A Three-Stage Amplification Mechanism for a Compact Piezoelectric Actuator

Abstract

1. Introduction

2. Instrumentation

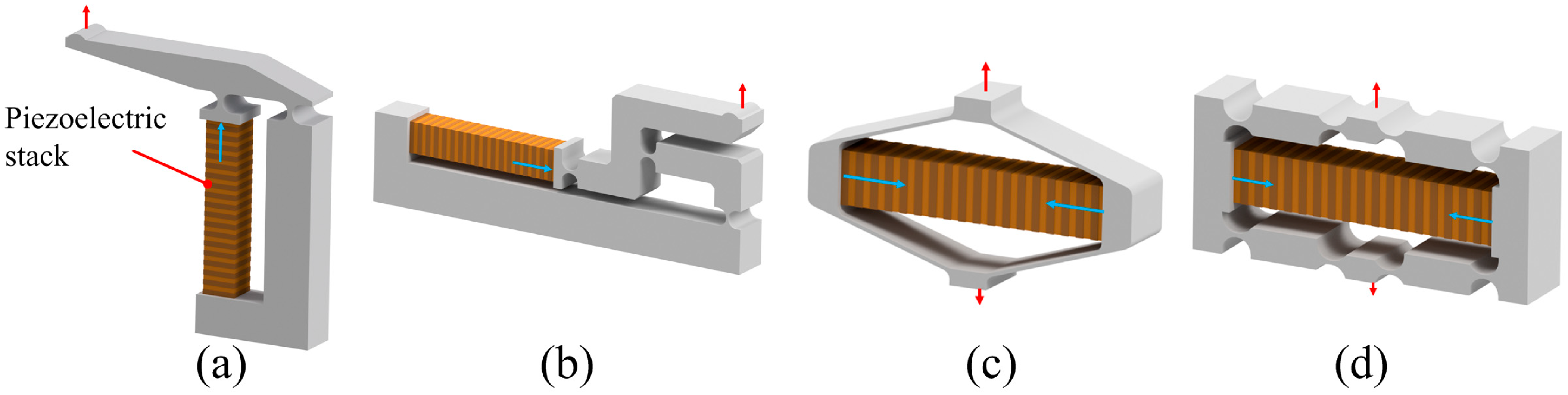

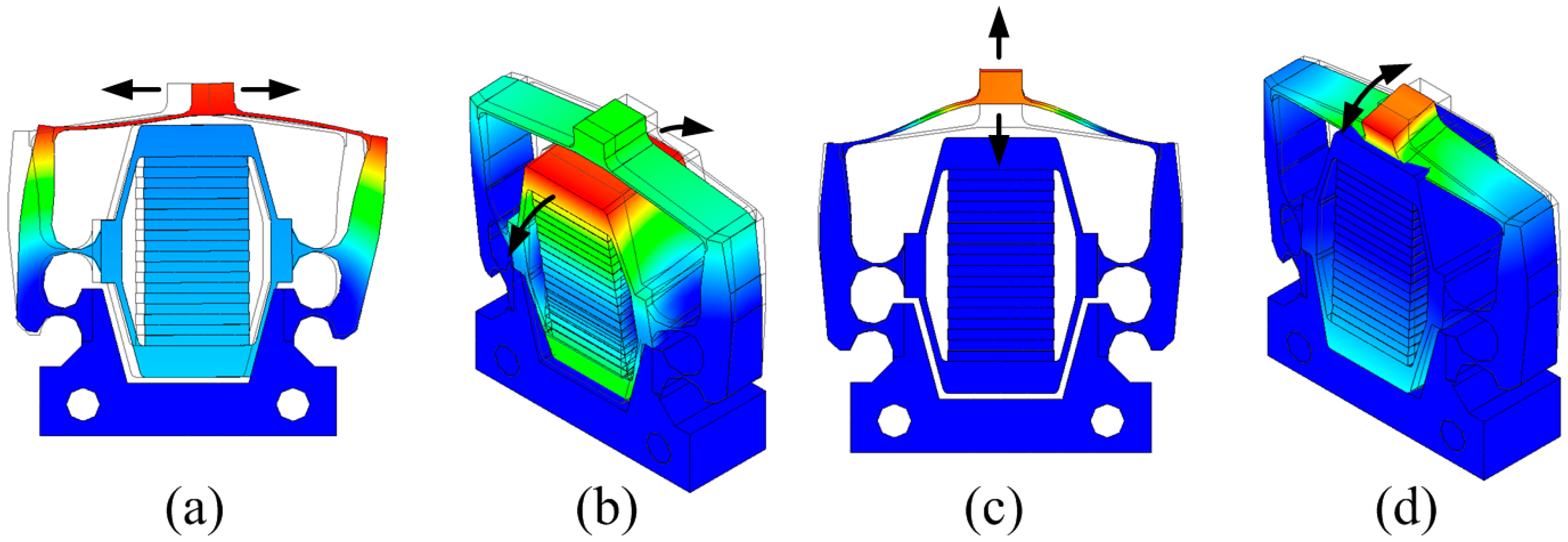

2.1. Mechanism of Three-Stage Amplification

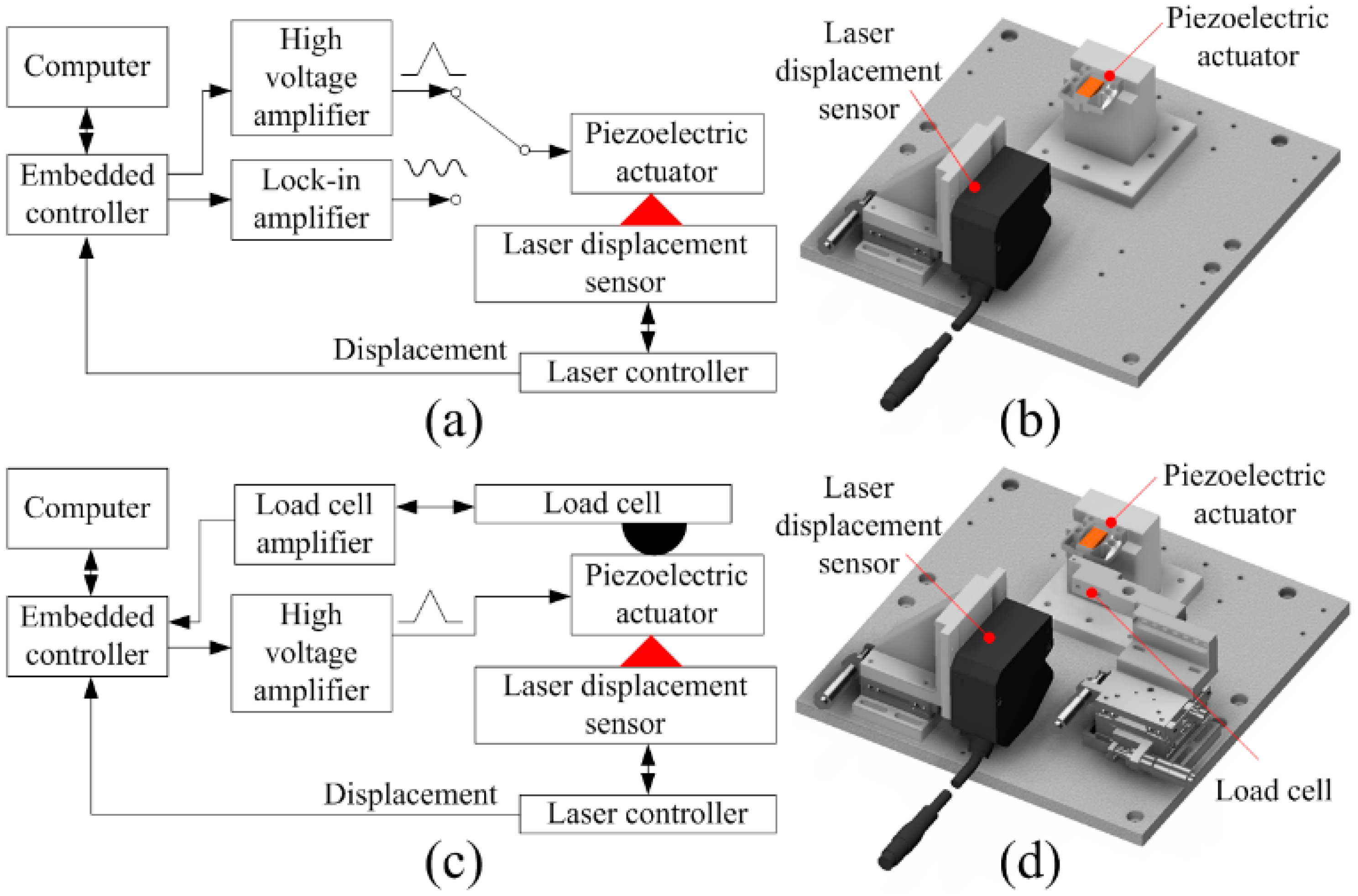

2.2. Setup for Displacement and Force Measurements

2.3. Test Setup for the Jetting Dispenser

3. Results and Discussion

3.1. Static Displacement of the Three-Stage Amplifier

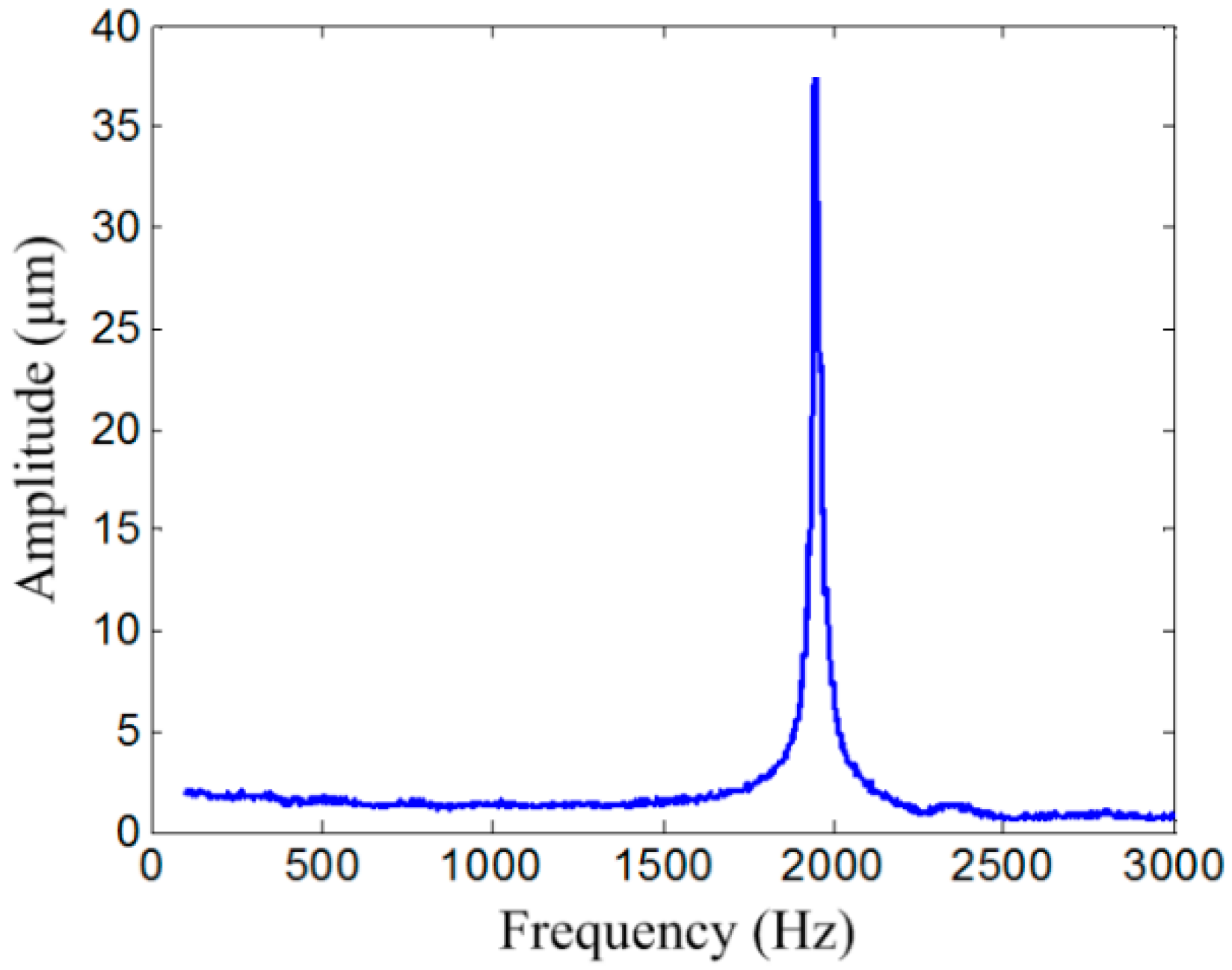

3.2. Dynamic Property of the Three-Stage Amplifier

3.3. Output Force of the Three-Stage Amplifier

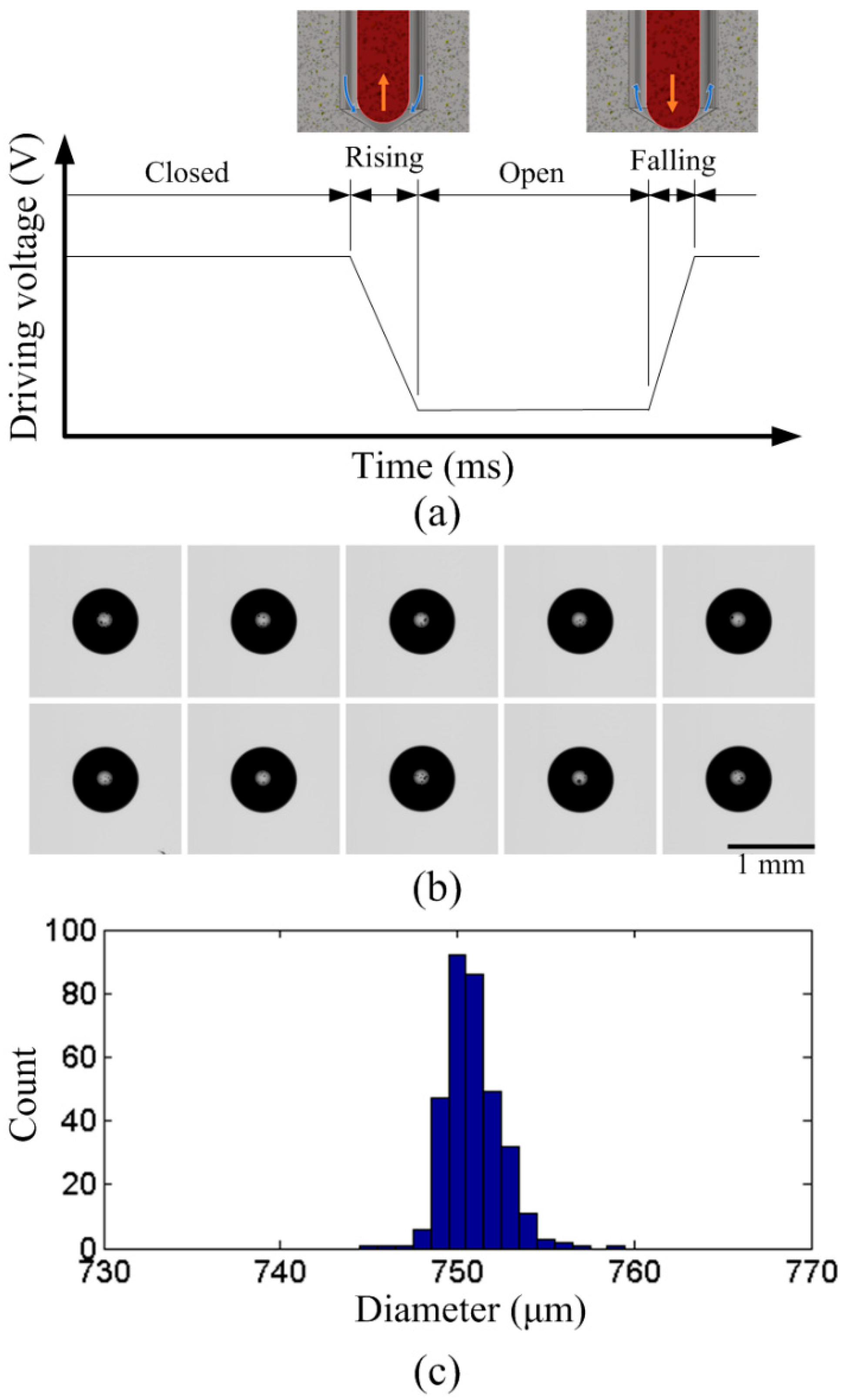

3.4. Performance of the Jetting Dispenser

