris, D.; Kotis, K.; Spiliotopoulos, D. The Implementation of “Smart” Technologies in the Agricultural Sector: A Review. Information 2024, 15, 466. [Google Scholar] [CrossRef]

- Chuang, J.-H.; Wang, J.-H.; Liou, Y.-C. Farmers’ Knowledge, Attitude, and Adoption of Smart Agriculture Technology in Taiwan. Int. J. Environ. Res. Public Health 2020, 17, 7236. [Google Scholar] [CrossRef]

- Yokamo, S. Adoption of improved agricultural technologies in developing countries: Literature review. Int. J. Sci. Food Agric. 2020, 4, 183–190. [Google Scholar] [CrossRef]

- Goel, R.K.; Yadav, C.S.; Vishnoi, S.; Rastogi, R. Smart agriculture–Urgent need of the day in developing countries. Sustain. Comput. Inform. Syst. 2021, 30, 100512. [Google Scholar] [CrossRef]

- Li, J.; Liu, G.; Chen, Y.; Li, R. Study on the influence mechanism of adoption of smart agriculture technology behavior. Sci. Rep. 2023, 13, 8554. [Google Scholar] [CrossRef]

- Zhao, C. State-of-the-art and recommended developmental strategic objectives of smart agriculture. Smart Agric. 2019, 1, 1–7. [Google Scholar]

- Zhao, C.; Li, J.; Feng, X. Development strategy of smart agriculture for 2035 in China. Strateg. Study Chin. Acad. Eng. 2021, 23, 1–9. [Google Scholar] [CrossRef]

- Sun, A.Y.; Scanlon, B.R. How can Big Data and machine learning benefit environment and water management: A survey of methods, applications, and future directions. Environ. Res. Lett. 2019, 14, 073001. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Chen, C.L.P.; Liu, Z.; Chen, K. Observer-based Practical Prescribed-Time Consensus Tracking Control for Multiagent Systems with Unknown Virtual Control Coefficients. IEEE/CAA J. Autom. Sin. 2025, in press. [Google Scholar]

- Li, D.; Nanseki, T. Practice, promotion and perspective of smart agriculture in China. In Agricultural Innovation in Asia: Efficiency, Welfare, and Technology; Nanseki, T., Ed.; Springer: Singapore, 2023; pp. 183–203. [Google Scholar]

- Mondal, P.; Basu, M. Adoption of precision agriculture technologies in India and in some developing countries: Scope, present status and strategies. Prog. Nat. Sci. 2009, 19, 659–666. [Google Scholar] [CrossRef]

- van Rooyen, A.F.; Ramshaw, P.; Moyo, M.; Stirzaker, R.; Bjornlund, H. Theory and application of Agricultural Innovation Platforms for improved irrigation scheme management in Southern Africa. Int. J. Water Resour. Dev. 2017, 33, 804–823. [Google Scholar] [CrossRef]

- Musa, S.F.P.D.; Basir, K.H. Smart farming: Towards a sustainable agri-food system. Br. Food J. 2021, 123, 3085–3099. [Google Scholar] [CrossRef]

- Reddy, R. Innovations in Agricultural Machinery: Assessing the Impact of Advanced Technologies on Farm Efficiency. J. Artif. Intell. Big Data 2022, 2, 1156. [Google Scholar] [CrossRef]

- El Mouedden, M.; Mabrouki, J.; Azdem, D.; El Hajjaji, S. The development of intelligent agriculture, the contribution of the Internet of Things (IoT) to modernization and its implications for precision farming: A review. Euro-Mediterr. J. Environ. Integr. 2025. [Google Scholar] [CrossRef]

- Obaideen, K.; Yousef, B.A.A.; AlMallahi, M.N.; Tan, Y.C.; Mahmoud, M.; Jaber, H.; Ramadan, M. An overview of smart irrigation systems using IoT. Energy Nexus 2022, 7, 100124. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X. Precise application of water and fertilizer to crops: Challenges and opportunities. Front. Plant Sci. 2024, 15, 1444560. [Google Scholar] [CrossRef] [PubMed]

