Thermal Characterization of Ceramic Composites for Optimized Surface Dielectric Barrier Discharge Plasma Actuators

Abstract

1. Introduction

2. Materials and Methods

Sample Manufacturing

3. Results and Discussion

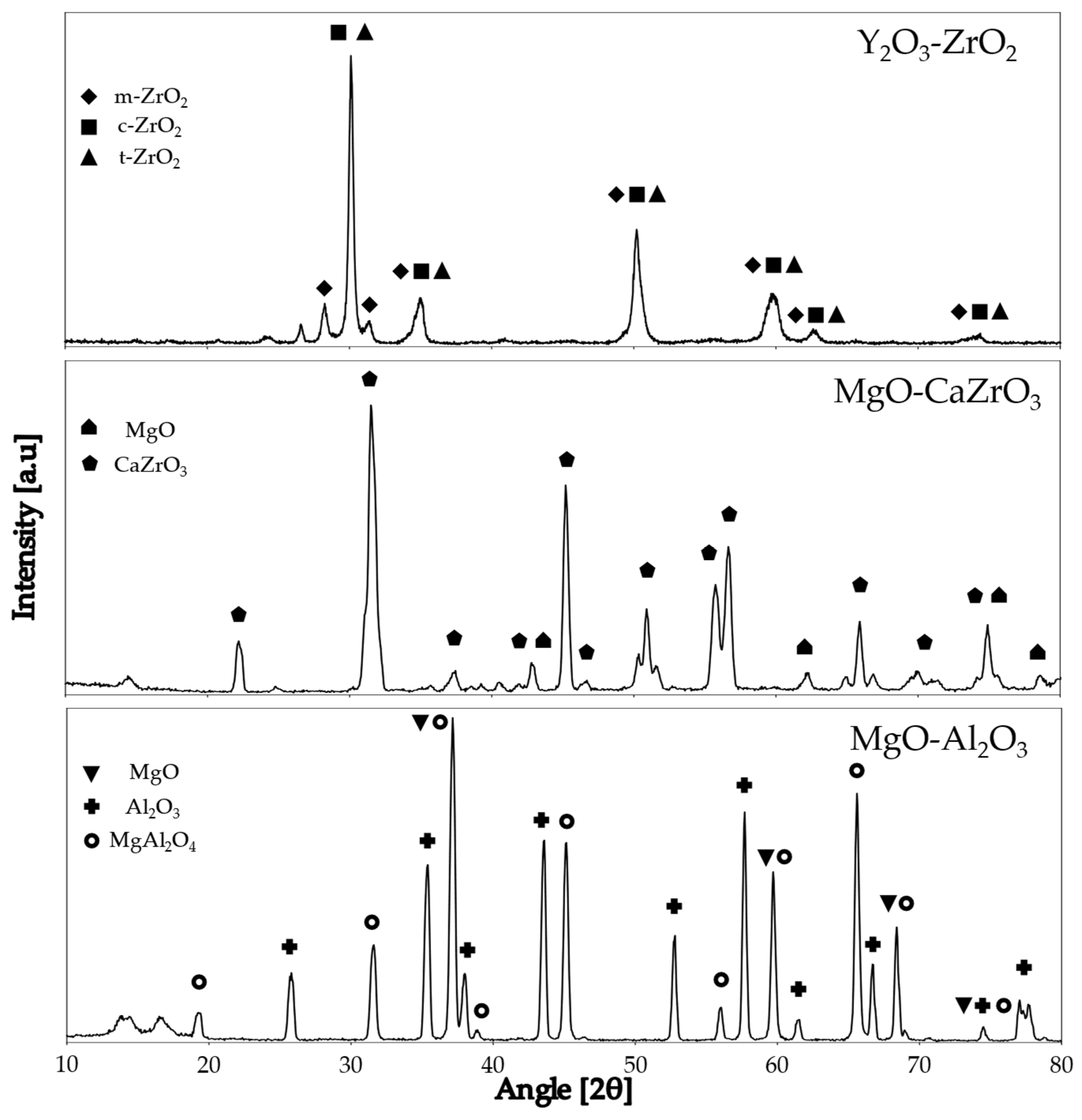

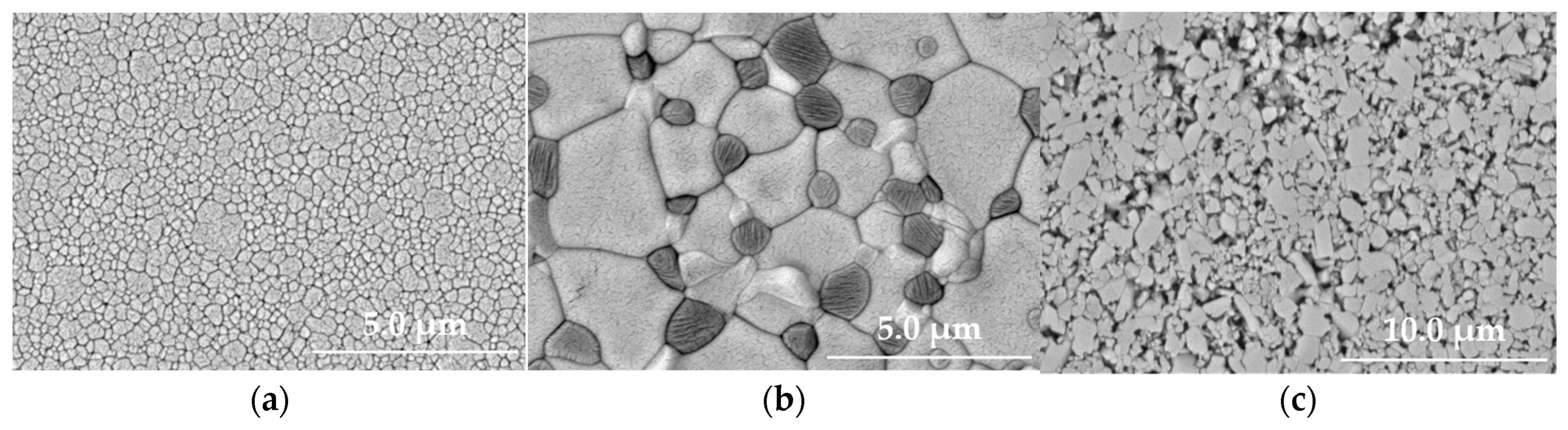

3.1. Dielectric Ceramic Sample Analysis

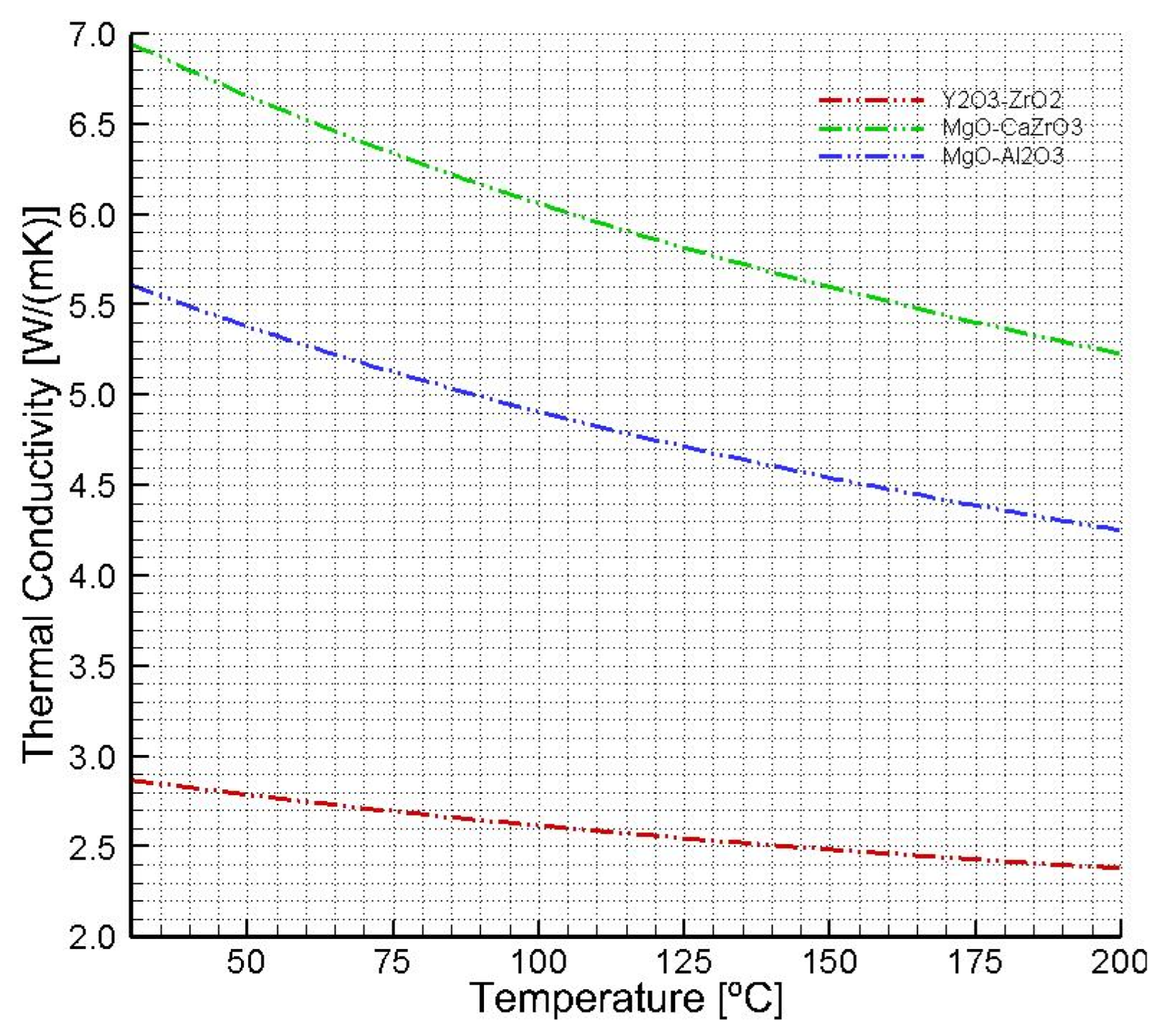

3.2. Thermal Conductivity of the Ceramic Samples

