In modern naval architecture, a propeller is determined based on the vessel information, and a motor is selected based on that propeller. However, this can build inefficiencies into the systems through these underwater actuators. Specifically, unless a custom motor is built [

1], the motor will not run at its designed operating point. This can lead to losses as the propellers are spun at higher speeds or torques than intended, and leave the region of maximum efficiency. This can also lead to a change in hull speeds, which either incur additional drag losses from excess speed or hulls that cannot meet the target speeds. For standard vessels and boats, this is not a concern as the propulsion unit will likely be designed and tailored for the individual vessel due to the costs involved. For smaller vessels, like Unmanned Surface Vessels (USVs) and Unmanned Underwater Vessels (UUVs) that are used as research platforms, this will not be the case, as they must use Commercial-Off-The-Shelf (COTS) motors. This paper looks to incorporate pre-selected motors into the calculations of efficiency of propeller designs to determine the benefits this may bring.

A complete guide to propeller design can be found in [

2], but a brief introduction to the concepts will be provided here. The propeller moves a vessel through the water by “screwing” through the fluid, using the aft, or pressure, side of the blade to press against it. This leads to a pressure drop on the forward, or suction, side of the propeller. In pressing against the fluid, the propeller no longer moves in a perfect screwing motion but instead “slips” slightly. The thrust produced is tied to the amount of slip incurred, but the relationship is non-linear. At a certain point, too much slip leads to the propeller “recutting” the same water. In this case, instead of a laminar flow entering the propeller from the open water ahead of the vessel, each blade of the propeller encounters water that was pressed upon by the previous blade. This causes performance to degrade exponentially. Another physical phenomenon that can cause performance degradation is cavitation. This occurs when the drop in pressure on the suction side of the blade is large enough to cause the water to transition into a vapor state. This leads to a sudden drop in thrust due to the compressible nature of water vapor, and can lead to propeller damage from the formation of the water vapor bubbles

1.1. Wageningen B-Series Propeller Modeling

The typical propeller design process for a marine propeller is detailed below, following standard outlines [

3,

4]. This process utilizes a Wageningen Propeller B-Series as a standardized propeller shape. It is commonly used in naval architecture and has been studied extensively [

3,

5,

6,

7]. An example of a typical B-Series propeller is shown in

Figure 1.

The designer will utilize a series of charts, equations, or existing generators to determine the optimal geometry to fully define the propeller. A B-Series propeller is fully defined using five key variables: the pitch to diameter ratio (PD ratio), the diameter in m (

), the expanded area ratio (EAR or

), and the number of blades (

). The speed of advance coefficient (

) is also used to determine the performance of the propellers. The propeller blade thickness in m (

) can be included, but standard values exist based on the diameter of the propeller [

3]. However, this process is independent of the driver behind the propeller shaft.

The PD ratio is the ratio of the pitch—the distance the propeller moves forward in one revolution—and the diameter. Since this ratio is dependent on the diameter, the pitch in m (

) will be used instead for this work. The EAR is the projected area of all blades (

) divided by the area of a circle with diameter D (

). Since this ratio is dependent on the diameter, the projected area of all blades—called the expanded area in m

2 (Ae)—will be used instead for this work. The speed of advance coefficient is the fluid velocity at the propeller divided by the rotational speed of the motor in revolutions per second (

) and the diameter of the propeller. This equation is shown below, where (

) is the speed of advance, or the fluid velocity at the propeller.

