1. Introduction

In most robot applications the manipulator is tasked to follow some designated path as precisely as possible. Therefore, trajectory tracking is one of the most important and fundamental problems in field of robotics that is posing significant challenges due to the complicated, highly nonlinear and time-varying behavior of robotic manipulators. This fundamental problem has inspired numerous solutions over the years. Among these, Computed Torque Control (CTC) is a widely used and well established solution that was developed at the end of the 20th century [

1]. This control method utilizes the dynamic model of the controlled system in a feed forward configuration with some linear error compensation rule, which is most commonly a PID (Proportional–Integral–Derivative) controller. Therefore, the effectiveness of the CTC method is limited by the accuracy of the system model and the precision of feedback signal measurements. In practice, position and velocity transducers are effected by quantization noise, and it also quickly became apparent that it presents significant challenges to develop precise enough robot models for control purposes [

2].

However, given its simple structure and computational efficiency in comparison with certain adaptive and robust control solutions, CTC remained a prevalent approach within the field of robotics throughout the years, e.g., [

3,

4,

5]. To address some of the design challenges, many researchers suggested adaptive or robust variations. For example, in the early years, a globally convergent Adaptive CTC method was suggested with a simple least square estimator in order to fine-tune the dynamic model parameters of the controlled manipulator [

6]. In [

7] a CTC was designed with a nonlinear PD (Proportional–Derivative) controller and an Extended State Observer to estimate external disturbances and modeling errors due to friction and temperature variations. It was shown that the nonlinear PD gains significantly improve the responsiveness of the controller, that way better tracking properties could be achieved for higher speed motion in case of a 6-DoF (Degree of Freedom) parallel manipulator. However, nonlinear PID controllers have a greater number of parameters that require careful tuning, thereby influencing the controller’s behavior in various unexpected manners. Hence, the use of soft computing methods, e.g., Particle Swarm Optimization [

8,

9], has been successfully investigated by many authors for tuning purposes. In order to ensure desired transient trajectory tracking behavior of a rehabilitation exoskeleton, a novel CTC design was introduced in [

10] with a Prescribed Performance Controller, which is a widely used technique in adaptive control [

11,

12]. In order to address the issue of modeling imprecisions, the utilization of a neural network, such as a radial basis function neural network, was considered in the literature [

13,

14]. These methods are capable of compensating for complex nonlinearities and dynamic uncertainties. However, their practical implementation can be constrained by the high computational cost associated with online learning, which may not be feasible in real-time applications [

15].

A robust iterative variation of the CTC method was developed in 2009 [

16] for controlling second-order systems with uncertain dynamics, such as robots or CNC machines. The proposed control strategy does not rely on refining the imprecise dynamic model and it places the deterministic decrease in the trajectory tracking error in the center of attention. It adaptively deforms the desired acceleration command—derived from the kinematic prescription of the CTC controller—in order to ensure accurate trajectory tracking despite model uncertainties. The adaptive deformation is executed in an iterative manner, with a single update executed in each control cycle with low computation cost. As a result, the method is referred to as Robust Fixed-Point Transformation (RFPT)-based adaptive control. The concept of “adaptive control” has a long development history from the early nineties to present day. The “Parameter Adaptive” solutions (early prototype is [

17]) used an analytically correct model form with imprecisely known parameters and learned the exact parameters of this model. The “Signal Adaptive” solutions (early example is, e.g., [

18]) applied strong signals in order to make the behavior of the controlled system identical to that of a “Reference Model”. Recently, good results were achieved by manipulating the originally available dynamic model by transforming it into a Linear Parameter Varying form (e.g., [

19]). Also, even model-free approaches can be found with Machine Learning (e.g., [

20]). The RFPT-based controller corresponds to an approximate model-based controller that does not wish to “learn” the precise dynamic model. Instead of that, based on recent observations it applies temporal corrections that do not have a persistent nature. Consequently it cannot achieve asymptotic convergence. The cost of this deficiency is the way of easy realization. The convergence of the iteration applied in the RFPT method and hence the local stability of the control law can be analyzed using Banach’s fixed-point theorem [

21], which states the following:

Let be a non-empty complete metric space, and let be a contractive self mapping, i.e., there exists a constant such that . Then, for any initial guess , the sequence generated by Φ in the form of converges to a unique such that .

This theorem provides the fundamentals for analyzing the convergence behavior of the proposed iterative control rule, ensuring that by the proper tuning of only a few parameters, the control signal converges reliably to a stable solution. The optimal tuning of the control parameters were investigated in [

22]. For the actual implementation of the adaptive deformation a few variations exists. For example, the original idea was extended for MIMO (Multiple-Input and Multiple-Output) systems in [

23,

24]. A continuous time RFPT method was investigated in [

25]. The noise sensitivity was addressed in [

26] with a Luenberg observer-inspired solution. Additionally, a geometric formulation was proposed in [

27], where the control signals were transformed into a higher-dimensional vector space, enabling abstract rotations that simplified the tuning process. A novel FPI control design was introduced in [

28] with a Steffensen accelerator in order to improve the convergence rate and thereby the tracking precision of the controller. This solution was later extended to an Adaptive Sliding Mode Control design as well [

29,

30].

The application of FPI control was suggested across various scientific domains, ranging from controlling classical mechanical systems [

31] to life sciences, such as automated anesthesiology [

32,

33] or blood glucose level regulation [

34]. However, most of the existing research has been limited to simulation-based analysis. This limitation has motivated the authors to pursue further investigation of FPI control through experimental implementation, which revealed several practical challenges. Notably, in the case of second-order systems (i.e., industrial robots), the controller requires feedback not only of the first-order derivatives of the generalized coordinates (i.e., velocities), but also of their second-order derivatives (i.e., accelerations), which introduces sensitivity to measurement noise and estimation errors.