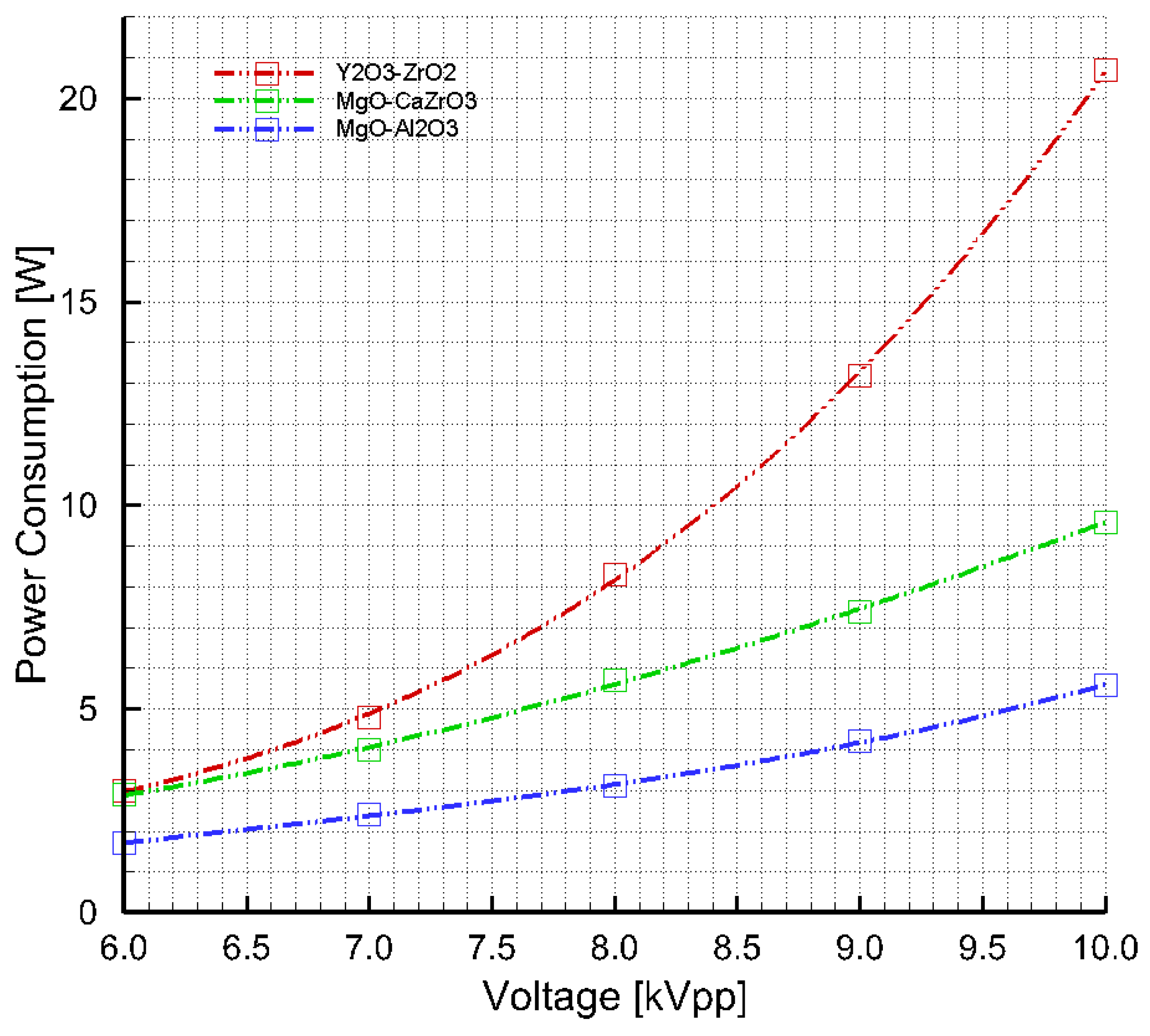

3.3. AC SDBD Consumed Power

3.4. AC SDBD Thermographic Analysis

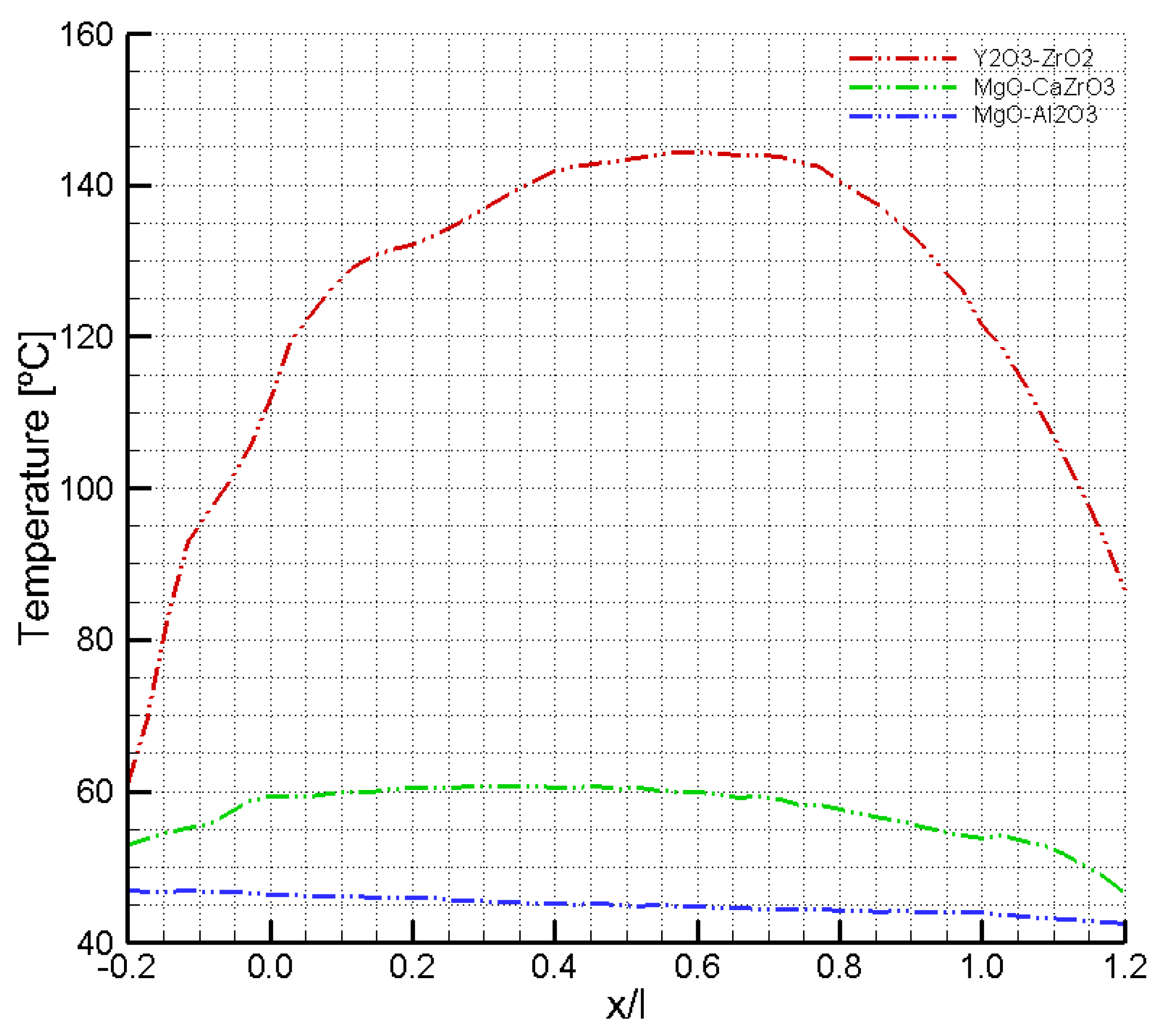

3.5. AC SDBD Spatial Temperature Variation for 10 kVpp

