Fault Detection and Diagnosis for Human-Centric Robotic Actuation in Healthcare: Methods, Failure Modes, and a Validation Framework

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Scope

2.2. Data Sources and Search Strategy

2.3. Eligibility Criteria (PICOS-Aligned)

2.4. Screening and Study Selection

2.5. Taxonomy and Variable Definitions

2.6. Outcomes

2.7. Statistical Analysis

2.8. Reproducibility and Data Handling

3. Results

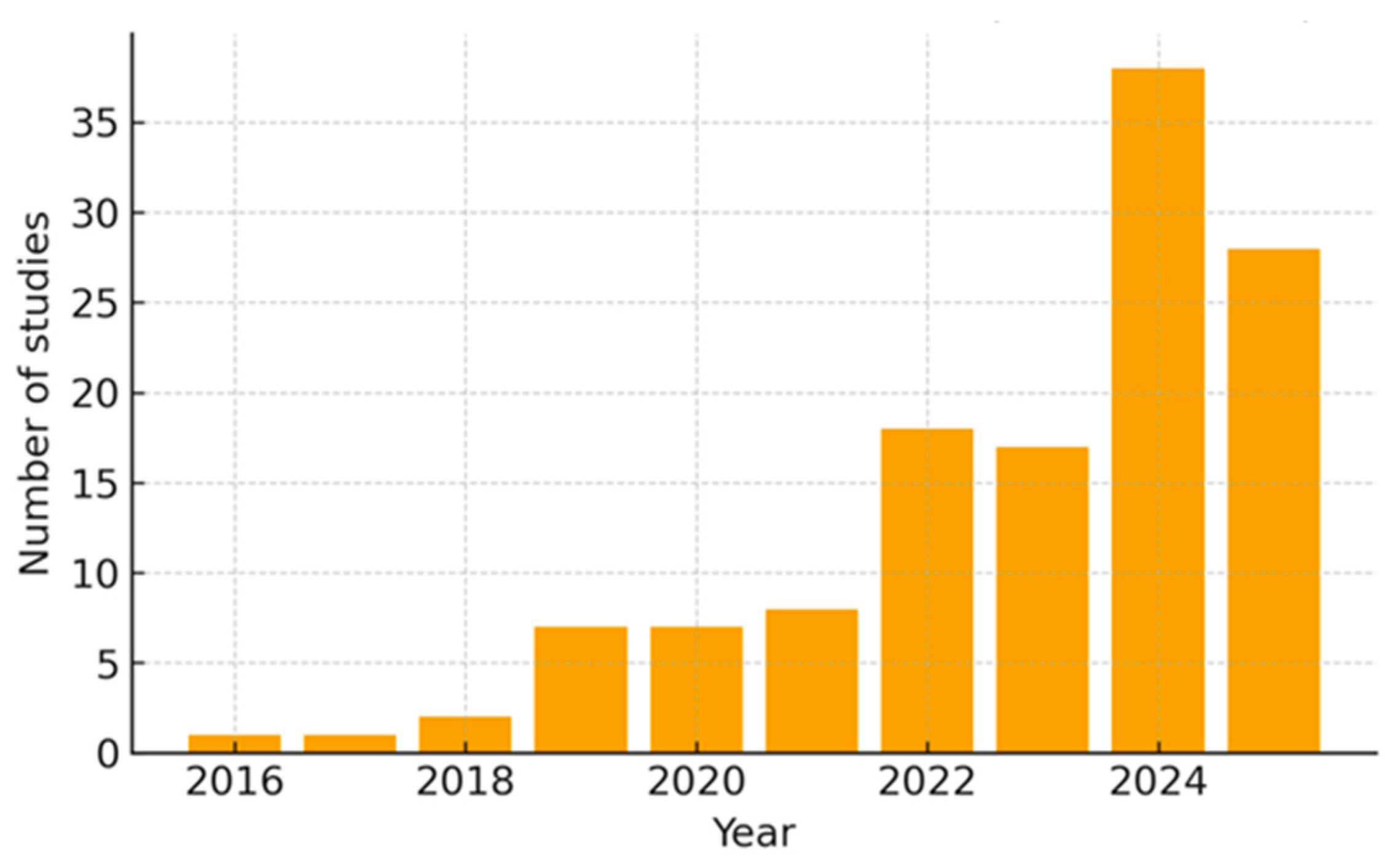

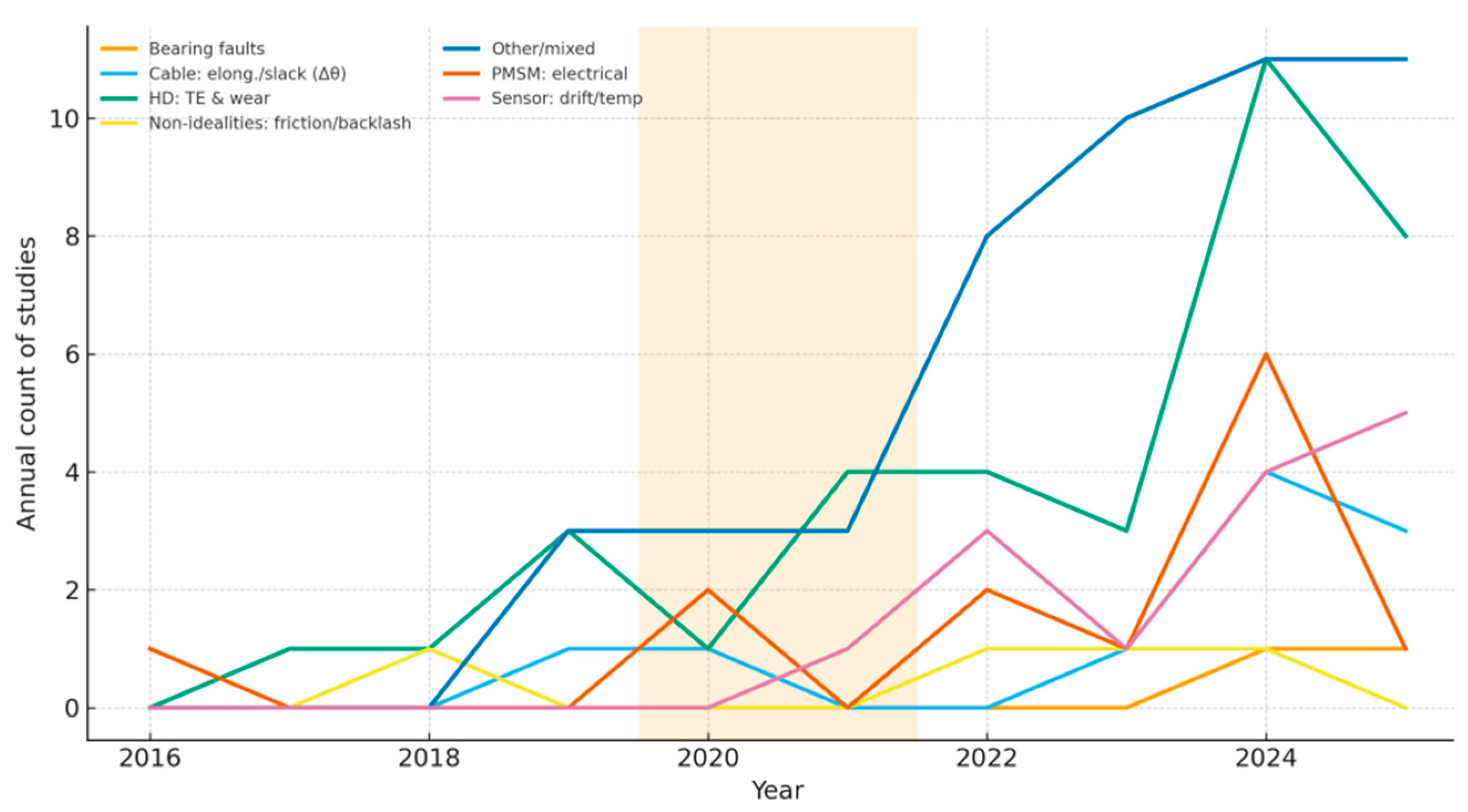

3.1. Overview of Study Set

3.2. Sub-Analyses by Actuator Families and Defect Types

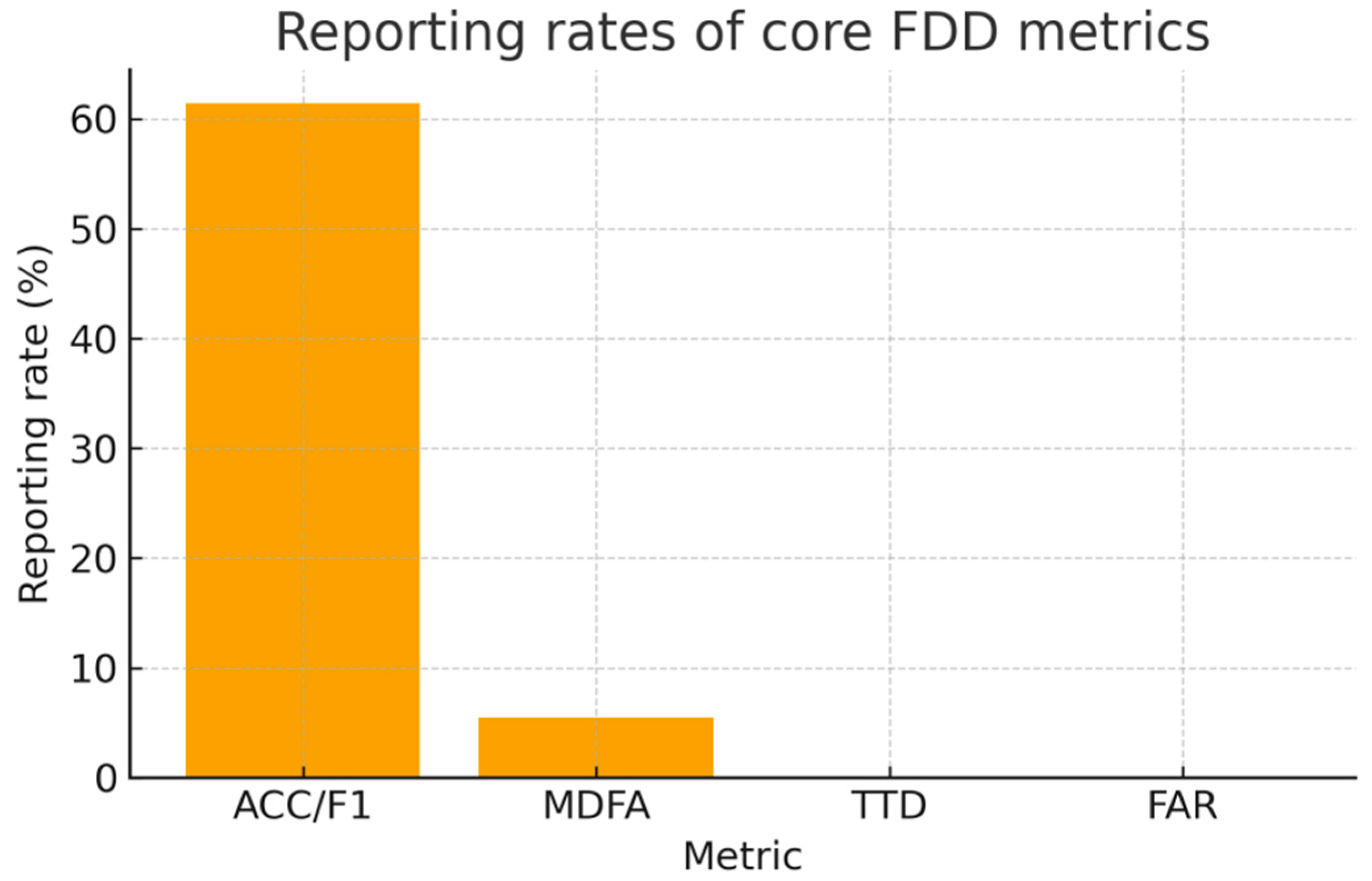

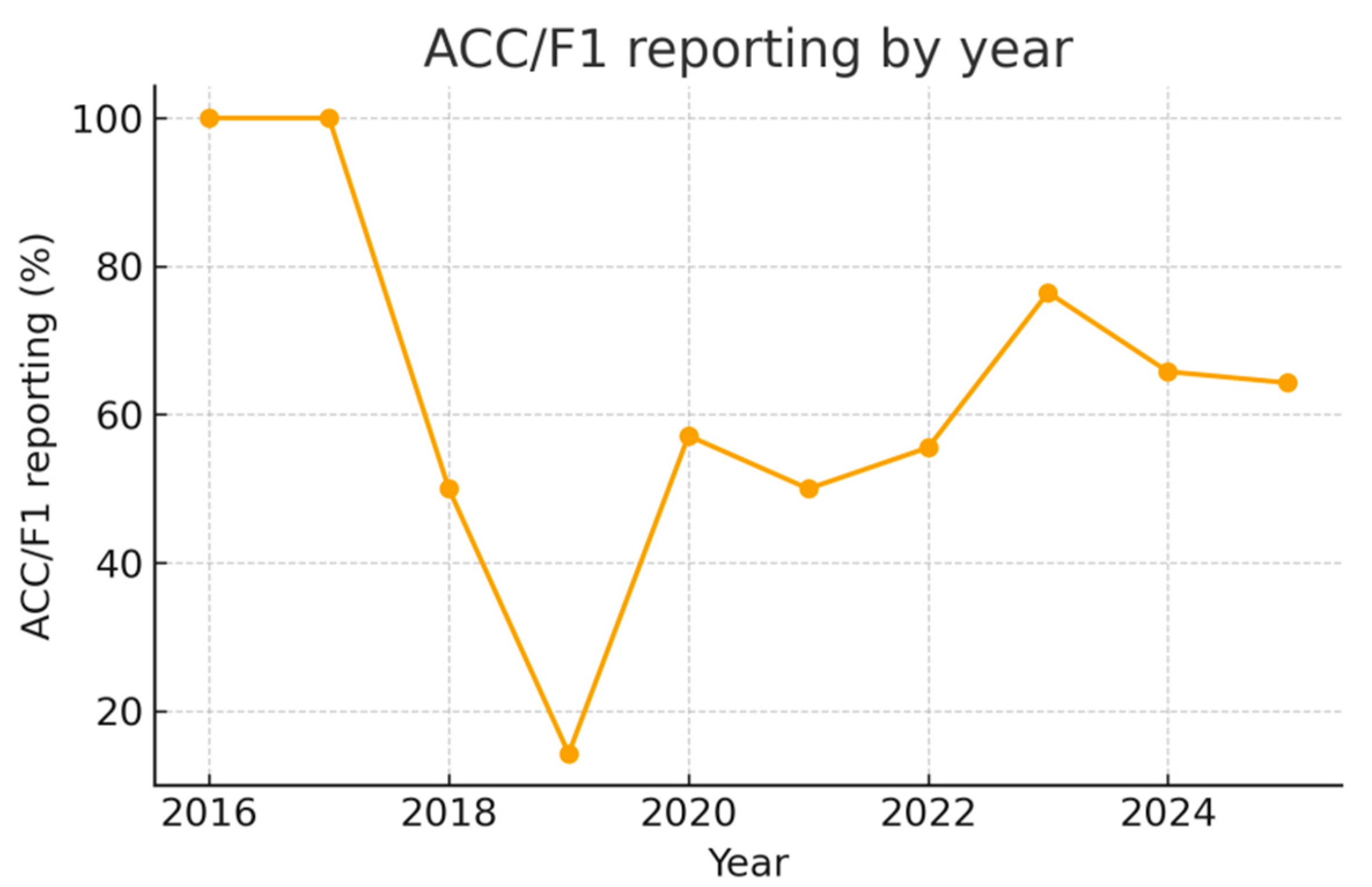

3.3. Metric Reporting and Gaps (TTD, MDFA, FAR, ACC/F1)

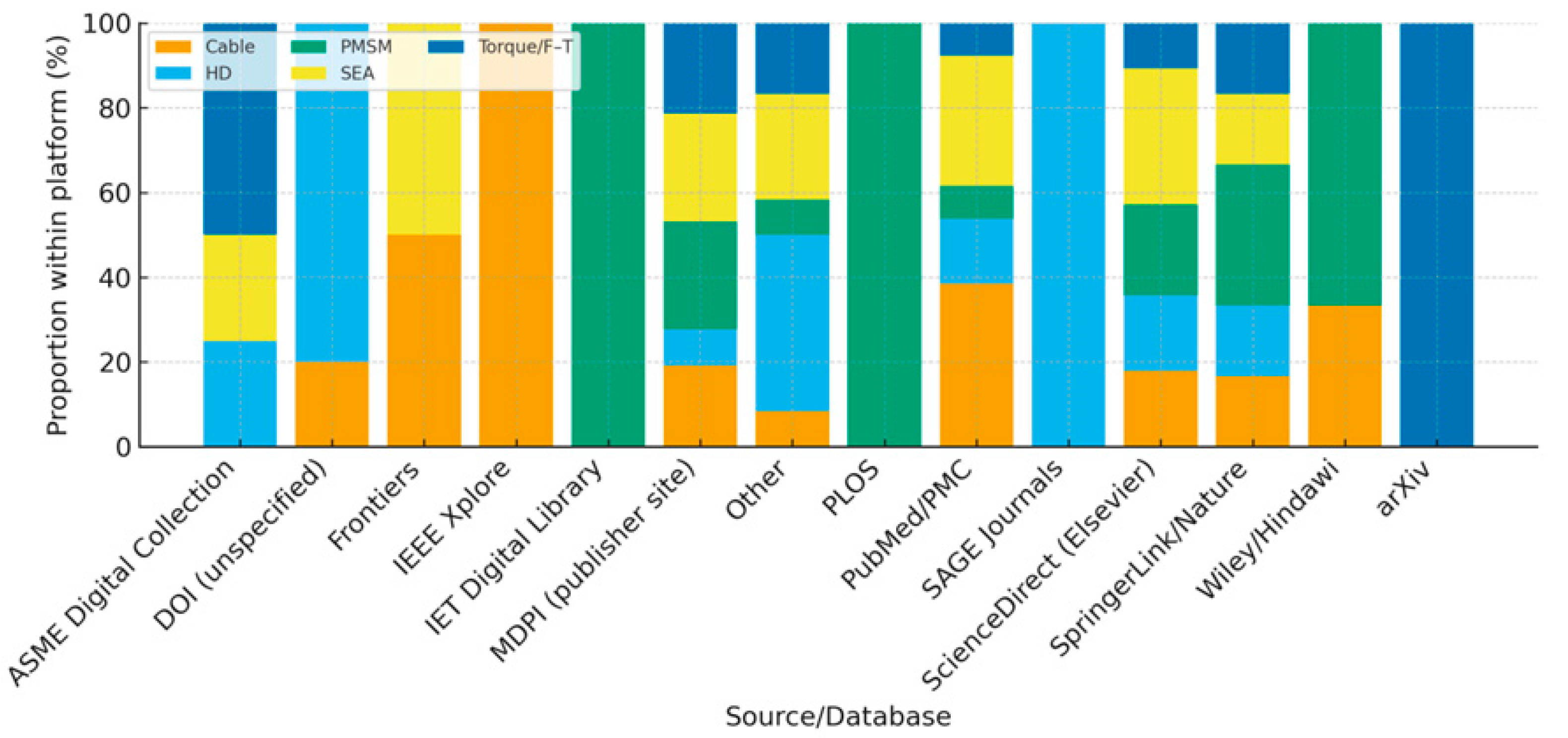

3.4. Database Coverage and Source Bias

3.5. Period Effects (Pre 2016–2019; Pandemic 2020–2021; Post 2022–2025)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACC | Accuracy |

| F1 | F1-score |

| MDFA | Minimal Detectable Fault Amplitude |

| TTD | Time-to-Detect |

| FAR | False-Alarm Rate |

| FDD | Fault Detection and Diagnosis |

