Global Fixed-Time Fault-Tolerant Control for Tracked Vehicles with Hierarchical Unknown Input Observers

Abstract

1. Introduction

2. Model Establishment

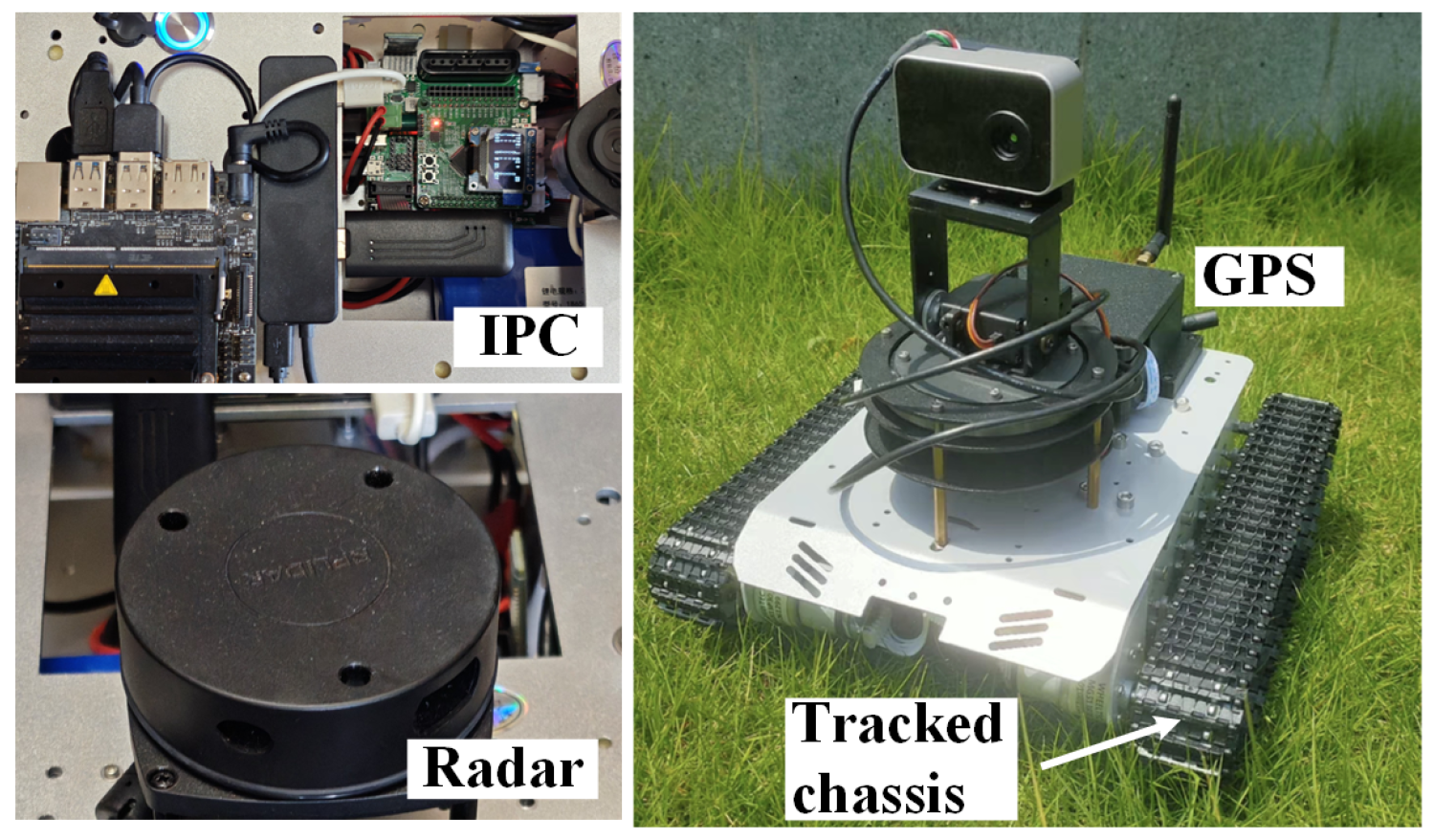

2.1. TMV System

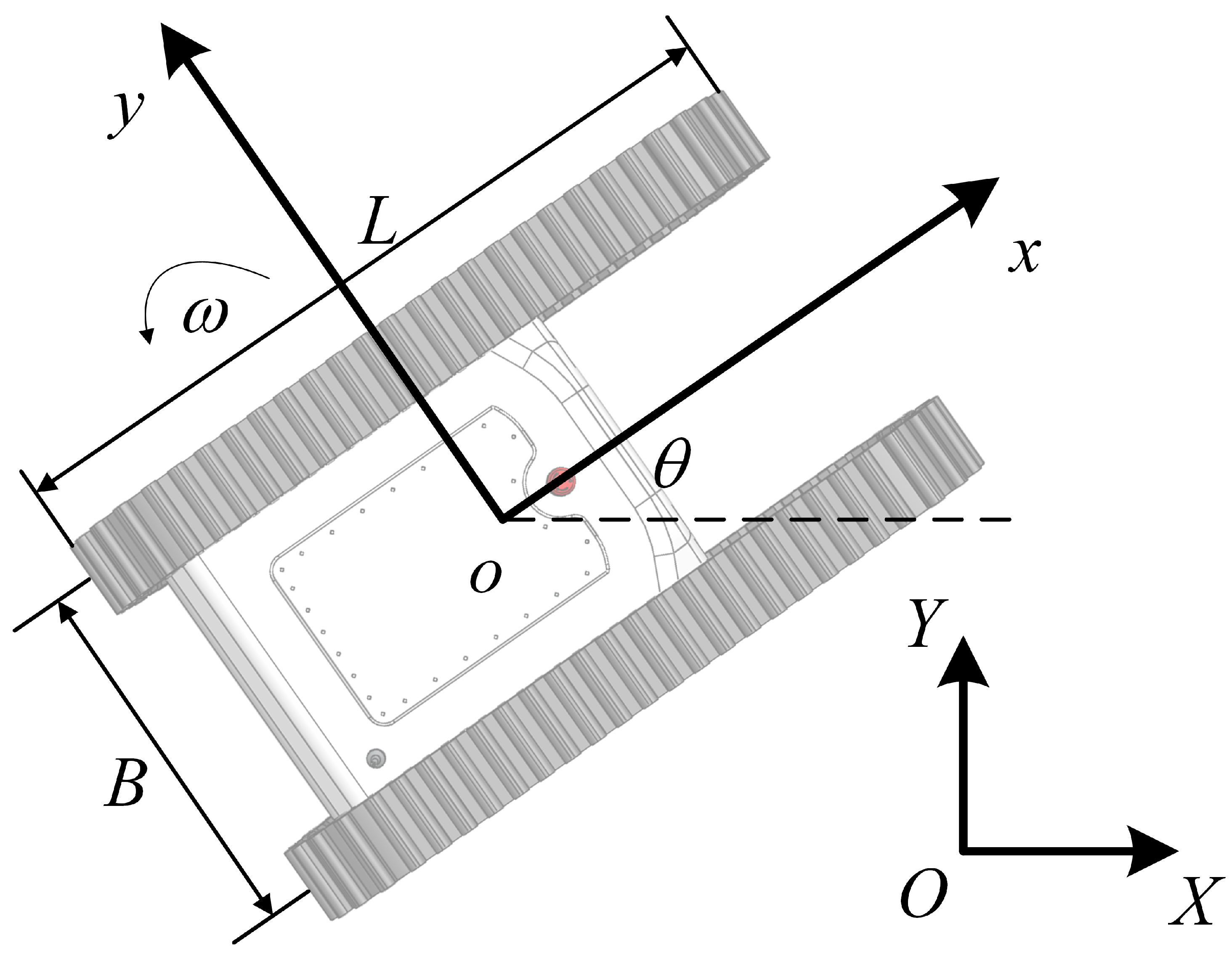

2.2. Kinematic Model

2.3. Dynamic Model

2.4. LPV Model Establishment

3. Distributed Unknown Input Observer

3.1. System Construction

- 1.

- External disturbances such as friction forces and lateral slip forces between tracks and ground are physically bounded by nature, and their rates of change are constrained by the inertia of the mechanical system;

- 2.

- Sensor faults typically manifest as gradual processes rather than abrupt changes, thereby ensuring that fault signals and their derivatives exhibit bounded characteristics;

- 3.

- Time-varying scheduling parameters reflect the operational states of the system, and their variations remain smooth during continuous operation;

- 4.