In our previous investigations the issues of noise filtering and delay were considered as formally separated issues, i.e., certain noise filtering techniques were applied for the signals, and the filtered signals were sampled with some exact delay. In this approach the inevitable delaying effect of the noise filtering technique was not taken into account, and it had an accumulated effect with that of the formally delayed sampling. In the present approach a delay modeling technique was borrowed from life sciences that corresponded to the application of a complementary, “anatomically not interpreted compartment”, in the state variable of which the effects of the “harsh”, non-continuous input appeared in a smoothed, smeared manner. Recognizing that besides modeling the delay effect this signal tackling also provided the controller with some noise filtering ability, the formerly accumulated effects of noise filtering and formally delayed sampling were avoided. A complementary benefit was that while the formally applied delay time must be very precisely specified in the calculations, this smeared effect was noticeable even slightly later in time, making the adaptive method based on it more robust.

The main challenge of the investigated problem consists in the fact that the above listed results related to the FPI-based adaptive solutions were made on the theoretical basis of Banach’s simple and efficient fixed-point theorem and were illustrated via simulations. These simulations had certain tacit assumptions that lead to a simplified model of the operation of the controlled system that cannot precisely cover the reality. While the issue of measurement noise was placed into the center of the considerations, subtle excerpts such as the properties of the operating system of the implementation, the cooperation of the signal measuring system with the control program, and the features of a possible embedded realization were not precisely simulated. This made the experimental investigations inevitable, which soon revealed differences between the simulation and the measurement results. The simple assumption of a fixed cycle time of the digital controller certainly is not realistic for several operating systems that can produce a control signal during longer or shorter times, depending on its other actual tasks and the computational need of the problem. Furthermore, the signal measuring system is not in harmony with the cycles of the controller. Normally it produces signals that are processed via interrupts. Since the method is based on the observation of the control signal and the observed response to it in the near past, timing discrepancies may have critical effects. The measurement results presented in this paper that the suggested low frequency noise filtering combined with the use of its inherent, inevitable delay, and a simple delay-smearing technology realized by common and cheap hardware and software tools are the first very successful experimental proofs of the real applicability of the adaptive method in a realistic problem. It reveals that the subtle details neglected in the simulations do not play a significant role in the system’s operation.

This proof widely extends the expected circle of the practical application of the FPI-based adaptive controller. For instance, the problem of fixed time stabilization of linear control systems solved in [

35] may be extended to the stabilization of nonlinear ones by replacing the complicated Lyapunov function-based proofs with that based on the simple Banach’s theorem. Also, controlling the behavior of connected robots or other nonlinear systems governed by sophisticated, beyond nearest neighbor rules considered in [

36] can be really tackled by this simpler approach. Formerly, simulation results were presented by the application of decentralized adaptive control of very imprecisely modeled coupled dynamic systems in [

37], or that in the topologically less complex, “linear arrangement” of platoons considered in [

38] arrived to the phase of physical realization. This adaptive method can be combined with topologically formulated, more complex and sophisticated task definitions.

The article is structured in the following manner. In

Section 2 some implementation details of RFPT-based control is presented, including the formulation of the kinematic prescription and the adaptive deformation. In this section convergence criteria will be presented as well.

Section 3 presents the proposed solution for noise filtering with feedback delay. In

Section 4 some simulation and experimental results are presented. Finally, in

Section 5 the conclusions are summarized.

2. On the Implementation of RFPT Control

In case of a second-order systems such as industrial robots, the second-order derivatives of the generalized coordinates can be instantaneously set by some control input, i.e., through a force input for linear or through torque for rotational actuators. Meanwhile lower-order derivatives are changing significantly slower. The idea of the CTC method is that by the use of some kinematic prescription the error dynamics is defined, which could be achieved through the implementation of some desired acceleration (

) command. The kinematic prescription is usually defined by a linear control rule and the nonlinear dynamics of the controlled system is decoupled by the use of the inverse dynamic model (

) such as

where

is the control force, and

is the realized position; finally,

is the realized velocity of the system. However, in most scenarios the available dynamic model (

) is neither precise nor complete, which gives an approximate control force

where

is some response function representing the actual dynamics of the controlled system. The idea presented in [

16] is that by introducing an appropriate deformation function (

)

In the RFPT method the approximate control force (

3b) is calculated from the deformed second derivative

instead of the desired one. In Equation (3)

denotes some feedback delay, which is usually the sampling time of the controller.