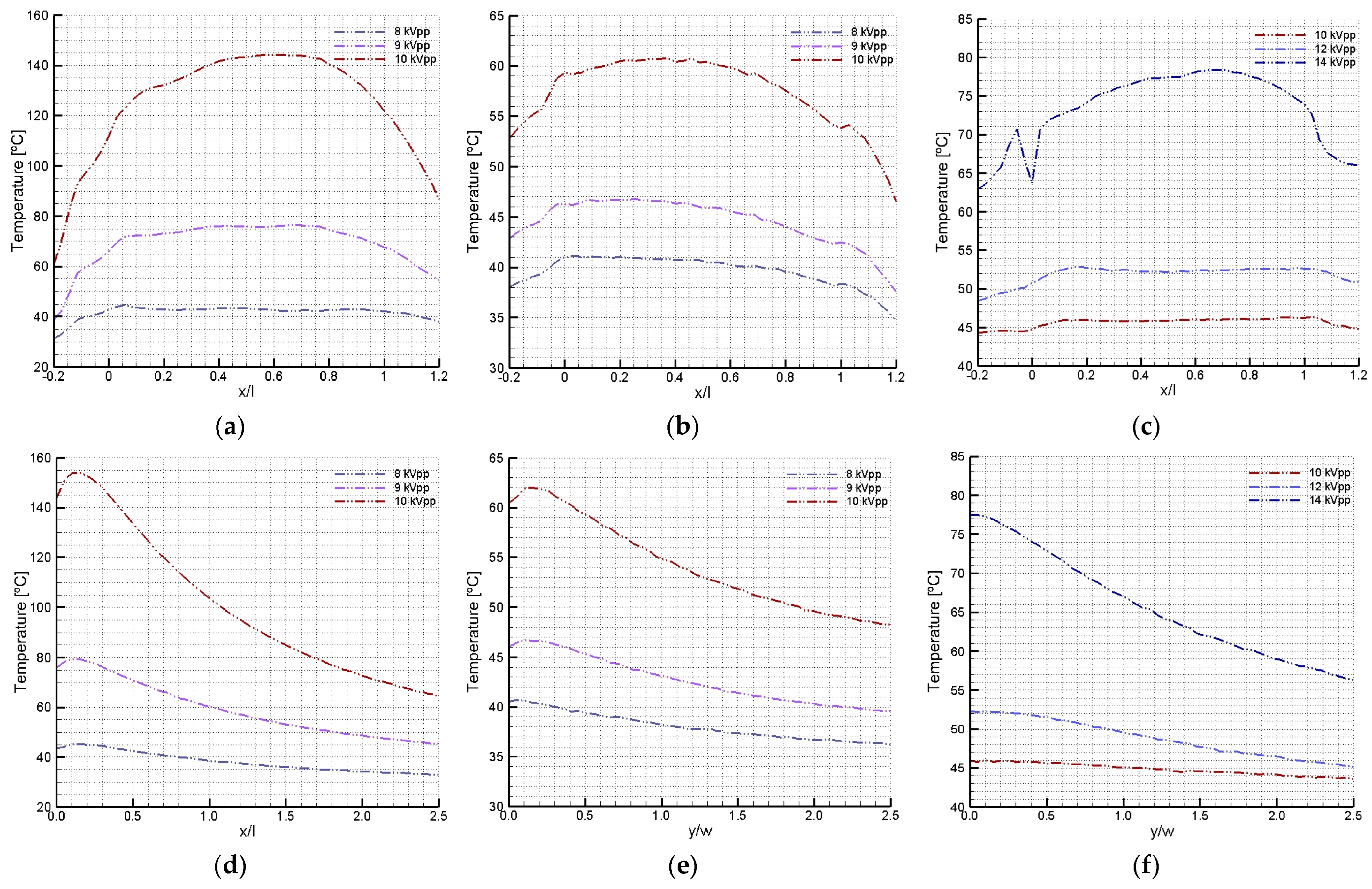

3.6. AC SDBD Spatial Temperature Variation for Different Input Voltage Levels

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- In Flight Icing. EGAST: European General Aviation Safety Team, Köln, Germany. 2015. Available online: https://www.easa.europa.eu/en/document-library/general-publications/egast-leaflet-ga-10-flight-icing (accessed on 25 July 2024).