| pHRI | Physical Human–Robot Interaction |

| HRI | Human–Robot Interaction |

| SEA | Series-Elastic Actuator |

| HD | Harmonic Drive |

| PMSM | Permanent-Magnet Synchronous Motor |

| F–T | Force–Torque |

| HIL | Hardware-in-the-Loop |

| GLM | Generalised Linear Model |

| OR | Odds Ratio |

| CI | Confidence Interval |

| FDR | False Discovery Rate |

| BH | Benjamini–Hochberg (procedure) |

| DOI | Digital Object Identifier |

| NA–NA | Not estimable (both confidence limits not available) |

| BPFO | Ball Pass Frequency (Outer race) |

| CNN | Convolutional Neural Network |

| CUSUM | Cumulative Sum Control Chart |

| EKF | Extended Kalman Filter |

| FBG | Fiber Bragg Grating |

| GLR | Generalised Likelihood Ratio |

| IMU | Inertial Measurement Unit |

| RF | Random Forest |

| SPC | Statistical Process Control |

| SVM | Support Vector Machine |

| THD | Total Harmonic Distortion |

| UIO | Unknown Input Observer |

References

- Sharkawy, A.-N.; Koustoumpardis, P.N. Human–Robot Interaction: A Review and Analysis on Variable Admittance Control, Safety, and Perspectives. Machines 2022, 10, 591. [Google Scholar] [CrossRef]

