Safety-Critical End-Effector Formation Control for Planar Underactuated Manipulators

Abstract

1. Introduction

2. Preliminaries

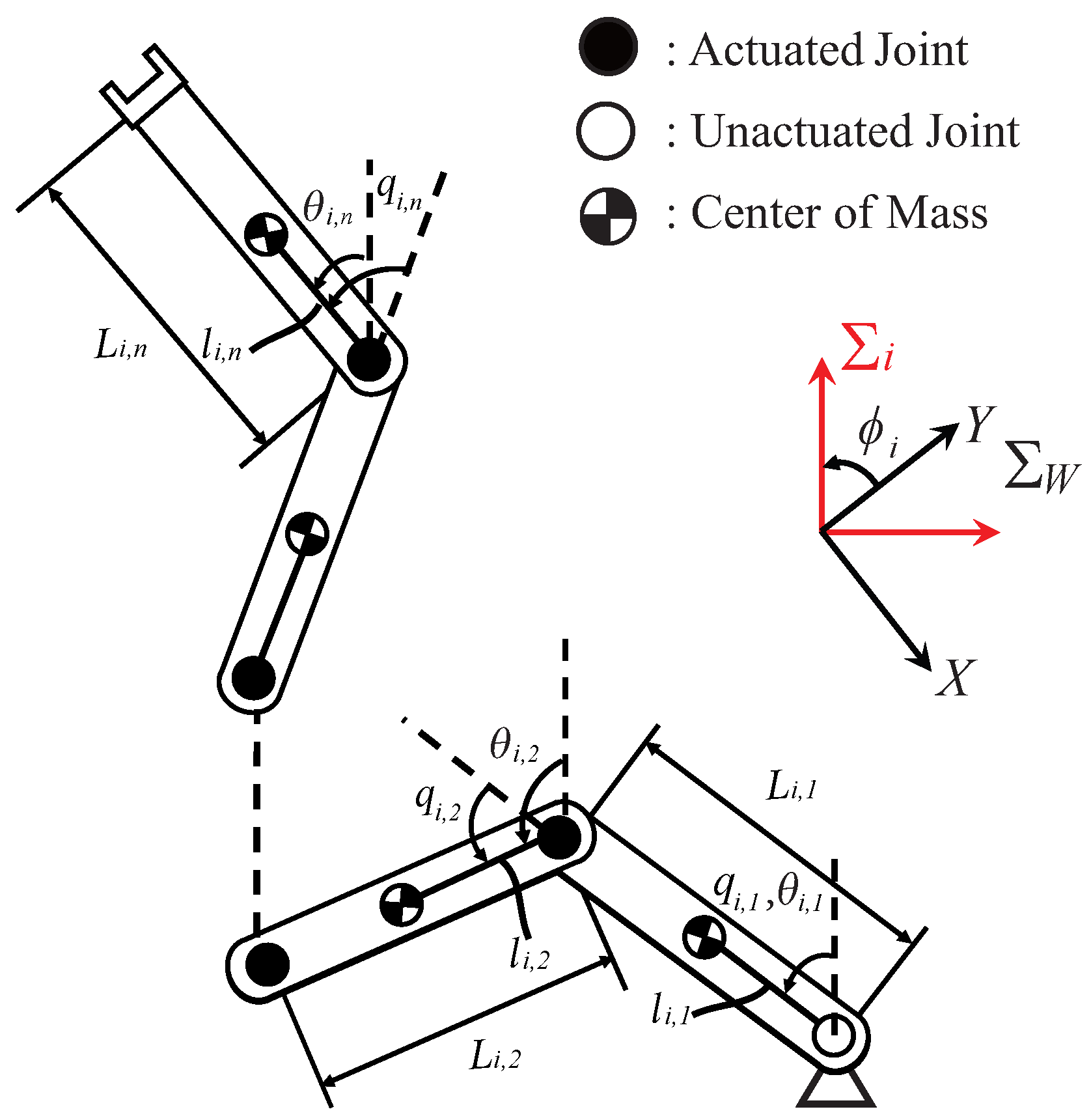

2.1. Dynamics of Underactuated Manipulators

2.2. Control Barrier Functions

3. Problem Formulation

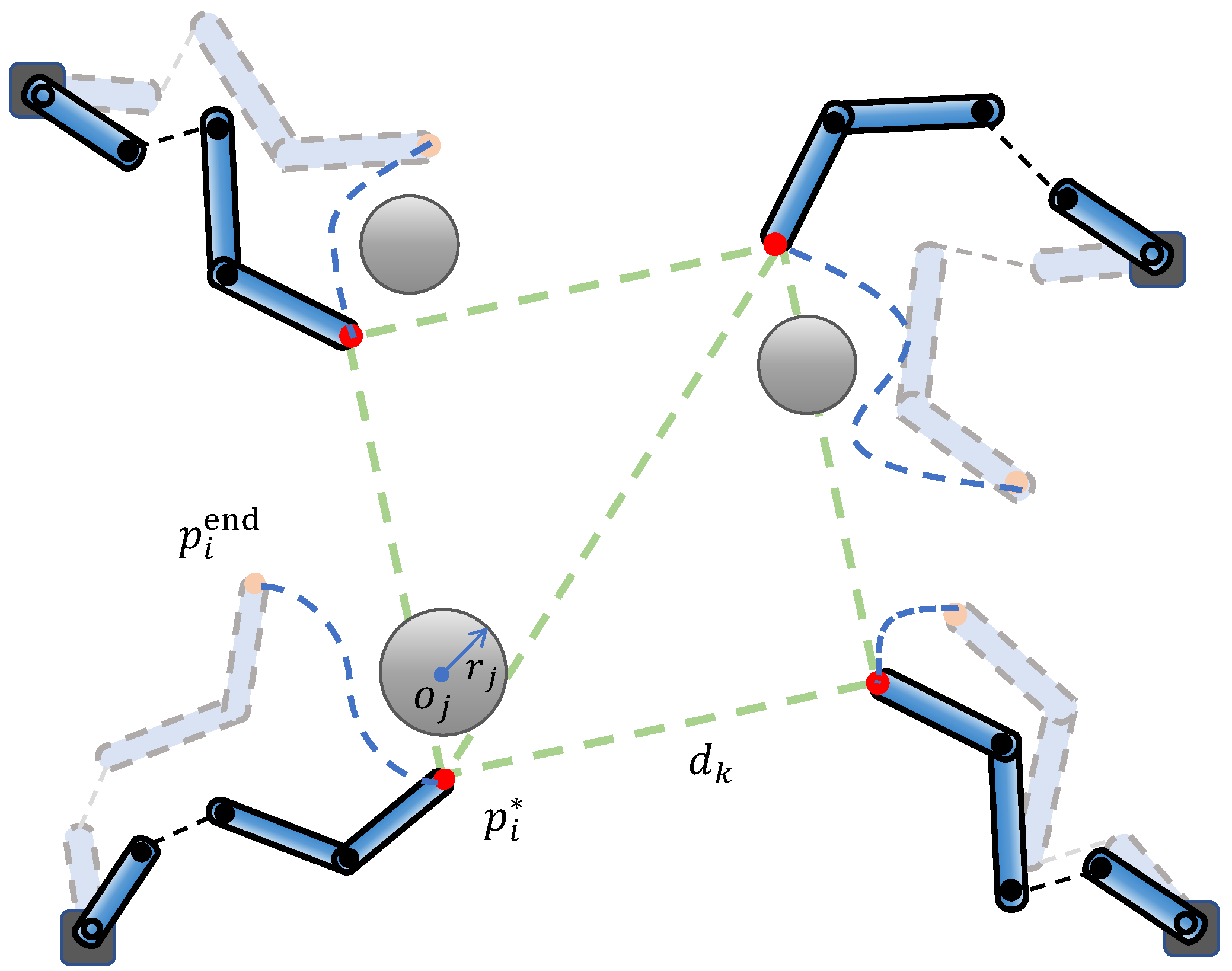

3.1. Formation Shape Specification

3.2. Obstacle Avoidance Constraints

3.3. Control Objectives

- Formation Keeping: Develop a control strategy ensuring that the manipulators’ end-effectors converge into the feasible set , achieving and maintaining the desired geometric shape.

- Obstacle Avoidance: Guarantee that the positions of all end-effectors satisfy the safety constraints in Equation (18) at all times, thus preventing collisions.

