Design and Optimization of Support and Drive System for Magnetic Levitation Air Compressor for Fuel Cells

Abstract

1. Introduction

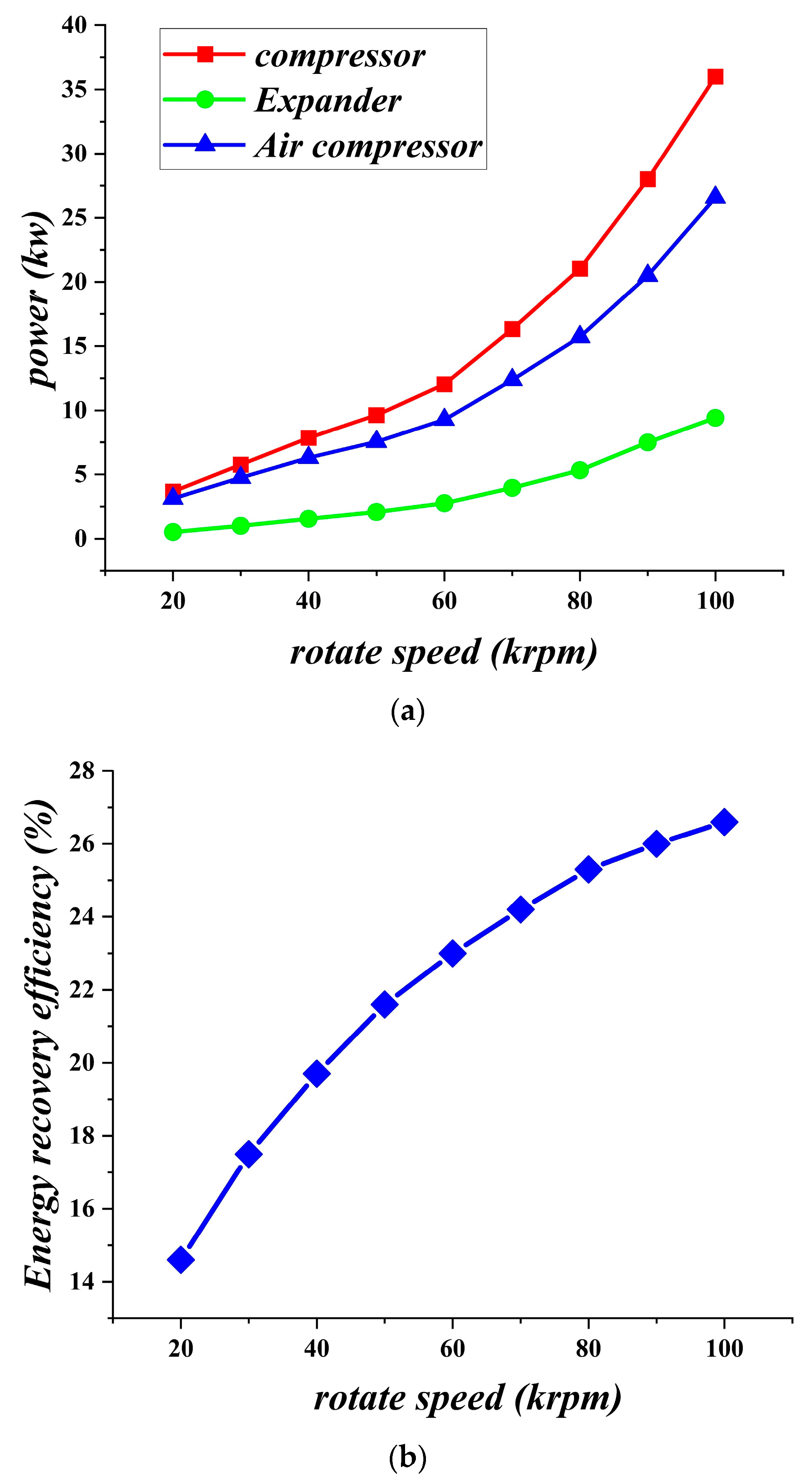

- Combining 5-DOF AMB with HPMSM and realizing integrated design and application in fuel cell air compressors fills the research gap in China.

- The multi-physics optimization design of HPMSM was carried out. After optimization, the end length of HPMSM was reduced by 37%. The critical speed of the rotor system has been greatly improved.