- SMBPB, S.; Valori, M.; Legnani, G.; Fassi, I. Assessing Safety in Physical Human–Robot Interaction in Industrial Settings: A Systematic Review of Contact Modelling and Impact Measuring Methods. Robotics 2025, 14, 27. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Vérité, F.; Bregoli, C.; Amici, C. Sensors and Actuation Technologies in Exoskeletons: A Review. Sensors 2022, 22, 884. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wu, J.; Gao, B.; Xia, L.; Lu, C.; Wang, H.; Cao, G. Fault Types and Diagnostic Methods of Manipulator Robots: A Review. Sensors 2025, 25, 1716. [Google Scholar] [CrossRef] [PubMed]

- Inoue, Y.; Kuroda, Y.; Yamanoi, Y.; Yabuki, Y.; Yokoi, H. Development of Wrist Separated Exoskeleton Socket of Myoelectric Prosthesis Hand for Symbrachydactyly. Cyborg Bionic Syst. 2024, 5, 0141. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, D.; Zhao, S.; Yu, Z.; Huang, Y.; Ruan, L.; Zhou, Z.; Wang, Q. Level-Ground and Stair Adaptation for Hip Exoskeletons Based on Continuous Locomotion Mode Perception. Cyborg Bionic Syst. 2025, 6, 0248. [Google Scholar] [CrossRef]

- Raviola, A.; De Martin, A.; Sorli, M. A preliminary experimental study on the effects of wear on the torsional stiffness of strain wave gears. Actuators 2022, 11, 305. [Google Scholar] [CrossRef]

- Li, W.; Hao, L. Study on the degradation law of harmonic gear drive backlash with wear and assembly errors. Eng. Fail. Anal. 2022, 140, 106614. [Google Scholar] [CrossRef]

- Hsieh, N.-K.; Yu, T.-Y. Fault detection in harmonic drive using multi-sensor data fusion and gravitational search algorithm. Machines 2024, 12, 831. [Google Scholar] [CrossRef]

- Noh, Y.R.; Khalid, S.; Kim, H.S.; Choi, S.-K. Intelligent fault diagnosis of robotic strain wave gear reducer using area-metric-based sampling. Mathematics 2023, 11, 4081. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, J.; Wang, L.; Chen, C.; Xu, S.; Wang, B. A novel on-line approach for evaluating transmission errors in harmonic drives. Adv. Mech. Eng. 2024, 16, 16878132241276666. [Google Scholar] [CrossRef]

- Guida, R.; Bertolino, A.C.; De Martin, A.; Sorli, M. Comprehensive analysis of major fault-to-failure mechanisms in harmonic drives (UR5 case). Machines 2024, 12, 776. [Google Scholar] [CrossRef]

- Raouf, I.; Lee, H.; Noh, Y.R.; Youn, B.D.; Kim, H.S. Prognostic health management of the robotic strain wave gear reducer based on variable speed of operation: A data-driven via deep learning approach. J. Comput. Des. Eng. 2022, 9, 1775–1788. [Google Scholar] [CrossRef]

- Tsolakis, E.; Vasileiou, G.; Rogkas, N.; Kalligeros, C.; Zalimidis, P.; Spitas, V. Dynamic modelling and torque ripple minimisation of a lightweight ultra-high transmission ratio harmonic drive. MATEC Web Conf. 2020, 317, 01007. [Google Scholar] [CrossRef]

- Raviola, A.; De Martin, A.; Guida, R.; Jacazio, G.; Mauro, S.; Sorli, M. Harmonic drive gear failures in industrial robots: An overview. In Proceedings of the 6th European Conference of the Prognostics and Health Management Society, Virtual, 28 June–2 July 2021; ISBN 978-1-936263-34-9. Available online: https://papers.phmsociety.org/index.php/phme/article/download/2849/1801 (accessed on 20 May 2025).

- Kißkalt, J.; Michalka, A.; Strohmeyer, C.; Horn, M.; Graichen, K. Fault Detection in Gauge-Sensorized Strain Wave Gears. In Proceedings of the 2024 European Control Conference (ECC), Stockholm, Sweden, 25–28 June 2024. [Google Scholar] [CrossRef]

- Velasco-Guillén, R.J.; Bliek, A.; Font-Llagunes, J.M.; Vanderborght, B.; Beckerle, P. Compensating elastic faults in a torque-assisted knee exoskeleton: Functional evaluation and user perception study. J. Neuroeng. Rehabil. 2024, 21, 230. [Google Scholar] [CrossRef]

- Velasco-Guillén, R.J.; Furnemoant, R.; Verstraten, T.; Vanderborght, B.; Font-Llagunes, J.M.; Beckerle, P. Stiffness-fault-tolerant control strategy for elastic actuators with interaction impedance adaptation. Mechatronics 2024, 104, 103265. [Google Scholar] [CrossRef]

- Sarkisian, S.V.; Gabert, L.; Lenzi, T. Series-elastic actuator with two-degree-of-freedom PID control improves torque control in a powered knee exoskeleton. Wearable Technol. 2023, 4, e25. [Google Scholar] [CrossRef] [PubMed]

- Rosales-Luengas, Y.; Centeno-Barreda, D.; Salazar, S.; Flores, J.; Lozano, R. Movement intent detection for upper-limb rehabilitation exoskeleton based on SEA as force sensor. Actuators 2024, 13, 284. [Google Scholar] [CrossRef]

- Wang, T.; Zheng, T.; Zhao, S.; Sui, D.; Zhao, J.; Zhu, Y. Design and control of a series–parallel elastic actuator (SPEA) for a load-carrying exoskeleton. Sensors 2022, 22, 1055. [Google Scholar] [CrossRef]

- Vantilt, J.; Tanghe, K.; Afschrift, M.; Bruijnes, A.K.B.D.; Junius, K.; Geeroms, J.; Aertbeliën, E.; De Groote, F.; Lefeber, D.; Jonkers, I.; et al. Model-based control for exoskeletons with series elastic actuators. J. NeuroEng. Rehabil. 2019, 16, 65. [Google Scholar] [CrossRef]

- Calanca, A.; Sartori, E.; Maris, B. Force control of lightweight series elastic systems using enhanced disturbance observers. Robot. Auton. Syst. 2023, 164, 104407. [Google Scholar] [CrossRef]

- Chiaradia, D.; Rinaldi, G.; Solazzi, M.; Vertechy, R.; Frisoli, A. Design and control of the REHAB-EXOS, a joint torque-controllable upper-limb exoskeleton. Robotics 2024, 13, 32. [Google Scholar] [CrossRef]

- Jenks, B.; Levan, H.; Stefanovic, F. OpenSEA: A 3D-printed planetary-gear SEA for elbow rehab (open design). Front. Robot. AI 2025, 12, 1528266. [Google Scholar] [CrossRef]

- Liao, H.; Chan, H.H.-T.; Gao, F.; Zhao, X.; Liu, G.; Liao, W.-H. Proxy-based torque control of motor-driven exoskeletons for safe and compliant human–exoskeleton interaction. Mechatronics 2022, 88, 102906. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, Z.; Yang, C.; Xie, F. Research on dynamic transmission error of harmonic drive with uncertain parameters by an interval method. Precis. Eng. 2021, 68, 285–300. [Google Scholar] [CrossRef]

- Kißkalt, J.; Michalka, A.; Strohmeyer, C.; Horn, M.; Graichen, K. Model-based fault simulation and detection for gauge-sensorized strain wave gears. IFAC-PapersOnLine 2025, 59, 271–276. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.; Wang, P.; Yang, F.; Peng, C.; Yun, X. Accelerated life test and performance degradation test of harmonic drive with failure analysis. Machines 2025, 13, 918. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.; Wang, P.; Peng, C.; Yang, F. Study on precision reliability evaluation method of harmonic drive based on NIPCE considering wear. Sci. Rep. 2025, 15, 14439. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Zhang, Z.; Zhang, H. Experimental study on transmission performance of harmonic drive under multiple factors. Mech. Ind. 2019, 20, 614. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, Z.; Cai, L.; Yang, C.; Zhang, T.; Wang, G. Research on prediction method of transmission accuracy of harmonic drive (IDETC-CIE 2019). In Proceedings of the ASME IDETC-CIE 2019, Anaheim, CA, USA, 18–21 August 2019; Available online: https://asmedigitalcollection.asme.org/IDETC-CIE/proceedings/IDETC-CIE2019/59308/V010T11A006/1070360 (accessed on 20 May 2025).

- Hu, Y.; Zhan, Y.; Han, L.; Hu, P.; Ye, B.; Yu, Y. An angle error compensation method based on harmonic analysis for integrated joint modules. Sensors 2020, 20, 1715. [Google Scholar] [CrossRef]

- Li, R.; Zhou, G.; Zhao, Z.; Li, J.; Wang, J. Analysis and prediction of transmission error of harmonic reducer for space robot. Space Sci. Technol. 2025, 5, 0233. [Google Scholar] [CrossRef]

- Li, R.; Zhou, G.; Li, D. Structural design of flexible wheel of harmonic reducer based efficiency improvement. Mech. Syst. Signal Process. 2023, 201, 110677. [Google Scholar] [CrossRef]

- Li, R.; Zhou, G.; Huang, J.; Li, J. Lightweight design and verification of space harmonic drive. Int. J. Mech. Sci. 2025, 296, 110302. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, J. Health monitoring of strain wave gear on industrial robots. In Proceedings of the IEEE 8th Data Driven Control and Learning Systems Conf. (DDCLS), Dali, China, 24–27 May 2019. [Google Scholar]

- de Gea Fernández, J.; Yu, B.; Bargsten, V.; Zipper, M.; Sprengel, H. Design, modelling and control of novel series-elastic actuators for industrial robots. Actuators 2020, 9, 6. [Google Scholar] [CrossRef]

- Bolívar-Nieto, E.; Rezazadeh, S.; Summers, T.; Gregg, R.D. Robust optimal design of energy-efficient series elastic actuators: Application to a powered prosthetic ankle. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; Available online: https://pubmed.ncbi.nlm.nih.gov/31374719/ (accessed on 20 May 2025).

