Research on a Passive-Tuned Magnetorheological Damper for Whole-Spacecraft Vibration Isolation †

Abstract

1. Introduction

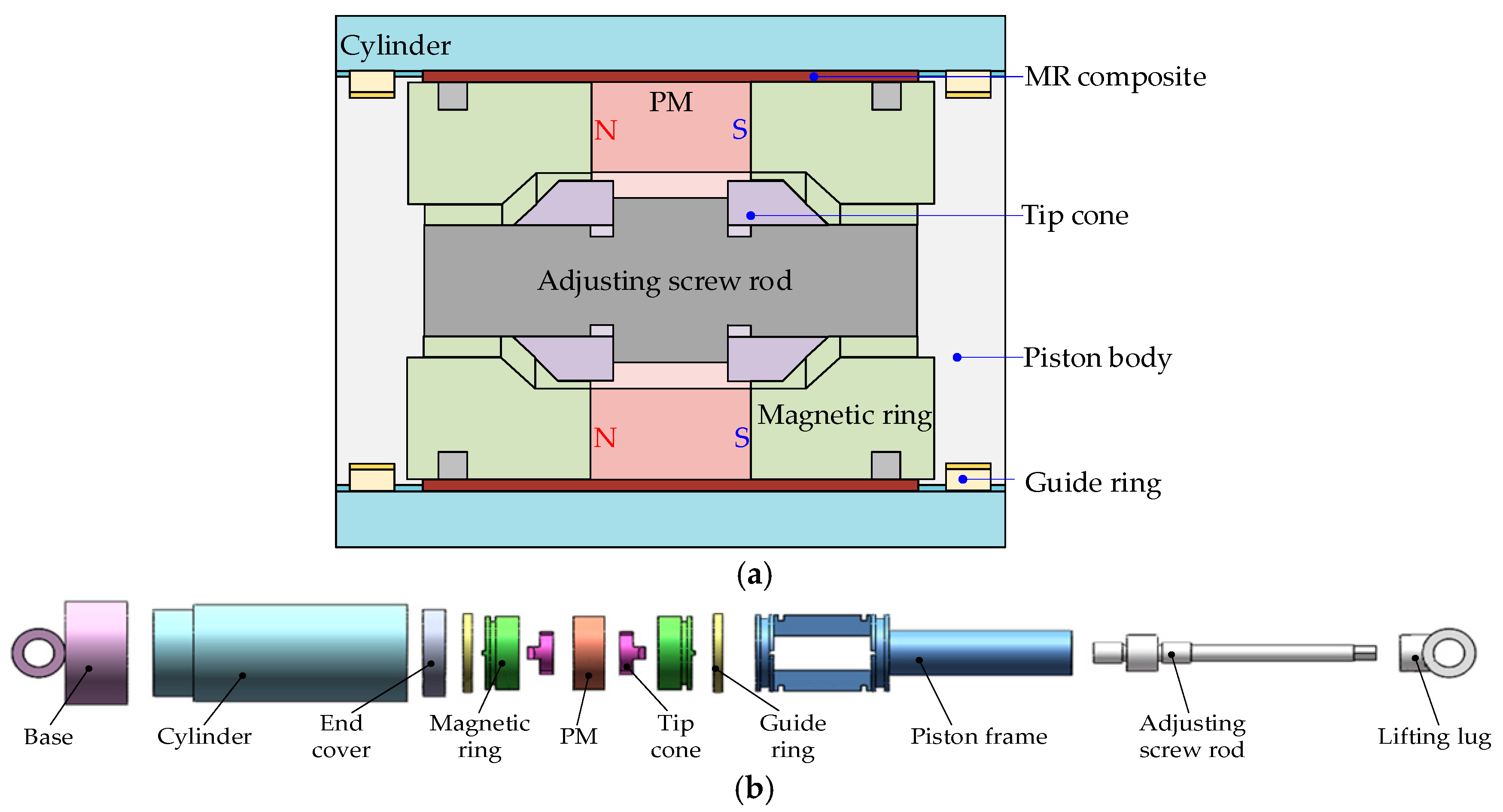

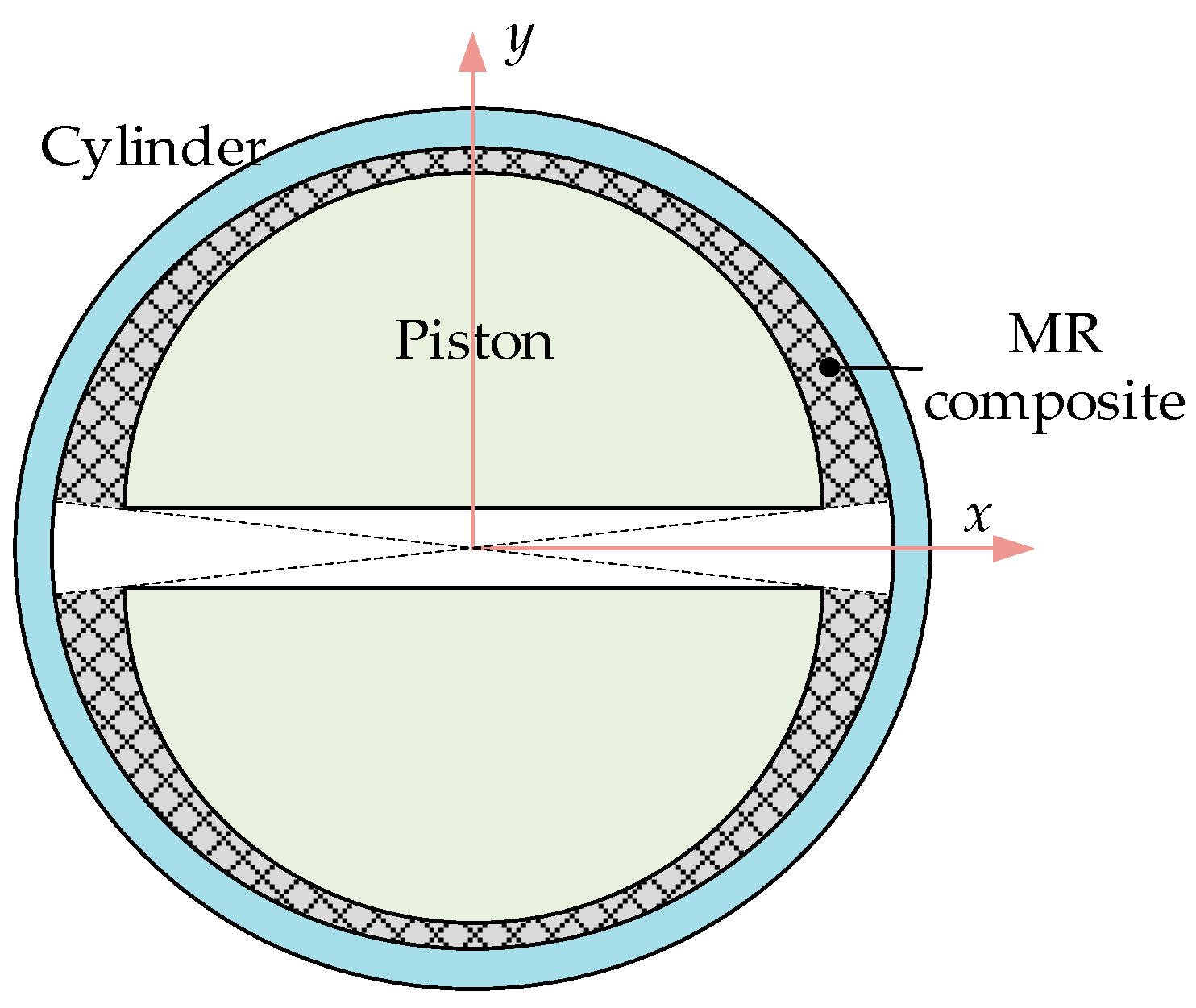

2. Structure of Proposed MR Damper

2.1. Structural Design

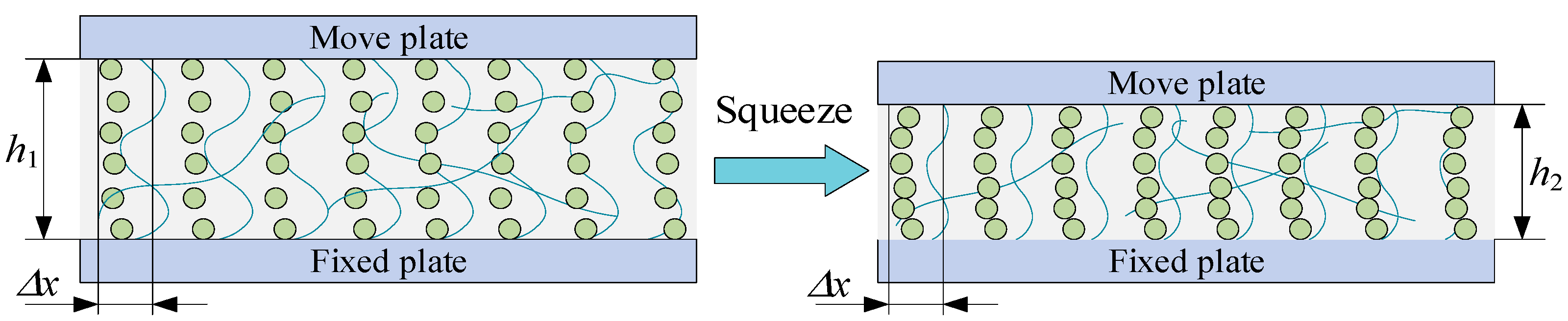

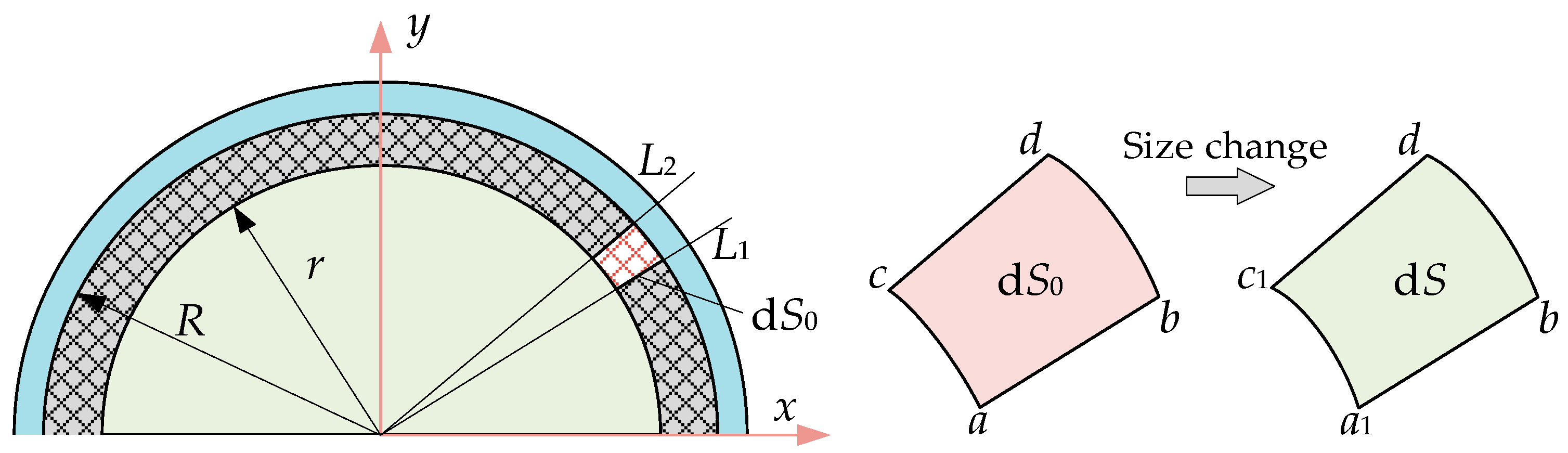

2.2. Analysis of Squeeze Strengthening Mechanism

- (1)

- The squeeze process will lead to an increase in the density of magnetic particles in the MR fluid. Due to the compressibility of silicone oil as the carrier liquid of the MR fluid, its total volume decreases under pressure, and the content of magnetic particles per unit volume increases. Under the action of the magnetic field, the number of magnetic chains formed by particles per unit volume increases, thereby increasing the shear stress of MR fluid.

- (2)

- The squeeze process will promote the transformation of a single magnetic chain in the MR fluid into more complex structures, such as dual chains, multiple chains, and magnetic particle columns. Compared with the single-chain structure of magnetic particle, the complex chain structure can resist stronger external shear, thereby increasing the shear stress of the MR fluid [32].