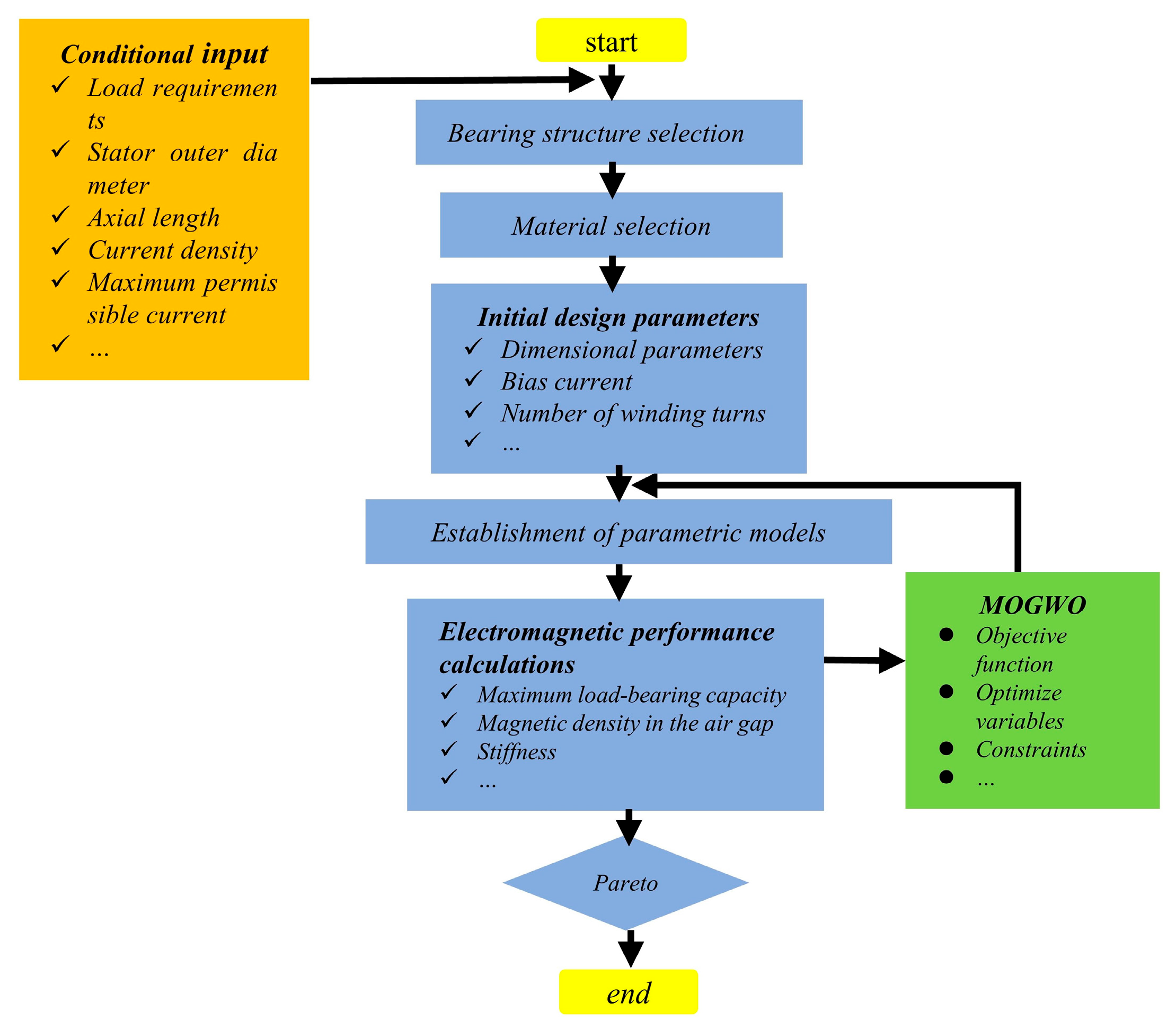

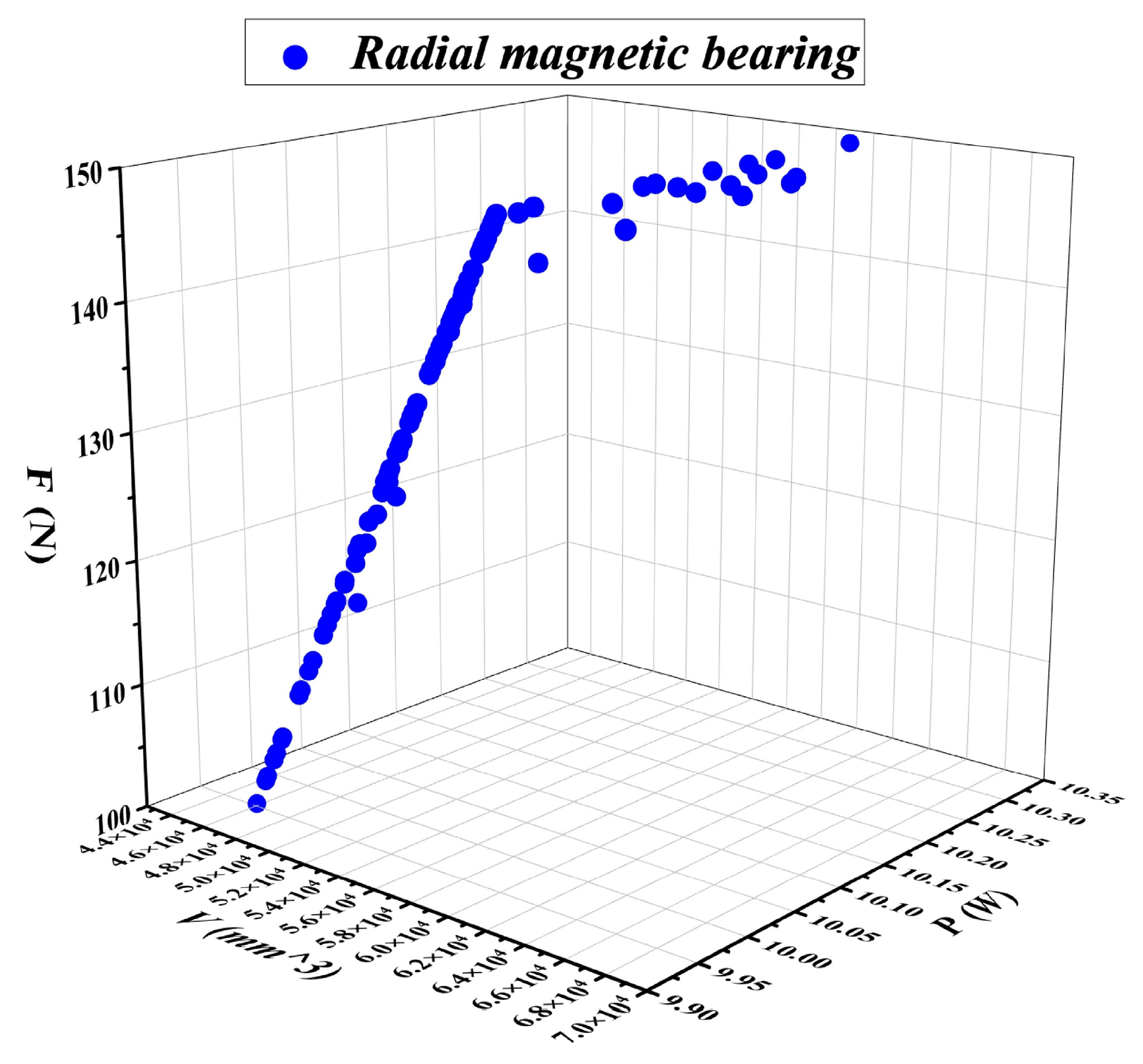

- Based on the MOGWO algorithm, the structural parameters of 5-DOF AMB are optimized with the maximization of bearing capacity and the minimization of volume and drag loss as the objective functions. After optimization, the volume of RMBs is reduced by 36.4%, the drag loss is reduced by 14.3%, and the bearing capacity is increased by 10%. The volume of the TMB has been reduced by 17.5%, the drag loss has been reduced by 12.5%, and the load-bearing capacity has been increased by 4%.

- Through the finite element software, the feasibility and reliability of the system design are ensured from the aspects of electromagnetism and rotor dynamics.