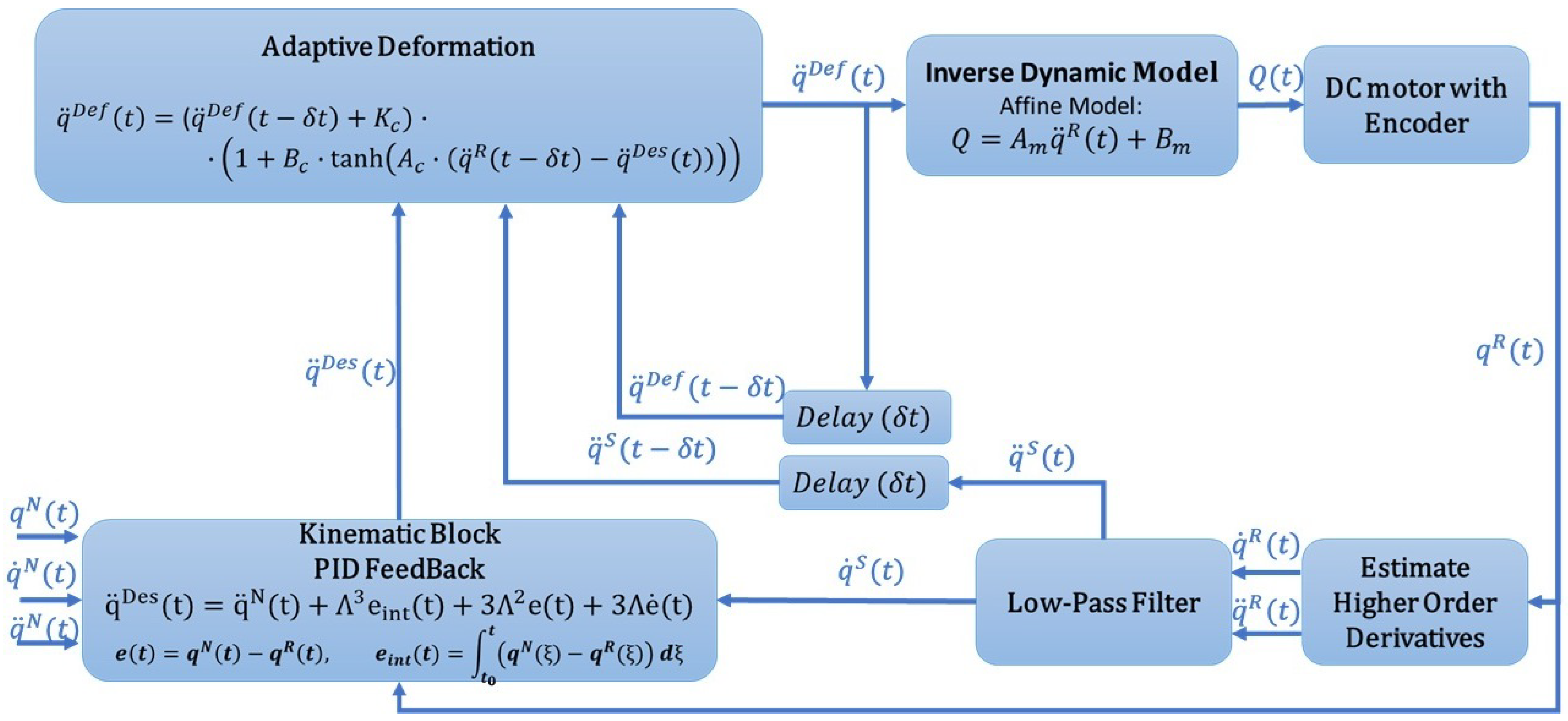

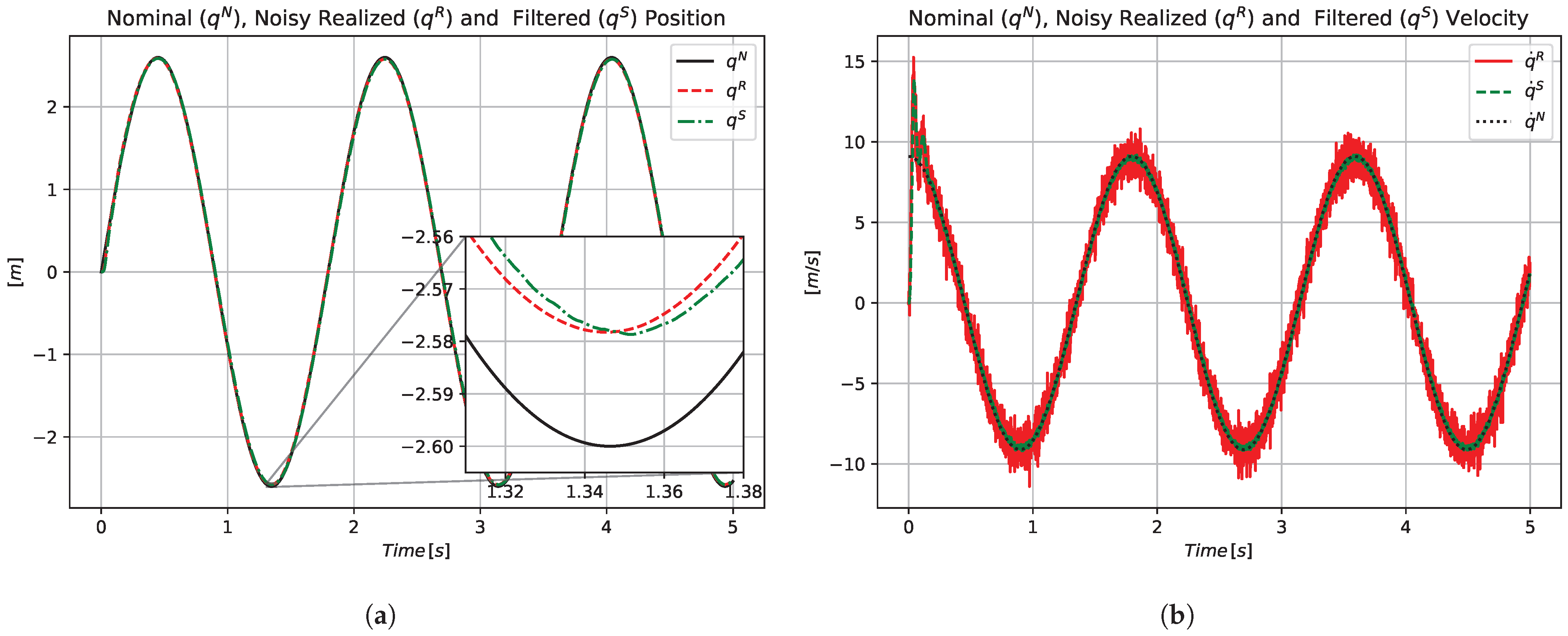

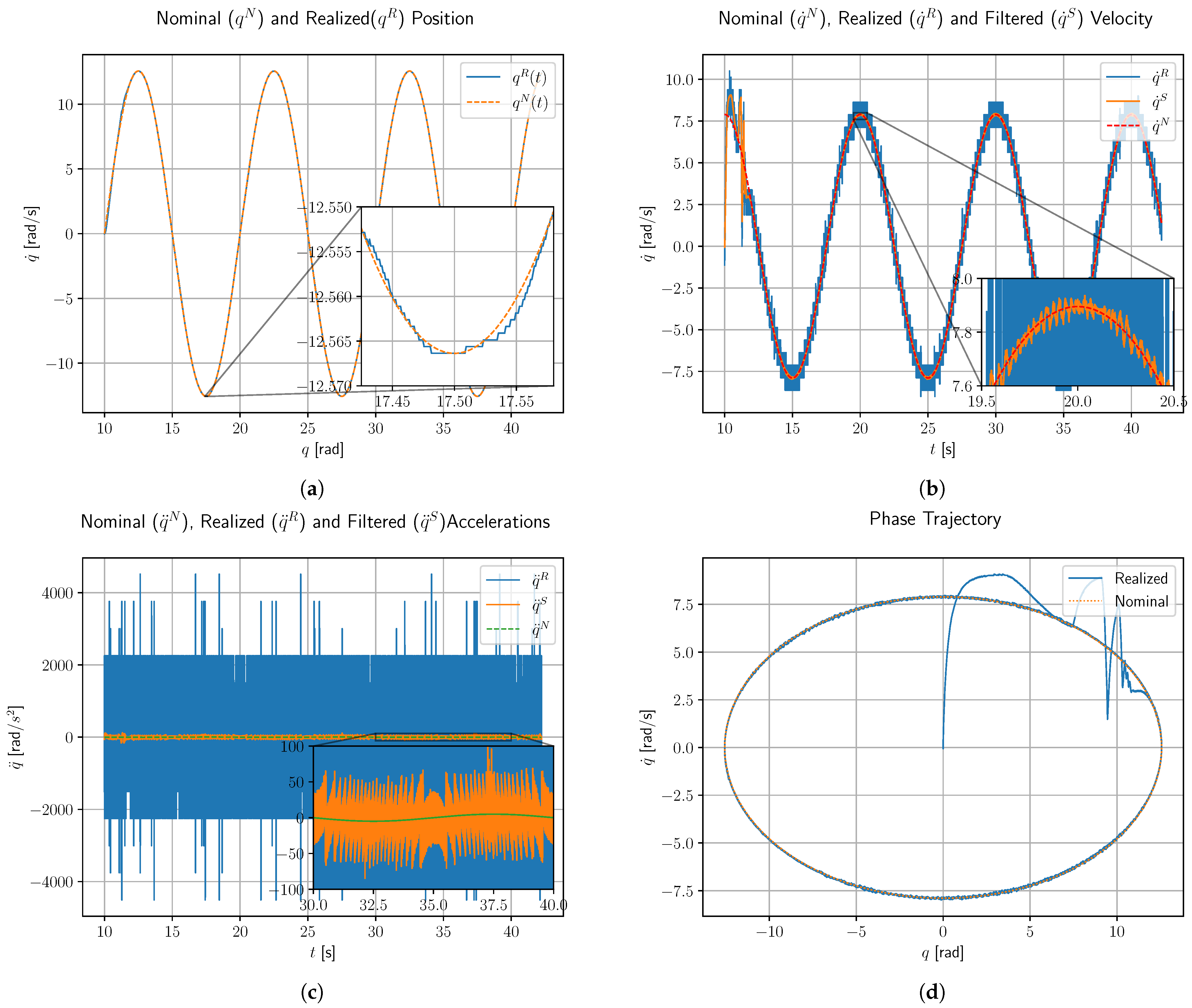

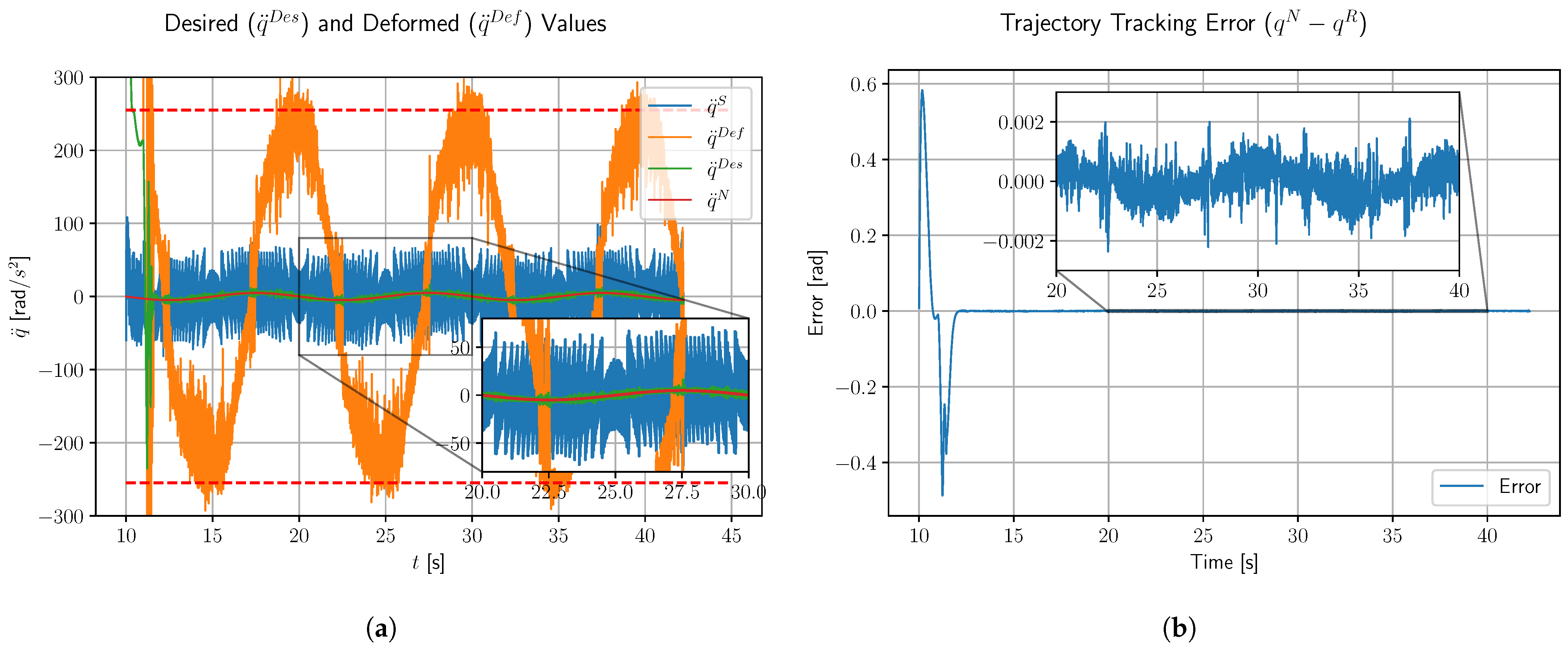

Figure 1 presents the practical implementation of RFPT-based adaptive controller for a motor control application, where some nominal trajectory

must be precisely followed. In this example the kinematic prescription is defined using simple PID-type error decrease rule, which is among the most commonly used formulations. However, the RFPT method is not limited to this approach; it can also be integrated with alternative control strategies, such as control Lyapunov function-based methods [

39] or Backstepping control [

40].

