Abstract

Conventional fertigation systems suffer from limited cross-regional adaptability, mainly due to unstable fertilizer flow from fixed-aperture units, poor terrain adaptability, and an inadequate response to environmental heterogeneity. This study proposes an autonomous, cross-regional intelligent fertigation system based on an STM32F1 microcontroller and UART communication protocols. The system integrates a mechanically adjustable iris fertilizer delivery unit, a dual-axis fertigation module, a data interconnection unit, and comprehensive control software with dynamic calibration capabilities. Prototype evaluations conducted on both sloped terrain (up to 38°) and flat surfaces demonstrate a stable performance, achieving fertilizer flow control errors below 3%, irrigation deviation under 5%, and fertilization deviation within 2%. Real-time data acquisition, remote monitoring, and intelligent operation are supported by a YOLOv5s-based visual recognition system, which attains an mAP@0.5 of 92.5%. This integrated solution offers a robust approach to precision agriculture across diverse environmental conditions.

1. Introduction

Agriculture, long the foundation of human civilization, is now undergoing a rapid transition from traditional practices to data-driven, intelligent systems [1]. Population growth, accelerating climate change, and the increasing pressure on finite natural resources have exposed the inability of conventional production models to secure food and environmental sustainability [2]. In this context, intelligent agricultural machinery has become a central driver of modernization, enabling higher efficiency, precision input use, and resilient production systems [3,4,5,6,7].

In recent years, governments and industries worldwide have positioned smart farming as a strategic priority [8,9,10,11,12]. In the US, precision farming research focuses on automated irrigation and sensor-based crop monitoring [13]. In China, Internet of Things (IoT) platforms using big data and machine learning optimize resource use and reduce environmental impact [14,15,16,17]. Meanwhile, developing nations are deploying tailored smart farming solutions to address food security and sustainability [18,19,20].

Against this backdrop, the development and implementation of intelligent agricultural machinery has become critical to advancing smart agriculture [21]. The deep integration of Internet of Things (IoT) technologies, cloud computing, and artificial intelligence (AI) enables agricultural producers to monitor crop growth conditions in real time, manage water and fertilizer inputs precisely, and operate and automate agricultural equipment remotely [22,23,24]. These capabilities significantly enhance production efficiency and provide robust technological support for addressing climate change and optimizing resource utilization [25,26].

Within this landscape, intelligent irrigation has emerged as a pivotal component of smart farming [27,28]. Existing systems can be broadly classified into three categories: (1) IoT-based sensing platforms that prioritize environmental data acquisition; (2) control algorithm-driven systems that optimize irrigation scheduling and fertilizer dosing through adaptive decision-making; (3) mechanically enhanced delivery units that stabilize the physical application of water and nutrients. Illustrative examples include low-power IoT data fusion networks [29], weather- and crop-specific scheduling frameworks for large-scale agriculture [30], and spiral or aperture-based fertilizer applicators [31,32,33]. Commercial platforms such as CropX [34] further highlight the integration of soil sensing into data-driven irrigation management.

Despite these advances, most current systems still struggle with cross-regional adaptability—the capacity to operate reliably across varied terrains, climatic conditions, and crop types without hardware modifications. Three persistent challenges prove particularly limiting: sustaining consistent fertilizer delivery, upholding a reliable performance across heterogeneous topographies, and dynamically allocating resources in response to environmental fluctuations.

First, regarding consistent fertilizer delivery: Fertilizer conveyance systems such as spiral conveyors (e.g., Zhang, M.Q. et al. [31]; Mondal, D. et al. [32]) and fluted rollers (Wang, Y. et al. [33]) have been widely adopted to improve dosing precision. These designs often incorporate feedback correction through weighing or optical sensors to mitigate pulsation and reduce variability. However, because the outlet geometry itself remains fixed, their performance is still strongly affected by the declining fertilizer height. As a result, most systems struggle to maintain a stable mass flow, leading to the persistent limitation of unstable fertilizer output from fixed-aperture dosing units.

Second, concerning reliable operation across heterogeneous terrains: Existing mobile irrigation systems have advanced but retain critical limitations. For instance, the irrigation mobile robot developed by Hassan et al. [35], despite its mobile operational capability, lacks dedicated mechanical structures or adaptive control strategies to accommodate terrain variations. Similarly, the precision irrigation robot developed by Chen’s team [36] incorporates a vibration-damping chassis to improve mobility but focuses exclusively on chassis stability, neglecting optimization at the actuator level. Such design gaps lead to vibrations and positioning errors when operating on sloped farmland. From a control perspective, Shafiei [37] applied a conventional PID framework to a quarter-car model to enhance stability under bump disturbances; however, its fixed gain parameters cannot compensate for gravitational torque on inclines, resulting in 5–8 Hz resonant oscillations. As a result, current systems remain vulnerable to slope-induced disturbances and resonance, highlighting poor terrain adaptability as a key limitation.

Third, in terms of adaptive resource allocation under environmental variability: Recent IoT-enabled fertigation systems remain constrained by rigid, rule-based control architectures. For example, the platform developed by Parimala, M. et al. [38], though capable of real-time sensing, relies entirely on farmer-defined fertilizer ratios without feedback-driven adjustments, making it unable to respond to sudden nutrient shifts during events like heatwaves. Similarly, Ali, M.I. et al.’s system [39] uses LoRa-based sensing but relies on fixed thresholds, activating irrigation only when soil moisture drops below 80% and temperature exceeds 30 °C. This fixed-scheme approach cannot dynamically respond to real-time environmental changes, leading to a misaligned water–fertilizer supply relative to actual crop demand. While such approaches function under stable conditions, they fail to capture temporal variability, highlighting a critical limitation: the lack of real-time, environment-adaptive feedback in existing autonomous fertigation systems.

Against this backdrop, we present an autonomous cross-regional fertigation system designed to overcome these limitations. Built on an STM32F1 microcontroller (STMicroelectronics, Geneva, Switzerland) platform with integrated sensing and UART-based wireless communication via an ESP8266 Wi-Fi module, the system integrates real-time environmental monitoring with intelligent decision-making—enhanced by a YOLOv5s-based visual recognition module (mAP@0.5 92.5%) for crop type and growth stage assessment—to dynamically adjust water–fertilizer ratios according to crop growth and site-specific conditions. A dual-axis motion unit with fuzzy PID control ensures stable operation on slopes up to 38°, while an iris-based fertilizer delivery unit maintains a consistent flow regardless of storage height. An MVC-based human–machine interface provides intuitive remote monitoring and control. The system can independently regulate flow stability, adapt to diverse terrains, and respond to environmental heterogeneity, collectively forming a versatile framework for advancing global smart agriculture.

2. System Design and Architecture

2.1. Overall Architecture

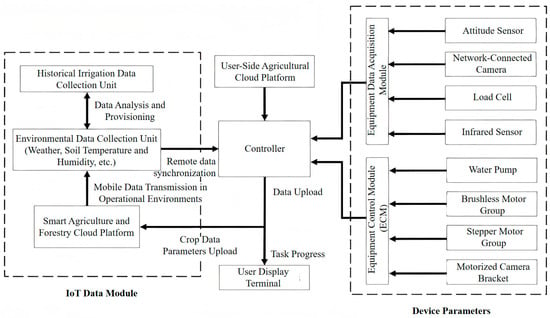

The proposed autonomous fertigation system adopts a modular architecture structured around the STM32F103VET6 microcontroller (72 MHz, STMicroelectronics, Geneva, Switzerland) [40], which serves as the central controller, integrating sensing, actuation, and decision-making functions. As illustrated in Figure 1, the architecture follows a layered design, comprising an equipment layer, an IoT data layer, and a cloud–user interface layer.

Figure 1.

Overall structure of the intelligent fertigation system.

In the equipment layer, sensors (ultrasonic, soil moisture, tilt, load cell, and camera) and actuators (fertilizer delivery unit, irrigation arm, pumps, and motors) are connected to the STM32 through dedicated acquisition and control modules. The IoT data layer utilizes the ESP8266 Wi-Fi module to enable asynchronous UART communication, facilitating the high-bandwidth exchange of data—such as weather conditions, soil humidity, and historical irrigation records—and supporting remote monitoring [41,42]. Finally, the cloud–user interface layer enables real-time visualization, parameter adjustment, and trajectory planning, thereby providing operators with full remote control capabilities across diverse environments.

This layered design ensures local, real-time responsiveness while maintaining seamless integration with cloud-based decision models, achieving both precision control at the edge and scalable cross-regional management.

2.2. Functional Modules

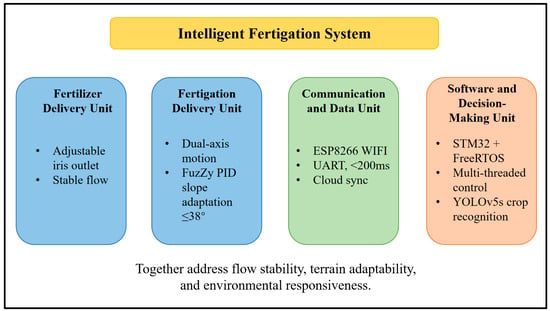

The system is composed of four major functional modules, as shown in Figure 2, each addressing a key limitation of conventional fertigation systems:

Figure 2.

Functional modules of the autonomous fertigation system.

- Fertilizer Delivery Unit—A mechanically adjustable iris mechanism dynamically regulates outlet aperture (0–1894 mm2), ensuring stable fertilizer flow regardless of storage height.