- Srivastav, A.L.; Dhyani, R.; Ranjan, M.; Madhav, S.; Sillanpää, M. Climate-resilient strategies for sustainable management of water resources and agriculture. Environ. Sci. Pollut. Res. 2021, 28, 41576–41595. [Google Scholar] [CrossRef]

- Chouhan, S.; Kumari, S.; Kumar, R.; Chaudhary, P.L. Climate resilient water management for sustainable agriculture. Int. J. Environ. Clim. Chang. 2023, 13, 411–426. [Google Scholar] [CrossRef]

- Abioye, E.A.; Abidin, M.S.Z.; Mahmud, M.S.A.; Buyamin, S.; Ishak, M.H.I.; Rahman, M.K.I.A.; Otuoze, A.O.; Onotu, P.; Ramli, M.S.A. A review on monitoring and advanced control strategies for precision irrigation. Comput. Electron. Agric. 2020, 173, 105441. [Google Scholar] [CrossRef]

- García, L.; Parra, L.; Jimenez, J.M.; Lloret, J.; Lorenz, P. IoT-Based Smart Irrigation Systems: An Overview on the Recent Trends on Sensors and IoT Systems for Irrigation in Precision Agriculture. Sensors 2020, 20, 1042. [Google Scholar] [CrossRef]

- Gong, L.; Yan, J.; Chen, Y.; An, J.; He, L.; Zheng, L.; Zou, Z. An IoT-based intelligent irrigation system with data fusion and a self-powered wide-area network. J. Ind. Inf. Integr. 2022, 29, 100367. [Google Scholar] [CrossRef]

- Keswani, B.; Mohapatra, A.G.; Mohanty, A.; Khanna, A.; Rodrigues, J.J.P.C.; Gupta, D.; de Albuquerque, V.H.C. Adapting weather conditions-based IoT enabled smart irrigation technique in precision agriculture mechanisms. Neural Comput. Appl. 2019, 31, 277–292. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Tang, Y.R.; Zhang, H.; Lan, H.P.; Niu, H. Parameter Optimization of Spiral Fertilizer Applicator Based on Artificial Neural Network. Sustainability 2023, 15, 1744. [Google Scholar] [CrossRef]

- Mondal, D.; Nabendu, G. Study on filling factor of short length screw conveyor with flood-feeding condition. Mater. Today Proc. 2018, 5, 1286–1291. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Y.; Wei, S.; Liao, M.; Zang, Y.; Zeng, S. Design and experimental study of the fertilizer applicator with vertical spiral fluted rollers. Int. J. Agric. Biol. Eng. 2023, 16, 80–87. [Google Scholar] [CrossRef]

- Siddegowda, C.J.; Devi, A.J. A study on the role of precision agriculture in agro-industry. Int. J. Appl. Eng. Manag. Lett. 2021, 5, 57–67. [Google Scholar] [CrossRef]

- Hassan, A.; Asif, R.M.; Rehman, A.U.; Nishtar, Z.; Kaabar, M.K.; Afsar, K. Design and Development of an Irrigation Mobile Robot. IAES Int. J. Robot. Autom. 2021, 10, 75. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Y.; Liu, B.; Yan, B.; Li, X.; Lu, K.; Ren, T.; Ma, B.; Tian, Y. Design and Implementation of A Novel Internet of Things Irrigation System With A Precision Irrigation Robot. In Proceedings of the 2021 IEEE International Conference on Real-time Computing and Robotics (RCAR), Xining, China, 15–19 July 2021. [Google Scholar]

- Shafiei, B. A Review on PID Control System Simulation of the Active Suspension System of a Quarter Car Model While Hitting Road Bumps. J. Inst. Eng. India Ser. C 2022, 103, 1001–1011. [Google Scholar] [CrossRef]