4. Main Results

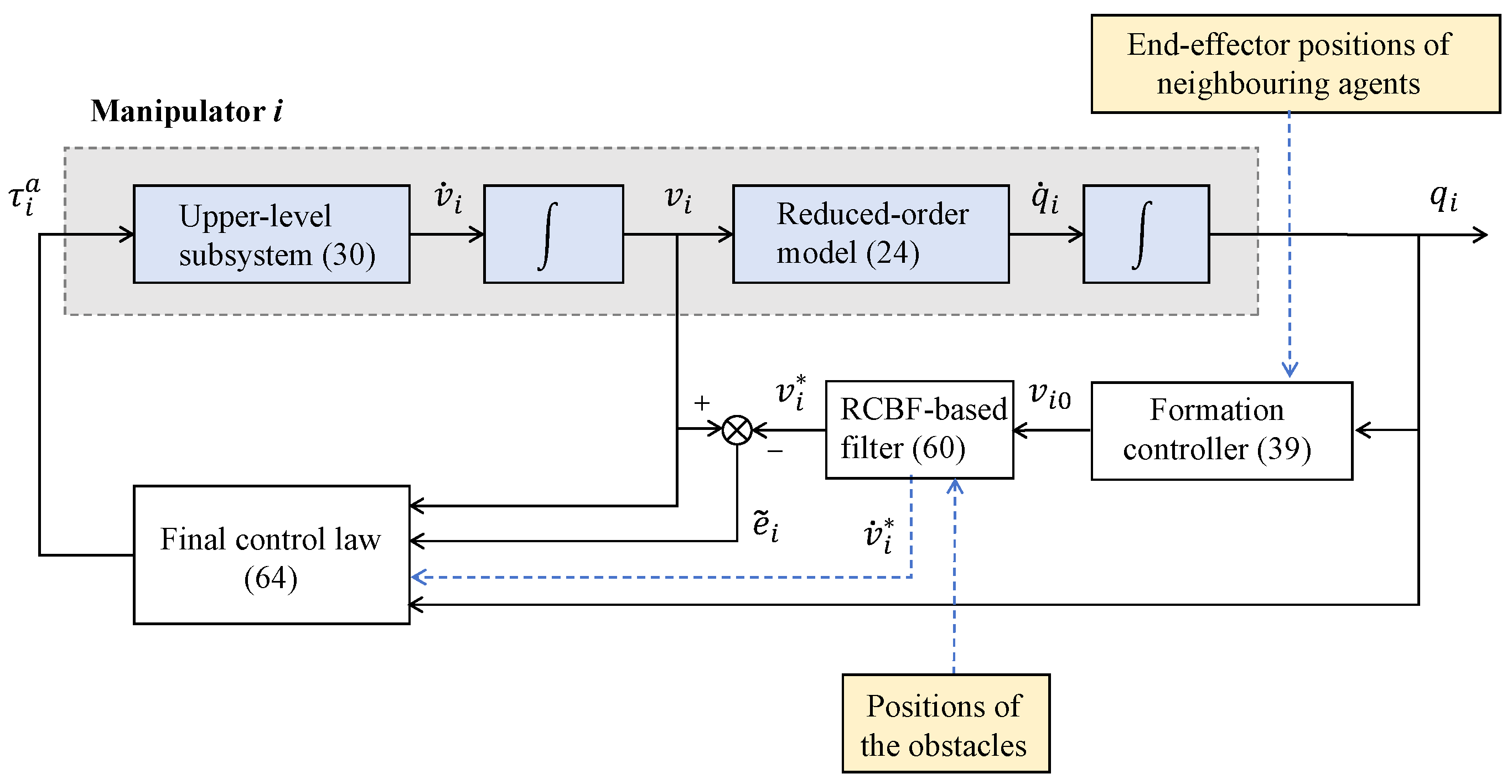

4.1. Modeling Underactuated Manipulators in the Cascaded Form

4.2. Safety-Critical Controller for End-Effector Formation

4.2.1. End-Effector Formation Control for Reduced-Order Model

4.2.2. RCBF-Based Safety-Critical Controller

5. Simulations

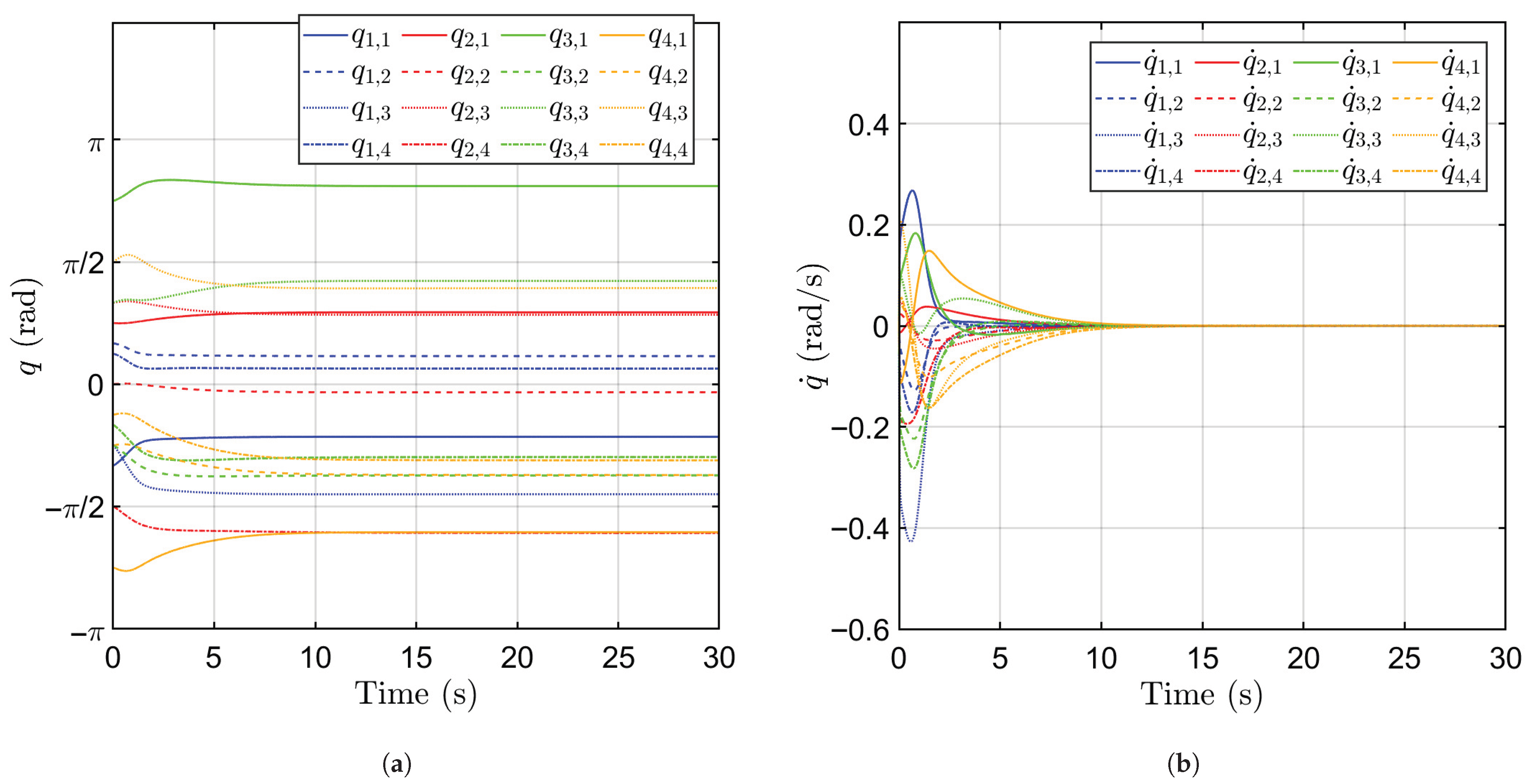