- Fertigation Delivery Unit—A dual-axis motion assembly with fuzzy PID control enables stable irrigation on slopes up to 38°, combining horizontal and rotational movements to achieve flexible canopy-level spraying and root-level fertilization.

- Communication and Data Unit—The ESP8266-based interconnection module provides Wi-Fi communication with <200 ms latency, supporting data synchronization, video streaming, and real-time human–machine interaction through a cloud dashboard.

- Software and Decision-Making Unit—An STM32F1 embedded platform running FreeRTOS executes multi-threaded control (fuzzy PID, water–fertilizer ratio optimization, trajectory control) with ≤50 ms response delay. Decision-making integrates sensor feedback, YOLOv5s-based crop recognition, and environmental data, enabling the adaptive adjustment of water–fertilizer strategies across diverse conditions.

Collectively, these modules establish a closed-loop fertigation process in which vision and multi-sensor data, fused with the remotely configurable Agricultural Operation Dataset, drive the water–fertilizer ratio model to compute precise irrigation demands. The iris-based fertilizer delivery unit dynamically adjusts its opening according to real-time material height, ensuring that fertilizer flows steadily into a weighing chamber equipped with an HX711 ADC. This stable inflow allows the HX711 to perform stable and relatively accurate weighing of fertilizer. Finally, the fuzzy PID-controlled delivery system compensates for slope-induced disturbances, enabling the stable application of water–fertilizer solutions to crops even on inclines up to 38°.

By combining these modules, the system achieves dynamic flow stability, terrain adaptability, and environmental responsiveness, thus addressing the three core challenges identified in Section 1 and laying the foundation for cross-regional precision agriculture.

3. Mechanical Structural Design

3.1. Fertilizer Delivery Unit

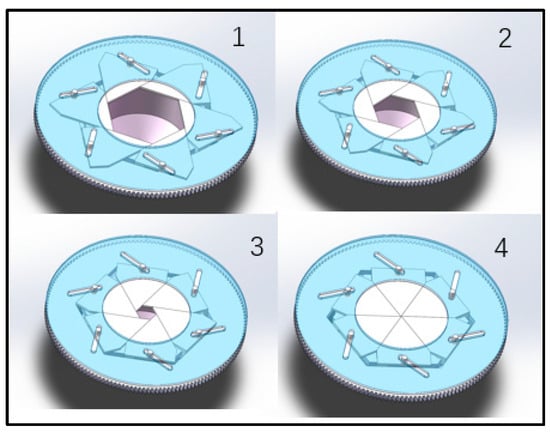

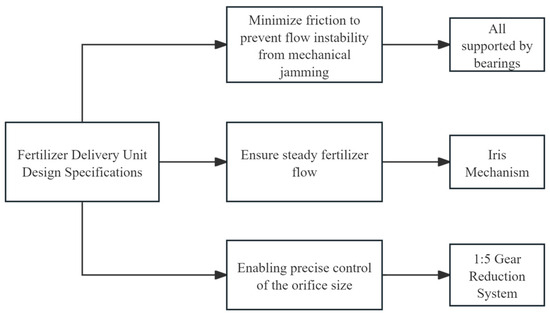

As shown in Figure 3, the fertilizer delivery unit consists of a fixed housing, an iris mechanism, a drive gear, and a delivery channel. High-precision bearings support these components, minimizing mechanical friction during operation. The key design parameters are listed in Table 1, with the principal design choices justified as follows. A 1:5 gear ratio (drive gear to bottom gear) was selected to optimize torque transmission and control precision. The regular hexagonal outlet minimizes fluid turbulence compared with circular or square apertures. Its symmetric geometry reduces edge-induced eddy currents, thereby stabilizing fertilizer flow.

Figure 3.

Operation flow of the fertilizer delivery unit.

Table 1.

Design parameters of the fertilizer delivery unit.

Figure 3 illustrates the fertilizer delivery unit’s aperture adjustment: (1) Maximum aperture: iris fully expanded, hexagonal outlet at 1894 mm2 for maximum flow. (2) Reduction: motor-driven gears rotate iris blades along grooves, increasing overlap to reduce outlet area proportionally. (3) Further closure: iris continues contracting, outlet area sharply reduced, flow adjusted to real-time demand via sensor data (ultrasonic-monitored fertilizer height). (4) Full closure: blades fully overlap, sealing outlet to stop supply.

During fertilizer discharge, the motor drives the outer gear, which meshes with the base gear of the fixed module at a 1:5 ratio. This interaction between the bottom and peripheral gears rotates the iris mechanism while simultaneously repositioning the drive gear. Sliding grooves, as shown in Figure 1, guide the iris module along a predefined path, allowing the continuous adjustment of the hexagonal aperture area (0–1894 mm2) and the precise modulation of the channel opening. This design enhances the accuracy of fertilizer flow into the weighing unit and compensates for variations in fertilizer height via ultrasonic sensing, ensuring a stable supply for precise weighing. Figure 4 further illustrates how the structural composition of the fertilizer delivery unit is engineered to stabilize flow, thereby providing a reliable basis for subsequent fertilizer weighing.

Figure 4.

Flowchart illustrating the main components of the fertilizer delivery unit.

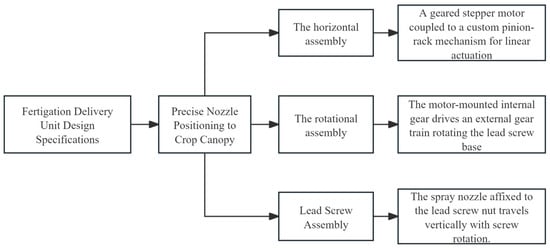

3.2. Fertigation Delivery Unit

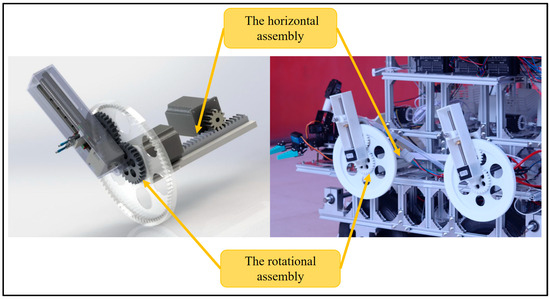

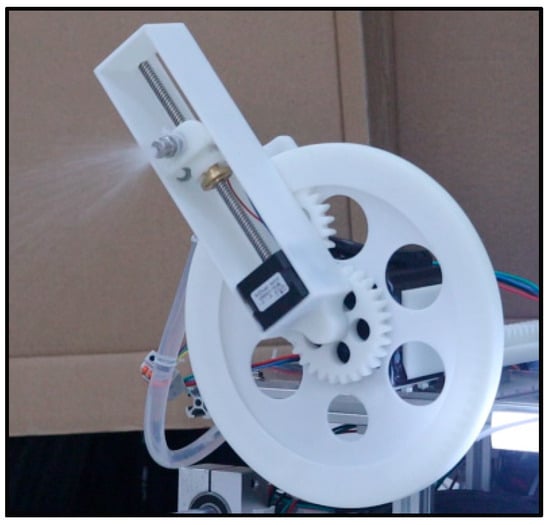

As shown in Figure 5, the fertigation delivery unit consists of horizontal translation and rotational assemblies. The horizontal assembly employs a reduction stepper motor coupled with a custom gear-and-rack mechanism to enable linear movement. The rotational assembly includes an internal gear mounted on the motor shaft. An external gear and gear ring facilitate the rotation of the lead screw base. The spray nozzle is mounted on the lead screw nut, allowing vertical movement as the lead screw rotates. The detailed design parameters are listed in Table 2, and the corresponding design flow chart is shown in Figure 6.

Figure 5.

Model and physical drawing of the fertigation delivery unit.

Table 2.

Design parameters of the fertigation delivery unit.

Figure 6.

Flowchart illustrating the main components of the fertigation delivery unit.

4. Control and Sensing Modules

4.1. Software Control Architecture

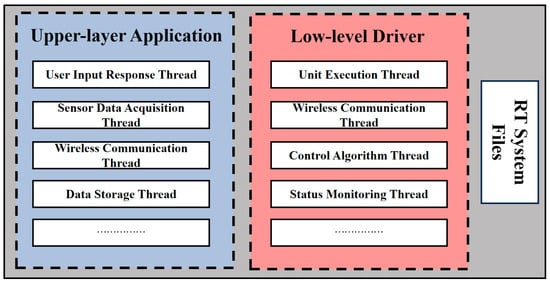

The software for the intelligent fertigation system includes the design of system application programs, operating system (FreeRTOS) design, driver design, and file management system design, as illustrated in Figure 7. The key modules and threads are as follows:

Figure 7.

Software architecture of the intelligent fertigation system.

- Upper-layer Application: User interaction, irrigation logic control, and data visualization;

- Control Algorithm Thread: Runs fuzzy PID and water–fertilizer ratio calculation (priority: 10, scheduling period: 10 ms);

- Sensor Data Acquisition Thread: Collects environmental and equipment status data (priority: 8, scheduling period: 50 ms);

- Wireless Communication Thread: Handles MQTT data transmission/reception (priority: 6, scheduling period: 100 ms);

- Data Storage Thread: Logs operational data to MySQL database (priority: 4, scheduling period: 1 s).

To ensure effective operation, a logical control approach utilizing system instructions regulates the system’s status and operation. The key performance indicators were as follows: average response delay ≤ 50 ms, memory usage ≤ 64 KB, and standby power consumption ≤ 100 mW.