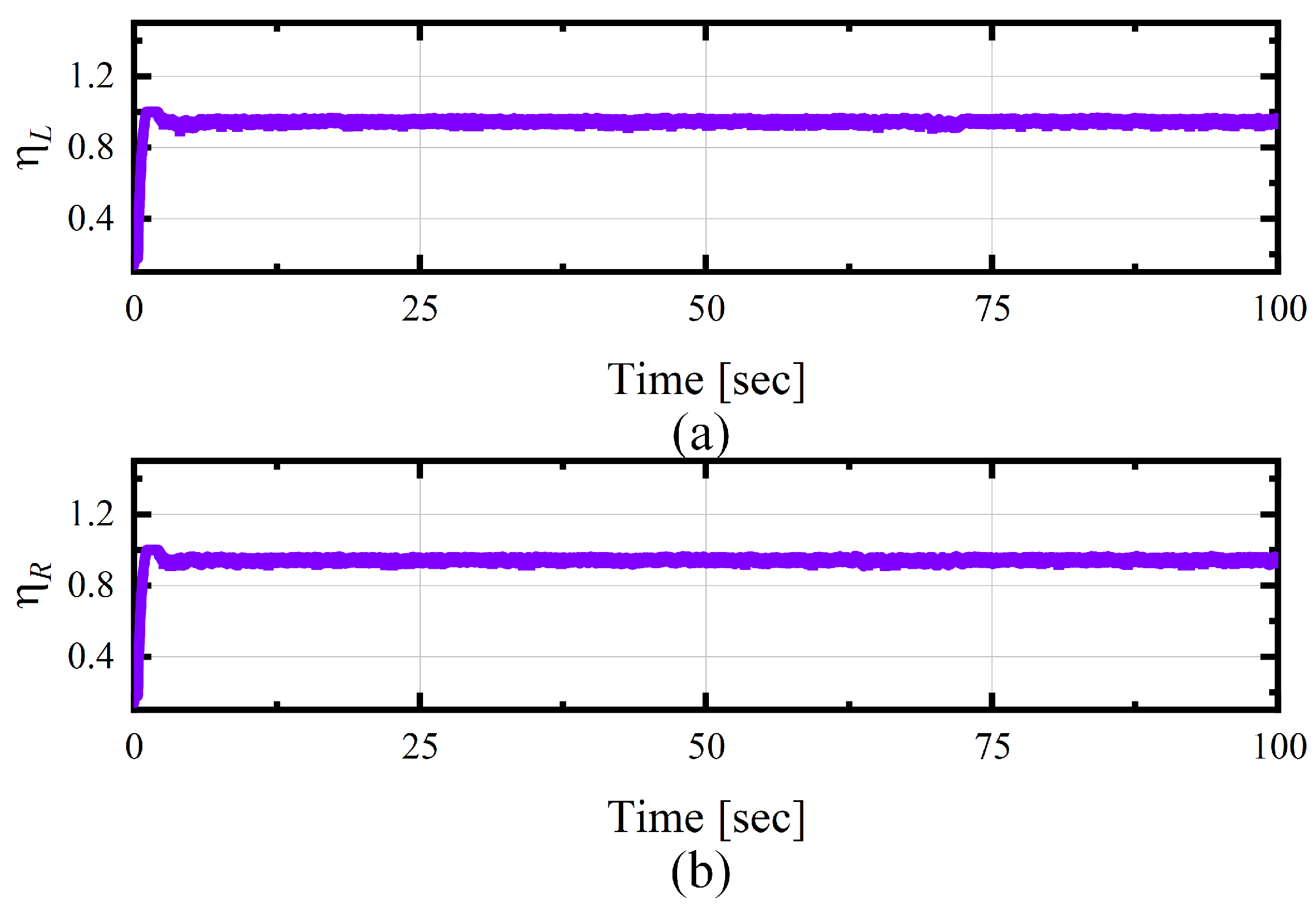

- Motor efficiency degradation represents a slow aging process that does not undergo sudden changes during normal operation;

- 5.

- Measurement noise in practical applications generally satisfies statistical boundedness requirements.