- Parimala, M.; Rani, M.J.; Sai, K.B.; Sunitha, M. IoT based Intelligent Fertigation through Drip Irrigation. In Proceedings of the 2021 Third International Conference on Intelligent Communication Technologies and Virtual Mobile Networks (ICICV), Tirunelveli, India, 4–6 February 2021; pp. 410–414. [Google Scholar]

- Ali, M.I.; Khan, M.R. Design and Development of Microcontroller Based Agroponic Agriculture System. Malays. J. Sci. Adv. Technol. 2021, 1, 45–53. [Google Scholar]

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated irrigation system using a wireless sensor network and GPRS module. IEEE Trans. Instrum. Meas. 2013, 63, 166–176. [Google Scholar] [CrossRef]

- Bilotta, G.; Genovese, E.; Citroni, R.; Cotroneo, F.; Meduri, G.M.; Barrile, V. Integration of an Innovative Atmospheric Forecasting Simulator and Remote Sensing Data into a Geographical Information System in the Frame of Agriculture 4.0 Concept. AgriEngineering 2023, 5, 1280–1301. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, T.; Tantashutikun, N.; Hussain, N.; Cocetta, G. Application of Smart Techniques, Internet of Things and Data Mining for Resource Use Efficient and Sustainable Crop Production. Agriculture 2023, 13, 397. [Google Scholar] [CrossRef]

- Xiao, Z.; Liu, D.; Cao, D.; Wang, X. Design of home appliance control system in smart home based on WiFi IoT. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 765–770. [Google Scholar]

- Hala, M.; Menon, R. Examining the impact of an asynchronous communication platform versus existing communication methods: An observational study. BMJ Innov. 2021, 7, 68–74. [Google Scholar]

- Wu, J.; Tan, R.; Wang, M. Streaming high-definition real-time video to mobile devices with partially reliable transfer. IEEE Trans. Mob. Comput. 2018, 18, 458–472. [Google Scholar] [CrossRef]

- Long, S.; Huang, W.; Wang, J.; Liu, J.; Gu, Y.; Wang, Z. A Fixed-Time Consensus Control with Prescribed Performance for Multi-Agent Systems Under Full-State Constraints. IEEE Trans. Autom. Sci. Eng. 2024, 22, 6398–6407. [Google Scholar] [CrossRef]

- Kabilan, N.; Selvi, M.S. Surveillance and steering of irrigation system in cloud using Wireless Sensor Network and Wi-Fi module. In Proceedings of the 2016 International Conference on Recent Trends in Information Technology (ICRTIT), Chennai, India, 22–23 April 2016; pp. 1–5. [Google Scholar]

- Xu, W.; Feng, X.; Xing, H. Modeling and analysis of adaptive temperature compensation for humidity sensors. Electronics 2019, 8, 425. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Wang, X.; Wei, Z.; Cheng, X.; Zhang, Y.; Jiao, X. Design and experiment of a multi-channel real-time weighing device. INMATEH-Agric. Eng. 2024, 73, 2. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Crop Evapotranspiration: Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper No 56; FAO: Rome, Italy, 1998. [Google Scholar]

- Arief, D.; Shiddiq, M.; Prayitno, A.; Badri, M.; Nugraha, A.; Muflihana, A. Calibration of 40 Kg capacity digital scale on automatic machine measurement mass and dimension based on Arduino Uno using CSIRO-NML: 1995 method. Proc. Ocean. Mech. Aerosp. Sci. Eng. 2018, 5, 97–102. [Google Scholar]

- Savran, A. A multivariable predictive fuzzy PID control system. Appl. Soft Comput. 2013, 13, 2658–2667. [Google Scholar] [CrossRef]

- Alaan, M.; Manuel, E.; Reyes, J.; Mercado, C.R.; Concepcion, R. Design of an optimized second-order soil-based drip fertigation control system with Internet-of-Things integration. In Proceedings of the 2023 8th International Conference on Business and Industrial Research (ICBIR), Jakarta, Indonesia, 22–24 May 2023; pp. 477–482. [Google Scholar]