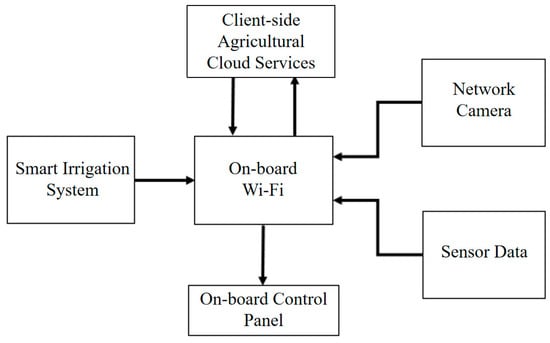

4.2. Communication and IoT Integration

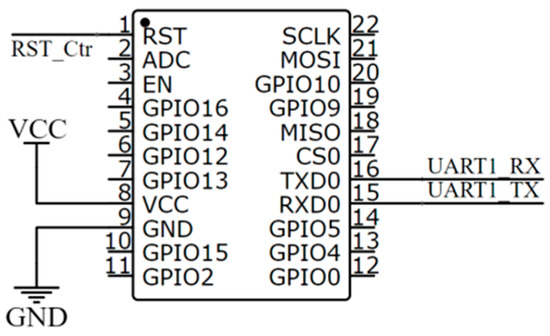

The ESP8266 module interfaces with the STM32F103VET6 microcontroller via asynchronous UART communication, enabling high-speed, clockless data transmission [43,44]. As an ESP8266-based interconnection module, it provides Wi-Fi connectivity with <200 ms latency and interfaces with a network camera. Through Wi-Fi, it supports high-bandwidth data exchange, HD video streaming, and real-time human–machine interaction via a cloud dashboard (Figure 8). Wireless communication also reduces cabling complexity and improves deployment flexibility [45,46,47].

Figure 8.

Structural diagram of the equipment communication interconnection unit.

A cloud-based dashboard, accessible through the human–machine interface, displays real-time system status using data transmitted in JSON format, enabling operators to adjust settings dynamically. The network camera provides live visual feedback of the irrigation environment and is streamed to the interface to support informed decision-making. Figure 9 presents the interface diagram of the equipment communication interconnection unit, highlighting key connections (ESP8266 TX → STM32 PA9, ESP8266 RX → STM32 PA10).

Figure 9.

Interface diagram of the equipment communication interconnection unit.

4.3. Fertilizer Weighing and Mixing Unit

Temperature, humidity, weather conditions, crop type, spatial distribution, and growth stage data collected by the sensors are transmitted in real time to the controller and user interface. Using the proposed irrigation calculation model, the required irrigation amount is dynamically calculated based on real-time temperature and relative humidity data, while taking crop type and planting area into account. The specific formula is as follows:

where

: Preliminary theoretical irrigation (L);

: Crop coefficient (tomato = 1.1, corn = 1.2, according to FAO-56 [48]);

: Reference evapotranspiration, can be obtained from the current weather data of the local meteorological bureau (L/m2);

Real-time ambient temperature (°C), measured via temperature sensor;

: Real-time relative humidity (%), measured by the humidity sensor on the prototype;

: Optimal relative humidity for crop growth (%), varying by growth stage and obtained from the Agricultural Operation Dataset after crop stage recognition via the visual system;

: Humidity compensation coefficient, determined via orthogonal experiments [49] and set through the human–machine interface;

: Crop area in target region (m2).

Note: When , the humidity loss term is 0, that is, no irrigation amount is increased.

Furthermore, soil moisture data serves as an independent input for real-time irrigation control. Following the calculation of the theoretical irrigation amount, the system adjusts it based on current soil moisture levels: if soil moisture exceeds the upper bound of the crop’s optimal range, the irrigation amount is proportionally reduced; otherwise, it is increased accordingly. The adjustment strategy is defined as follows. Let the measured soil moisture from the sensor be , and the crop’s optimal range be , as provided in the Agricultural Operations Dataset. The adjustment factor is then calculated as follows:

Therefore, the final theoretical irrigation amount is

The system determines the optimal irrigation amount for crops based on the calculation results to achieve precise irrigation and enhance water use efficiency.

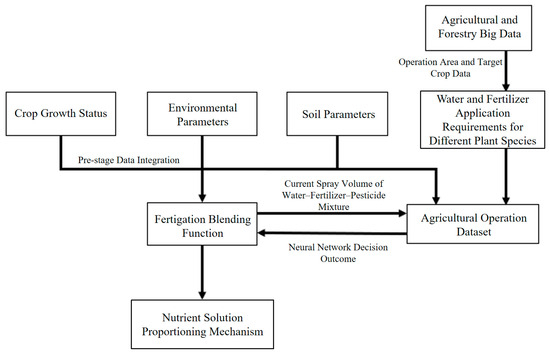

In addition, as shown in Figure 10, the fertilization mixing flow chart, the system also establishes the water and fertilizer mixing function according to the comprehensive analysis of crop growth status identified by visual neural network, environmental parameters and soil parameters transmitted by sensors, and operational big data.

where

Figure 10.

Fertilization mixing flowchart.

: Water–fertilizer mixing ratio (fertilizer concentration, unit g/L);

: Crop growth status (disease severity, growth stage coefficient, biomass);

: Environmental parameters (temperature, humidity);

: Soil parameters (moisture content, pH);

: Agricultural and forestry big data (crop area, target crop type, historical water, and fertilizer application conditions);

: Nonlinear influence functions of various parameters on the water–fertilizer ratio, fitted by neural network;

Weight coefficients (obtained via random forest regression on historical data, ), satisfying .

In real time operation, after calculating the water and fertilizer mixing ratio, the actual fertilizer amount can be further calculated based on the current sprinkler irrigation amount as follows:

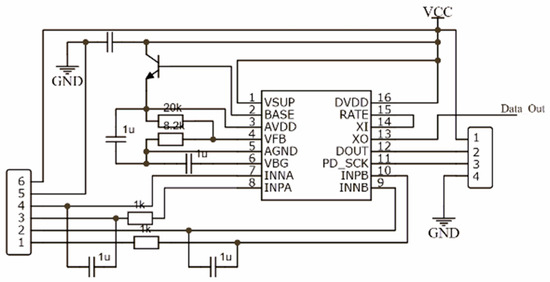

After determining the actual amount of fertilizer needed, the fertilizer delivery unit transfers the fertilizer from the storage bin to a box with a weighing sensor for weighing at a steady flow. For weighing fertilizer, the system employs the HX711, a cost-effective, high-precision Analog-to-Digital Converter (ADC) designed for reading bridge sensor outputs [50,51]. The HX711 communicates with the STM32 via SPI (clock frequency: 1 MHz) and is calibrated using a three-point method (0 g, 500 g, and 1000 g standard weights), achieving a measurement error ≤±0.2 g. The STM32 collects, filters, and processes these readings via SPI, UART, and I2C for accurate measurements. Figure 11 shows the circuit. With the steady flow delivery of the fertilizer delivery unit and the precise measurement of the ADC, more accurate fertilizer results can be achieved.

Figure 11.

Schematic diagram of the internal circuit of the weighing module.

4.4. Fertilizer Delivery Motion Control

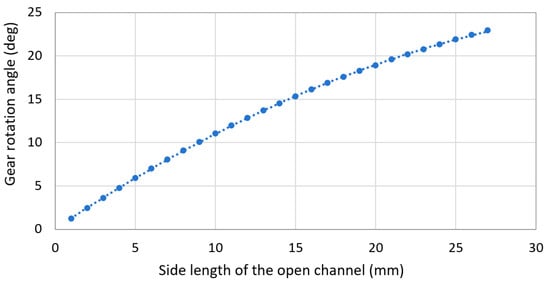

Figure 12 presents simulation results from the fertilizer delivery unit model, showing the relationship between aperture side length (a) and base gear rotation angle (β). The fitted relationship between aperture side length a and base gear angle (β) is

with a coefficient of determination R2 = 0.98, indicating strong fitting accuracy. Given the 1:5 gear ratio, the motor rotation angle () relates to aperture side length as

Figure 12.

Simulation results of fertilization delivery unit model (simulated value, residual ≤ ±0.5°).

Note: The negative root is retained in Equation (8) to ensure (positive side length).

The cross-sectional area (A) of the regular hexagonal aperture is

The fertilizer mass flow rate (Q) follows the hydraulic equation as follows:

where

converts mm2 to m2;

: discharge coefficient, is experimentally calibrated as 0.65 ± 0.03 for granular fertilizers;

: the density of the fertilizer (kg/m3);

: signifies the gravitational acceleration (9.81 m/s2);

: instantaneous fertilizer height (m) measured by an ultrasonic sensor (installed at the top of the storage bin, measurement accuracy ±1 mm, sampling frequency 10 Hz; height error induces ≤0.5% flow fluctuation).

The flow angle equation is as follows:

with the system constant calculated as follows:

A closed-loop control system is implemented to maintain stable flow: ultrasonic sensors continuously monitor h, and the STM32 microcontroller adjusts the stepper motor rotation angle () in real time based on Equations (7)–(13). This dynamic compensation eliminates flow deviations caused by decreasing fertilizer height (e.g., a 50 mm drop in h would induce significant flow reduction without adjustment, but the closed-loop system suppresses this to within the overall flow control error range). Compared with traditional fixed-aperture designs (which exhibit >10% flow fluctuation), this system achieves precise regulation with errors <3% (validated in Section 5.2), ensuring stable fertilizer flow into the weighing module for accurate measurement.