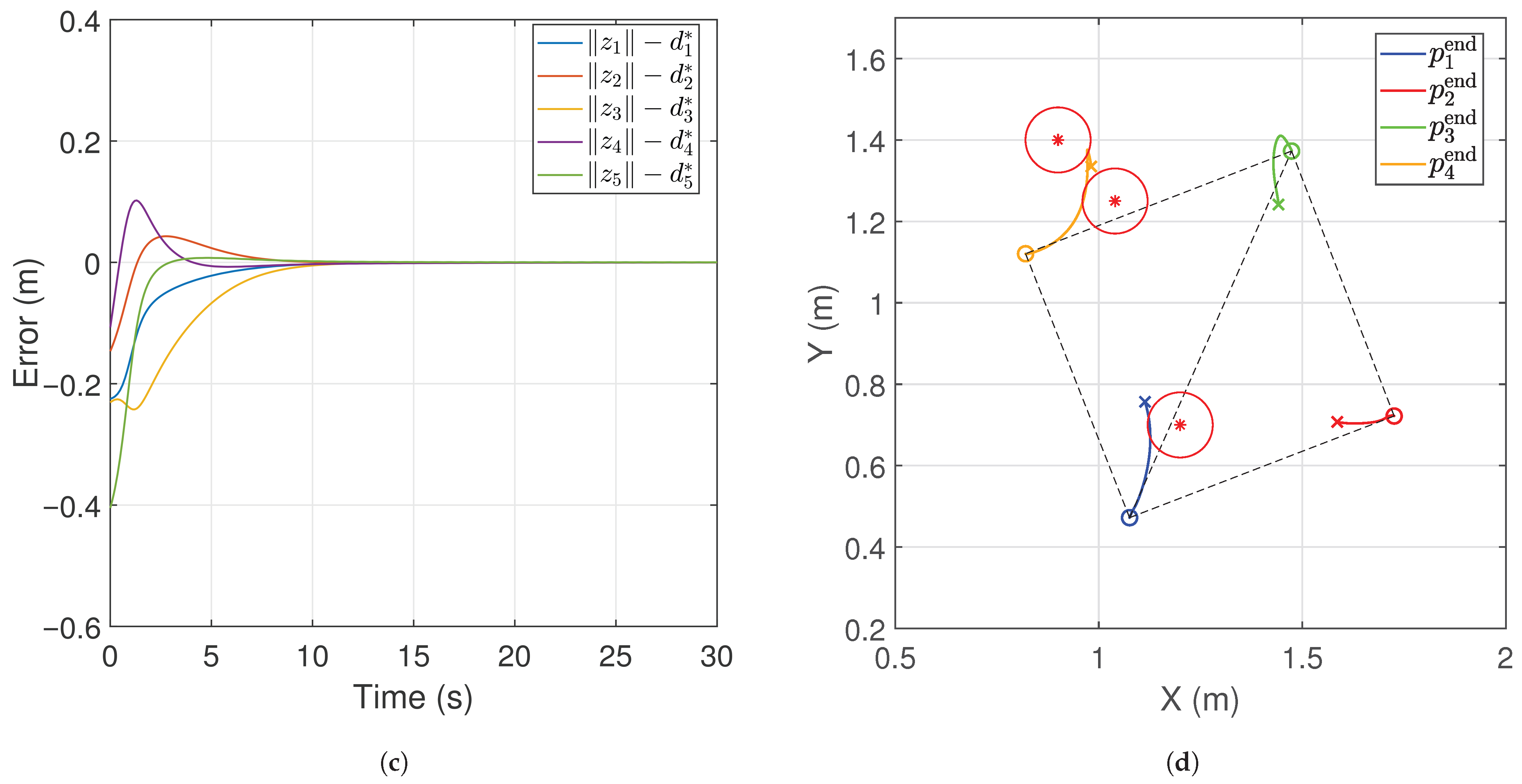

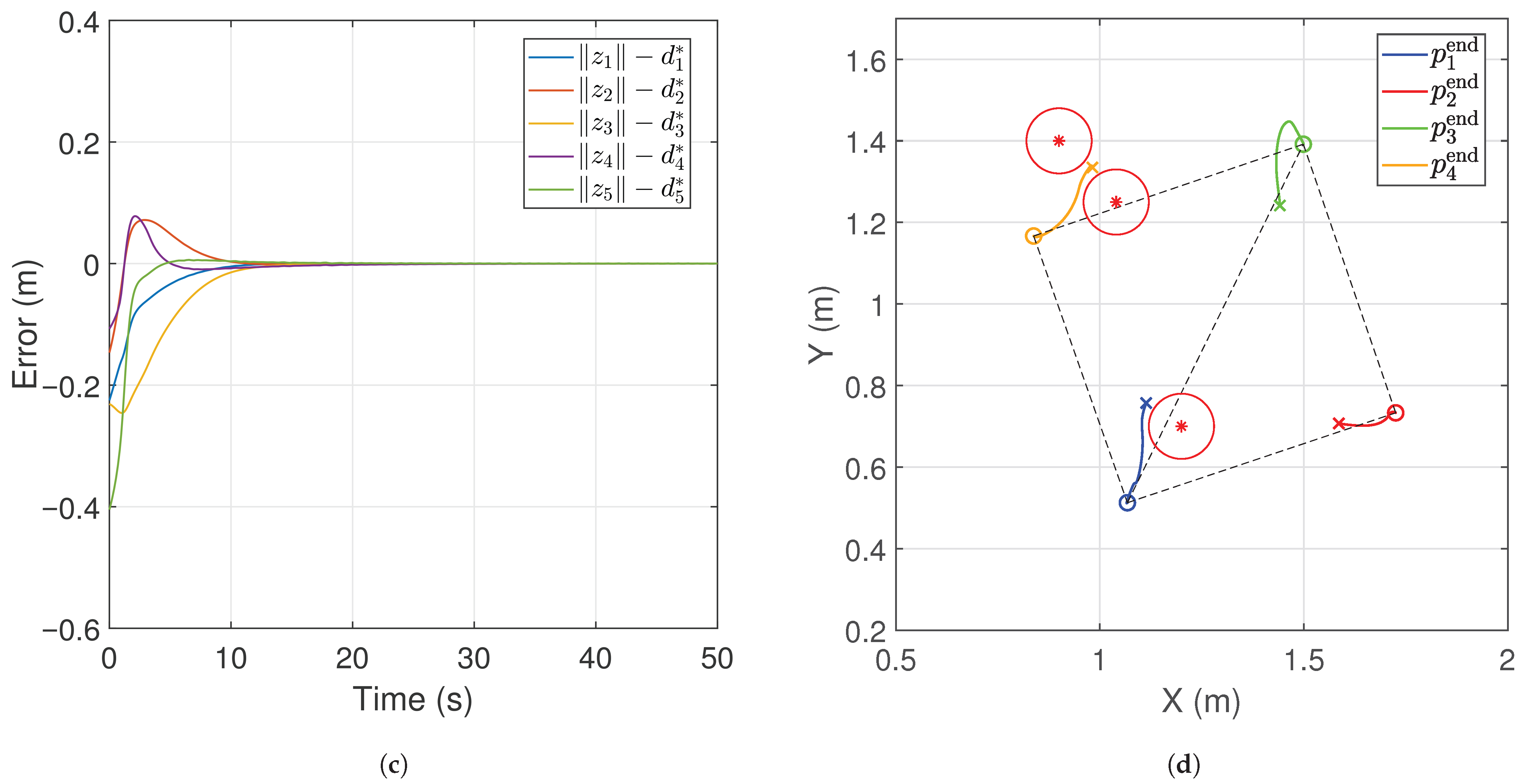

5.1. Manipulator Group Formed by PA3 Manipulators

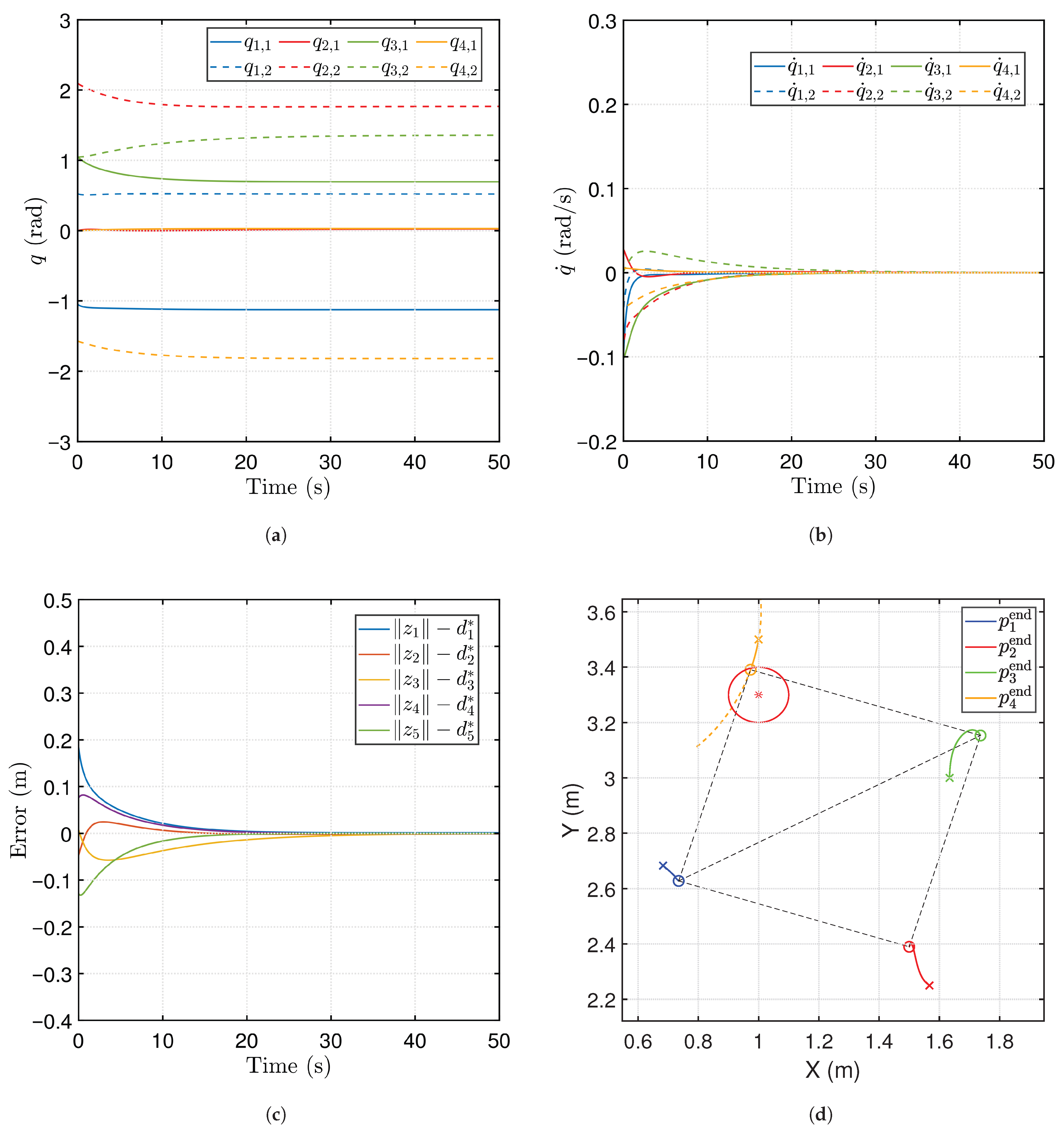

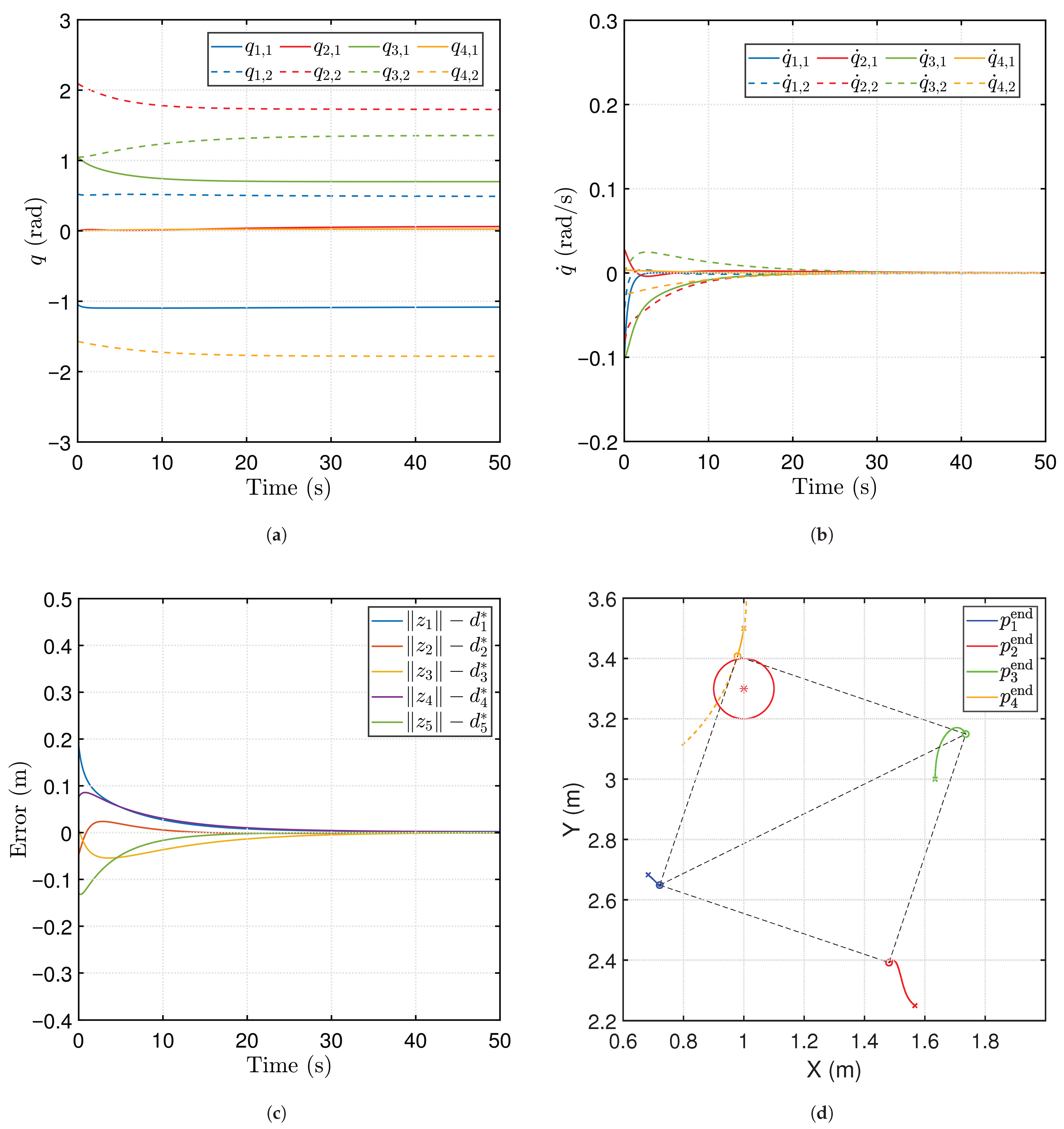

5.2. Manipulator Group Including the PA Manipulator

6. Conclusions and Discussion

6.1. Brief Review of Our Work and Potential Applications

6.2. Comparison with Previous Work

6.3. Limitations and Future Research Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CBF | Control barrier function |

| CoM | Center of mass |

| ISSf | Input-to-state safe |

| PA | The two-link manipulator with a passive first joint and an active second joint. |

| PAn−1 | The n-link manipulator with a passive first joint and all subsequent joints being active. |

| QP | Quadratic program |

| RCBF | Robust control barrier function |

References

- Chen, J.; Jayawardhana, B.; De Marina, H.G. Scaling up the formation of agents with heterogeneous sensing: Mixed distance and bearing-only. IEEE Trans. Autom. Control 2024, 69, 8011–8017. [Google Scholar] [CrossRef]