- About the NTSB. NTSB: National Transportation Safety Board. 2013. Available online: https://www.ntsb.gov/about/Pages/default.aspx (accessed on 25 July 2024).

- Appendix G-Embraer Icing Guidance/Procedures. Brasilia, Embraer EMB120. NTSB: National Transportation Safety Board, Florida, USA. 1995. Available online: https://www.ntsb.gov/investigations/AccidentReports/Reports/AAR9804_G.pdf (accessed on 25 July 2024).

- Engine Power Loss Due to Carburetor Icing. NTSB: National Transportation Safety Board, Washington, DC, USA. 2015. Available online: https://www.ntsb.gov/Advocacy/safety-alerts/Documents/SA-029.pdf (accessed on 25 July 2024).

- Super-IcePhobic Surfaces to Prevent Ice Formation on Aircraft. CORDIS-EU, Warsaw, Poland. 2015. Available online: https://cordis.europa.eu/project/id/690819 (accessed on 25 July 2024). [CrossRef]

- Gao, L.; Hu, H. Wind turbine icing characteristics and icing-induced power losses to utility-scale wind turbines. Proc. Natl. Acad. Sci. USA 2021, 118, e2111461118. [Google Scholar] [CrossRef] [PubMed]

- Kolbakir, C.; Hu, H.; Liu, Y.; Hu, H. An Experimental Investigation on the Thermodynamic Characteristics of DBD Plasma Actuations for Aircraft Icing Mitigation. In Plasma Science and Technology; IntechOpen: London, UK, 2022; p. 25. [Google Scholar] [CrossRef]

- Liu, Y.; Kolbakir, C.; Hu, H. A parametric study to explore ns-DBD plasma actuation for aircraft icing mitigation. In Proceedings of the 2018 Flow Control Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar] [CrossRef]

- Kolbakir, C.; Gao, L.; Liu, Y.; Hu, H. A Parametric Study on the Thermodynamic Characteristics of DBD Plasma Actuation and Its Potential for Wind Turbine Icing Mitigation; SAE Technical Paper 2019-01-2031; SAE: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Lindner, M.; Pipa, A.; Karpen, N.; Hink, R.; Berndt, D.; Foest, R.; Bonaccurso, E.; Weichwald, R.; Friedberger, A.; Caspari, R.; et al. Icing mitigation by MEMS-Fabricated surface dielectric barrier discharge. Appl. Sci. 2021, 11, 11106. [Google Scholar] [CrossRef]

- Zhuoling, R.; Xuanshi, M.; Xian, Y.; Senyun, L. Simulation of in-flight Anti-Icing based AC-SDBD plasma actuation. In Proceedings of the AIAA Aviation 2023 Forum, San Diego, CA, USA, 12–16 June 2023; p. 3806. [Google Scholar] [CrossRef]

- Borghi, C.; Cristofolini, A.; Carraro, M.; Neretti, G. An analysis of a three phase flat panel uniform barrier discharge at atmospheric pressure. In Proceedings of the 37th AIAA Plasmadynamics and Lasers Conference, San Francisco, CA, USA, 5–8 June 2006. [Google Scholar] [CrossRef]

- Moreau, E. Airflow control by non-thermal plasma actuators. J. Phys. D Appl. Phys. 2007, 40, 605. [Google Scholar] [CrossRef]

- Jukes, T.N.; Choi, K.S.; Segawa, T.; Yoshida, H. Jet flow induced by a surface plasma actuator. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2008, 222, 347–356. [Google Scholar] [CrossRef]

- Dong, B.; Bauchire, J.; Pouvesle, J.; Magnier, P.; Hong, D. Experimental study of a DBD surface discharge for the active control of subsonic airflow. J. Phys. D Appl. Phys. 2008, 41, 155301. [Google Scholar] [CrossRef]

- Stanfield, S.; Menart, J.; DeJoseph, J.C.; Kimmel, R.; Hayes, J. Rotational and vibrational temperature distributions for a dielectric barrier discharge in air. AIAA J. 2009, 47, 1107–1115. [Google Scholar] [CrossRef]