4.5. Fertigation Motion Control

The system employs a YOLOv5s neural network (trained on 100,000 annotated images of five crop types, mAP@0.5 = 92.5%) to process camera images in real time, enabling the accurate identification of plant species and growth stages. The main control unit, a 72 MHz STM32F1 microcontroller (STMicroelectronics, Geneva, Switzerland), executes the control tasks and applies fuzzy control to model the polar motion of the irrigation arm while managing pulse output.

However, conventional PID controllers show notable limitations in cross-terrain fertigation systems. When operating on slopes, gravitational torque disturbances arise and interact with the fixed controller gains, often inducing oscillations in actuator response. These interactions can trigger resonant vibrations at frequencies of 5–8 Hz, reducing control stability and precision.

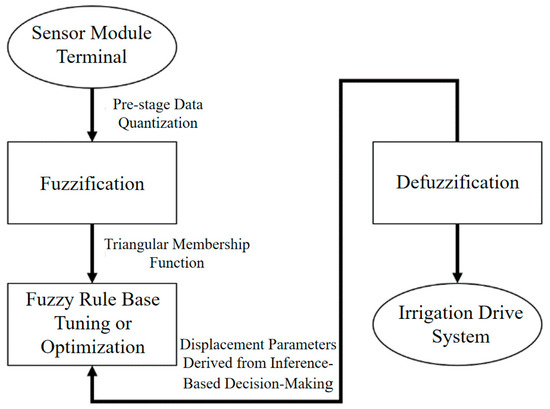

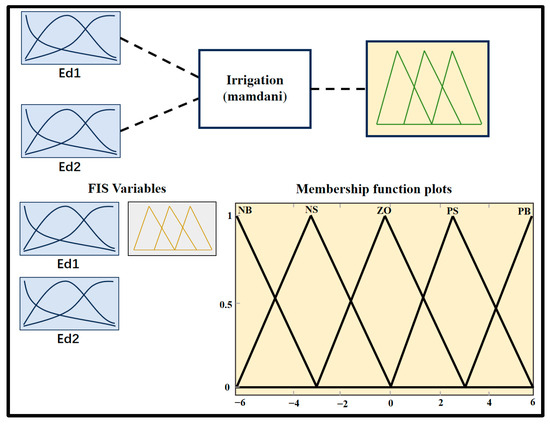

To overcome these challenges, our system integrates a fuzzy adaptive PID control algorithm. The controller is designed based on a single-input single-output configuration [52,53,54,55], where the deviation between the sensing device and the target crops (or fruits) is quantified as , and the desired target distance is denoted as . The input variables are defined as follows:

Fuzzy inputs and outputs range from –6 to +6 and are partitioned into five states: Negative Big (NB), Negative Small (NS), Zero (ZO), Positive Small (PS), and Positive Big (PB). The fuzzy rule is: if (E is NB) then (Pul is PB). It means that when the deviation belongs to NB (Negative Large), the corresponding pulse output is PB (Positive Large). The output pulse count (PUL) moves the irrigation arm in polar coordinates. We use triangular membership functions and the maximum membership method to convert the fuzzy results into movement distances [56].

Compared with conventional PID control, the fuzzy PID significantly reduces overshoot to below 5% and decreases the stabilization time to 0.8 s. For large error deviations, the controller prioritizes rapid reduction in the error magnitude; as the deviation decreases, the focus shifts to maintaining overall system stability, thereby effectively suppressing unnecessary oscillations. These adaptive control adjustments enable the stepper motors to achieve accurate three-dimensional positioning. To further minimize motion errors, the host system imposes constraints on motor speed and direction while continuously recording operational data. The overall control architecture of the fertigation delivery unit is presented in Figure 13.

Figure 13.

Control schematic diagram of fertigation delivery unit.

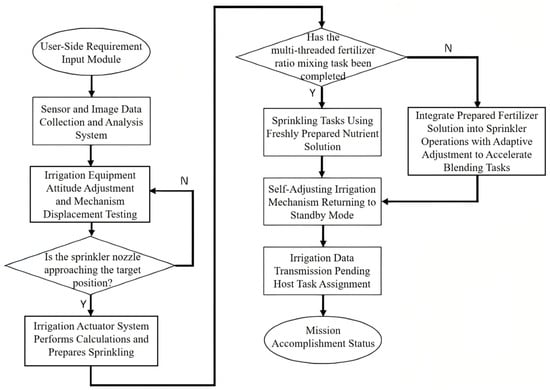

Upon receiving a control signal, the nozzle moves to the target area to initiate irrigation. A camera mounted on the nozzle captures live images to assess crop status. Once positioned—defined as distance to target ≤0.1 m and speed ≤0.05 m/s—the system reports its status and begins spraying. For irrigation-only operations, the nozzle continuously tracks the crop canopy, whereas during integrated water–fertilizer application, it precisely follows the root zone, realizing a precision application strategy of ‘spray follows fruit, fertilizer follows roots.’ The process flowchart is shown in Figure 14.

Figure 14.

State transition diagram of the fertigation unit.

5. Experimental Setup and Results

5.1. Prototype and Testbed

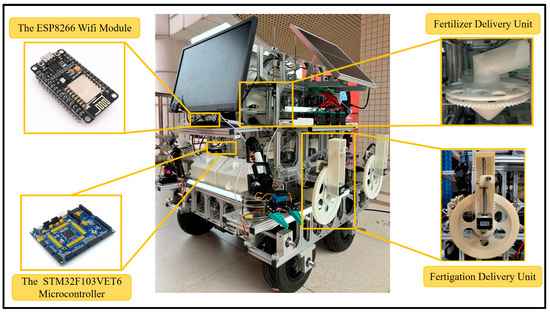

The mobile platform shown in Figure 15 represents a newly developed irrigation robot for this study. It integrates a modular hardware system consisting of a power unit, a fertilizer delivery unit, a fertigation unit, a microcontroller (STM32F103VET6) running FreeRTOS, and a WiFi module (ESP8266). As summarized in Table 3, the prototype’s key specifications include dimensions of 1200 mm × 800 mm × 600 mm, a total weight of 50 kg, and a 24 V/100 Ah lithium battery providing an operational endurance of 8 h. The main innovations of the system are as follows:

Figure 15.

Physical image of the fertigation system.

Table 3.

Technical specifications of the fertigation system prototype.

- A sliding iris switch mechanism for fertilizer delivery (validated in Section 5.2);

- Dynamic water–fertilizer adjustment based on environmental parameters (validated in Section 5.5);

- An integrated STM32F4-based real-time scheduling architecture using RTOS.

We tested it with fuzzy control, ramp response, water and fertilizer application measurements, and image recognition.

The robot was evaluated through tests involving fuzzy control, ramp response, fertilizer delivery flow measurements, water and fertilizer application measurements, and image recognition. The ramp response experiments were conducted on the Controllable Slope Test Platform of Guangzhou University’s Engineering Center, while the remaining tests—including fuzzy control, fertilizer delivery flow, water and fertilizer application measurements, and image recognition—were performed in a 3 m2 tomato greenhouse with sandy loam soil at Guangzhou University using tomato crops at 30 days of growth as the test subjects.

5.2. Fertilizer Delivery Tests

An electromagnetic flowmeter (model DN20, accuracy ±0.2% FS) was used to measure fertilizer flow at the outlet of the fertilizer delivery unit. The prototype was placed horizontally on a level surface at rest, with the initial fertilizer height in the storage bin set to 50 mm. A constant flow rate of 200 g/s was maintained using an STM32-based closed-loop control system with an adjustment frequency of 10 Hz. To exclude transient effects during startup, data were sampled from 1 to 5 s after activation. Actual flow measurements were recorded at 0.5 s intervals over three repetitions for each slope condition, which were tested in a random order. The experimental results are summarized in Table 4.

Table 4.

Actual fertilizer flow rate at the opening of the fertilizer delivery unit.

During the experiment, fertilizer height h decreased from 50 mm to 30 mm over 20 s, and the closed-loop control system (Section 3.2) dynamically adjusted the iris aperture to suppress flow fluctuations to <3%. The test results confirm that the fertilizer delivery unit effectively stabilizes the output flow, enabling the weighing module to perform reliable and accurate measurements of the fertilizer, which in turn supports precise fertilization.

5.3. Motion Control Tests

Based on the requirements of the fertilization model, a two-dimensional fuzzy controller was constructed with two input variables ( and ) and one output variable (). A detailed representation is shown in Figure 16. The primary input variable is defined as , where is the actual distance measured by the sensor and is the target distance, both expressed in meters.

Figure 16.

Construction of the fuzzy controller.

The tests were conducted under simulated scenarios with slopes ranging from 0° to 38° and target distances between 0.5 m and 2 m, focusing on performance indicators such as adjustment time (≤0.8 s) and overshoot (<5%). The fuzzy control rule is: “If E is NB, then Pul is PB,” which physically means that a large negative deviation requires a large positive pulse output to accelerate convergence to the target. Figure 16 illustrates the triangular membership functions, with vertex coordinates defined as NB (−6, −6, −3), NS (−4, −2, 0), ZO (−1, 0, 1), PS (0, 2, 4), and PB (3, 6, 6).

To satisfy the design requirements, 25 fuzzy inference rules were established using five linguistic terms—Negative Large (NL), Negative Small (NS), Zero (ZE), Positive Small (PS), and Positive Large (PL). Large deviations trigger rapid error reduction actions, whereas small deviations prioritize system stability to prevent overshoot and unwanted oscillations. The complete set of rules is presented in Table 5.