2.3. Mechanical Model

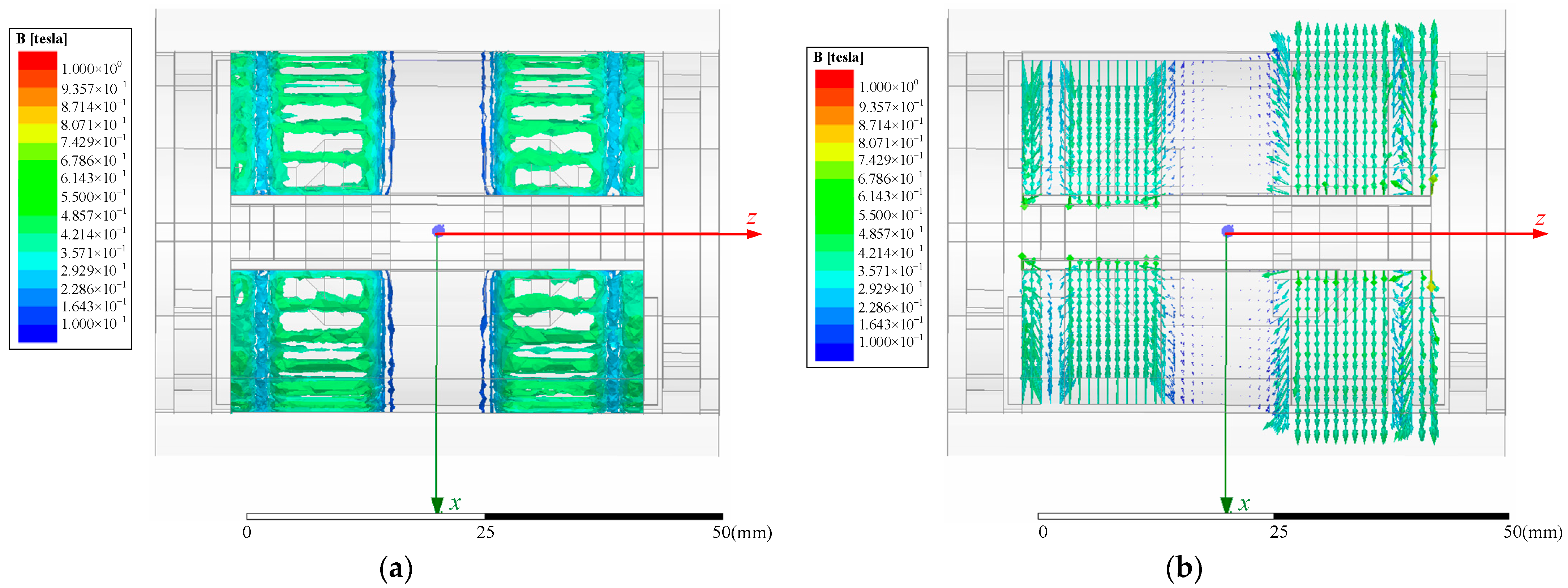

2.4. Simulated Analysis of Magnetic Circuit

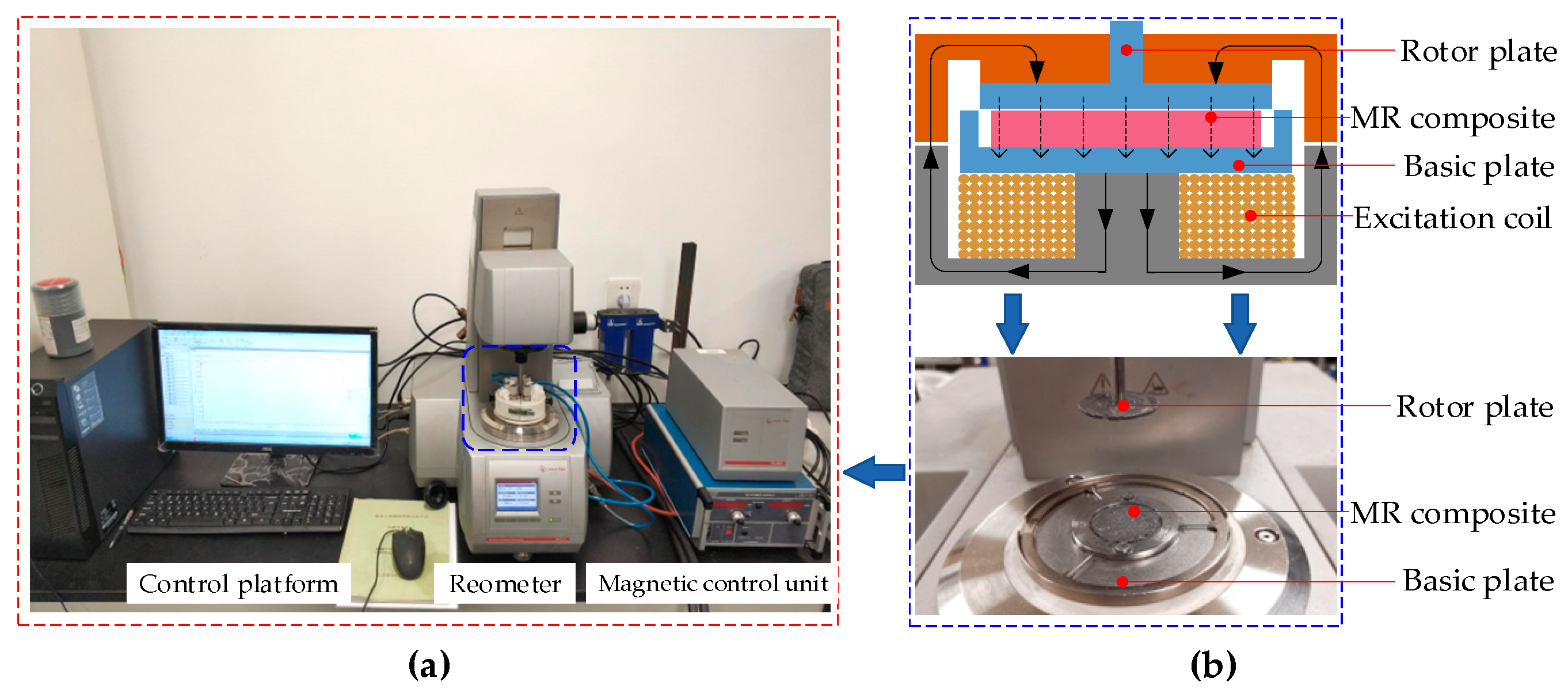

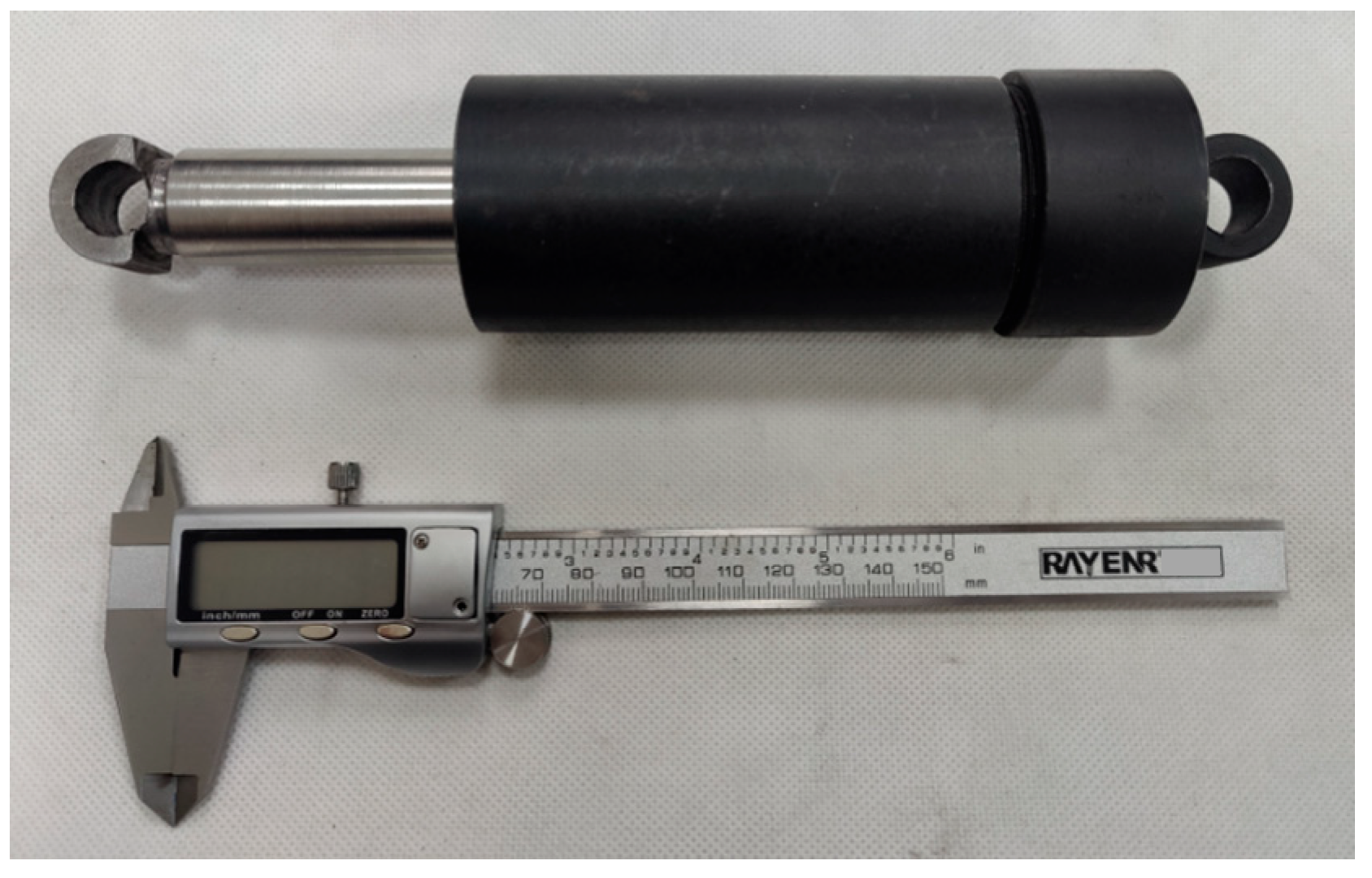

3. Experimental Analysis of Proposed MR Damper

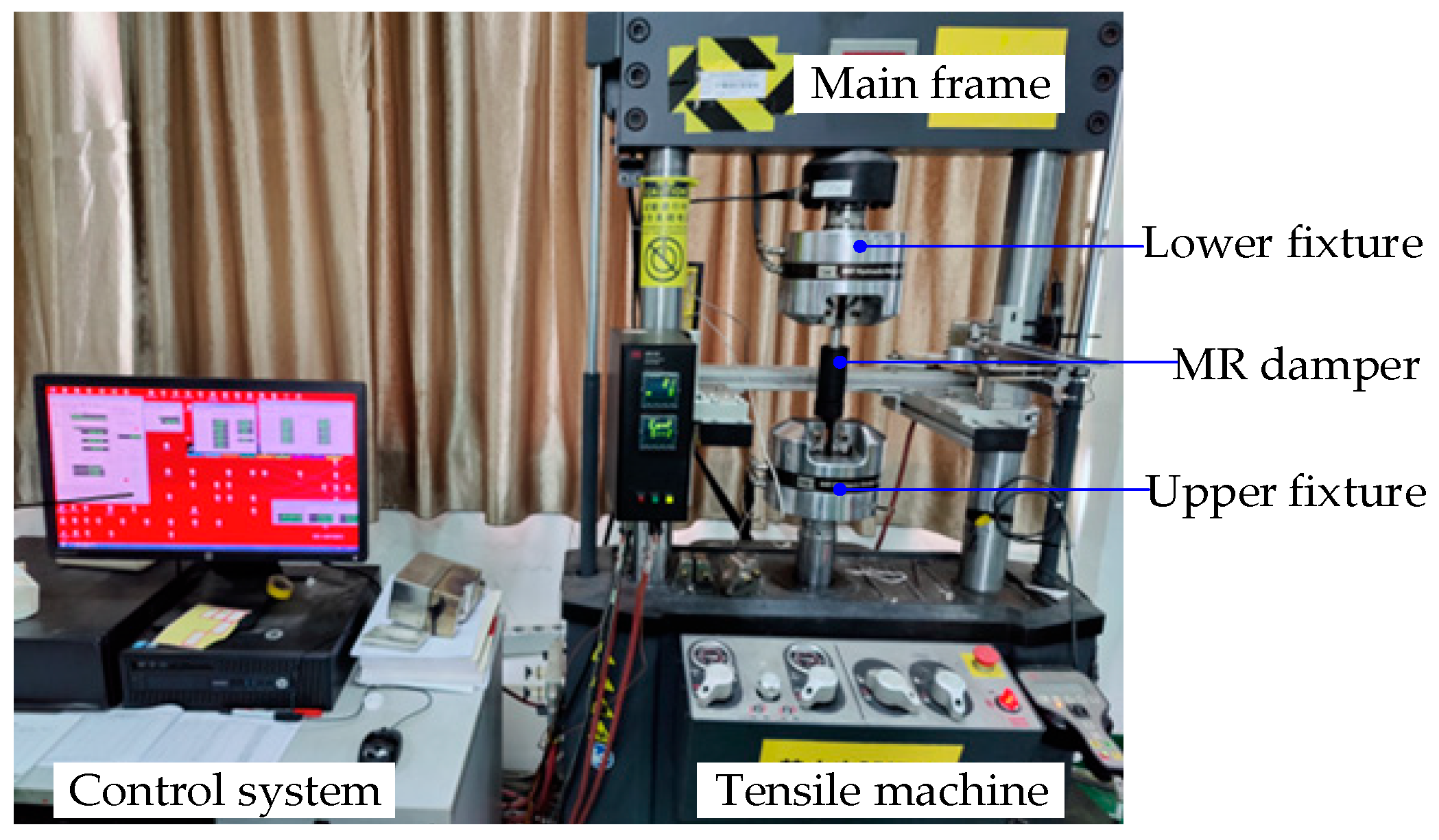

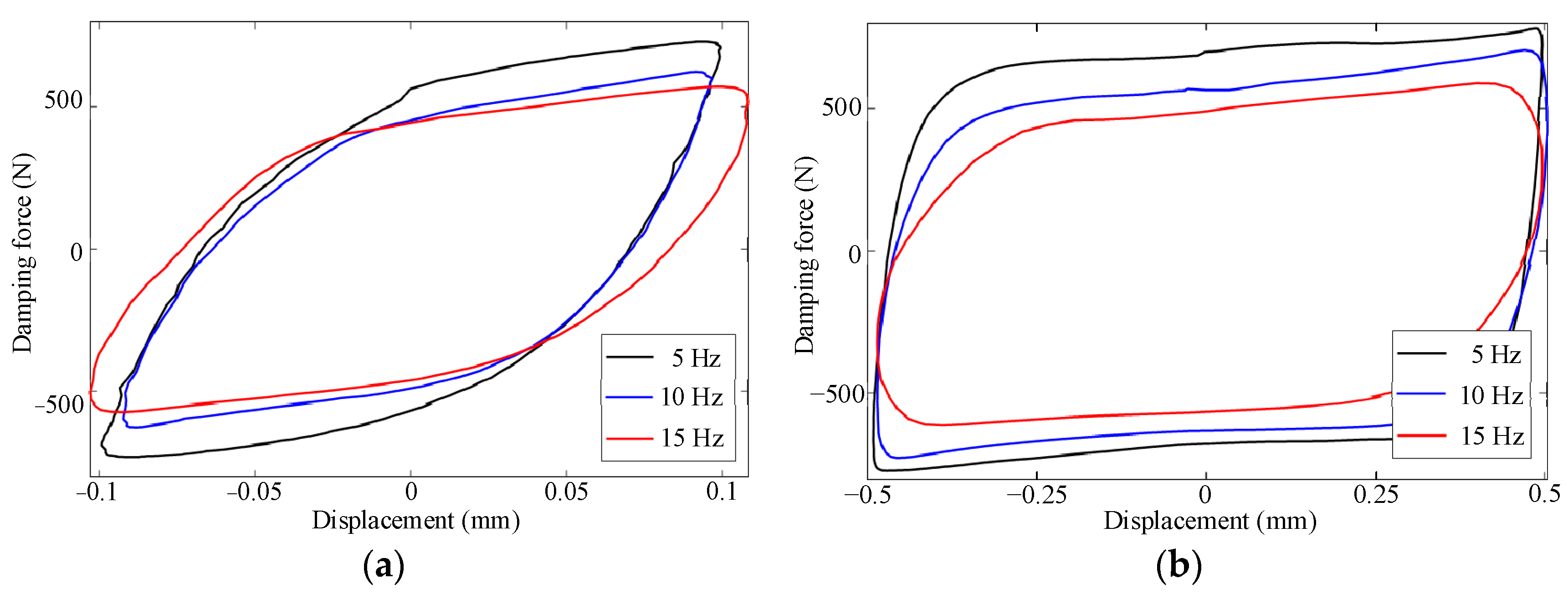

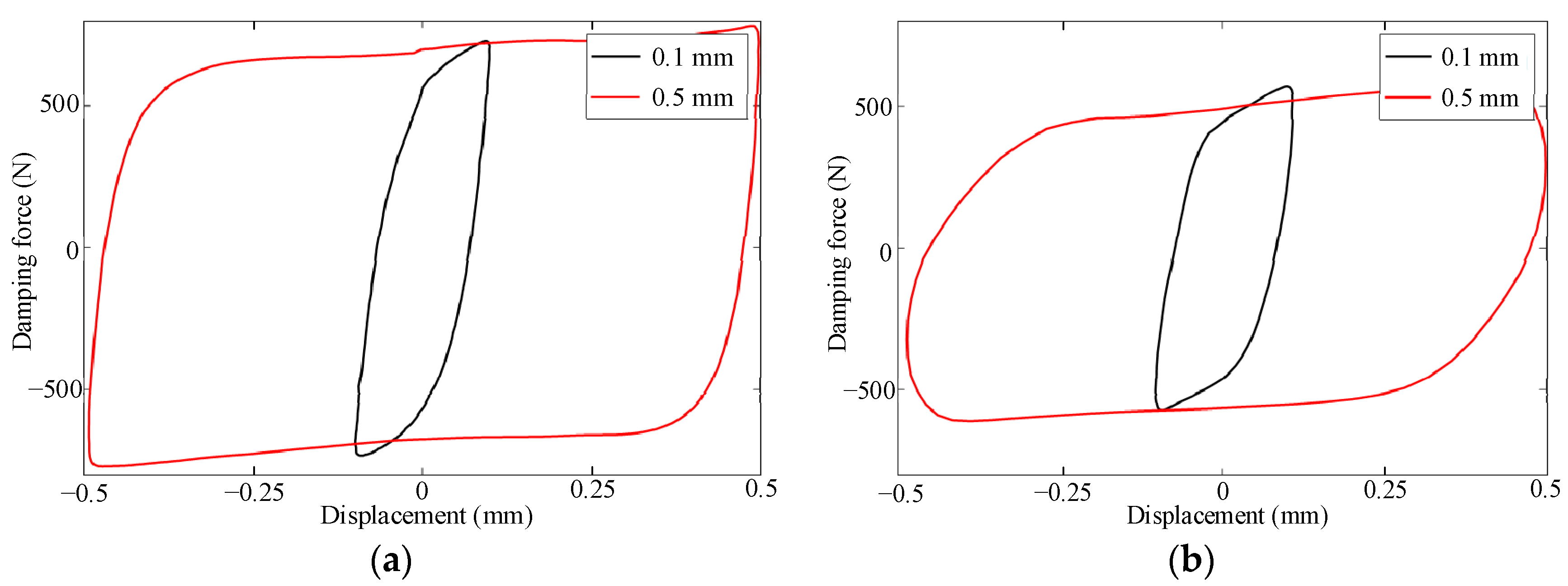

3.1. Experimental Test

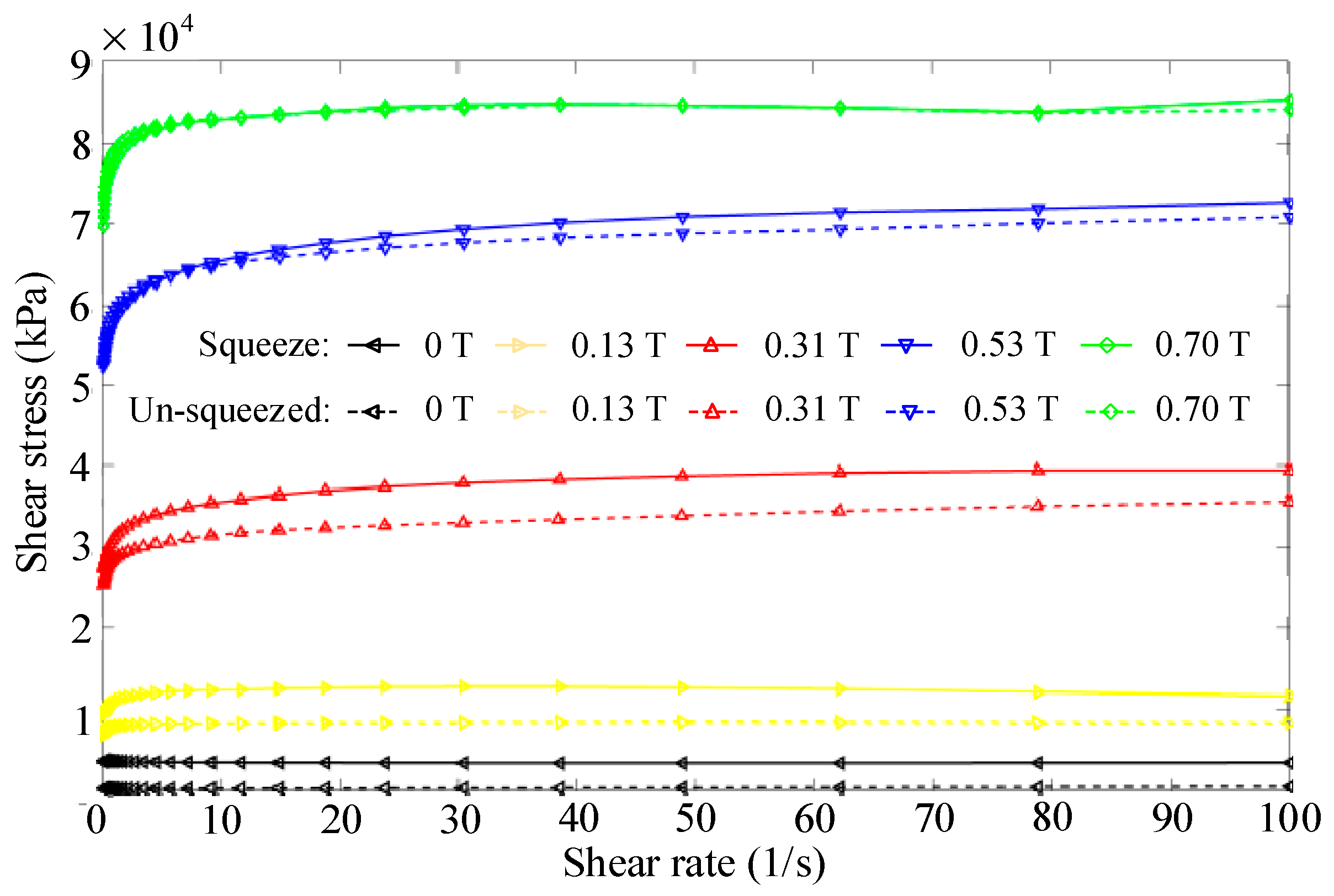

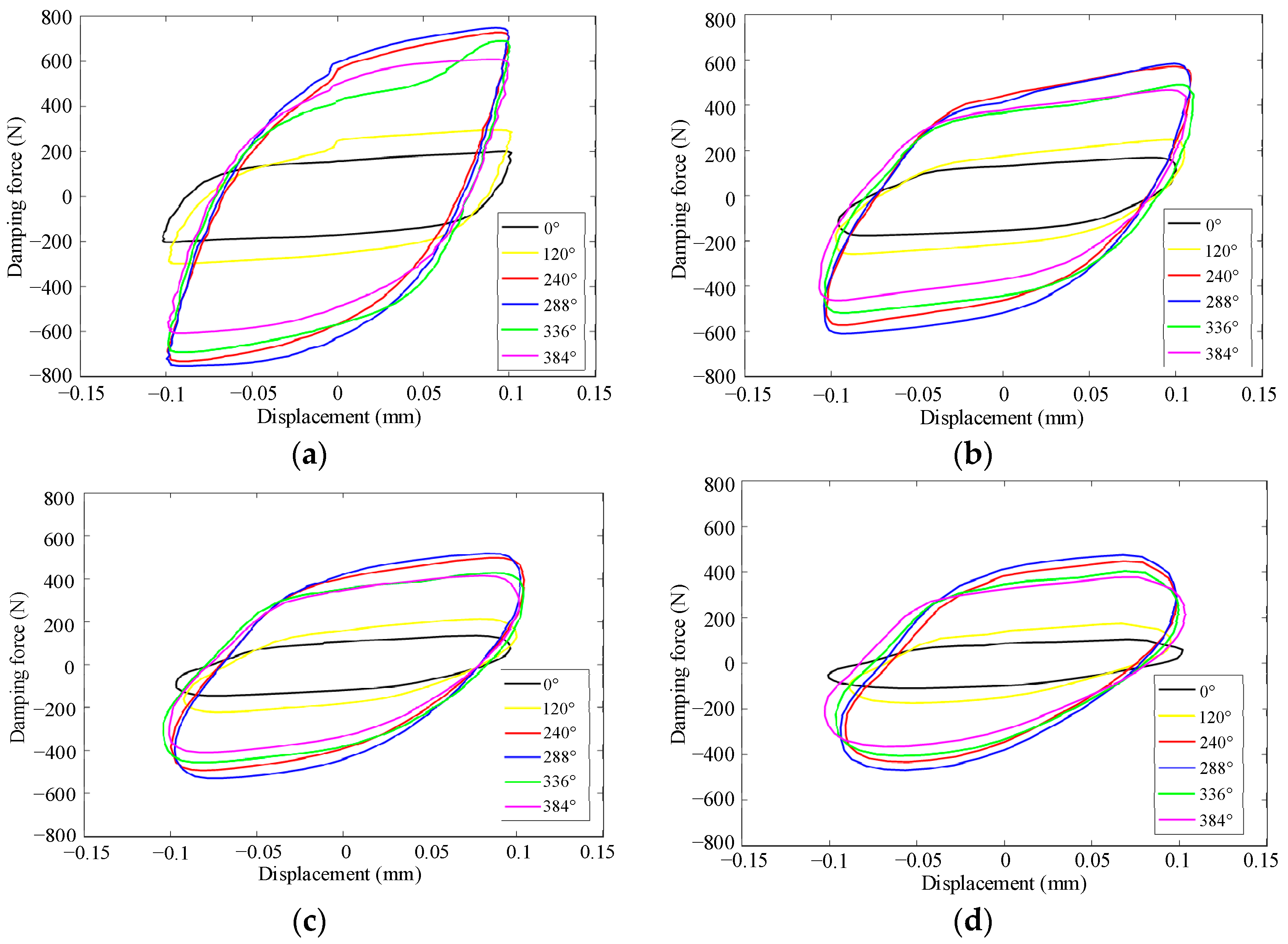

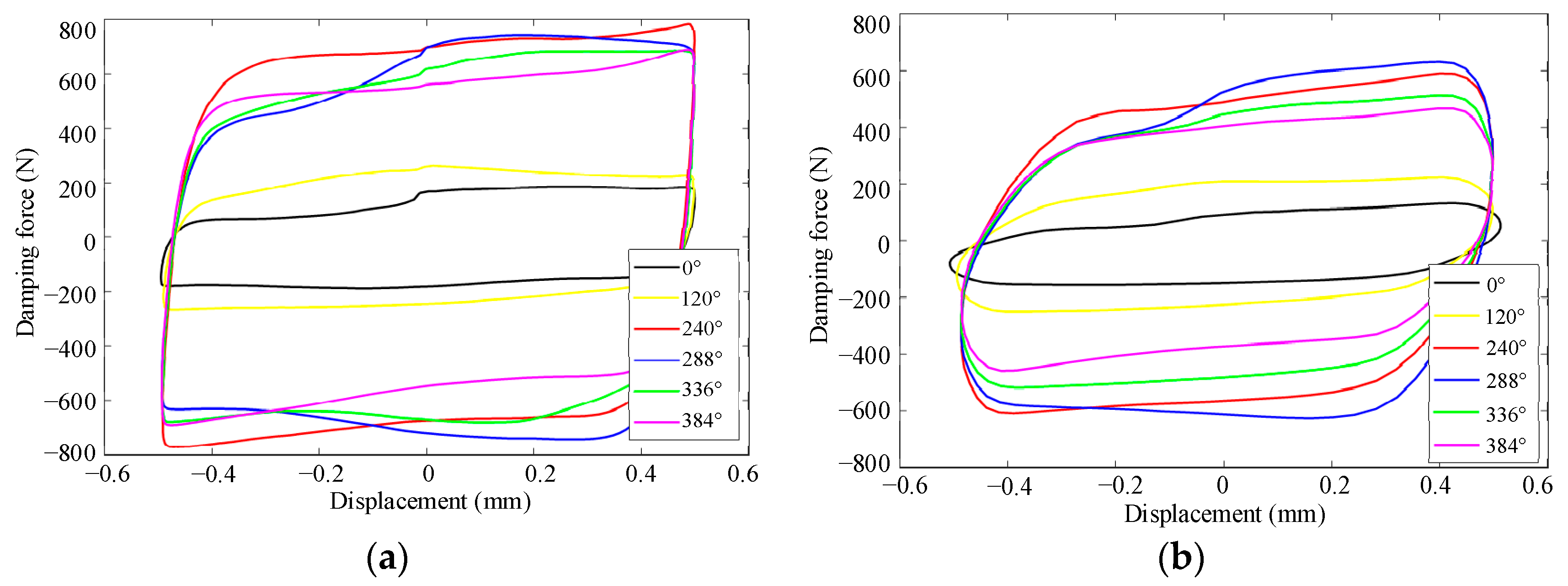

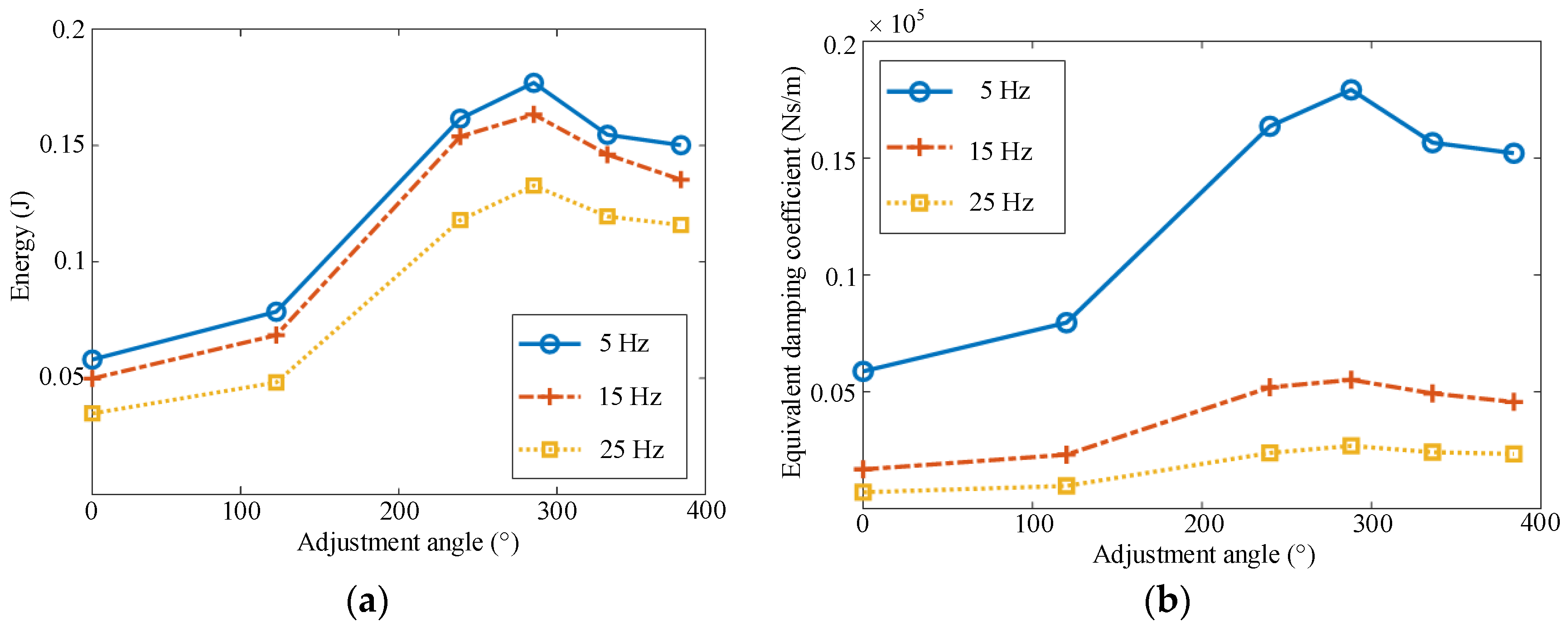

3.2. Experimental Analysis

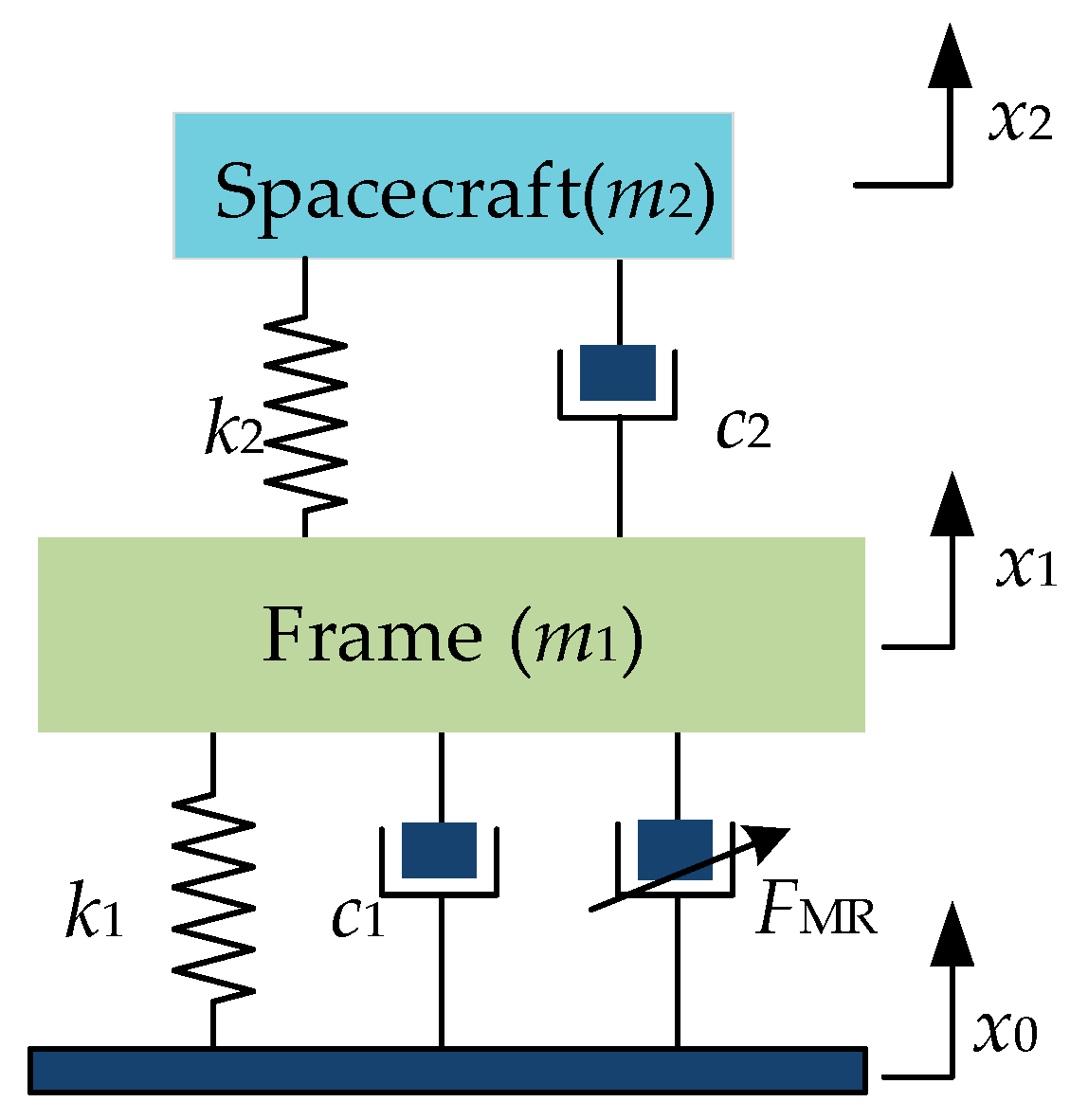

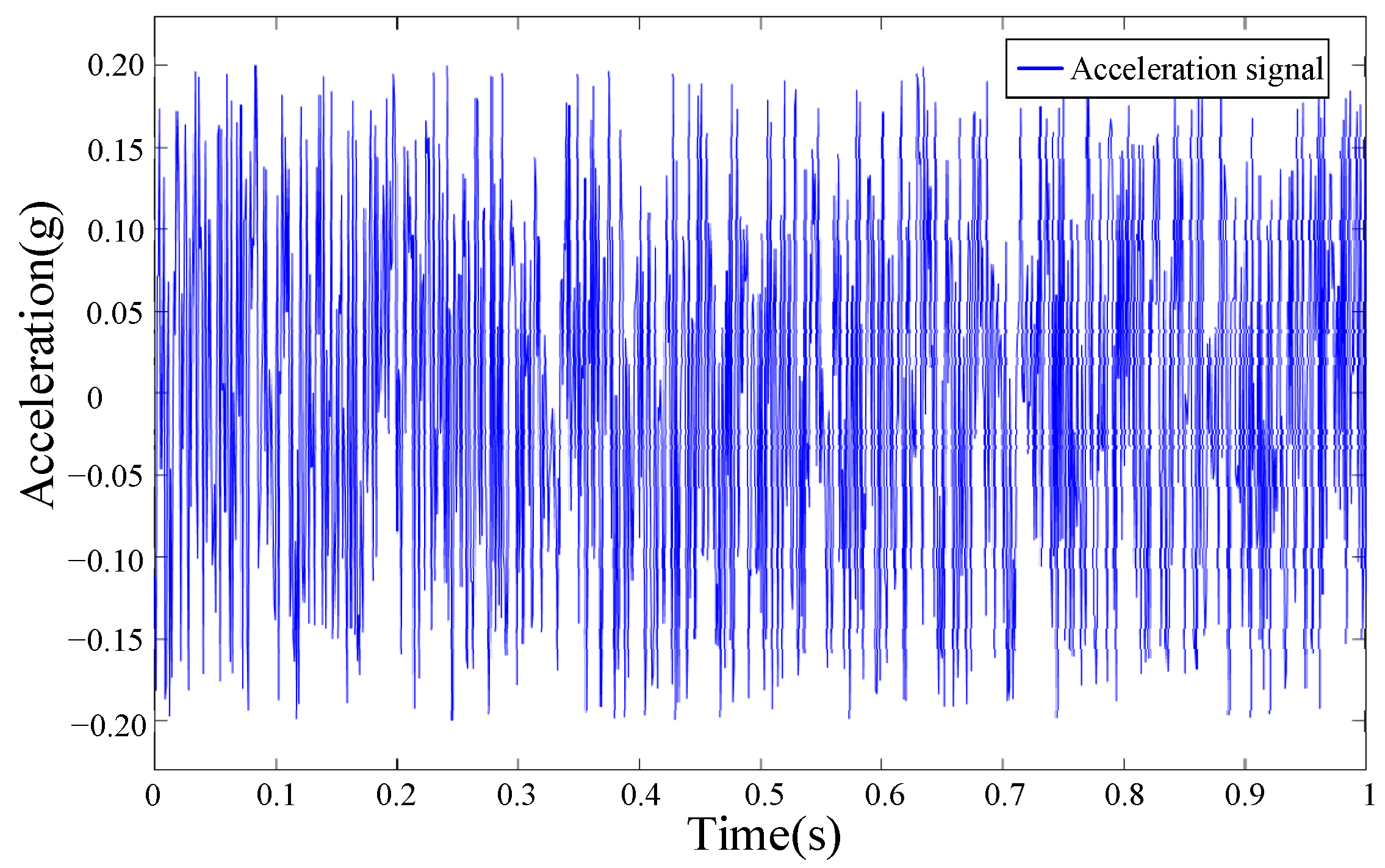

4. Whole-Spacecraft System Simulation Analysis

5. Conclusions

- (1)