- Bolívar-Nieto, E.A.; Summers, T.; Gregg, R.D.; Rezazadeh, S. A convex optimisation framework for robust-feasible series elastic actuators. Mechatronics 2021, 79, 102635. [Google Scholar] [CrossRef]

- Toubar, H.; Awad, M.I.; Boushaki, M.N.; Niu, Z.; Khalaf, K.; Hussain, I. Design, modeling, and control of a series elastic actuator with discretely adjustable stiffness (SEADAS). Mechatronics 2022, 86, 102863. [Google Scholar] [CrossRef]

- Wu, L.; Wang, C.; Liu, J.; Zou, B.; Chakrabarty, S.; Bao, T.; Xie, S.Q. Novel design on knee exoskeleton with compliant actuator for post-stroke rehabilitation. Sensors 2025, 25, 153. [Google Scholar] [CrossRef]

- Kang, I.; Peterson, R.R.; Herrin, K.R.; Mazumdar, A.; Young, A.J. Design and validation of a torque-controllable series elastic actuator-based hip exoskeleton for dynamic locomotion. ASME J. Mech. Robot. 2023, 15, 021007. [Google Scholar] [CrossRef]

- Al-Dahiree, O.S.; Ghazilla, R.A.R.; Tokhi, M.O.; Yap, H.J.; Albaadani, E.A. Design of a compact energy storage with rotary series elastic actuator for lumbar support exoskeleton. Machines 2022, 10, 584. [Google Scholar] [CrossRef]

- Sanfilippo, F.; Økter, M.; Dale, J.; Tuan, H.M.; Zafar, M.H.; Ottestad, M. Open-source design of low-cost sensorised elastic actuator for collaborative prosthetics and orthotics. HardwareX 2024, 19, e00564. [Google Scholar] [CrossRef]

- Zhao, W.; Liao, J.; Qian, W.; Yu, H.; Guo, Z. A novel design of series elastic actuator using tensile springs array. Mech. Mach. Theory 2024, 192, 105541. [Google Scholar] [CrossRef]

- Wang, R.; Lin, X.; Yin, C.; Liu, Z.; Zhang, Y.; Liu, W.; Du, F. Robust continuous sliding-mode-based assistive torque control for SEA-driven lower-limb hip exoskeleton. Actuators 2025, 14, 239. [Google Scholar] [CrossRef]

- Lee, S.; Choi, S.; Ko, C.; Kim, T.; Kong, K. Design and control of the compact cable-driven series elastic actuator module in soft wearable robot for ankle assistance. Int. J. Control Autom. Syst. 2023, 21, 1624–1633. [Google Scholar] [CrossRef]

- Xu, J.; Chen, S.; Li, S.; Liu, Y.; Wan, H.; Xu, Z.; Zhang, C. A survey on design and control methodologies of high-torque-density joints for compliant lower-limb exoskeleton. Sensors 2025, 25, 4016. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, W.; Pradhan, S.; Bravo, C.; Tzvi, P.B. Data-driven calibration and control of compact lightweight series elastic actuators for robotic exoskeleton gloves. IEEE Access 2021, 21, 21120–21130. [Google Scholar] [CrossRef]

- Shakeriaski, F.; Mohammadian, M. Enhancing upper-limb exoskeletons using sensor-based deep learning torque prediction and PID control. Sensors 2025, 25, 3528. Available online: https://www.mdpi.com/1424-8220/25/11/3528 (accessed on 20 May 2025). [CrossRef]

- Hochreiter, D.; Schmermbeck, K.; Vazquez-Pufleanu, M.; Ferscha, A. Intention prediction for active upper-limb exoskeletons in industrial applications: A systematic literature review. Sensors 2025, 25, 5225. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Xu, C.; Gu, J.; Zhao, L.; Hu, Y. Design, modeling and optimal control of a novel compliant actuator. Control Eng. Pract. 2024, 148, 105967. [Google Scholar] [CrossRef]

- Karasheva, M.; Saudanbekova, A.; Utepbergen, A.; Akkulova, S.; Niyetkaliyev, A.; Ozhikenov, K.; Ozhiken, A.; Alimbayev, C.; Shylmyrza, U.; Aimukhanbetov, Y. Sensor-driven control strategies for post-stroke shoulder rehabilitation exoskeletons: A systematic review. MethodsX 2025, 15, 103648. [Google Scholar] [CrossRef]

- Dežman, M.; Asfour, T.; Ude, A.; Gams, A. Mechanical design and friction modelling of a cable-driven upper-limb exoskeleton. Mech. Mach. Theory 2022, 171, 104746. [Google Scholar] [CrossRef]

- Wei, W.; Qu, Z.; Wang, W.; Zhang, P.; Hao, F. Design on the Bowden cable-driven upper limb soft exoskeleton. Appl. Bionics Biomech. 2018, 2018, 1925694. [Google Scholar] [CrossRef]

- Shi, Y.; Guo, M.; Hui, C.; Li, S.; Ji, X.; Yang, Y.; Luo, X. Learning-based repetitive control of a Bowden-cable-actuated exoskeleton with frictional hysteresis. Micromachines 2022, 13, 1674. [Google Scholar] [CrossRef]

- Li, X.; Ma, G.; Wang, D. Research on Bowden cable–fabric force transfer system based on force/displacement compensation and impedance control. Appl. Sci. 2023, 13, 11766. [Google Scholar] [CrossRef]

- Vatan, H.; Theodoridis, T.; Wei, G.; Saffari, Z.; Holderbaum, W. The design and development of a wearable cable-driven shoulder exosuit (CDSE) for multi-DoF upper limb assistance. Appl. Sci. 2025, 15, 10673. [Google Scholar] [CrossRef]

- Tian, M.; Liu, Y.; Chen, Z.; Wang, X.; Zhang, Q.; Liu, B. Biomimetic design and validation of an adaptive cable-driven elbow exoskeleton inspired by the shrimp shell. Biomimetics 2025, 10, 271. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Song, A.; Li, Y.; Li, H.; Chen, D.; Zhu, L. A cable-driven three-DoF wrist rehabilitation exoskeleton with improved performance. Front. Neurorobot. 2021, 15, 664062. [Google Scholar] [CrossRef] [PubMed]

- Sanjuan, J.D.; Castillo, A.D.; Padilla, M.A.; Quintero, M.C.; Gutierrez, E.E.; Sampayo, I.P.; Hernandez, J.R.; Rahman, M.H. Cable-driven exoskeleton for upper-limb rehabilitation: A design review. Robot. Auton. Syst. 2020, 126, 103445. [Google Scholar] [CrossRef]

- Zhang, F.; Fu, Y.; Yang, L.; Fu, Y. A novel cable configuration method for fully-actuated parallel cable-driven systems: Application in a shoulder rehabilitation exoskeleton. Mech. Mach. Theory 2024, 199, 105693. [Google Scholar] [CrossRef]

- Dinh, B.K.; Xiloyannis, M.; Cappello, L.; Antuvan, C.W.; Yen, S.; Masia, L. Adaptive backlash compensation in upper-limb soft wearable exoskeletons. Robot. Auton. Syst. 2017, 92, 173–186. [Google Scholar] [CrossRef]

- Jin, X.; Ding, W.; Baumert, M.; Wei, Y.; Li, Q.; Yang, W.; Yan, Y. Mechanical design, analysis and dynamics simulation of a cable-driven wearable flexible exoskeleton system. Technologies 2024, 12, 238. [Google Scholar] [CrossRef]

- Park, D.; Di Natali, C.; Sposito, M.; Caldwell, D.G.; Ortiz, J. Elbow-sideWINDER (Elbow-side Wearable INDustrial Ergonomic Robot): Design, Control, and Validation of a Novel Elbow Exoskeleton. Front. Neurorobot. 2023, 17, 1168213. [Google Scholar] [CrossRef]

- Prasad, R.; El-Rich, M.; Awad, M.I.; Agrawal, S.K.; Khalaf, K. Muscle-Inspired Bi-Planar Cable Routing: A Novel Framework for Designing Cable-Driven Lower-Limb Rehabilitation Exoskeletons (C-LREX). Sci. Rep. 2024, 14, 55785. [Google Scholar] [CrossRef] [PubMed]

- Alapati, S.; Seth, D.; Nakka, S.; Aoustin, Y. Validation of Cable-Driven Experimental Setup to Assess Movements with Elbow Joint Assistance. Appl. Sci. 2025, 15, 1892. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Li, W.; Huang, Y.; Zhan, G. Force Transmission Analysis and Optimization of Bowden Cable on Body in a Flexible Exoskeleton. Appl. Bionics Biomech. 2022, 2022, 5552166. [Google Scholar] [CrossRef]

- Chen, W.; Li, Z.; Cui, X.; Zhang, J.; Bai, S. Mechanical Design and Kinematic Modeling of a Cable-Driven Arm Exoskeleton Incorporating Inaccurate Anthropomorphic Parameters. Sensors 2019, 19, 4461. [Google Scholar] [CrossRef]

- Li, X.; Yang, Q.; Song, R. Performance-Based Hybrid Control of a Cable-Driven Upper-Limb Rehabilitation Robot. IEEE Trans. Biomed. Eng. 2021, 68, 1351–1359. [Google Scholar] [CrossRef] [PubMed]

- Andrade Chavez, F.J.; Traversaro, S.; Pucci, D. Six-Axis Force–Torque Sensor Model-Based In Situ Calibration Method and Its Impact in Floating-Based Robot Dynamic Performance. Sensors 2019, 19, 5521. [Google Scholar] [CrossRef]

- Yao, L.; Xu, Y.; Sun, B.; Yang, X.; Zhang, G.; Wang, H.; Wang, S. An Integrated Compensation Method for Force Disturbance of a Six-Axis Force Sensor in Complex Manufacturing Scenarios. Sensors 2021, 21, 4706. [Google Scholar] [CrossRef]

- Sun, Y. Design, Manufacture, Test and Experiment of Six-Axis Force/Torque Sensor for Chinese Experimental Module Manipulator. Sensors 2022, 22, 3603. [Google Scholar] [CrossRef]

- Dong, X.; Ding, F.; Zhou, H.; Wang, N.; Sun, W. Temperature Compensation of Wind Tunnel Balance Signal Detection System Based on IGWO-ELM. Sensors 2023, 23, 7224. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Revzen, S. In-Situ Calibration of Six-Axis Force/Torque Transducers on a Legged Robot. J. Dyn. Syst. Meas. Control 2025, 147, 031003. [Google Scholar] [CrossRef]

- Chávez, F.J.A.; Traversaro, S.; Nori, F. Model-Based In Situ Calibration of Six-Axis Force/Torque Sensors. arXiv 2018, arXiv:1812.00650. [Google Scholar]