- Wang, J.; Wu, Y.; Chen, C.L.P.; Liu, Z.; Wu, W. Adaptive PI Event-Triggered Control for MIMO Nonlinear Systems with Input Delay. Inf. Sci. 2024, 677, 120817. [Google Scholar] [CrossRef]

- Goodchild, M.S.; Kühn, K.D.; Jenkins, M.D.; Burek, K.J.; Button, A.J. A method for precision closed-loop irrigation using a modified PID control algorithm. Sens. Transducers 2015, 188, 61. [Google Scholar]

- Jaiswal, S.; Ballal, M.S. Fuzzy inference based irrigation controller for agricultural demand side management. Comput. Electron. Agric. 2020, 175, 105537. [Google Scholar] [CrossRef]

- Schwarz, D.; Thompson, A.J.; Kläring, H.-P. Guidelines to use tomato in experiments with a controlled environment. Front. Plant Sci. 2014, 5, 625. [Google Scholar] [CrossRef]

| Design Category | Design Parameters |

|---|---|

| Fixed housing diameter | 150 mm |

| Number of the iris | 6 |

| Number of teeth on the bottom gear | 100 |

| Number of teeth on the drive gear | 20 |

| Module of the bottom gear and the drive gear | 1.5 |

| Shape of fertilizer outlet opening | regular hexagonal aperture |

| Area range of fertilizer output opening | 0–1894 mm2 |

| Design Category | Design Parameters |

|---|---|

| Travel Range of the Horizontal Assembly | 0~0.2 m |

| Swept Area of the Rotational Assembly | 0.09Π m2 |

| Length of screw | 0.25 m |

| Linear Velocity of the Horizontal Assembly | 0.15 m/s |

| Angular Velocity of the Lead Screw Assembly | 0.5 rad/s |

| Relative Linear Velocity Between Spray Nozzle and Lead Screw | 0.2 m/s |

| Design Category | Unit | Design Parameters |

|---|---|---|

| Material | / | Acrylic, reinforced resin, aluminum profiles, etc. |

| Overall dimensions (L × W × H) | mm | 820 × 780 × 780 |

| Effective working area per unit | m2/h | 525–735 |

| Maximum load capacity | kg | 60 |

| Total machine weight | kg | 62.6 |

| Working speed range | km/h | 3.6–7.9 |

| Power source | / | 24 V/100 Ah lithium battery |

| Endurance time | h | 8 |

| Test No. | Time(s) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | Actual Traffic (g/s) | 204.1 | 202.3 | 196.5 | 197.2 | 195.2 | 199.3 | 198.4 | 201.3 | 197.5 |

| Deviation * | +2.05% | +1.15% | −1.75% | −1.40% | −2.40% | −0.35% | −0.80% | +0.65% | +1.25% | |

| No. 2 | Actual Traffic (g/s) | 204.8 | 198.2 | 197.3 | 202.8 | 201.3 | 196.4 | 197.8 | 198.3 | 198.2 |

| Deviation * | +2.4% | −0.90% | −1.35% | +1.40% | +0.65% | −1.80% | −1.10% | −0.85% | −0.90% | |

| No. 3 | Actual Traffic (g/s) | 202.5 | 198.6 | 201.3 | 195.1 | 196.3 | 198.2 | 203.6 | 197.5 | 198.9 |

| Deviation * | +1.25% | −0.70% | +0.65% | −2.45% | +1.85% | −0.90% | +1.80% | −1.25% | −0.55% |

| PUL | Ed2 | |||||

|---|---|---|---|---|---|---|

| NB | NS | ZO | PS | PB | ||

| Ed1 | NB | PB | PS | PS | ZO | ZO |

| NS | PB | PS | ZO | NS | NS | |

| ZO | PB | PS | ZO | NS | NB | |

| PS | PS | PS | ZO | NS | NB | |

| PB | PS | ZO | NS | NB | NB | |

| Test No. | Travel Gradient | Grade Climbing Speed (m/s) | Body Tilt Deviation (°) | Vibration Acceleration (g) | Average Power Consumption (W) |