- The squeeze strengthening effect of the MR composite at the damping gap was analyzed, and the mechanical model of the damper was derived based on the squeeze principle.

- (2)

- The mechanical performance of the PT-MR damper was tested and analyzed. The results indicate that the proposed damper can generate a damping force greater than 800 N, and the output force increases with the adjustment angle within a certain range.

- (3)

- A whole-spacecraft vibration simulation system was built, and the results showed that the damper had a good damping effect at the adjustment angle of 288°. Compared with the situation without the proposed damper installed, the RMS of spacecraft acceleration decreased from 0.0806 to 0.0528, a decrease of 34.49%. This indicates that the proposed damper can effectively dissipate the vibration energy of the vibration isolation platform and improve the vibration situation of the spacecraft.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PT-MR | Passive-tuned magnetorheological |

| MR | Magnetorheological |

| PMs | Permanent magnets |

| RMS | Root mean square |

References

- Chiu, M.C.; Von-Mehlem, U.I.; Willey, C.E.; Betenbaugh, T.M.; Maynard, J.J.; Krein, J.A.; Conde, R.F.; Gray, W.T.; Hunt, J.W.; Mosher, L.E.; et al. ACE spacecraft. Space Sci. Rev. 1998, 86, 257–284. [Google Scholar] [CrossRef]

- Zhang, W.; Che, J.; Shu, H.; Bai, Y.; Liu, X.; Jiang, W.; Wu, J.; Chen, X. Stewart-inspired vibration isolation mechanisms for precision equipment: Current status and future research trend. Mech. Mach. Theory 2025, 214, 106153. [Google Scholar] [CrossRef]