3.2. Fixed-Time Differentiator

3.3. State Observer

3.4. Coupled Stability Analysis

4. Actuator Fault-Tolerant Design

4.1. Actuator Fault-Tolerant System

4.2. Actuator Fault-Tolerant Observer

4.3. Adaptive Fault-Tolerant Controller Design

4.4. Actuator Fault-Tolerant Closed-Loop Stability

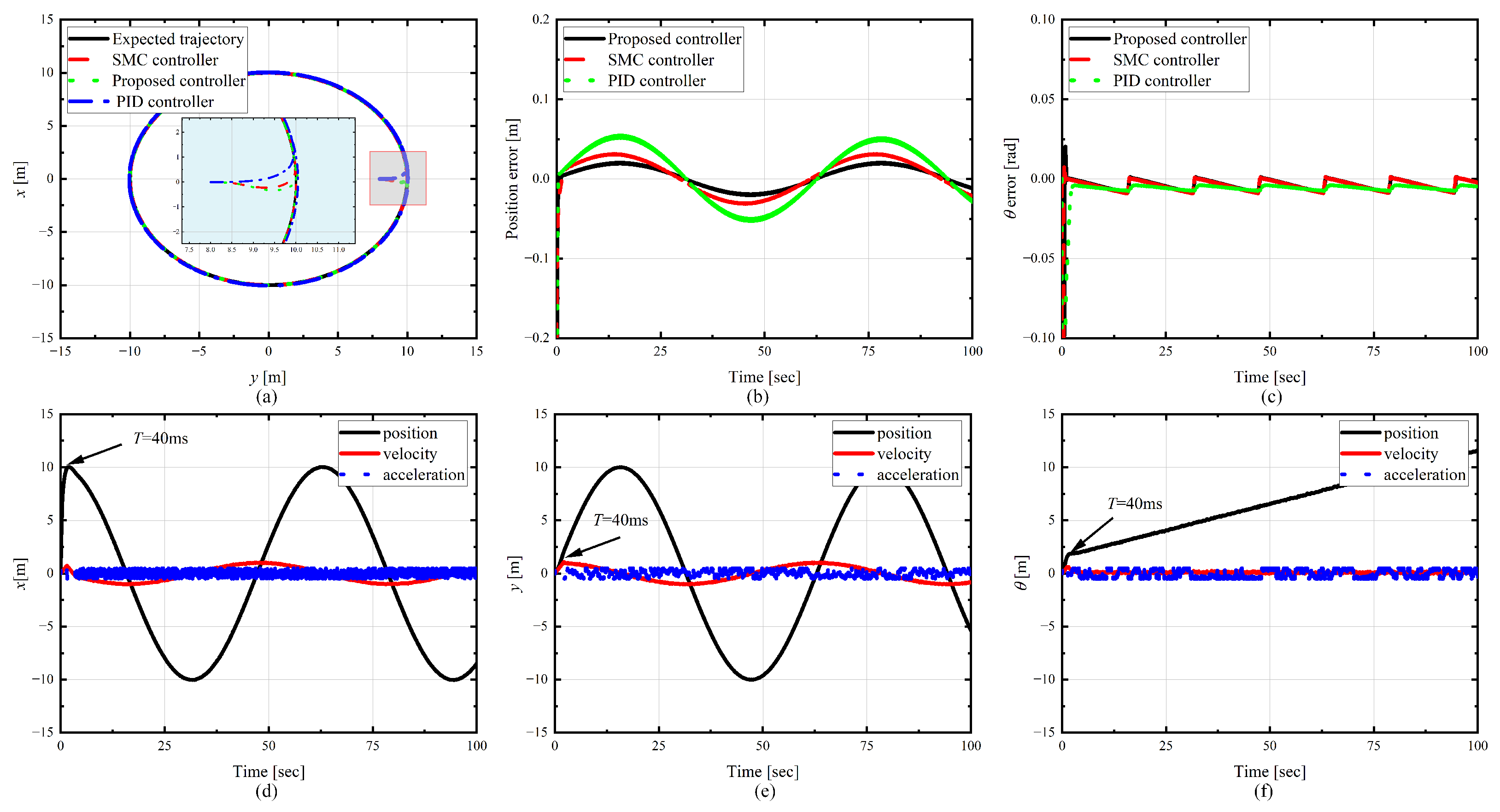

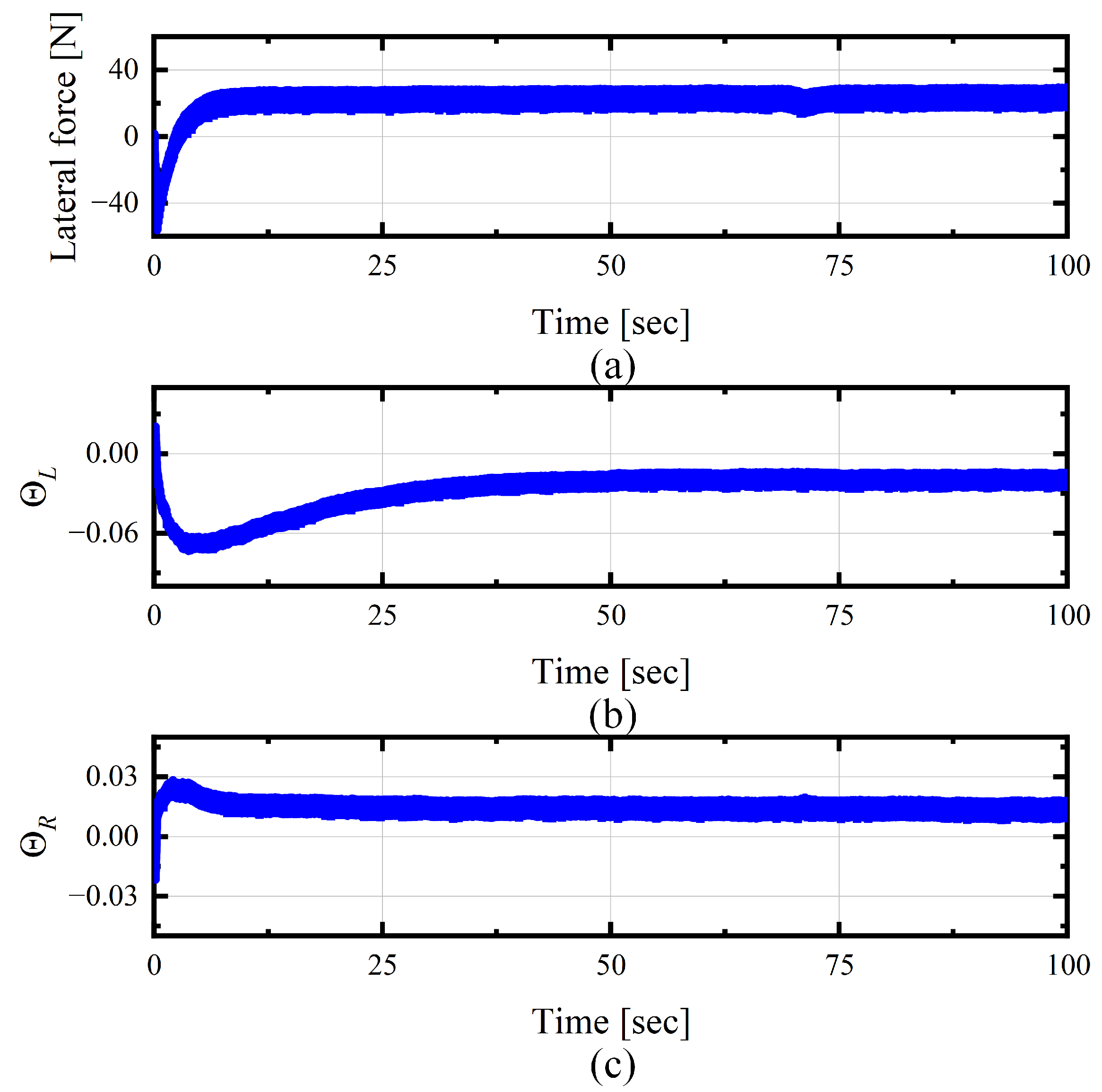

5. Experimental Verification

6. Conclusions

- 1.

- A kinematic and dynamic model of the TMV was created, considering side slip and track slip, and through parameter-dependent linearization, an LPV model was constructed that is suitable for controller design, laying the foundation for subsequent observer and controller design.

- 2.

- A distributed unknown input observer structure was created that decomposes high-dimensional observation tasks into four collaborating low-dimensional observers, reducing computational complexity, improving the estimation accuracy of states, disturbances, and faults, and proving the fixed-time convergence characteristics of the closed-loop system.

- 3.

- A fixed-time fault-tolerant controller was proposed based on a dual-power sliding mode surface. This controller combines nominal control, disturbance compensation, and sliding mode switching terms, ensuring system convergence within a finite and determined time under conditions of sensor faults and actuator efficiency degradation.

- 4.

