Dynamic Modeling and Analysis of Industrial Robots for Enhanced Manufacturing Precision

Abstract

1. Introduction

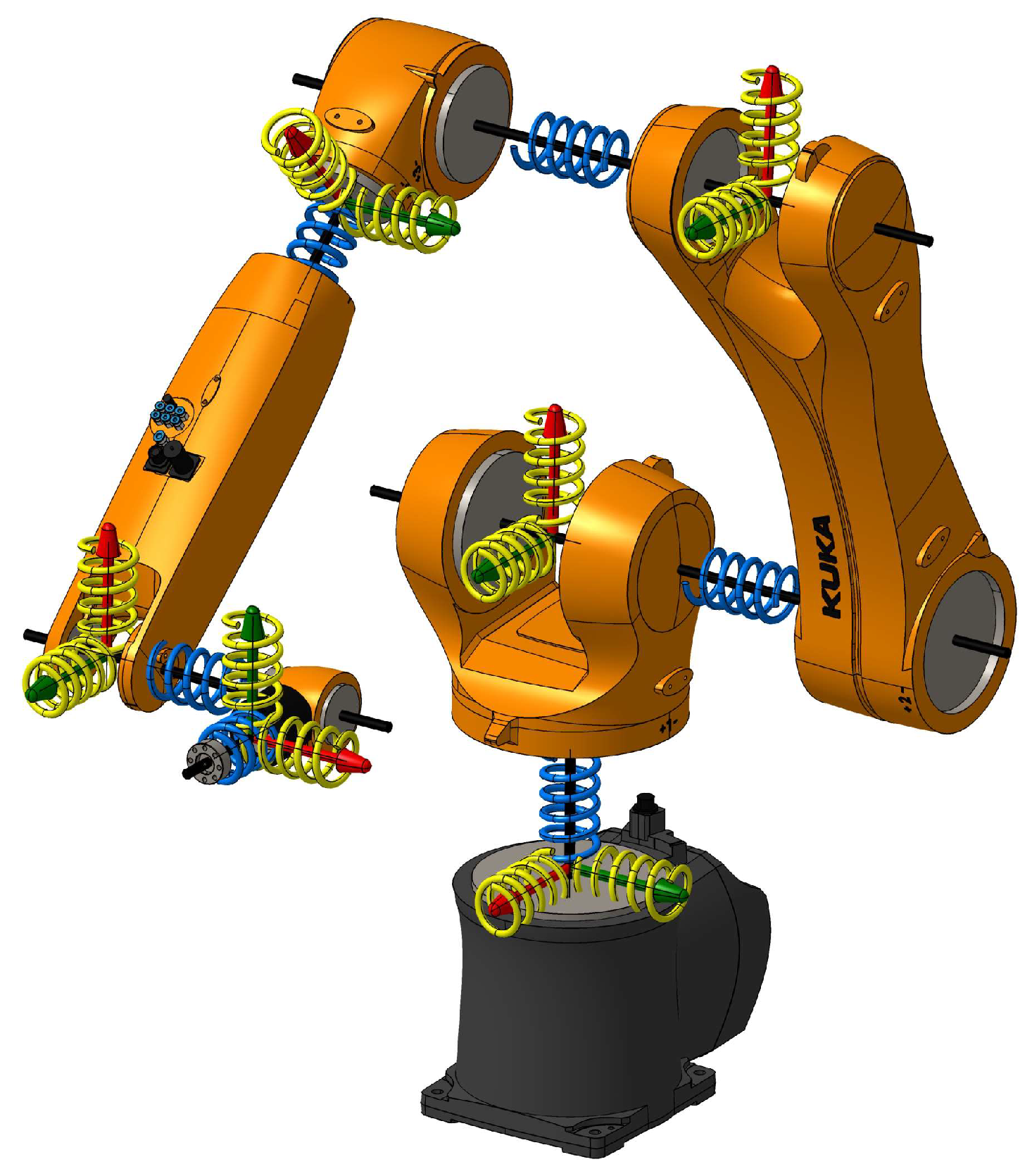

- Develop two distinct dynamic simulation models of a KUKA KR10 industrial robot in Matlab/Simscape Multibody: a 12-parameter model (12P) with only rotational joint compliance and a 24-parameter model (24P) including both rotational and effective transverse joint compliance.