- Shi, H.T.; Abubakar, M.; Bai, X.T.; Luo, Z. Vibration isolation methods in spacecraft: A review of current techniques. Adv. Space Res. 2024, 73, 3993–4023. [Google Scholar] [CrossRef]

- Liu, L.K.; Zheng, G.T. Parameter analysis of PAF for whole-spacecraft vibration isolation. Aerosp. Sci. Technol. 2007, 11, 464–472. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, B.; Zang, J. Dynamic features of passive whole-spacecraft vibration isolation platform based on non-probabilistic reliability. J. Vib. Control 2015, 21, 60–67. [Google Scholar] [CrossRef]

- Dai, J.; Gai, P.P.; Xu, Z.D.; Yan, X.; Guo, Y.Q.; Huang, X.H. A hybrid constitutive model of high-damping viscoelastic materials used for vibration control of civil structures. Eng. Struct. 2024, 210, 117648. [Google Scholar] [CrossRef]

- Wilke, P.S.; Johnson, C.D.; Fosness, E.R. Whole-spacecraft passive launch isolation. J. Spacecr. Rocket. 1998, 35, 690–694. [Google Scholar] [CrossRef]

- Li, H.; Li, H.Y.; Chen, Z.B.; Tzou, H.S. Experiments on active precision isolation with a smart conical adapter. J. Sound Vib. 2016, 374, 17–28. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.B.; Tzou, H.S. Torsion and transverse sensing of conical shells. Mech. Syst. Signal Process. 2010, 24, 2235–2249. [Google Scholar] [CrossRef]

- de Marneffe, B.; Avraam, M.; Deraemaeker, A.; Horodinca, M.; Preumont, A. Vibration isolation of precision payloads: A six-axis electromagnetic relaxation isolator. J. Guid. Control Dynam. 2012, 32, 395–401. [Google Scholar] [CrossRef]