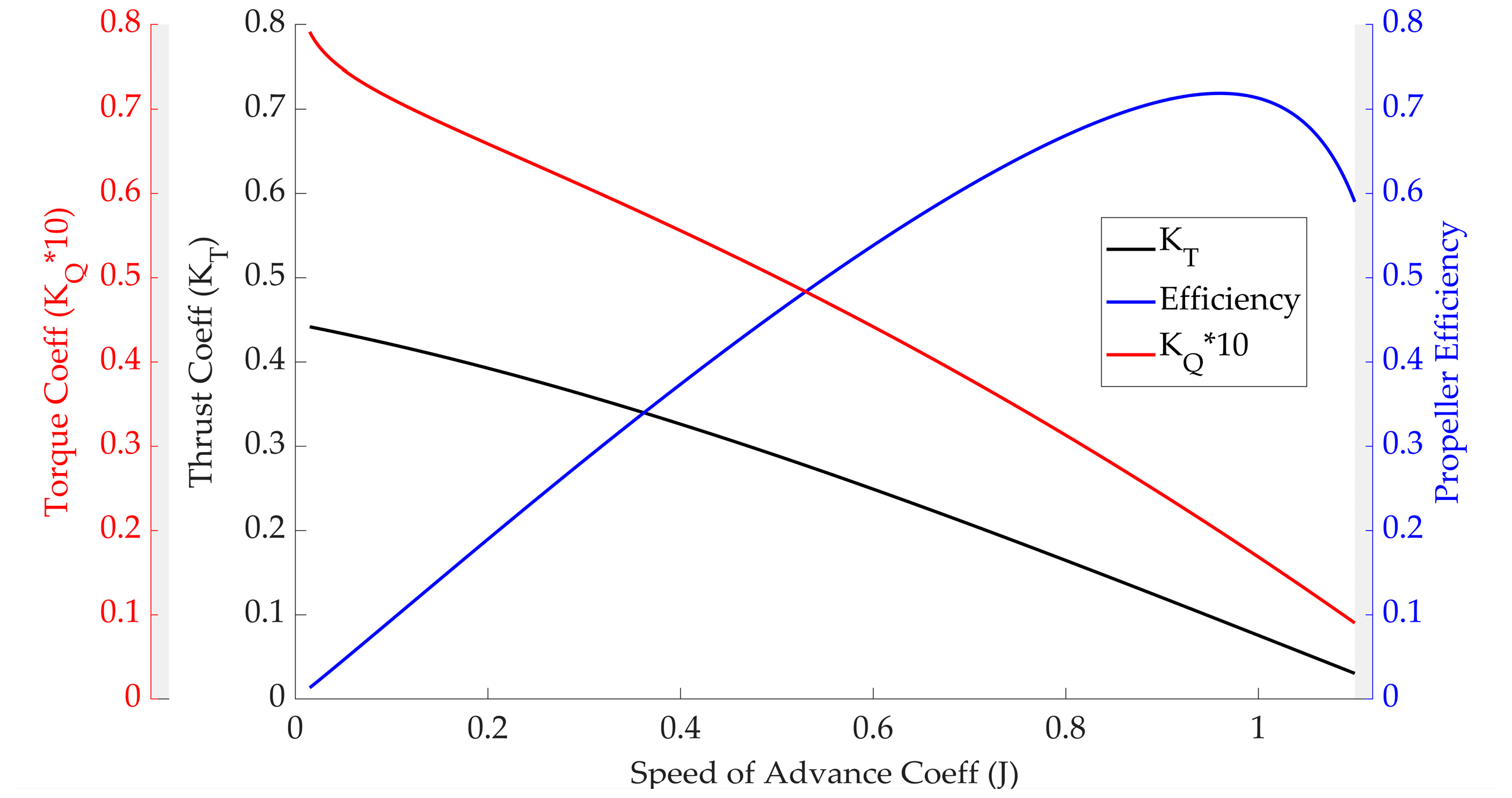

Utilizing these parameters, existing Wageningen Propeller B-Series experimental data can be used to determine the thrust coefficients (

) and torque coefficients (

) for the propeller. These are represented by the black and red curves in

Figure 2. These coefficients can, in turn, be used to determine the thrust generated by the propeller in N (

) and the shaft torque in N-m (

) that would be needed to drive the propeller at that speed. These are shown in the equations below, where the density of seawater (

) is given in kg/m

3 following standard data [

9].

With the shaft torque (

) and speed (

) known, the mechanical shaft power in kW (

) can be calculated through multiplication and unit conversions.

The open-water efficiency of the propeller (

) can be determined through the equation below based on the relationship between the output thrust coefficient and the input torque coefficient, along with a scaling factor built on the speed of advance coefficient.

Utilizing Equations (2)–(5), the efficiency of a given propeller can be obtained for any combination of vessel and motor speed. This is shown in the blue curve of

Figure 2. This then defines the objective function for the optimization problem. However, this is a source of losses for actuator design. As the drive characteristics of the shaft are not included in Equation (5), the result of any propeller optimization may not optimize the complete system efficiency.

With the objective function defined, the constraints can be considered. The three main constraints are thrust, cavitation, and strength. Simply, the thrust generated in N (T) must meet or exceed the minimum thrust necessary to drive the vessel in N (

), the propeller blades must not cause the water around the propeller to cavitate, and the propeller blades must be thick enough to avoid failing. The thrust constraint is given in Equation (6), the cavitation constraint is given in Equation (7) assuming there are no more than 2 propellers, and the strength constraint is given in Equation (8). These are listed as negative semi-definite inequality constraints to set up for future optimization methods.

The pressure terms in pascals (

and

) are the water pressure at the midline of the propeller and the vapor pressure. The vapor pressures are taken from standard values [

9]. Common practice is for the propeller to be assumed to be located at a depth equal to the maximum allowable diameter of the propeller [

2]. The term (

) is the number of propellers in the design. The term (

) is the maximum allowable stress for the propeller’s material. Depending on the application, this will be the yield strength or endurance limit of the material with a factor of safety applied.

The standard approach in naval architecture is to select the number of blades based on vibratory interactions around the vessel, to select the maximum propeller diameter allowed by the design of the hull, and then select the lowest EAR that does not cause cavitation according to Equation (7) [

2]. With three of the five design parameters defined, either the pitch or the speed of advance is optimized while the other is calculated as an output. Often, the point of maximum efficiency is tied to the maximum viable pitch value [

2], so the process can be simplified further in some cases. Variations on this approach are prevalent. Some prefer this to be performed through an iterative process, selecting the pitch based on empirical graphs and backing out the appropriate motor speed [

2], while others prefer optimization of the diameter [

10]. Research has also been done with engine propeller matching, but these are for large vessels, such as a 60-m patrol boat [

7].