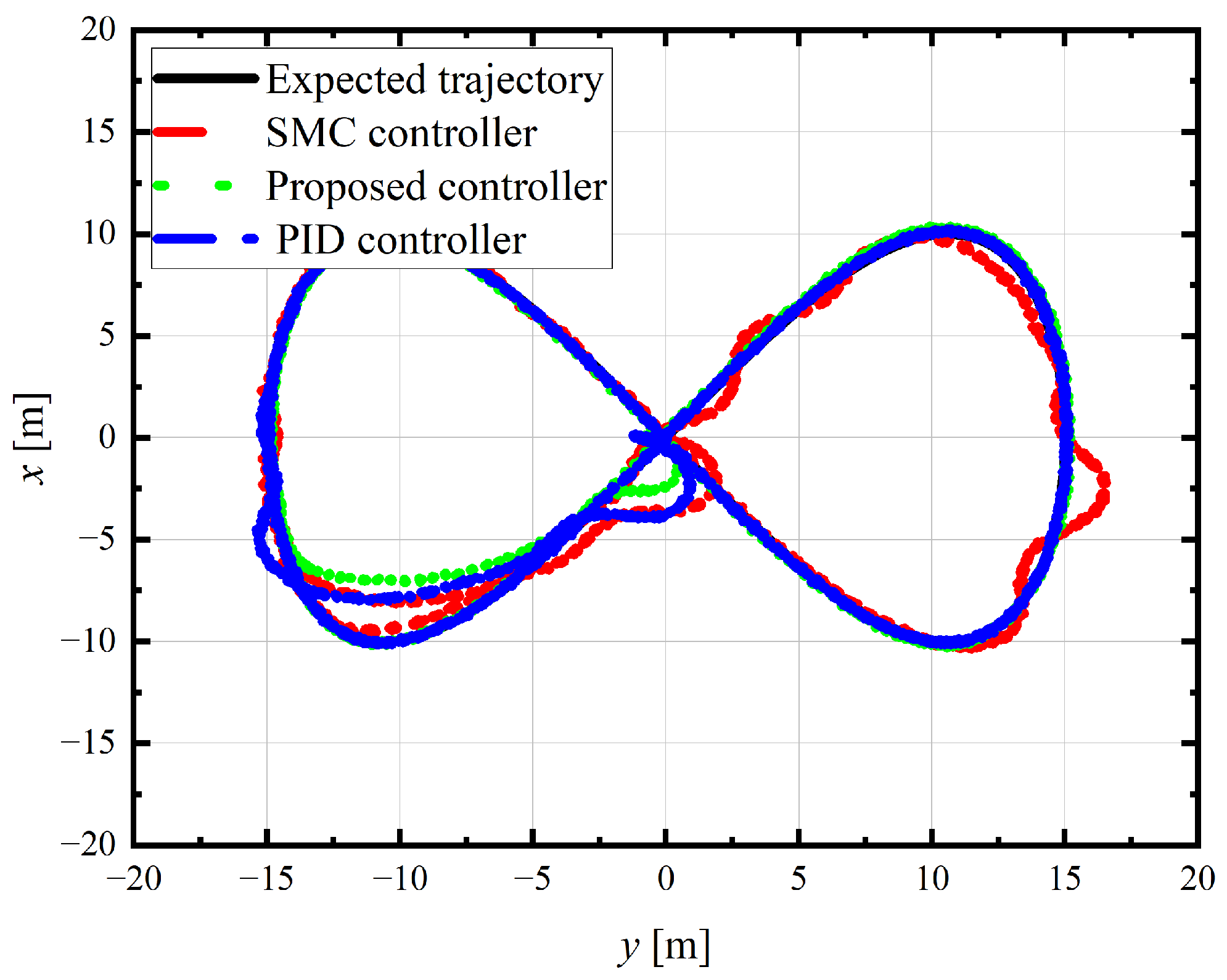

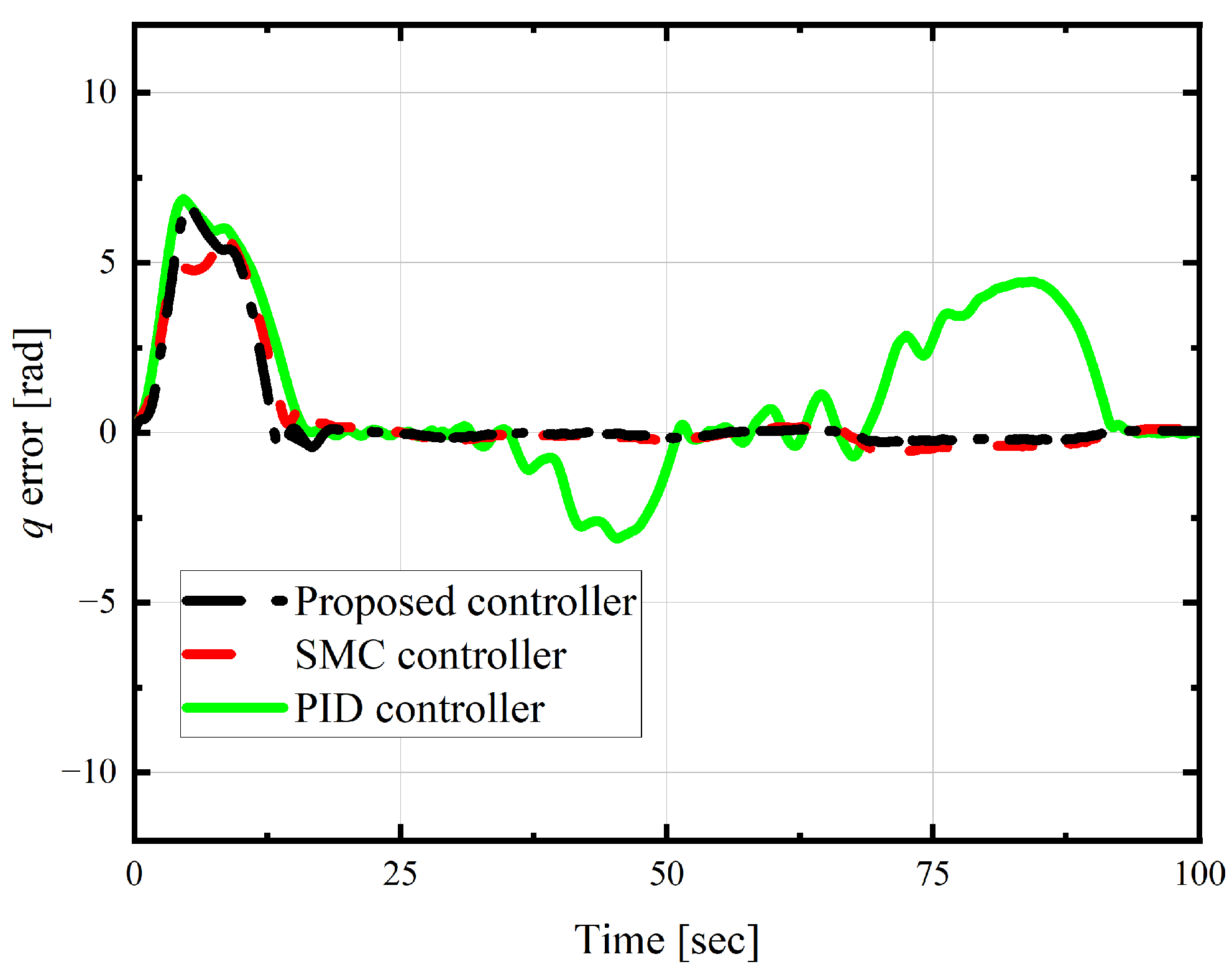

- The experimental results verified the effectiveness of the proposed scheme. Even in the presence of both sensor and actuator faults, the trajectory tracking error remained within 0.1 m, while the error of the PID controller exceeded 0.4 m, and the error of the SMC controller was about 0.2 m. The actuator fault observer could accurately estimate power loss factors, providing necessary compensation information for the controller.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Definition |