Table 5.

List of fuzzy control rules.

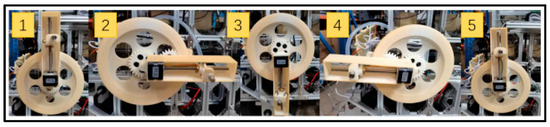

In the fertigation motion control system, the precision of the rotational assembly directly affects the uniformity of water–fertilizer application. As shown in Figure 17 (physical image of the fertigation unit in operation), a 90° step rotation test—wherein stages 1–5 correspond to 0°, 90°, 180°, 270°, and 360° rotations—demonstrated that the motor-driven central gear, which actuates the outer gear to rotate the mechanism, achieves a rotation accuracy of ≤±0.5°. This high precision ensures that the spray nozzle maintains consistent positioning relative to crop canopies, as identified by YOLOv5s, complementing the fuzzy PID control’s terrain adaptation and enabling targeted application even on sloped terrain.

Figure 17.

Physical image of the fertigation unit in operation.

5.4. Terrain Adaptability Tests

The system’s terrain adaptability was evaluated using the Controllable Slope Test Platform at Guangzhou University’s Engineering Center. The platform features a hydraulically adjustable slope plate coated with quartz sand (friction coefficient μ = 0.62) to simulate field soil conditions and prevent slippage. Tested slope angles (20°, 24°, 32°, 35°, 36°, 37°, and 38°) were selected based on the typical distribution of hilly farmland in southern China (15–40°), ensuring coverage of critical operational conditions.

A total of 21 slope tests were conducted (three repetitions per slope, randomized order), and the results were averaged. The key performance indicators included the following:

- Body Tilt Deviation: Measured using an MPU6050 tilt sensor (±45° range, ±0.1° accuracy, TDK InvenSense, San Jose, CA, USA) mounted at the system’s center of gravity; data were sampled at 10 Hz and averaged over 5 s.

- Vibration Acceleration: Recorded with an ADXL345 accelerometer (±2 g range, ±0.01 g accuracy, Analog Devices, Inc., Norwood, MA, USA) installed on the drive wheel axle. Spectral analysis indicated that terrain-induced oscillations (5–8 Hz) were effectively suppressed, accounting for <5% of total vibration energy.

- Average Power Consumption: Monitored with a YHDC AC current sensor (±0.5% accuracy) over 3 min of continuous operation. Power consumption exhibited a positive correlation with slope, increasing by 8.3% on average for every 5° increment.

- Test results (averaged across repetitions) are summarized in Table 6.

Table 6. Data from the ramp testing of the irrigation system.

Table 6. Data from the ramp testing of the irrigation system.

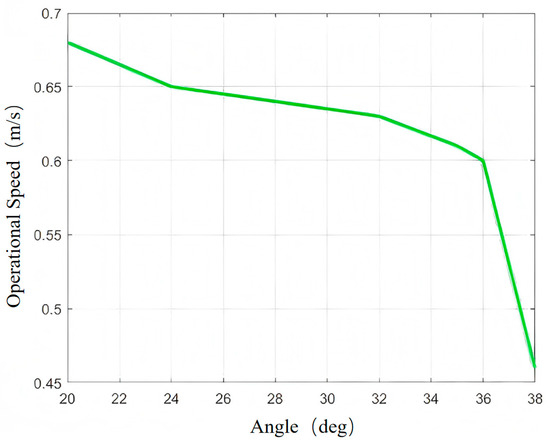

Figure 18 (curve of slope angle versus operational speed) depicts the relationship between terrain slope and the system’s operational speed. Through experimental testing, the maximum stable climbing angle was determined to be 38°, based on two key thresholds: vibration acceleration ≤ 0.5 g (to ensure structural stability) and body tilt deviation ≤ ±1.5° (to maintain application accuracy). At a slope angle of 39°, the system exhibited slippage due to insufficient friction (measured friction coefficient μ = 0.62), indicating the practical operational limit. The observed speed reduction at 38° (0.46 m/s) corresponds to the torque saturation threshold of the fuzzy PID controller (maximum output torque: 30 N·m), validating the controller’s ability to adapt the torque under extreme terrain and maintain stable operation near the operational limit.

Figure 18.

Curve of slope angle versus operational speed.

5.5. Irrigation/Fertilization Performance

The controller dynamically optimizes the operational parameters using historical irrigation data while continuously updating motion profiles according to cloud-configured user settings. The irrigation calculation model (Equations (1)–(3)) determines the theoretical water requirements of crops, based on which the water–fertilizer ratio function (Equations (4) and (5)) derives the corresponding target fertilizer quantities. Accurately weighed fertilizer is then conveyed to the mixing chamber for integration with irrigation water, enabling precise application via the fertigation delivery unit, as shown in Figure 19.

Figure 19.

Fertilization unit testing diagram.

The field tests were conducted in a 3 m2 tomato greenhouse at Guangzhou University under three environmental conditions, moderate, humid, and simulated arid climates, covering the typical growth environments of the target crop. The key parameters measured included real-time soil moisture (), ambient temperature (), and relative humidity (), which served as critical inputs for the irrigation calculation model (Equations (1)–(3)). Table 7 summarizes the recorded values for each test region, including mean, minimum, and maximum measurements for soil moisture, temperature, and relative humidity. These data were used to validate dynamic water–fertilizer adjustments. All measured parameters fell within typical ranges for tomato cultivation, confirming the ecological validity of the experimental conditions [57]. Actual irrigation volume was quantified using an ultrasonic liquid level sensor (accuracy: ±1 mm) by monitoring the water level reduction in the prototype tank, while fertilizer consumption was recorded via the HX711 weighing module (calibration error: ±0.2 g).

Table 7.

Environmental conditions for irrigation tests.

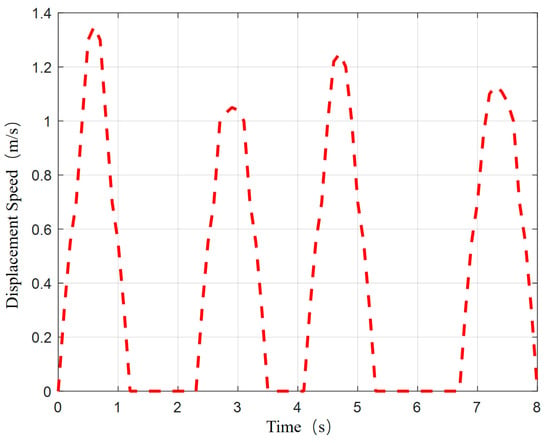

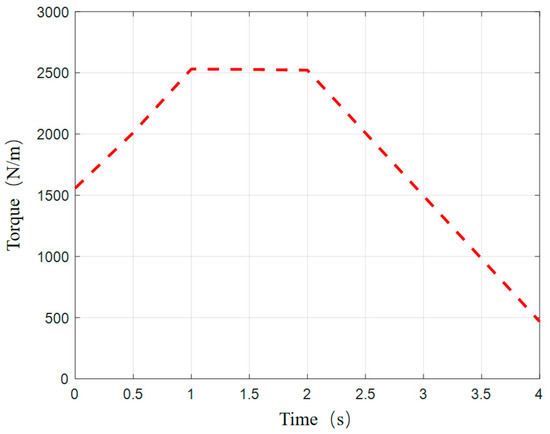

As Table 8 demonstrates, the deviations between the measured and theoretical values were below 5% for irrigation and 2% for fertilization, confirming precise fluid delivery and effective dynamic ratio optimization. Velocity profiles during operation were monitored in real time, with each operational cycle including startup, acceleration, constant-speed motion, deceleration, and stationary phases (peak velocity: 1.35 m/s; minimum velocity: 1.12 m/s). Observed fluctuations were primarily attributed to mild slopes (<5°), motor response latency, and variations in load. The dynamic parameter profiles are detailed in Figure 20.

Table 8.

Irrigation and fertilization performance data.

Figure 20.

Variation in displacement speed with time.

As depicted in Figure 21, the irrigation system demonstrates a complete dynamic torque response cycle. During startup, motor torque increases to initiate acceleration, raising the operational velocity to the target value within 0.5 s. At steady state, torque stabilizes to sustain uniform motion, whereas during deceleration, the motor applies negative torque for controlled braking, linearly decreasing velocity to zero within 0.8 s. Similarly, the steering unit achieves precise course correction via real-time differential torque modulation.

Figure 21.

Variation in torque with time.

5.6. Visual Recognition Performanc

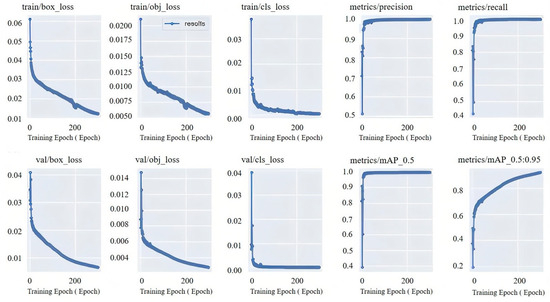

The YOLOv5s system, implemented in PyTorch 1.10.0 (with CUDA 11.3 support for GPU acceleration) with an input resolution of 640 × 480, facilitates dynamic water–fertilizer adjustments by enabling the real-time detection of crop growth stages and diseases (mAP@0.5 = 92.5%). This capability directly informs dynamic water–fertilizer ratio adjustment (Equations (1)–(5)) as well as terrain-specific path planning. The model was trained on 100,000 annotated images of five crop types: tomato (30,000), corn (25,000), rice (20,000), wheat (15,000), and cucumber (10,000). Each crop dataset was divided into three growth stages—seedling (30%), flowering (30%), and maturity (40%)—and two disease states (powdery mildew: 12,000 images; leaf spot: 8000 images), with bounding boxes marking object locations and categories. The model was trained for 200 epochs with a batch size of 32 using an SGD optimizer (initial learning rate = 0.01, weight decay = 1 × 10−4, momentum = 0.937). The dataset was split into 70% training, 20% validation, and 10% testing.