2.1. Kinematic Prescription

In case of the CTC method, accurate tracking of the nominal trajectory can be achieved by shaping the error dynamics of the controlled system. A third-order rule for the decrease in the integrated trajectory tracking error (

) is often employed to achieve robustness against steady-state error and disturbances, i.e., with a constant positive parameter

Equation (

4a) expands to a third-order ordinary differential equation of the form

Equation (

5) is obtained from Equation (

4a), it must be noted that for differentiable functions the linear operators

and

with a constant parameter

commute since

therefore this algebra is commutative as that defined with the real constant numbers

:

, therefore the binomial coefficients can be applied in the same form for any

as

It is important to note that this algebra is not as associative as that of the multiplication with real numbers:

that is, the order of multiplications is strictly determined as a direction from right to left. Equation (

4a)—that is identical to (

5)—corresponds to a linear, time-invariant, homogeneous differential equation with constant coefficients. It is known that any linear combination of two solutions made by the use of constant coefficients is its solution, too. Consequently its solutions form a linear space. Since for each

, for the functions

it holds that

evidently

,

, and

, for constant real

,

, and

values

It is also known that the general solution of a third-order differential equation has three free parameters that are determined by the initial conditions

,

, and

. Therefore the above defined three constants

,

, and

must determine the general solution. In other words, the exponentially damped functions

,

, and

as basis vectors span the linear space of the general solutions as

Independently of the initial conditions each basis vector converges to 0 as

, consequently if this kinematically formulated strategy is precisely realized,

,

, and

as

. with

, where the values of the

and

constants depend on the initial conditions. The relationship between the initial conditions and the constant coefficients

,

,

can be found in a simple recursive manner as follows:

From the above equations the following recursion is obtained:

Since

, the desired acceleration command, based on Equation (

5), can be chosen as

where

is a single design parameter that is equivalent to

,

, and

PID gains. The

should be precisely implemented by controller in order to achieve precise trajectory tracking with exponentially decreasing errors.

2.2. Adaptive Deformation

In the presence of modeling errors the precise implementation of

is impossible in a CTC scheme. In RFPT-based adaptive control instead of refining the available dynamic model for a single input–single output (SISO) system a deformation function is introduced such as

and the deformed value is used to calculate the control force with the initial condition

. The behavior of this construction becomes mathematically more treatable if on the basis of Equation (3) an approximate “

Response Function” for the deformed input is introduced as

in which the “

slow drift” of the variables

and

are neglected. Also, if

does not vary in a too hectic manner, it can be written that

The fixed point

satisfies the equation

. With this the approximation can be written that

that is

That is, if

, the sequence converges to the fixed point. This evidently corresponds to Banach’s theorem since it can be written that in the vicinity of the fixed point

therefore if there exist

so that

, a sequence is obtained that converges toward the unique fixed point

.

Actually, the function has two distinct fixed points: one of them is a “false” stationary fixed point that is , which results in . The second one is a “dynamic” fixed point, which evolves with each control iteration. It is only reached when the realized acceleration matches the desired one, such that . Under this condition the adaptive deformation function is . It reflects a moving equilibrium where the control system continuously updates the desired acceleration to match the realized dynamics, ensuring smooth tracking.

Considering that

the derivative is expressed as

It is evident if

is in some vicinity of the desired trajectory, i.e.,

, then the hyperbolic functions can be approximated simply as

,

and by the proper choice of the sign of

—that depends on

—and setting the

sufficiently large the iteration is expected to converge. Furthermore, the basin of attraction for the dynamic fixed point is sensitive to the tuning of

, which governs the steepness of the tanh function and thus the responsiveness of the deformation mechanism to tracking errors. It is important to note that the conditions of convergence normally are valid only within a bounded basin of attraction. The properties of this basin mainly depend on the dynamic properties of the controlled system. In Equation (

19) the main factor is the derivative of the response function

that should be either positive or negative in the basin under consideration. In the case of underactuated mechanical systems this property—that in a more general MIMO case was defined as the sign of each eigenvalue of the symmetric matrix

—can vary in model-dependent regions. Where this derivative yields zero values the system cannot be controlled, and no any mathematical trick can compensate for this physical property of the controlled system. However, if the system behaves well, and the adaptive control parameters can be set, the controller can enter into a “chaotic regime” that was investigated in detail in [

41,

42]. This chaotic regime can be left by adjusting the adaptive parameters. It should be noted that in the case of the Lyapunov function-based control design the typical limiting factors normally are listed in the rigorous mathematical formulation of the conditions in the proofs. In the case of dynamic control in practice the nominal trajectory may start from the initial point of the controlled system with slowly increasing velocity, i.e., small initial acceleration that helps keep the controller in the stable basin. (For nonlinear systems the step function-like excitations that normally are applied for the linear models of electrical engineers are not a lucky approach).

2.3. Basic Assumptions in Problem Formulation

Before proceeding with the introduction of the details of the novelties, it is expedient to summarize the basic assumptions in the problem formulation. There are some common assumptions for the simulations and the experiments, and there are special ones only for the simulations, which do not apply to the experimental implementation.

The common assumption is that the iterative adaptive sequence of the deformed signals can converge in the case of the controlled system. This can be concluded from the properties of its dynamic model that provides the “

Response Function” in Equation (

16). In this simple SISO case that means that

is either positive or negative. Then, according to the detailed considerations it is possible to appropriately set the adaptive control parameters

,

, and

. For multiple input–multiple output (MIMO) systems in [

24] this requirement was so generalized that the real part of each eigenvector of the quadratic matrix

must be either positive or negative. In [

43] these properties were geometrically interpreted as “

approximately locally direction keeping” or direction reserving functions as the MIMO generalizations of the monotonic increasing or decreasing functions.

A further tacit common assumption is that the dynamic properties of the nominal trajectory and that of the desired second time-derivatives influenced by the PID type error feedback parameters are not too hectic and allow fast enough convergence for the single adaptive step per one control step adaptation mechanism. This property is important because this adaptive control does not “learn” an exact model: it works on the basis of the freshest available observations.

The assumptions that were made only in the simulations were that the digital controller has a fixed cycle time, and during each control cycle fresh measurement data are available.