- Joussot, R.; Boucinha, V.; Weber-Rozenbaum, R.; Rabat, H.; Leroy-Chesneau, A.; Hong, D. Thermal characterization of a DBD plasma actuator: Dielectric temperature measurements using infrared thermography. In Proceedings of the 40th Fluid Dynamics Conference and Exhibit, Chicago, IL, USA, 28 June–1 July 2010. [Google Scholar] [CrossRef]

- Likhanskii, A.; Shneider, M.; Opaits, D.; Macheret, S.; Miles, R. Limitations of the DBD effects on the external flow. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010. [Google Scholar] [CrossRef]

- Rodrigues, F.; Páscoa, J.; Trancossi, M. Heat generation mechanisms of DBD plasma actuators. Exp. Therm. Fluid Sci. 2018, 90, 55–65. [Google Scholar] [CrossRef]

- Abdollahzadeh, M.; Rodrigues, F.; Nunes-Pereira, J.; Páscoa, J.C.; Pires, L. Parametric optimization of surface dielectric barrier discharge actuators for ice sensing application. Sens. Actuators A Phys. 2022, 335, 113391. [Google Scholar] [CrossRef]

- Cai, J.; Yongqiang, T.; Xuanshi, M.; Xuzhao, H.; Duo, Z.; Haiyang, H. An experimental study of icing control using DBD plasma actuator. Exp. Fluids 2017, 58, 102. [Google Scholar] [CrossRef]

- Rodrigues, F.; Shvydyuk, K.; Nunes-Pereira, J.; Páscoa, J.; Silva, A. Plasma Actuators Based on Alumina Ceramics for Active Flow Control Applications. Ceramics 2024, 7, 192–207. [Google Scholar] [CrossRef]

- Deng, X.; Hou, Z. Thermal characteristic and spatial morphology between electrode and phase changing ice during de-icing process of dielectric barrier discharge and critical behavior of the surface charge density. Int. J. Heat Mass Transf. 2022, 190, 122556. [Google Scholar] [CrossRef]

- Shvydyuk, K.O.; Rodrigues, F.F.; Nunes-Pereira, J.; Páscoa, J.C.; Lanceros-Mendez, S.; Silva, A.P. Long-lasting ceramic composites for surface dielectric barrier discharge plasma actuators. J. Eur. Ceram. Soc. 2023, 43, 6112–6121. [Google Scholar] [CrossRef]

- ASTM C20-00; Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2022; p. 3.

- Ashpis, D.; Laun, M.; Elmer, G. Progress toward accurate measurements of power consumption of DBD plasma actuators. In Proceedings of the 50th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar] [CrossRef]

- Vollmer, M. Infrared Thermal Imaging. In Computer Vision; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Luykx, D.; Van Ruth, S. An overview of analytical methods for determining the geographical origin of food products. Food Chem. 2008, 107, 897–911. [Google Scholar] [CrossRef]

- Rodrigues, F.; Páscoa, J.; Trancossi, M. Experimental thermal characterization of DBD plasma actuators. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017. [Google Scholar] [CrossRef]

- Tirumala, R.; Benard, N.; Moreau, E.; Fenot, M.; Lalizel, G.; Dorignac, E. Temperature characterization of dielectric barrier discharge actuators: Influence of electrical and geometric parameters. J. Phys. D Appl. Phys. 2014, 47, 255203. [Google Scholar] [CrossRef]

- ASTM E1461–13; Standard Test Method for Determining Thermal Diffusivity by the Flash Method. ASTM International: West Conshohocken, PA, USA, 2007. Available online: https://www.astm.org/e1461-13r22.html (accessed on 15 May 2024).

- Ceramic Material Properties Chart. Precision Ceramic. Available online: https://precision-ceramics.com/materials/properties/chart/ (accessed on 19 December 2024).

- Thermal Conductivity Easily Transmits Heat. Fine Ceramics World. Available online: https://global.kyocera.com/fcworld/charact/heat/thermalcond.html (accessed on 19 December 2024).