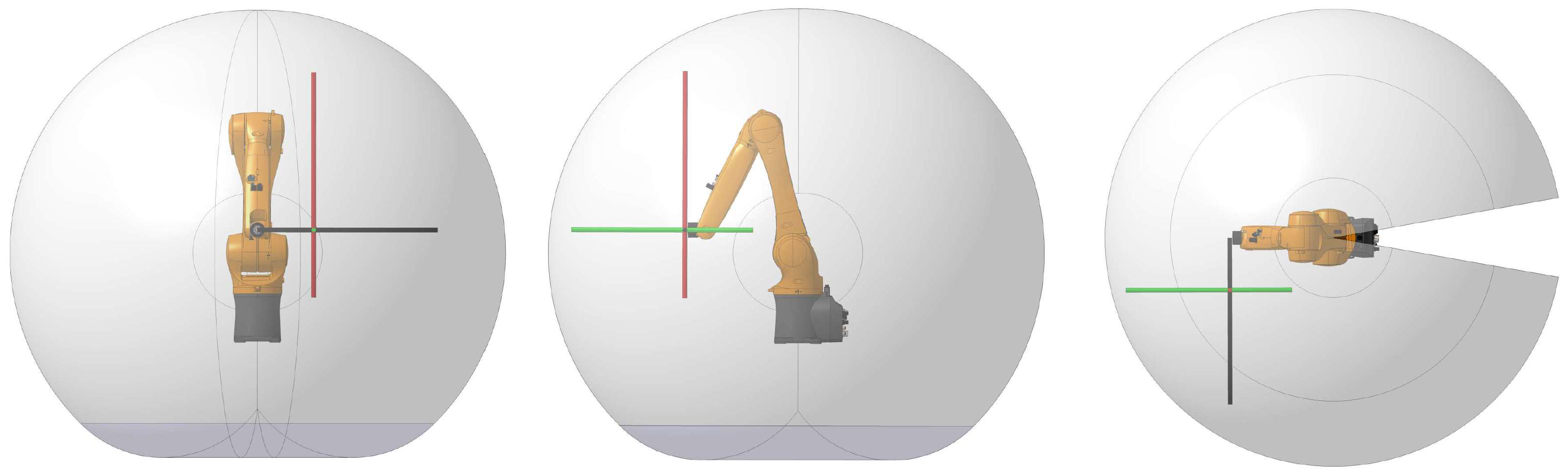

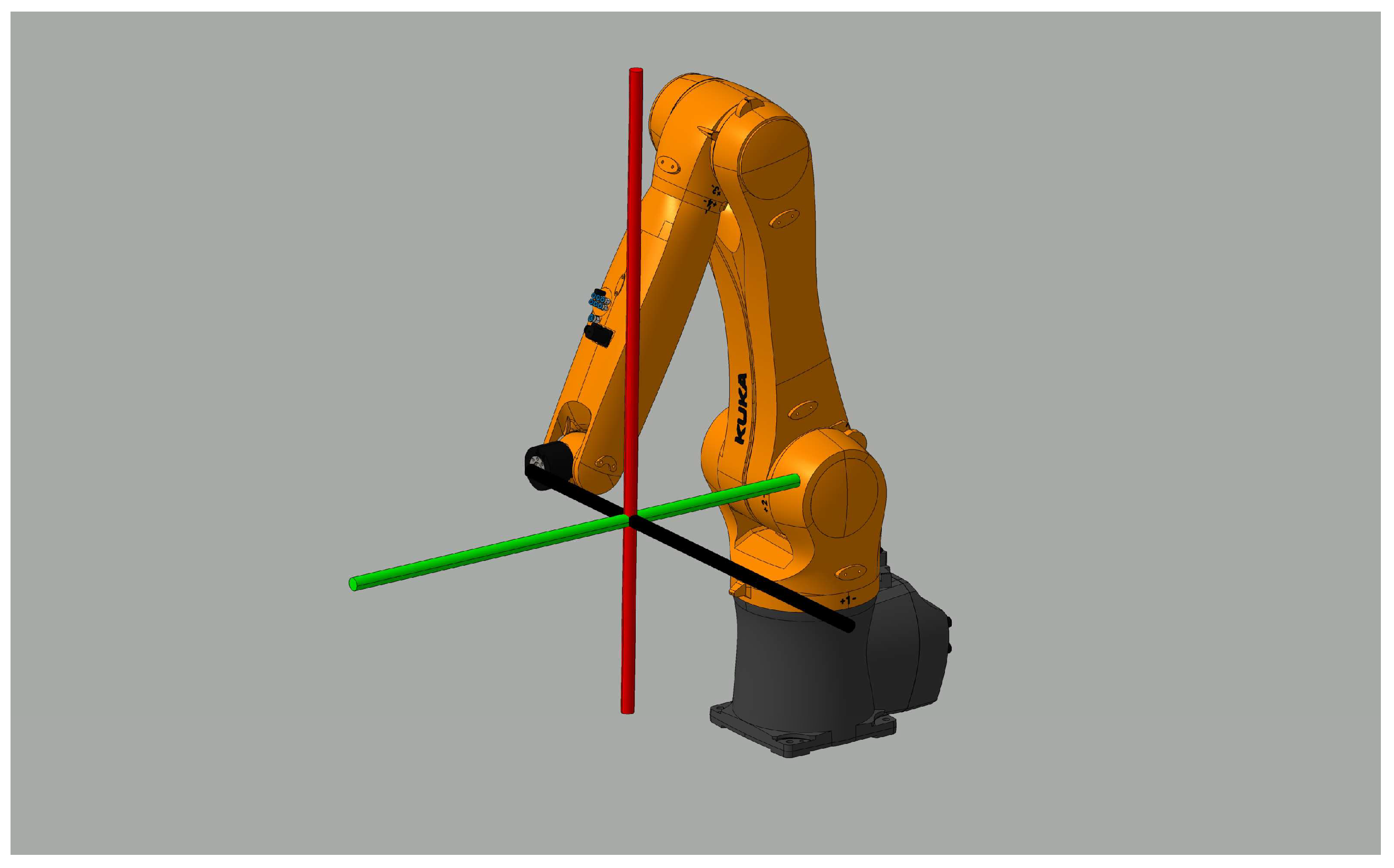

- Implement and validate a comprehensive experimental methodology using EMA (impulse hammer excitation, triaxial acceleration measurement) to acquire a rich dataset of FRFs across the robot’s workspace.

- Identify the parameters of both the 12P and 24P models using Genetic Algorithm (GA) optimization, minimizing the discrepancy between simulated and measured FRFs based on FRAC and RMSE metrics.

- Quantitatively compare the performance, accuracy, and generalizability of the identified 12P and 24P models, with a particular focus on the dynamics below 200 Hz relevant to precision manufacturing.