The limits on the allowable design parameters may also be dictated by definitions and the limitations on production. As the speed of advance coefficient is a ratio of speeds, it can be limited to between 0 and 1, though it can exceed this [

11]. For this application, the propellers will be targeted for manufacture utilizing a standard desktop 3D printer, so the minimum diameter of the propeller will be dictated by generating a sufficiently strong hub, and the maximum will be dictated by the available build volume. The propellers will be generated through an online tool that limits the PD Ratio to between 0.4 and 1.4 and limits the EAR to between 0.35 and 1.05 [

8]. This corresponds to the limits of the defining experimental data [

11]. The number of blades is technically any integer greater than or equal to 2, but the propeller generation tool allows between 3 and 5 blades, defining the limits on Z. These constraints will be converted into negative semi-definite inequality constraints as shown in the equations below.

Following the previous propeller design process, these values indicate that an optimal propeller would be expected to have three blades, a diameter of 0.215 m, an EAR of 0.35, a high value for pitch, and a very low speed. The actuators for USVs and UUVs under investigation in the rest of this paper are not expected to follow these rules, as the motor inefficiencies at low speeds will be significant.

1.2. Optimization Method Applicability

Before getting into the motor influence, the design and optimization of propellers without an iterative process and without following these rules of thumb can be discussed. A nonlinear optimization problem can be generated in a standard form to maximize the efficiency of the propeller in a manner that can be analyzed through Karush-Kuhn-Tucker (KKT) conditions and Augmented Lagrange Multipliers (ALM). The formulation is shown below, including the performance function along with the eleven constraint equations. The maximum condition previously discussed is inverted and used as a minimization for computational ease.

Minimize

subject to

where

It should be noted that for ALM methods, the variables are assumed to be continuous [

12]. While this may be acceptable for the first four design parameters, the number of blades is discrete. To account for this without loss of mathematical rigor, the number of blades can be treated as a constant for an iteration of the solution. That is, it can be set to a value of 3, and then the problem can be optimized. Afterwards, it can be set to 4 and optimized again. This can be repeated for all reasonable values of

. Since there are very few options regarding the number of blades and because increasing the number of blades will degrade the overall efficiency due to increased blade edges cutting through the water, it will be assumed that the solution can be found close to the minimum allowed. Alternatively, all of the design parameters can be treated as discrete and evolutionary, or genetic algorithms can be utilized [

13,

14,

15,

16].

The above is relatively straightforward mathematically, but the relationships for the thrust and torque coefficients are modeled from curve fits of experimental data. Proper modeling of these utilizes Equations (26) and (27) for the thrust and torque coefficients. The following is drawn from [

11] following the work of [

17], and is valid while the fluid at the characteristic distance has a Reynolds number below 2 × 10

6. Higher values for the Reynolds number will be discussed momentarily.

and

The first and second order derivatives for these equations are still continuous and fully defined, meaning the system of equations is technically solvable through analytical techniques such as Augmented Lagrange Multipliers. However, due to the size of the problem, this may not be feasible. After accounting for Z as a discrete parameter, there are a total of 4 continuous design parameters, 11 Lagrange multipliers (λ terms), and 11 augmentation or slack parameters (s terms). Taking the partial derivatives with respect to each of these terms generates 27 equations. The differentiation with respect to

alone generates an equation with 2123 terms and is 17 pages of 12-pt font. This can be simplified somewhat by breaking the problem into subsets and solving them multiple times [

4], but the overall computational load is substantial.

The inclusion of the Reynolds number adjustment complicates the issue further due to both length and an added discontinuity at the critical Reynolds number. Extensive empirical work has been performed in this region to evaluate propellers at the limits of performance [

17,

18,

19], though it can still break down at the extreme limits. For the application in this work, small vessels, the propeller speeds can end up being extremely high relative to traditional designs. In this instance, an adjustment must be made to the thrust and torque. As previously mentioned, this occurs when the Reynolds number is above 2 × 10

6 at a distance from the propeller’s rotational axis of 75% the radius. This distance is called the characteristic distance for the B-Series propeller (

). Note that some authors, such as [

19], prefer to use 70% of the radius for the Reynolds number, and corrections must be included if this value is to be used. The Reynolds number at the characteristic distance (

) is calculated as

where the constant term (

) is the chord length at the characteristic radius and can be determined from [

3]. The kinematic viscosity of the water is (

) and can be determined from standard sources [

9]. If required, the adjustment factor for the thrust coefficient (

) and the adjustment factor for torque coefficient (

) are given below.

Because these factors are only added to the thrust and torque coefficients when the is above 2 × 106, the derivatives of the thrust and torque coefficients have a discontinuity at that point. To account for this, the optimization techniques that require smooth derivatives can be solved twice: once using the unadjusted thrust and torque coefficients plus a constraint that the Reynolds number must be below the critical value, and once using the adjusted thrust and torque coefficients plus a constraint that the Reynolds number must be above the critical value.