- Zhao, H.; Yu, F.; Bennett, T.D.; Wadley, H.N. Morphology and thermal conductivity of yttria-stabilized zirconia coatings. Acta Mater. 2006, 54, 5195–5207. [Google Scholar] [CrossRef]

- Schlichting, K.W.; Padture, N.P.; Klemens, P.G. Thermal conductivity of dense and porous yttria-stabilized zirconia. J. Mater. Sci. 2001, 36, 3003–3010. [Google Scholar] [CrossRef]

- Zou, Y.; Gu, H.; Huang, A.; Fu, L.; Li, G. Fabrication and properties of in situ intergranular CaZrO3 modified microporous magnesia aggregates. Ceram. Int. 2020, 46 Pt B, 16956–16965. [Google Scholar] [CrossRef]

- Shvydyuk, K.; Nunes-Pereira, J.; Rodrigues, F.; Páscoa, J.; Lanceros-Mendez, S.; Silva, A. Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems. Ceramics 2024, 7, 364–384. [Google Scholar] [CrossRef]

- Heimann, R.B. Oxide Ceramics: Structure, Technology, and Applications. In Classic and Advanced Ceramics: From Fundamentals to Applications; Wiley & Sons: Hoboken, NJ, USA, 2010; pp. 175–252. [Google Scholar] [CrossRef]

- Sun, J.; Hu, Z.; Zhou, J.; Wang, X.; Sun, C. Thermal Properties of Highly Porous Fibrous Ceramics. In Proceedings of the 5th International Conference on Porous Media and their Applications in Science, Engineering and Industry, Kona, HI, USA, 22–27 June 2014; Available online: https://dc.engconfintl.org/cgi/viewcontent.cgi?article=1002&context=porous_media_V (accessed on 25 July 2024).

- Lu, X.; Zhi, F.; Dong, D.; Tao, S.; Feng, L.; Cheng, Z.; Dawei, L.; Lanlan, N.; Chunqi, J. On the chronological understanding of the homogeneous dielectric barrier discharge. High Volt. 2023, 8, 1132–1150. [Google Scholar] [CrossRef]

- Kolbakir, C.; Hu, H.; Liu, Y.; Hu, H. An experimental study on different plasma actuator layouts for aircraft icing mitigation. Aerosp. Sci. Technol. 2020, 107, 106325. [Google Scholar] [CrossRef]

| Ceramic Sample | Y2O3-ZrO2 | MgO-CaZrO3 | MgO-Al2O3 |

|---|---|---|---|

| Apparent porosity [%] | 0.06 ± 0.04 | 0.04 ± 0.02 | 6.7 ± 0.3 |

| Relative density [%] | 98.0 ± 0.1 | 98.9 ± 0.3 | 71.3 ± 0.3 |

| Input Voltage [kVpp] | Y2O3-ZrO2 | MgO-CaZrO3 | MgO-Al2O3 |

|---|---|---|---|

| 6 | 3.0 ± 0.060 | 2.9 ± 0.058 | 1.7 ± 0.034 |

| 7 | 4.8 ± 0.096 | 4.0 ± 0.080 | 2.4 ± 0.048 |

| 8 | 8.3 ± 0.166 | 5.7 ± 0.114 | 3.1 ± 0.062 |

| 9 | 13.2 ± 0.264 | 7.4 ± 0.148 | 4.2 ± 0.084 |

| 10 | 20.7 ± 0.414 | 9.6 ± 0.192 | 5.6 ± 0.112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shvydyuk, K.O.; Rodrigues, F.F.; Nunes-Pereira, J.; Páscoa, J.C.; Silva, A.P. Thermal Characterization of Ceramic Composites for Optimized Surface Dielectric Barrier Discharge Plasma Actuators. Actuators 2025, 14, 127. https://doi.org/10.3390/act14030127

Shvydyuk KO, Rodrigues FF, Nunes-Pereira J, Páscoa JC, Silva AP. Thermal Characterization of Ceramic Composites for Optimized Surface Dielectric Barrier Discharge Plasma Actuators. Actuators. 2025; 14(3):127. https://doi.org/10.3390/act14030127

Chicago/Turabian StyleShvydyuk, Kateryna O., Frederico F. Rodrigues, João Nunes-Pereira, José C. Páscoa, and Abílio P. Silva. 2025. "Thermal Characterization of Ceramic Composites for Optimized Surface Dielectric Barrier Discharge Plasma Actuators" Actuators 14, no. 3: 127. https://doi.org/10.3390/act14030127

APA StyleShvydyuk, K. O., Rodrigues, F. F., Nunes-Pereira, J., Páscoa, J. C., & Silva, A. P. (2025). Thermal Characterization of Ceramic Composites for Optimized Surface Dielectric Barrier Discharge Plasma Actuators. Actuators, 14(3), 127. https://doi.org/10.3390/act14030127