2. Materials and Methods

2.1. Experimental Setup

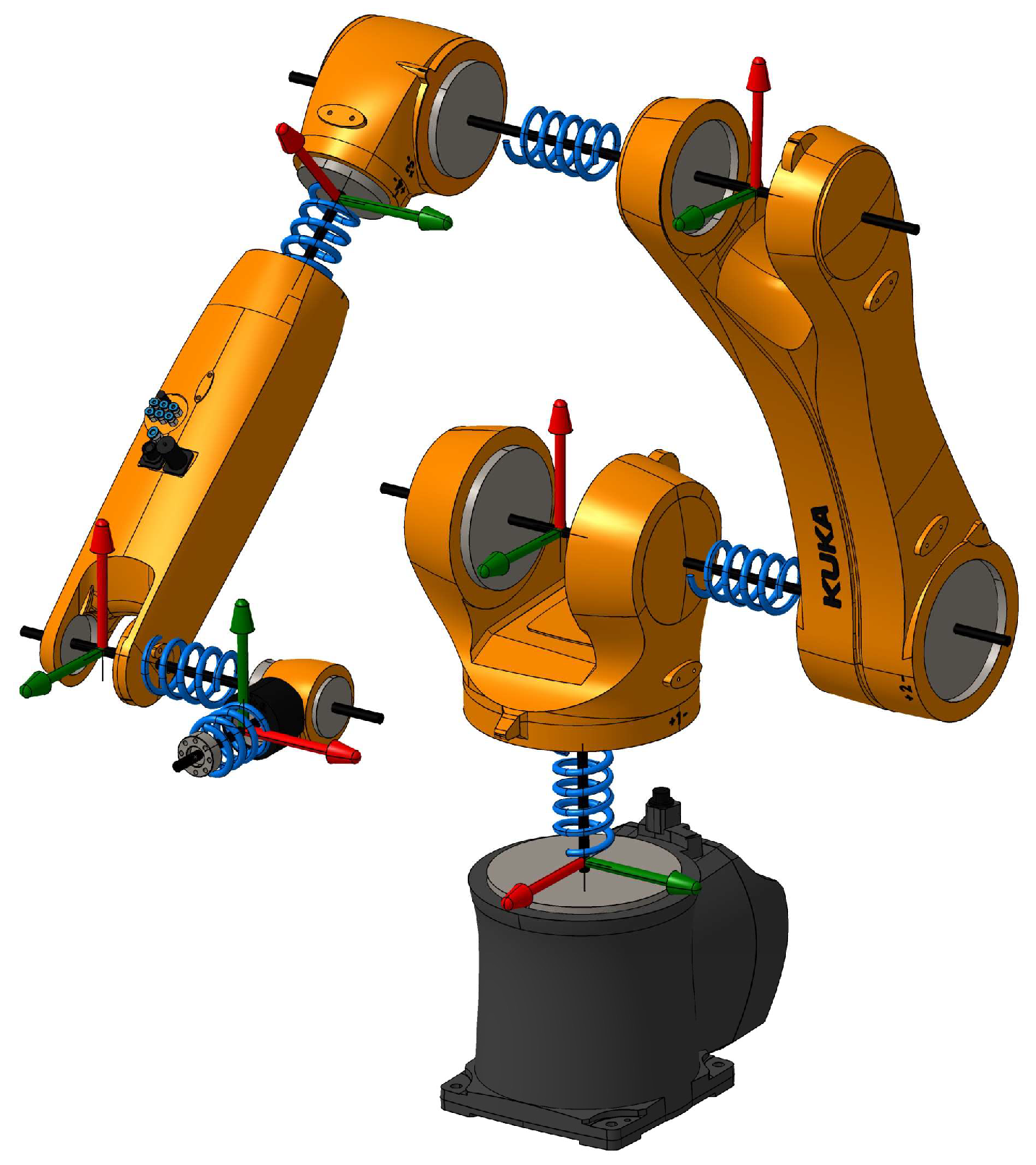

2.2. Dynamic Modeling Approach

2.3. Genetic Algorithm Optimization

2.4. Evaluation Metrics

2.4.1. Global FRAC (Frequency Response Assurance Criterion)

2.4.2. Frobenius Similarity

2.5. Data Processing

- Signal Preprocessing: Raw time signals (force and acceleration) were initially processed using OROS Modal 2 software (for experimental data). Key parameters included the 640 ms signal duration and −30 ms pre-trigger time.

- FFT Calculation and Windowing: Fast Fourier Transform (FFT) was applied to convert time domain signals to the frequency domain. Standard practice for impact testing involves applying windowing functions to minimize spectral leakage caused by the finite signal duration [15]. Specifically, a force window (implicitly rectangular in this work, applied to the hammer impact signal) and an exponential window (with 25% decay over the window length, applied to the acceleration response signal) were used prior to the FFT. This combination is known to improve the quality of FRF estimates by reducing noise and leakage effects [27].

- FRF Calculation: The H1 estimator was employed to compute the FRFs (acceleration/force). The H1 estimator is commonly used in modal analysis and is known to minimize the influence of noise on the output (acceleration) measurement [15].