3. Modeling Signal Delay at Low Frequency

In life sciences, e.g., in [

44], delay effects at low frequency are often modeled with the insertion of a fictitious “ancillary” compartment that does not model a particular, anatomically realistic “organ”. Let

[s] model some time delay. Let

be a noisy signal to be tackled by the use of two compartments, i.e.,

and

, in which

is directly fed by

, and

is fed by

according to the equations as follows:

The above linear operations in the frequency domain using the Laplace transform take the form

that corresponds to a transfer function for

as

At

it yields

. The inverse Laplace transform of this signal is

If the excitation signal is an element of function class

, i.e., it has a finite support and it can be continuously differentiated infinitely many times (e.g., [

45]), around

where

,

can be approximated as

The signal delayed by

, i.e.,

in the frequency domain can be computed as

By comparing these equations it can be seen that this signal tackling means a delay

Note that after elapsing the contribution of the initial state, in the noise filter only the effects of the persistent excitation can be considered. No any complementary assumption is needed to arrive at Equation (

28) from Equation (

25): only mathematical analogies are physically interpreted in the following manner. Assume that

has only a very narrow support around a value

as

. This means that the excitation has a fixed frequency. For a function

that is continuous along the route of integration (it has poles only in one half of the complex plane) the integral

can be reduced to

, and the integral can be estimated as

. In this case

is the “

phase shift” that according to Equation (

27) corresponds to a delay. In other words, the LTI system that is excited with a fixed frequency signal, after elapsing the effects of the initial conditions, moves with the frequency of the excitation with an attenuation factor and a phase shift. The technical literature always considers the “phase shift” due to the traditions made by Bode’s work [

46] and does not mention that the phase shift physically means a delay. For non-monochromatic excitation the output signal is deformed because its various frequency components are attenuated and delayed in various manners.