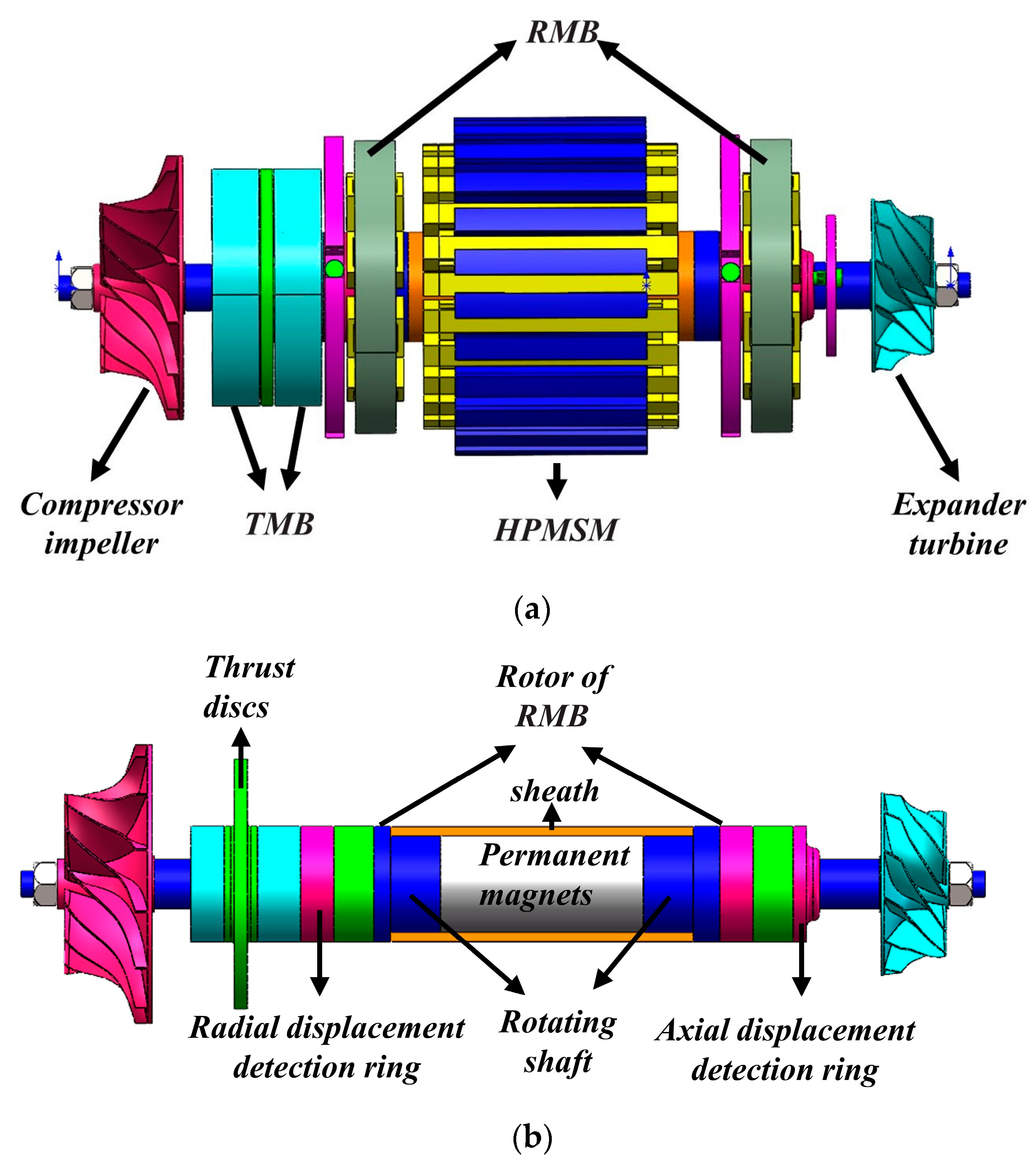

2. Support and Drive Scheme and Their HPMSM Design

2.1. Support and Drive Scheme Design

2.2. HPMSM Electromagnetic Design and Analysis

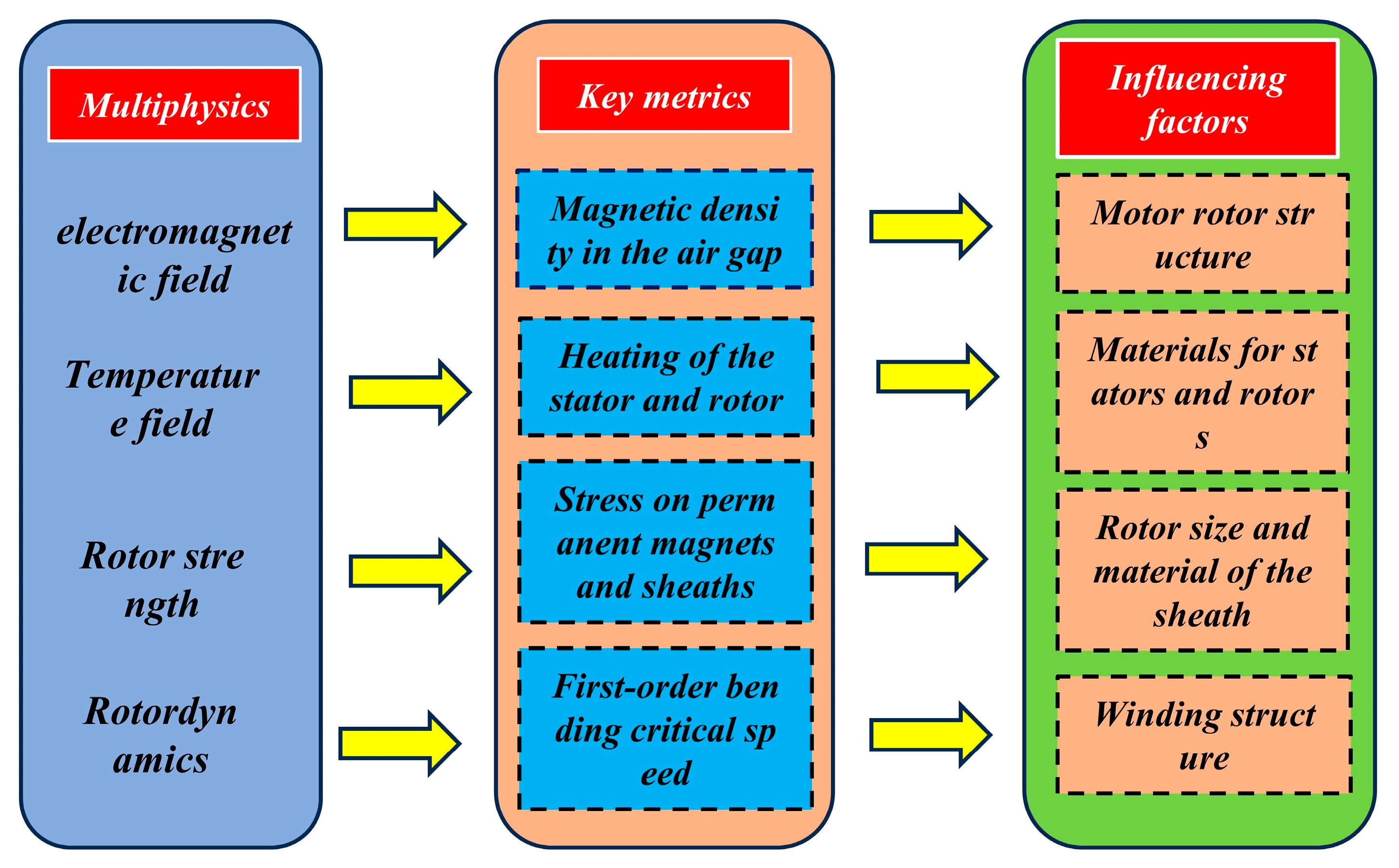

2.2.1. HPMSM Design Considering Multi-Physics Fields

- (1)