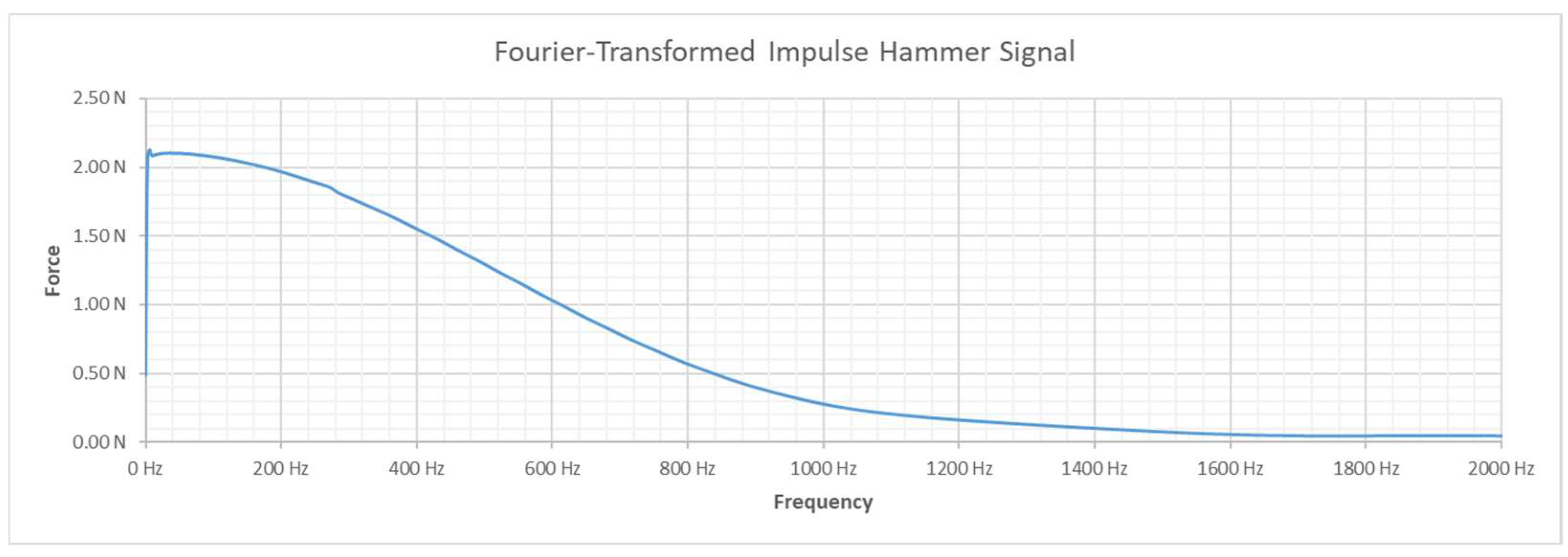

- Frequency Limitation: The analysis was conducted over two frequency ranges: the “full” range (0–800 Hz), corresponding roughly to the effective excitation bandwidth (Figure 4), and a “limited” range (0–200 Hz), selected as being most relevant to the dynamics affecting precision in typical manufacturing operations.