The first iteration would be as follows:

Minimize

subject to

where

The second iteration would be as follows:

Minimize

subject to

where

A numerical KKT approach can be beneficial in situations such as this, where problems are complex and the gradients are defined, but it can be a poor choice here because it provides necessary but not sufficient conditions for optimality. Because the problem is highly variable, there are many local maxima and minima and discontinuous feasibility regions. This leads to the algorithms often getting stuck outside the global maximum, indicating that a method with randomization included may be necessary, such as multiple starting points, simulated annealing, genetic algorithms, or random sampling. Alternatively, an analytical solution could potentially be determined.

Additionally, the algorithms for the computation of the propeller thrust and torque coefficients can generate negative results unexpectedly. For example, the motor torque can become negative if the speed of advance coefficient goes too high, indicating that the motor is operating as a generator. A constraint can be added to eliminate conditions where the shaft torque is negative, but it adds complexity. This constraint is labeled with a subscript of (

) and is added here for completeness.

One approach for a situation such as this, where the optimization calculation could be troublesome, is to conduct an exhaustive search. Manufacturing precision means there is a finite resolution on propeller diameter, pitch, and areas. Motor controllers are also digital machines, meaning they also provide a finite resolution for the speed of advance coefficient given a target fluid velocity at the propeller. In that case, all different combinations of the design parameters can be tested. Since this can be done through simulation and analysis utilizing standardized B-Series propeller data, the exhaustive search is a valid approach. It should be noted that, as an exhaustive search, this is both slow and energy-intensive.

1.3. Vessel Considerations in Optimization

Given these challenges, it is unsurprising that adding the additional complexity of motor performance characteristics is often not done. However, they significantly impact the feasibility and efficiency of the design for USVs. In general, the best solutions mimic those of large cargo vessels; large propellers spinning at speeds of tens or hundreds of RPM to provide immense amounts of thrust. Small DC motors often cannot produce these torque–speed combinations or cannot do so effectively.

Commonly seen exceptions to these values are vessels designed to ride up and glide over the water, as many RC boats do. These utilize a planing hull design rather than a displacement hull design. In a planing design, the vessels exert a significant amount of energy to get up on top of the bow wave, with water pushed out in front of the boat as it moves. Once up on the bow wave, the overall drag coefficient of the vessel decreases drastically, leading to higher maximum speeds. The vessel characteristic that defines whether a vessel should use a planing hull or a displacement hull is the speed-to-length ratio. The details are beyond the scope of this paper, but as the speed of the vessel increases, it will eventually start to try to ride up the bow wave it creates if the hull shape allows it [

3].

Many small personal watercraft, like jet-skis and bass boats, incorporate elements of a planing hull design. While significantly faster, these are not the most efficient from a power, weight, and energy perspective since significant amounts of thrust must be generated to get up on the bow wave. For smaller USVs like RC boats, planing hulls are often an excellent choice since they can be lightweight, and they must have high speeds relative to their short length, and they need short durations. But for vessels used as long-term research platforms, it is not viable. In addition, planing vessels struggle in waters that are not flat. Due to the size of oceanic waves relative to the size of the vessels, the water is virtually guaranteed not to be flat.

This means these USVs will be small, displacement hulls that will be battery-powered, sometimes with solar power regeneration. This leads to the requirement of the use of brushed or brushless DC motors. These motors typically operate in the tens of thousands of RPM and struggle to produce high torque at the low speeds dictated by the propeller design. The most common solutions are to utilize a custom or manufacturer-supplied gearbox or use a mismatched propeller and motor from available COTS sources. Both approaches introduce additional and unnecessary inefficiency to the system.

In contrast, this paper looks to combine the expected or known performance characteristics of motors into the design of propellers. This will increase the computational complexity of the problem, but this paper hopes to demonstrate that this will improve overall performance for the vessel.

The consideration of electric motor performance along with propeller characteristics has begun to be studied in industry, but it is in its early stages [

20]. These designs are highly variable and have yet to come towards standardized solutions like the B-Series propellers. One major consideration for this is that there are few electric vessels currently in use or under construction, roughly 0.3% of the global fleet [

21]. Propeller manufacturers are designing their products towards the majority of vessels, which utilize internal combustion engines. However, that is not to say that no designers are looking at this. A few are beginning to consider this market and are developing propellers that must be designed with the output of the drive systems in mind. The scientific community is working to validate these designs through CFD modeling as well as physical experimentation [

22].

As an example, the BlueNav Whale Design uses an internal, rim-driven propeller design with blade shapes derived from biomimicry of humpback whale fins, including tubercles [

23]. However, the rim-driven propeller’s nozzle shape, the tubercles, and even surface conditions of the blades need to be optimized for each use case [

20]. Surface protrusions are an area of study that leads to promising gains in efficiency [

24] and CFD studies have been performed to indicate the benefits of these tubercles [

25]. This reinforces the need for the propeller to be designed with the motor in mind.