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tressler, J.F.; Alkoy, S.; Newnham, R.E. Piezoelectric sensors and sensor materials. J. Electr. 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Schitter, G.; Astrom, K.J.; DeMartini, B.E.; Thurner, P.J.; Turner, K.L.; Hansma, P.K. Design and modeling of a high-speed AFM-scanner. IEEE Trans. Control Syst. Technol. 2007, 15, 906–915. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.M.; Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: A review. Smart Mater. Struct. 2020, 30, 013002. [Google Scholar] [CrossRef]

- Main, J.A.; Garcia, E. Piezoelectric stack actuators and control system design: Strategies and pitfalls. J. Guid. Control. Dynam. 1997, 20, 479–485. [Google Scholar] [CrossRef]

- Xiao, R.; Shao, S.; Xu, M.; Jing, Z. Design and analysis of a novel piezo-actuated XYθz micropositioning mechanism with large travel and kinematic decoupling. Adv. Mater. Sci. Eng. 2019, 1, 5461725. [Google Scholar] [CrossRef]

- Juuti, J.; Kordas, K.; Lonnakko, R.; Moilanen, V.P.; Leppävuori, S. Mechanically amplified large displacement piezoelectric actuators. Sens. Actuator A Phys. 2005, 120, 225–231. [Google Scholar] [CrossRef]

- Yong, Y.K.; Moheimani, S.O.R.; Kenton, B.J.; Leang, K.K. Invited review article: High-speed flexure-guided nanopositioning: Mechanical design and control issues. Rev. Sci. Instr. 2012, 83, 121101. [Google Scholar] [CrossRef]

- Jeon, J.; Han, C.; Chung, J.U.; Choi, S.B. Performance evaluation of a piezoactuator-based single-stage valve system subjected to high temperature. Smart Mater. Struct. 2014, 24, 015022. [Google Scholar] [CrossRef]