| Position coordinates and orientation angle in global frame | |

| Linear and angular velocities in body frame | |

| State vector | |

| Control input vector | |

| Left and right track slip rates | |

| Side slip angle | |

| External disturbance vector | |

| Sensor fault vector | |

| Actuator efficiency factor | |

| State and disturbance estimates | |

| Position and wheel speed sensor fault estimates | |

| Tracking error vector | |

| Controller sliding mode surface | |

| Nominal control, disturbance compensation, and sliding mode switching terms |

References

- Ye, F.; Su, Y. Research on modeling and control algorithm of self-balancing platform of spraying robot. J. Phys. Conf. Ser. 2023, 2437, 012109. [Google Scholar] [CrossRef]

- Du, G.; Zou, Y.; Zhang, X.; Guo, L.; Guo, N. Energy management for a hybrid electric vehicle based on prioritized deep reinforcement learning framework. Energy 2022, 241, 122523. [Google Scholar] [CrossRef]

- Febbraro, A.; Dutto, M.; Bascetta, L.; Ferretti, G. Object-oriented modelling of a tracked vehicle for agricultural applications. Comput. Electron. Agric. 2025, 230, 109921. [Google Scholar] [CrossRef]

- Zou, T.; Angeles, J.; Hassani, F. Dynamic modeling and trajectory tracking control of unmanned tracked vehicles. Robot. Auton. Syst. 2018, 110, 102–111. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.; Zou, W.; Zhang, H.; Zhou, B.; Xu, D. Dynamic modeling and learning based path tracking control for ROV-based deep-sea mining vehicle. Expert Syst. Appl. 2025, 262, 125612. [Google Scholar] [CrossRef]

- Cho, S.G.; Park, S.; Oh, J.; Min, C.; Kim, H.; Hong, S.; Jang, J.; Lee, T.H. Design optimization of deep-seabed pilot miner system with coupled relations between constraints. J. Terramechanics 2019, 83, 25–34. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, X.; Li, Y.; Zhang, X.; Liu, Y.; Zhang, X. Vehicle-following control based on deep reinforcement learning. Appl. Sci. 2022, 12, 10648. [Google Scholar] [CrossRef]

- Luo, H.; Duan, J.; Wang, G. Mathematical Models for Truck-Drone Routing Problem: Literature Review. Appl. Math. Model. 2025, 114, 116074. [Google Scholar] [CrossRef]

- Subari, M.A.; Hudha, K.; Kadir, Z.A.; Dardin, S.M.F.B.S.M.; Amer, N.H. Development of path tracking control of a tracked vehicle for an unmanned ground vehicle. Int. J. Adv. Mechatron. Syst. 2020, 8, 136–143. [Google Scholar] [CrossRef]

- Yang, J.; Wu, Y. Observer-based adaptive control for uncertain nonholonomic systems subject to time-varying function constraints on states. Nonlinear Dyn. 2024, 113, 10175–10190. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Sun, Q.; Chen, Y.; Al-Zahran, A. Adaptive robust control of unmanned tracked vehicles for trajectory tracking based on constraint modeling and analysis. Nonlinear Dyn. 2024, 112, 9117–9135. [Google Scholar] [CrossRef]

- Endo, D.; Okada, Y.; Nagatani, K.; Yoshida, K. Path following control for tracked vehicles based on slip-compensating odometry. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 2871–2876. [Google Scholar]

- Burke, M. Path-following control of a velocity constrained tracked vehicle incorporating adaptive slip estimation. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St Paul, MN, USA, 14–18 May 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 97–102. [Google Scholar]

- Kanayama, Y.; Kimura, Y.; Miyazaki, F.; Noguchi, T. A Stable Tracking Control Method for a Non-Holonomic Mobile Robot; IEEE: Osaka, Japan, 1991. [Google Scholar]

- Zhou, B.; Peng, Y.; Han, J. UKF based estimation and tracking control of nonholonomic mobile robots with slipping. In Proceedings of the 2007 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 15–18 December 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 2058–2063. [Google Scholar]

- Martínez, J.L.; Mandow, A.; Morales, J.; Garcia-Cerezo, A.; Pedraza, S. Kinematic modelling of tracked vehicles by experimental identification. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE Cat. No. 04CH37566), Sendai, Japan, 28 September–2 October 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 2, pp. 1487–1492. [Google Scholar]

- Balamurugan, S.; Srinivasan, R. Tracked vehicle performance evaluation using multi body dynamics. Def. Sci. J. 2017, 67, 476. [Google Scholar] [CrossRef]