- Suciu, C.C.; Stoica, V.; Ilie, M.; Ionel, I.; Ionel, R. A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology. Appl. Sci. 2025, 15, 8158. [Google Scholar] [CrossRef]

- Zhao, H.; Lu, C.; Sun, Y.; Luo, Y.; Fu, Y.; Dong, Y.; Xue, B. Research on Calibration Methods and Experiments for Six-Component Force. J. Mar. Sci. Eng. 2025, 13, 1811. [Google Scholar] [CrossRef]

- Ahmad, A.R.; Wynn, T.; Lin, C.-Y. A Comprehensive Design of Six-Axis Force/Moment Sensor. Sensors 2021, 21, 4498. [Google Scholar] [CrossRef]

- Li, X.; Zhang, F.; Zhang, Y.; Zhang, S.; Yuan, W.; Zhang, Z. A Temperature Compensation Method for a Six-Axis Force/Torque Sensor Utilising Ensemble hWOA-LSSVM Based on Improved Trimmed Bagging. Sensors 2022, 22, 5056. [Google Scholar] [CrossRef] [PubMed Central]

- Kim, H.B.; Park, S.; Lee, J.; Kim, H.; Lee, D. Temperature Compensation Method of Six-Axis Force/Torque Sensor Using Gated Recurrent Unit. arXiv 2025, arXiv:2502.17528. [Google Scholar] [CrossRef]

- Chen, L.; Shen, J.; Li, B.; Zhang, C.; Yin, Y.; Wang, L.; Li, J.; Yang, J. Fault Mechanism Analysis and Diagnosis for Closed-Loop Drive System of Industrial Robot Based on Nonlinear Spectrum. Sci. Rep. 2022, 12, 21691. [Google Scholar] [CrossRef]

- Fonseca, D.S.B.; Antunes, H.R.P.; Cardoso, A.J.M. Stator Inter-Turn Short-Circuits Fault Diagnostics in Three-Phase Line-Start Permanent Magnet Synchronous Motors Fed by Unbalanced Voltages. Machines 2023, 11, 744. [Google Scholar] [CrossRef]

- Demirel, A.; Keysan, O.; El-Dalahmeh, M.D.; Al-Greer, M. Non-Invasive Real-Time Diagnosis of PMSM Faults Implemented in Motor Control Software for Mission-Critical Applications. Measurement 2024, 232, 114684. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.; Liu, C.; Zhang, Y.; Liu, J.; Zhang, X. Permanent Magnet Synchronous Motor Demagnetization Fault Diagnosis Based on PCA-ISSA-PNN. Sci. Rep. 2024, 14, 72596. [Google Scholar] [CrossRef]

- He, X.; Wang, J.; Wang, H.; Li, X.; Wang, X. Early Bearing Fault Diagnosis in PMSMs Based on HO-VMD and Weighted Evidence Fusion of Current–Vibration Signals. Sensors 2025, 25, 4591. [Google Scholar] [CrossRef]

- Mazzoletti, M.A.; Bossio, G.R.; De Angelo, C.H. Interturn Short-Circuit Fault Diagnosis in PMSM with Partitioned Stator Windings. IET Electr. Power Appl. 2020, 14, 2365–2374. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Z.-Q.; Azar, Z.; Clark, R.; Wu, Z. Fault Detection of Permanent Magnet Synchronous Machines: An Overview. Energies 2025, 18, 534. [Google Scholar] [CrossRef]

- Li, L.; Liao, S.; Zou, B.; Liu, J. Mechanism-Based Fault Diagnosis Deep Learning Method for Permanent Magnet Synchronous Motor. Sensors 2024, 24, 6349. [Google Scholar] [CrossRef] [PubMed]

- Ullah, Z.; Lodhi, B.A.; Hur, J. Detection and Identification of Demagnetization and Bearing Faults in PMSM Using Transfer Learning-Based VGG. Energies 2020, 13, 3834. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Meng, D.; Zhao, X.; Zhang, K. Fault Diagnosis of PMSMs Based on Image Features of Multi-Sensor Fusion. Sensors 2023, 23, 8592. [Google Scholar] [CrossRef] [PubMed]

- El-Dalahmeh, M.; Al-Greer, M.; Bashir, I.; El-Dalahmeh, M.; Demirel, A.; Keysan, O. Autonomous Fault Detection and Diagnosis for Permanent Magnet Synchronous Motors Using Combined Variational Mode Decomposition, the Hilbert–Huang Transform, and a Convolutional Neural Network. Comput. Electr. Eng. 2023, 110, 108894. [Google Scholar] [CrossRef]

- Tan, K.; Shi, J.; Mei, X.; Geng, J.; Yang, Y. Control of force transmission for cable-driven actuation system based on modified friction model with compensation parameters. Control. Eng. Pr. 2024, 151, 106035. [Google Scholar] [CrossRef]

- Bales, I.; Zhang, H. Kinematic benefits of a cable-driven exosuit for head–neck mobility. IEEE Robot. Autom. Lett. 2024, 9, 11849–11856. [Google Scholar] [CrossRef]

- KhalilianMotamed Bonab, A.; Chiaradia, D.; Frisoli, A.; Leonardis, D. A framework for modeling, optimisation, and musculoskeletal simulation of an elbow–wrist exosuit. Robotics 2024, 13, 60. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Vaisson, J.-C.; Russo, M. Design of a cable-driven finger exoskeleton. Designs 2025, 9, 35. [Google Scholar] [CrossRef]

- Liang, Z.; Quan, Z.; Di, P. Stiffness regulation of cable-driven redundant manipulators through combined optimisation of configuration and cable tension. Mathematics 2025, 13, 1714. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Wang, Z.-Q.; Feng, Y.; Xu, Y. Research on robot force compensation and collision detection based on six-dimensional force sensor. Machines 2025, 13, 544. [Google Scholar] [CrossRef]

- Ma, J.; Chen, S.; Di, H.; Liu, K. A fiber-optic six-axis force sensor based on a 3-UPU-compliant parallel mechanism. Appl. Sci. 2025, 15, 7548. [Google Scholar] [CrossRef]

- Choi, H.; Low, J.E.; Huh, T.M.; Uribe, G.A.; Hong, S.; Hoffman, K.A.W.; Di, J.; Chen, Y.; Stanley, A.A.; Cutkosky, M.R. CoinFT: A coin-sized, capacitive 6-axis force–torque sensor for robotic applications. arXiv 2025, arXiv:2503.19225. [Google Scholar]

- Tang, M.; Liang, L.; Zheng, H.; Chen, J.; Chen, D. Anomaly detection of permanent-magnet synchronous motor based on improved DWT–CNN multi-current fusion. Sensors 2024, 24, 2553. [Google Scholar] [CrossRef]

- Cao, J.; Yang, Z.; Sun, R.; Chen, X. Current signature identification and analysis for demagnetisation fault diagnosis of permanent-magnet synchronous motors. Mech. Syst. Signal Process. 2024, 214, 111377. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, C.; Zhang, Y.; Chen, L.; Zhang, D. Demagnetization fault diagnosis of a PMSM for electric drilling tools using GAF and CNN. Electronics 2024, 13, 189. [Google Scholar] [CrossRef]

- Li, M.; Geng, Y.; Wang, W.; Tu, M.; Wu, X. Permanent magnet synchronous motor inter-turn short circuit diagnosis based on physical-data dual model under oil-drilling environment. Eng. Appl. Artif. Intell. 2024, 132, 107938. [Google Scholar] [CrossRef]

- Ye, G.; Lu, Y.; Ju, J.; Sheng, L. Research on demagnetisation fault diagnosis of mine-cutting permanent-magnet synchronous motor. Int. J. Rotating Mach. 2024, 2024, 6648925. [Google Scholar] [CrossRef]

- Belgacem, A.M.; Hadef, M.; Ali, E.; Elsayed, S.K.; Paramasivam, P.; Ghoneim, S.S.M. Fault diagnosis of inter-turn short circuits in PMSM based on deep regulated neural network. IET Electr. Power Appl. 2024, 18, 1991–2007. [Google Scholar] [CrossRef]

- Romdhane, M.; Naoui, M.; Mansouri, A. PMSM inter-turn short-circuit fault detection using the fuzzy–extended Kalman filter in electric vehicles. Electronics 2023, 12, 3758. [Google Scholar] [CrossRef]

- Hasan Ebrahimi, S.; Choux, M.; Huynh, V.K. Real-Time Detection of Incipient Inter-Turn Short Circuit and Sensor Faults in Permanent Magnet Synchronous Motor Drives Based on Generalised Likelihood Ratio Test and Structural Analysis. Sensors 2022, 22, 3407. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Lee, H.-J. Torque Ripple and Electromagnetic Vibration Suppression of Fractional Slot Distributed Winding ISG Motors by Rotor Notching and Skewing. Energies 2024, 17, 4964. [Google Scholar] [CrossRef]

- Feng, L.; Yu, S.; Zhang, F.; Jin, S.; Sun, Y. Study on performance of low-speed high-torque permanent magnet synchronous motor with dynamic eccentricity rotor. Energy Rep. 2022, 8, 1421–1428. [Google Scholar] [CrossRef]

- Cui, Y.; Lu, H.; Xu, J.; Zhang, Y.; Zou, L. Study on Vibration Characteristics and Harmonic Suppression of an Integrated Electric Drive System Considering the Electromechanical Coupling Effect. Actuators 2025, 14, 386. [Google Scholar] [CrossRef]

- Jia, H.; Xin, H. Study on Lubrication Characteristics of Novel Forced Wave Generator of Harmonic Drive without Flexible Bearing. Materials 2022, 15, 175. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, Y.; Ma, C.; Han, X.; Zhang, D.; Zhang, L.; Zhang, Y.; Wu, X.; Liu, L.; Han, Z.; et al. Towards Human-Like Walking with Biomechanical and Neuromuscular Control Features: Personalised Attachment Point Optimisation Method of Cable-Driven Exoskeleton. Front Aging Neurosci. 2024, 16, 1333985. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Nath, K.; Bera, M.K.; Laskar, S.H. A Two Loop Sliding Mode Controller for Upper Limb Exosuit in Presence of Actuator Non-linearities. IFAC-PapersOnLine 2024, 57, 244–249. [Google Scholar] [CrossRef]

- Prasad, R.; El-Rich, M.; Awad, M.I.; Khalaf, K. Simulation of stroke gait impairment correction using cable-driven lower limb rehabilitation exoskeleton (C-LREX). Wearable Technol. 2025, 6, e39. [Google Scholar] [CrossRef]