- Cheng, M.; Xing, J.; Chen, Z.; Pan, Z. Design, analysis and experimental investigation on the whole-spacecraft vibration isolation platform with magnetorheological dampers. Smart Mater. Struct. 2019, 28, 075016. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, Z.; Yin, X. Research on multi-dimensional vibration isolation control system based on a parallel mechanism. In Proceedings of the 2017 IEEE International Conference on Information and Automation, Macao, China, 18–20 July 2017. [Google Scholar]

- Deng, X.; Pan, Z.; Xing, J.; Zhang, Z.; Li, Y.; Yan, M.; Dong, X. Controllability analysis and intelligent control of magnetorheological whole-satellite under small amplitude and medium-high frequency vibration. J. Intell. Mater. Syst. Struct. 2023, 34, 229–248. [Google Scholar] [CrossRef]

- Edberg, D.L.; Wilke, P.; Davis, T.; Fosness, E. On the design and testing of a spacecraft launch vibration isolation system (LVIS). In Proceedings of the 38th Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 7–10 April 1997; pp. 1494–1499. [Google Scholar]

- Wang, S.; Chen, Z.; Jiao, Y.; Liu, X. Active vibration isolation using a six-axis orthogonal vibration isolation platform with piezoelectric actuators. J. Vibroeng. 2017, 19, 6105–6121. [Google Scholar] [CrossRef]

- Hu, G.; Ying, S.; Qi, H.; Yu, L.; Li, G. Design, analysis and optimization of a hybrid fluid flow magnetorheological damper based on multiphysics coupling model. Mech. Syst. Signal Process. 2023, 205, 110877. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Liu, Y.; Qin, Z.; Ma, L.; Chu, F. Rotor vibration control via integral magnetorheological damper. Int. J. Mech. Sci. 2023, 252, 108362. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Y. Numerical simulation and torsional vibration mitigation of spatial eccentric structures with multiple magnetorheological dampers. Actuators 2022, 11, 235. [Google Scholar] [CrossRef]

- Gong, X.; Ruan, X.; Xuan, S.; Yan, Q.; Deng, H. Magnetorheological damper working in squeeze mode. Adv. Mech. Eng. 2014, 6, 410158. [Google Scholar] [CrossRef]

- Lin, C.; Yau, H.; Lee, C.; Tung, K. System identification and semiactive control of a squeeze-mode magnetorheological damper. IEEE-ASME Trans. Mech. 2013, 18, 1691–1701. [Google Scholar] [CrossRef]

- Ko, H.; Yoon, I.; Kim, B.; Han, Y.; Park, S.; Hwang, H.; Kim, S. A haptic knob based on the combination of shear mode and flow mode magnetorheological behaviors. Smart Mater. Struct. 2023, 32, 75011. [Google Scholar] [CrossRef]

- Horak, W. Modeling of magnetorheological fluid in quasi-static squeeze flow mode. Smart Mater. Struct. 2018, 27, 65022. [Google Scholar] [CrossRef]

- Senkal, D.; Gurocak, H. Serpentine flux path for high torque MRF brakes in haptics applications. Mechatronics 2010, 20, 377–383. [Google Scholar] [CrossRef]

- Mao, M.; Hu, W.; Choi, Y.T.; Wereley, N.M.; Browne, A.L.; Ulicny, J.; Johnson, N. Nonlinear modeling of magnetorheological energy absorbers under impact conditions. Smart Mater. Struct. 2013, 22, 115015. [Google Scholar] [CrossRef]

- Zuo, S.; Mao, Y.; Wu, X.; Jiang, W.; Wei, X. Modelling and optimization of high frequency hardening characteristics of magneto rheological damper. J. Vib. Shock. 2016, 35, 120–125. (In Chinese) [Google Scholar] [CrossRef]

- Wu, L.; Dong, X.; Xu, D. A passive-tuned damper based on magnetorheological porous fabric composite. Smart Mater. Struct. 2024, 33, 115013. [Google Scholar] [CrossRef]

- Goldasz, J.; Alexandridis, A.A. Medium- and high-frequency analysis of magnetorheological fluid dampers. J. Vib. Control 2012, 18, 2140–2148. [Google Scholar] [CrossRef]

- Dong, X.M.; Li, P.Y.; Yan, M.S.; Li, X. Characteristic analysis under small-stroke and medium-high frequency of magneto-rheological damper with pressure controlled mechanism. Smart Mater. Struct. 2022, 31, 045011. [Google Scholar] [CrossRef]

- Tu, F.; Chen, Z.; Hua, L.; Jiao, Y.H.; Li, M.Z.; Huang, W.H. Research on dynamic characteristics of a magnetorheological damper with decoupling mechanism. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Las Vegas, NV, USA, 4–7 September 2007; pp. 69–77. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, Z.B.; Xing, J.W. Design, analysis, and experimental evaluation of a magnetorheological damper with meandering magnetic circuit. IEEE Trans. Magn. 2018, 54, 1–10. [Google Scholar] [CrossRef]

- Li, P.; Dong, X.; Yan, H.; Wang, K.; Ran, J.; Yang, R. Performance evaluation of magnetorheological fluid porous fabric composite based on a novel constitute model. Compos. Struct. 2023, 322, 117363. [Google Scholar] [CrossRef]

- Tao, R. Super-strong magnetorheological fluids. J. Phys.-Condens. Mat. 2001, 13, 979–999. [Google Scholar] [CrossRef]

- Wu, L.; Wu, H.; Ran, J.; Shan, H.; Luo, Y.; Zhang, X.; Yang, R.; Dong, X. Industrial pipeline vibration attenuation with magnetorheological tuned mass damper. J. Intell. Mater. Syst. Struct. 2025, 36, 697–713. [Google Scholar] [CrossRef]

| Adjustment Angle θ/° | Minimum Gap Size h/mm |

|---|---|

| 0 | 2 |

| 120 | 1.5 |

| 240 | 1 |

| 288 | 0.8 |

| 336 | 0.6 |

| 384 | 0.4 |

| Parameter | Symbol | Value |

|---|---|---|

| Concentrated mass of transition support | m1 | 332 kg |

| Concentrated mass of simulated spacecraft | m2 | 1056 kg |

| Damping coefficient of transition support | c1 | 44,380,000 N·s/m |

| Damping coefficient of spacecraft support | c2 | 44,200,000 N·s/m |

| Equivalent stiffness of transition support | k1 | 100,000 N/m |

| Equivalent stiffness of spacecraft support | k2 | 40,000 N/m |

| Condition | Maximum Acceleration Value (g) | RMS Value (g) |

|---|---|---|

| Without damper | 0.2358 | 0.0806 |

| Damper, 0° | 0.1825 | 0.0563 |

| Damper, 120° | 0.1848 | 0.0568 |

| Damper, 240° | 0.1687 | 0.0558 |

| Damper, 288° | 0.1628 | 0.0528 |

| Damper, 336° | 0.1643 | 0.0533 |

| Damper, 384° | 0.1669 | 0.0562 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Dong, X.; Wang, K.; Wang, J.; Fang, X.; Zhou, H. Research on a Passive-Tuned Magnetorheological Damper for Whole-Spacecraft Vibration Isolation. Actuators 2025, 14, 600. https://doi.org/10.3390/act14120600

Wu L, Dong X, Wang K, Wang J, Fang X, Zhou H. Research on a Passive-Tuned Magnetorheological Damper for Whole-Spacecraft Vibration Isolation. Actuators. 2025; 14(12):600. https://doi.org/10.3390/act14120600

Chicago/Turabian StyleWu, Lifan, Xiaomin Dong, Kaixiang Wang, Jialong Wang, Xiangcheng Fang, and Huan Zhou. 2025. "Research on a Passive-Tuned Magnetorheological Damper for Whole-Spacecraft Vibration Isolation" Actuators 14, no. 12: 600. https://doi.org/10.3390/act14120600

APA StyleWu, L., Dong, X., Wang, K., Wang, J., Fang, X., & Zhou, H. (2025). Research on a Passive-Tuned Magnetorheological Damper for Whole-Spacecraft Vibration Isolation. Actuators, 14(12), 600. https://doi.org/10.3390/act14120600