- Wang, H.; Li, W.; Ning, J. Collision avoidance and formation tracking control for heterogeneous UAV/USV systems with input quantization. Actuators 2025, 14, 309. [Google Scholar] [CrossRef]

- Oh, K.K.; Park, M.C.; Ahn, H.S. A survey of multi-agent formation control. Automatica 2015, 53, 424–440. [Google Scholar] [CrossRef]

- Yang, W.; Shi, Z.; Zhong, Y. Distributed robust adaptive formation control of multi-agent systems with heterogeneous uncertainties and directed graphs. Automatica 2023, 157, 111275. [Google Scholar] [CrossRef]

- Wu, H.; Jayawardhana, B.; De Marina, H.G.; Xu, D. Distributed formation control for manipulator end-effectors. IEEE Trans. Autom. Control 2023, 68, 5413–5428. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Wu, Y.; Liu, Z.; Chen, K.; Chen, C.P. Fixed-time formation control for uncertain nonlinear multiagent systems with time-varying actuator failures. IEEE Trans. Fuzzy Syst. 2024, 32, 1965–1977. [Google Scholar] [CrossRef]

- Deng, C.; Jin, X.Z.; Che, W.W.; Wang, H. Learning-based distributed resilient fault-tolerant control method for heterogeneous MASs under unknown leader dynamic. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 5504–5513. [Google Scholar] [CrossRef]

- Jin, X.; Lü, S.; Yu, J. Adaptive NN-based consensus for a class of nonlinear multiagent systems with actuator faults and faulty networks. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 3474–3486. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; An, L.; Zhao, C. Collision/obstacle avoidance coordination of multi-robot systems: A survey. Actuators 2025, 14, 85. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Y.; Svinin, M.; Magid, E.; Sun, R. Adaptive multi-agent coverage control with obstacle avoidance. IEEE Control Syst. Lett. 2021, 6, 944–949. [Google Scholar] [CrossRef]

- Peng, Z.; Jayawardhana, B.; Xin, X. Distributed formation control of end-effector of mixed planar fully-and under-actuated manipulators. IEEE Control Syst. Lett. 2023, 7, 3735–3740. [Google Scholar] [CrossRef]

- Peng, Z.; Jayawardhana, B.; Xin, X. Distributed end-effector formation control for networked 2-DoF flexible-joint manipulators with partially underactuated agents. Automatica 2025, 179, 112453. [Google Scholar] [CrossRef]

- Agrawal, D.R.; Panagou, D. Safe and robust observer-controller synthesis using control barrier functions. IEEE Control Syst. Lett. 2022, 7, 127–132. [Google Scholar] [CrossRef]

- Ferraguti, F.; Landi, C.T.; Singletary, A.; Lin, H.C.; Ames, A.; Secchi, C.; Bonfe, M. Safety and efficiency in robotics: The control barrier functions approach. IEEE Robot. Autom. Mag. 2022, 29, 139–151. [Google Scholar] [CrossRef]

- Cohen, M.H.; Molnar, T.G.; Ames, A.D. Safety-critical control for autonomous systems: Control barrier functions via reduced-order models. Annu. Rev. Control 2024, 57, 100947. [Google Scholar] [CrossRef]

- Taylor, A.J.; Ong, P.; Molnar, T.G.; Ames, A.D. Safe backstepping with control barrier functions. In Proceedings of the 2022 IEEE 61st Conference on Decision and Control (CDC), Cancun, Mexico, 6–9 December 2022; pp. 5775–5782. [Google Scholar]

- Oriolo, G.; Nakamura, Y. Control of mechanical systems with second-order nonholonomic constraints: Underactuated manipulators. In Proceedings of the 30th IEEE Conference on Decision and Control, Brighton, UK, 11–13 December 1991; Volume 3, pp. 2398–2403. [Google Scholar]

- Lai, X.; She, J.; Cao, W.; Yang, S.X. Stabilization of underactuated planar Acrobot based on motion-state constraints. Int. J. Non-Linear Mech. 2015, 77, 342–347. [Google Scholar] [CrossRef]

- Jiang, Z.P.; Nijmeijer, H. Tracking control of mobile robots: A case study in backstepping. Automatica 1997, 33, 1393–1399. [Google Scholar] [CrossRef]

- Davila, J. Exact tracking using backstepping control design and high-order sliding modes. IEEE Trans. Autom. Control 2013, 58, 2077–2081. [Google Scholar] [CrossRef]

- Li, Y.; Tong, S. Adaptive backstepping control for uncertain nonlinear strict-feedback systems with full state triggering. Automatica 2024, 163, 111574. [Google Scholar] [CrossRef]

- Liu, Y.; Xin, X. Controllability and observability of an n-Link planar robot with a single actuator having different actuator–sensor configurations. IEEE Trans. Autom. Control 2015, 61, 1129–1134. [Google Scholar] [CrossRef]