- Trimzi, M.A.; Ham, Y.B.; An, B.C.; Choi, Y.M.; Park, J.H.; Yun, S.N. Development of a piezo-driven liquid jet dispenser with hinge-lever amplification mechanism. Micromachines 2020, 11, 117. [Google Scholar] [CrossRef]

- Tian, Y.; Shirinzadeh, B.; Zhang, D.; Alici, G. Development and dynamic modelling of a flexure-based Scott–Russell mechanism for nano-manipulation. Mechan. Syst. Signal Process 2009, 23, 957–978. [Google Scholar] [CrossRef]

- Chen, C.M.; Fung, R.F. The effects of geometric offsets on the dynamic responses of a Scott—Russell amplifying mechanism with flexible hinges. Proc. Instit. Mechan. Eng. Part C J. Mechan. Eng. Sci. 2009, 223, 2413–2423. [Google Scholar] [CrossRef]

- Lu, S.; Liu, Y.; Yao, Y.; Huang, B.; Sun, L. Design and analysis of a piezostack driven jetting dispenser for high viscosity adhesives. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besancon, France, 8–11 July 2010; pp. 227–232. [Google Scholar]

- Ling, M.; Cao, J.; Zeng, M.; Lin, J.; Inman, D.J. Enhanced mathematical modeling of the displacement amplification ratio for piezoelectric compliant mechanisms. Smart Mater. Struct. 2016, 25, 075022. [Google Scholar] [CrossRef]

- Xiang, K.Q.; Qi, Y.; Fang, C.; Zhang, Y.; Yu, C.S. Analysis of the displacement amplification ratio of bridge-type mechanism. Mechan. Mach. Theory 2015, 87, 45–56. [Google Scholar]

- Chen, F.; Du, Z.J.; Yang, M.; Gao, F.; Dong, W.; Zhang, D. Design and analysis of a three-dimensional bridge-type mechanism based on the stiffness distribution. Prec. Eng. 2018, 51, 48–58. [Google Scholar] [CrossRef]