- Lee, H.D.; Park, H.; Hong, D.H.; Kang, T.H. Development of a Series Elastic Tendon Actuator (SETA) Based on Gait Analysis for a Knee Assistive Exosuit. Actuators 2022, 11, 166. [Google Scholar] [CrossRef]

- Kant, S.; Pal, R.; Srivastava, R.; Jaiswal, A.K.; Salman, M.; Srivastava, R. Development of intelligent hybrid controller for torque ripple minimisation in electric drive system with adaptive flux estimator: An experimental case study. PLoS ONE 2025, 20, e0312946. [Google Scholar] [CrossRef] [PubMed]

- Preethichandra, D.M.G.; Piyathilaka, L.; Sul, J.-H.; Izhar, U.; Samarasinghe, R.; Arachchige, S.D.; de Silva, L.C. Passive and Active Exoskeleton Solutions: Sensors, Actuators, Applications, and Recent Trends. Sensors 2024, 24, 7095. [Google Scholar] [CrossRef]

- Supriyono, C.S.A.; Dragusanu, M.; Malvezzi, M. A Comprehensive Review of Elbow Exoskeletons: Classification by Structure, Actuation, and Sensing Technologies. Sensors 2025, 25, 4263. [Google Scholar] [CrossRef]

- Idà, E.; Mattioni, V. Cable-Driven Parallel Robot Actuators: State of the Art and Novel Servo-Winch Concept. Actuators 2022, 11, 290. [Google Scholar] [CrossRef]

- Kuo, J.-Y.; Hsu, C.-Y.; Wang, P.-F.; Lin, H.-C.; Nie, Z.-G. Constructing Condition Monitoring Model of Harmonic Drive. Appl. Sci. 2022, 12, 9415. [Google Scholar] [CrossRef]

- Vlachou, V.I.; Karakatsanis, T.S. Development of a Fault-Tolerant Permanent Magnet Synchronous Motor Using a Machine-Learning Algorithm for a Predictive Maintenance Elevator. Machines 2025, 13, 427. [Google Scholar] [CrossRef]

- Bai, H.; Lee, B.G.; Yang, G.; Shen, W.; Qian, S.; Zhang, H.; Zhou, J.; Fang, Z.; Zheng, T.; Yang, S.; et al. Unlocking the Potential of Cable-Driven Continuum Robots: A Comprehensive Review and Future Directions. Actuators 2024, 13, 52. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.; Runciman, M.; Avery, J.; Zhou, Z.; Sun, Z.; Mylonas, G. A Novel, Soft, Cable-Driven Parallel Robot for Minimally Invasive Surgeries Based on Folded Pouch Actuators. Appl. Sci. 2024, 14, 4095. [Google Scholar] [CrossRef]

- Urrea, C.; Domínguez, C. Fault Diagnosis in a Four-Arm Delta Robot Based on Wavelet Scattering Networks and Artificial Intelligence Techniques. Technologies 2024, 12, 225. [Google Scholar] [CrossRef]

| Actuator Family | Typical Faults | Common Sensors | Residuals/Indicators | Decision Logic |

|---|---|---|---|---|

| Harmonic drive (HD) | Transmission error (TE), tooth wear, lubrication loss, stiffness loss | Encoders (motor/joint), motor currents, accelerometers/vibration, torque proxy | TE estimate, backlash/friction proxies, vibration RMS/BPFO band, current harmonics | Observers/UIO, parity relations, H∞/EKF, GLR/CUSUM, thresholding |

| Series-elastic actuation (SEA) | Spring fatigue/stiffness drift, torque bias, friction changes, sensor drift | Torque sensor/strain gauge, dual encoders, IMU, temperature | Torque residual (τ_meas − τ_model), stiffness/deflection residuals, drift slope | Model-based observers, change-point detection, SPC/Shewhart, Bayesian filters |

| Cable/Bowden | Tendon elongation and slack, routing wear, friction/hysteresis, Δθ trend | Motor and joint en-coders, FBG/strain, load cells, IMU | Δθ = θ_motor − θ_joint, stick–slip features, tension residuals | Trend tests (Mann–Kendall), GLR/CUSUM, SVM/RF for features |

| PMSM (electric drives) | Inter-turn short-circuit (ITSC), partial demagneti-sation, static/dynamic ec-centricity. | Phase cur-rents/voltages, Park’s vector, temperature, vibration | Negative-sequence current, current sig-nature (THD), sali-ency harmonics | Model-based estimators, spectral tests, SVM/CNN on signatures |

| Torque-sensed (F–T)-based | Sensor bias/drift/saturation, miscalibration, overload | 6-axis F–T, encoders, temperature | Zero-load offset, cross-axis coherence, drift rate | Calibration checks, drift estimation, SPC, robust outlier tests |

| Actuator | Fault | n | N Act | Prop (%) | CI_Low (%) | CI_High (%) |

|---|---|---|---|---|---|---|

| Cable/Bowden | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 13 | 25 | 52 | 33.5 | 70.0 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 0 | 25 | 0 | 0.0 | 13.3 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 0 | 25 | 0 | 0.0 | 13.3 | |

| Other or mixed fault classes | 1 | 25 | 4 | 0.7 | 19.5 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 25 | 0 | 0.0 | 13.3 | |

| Cable-/tendon-driven: elongation, slack, routing (Δθ) | 13 | 25 | 52 | 33.5 | 70.0 | |

| HD | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 0 | 23 | 0 | 0.0 | 14.3 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 0 | 23 | 0 | 0.0 | 14.3 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 16 | 23 | 69.6 | 49.1 | 84.4 | |

| Other or mixed fault classes | 7 | 23 | 30.4 | 15.6 | 50.9 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 23 | 0 | 0.0 | 14.3 | |

| Transmission non-idealities: friction, hysteresis, backlash | 0 | 23 | 0 | 0.0 | 14.3 | |

| PMSM | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 0 | 26 | 0 | 0.0 | 12.9 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 0 | 26 | 0 | 0.0 | 12.9 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 0 | 26 | 0 | 0.0 | 12.9 | |

| Other or mixed fault classes | 6 | 26 | 23.1 | 11.0 | 42.1 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 20 | 26 | 76.9 | 57.9 | 89.0 | |

| Transmission non-idealities: friction, hysteresis, backlash | 0 | 26 | 0 | 0.0 | 12.9 | |

| SEA | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 0 | 31 | 0 | 0.0 | 11.0 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 1 | 31 | 3.2 | 0.6 | 16.2 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 0 | 31 | 0 | 0.0 | 11.0 | |

| Other or mixed fault classes | 30 | 31 | 96.8 | 83.8 | 99.4 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 31 | 0 | 0.0 | 11.0 | |

| Transmission non-idealities: friction, hysteresis, backlash | 0 | 31 | 0 | 0.0 | 11.0 | |

| Torque-sensed (F–T) | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 0 | 22 | 0 | 0.0 | 14.9 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 17 | 22 | 77.3 | 56.6 | 89.9 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 0 | 22 | 0 | 0.0 | 14.9 | |

| Other or mixed fault classes | 5 | 22 | 22.7 | 10.1 | 43.4 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 22 | 0 | 0.0 | 14.9 | |

| Transmission non-idealities: friction, hysteresis, backlash | 0 | 22 | 0 | 0.0 | 14.9 |

| Fault Class | OR Per +1 Year | 95% CI | p-Value | q-Value |

|---|---|---|---|---|

| Bearing faults | 2.66 | 0.41–17.18 | 0.3032 | 0.6743 |

| Cable/Bowden: elong./slack (Δθ) | 1.12 | 0.78–1.61 | 0.5360 | 0.8711 |

| HD: TE and wear | 0.93 | 0.77–1.12 | 0.4231 | 0.8682 |

| Non-idealities: friction/backlash | 0.78 | 0.52–1.18 | 0.2489 | 0.6254 |

| Other/mixed | 1.02 | 0.85–1.21 | 0.8682 | 1.0000 |

| PMSM: electrical | 0.89 | 0.68–1.16 | 0.3853 | 0.7075 |

| Sensor: drift/temp | 1.29 | 0.90–1.86 | 0.1625 | 0.5924 |

| Metric | Actuator | n (Yes) | N | Prop (%) | CI_Low (%) | CI_High (%) |

|---|---|---|---|---|---|---|

| ACC/F1 | Cable/Bowden | 13 | 25 | 52.0 | 33.5 | 70.0 |

| HD | 4 | 23 | 17.4 | 7.0 | 37.1 | |

| PMSM | 23 | 26 | 88.5 | 71.0 | 96.0 | |

| SEA | 16 | 31 | 51.6 | 34.8 | 68.0 | |

| Torque-sensed (F–T) | 22 | 22 | 100.0 | 85.1 | 100.0 | |

| MDFA | Cable/Bowden | 0 | 25 | 0.0 | 0.0 | 13.3 |

| HD | 7 | 23 | 30.4 | 15.6 | 50.9 | |

| PMSM | 0 | 26 | 0.0 | 0.0 | 12.9 | |

| SEA | 0 | 31 | 0.0 | 0.0 | 11.0 | |

| Torque-sensed (F–T) | 0 | 22 | 0.0 | 0.0 | 14.9 | |

| TTD | Cable/Bowden | 0 | 25 | 0.0 | 0.0 | 13.3 |

| HD | 0 | 23 | 0.0 | 0.0 | 14.3 | |

| PMSM | 0 | 26 | 0.0 | 0.0 | 12.9 | |

| SEA | 0 | 31 | 0.0 | 0.0 | 11.0 | |

| Torque-sensed (F–T) | 0 | 22 | 0.0 | 0.0 | 14.9 | |

| FAR | Cable/Bowden | 0 | 25 | 0.0 | 0.0 | 13.3 |

| HD | 0 | 23 | 0.0 | 0.0 | 14.3 | |

| PMSM | 0 | 26 | 0.0 | 0.0 | 12.9 | |

| SEA | 0 | 31 | 0.0 | 0.0 | 11.0 | |

| Torque-sensed (F–T) | 0 | 22 | 0.0 | 0.0 | 14.9 |

| Metric | Source Platform (Publisher/Indexer) | n | N Act | Prop (%) | CI_Low (%) | CI_High (%) |