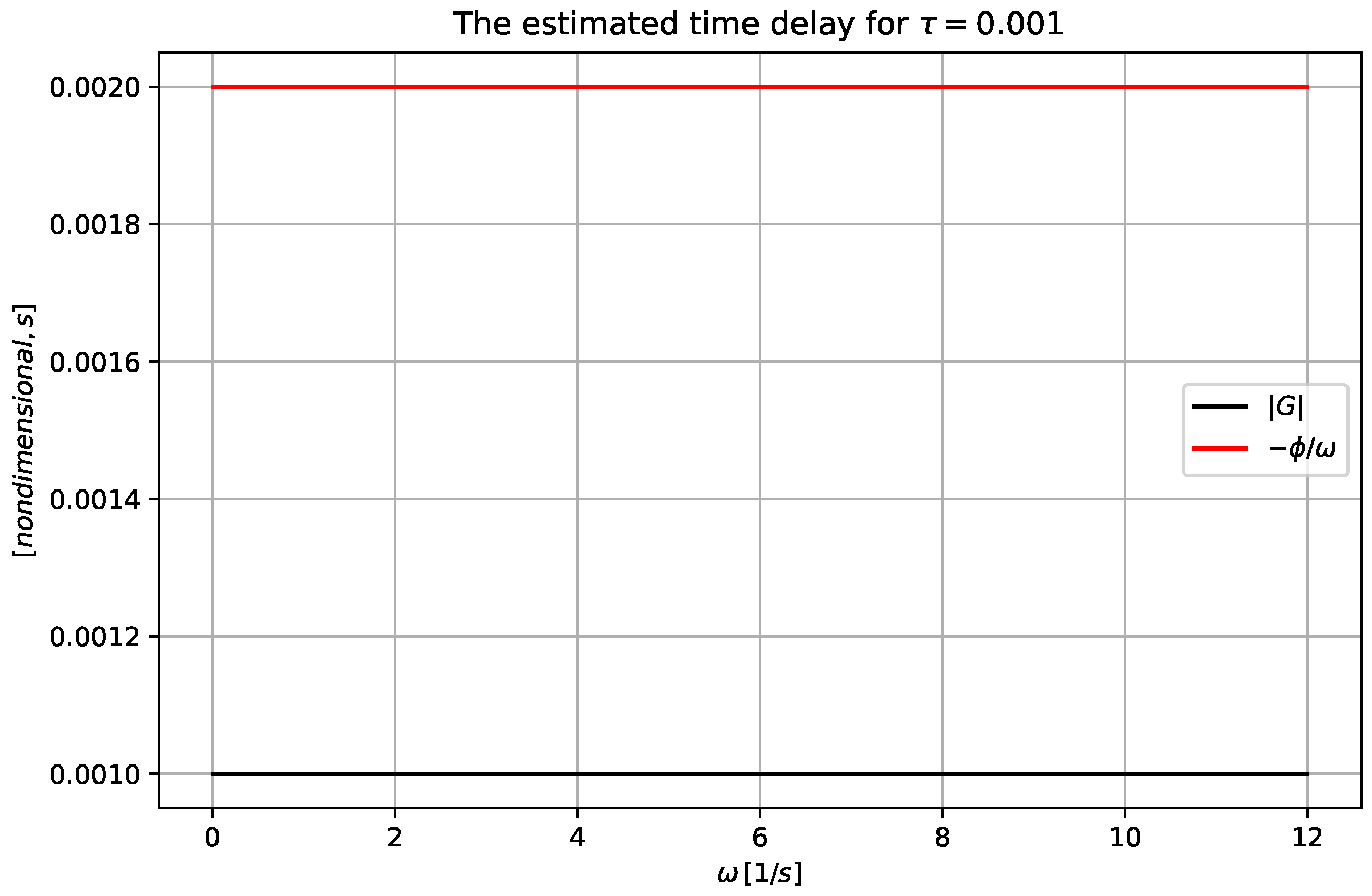

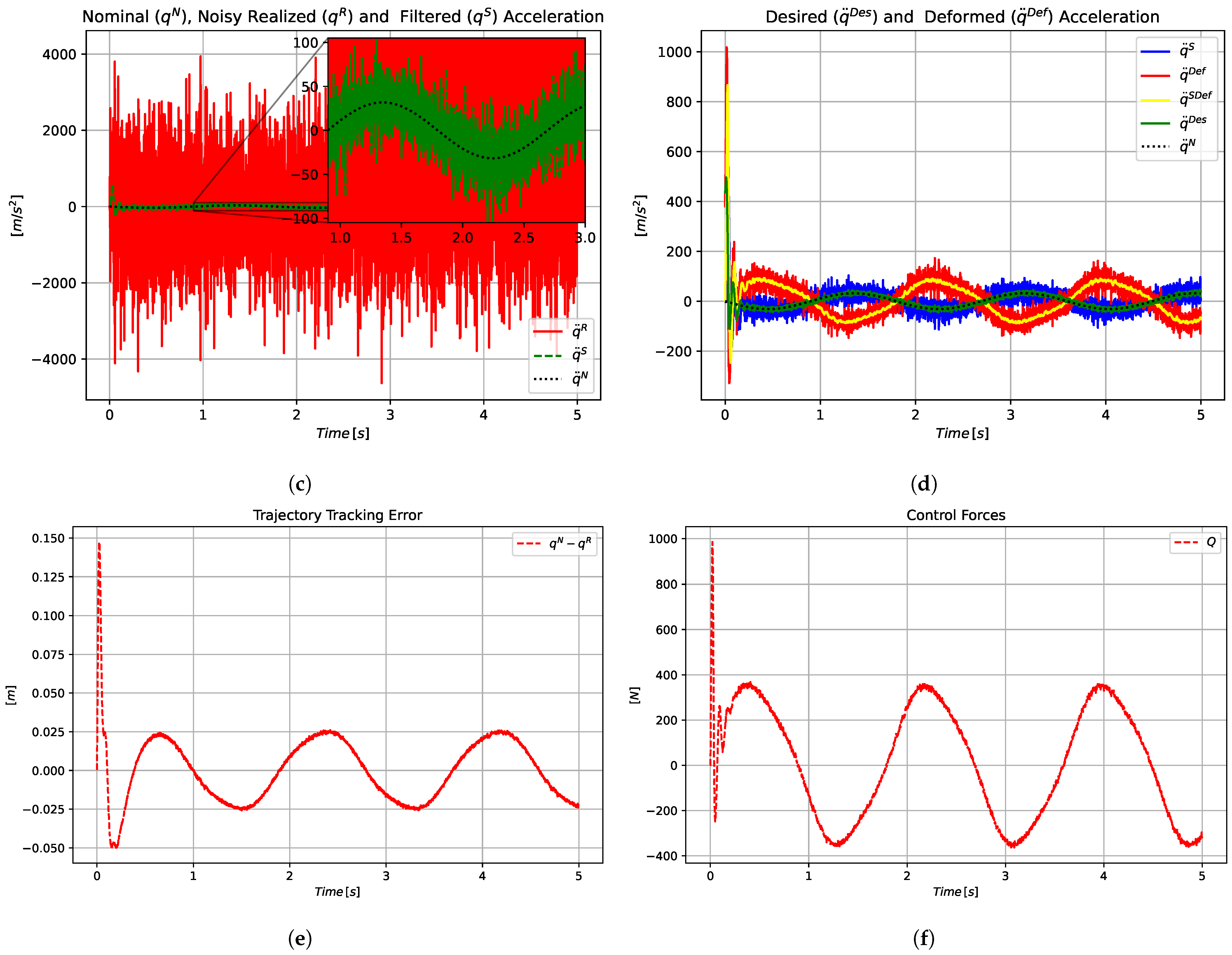

In the motion control of mechanical systems for a fast motion the upper frequency limit is approximately

, for which a delay

[s]; the low frequency transfer function is depicted in

Figure 2.