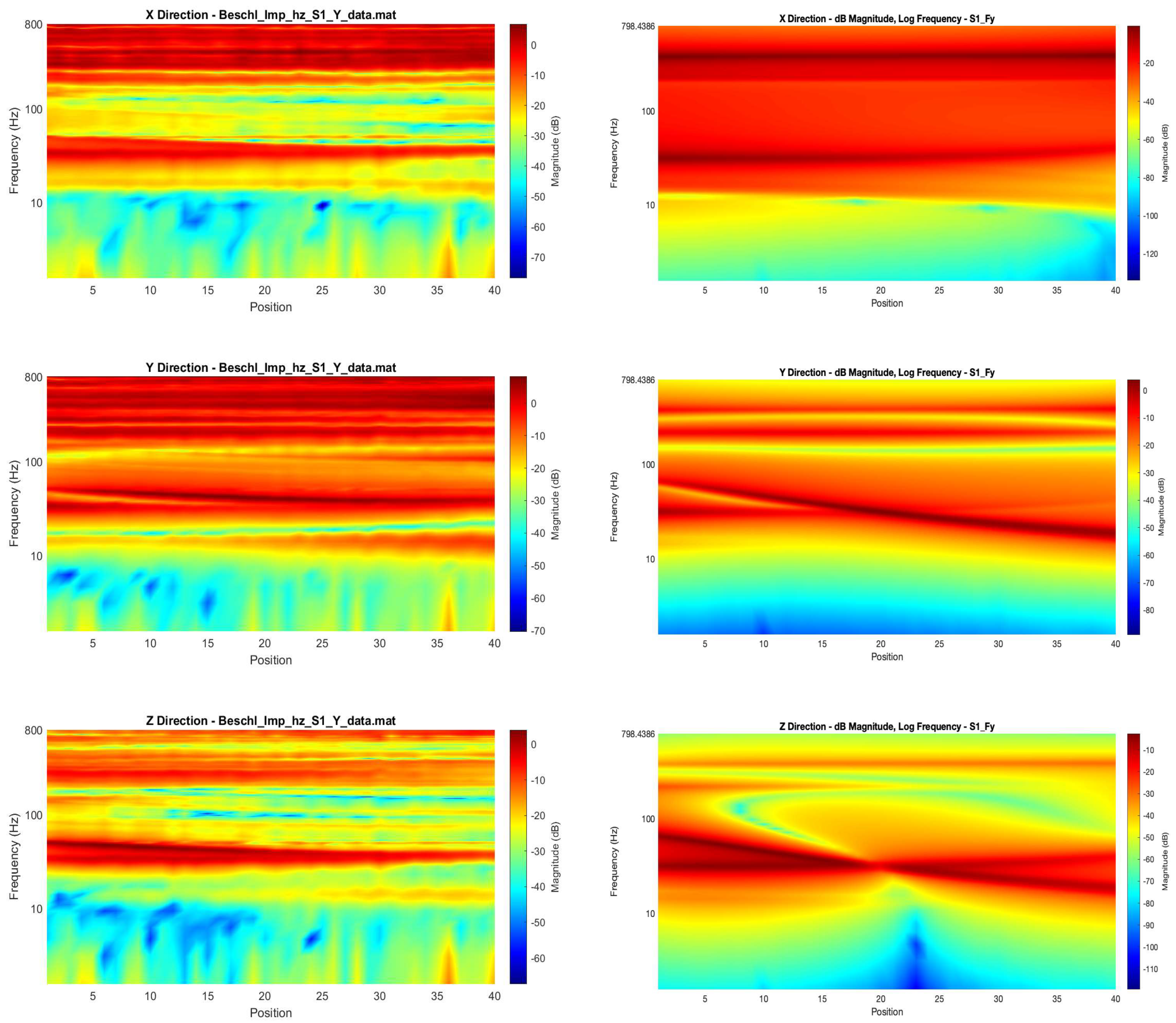

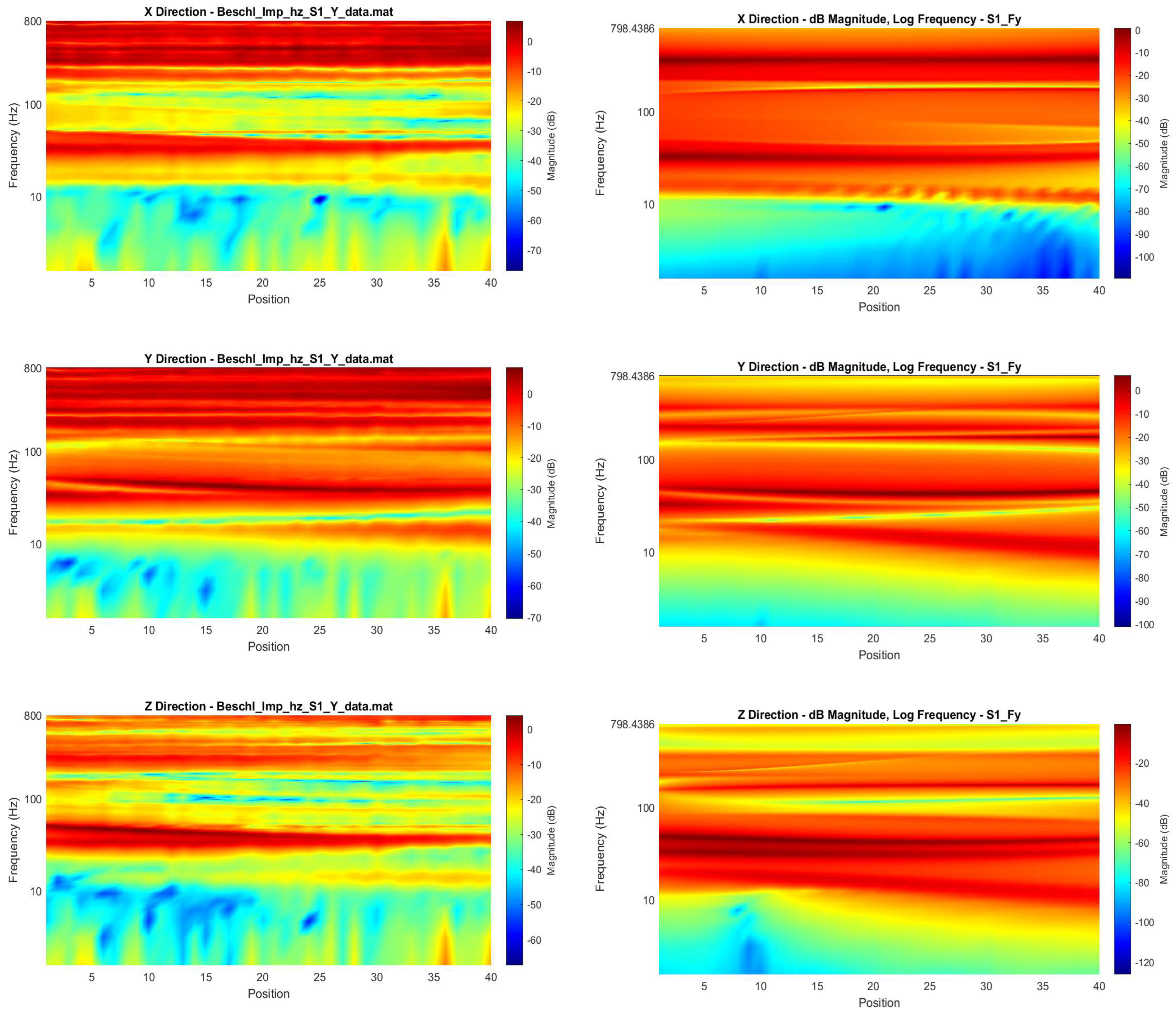

- Campbell Diagram Generation: To visualize pose-dependent dynamic behavior, FRF data was organized into Campbell diagrams [28,29]. These plots display the FRF magnitude (often in dB) as a function of frequency and measurement position along a path, providing a clear view of how resonances shift and change amplitude with robot configuration.

3. Results

3.1. Model Performance

- The 24P model, incorporating transverse joint compliance, significantly outperforms the 12P model across both metrics and both frequency ranges. The improvement is particularly pronounced in the limited frequency range.

- Both models achieve substantially better performance when evaluated only within the limited frequency range (≤200 Hz), indicating that the models capture the lower-frequency dynamics, most relevant for manufacturing precision, more effectively than the higher-frequency behavior.

- Global FRAC scores are consistently higher than Frobenius similarity scores for both models. This suggests that the models are generally better at predicting the shape and frequency locations of the dynamic response (captured by FRAC) than the precise amplitudes of the FRF peaks and valleys (reflected in Frobenius similarity). This discrepancy might point towards limitations in modeling damping accurately or the presence of unmodeled nonlinear amplitude-dependent effects.

3.2. Campbell Diagram Analysis

- The 12P model simulation (Figure 8) captures some of the very low-frequency behavior but fails to accurately replicate the number, location, and pose-dependent shifting of most resonances observed in the measurements, particularly in the 50–200 Hz range. The predicted patterns differ substantially from the measured ones.

- The 24P model simulation (Figure 9) demonstrates significantly better agreement with the measured data. It successfully predicts the presence and approximate location of the major resonances below ~100–200 Hz. Crucially, it also captures the characteristic pose-dependency—how the frequencies and magnitudes of these resonances evolve along the path—much more accurately than the 12P model. For instance, the diagonal resonance pattern clearly visible in the measured Y direction response (Figure 8) between ~30 Hz and ~80 Hz is well-replicated by the 24P model (Figure 9).

- Above approximately 200 Hz, the agreement between the 24P simulation and the measurement deteriorates, and both models struggle to capture the complexity of the higher-frequency dynamics.