These actuators often see high thrust requirements due to the relative sizes of the actuators on UUVs and USVs. Thus, propeller designs that incorporate high-thrust principles over high-speed principles are more common, such as the Hydro Impulse HI-RF 11 Mitek [

26]. While this propeller is not designed specifically for electric motors, the principles it uses are more suitable for electric motors than traditional internal combustion engines. This can lead designers towards a trend of selecting and designing propellers that match the drive system.

One designer who is considering electric motors in their propeller designs is Sharrow Marine. The Sharrow Marine toroidal propeller has a twisting loop design, a highly innovative approach [

27], that the inventor claims will be able to operate at 30% higher efficiency at the high-torque regions of electric motors [

20]. It should be noted that this design is not dedicated to only electric motor applications, as it claims to produce up to 40% higher efficiency than traditional designs, regardless of the driving source [

28]. Current academic research is attempting to properly model and validate these designs, such as in [

22].

As an alternative approach from the UUV perspective, many manufacturers. In this space, they prefer to maximize bollard test ratings where the actuator is held stationary and the efficiency is measured as the thrust output per Watt consumed. BlueRobotics pioneered a flooded brushless DC motor that allows high efficiency while being essentially depth-unrestricted [

1]. However, this approach is entirely focused on the performance under conditions where the speed of advance coefficient is zero and the thruster is stationary [

29]. Data is unavailable for varying speed of advance coefficients, i.e., when the vessel is underway. While this is an acceptable assumption for UUVs due to their relatively slow speed, it may not be acceptable in higher-speed USV applications or for long-duration missions where the thrusters are run continuously.

1.4. Motor Performance Modelling

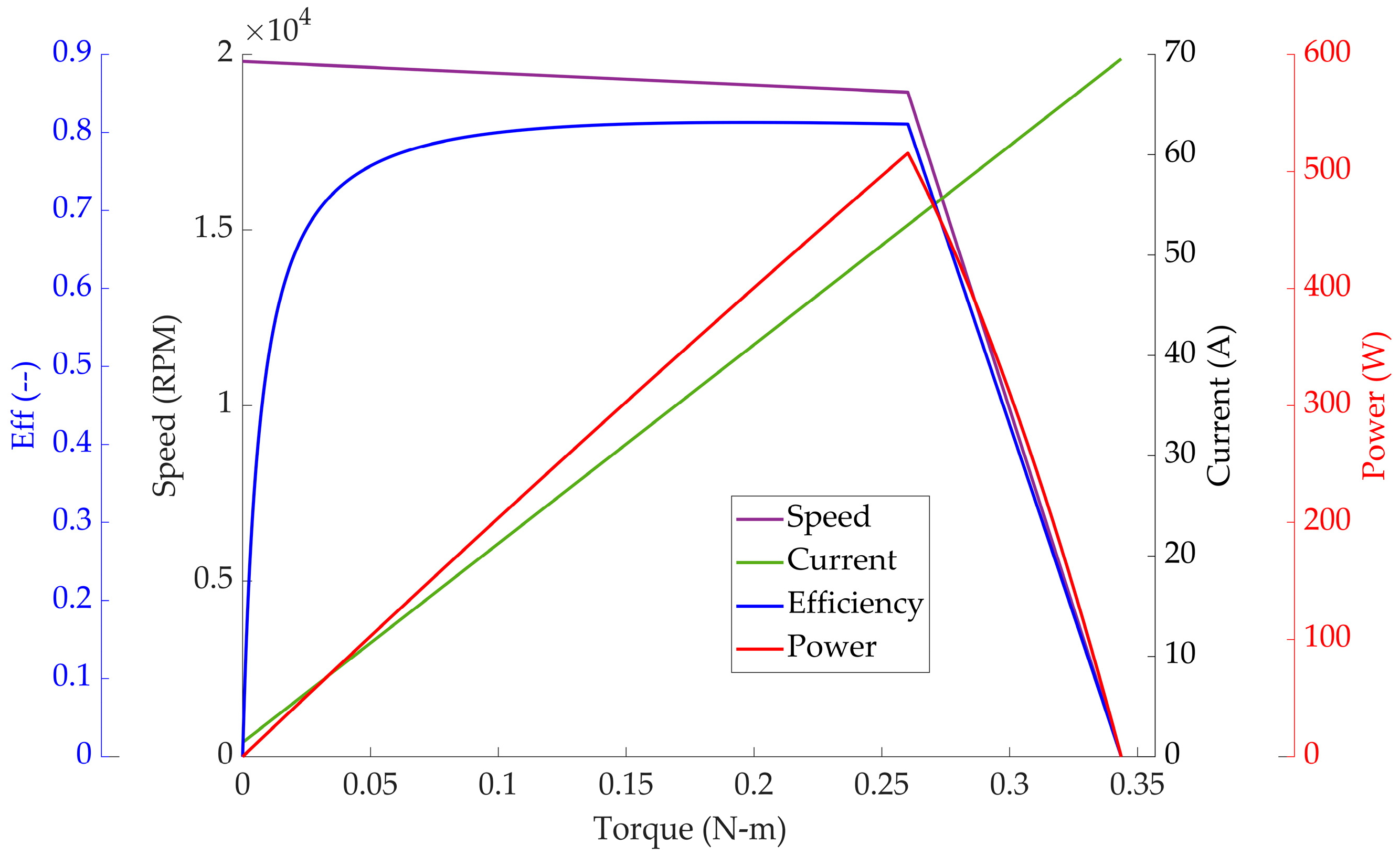

Between the brushed and brushless DC motor, this work will begin with the brushed motor since it can be used to model part of the brushless motor’s performance. The typical torque-speed performance curve for a brushed DC motor is shown in

Figure 3. This motor will be used in the case study done later in this work.