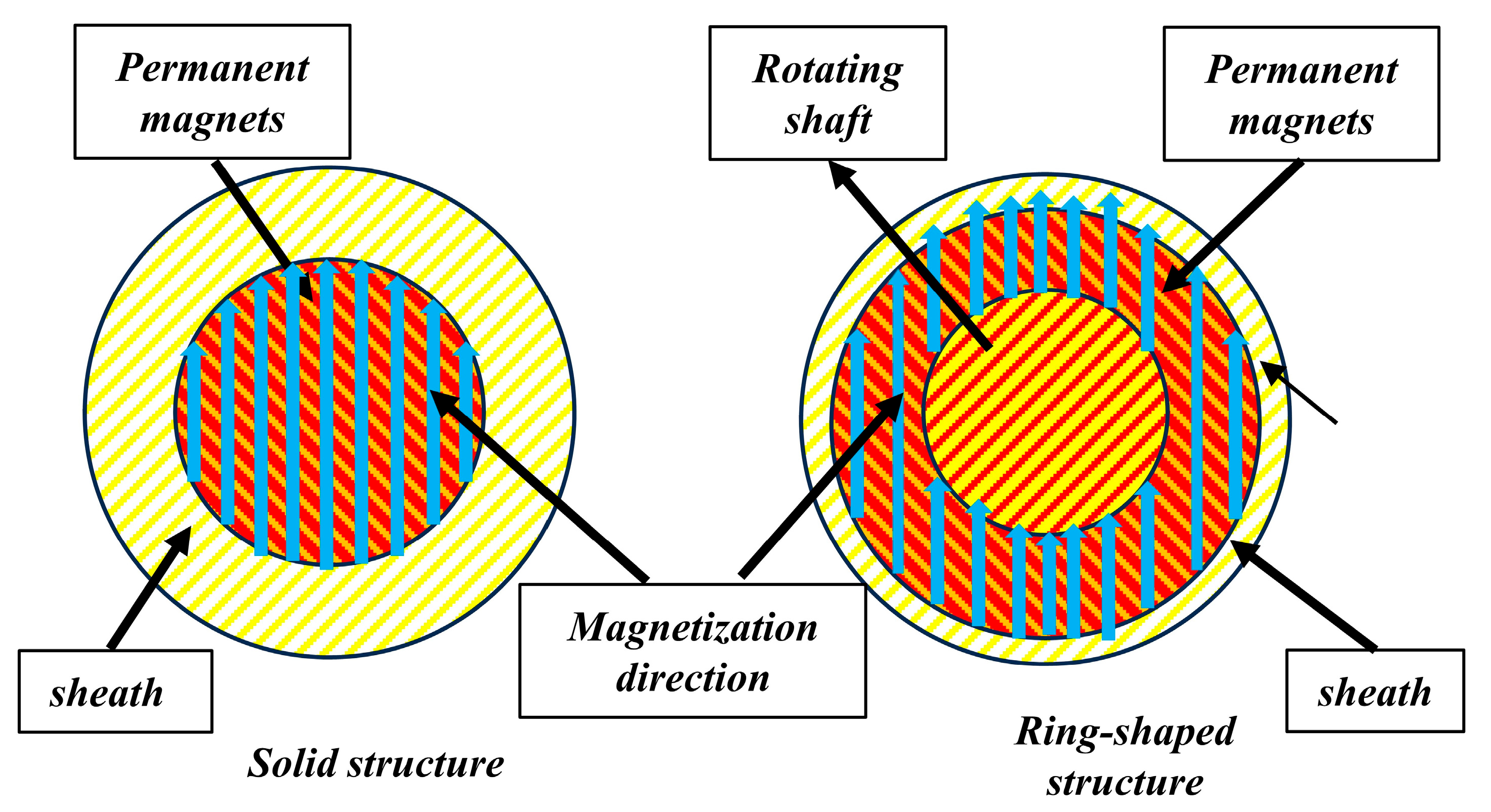

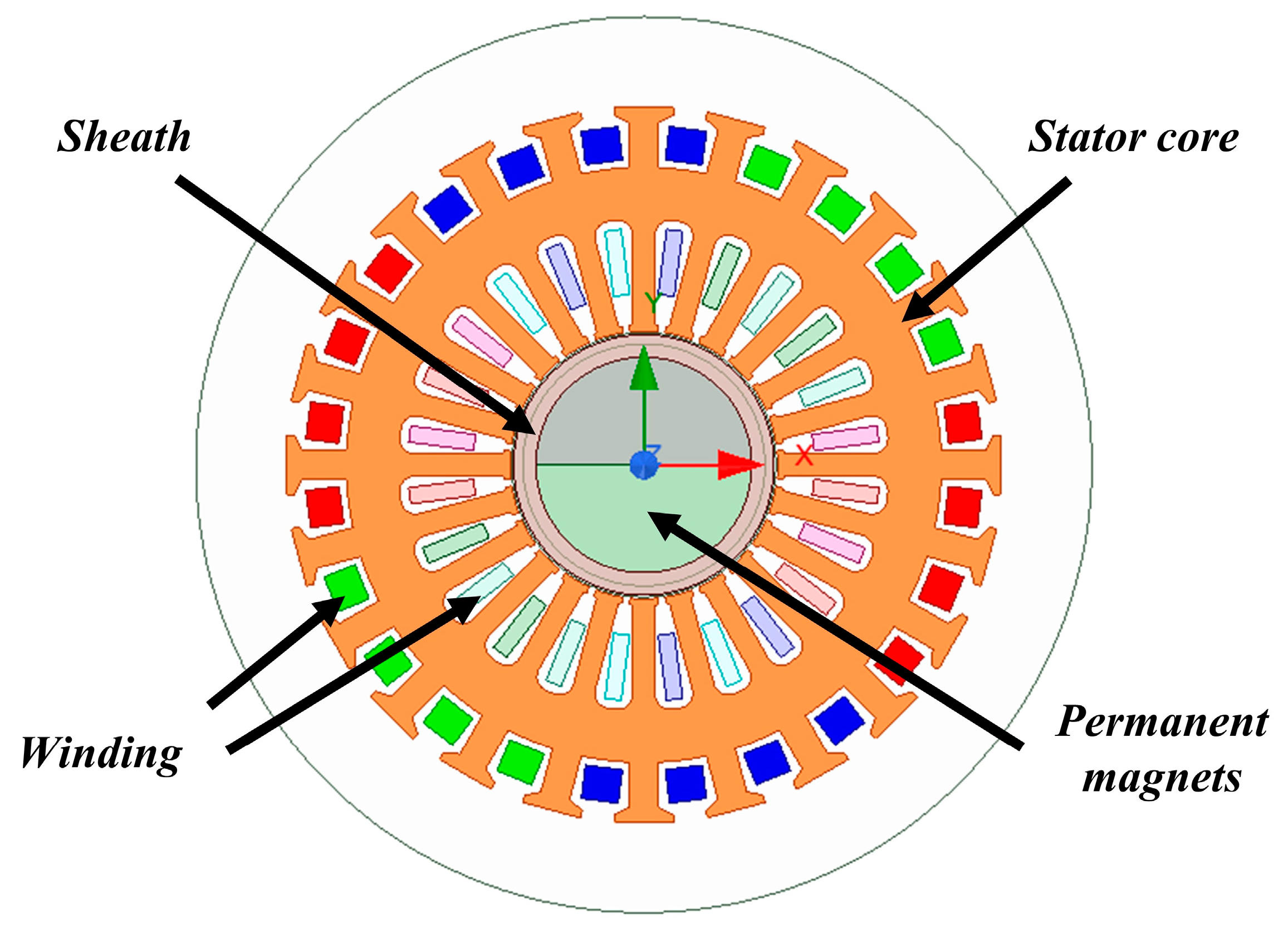

- Stator–rotor structure design considering electromagnetic performance: As shown in Figure 5, the 1-pair pole rotor structure suitable for HPMSM has 1-pair solid and ring-shaped permanent magnet structures, whose magnetizing directions are parallel with each other. Both structures have their advantages and disadvantages. This study chose a solid structure. The solid type uses a whole-piece permanent magnet, which has high structural strength and a smaller radial length of HPMSM and is easy to fabricate industrially [37,38]. In terms of the stator structure of HPMSM, the stator groove structure is usually divided into three types: no groove, few grooves, and multiple grooves [39]. For the HPMSM with a pole pair of 1 designed in this paper, the coordination of integer slots is mostly adopted, and to reduce harmonics, the multi-slot structure is generally adopted. This also contributes to the reduction in the peak cogging torque and the magnetic flux density ripple on the rotor sheath surface. However, the increase in the number of slots will reduce the width of the stator teeth and the area in the slots, which is not conducive to the offline operation of the stator winding, affects the structural strength, and increases the manufacturing cost [39,40]. Therefore, combined with the parallel magnetization method of solid permanent magnet in this paper, the slotted stator structure with 2 poles and 24 slots was finally selected.

- (2)

- Selection of permanent magnet and core material considering heat generation: To ensure the performance of HPMSM, reduce the size of the motor, and avoid demagnetization at high temperatures, the permanent magnet material with high magnetic energy product and high-temperature resistance was preferred. Given the high operating temperature in this paper, a samarium cobalt (SmCo30, which is manufactured by Hangzhou Permanent Magnet Group Co., Ltd., Hangzhou, China) permanent magnet was used. Meanwhile, the high frequency of HPMSM leads to high eddy current loss. Therefore, it is necessary to use core materials with excellent properties such as ultra-thinness, high permeability, high resistivity, and low loss coefficient to effectively suppress the eddy current loss in the core [41]. The 0.1 mm 10JNEX900 silicon steel sheet (10JNEX900, which is manufactured by Kawasaki in Tokyo, Japan) has a lower specific iron loss, but the material is too thin and not easy to process. Considering that the structure of the stator punching piece in this paper is complex and the tooth width is small, the 0.2 mm B20AT1500 silicon steel sheet (B20AT1500, which is manufactured by China Baowu Iron & Steel Group Co., Shanghai, China) is selected as the core material. The main advantages are a low unit loss value, easy machining, and a high tensile strength [42].