|---|---|---|---|---|---|

| 1 | 20° | 0.68 | ±1.2 | 0.35 | 80 |

| 2 | 24° | 0.65 | ±1.3 | 0.38 | 85 |

| 3 | 32° | 0.63 | ±1.4 | 0.42 | 100 |

| 4 | 35° | 0.61 | ±1.5 | 0.45 | 110 |

| 5 | 36° | 0.60 | ±1.5 | 0.48 | 115 |

| 6 | 37° | 0.53 | ±1.5 | 0.50 | 118 |

| 7 | 38° | 0.46 | ±1.6 | 0.51 | 120 |

| Test No. | (°C) | ||||||

|---|---|---|---|---|---|---|---|

| No. 1 | 28.2 | 60% | 5.5 | 62% | 65% | 0.6 | 60–80% |

| No. 2 | 26.7 | 71% | 3.2 | 74% | 65% | 0.6 | 60–80% |

| No. 3 | 31.2 | 46% | 6.1 | 50% | 55% | 0.6 | 60–80% |

| Test No. | (L) | (L) | Irrigation Deviation | (g/L) | (g) | (g) | Fertilizer Application Deviation |

|---|---|---|---|---|---|---|---|

| No. 1 | 8.35 | 8.50 | 1.80% | 1.6 | 13.36 | 13.52 | 1.20% |

| No. 2 | 4.12 | 4.30 | 4.37% | 1.8 | 7.416 | 7.51 | 1.27% |

| No. 3 | 14.13 | 14.50 | 2.62% | 1.2 | 16.956 | 17.16 | 1.20% |

| Feature | This Study | Hassan et al. [34] | Chen et al. [35] | Parimala et al. [37] |

|---|---|---|---|---|

| Terrain Adaptability | Operates stably on slopes up to 38° (fuzzy PID control) | Unstable on slopes (no terrain-specific adjustments; vibrations/positioning errors) | Chassis stability only (no actuator-level optimization) | Not applicable (static system) |

| Fertilizer Flow Control | <3% error (closed-loop iris adjustment) | Not addressed (focus on irrigation mobility without fertilizer delivery optimization) | Not addressed | Not addressed |

| Decision-Making Loop | Dynamic, feedback-driven (integrates multi-source data) | No dynamic decision model | No dynamic model | Rigid, farmer-defined ratios |

| Cross-Regional Scalability | IoT + cloud integration with low operational error (2.1%) | Limited (slope instability) | Limited (actuator-level gaps) | Limited (requires manual ratio adjustment) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, R.; Hu, H.; Lin, H.; Li, J.; Wang, Z.; Zhu, G.; Mei, Z.; Dai, J. Design and Implementation of an Autonomous Intelligent Fertigation System for Cross-Regional Applications. Actuators 2025, 14, 413. https://doi.org/10.3390/act14090413

Tang R, Hu H, Lin H, Li J, Wang Z, Zhu G, Mei Z, Dai J. Design and Implementation of an Autonomous Intelligent Fertigation System for Cross-Regional Applications. Actuators. 2025; 14(9):413. https://doi.org/10.3390/act14090413

Chicago/Turabian StyleTang, Ruizhi, Hanhong Hu, Hai Lin, Jiahao Li, Zian Wang, Guanquan Zhu, Ziyou Mei, and Jietao Dai. 2025. "Design and Implementation of an Autonomous Intelligent Fertigation System for Cross-Regional Applications" Actuators 14, no. 9: 413. https://doi.org/10.3390/act14090413

APA StyleTang, R., Hu, H., Lin, H., Li, J., Wang, Z., Zhu, G., Mei, Z., & Dai, J. (2025). Design and Implementation of an Autonomous Intelligent Fertigation System for Cross-Regional Applications. Actuators, 14(9), 413. https://doi.org/10.3390/act14090413