The relationship between torque and speed can be modeled as a linear relationship with a form of

where (

) represents the torque generated by the motor and (

) represents the speed of the motor in RPM. The stall torque (

) serves as the y-intercept of the linear equation. Connecting this to the previous conversations, the required shaft torque (

) will be equal to the motor output torque at steady state. The parameter (

) is the torque coefficient of the motor and provides a constant value slope.

The relationship between torque and current is also a linear relationship with a form of

where (

) is the current draw of the motor under the torque load. The no-load current draw of the motor (

) serves as the y-intercept of the linear equation and the parameter (

) is the motor torque constant, and is another constant linear slope.

The efficiency of the motor is the mechanical output power—torque multiplied by speed—divided by the electrical input power—current multiplied by voltage.

Note that the speed of the motor here is generally represented with (

) for a speed in radians per second, while the motor performance coefficients are often provided in revolutions per minute. For consistency, the speed will be represented in revolutions per minute throughout, with the unit conversion occurring only here. It must be stressed that the motor speed (

) is in revolutions per minute (RPM) while the propeller speed (

) is in revolutions per second (RPS). Substituting in the previous equations provides a single equation for motor efficiency based on speed.

Since the speed of the motor can be connected to the propeller design parameters through the definition of the speed of advance, the efficiency equation can be rewritten in terms of the design parameters as

For a brushless DC motor (BLDC), the performance limits are broken into two regions: a constant or semi-constant speed region and a constant or semi-constant torque region. In either case, performance decays if the torque exceeds an operating point where the motor is rated, and it performs similarly to a brushed DC motor. Below this point, the torque available at the speed is constant or semi-constant, depending on the motor’s construction. This is represented by the torque-speed curve shown in

Figure 4. The following estimate of performance is rough, as the true values will be more continuously differentiable instead of showing a sharp peak at the rated torque.

The motor begins intermittent operation if it is overloaded and the required torque is outside of this boundary. In

Figure 4, overloading the motor would look like a shift to the right. This can become perilous with the motor potentially overheating. In practice, therefore, if the desired speed is below the rated speed, then the torque output should be kept at or below the rated torque. Above the rated torque, the motor will have a torque-speed curve like that of a brushed DC motor with a linearly decreasing relationship. Note that the winding methods inside the motor can be represented as either a true BLDC or a permanent magnet synchronous motor (PMSM). This difference may only be detectable by disassembling the motor or measuring the back-EMF from the motor to judge whether the waveform is sinusoidal or trapezoidal. Due to the variability involved, the relationship for the torque to the voltage constant will be modeled as a PMSM and is defined by the equation below where (

) is a constant, (

) is the current draw, (

) is the no-load current draw, and (

) is the motor’s voltage constant [

30].

The constant C is based on conversion factors for three-phase PMSM and has a theoretical value of

but a value of 8.1 is more conservative based on experimental motor performance due to losses [

31].

Combining the two theoretical torque regions for those above and below the rated speed produces a piece-wise function for the available motor torque, as shown below.

Here again, it should be noted that this approach is an estimation of the performance of the motor, as the BLDC motors and PMSM have slight performance variations and can be significantly impacted by the control methodology used, such as pulse frequency modulation for the BLDC and field-oriented control for the PMSM. However, these are considered beyond the scope of this paper.

In this paper, the conservative semi-constant relationships will be used, so the torque-speed curve will be defined by

and the current draw of the motor at the required torque will be

These are the relationships used to generate the curves shown in

Figure 4.

1.5. Combining Propeller Performance and Motor Performance

To incorporate these equations into the system of inequality constraints previously given, a different set of equations will need to be satisfied, depending on the type of motor used. If a brushed DC motor is used, one additional constraint can be added using Equation (46) as shown below. An index of (

) is used here as the implementation will need to be changed for different conditions.