As shown in Figure 22, the model accurately detects tomato fruits, outlining them with bounding boxes and annotating their maturity stage. This not only validates the model’s detection capability but also provides reliable crop status information, which feeds into the water–fertilizer decision-making module. Leveraging these visual recognition results, the system dynamically adjusts fertilizer allocation, thereby effectively addressing the challenges in adaptive resource allocation under environmental variability in cross-regional irrigation systems. Consequently, irrigation and fertilization strategies are optimized based on crop growth and health status.

Figure 22.

Crop maturity recognition diagram.

As illustrated in Figure 23 (visualization of model training), the validation set metrics exhibited convergence after approximately 200 epochs. The training loss trajectories revealed that the bounding box regression loss (box_loss) stabilized at 0.0092, indicating a substantial reduction in localization errors. The objectness loss (obj_loss) declined to 0.0046, signifying improved detection sensitivity, while the classification loss (cls_loss) decreased to 0.0062, evidencing effective discrimination between disease states and maturity levels.

Figure 23.

Visualization of model training.

By leveraging domain-specific optimization, the proposed model attained a mean average precision (mAP@0.5) of 92.5%, with class-specific accuracies of 95% for tomato maturity recognition and 88% for disease detection. Relative to a baseline model trained on generic datasets (untuned YOLOv5s in an NVIDIA Jetson Nano environment), this corresponds to a 5.8 percentage point improvement in detection accuracy and a 22.6% reduction in inference latency, achieving 48 ms per inference. Collectively, these results demonstrate that domain-specific training strategies substantially enhance recognition accuracy while improving real-time operational efficiency.

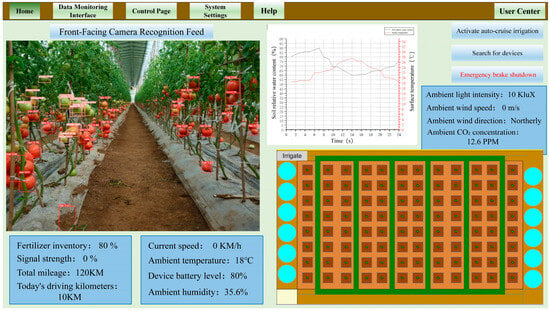

5.7. Human–Machine Interface Usability

As illustrated in Figure 24 and Figure 25, an MVC-based human–machine interface was developed to enhance the management efficiency of the intelligent fertigation system. The Vue.js frontend communicates with the PHP backend via the REST API, while the backend synchronizes sensor data with the STM32 controllers through the MQTT protocol at a 1 Hz update rate. The system parameters are stored in a MySQL database. The interface comprises three functional modules:

Figure 24.

Planting data monitoring interface.

Figure 25.

Fertigation system control interface.

- Data monitoring visualizes real-time environmental parameters (soil/air temperature, humidity, and light intensity) via integrated dashboards, highlighting microclimatic variations across regions. This real-time feedback mechanism allows operators to fine-tune water–fertilizer strategies (Equations (1)–(5)) based on local conditions and to intervene promptly in response to unexpected events, ensuring that resource allocation aligns with environmental heterogeneity and effectively addressing challenges in adaptive resource allocation under environmental variability.

- Remote control enables irrigation path planning by converting user-drawn trajectories into Bézier curve waypoints, transmitted via UART with a latency of <200 ms. For slopes up to 38°, operators can refine trajectories based on real-time crop position data from the YOLOv5s system, ensuring alignment with target crops. This manual optimization complements the fuzzy PID controller’s automatic torque and speed adjustments: the controller suppresses 5–8 Hz slope-induced vibrations and maintains body tilt deviation within ±1.5°, whereas manual refinement compensates for terrain undulations or uneven crop distribution beyond the algorithm’s adaptive capacity. The integration of both mechanisms ensures responsive fertigation under heterogeneous conditions and improves overall terrain adaptability.

- System configuration manages region-specific parameters such as autonomous navigation thresholds (e.g., slope limits), communication protocols (MQTT/UART), and data logging strategies. Recorded operational data continuously refine water–fertilizer decision models and aperture control curves, minimizing fertigation deviations. Tailored parameter settings can further enhance stability across varied terrains, thereby strengthening the system’s cross-region adaptability.

User evaluations involving 15 agricultural professionals (8 with >10 years’ experience and 7 with <5 years’ experience) indicated an average task completion time of 28.7 s for critical operations (emergency stop, parameter adjustment, and path planning), with an error rate of 2.1%. The MVC-based touchscreen interface significantly reduces operational complexity, as exemplified by real-time previews of irrigation volume (Equations (1)–(3)) and application effects (Equations (4) and (5)) during parameter adjustments. Confirmed commands are automatically dispatched to the fertilizer dosing units.

6. Discussion

This study presents an autonomous cross-regional intelligent fertigation system that addresses three long-standing limitations of conventional fertigation technologies: unstable fertilizer flow, terrain-induced performance degradation, and environment-insensitive resource allocation. By integrating a dynamically adjustable iris fertilizer delivery mechanism, slope-adaptive fuzzy PID control, and YOLOv5s-based intelligent decision-making, the system achieves flow control errors below 3%, stable operation on slopes up to 38°, and fertigation deviations within 5%—providing robust technical support for precision agriculture across diverse geographical and environmental contexts.

6.1. Mechanistic Innovation Addressing Core Limitations

6.1.1. Dynamic Fertilizer Delivery Control: Rethinking Flow Stability

The iris-based fertilizer delivery unit breaks through the bottleneck of fixed-aperture designs (e.g., spiral conveyors [30,31] and fluted rollers [32]) that suffer from flow fluctuations due to decreasing fertilizer height. Unlike traditional systems that rely solely on feedback correction to mitigate pulsation, our solution combines passive mechanical optimization with active real-time control: the regular hexagonal outlet minimizes turbulence by reducing edge-induced eddy currents, while a closed-loop control model (Equations (2)–(6)) dynamically adjusts the aperture area (0–1894 mm2) based on the ultrasonic monitoring of fertilizer height (h). This synergy ensures that flow regulation errors remain below 3% even as h decreases from 50 mm to 30 mm. This finding highlights a critical insight—stable fertilization requires both geometric optimization to reduce inherent flow disturbances and active compensation for real-time changes in material status—addressing the gap in existing research that often focuses on either mechanical design or control algorithms in isolation.

6.1.2. Terrain-Adaptive Actuation: Overcoming Slope-Induced Instability

The dual-axis fertigation module with fuzzy PID control effectively counteracts gravitational torque disturbances () on sloped terrain, a challenge unaddressed by existing mobile irrigation systems. For instance, Hassan et al.’s irrigation robot [34], despite its mobility, lacks terrain-specific mechanical or control adaptations, leading to vibrations and positioning errors on slopes. Chen’s team [35] improved chassis stability with vibration damping but ignored actuator-level optimization, leaving flow and positioning accuracy unimproved. Shafiei’s conventional PID control [36], while enhancing bump stability, uses fixed gains that fail to compensate for slope-induced torque, resulting in 5–8 Hz resonant oscillations.

Our fuzzy PID controller dynamically adjusts proportional gain (Kp) and integral time (Ti) based on real-time tilt deviations and vibration acceleration, enabling stable operation on slopes up to 38°. By treating slope-induced torque as a variable to be adapted rather than a disturbance to be suppressed, the system ensures precise fertigation across both flat and sloped regions—a key requirement for cross-regional deployment.

6.1.3. Data-Driven Water–Fertilizer Synergy: Enabling Environment-Responsive Allocation

The integrated decision model (Equations (1)–(5)) overcomes the rigidity of conventional IoT-based fertigation systems. For example, Parimala et al.’s platform [37] applies static farmer-defined fertilizer ratios with real-time sensing capabilities, rendering it misaligned with sudden changes such as heatwaves. Similarly, Ali et al.’s system [38] relies on fixed thresholds (soil moisture <80%, temperature >30 °C), making it insensitive to dynamic crop requirements.

In contrast, our model fuses real-time environmental data , soil moisture , and YOLOv5s crop analytics (achieving 92.5% mAP@0.5 for maturity and disease detection). This integration enables irrigation deviations below 5% and fertilization deviations below 2%. For instance, high temperatures trigger adjustments to account for elevated evapotranspiration, while crop maturity data dynamically refines fertilizer ratios. Consequently, the system ensures that water–fertilizer allocation closely matches actual crop demand, directly addressing the environmental insensitivity of conventional systems.

6.1.4. Cross-Regional Autonomy: Balancing Edge Control and Cloud Coordination

The STM32F1-centric architecture bridges the gap between local real-time control and cross-regional oversight, a longstanding challenge in scalable agricultural systems. The 72 MHz STM32F1 microcontroller runs FreeRTOS-based multi-threaded tasks (e.g., fuzzy PID control with a 10 ms scheduling period) to handle immediate adjustments like slope-induced torque compensation, achieving a response delay ≤ 50 ms. An ESP8266 module provides UART (TX→PA9, RX→PA10) and MQTT connectivity, ensuring <200 ms latency for remote adjustments of fertilizer flow, irrigation trajectories, and water–fertilizer ratios.