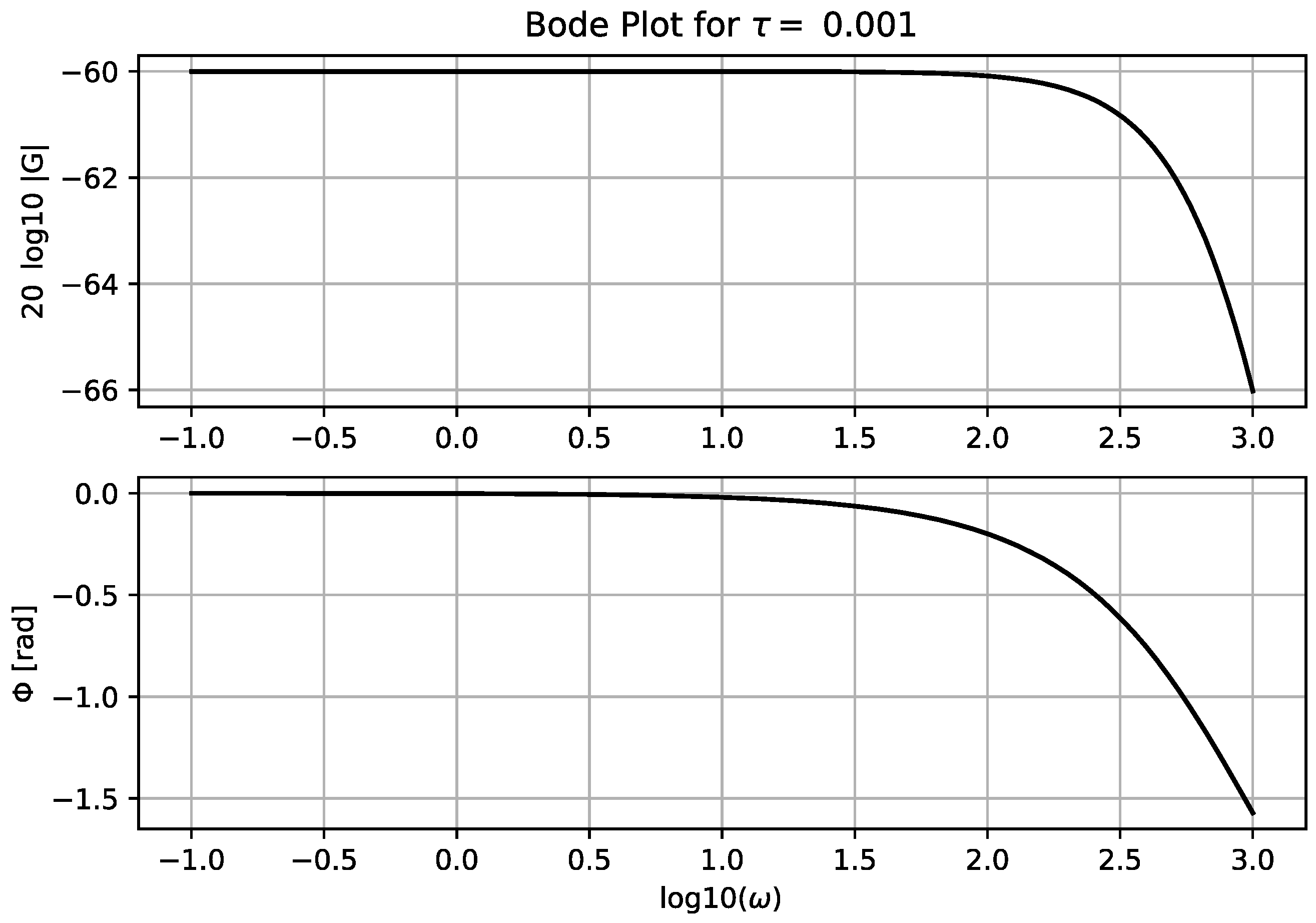

The transfer function for higher frequencies are depicted in the Bode plot,

Figure 3.

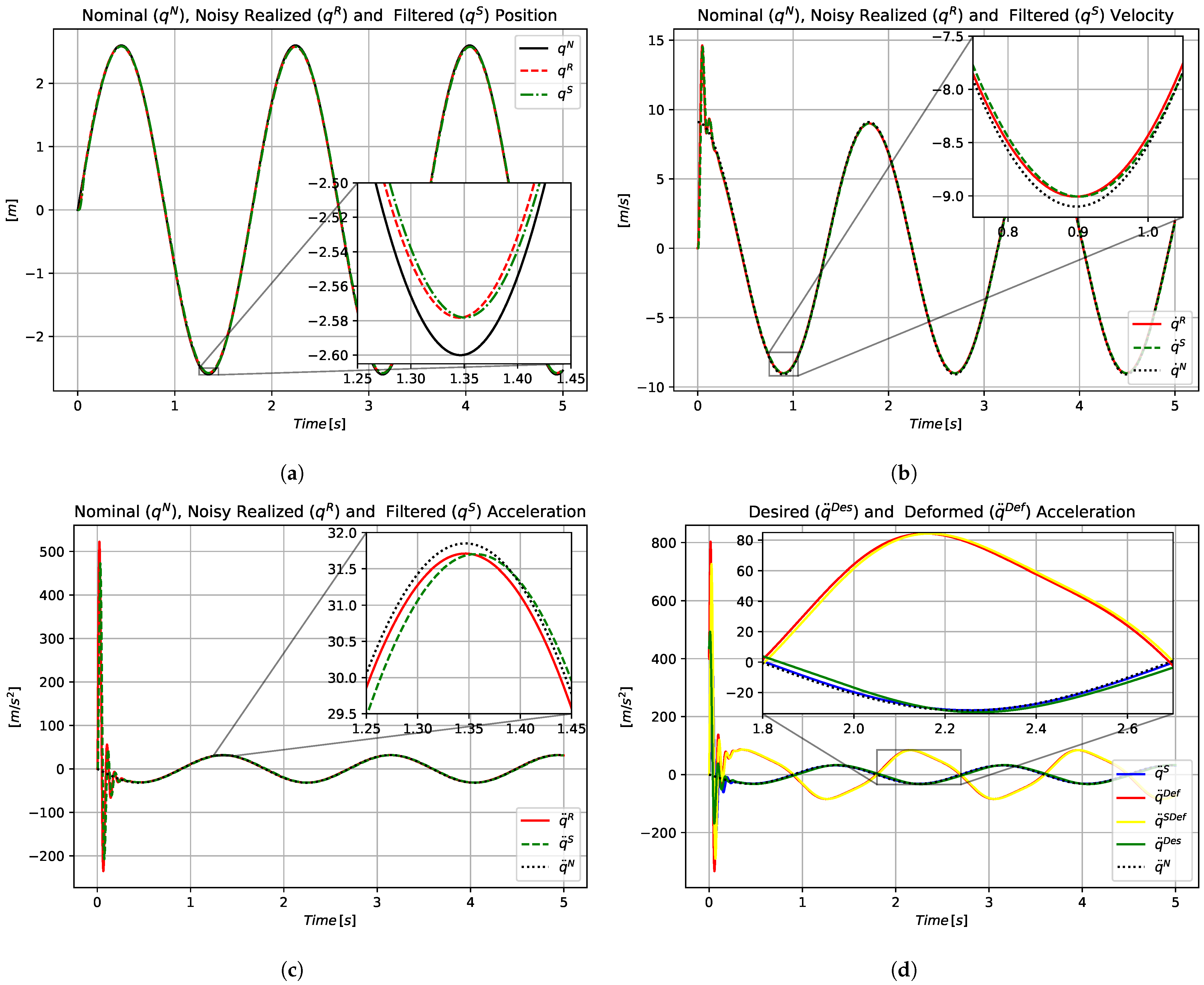

While in our previous investigations the issues of noise filtering and delay were considered separate issues, i.e., certain noise filtering techniques were applied and the filtered signal was sampled with some exact delay, in the present approach the low frequency delay was utilized and the high frequency filtering, as an additional service, was directly utilized too, as in

In this way, the cumulative effects of noise filtering and formal delay could be avoided in the FPI-based control. Furthermore, while the formally applied delay time must be very precisely specified in the calculations, this smeared delay has a noticeable effect even slightly later in time, making the adaptive method based on it more robust. Such effects were investigated in the sequel.

It is important to note that this filtering and delaying model is exactly valid in the application and it is independent of the dynamic model of the controller. Also, in the control process it is utilized in the time domain via numerical integration. For the composite array

its equation of motion has the standard “canonical form” of

with constant matrices

and

and the general solution of this equation of motion has the form

with a stable matrix. The first term is the general solution of the homogeneous equation

that contains the initial conditions at

, the second one is a particular solution of the inhomogeneous one. Due to the stability of the system the first term converges to zero, therefore its significance soon elapses. The second term corresponds to a persistent excitation that evidently contains delayed effects from the past. In the frequency domain only the effect of this persistent part was investigated in order to distinguish between the delays pertaining to the low frequency and the high frequency components of the excitation.