3.3. Optimized Parameters

- Damping parameters (, ) tend to show relatively more variability or proximity to their bounds compared to stiffness parameters (, ). This might reflect greater difficulty in identifying damping accurately from FRF data or suggest that the simple linear viscous damping model is less representative than the linear stiffness model.

- Crucially, in the 24P model (Table 7), the identified transverse stiffness values () are consistently and significantly larger than the corresponding rotational stiffness values () for each joint. This aligns with physical expectations and literature suggesting that joints are typically much stiffer with respect to forces/moments perpendicular to their primary axis of rotation [23].

3.4. Generalizability Analysis

4. Discussion

4.1. Model Performance Interpretation

4.2. Methodological Contributions

- Detailed Experimentation: Demonstrating a systematic and comprehensive experimental procedure for acquiring FRF data across a large portion of a robot’s workspace using standard EMA tools (impulse hammer, triaxial accelerometer). The multi-path, multi-direction measurement strategy ensures thorough dynamic characterization. The justification for specific choices, such as wax mounting [19,20] and windowing functions [27], based on established best practices [15] enhances the rigor and reproducibility of the experimental phase.

- Comparative Modeling: Quantitatively evaluating the impact of increased joint model dimensionality (12P vs. 24P) on simulation accuracy within the same Simscape Multibody framework, clearly demonstrating the substantial benefits of the higher-dimensional 24P model for this class of robot.

- Robust Parameter Identification: Showcasing the application of Genetic Algorithms for identifying parameters in complex, nonlinearizable multi-body dynamic models using frequency-domain data. The use of a tailored initial population strategy (“lhs_and_similarity”, including LHS [24] and damper restriction) and objective functions based on weighted FRF comparison metrics (FRAC, RMSE) proved effective. Notably, the successful identification and subsequent generalization achieved using only a small, representative subset of the available data (9 out of 120 positions) for optimization highlights an efficient approach to parameter identification when faced with computationally expensive simulations. This suggests that, with careful selection, a limited experimental dataset can be sufficient to capture the essential dynamics for model parameterization, mitigating the prohibitive computational cost of using the full dataset during optimization.

4.3. Limitations

- High-Frequency Accuracy: The model fidelity significantly decreases above approximately 100–200 Hz due to the simplifying assumptions made.

- Nonlinear Effects: The models employ linear spring-damper elements for joint compliance. They do not explicitly account for the known nonlinear stiffness, hysteresis, and complex friction characteristics of Harmonic Drives [31], nor potential backlash or general joint friction nonlinearities. These omissions likely contribute to discrepancies, especially under conditions involving high loads, rapid direction reversals, or very small motions where such effects are prominent.

- Rigid Links: While justified for the target frequency range, neglecting link flexibility limits accuracy at frequencies approaching or exceeding the natural frequencies of the links themselves (~300 Hz and above). Tasks involving very high accelerations or impacts might excite these modes.

- Linear Parameterization: The fundamental representation of joints using linear springs and dampers is an approximation of the likely more complex, potentially nonlinear, physical behavior.

- Computational Cost: Optimization of the 24P model remains computationally expensive (Table 3), potentially limiting the feasibility of exploring even more complex models (e.g., fully nonlinear joints or flexible links) or performing exhaustive sensitivity analyses.

- Parameter Identifiability: While GA explores the search space broadly, guaranteeing that the identified parameters represent the unique global optimum for such complex models is challenging. However, the consistency of the results (e.g., , ) and the good generalization performance provide confidence in the identified solution.

4.4. Practical Implications:

- Improved Simulation Fidelity: More accurate models enable more reliable virtual commissioning, offline programming, and simulation-based process planning, reducing the need for costly physical trials and debugging on the actual robot.

- Enhanced Precision Task Performance: By predicting dynamic behavior (vibrations, deflections) more accurately, these models can be used to optimize trajectories, select process parameters (e.g., cutting speeds/feeds in robotic milling [5]), or design compensation strategies to improve path accuracy and surface finish in precision manufacturing tasks.

- Model-Based Control: Accurate dynamic models form the foundation for advanced model-based control algorithms aimed at actively compensating for vibrations or improving trajectory tracking performance, potentially enabling robots to perform tasks currently beyond their capabilities [7].

- Optimized Workcell Design: Simulations incorporating accurate robot dynamics can facilitate better design of robot workcells, tooling, and fixtures by predicting dynamic interactions between the robot and its environment, potentially avoiding unforeseen vibration issues.

5. Conclusions

- Incorporating nonlinear joint models, specifically targeting the known characteristics of Harmonic Drives such as nonlinear stiffness and hysteresis, potentially using advanced system identification techniques or component-level models.

- Including link flexibility through flexible multibody dynamics (FMBD) techniques, using model order reduction methods to maintain computational tractability.

- Investigating optimized experimental designs to determine the minimum number and optimal placement of measurement points and excitation directions required to reliably identify parameters for complex models, further improving the efficiency of the characterization process.

- Employing an analytical dynamic model as a surrogate to guide parameter searches and to ensure globally optimal solutions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EMA | Experimental Modal Analysis |

| FRAC | Frequency Response Assurance Criterion |

| FRF | Frequency Response Function |

| GA | Genetic Algorithm |

| HD | Harmonic Drive |

| ICP | Integrated Circuit Piezoelectric (refers to accelerometer type) |

| LHS | Latin Hypercube Sampling |

| RMSE | Root Mean Square Error |

| TCP | Tool Center Point |

| 12P | 12-Parameter (Model) |

| 24P | 24-Parameter (Model) |

Appendix A

Appendix B

Appendix B.1. Global FRAC-Position-Wise Averaged Vector Correlation

Appendix B.2. Frobenius Norm Similarity

References

- Siciliano, B.; Khatib, O. (Eds.) Springer Handbook of Robotics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Craig, J.J. Introduction to Robotics: Mechanics and Control, 4th ed.; Pearson: London, UK, 2017; ISBN 978-0133489798. [Google Scholar]