Unlike fragmented systems where edge devices and cloud platforms operate independently [28], this hierarchical design enables local controllers to maintain stability while cloud platforms aggregate cross-regional data—including YOLOv5s crop analytics—to iteratively refine decision models. This dual-level intelligence ensures scalable operation without compromising precision, a prerequisite for deployment across diverse agricultural environments.

6.2. Comparative Advantages

Building on the validated performance, the system’s comparative advantages over existing approaches are summarized in Table 9 and discussed below.

Table 9.

Comparison of key features among fertigation system studies.

As shown in Table 9, the proposed system demonstrates clear comparative advantages. Mechanically, the iris-based unit reduces fertilizer flow variability to below 3%, outperforming fixed-aperture or spiral-based applicators that typically exhibit fluctuations exceeding 10%. In terms of terrain adaptability, the fuzzy PID-driven motion platform maintains stability on steep slopes where previous mobile irrigation systems become unreliable. At the decision-making level, the integration of sensing, analysis, and actuation into a closed-loop framework differentiates this design from IoT platforms that are limited to data collection or partial automation. The combination of edge-level real-time control with cloud-enabled cross-regional coordination further enhances the scalability of the system, positioning it as a robust alternative to fragmented solutions.

6.3. Limitations and Future Directions

Scalability Constraints: Field tests were conducted in a 3 m2 greenhouse, which cannot fully simulate large-scale agricultural scenarios (e.g., 1000 + m2 farmlands with heterogeneous soil and crop distributions). Future work will validate the system in multi-hectare fields, focusing on (1) the uniformity of water/fertilizer distribution across large areas (target: ≤5% deviation between zones); (2) the reliability of multi-device coordination (e.g., 5+ units operating simultaneously with <200 ms communication latency).

Communication Range: The ESP8266 Wi-Fi module restricts remote control to a maximum of 100 m in open areas and 50 m when obstructed by crops, limiting its suitability for ultra-long-distance, cross-regional management. To address this, we plan to integrate LoRaWAN and NB-IoT modules, which offer transmission ranges of 1 to 10 km, thereby enhancing coverage in rural areas with sparse infrastructure.

Energy Autonomy: The 24 V/100 Ah lithium battery provides 8 h of operation, which is insufficient for continuous multi-day use. Solar panels (100 W) and kinetic energy recovery systems (from wheel rotation) will be added to extend endurance to ≥24 h.

Model Generalization: The water–fertilizer ratio weights (α, β, γ, δ) require calibration specific to each crop. To extend applicability beyond tomatoes, transfer learning will be employed to adapt the current tomato-optimized model to other crops such as corn and rice, aiming to reduce the required retraining data volume by 70%.

This revised discussion strengthens logical cohesion by explicitly linking innovations to initial challenges, enhancing comparability with the existing literature via quantitative metrics, and proposing actionable future work tied to current limitations.

7. Conclusions

This study developed an autonomous intelligent fertigation system that integrates mechanical innovation, adaptive control, and IoT-based decision-making to address the limitations of conventional systems in complex and diverse environments. The system’s core components—including a dynamically adjustable iris fertilizer delivery unit, a terrain-adaptive dual-axis fertigation module, and an STM32F1-based centralized controller—demonstrated stable performance on sloped terrain, precise resource management with minimal deviation, and high-accuracy crop recognition via an integrated YOLOv5s model. The MVC-based human–machine interface further enhanced operational efficiency and reduced user errors, enabling effective real-time monitoring and remote control.

While the prototype validation yielded promising results, it was primarily conducted under controlled conditions with tomato crops in a single location. Future research should focus on scaling the system to larger, heterogeneous fields; expanding crop applicability; improving durability and maintenance strategies; and integrating advanced communication (LoRaWAN) and energy solutions (solar power) to enhance coverage and autonomy. Comprehensive multi-environment testing and economic feasibility assessments will be critical to establish the system’s practical viability and broad applicability in precision agriculture.

Author Contributions

Data curation, J.L.; Investigation, H.H. and H.L.; Methodology, R.T.; Project administration, H.L.; Software, Z.W. and G.Z.; Supervision, Z.W.; Validation, R.T., H.L. and G.Z.; Visualization, H.H. and Z.M.; Writing—original draft, R.T. and H.H.; Writing—review and editing, R.T., H.H., Z.M. and J.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Student Innovation Training Program of Guangzhou University (No. 202411078075).

Data Availability Statement

The dataset used in this research is available upon reasonable request from the corresponding author. This dataset is not available to the public because of the laboratory privacy concerns.

Conflicts of Interest

There are no conflicts of interest for this article.

References

- Charania, I.; Li, X. Smart farming: Agriculture’s shift from a labor intensive to technology native industry. Internet Things 2020, 9, 100142. [Google Scholar] [CrossRef]

- Pawlak, K.; Kołodziejczak, M. The Role of Agriculture in Ensuring Food Security in Developing Countries: Considerations in the Context of the Problem of Sustainable Food Production. Sustainability 2020, 12, 5488. [Google Scholar] [CrossRef]

- Wei, X. Intelligent agricultural mechanization: A new era engine for agricultural development. Appl. Comput. Eng. 2024, 102, 55–60. [Google Scholar] [CrossRef]

- Shi, L.; Shi, G.; Qiu, H. General review of intelligent agriculture development in China. Chin. Agric. Econ. Rev. 2019, 11, 39–51. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Murase, H.; Morimoto, T.; Torii, T. Intelligent systems for agriculture in Japan. IEEE Control Syst. Mag. 2001, 21, 71–85. [Google Scholar]

- Adli, H.K.; Remli, M.A.; Wan Salihin Wong, K.N.S.; Ismail, N.A.; González-Briones, A.; Corchado, J.M.; Mohamad, M.S. Recent Advancements and Challenges of AIoT Application in Smart Agriculture: A Review. Sensors 2023, 23, 3752. [Google Scholar] [CrossRef]

- Chen, J.; Yang, A. Intelligent agriculture and its key technologies based on internet of things architecture. IEEE Access 2019, 7, 77134–77141. [Google Scholar] [CrossRef]

- Assimakopoulos, F.; Vassilakis, C.; Margaris, D.; Kotis, K.; Spiliotopoulos, D. The Implementation of “Smart” Technologies in the Agricultural Sector: A Review. Information 2024, 15, 466. [Google Scholar] [CrossRef]

- Chuang, J.-H.; Wang, J.-H.; Liou, Y.-C. Farmers’ Knowledge, Attitude, and Adoption of Smart Agriculture Technology in Taiwan. Int. J. Environ. Res. Public Health 2020, 17, 7236. [Google Scholar] [CrossRef]

- Yokamo, S. Adoption of improved agricultural technologies in developing countries: Literature review. Int. J. Sci. Food Agric. 2020, 4, 183–190. [Google Scholar] [CrossRef]

- Goel, R.K.; Yadav, C.S.; Vishnoi, S.; Rastogi, R. Smart agriculture–Urgent need of the day in developing countries. Sustain. Comput. Inform. Syst. 2021, 30, 100512. [Google Scholar] [CrossRef]

- Li, J.; Liu, G.; Chen, Y.; Li, R. Study on the influence mechanism of adoption of smart agriculture technology behavior. Sci. Rep. 2023, 13, 8554. [Google Scholar] [CrossRef]

- Zhao, C. State-of-the-art and recommended developmental strategic objectives of smart agriculture. Smart Agric. 2019, 1, 1–7. [Google Scholar]

- Zhao, C.; Li, J.; Feng, X. Development strategy of smart agriculture for 2035 in China. Strateg. Study Chin. Acad. Eng. 2021, 23, 1–9. [Google Scholar] [CrossRef]

- Sun, A.Y.; Scanlon, B.R. How can Big Data and machine learning benefit environment and water management: A survey of methods, applications, and future directions. Environ. Res. Lett. 2019, 14, 073001. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Chen, C.L.P.; Liu, Z.; Chen, K. Observer-based Practical Prescribed-Time Consensus Tracking Control for Multiagent Systems with Unknown Virtual Control Coefficients. IEEE/CAA J. Autom. Sin. 2025, in press. [Google Scholar]

- Li, D.; Nanseki, T. Practice, promotion and perspective of smart agriculture in China. In Agricultural Innovation in Asia: Efficiency, Welfare, and Technology; Nanseki, T., Ed.; Springer: Singapore, 2023; pp. 183–203. [Google Scholar]

- Mondal, P.; Basu, M. Adoption of precision agriculture technologies in India and in some developing countries: Scope, present status and strategies. Prog. Nat. Sci. 2009, 19, 659–666. [Google Scholar] [CrossRef]

- van Rooyen, A.F.; Ramshaw, P.; Moyo, M.; Stirzaker, R.; Bjornlund, H. Theory and application of Agricultural Innovation Platforms for improved irrigation scheme management in Southern Africa. Int. J. Water Resour. Dev. 2017, 33, 804–823. [Google Scholar] [CrossRef]

- Musa, S.F.P.D.; Basir, K.H. Smart farming: Towards a sustainable agri-food system. Br. Food J. 2021, 123, 3085–3099. [Google Scholar] [CrossRef]