|---|---|---|---|---|---|---|

| ACC/F1 | Elsevier/ScienceDirect | 13 | 28 | 46.4 | 29.5 | 64.2 |

| Indexers (PubMed/DOI) | 9 | 18 | 50.0 | 29.9 | 70.1 | |

| MDPI | 35 | 47 | 74.5 | 60.5 | 84.7 | |

| Other publisher platforms | 18 | 31 | 58.1 | 40.8 | 73.6 | |

| Preprints (arXiv) | 3 | 3 | 100.0 | 43.8 | 100.0 | |

| MDFA | Elsevier/ScienceDirect | 1 | 28 | 3.6 | 0.6 | 17.7 |

| Indexers (PubMed/DOI) | 1 | 18 | 5.6 | 1.0 | 25.9 | |

| MDPI | 1 | 47 | 2.1 | 0.4 | 11.1 | |

| Other publisher platforms | 4 | 31 | 12.9 | 5.1 | 28.9 | |

| Preprints (arXiv) | 0 | 3 | 0.0 | 0.0 | 56.2 | |

| TTD | Elsevier/ScienceDirect | 0 | 28 | 0.0 | 0.0 | 12.1 |

| Indexers (PubMed/DOI) | 0 | 18 | 0.0 | 0.0 | 18.5 | |

| MDPI | 0 | 47 | 0.0 | 0.0 | 7.6 | |

| Other publisher platforms | 0 | 31 | 0.0 | 0.0 | 11.0 | |

| Preprints (arXiv) | 0 | 3 | 0.0 | 0.0 | 56.2 | |

| FAR | Elsevier/ScienceDirect | 0 | 28 | 0.0 | 0.0 | 12.1 |

| Indexers (PubMed/DOI) | 0 | 18 | 0.0 | 0.0 | 18.5 | |

| MDPI | 0 | 47 | 0.0 | 0.0 | 7.6 | |

| Other publisher platforms | 0 | 31 | 0.0 | 0.0 | 11.0 | |

| Preprints (arXiv) | 0 | 3 | 0.0 | 0.0 | 56.2 |

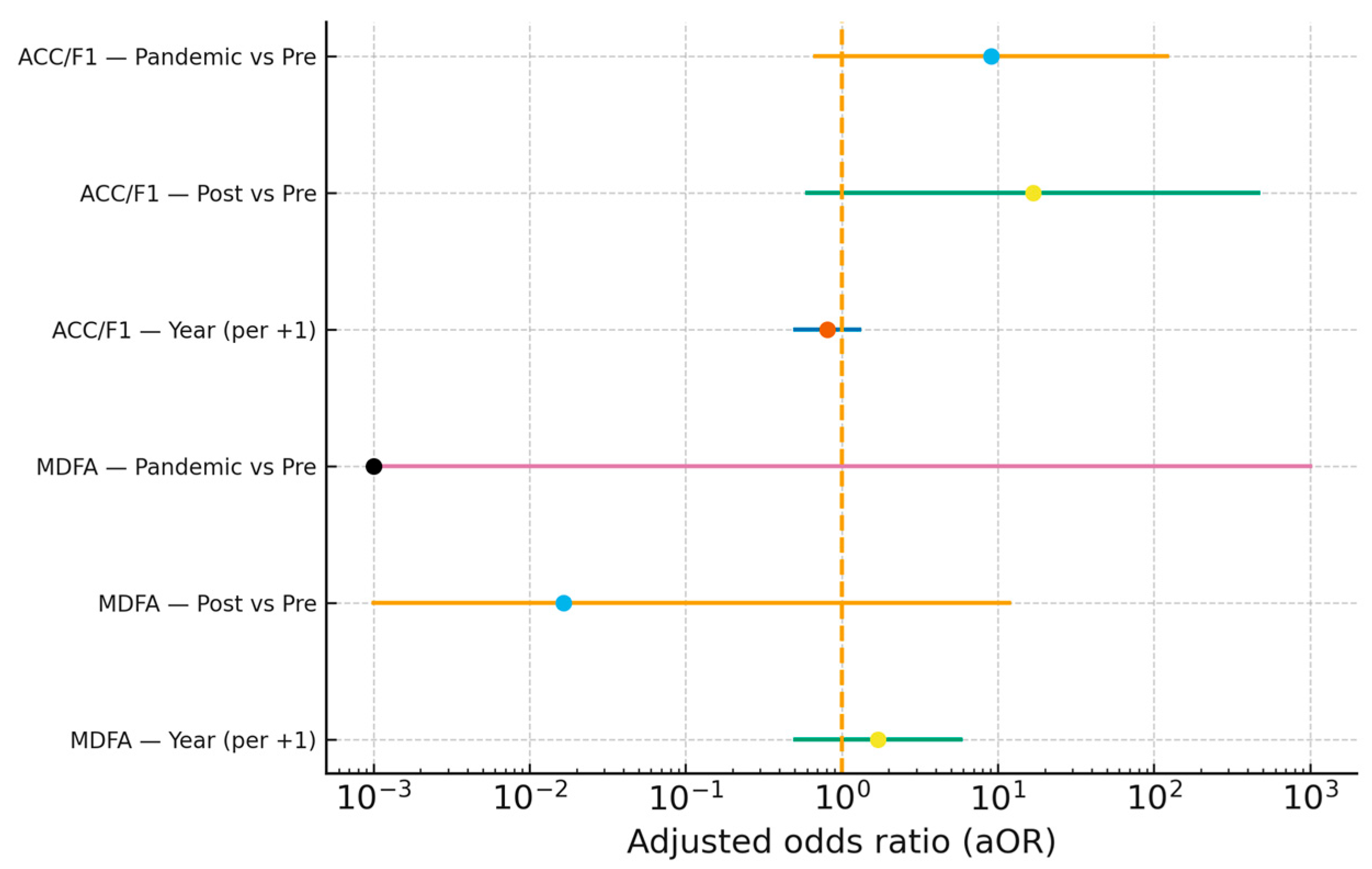

| Outcome | Contrast | aOR | 95% CI | p-Value |

|---|---|---|---|---|

| ACC/F1 | Pandemic vs. Pre | 9.06 | 0.68–120.84 | 0.0954 |

| Post vs. Pre | 16.78 | 0.60–466.52 | 0.0965 | |

| Year (per +1) | 0.81 | 0.50–1.30 | 0.3772 | |

| MDFA | Pandemic vs. Pre | NA | NA–NA | 0.9990 |

| Post vs. Pre | 0.02 | 0.00–11.78 | 0.2209 | |

| Year (per +1) | 1.70 | 0.50–5.75 | 0.3931 |

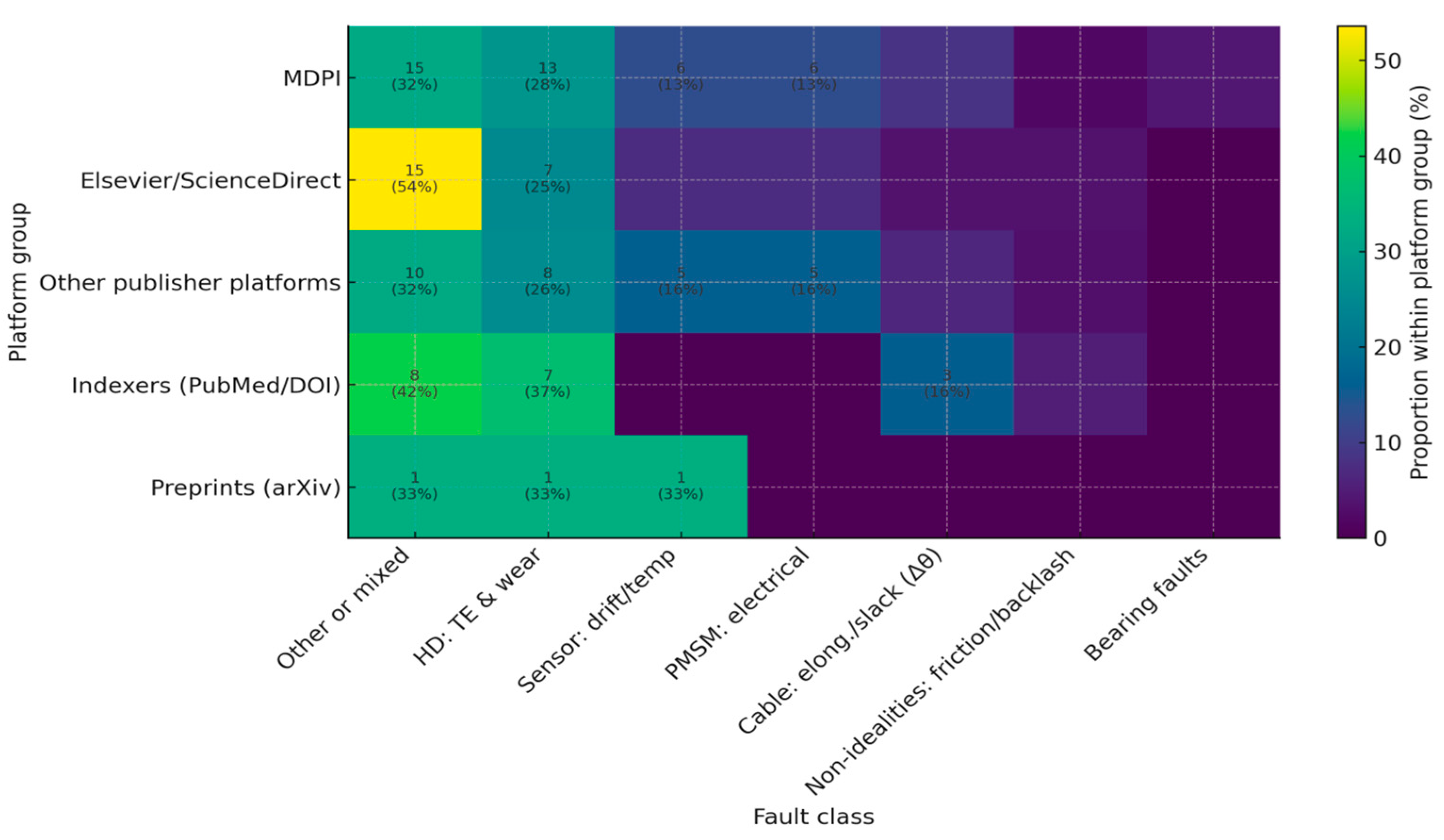

| Source Platform (Publisher/Indexer) | Fault | n | N_Group | Prop (%) |

|---|---|---|---|---|

| MDPI | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 6 | 47 | 12.8 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 7 | 47 | 14.9 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 3 | 47 | 6.4 | |

| Other or mixed fault classes | 19 | 47 | 40.4 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 9 | 47 | 19.1 | |

| Transmission non-idealities: friction, hysteresis, backlash | 3 | 47 | 6.4 | |

| Elsevier/ScienceDirect | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 1 | 28 | 3.6 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 3 | 28 | 10.7 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 3 | 28 | 10.7 | |