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control, 2nd ed.; Wiley: Hoboken, NJ, USA, 2020; ISBN 978-1119523994. [Google Scholar]

- Wu, K.; Kuhlenkötter, B. Experimental Analysis of the Dynamic Stiffness in Industrial Robots. Appl. Sci. 2020, 10, 8332. [Google Scholar] [CrossRef]

- Mejri, S.; Gagnol, V.; Le, T.P.; Sabourin, L.; Ray, P.; Paultre, P. Dynamic characterization of machining robot and stability analysis. Int. J. Adv. Manuf. Technol. 2016, 82, 351–359. [Google Scholar] [CrossRef]

- Swevers, J.; Verdonck, W.; De Schutter, J. Dynamic Model Identification for Industrial Robots. IEEE Control. Syst. Mag. 2007, 27, 58–71. [Google Scholar] [CrossRef]

- Albu-Schäffer, A.; Ott, C.; Hirzinger, G. A Unified Passivity-based Control Framework for Position, Torque and Impedance Control of Flexible Joint Robots. Int. J. Robot. Res. 2007, 26, 23–39. [Google Scholar] [CrossRef]

- Harmonic Drive SE. Products. Available online: https://harmonicdrive.de/de/produkte (accessed on 15 May 2024).

- Rhéaume, F.-E.; Champliaud, H.; Liu, Z. Understanding and modelling the torsional stiffness of harmonic drives through finite-element method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 515–524. [Google Scholar] [CrossRef]

- Karim, A.; Hitzer, J.; Lechler, A.; Verl, A. Analysis of the dynamic behavior of a six-axis industrial robot within the entire workspace in respect of machining tasks. Int. J. Adv. Manuf. Technol. 2020, 108, 1–17. [Google Scholar] [CrossRef]

- Wernholt, E.; Gunnarsson, S. Frequency-Domain Gray-Box Identification of Industrial Robots. In Proceedings of the 17th IFAC World Congress, Seoul, Republic of Korea, 6–11 July 2008; Volume 41, Issue 2. pp. 15–20. [Google Scholar] [CrossRef]

- Huynh, H.N.; Verlinden, O. Direct method for updating flexible multibody systems applied to a milling robot. Robot. Comput.-Integr. Manuf. 2021, 68, 102049. [Google Scholar] [CrossRef]

- Wu, K.; Li, J.; Zhao, H.; Zhong, Y. Review of Industrial Robot Stiffness Identification and Modelling. Appl. Sci. 2022, 12, 8719. [Google Scholar] [CrossRef]

- Wernholt, E.; Gunnarsson, S. Nonlinear Identification of a Physically Parameterized Robot Model. In Proceedings of the 16th IFAC Symposium on System Identification, Newcastle, Australia, 29–31 March 2006; Volume 39, Issue 1. pp. 143–148. [Google Scholar] [CrossRef]

- Ewins, D.J. Modal Testing: Theory, Practice and Application, 2nd ed.; Research Studies Press: Baldock, UK, 2000; ISBN 978-0-863-80218-8. [Google Scholar]

- Karim, A.; Schmid, M.; Verl, A.; Hitzer, J. Autonomous modal analysis method for industrial robots based on output-only measurements. Sci. Rep. 2024, 14, 21657. [Google Scholar] [CrossRef]

- Moberg, S.; Ohr, J.; Gunnarsson, S. A Benchmark Problem for Robust Feedback Control of a Flexible Manipulator. IEEE Trans. Control. Syst. Technol. 2009, 17, 1398–1405. [Google Scholar] [CrossRef]

- Abele, E.; Rothenbücher, S.; Weigold, M. Cartesian Compliance Model for Industrial Robots Using Virtual Joints. Prod. Eng. Res. Dev. 2008, 2, 339–343. [Google Scholar] [CrossRef]

- PCB Piezotronics, Inc. Model 356A45 Miniature Triaxial ICP® Accelerometer Specification Sheet. Available online: https://www.pcb.com/products?m=356a45 (accessed on 15 May 2024).

- Avitabile, P. Modal Testing: A Practitioner’s Guide; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization and Machine Learning; Addison-Wesley: Boston, MA, USA, 1989; ISBN 978-0-201-15767-3. [Google Scholar]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley: Chichester, UK, 2001; ISBN 978-0-471-87339-6. [Google Scholar]

- Nubla, M.M.; Feng, L.; Menq, C.H. Joint stiffness identification of six-revolute industrial serial robots. Robot. Comput.-Integr. Manuf. 2011, 27, 947–956. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. A Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics 1979, 21, 239–245. [Google Scholar] [CrossRef]

- Allemang, R.J. The Modal Assurance Criterion—Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–21. [Google Scholar]

- Golub, G.H.; Van Loan, C.F. Matrix Computations, 4th ed.; Johns Hopkins University Press: Baltimore, MD, USA, 2013; ISBN 978-1-4214-0794-4. [Google Scholar]

- Wang, M.Q.; Wang, Y. Unbiased expression of FRF with exponential window function in impact hammer testing. J. Sound Vib. 2004, 271, 1147–1155. [Google Scholar] [CrossRef]

- Rao, S.S. Mechanical Vibrations, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010; ISBN 978-0-13-212819-3. [Google Scholar]

- Berninger, T. Evaluation of an External Vibration Damping Approach for Robot Manipulators Using a Flexible Multi Body Simulation. In Proceedings of the 2019 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Hong Kong, China, 8–12 July 2019. [Google Scholar] [CrossRef]

- Li, Y.; Gao, G.; Na, J.; Xing, Y. Error Sensitivity Flexibility Compensation of Joints for Improving the Positioning Accuracy of Industrial Robots. IEEE Trans. Autom. Sci. Eng. 2025, 22, 5335–5348. [Google Scholar] [CrossRef]