- Reddy, R. Innovations in Agricultural Machinery: Assessing the Impact of Advanced Technologies on Farm Efficiency. J. Artif. Intell. Big Data 2022, 2, 1156. [Google Scholar] [CrossRef]

- El Mouedden, M.; Mabrouki, J.; Azdem, D.; El Hajjaji, S. The development of intelligent agriculture, the contribution of the Internet of Things (IoT) to modernization and its implications for precision farming: A review. Euro-Mediterr. J. Environ. Integr. 2025. [Google Scholar] [CrossRef]

- Obaideen, K.; Yousef, B.A.A.; AlMallahi, M.N.; Tan, Y.C.; Mahmoud, M.; Jaber, H.; Ramadan, M. An overview of smart irrigation systems using IoT. Energy Nexus 2022, 7, 100124. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X. Precise application of water and fertilizer to crops: Challenges and opportunities. Front. Plant Sci. 2024, 15, 1444560. [Google Scholar] [CrossRef] [PubMed]

- Srivastav, A.L.; Dhyani, R.; Ranjan, M.; Madhav, S.; Sillanpää, M. Climate-resilient strategies for sustainable management of water resources and agriculture. Environ. Sci. Pollut. Res. 2021, 28, 41576–41595. [Google Scholar] [CrossRef]

- Chouhan, S.; Kumari, S.; Kumar, R.; Chaudhary, P.L. Climate resilient water management for sustainable agriculture. Int. J. Environ. Clim. Chang. 2023, 13, 411–426. [Google Scholar] [CrossRef]

- Abioye, E.A.; Abidin, M.S.Z.; Mahmud, M.S.A.; Buyamin, S.; Ishak, M.H.I.; Rahman, M.K.I.A.; Otuoze, A.O.; Onotu, P.; Ramli, M.S.A. A review on monitoring and advanced control strategies for precision irrigation. Comput. Electron. Agric. 2020, 173, 105441. [Google Scholar] [CrossRef]

- García, L.; Parra, L.; Jimenez, J.M.; Lloret, J.; Lorenz, P. IoT-Based Smart Irrigation Systems: An Overview on the Recent Trends on Sensors and IoT Systems for Irrigation in Precision Agriculture. Sensors 2020, 20, 1042. [Google Scholar] [CrossRef]

- Gong, L.; Yan, J.; Chen, Y.; An, J.; He, L.; Zheng, L.; Zou, Z. An IoT-based intelligent irrigation system with data fusion and a self-powered wide-area network. J. Ind. Inf. Integr. 2022, 29, 100367. [Google Scholar] [CrossRef]

- Keswani, B.; Mohapatra, A.G.; Mohanty, A.; Khanna, A.; Rodrigues, J.J.P.C.; Gupta, D.; de Albuquerque, V.H.C. Adapting weather conditions-based IoT enabled smart irrigation technique in precision agriculture mechanisms. Neural Comput. Appl. 2019, 31, 277–292. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Tang, Y.R.; Zhang, H.; Lan, H.P.; Niu, H. Parameter Optimization of Spiral Fertilizer Applicator Based on Artificial Neural Network. Sustainability 2023, 15, 1744. [Google Scholar] [CrossRef]

- Mondal, D.; Nabendu, G. Study on filling factor of short length screw conveyor with flood-feeding condition. Mater. Today Proc. 2018, 5, 1286–1291. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Y.; Wei, S.; Liao, M.; Zang, Y.; Zeng, S. Design and experimental study of the fertilizer applicator with vertical spiral fluted rollers. Int. J. Agric. Biol. Eng. 2023, 16, 80–87. [Google Scholar] [CrossRef]

- Siddegowda, C.J.; Devi, A.J. A study on the role of precision agriculture in agro-industry. Int. J. Appl. Eng. Manag. Lett. 2021, 5, 57–67. [Google Scholar] [CrossRef]

- Hassan, A.; Asif, R.M.; Rehman, A.U.; Nishtar, Z.; Kaabar, M.K.; Afsar, K. Design and Development of an Irrigation Mobile Robot. IAES Int. J. Robot. Autom. 2021, 10, 75. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Y.; Liu, B.; Yan, B.; Li, X.; Lu, K.; Ren, T.; Ma, B.; Tian, Y. Design and Implementation of A Novel Internet of Things Irrigation System With A Precision Irrigation Robot. In Proceedings of the 2021 IEEE International Conference on Real-time Computing and Robotics (RCAR), Xining, China, 15–19 July 2021. [Google Scholar]

- Shafiei, B. A Review on PID Control System Simulation of the Active Suspension System of a Quarter Car Model While Hitting Road Bumps. J. Inst. Eng. India Ser. C 2022, 103, 1001–1011. [Google Scholar] [CrossRef]

- Parimala, M.; Rani, M.J.; Sai, K.B.; Sunitha, M. IoT based Intelligent Fertigation through Drip Irrigation. In Proceedings of the 2021 Third International Conference on Intelligent Communication Technologies and Virtual Mobile Networks (ICICV), Tirunelveli, India, 4–6 February 2021; pp. 410–414. [Google Scholar]

- Ali, M.I.; Khan, M.R. Design and Development of Microcontroller Based Agroponic Agriculture System. Malays. J. Sci. Adv. Technol. 2021, 1, 45–53. [Google Scholar]

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated irrigation system using a wireless sensor network and GPRS module. IEEE Trans. Instrum. Meas. 2013, 63, 166–176. [Google Scholar] [CrossRef]

- Bilotta, G.; Genovese, E.; Citroni, R.; Cotroneo, F.; Meduri, G.M.; Barrile, V. Integration of an Innovative Atmospheric Forecasting Simulator and Remote Sensing Data into a Geographical Information System in the Frame of Agriculture 4.0 Concept. AgriEngineering 2023, 5, 1280–1301. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, T.; Tantashutikun, N.; Hussain, N.; Cocetta, G. Application of Smart Techniques, Internet of Things and Data Mining for Resource Use Efficient and Sustainable Crop Production. Agriculture 2023, 13, 397. [Google Scholar] [CrossRef]

- Xiao, Z.; Liu, D.; Cao, D.; Wang, X. Design of home appliance control system in smart home based on WiFi IoT. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 765–770. [Google Scholar]

- Hala, M.; Menon, R. Examining the impact of an asynchronous communication platform versus existing communication methods: An observational study. BMJ Innov. 2021, 7, 68–74. [Google Scholar]

- Wu, J.; Tan, R.; Wang, M. Streaming high-definition real-time video to mobile devices with partially reliable transfer. IEEE Trans. Mob. Comput. 2018, 18, 458–472. [Google Scholar] [CrossRef]

- Long, S.; Huang, W.; Wang, J.; Liu, J.; Gu, Y.; Wang, Z. A Fixed-Time Consensus Control with Prescribed Performance for Multi-Agent Systems Under Full-State Constraints. IEEE Trans. Autom. Sci. Eng. 2024, 22, 6398–6407. [Google Scholar] [CrossRef]

- Kabilan, N.; Selvi, M.S. Surveillance and steering of irrigation system in cloud using Wireless Sensor Network and Wi-Fi module. In Proceedings of the 2016 International Conference on Recent Trends in Information Technology (ICRTIT), Chennai, India, 22–23 April 2016; pp. 1–5. [Google Scholar]

- Xu, W.; Feng, X.; Xing, H. Modeling and analysis of adaptive temperature compensation for humidity sensors. Electronics 2019, 8, 425. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Wang, X.; Wei, Z.; Cheng, X.; Zhang, Y.; Jiao, X. Design and experiment of a multi-channel real-time weighing device. INMATEH-Agric. Eng. 2024, 73, 2. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Crop Evapotranspiration: Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper No 56; FAO: Rome, Italy, 1998. [Google Scholar]

- Arief, D.; Shiddiq, M.; Prayitno, A.; Badri, M.; Nugraha, A.; Muflihana, A. Calibration of 40 Kg capacity digital scale on automatic machine measurement mass and dimension based on Arduino Uno using CSIRO-NML: 1995 method. Proc. Ocean. Mech. Aerosp. Sci. Eng. 2018, 5, 97–102. [Google Scholar]

- Savran, A. A multivariable predictive fuzzy PID control system. Appl. Soft Comput. 2013, 13, 2658–2667. [Google Scholar] [CrossRef]

- Alaan, M.; Manuel, E.; Reyes, J.; Mercado, C.R.; Concepcion, R. Design of an optimized second-order soil-based drip fertigation control system with Internet-of-Things integration. In Proceedings of the 2023 8th International Conference on Business and Industrial Research (ICBIR), Jakarta, Indonesia, 22–24 May 2023; pp. 477–482. [Google Scholar]

- Wang, J.; Wu, Y.; Chen, C.L.P.; Liu, Z.; Wu, W. Adaptive PI Event-Triggered Control for MIMO Nonlinear Systems with Input Delay. Inf. Sci. 2024, 677, 120817. [Google Scholar] [CrossRef]

- Goodchild, M.S.; Kühn, K.D.; Jenkins, M.D.; Burek, K.J.; Button, A.J. A method for precision closed-loop irrigation using a modified PID control algorithm. Sens. Transducers 2015, 188, 61. [Google Scholar]

- Jaiswal, S.; Ballal, M.S. Fuzzy inference based irrigation controller for agricultural demand side management. Comput. Electron. Agric. 2020, 175, 105537. [Google Scholar] [CrossRef]

- Schwarz, D.; Thompson, A.J.; Kläring, H.-P. Guidelines to use tomato in experiments with a controlled environment. Front. Plant Sci. 2014, 5, 625. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).