| Other or mixed fault classes | 12 | 28 | 42.9 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 6 | 28 | 21.4 | |

| Transmission non-idealities: friction, hysteresis, backlash | 3 | 28 | 10.7 | |

| Other publisher platforms (Springer/Wiley/ASME/SAGE/PLOS/Frontiers/IEEE/IET/Other) | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 2 | 31 | 6.5 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 5 | 31 | 16.1 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 5 | 31 | 16.1 | |

| Other or mixed fault classes | 11 | 31 | 35.5 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 5 | 31 | 16.1 | |

| Transmission non-idealities: friction, hysteresis, backlash | 3 | 31 | 9.7 | |

| Indexers (PubMed/DOI) | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 4 | 18 | 22.2 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 1 | 18 | 5.6 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 5 | 18 | 27.8 | |

| Other or mixed fault classes | 6 | 18 | 33.3 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 18 | 0.0 | |

| Transmission non-idealities: friction, hysteresis, backlash | 2 | 18 | 11.1 | |

| Preprints (arXiv) | Cable-/tendon-driven: elongation, slack, routing (Δθ) | 0 | 3 | 0.0 |

| Force/torque sensing: drift, temperature sensitivity, cross-talk | 2 | 3 | 66.7 | |

| Harmonic drive (strain-wave): transmission error and wear (incl. lubrication) | 0 | 3 | 0.0 | |

| Other or mixed fault classes | 1 | 3 | 33.3 | |

| PMSM: electrical faults (ITSC, demagnetisation, eccentricity) | 0 | 3 | 0.0 | |

| Transmission non-idealities: friction, hysteresis, backlash | 0 | 3 | 0.0 |

| Fault Class | RR (Pandemic vs. Pre) | 95% CI | RR (Post vs. Pre) | 95% CI (Post) |

|---|---|---|---|---|

| Bearing faults | - | - | - | - |

| Cable/Bowden: elong./slack (Δθ) | 1.00 | 0.06–15.99 | 0.67 | 0.08–5.33 |

| HD: TE and wear | 0.67 | 0.19–2.30 | 0.51 | 0.20–1.33 |

| Non-idealities: friction/backlash | NA | NA | 0.08 | 0.01–0.79 |

| Other/mixed | 0.93 | 0.23–3.73 | 0.92 | 0.28–2.96 |

| PMSM: electrical | 0.29 | 0.03–3.15 | 0.10 | 0.01–0.77 |

| Sensor: drift/temp | NA | NA | NA | NA |

| Contrast | OR | 95% CI | Notes |

|---|---|---|---|

| Pandemic vs. Pre | 0.30 | 0.05–1.70 | Unadjusted (2 × 2). |

| Post vs. Pre | 0.41 | 0.12–1.46 | Unadjusted (2 × 2). |

| Outcome | Contrast | 95% CI | OR | Notes |

|---|---|---|---|---|

| ACC/F1 | Pandemic vs. Pre | 0.41–9.84 | 2.00 | Unadjusted (2 × 2). |

| Post vs. Pre | 0.88–11.70 | 3.21 | Unadjusted (2 × 2). | |

| MDFA | Pandemic vs. Pre | 0.03–4.09 | 0.32 | Unadjusted (2 × 2). |

| Post vs. Pre | 0.03–1.14 | 0.18 | Unadjusted (2 × 2). |

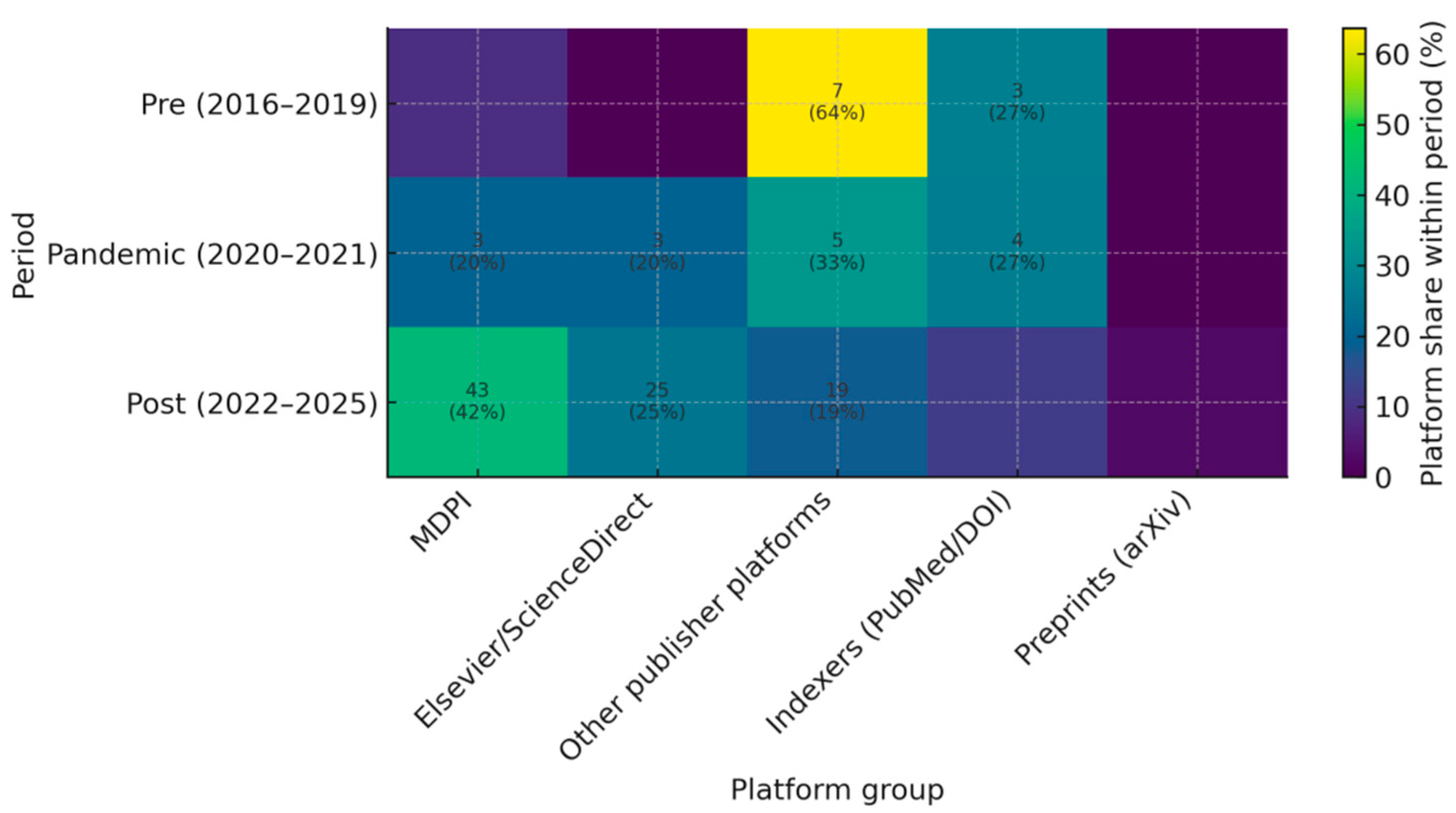

| Source Platform (Publisher/Indexer) | Pre n (%) | Pandemic n (%) | Post n (%) |

|---|---|---|---|

| Elsevier/ScienceDirect | 0 (0.0%) | 3 (20.0%) | 25 (24.5%) |

| Indexers (PubMed/DOI) | 3 (27.3%) | 4 (26.7%) | 12 (11.8%) |

| MDPI | 1 (9.1%) | 3 (20.0%) | 43 (42.2%) |

| Other publisher platforms | 7 (63.6%) | 5 (33.3%) | 19 (18.6%) |

| Preprints (arXiv) | 0 (0.0%) | 0 (0.0%) | 3 (2.9%) |

| No | Domain | Recommandation |

|---|---|---|

| 1 | Task and population | Describe task context; if applicable, indicate whether the human phase was controlled. |

| 2 | Actuator and transmission | Specify actuator family (HD/SEA/Cable/PMSM/Torque-sensed) and reducer/compliance. |

| 3 | Fault ground-truth | Fault induction protocol or labelling procedure documented. |

| 4 | Sensors and sampling | List sensors (F/T, encoder/IMU, currents, vibration/FBG) and sampling rate. |

| 5 | Residual/features | Observer/parity, spectral features, or learned features are described. |

| 6 | Decision threshold (τ) | How τ is set (validation/ROC/clinical constraint) and its value. |

| 7 | ACC/F1 | Accuracy and/or F1 reported; class-wise if applicable. |

| 8 | MDFA | Minimal detectable fault amplitude (units) and procedure. |

| 9 | TTD | Detection latency (ms or gait cycles). |

| 10 | FAR@τ | False-alarm rate at the stated decision threshold τ. |

| 11 | Safety response | Post-detection fallback/reconfiguration strategy. |

| 12 | Reproducibility | Code/data availability; DOI/URL provided. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maican, C.A.; Pană, C.F.; Vrăjitoru, N.R.; Pătrașcu-Pană, D.M.; Rădulescu, V.M. Fault Detection and Diagnosis for Human-Centric Robotic Actuation in Healthcare: Methods, Failure Modes, and a Validation Framework. Actuators 2025, 14, 566. https://doi.org/10.3390/act14120566

Maican CA, Pană CF, Vrăjitoru NR, Pătrașcu-Pană DM, Rădulescu VM. Fault Detection and Diagnosis for Human-Centric Robotic Actuation in Healthcare: Methods, Failure Modes, and a Validation Framework. Actuators. 2025; 14(12):566. https://doi.org/10.3390/act14120566

Chicago/Turabian StyleMaican, Camelia Adela, Cristina Floriana Pană, Nicolae Răzvan Vrăjitoru, Daniela Maria Pătrașcu-Pană, and Virginia Maria Rădulescu. 2025. "Fault Detection and Diagnosis for Human-Centric Robotic Actuation in Healthcare: Methods, Failure Modes, and a Validation Framework" Actuators 14, no. 12: 566. https://doi.org/10.3390/act14120566

APA StyleMaican, C. A., Pană, C. F., Vrăjitoru, N. R., Pătrașcu-Pană, D. M., & Rădulescu, V. M. (2025). Fault Detection and Diagnosis for Human-Centric Robotic Actuation in Healthcare: Methods, Failure Modes, and a Validation Framework. Actuators, 14(12), 566. https://doi.org/10.3390/act14120566