- Xin, X.; Liu, Y. Control Design and Analysis for Underactuated Robotic Systems; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Wu, J.; Zhang, P.; Meng, Q.; Wang, Y. Control of Underactuated Manipulators: Design and Optimization; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Anderson, B.D.; Yu, C.; Fidan, B.; Hendrickx, J.M. Rigid graph control architectures for autonomous formations. IEEE Control Syst. Mag. 2008, 28, 48–63. [Google Scholar]

- Marina, H.G.D. Distributed Formation Control for Autonomous Robots. Ph.D. Thesis, University of Groningen, Groningen, The Netherlands, 2016. [Google Scholar]

- Dixon, W.E. Adaptive regulation of amplitude limited robot manipulators with uncertain kinematics and dynamics. IEEE Trans. Autom. Control 2007, 52, 488–493. [Google Scholar] [CrossRef]

- Wang, H.; Ren, W.; Cheah, C.C.; Xie, Y.; Lyu, S. Dynamic modularity approach to adaptive control of robotic systems with closed architecture. IEEE Trans. Autom. Control 2020, 65, 2760–2767. [Google Scholar] [CrossRef]

- Khalil, H.K. Nonlinear Systems, 3rd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Molnar, T.G.; Ames, A.D. Composing control barrier functions for complex safety specifications. IEEE Control Syst. Lett. 2023, 7, 3615–3620. [Google Scholar] [CrossRef]

- Chen, T.; Shan, J. Distributed tracking of a class of underactuated Lagrangian systems with uncertain parameters and actuator faults. IEEE Trans. Ind. Electron. 2019, 67, 4244–4253. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L. Adaptive leader-follower consensus control of multiple flexible manipulators with actuator failures and parameter uncertainties. IEEE/CAA J. Autom. Sin. 2023, 10, 1020–1031. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, X.; Zhao, W. Distributed neural-based fault-tolerant control of multiple flexible manipulators with input saturations. Automatica 2023, 156, 111202. [Google Scholar] [CrossRef]

- Yao, X.Y.; Park, J.H.; Ding, H.F.; Ge, M.F. Event-triggered consensus control for networked underactuated robotic systems. IEEE Trans. Cybern. 2022, 52, 2896–2906. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Hu, Z.; Liu, J.; Zhang, Y.; Gu, Y.; Huang, W.; Tang, R.; Wang, F. Adaptive self-triggered control for multi-agent systems with actuator failures and time-varying state constraints. Actuators 2023, 12, 364. [Google Scholar] [CrossRef]

- Wang, Y.; Lai, X.; Zhang, P.; Su, C.Y.; Wu, M. A new control method for planar four-link underactuated manipulator based on intelligence optimization. Nonlinear Dyn. 2019, 96, 573–583. [Google Scholar] [CrossRef]

- Wang, Y.; Lai, X.; Zhang, P.; Wu, M. Control strategy based on model reduction and online intelligent calculation for planar n-link underactuated manipulators. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 1046–1054. [Google Scholar] [CrossRef]

- Şekercioğlu, P.; Jayawardhana, B.; Sarras, I.; Loria, A.; Marzat, J. Formation control of cooperative-competitive robot manipulators with inter-agent constraints. IFAC-PapersOnLine 2024, 58, 49–54. [Google Scholar] [CrossRef]

- Ning, B.; Han, Q.L.; Ding, L. A brief overview of recent advances in distributed accelerated secondary control for islanded AC microgrids. IEEE Trans. Ind. Inform. 2025, 21, 6605–6614. [Google Scholar] [CrossRef]

- Nguyen, Q.; Sreenath, K. Exponential control barrier functions for enforcing high relative-degree safety-critical constraints. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016; pp. 322–328. [Google Scholar]

- Wabersich, K.P.; Zeilinger, M.N. Predictive control barrier functions: Enhanced safety mechanisms for learning-based control. IEEE Trans. Autom. Control 2022, 68, 2638–2651. [Google Scholar] [CrossRef]

- Zhao, P.; Ghabcheloo, R.; Cheng, Y.; Abdi, H.; Hovakimyan, N. Convex synthesis of control barrier functions under input constraints. IEEE Control Syst. Lett. 2023, 7, 3102–3107. [Google Scholar] [CrossRef]

- Chen, H.; Sun, N. Nonlinear control of underactuated systems subject to both actuated and unactuated state constraints with experimental verification. IEEE Trans. Ind. Electron. 2019, 67, 7702–7714. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Xin, X. Safety-Critical End-Effector Formation Control for Planar Underactuated Manipulators. Actuators 2025, 14, 475. https://doi.org/10.3390/act14100475

Peng Z, Xin X. Safety-Critical End-Effector Formation Control for Planar Underactuated Manipulators. Actuators. 2025; 14(10):475. https://doi.org/10.3390/act14100475

Chicago/Turabian StylePeng, Zhiyu, and Xin Xin. 2025. "Safety-Critical End-Effector Formation Control for Planar Underactuated Manipulators" Actuators 14, no. 10: 475. https://doi.org/10.3390/act14100475

APA StylePeng, Z., & Xin, X. (2025). Safety-Critical End-Effector Formation Control for Planar Underactuated Manipulators. Actuators, 14(10), 475. https://doi.org/10.3390/act14100475