- Zhang, H.; Ahmad, S.; Liu, G. Torque Estimation for Robotic Joint with Harmonic Drive Transmission Based on Position Measurements. IEEE Trans. Robot. 2015, 31, 322–330. [Google Scholar] [CrossRef]

| Axis | Parameter | Lower Bound | Upper Bound |

|---|---|---|---|

| 1 | 500 Nm/deg | 5000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 2 | 500 Nm/deg | 5000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 3 | 250 Nm/deg | 3000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 4 | 100 Nm/deg | 1500 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 5 | 30 Nm/deg | 1000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 6 | 30 Nm/deg | 1000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) |

| Axis | Parameter | Lower Bound | Upper Bound |

| 1 | 500 Nm/deg | 5000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 2500 Nm/deg | 80,000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 2 | 500 Nm/deg | 5000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 2500 Nm/deg | 80,000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 3 | 250 Nm/deg | 3000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 1250 Nm/deg | 40,000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 4 | 100 Nm/deg | 1500 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 500 Nm/deg | 5000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 5 | 30 Nm/deg | 1000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 150 Nm/deg | 12,000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 6 | 30 Nm/deg | 1000 Nm/deg | |

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) | ||

| 150 Nm/deg | 12,000 Nm/deg | ||

| 0.0001 Nm/(deg/s) | 0.7 Nm/(deg/s) |

| Model | One Position One Force Direction | One Position Three Force Directions | Three Positions Three Force Directions | Nine Positions Three Force Directions |

|---|---|---|---|---|

| 12P | 2 h 18 min | 6 h 54 min | 20 h 42 min | 62 h 8 min |

| 24P | 3 h 44 min | 11 h 11 min | 33 h 24 min | 100 h 43 min |

| Model | Metric | Full Range (0–800 Hz) | Limited Range (≤200 Hz) |

|---|---|---|---|

| 12P | Global FRAC | 22.6% | 40.8% |

| Frobenius Similarity | 5.0% | 19.13% | |

| 24P | Global FRAC | 36.9% | 70.5% |

| Frobenius Similarity | 11.51% | 44.9% |

| Model | Path Group | Global FRAC | Frobenius Similarity |

|---|---|---|---|

| 12P | S1 | 41.8% | 19.6% |

| S2 | 46.7% | 22.3% | |

| S3 | 33.9% | 15.6% | |

| 24P | S1 | 75.0% | 48.9% |

| S2 | 70.1% | 44.2% | |

| S3 | 66.2% | 41.7% |

| Axis | ||

|---|---|---|

| 1 | 1962.5 Nm/deg | 0.55 Nm/(deg/s) |

| 2 | 765.2 Nm/deg | 0.553 Nm/(deg/s) |

| 3 | 789.5 Nm/deg | 0.523 Nm/(deg/s) |

| 4 | 577.3 Nm/deg | 0.059 Nm/(deg/s) |

| 5 | 232.0 Nm/deg | 0.012 Nm/(deg/s) |

| 6 | 268.4 Nm/deg | 0.258 Nm/(deg/s) |

| Axis | ||||

|---|---|---|---|---|

| 1 | 881.7 Nm/deg | 0.316 Nm/(deg/s) | 5500.9 Nm/deg | 0.204 Nm/(deg/s) |

| 2 | 1503.8 Nm/deg | 0.457 Nm/(deg/s) | 22,403.9 Nm/deg | 0.029 Nm/(deg/s) |

| 3 | 896.7 Nm/deg | 0.468 Nm/(deg/s) | 10,884.6 Nm/deg | 0.235 Nm/(deg/s) |

| 4 | 600.8 Nm/deg | 0.045 Nm/(deg/s) | 10,358.5 Nm/deg | 0.118 Nm/(deg/s) |

| 5 | 208.8 Nm/deg | 0.01 Nm/(deg/s) | 6176.4 Nm/deg | 0.154 Nm/(deg/s) |

| 6 | 409.6 Nm/deg | 0.233 Nm/(deg/s) | 5528.6 Nm/deg | 0.178 Nm/(deg/s) |

| Axis | Ratio | ||

|---|---|---|---|

| 1 | 881.7 Nm/deg | 5500.9 Nm/deg | 6.2 |

| 2 | 1503.8 Nm/deg | 22,403.9 Nm/deg | 14.9 |

| 3 | 896.7 Nm/deg | 10,884.6 Nm/deg | 12.1 |

| 4 | 600.8 Nm/deg | 10,358.5 Nm/deg | 17.2 |

| 5 | 208.8 Nm/deg | 6176.4 Nm/deg | 29.6 |

| 6 | 409.6 Nm/deg | 5528.6 Nm/deg | 13.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birk, C.; Kipfmüller, M.; Kotschenreuther, J. Dynamic Modeling and Analysis of Industrial Robots for Enhanced Manufacturing Precision. Actuators 2025, 14, 311. https://doi.org/10.3390/act14070311

Birk C, Kipfmüller M, Kotschenreuther J. Dynamic Modeling and Analysis of Industrial Robots for Enhanced Manufacturing Precision. Actuators. 2025; 14(7):311. https://doi.org/10.3390/act14070311

Chicago/Turabian StyleBirk, Claudius, Martin Kipfmüller, and Jan Kotschenreuther. 2025. "Dynamic Modeling and Analysis of Industrial Robots for Enhanced Manufacturing Precision" Actuators 14, no. 7: 311. https://doi.org/10.3390/act14070311

APA StyleBirk, C., Kipfmüller, M., & Kotschenreuther, J. (2025). Dynamic Modeling and Analysis of Industrial Robots for Enhanced Manufacturing Precision. Actuators, 14(7), 311. https://doi.org/10.3390/act14070311