- Li, Y.; Bi, S.; Zhao, C. Analytical modeling and analysis of rhombus-type amplifier based on beam flexures. Mechan. Mach. Theory 2019, 139, 195–211. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhao, X.; Li, A.; Yu, X. Design and characteristic analysis of magnetostrictive vibration harvester with double-stage rhombus amplification mechanism. Machines 2022, 10, 848. [Google Scholar] [CrossRef]

- Choi, S.B.; Han, S.S.; Han, Y.M.; Thompson, B.S. A magnification device for precision mechanisms featuring piezoactuators and flexure hinges: Design and experimental validation. Mechan. Mach. Theory 2007, 42, 1184–1198. [Google Scholar] [CrossRef]

- Muraoka, M.; Sanada, S. Displacement amplifier for piezoelectric actuator based on honeycomb link mechanism. Sens. Actuat. A Phys. 2010, 157, 84–90. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, X.; Wen, Z.; Ren, J.; Liu, P. A novel flexure-based vertical nanopositioning stage with large travel range. Rev. Sci. Instr. 2015, 86, 105112. [Google Scholar] [CrossRef]

- Zhu, W.L.; Zhu, Z.; Shi, Y.; Wang, X.; Guan, K.; Ju, B.F. Design, modeling, analysis and testing of a novel piezo-actuated XY compliant mechanism for large workspace nano-positioning. Smart Mater. Struct. 2016, 25, 115033. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, L.; Li, S.; Zhu, W.; Ji, C. Development of a novel pile-up structure based nanopositioning mechanism driven by piezoelectric actuator. IEEE/ASME Trans. Mechatr. 2020, 25, 502–512. [Google Scholar] [CrossRef]

- Ling, M.; Yuan, L.; Luo, Z.; Huang, T.; Zhang, X. Enhancing dynamic bandwidth of amplified piezoelectric actuators by a hybrid lever and bridge-type compliant mechanism. Actuators 2022, 11, 134. [Google Scholar] [CrossRef]

- Sohn, J.W.; Choi, S.B. Identification of operating parameters most strongly influencing the jetting performance in a piezoelectric actuator-driven dispenser. Appl. Sci. 2018, 8, 243. [Google Scholar] [CrossRef]

- Cao, L.; Gong, S.G.; Tao, Y.R.; Duan, S.Y. Optimizing dispensing performance of needle-type piezoelectric jet dispensers: A novel drive waveform approach. Smart Mater. Struct. 2014, 33, 045001. [Google Scholar] [CrossRef]

- Shi, Y.; Huang, A.; Fu, B. Design and performance analysis of a piezoelectric jetting dispensing valve. J. Intell. Mater. Syst. Struct. 2014, 35, 920–941. [Google Scholar] [CrossRef]

- Watanabe, H.; Uchihashi, T.; Kobashi, T.; Shibata, M.; Nishiyama, J.; Yasuda, R.; Ando, T. Wide-area scanner for high-speed atomic force microscopy. Rev. Sci. Instr. 2013, 84, 053702. [Google Scholar] [CrossRef]

- Nah, S.K.; Zhong, Z.W. A microgripper using piezoelectric actuation for micro-object manipulation. Sens. Actuator A Phys. 2007, 133, 218–224. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, H.-S.; Wu, C.-Y.; Lin, C.-H. A Three-Stage Amplification Mechanism for a Compact Piezoelectric Actuator. Actuators 2025, 14, 612. https://doi.org/10.3390/act14120612

Liao H-S, Wu C-Y, Lin C-H. A Three-Stage Amplification Mechanism for a Compact Piezoelectric Actuator. Actuators. 2025; 14(12):612. https://doi.org/10.3390/act14120612

Chicago/Turabian StyleLiao, Hsien-Shun, Chi-Yun Wu, and Chung-Hsu Lin. 2025. "A Three-Stage Amplification Mechanism for a Compact Piezoelectric Actuator" Actuators 14, no. 12: 612. https://doi.org/10.3390/act14120612

APA StyleLiao, H.-S., Wu, C.-Y., & Lin, C.-H. (2025). A Three-Stage Amplification Mechanism for a Compact Piezoelectric Actuator. Actuators, 14(12), 612. https://doi.org/10.3390/act14120612