- Sabiha, A.D.; Kamel, M.A.; Said, E.; Hussein, W.M. Dynamic modeling and optimized trajectory tracking control of an autonomous tracked vehicle via backstepping and sliding mode control. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2022, 236, 620–633. [Google Scholar] [CrossRef]

- Conejo, C.; Puig, V.; Morcego, B.; Navas, F.; Milanés, V. Enhancing safety in autonomous vehicles using zonotopic LPV-EKF for fault detection and isolation in state estimation. Control Eng. Pract. 2025, 156, 106192. [Google Scholar] [CrossRef]

- Dong, H.; Yu, H.; Xi, J. Phase portrait analysis and drifting control of unmanned tracked vehicles. IEEE Trans. Intell. Veh. 2024, 9, 5650–5664. [Google Scholar] [CrossRef]

- Li, Z.; Wang, W.; Zhang, C.; Zheng, Q.; Liu, L. Fault-tolerant control based on fractional sliding mode: Crawler plant protection robot. Comput. Electr. Eng. 2023, 105, 108527. [Google Scholar] [CrossRef]

- Fu, M.; Li, M.; Xie, W. Finite-time trajectory tracking fault-tolerant control for surface vessel based on time-varying sliding mode. IEEE Access 2017, 6, 2425–2433. [Google Scholar] [CrossRef]

- Gáspár, P.; Szabó, Z.; Bokor, J. LPV design of fault-tolerant control for road vehicles. In Proceedings of the 2010 Conference on Control and Fault-Tolerant Systems (SysTol), Nice, France, 6–8 October 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 807–812. [Google Scholar]

- Li, B.; Du, H.; Li, W. Fault-tolerant control of electric vehicles with in-wheel motors using actuator-grouping sliding mode controllers. Mech. Syst. Signal Process. 2016, 72, 462–485. [Google Scholar] [CrossRef]

- Dai, H.; Chen, P.; Yang, H. Metalearning-based fault-tolerant control for skid steering vehicles under actuator fault conditions. Sensors 2022, 22, 845. [Google Scholar] [CrossRef]

- Xi, Z.J.; Hong, Y.G. Fault-Tolerant Fixed-Time Trajectory Tracking Control of Autonomous Surface Vessels with Specified Accuracy. IEEE Trans. Ind. Electron. 2020, 67, 4889–4899. [Google Scholar]

- Geng, K.; Chulin, N.A.; Wang, Z. Fault-tolerant model predictive control algorithm for path tracking of autonomous vehicle. Sensors 2020, 20, 4245. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.Y. Theory of Ground Vehicles; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Zhu, Y.; Xu, Z. A method of LPV model identification for control. IFAC Proc. Vol. 2008, 41, 5018–5023. [Google Scholar] [CrossRef]

- Chen, M.; Wang, H.; Liu, X. Adaptive fuzzy practical fixed-time tracking control of nonlinear systems. IEEE Trans. Fuzzy Syst. 2019, 29, 664–673. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Q.; Chen, G.; Wu, Z. Sliding mode fault-tolerant control for nonlinear high-order fully actuated systems. IEEE Trans. Cybern. 2024, 55, 184–193. [Google Scholar] [CrossRef]

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control 2003, 76, 924–941. [Google Scholar] [CrossRef]

- Hunter, S.K.; Pereira, H.M.; Keenan, K.G. The aging neuromuscular system and motor performance. J. Appl. Physiol. 2016, 121, 982–995. [Google Scholar] [CrossRef]

- Yan, X.; Wang, S.; He, Y.; Ma, A.; Zhao, S. Autonomous Tracked Vehicle Trajectory Tracking Control Based on Disturbance Observation and Sliding Mode Control. Actuators 2025, 14, 51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Wang, D.; Ma, A.; Zheng, W.; Zhao, S. Global Fixed-Time Fault-Tolerant Control for Tracked Vehicles with Hierarchical Unknown Input Observers. Actuators 2025, 14, 330. https://doi.org/10.3390/act14070330

Yan X, Wang D, Ma A, Zheng W, Zhao S. Global Fixed-Time Fault-Tolerant Control for Tracked Vehicles with Hierarchical Unknown Input Observers. Actuators. 2025; 14(7):330. https://doi.org/10.3390/act14070330

Chicago/Turabian StyleYan, Xihao, Dongjie Wang, Aixiang Ma, Weixiong Zheng, and Sihai Zhao. 2025. "Global Fixed-Time Fault-Tolerant Control for Tracked Vehicles with Hierarchical Unknown Input Observers" Actuators 14, no. 7: 330. https://doi.org/10.3390/act14070330

APA StyleYan, X., Wang, D., Ma, A., Zheng, W., & Zhao, S. (2025). Global Fixed-Time Fault-Tolerant Control for Tracked Vehicles with Hierarchical Unknown Input Observers. Actuators, 14(7), 330. https://doi.org/10.3390/act14070330