For a brushless DC motor, the piece-wise function in Equation (53) can be converted into two separate constraints that must be satisfied. Indices of (

) and (

) are used here as the implementation will need to be changed for different conditions listed in the Materials and Methods section.

and

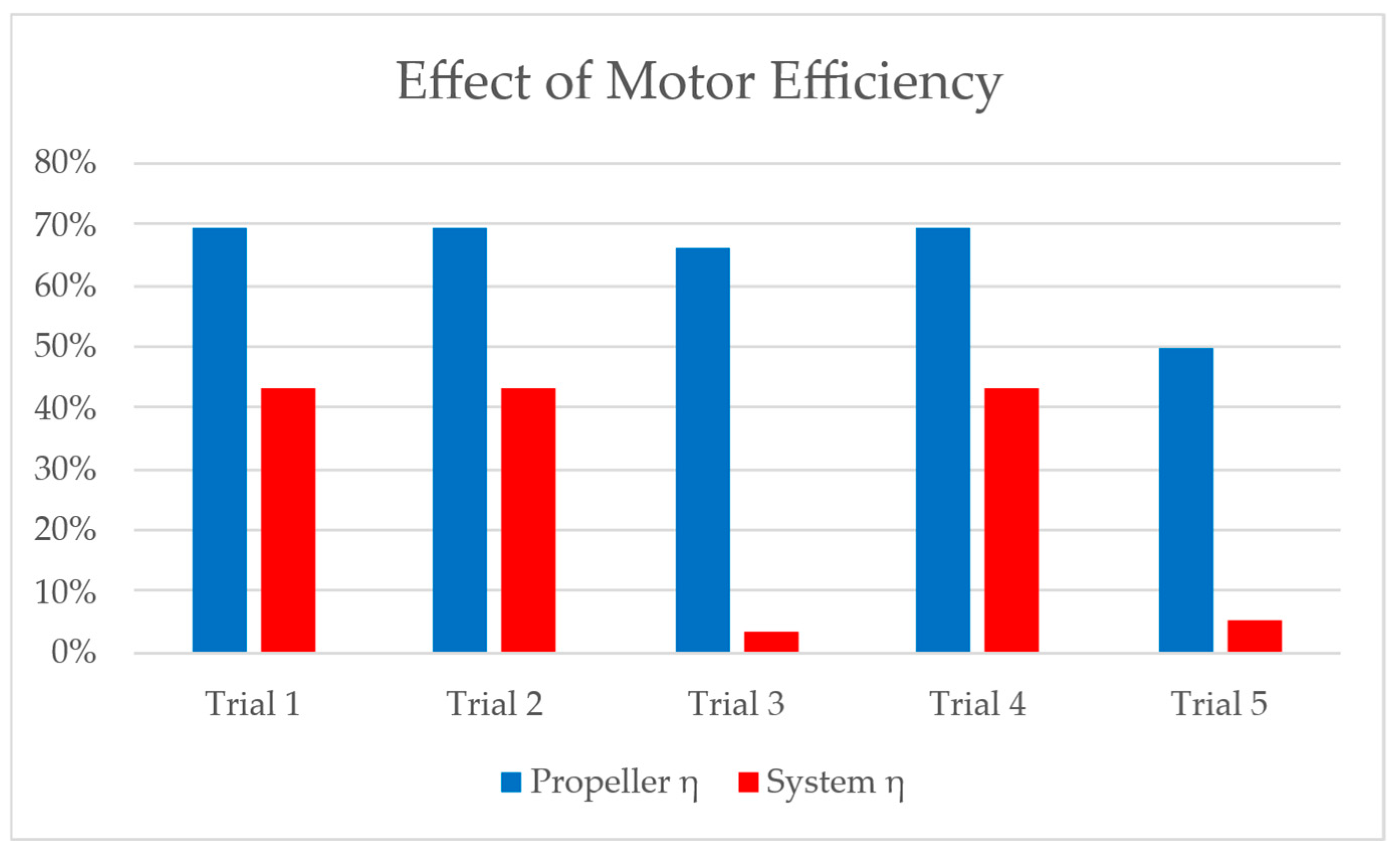

Motor efficiency can be combined with propeller efficiency by multiplication to generate a performance function to capture system-wide efficiency (

). An additional term for gearbox efficiency (

) can be added for completeness for designs that wish to pursue including a gearbox. For this work, the gearbox efficiency will be unity for all but the brushed DC motor with the gearbox. Thus, the system-wide efficiency is

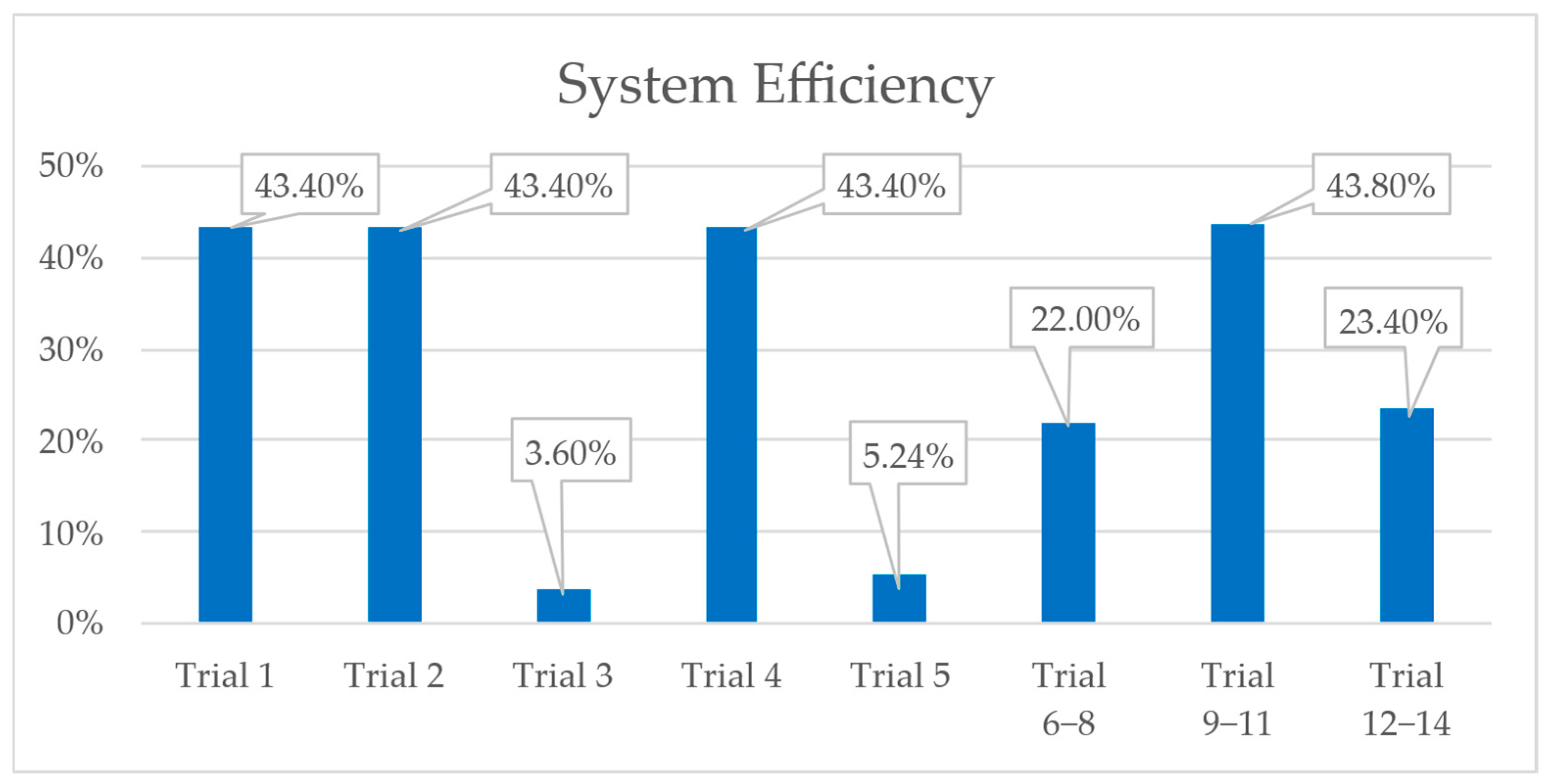

The research question posed in this paper is whether including the motor efficiency in the performance function and/or constraint equations for the optimization algorithm improves the overall performance of the system. For this paper, the available motors will be constrained to a finite set to represent a range of motors available at a manufacturer’s website. First, the propeller efficiency problem will be solved through exhaustive searches without considering the motors’ limitations (Equations (55)–(57)). Then, a second round of exhaustive searches will be repeated, but this time considering the performance limits of each motor. The most appropriate motor(s) for the propeller will be selected, and the system efficiency will be calculated utilizing the relationship in Equation (59). Lastly, the system will be optimized using a third round of exhaustive searches, considering the motor limitations and the overall system efficiency. It is expected that the overall performance will increase in these final iterations, with the efficiency greater than during these trials than during the others.

1.6. Limitations of Considered Approach

This paper will not address the complete vessel optimization and will solely focus on the optimization of the actuator itself. The performance of a particular vessel hull has been studied extensively in general terms [

32], relative to destroyers [

33,

34], relative to conventional reefer ships [

35], and relative to bulkers [

36].

Similarly, this paper will not address final design validation under real-world conditions. This area of study will be a critical portion of future work that will need to be completed. However, the process of propeller validation is well studied through the Wageningen B-series propeller data generated from the Netherlands Ship Model Basin and is considered requisite for any theory or mathematical model [

37]. Any model is compared to this data set, as it is the most exhaustive and comprehensive data available for marine propellers.

Initial validation will need to be performed through Computational Fluid Dynamics (CFD). This is an active area of research [

37,

38,

39,

40]. A particularly challenging aspect is the modeling of cavitation [

37,

41,

42]. Some authors prefer a two-equation k-ω model for a Reynolds-averaged Navier–Stokes equation [

43] while others prefer the three-equation k-ε version [

42] or a hybrid 2.5D numerical approach [

44]. The details of this CFD approach are beyond the scope of this paper, but a calibration study is provided in [

45] which will be the guiding document for future work. It should be noted that the generally accepted variation is 10% [

46]. The efficiency improvements for larger propellers may not be sufficiently significant to register changes within that band, but the values for smaller propellers may. The difference will depend on the motors and constraints selected for future work. Once an appropriate CFD model has been generated, the results of this paper will be validated or corrected, and prototype testing will commence. However, as noted in [

24,

45], the surface roughness can have a significant impact on performance and would need to be included in the model if FDM fabrication is used.