- (3)

- Dimensional design and sheath material selection considering rotor strength: Unlike normal speed motors, the selection of a rotor outer diameter and length for HPMSM was prioritized to ensure that the permanent magnets are not damaged by centrifugal tension. A preliminary estimation of the rotor outer diameter can be made from the following equations and in conjunction with the electromagnetic design [43,44].where is the mass of the permanent magnet rotor, is the rotor linear velocity, is the radius of the rotor, is the outer surface area of the material, is the density of the material, is the angular velocity of the rotation, is the allowable stress of the material, is the safety margin. is the maximum linear velocity of the rotor surface, and is the maximum outer diameter of the rotor. In addition, to ensure reliable operation of the rotor, it is necessary to add a sheath outside the permanent magnet to protect the permanent magnet. The commonly used rotor sheaths are mainly made of carbon fiber composite materials, metal materials, etc. Since the rotor structure in this paper is a solid permanent magnet structure, the alloy material GH4169(GH4169, which is manufactured by China’s Jiangxi Province Baoshunchang Special Alloy Manufacturing Co., Xinyu, China) with higher strength was selected to stably connect the spindle and permanent magnets.

- (4)

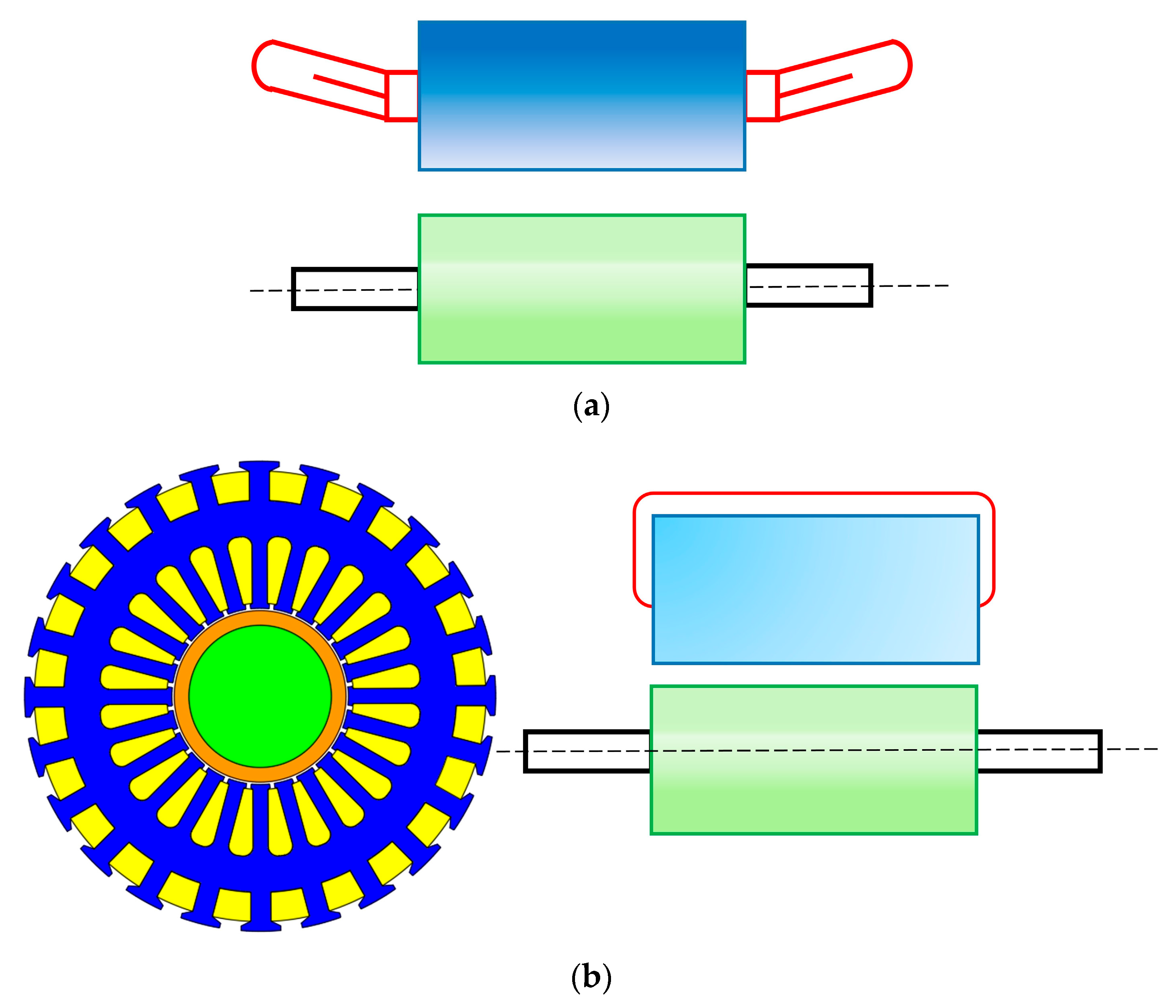

- Winding design considering rotor dynamics: As shown in Figure 6, the stator winding suitable for HPMSM mainly has two structures: double-layer short-pitch distributed winding and toroidal winding [45]. In particular, when the number of pole pairs is 1, the toroidal winding can significantly reduce the axial length of the rotor relative to the double-layer short-pitch distributed winding, thereby increasing the critical speed of the rotor system [37,45]. Table 2 shows the end length values of double-layer short-pitch distributed winding and toroidal winding. From the table, it can be seen that the end length is 27 mm for the double-layer short-pitch distributed winding scheme, while the end length is approximately equal to the slot depth of the motor (17 mm) for the toroidal winding scheme, which is a reduction of 37% compared to the former.

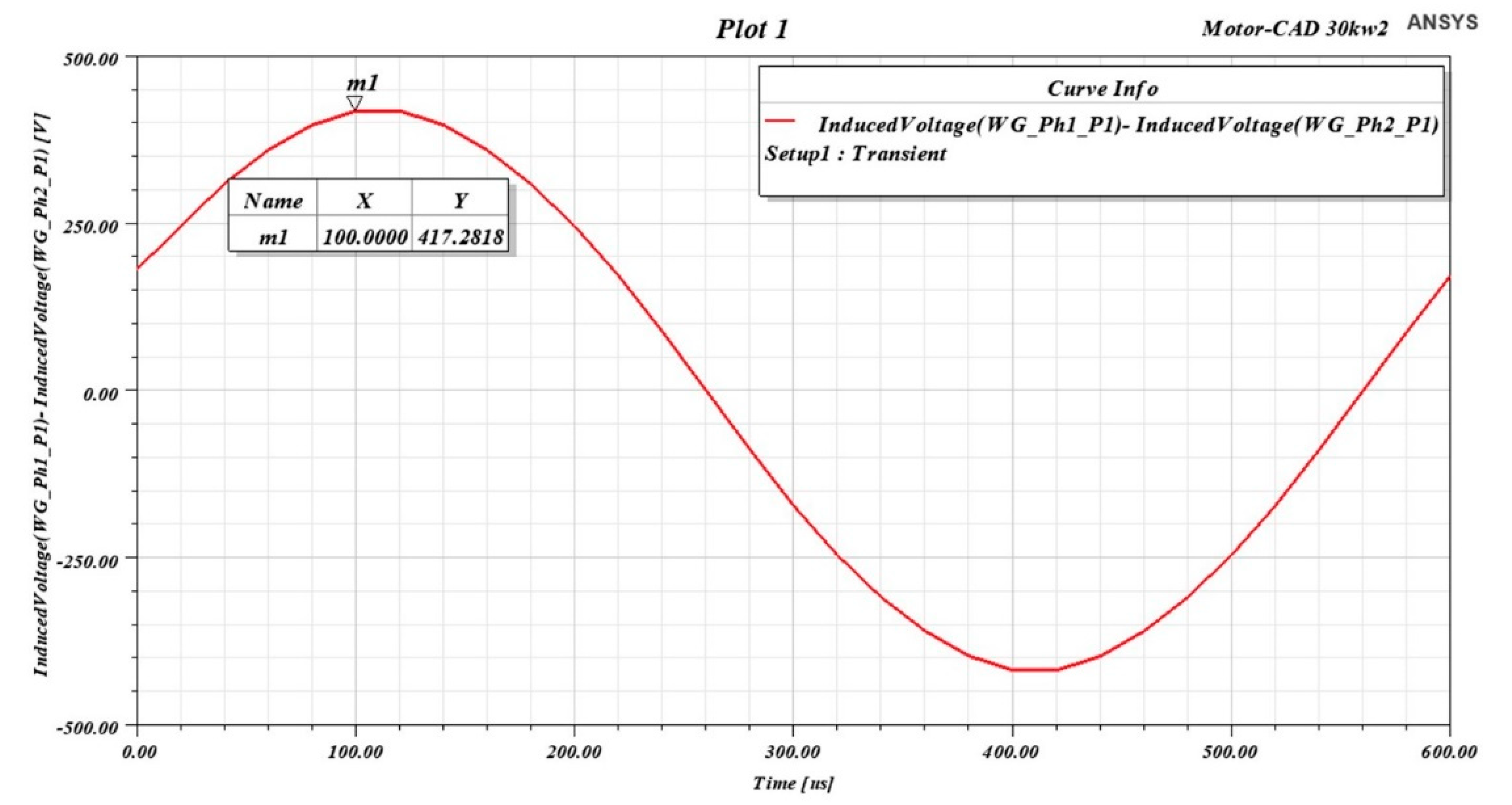

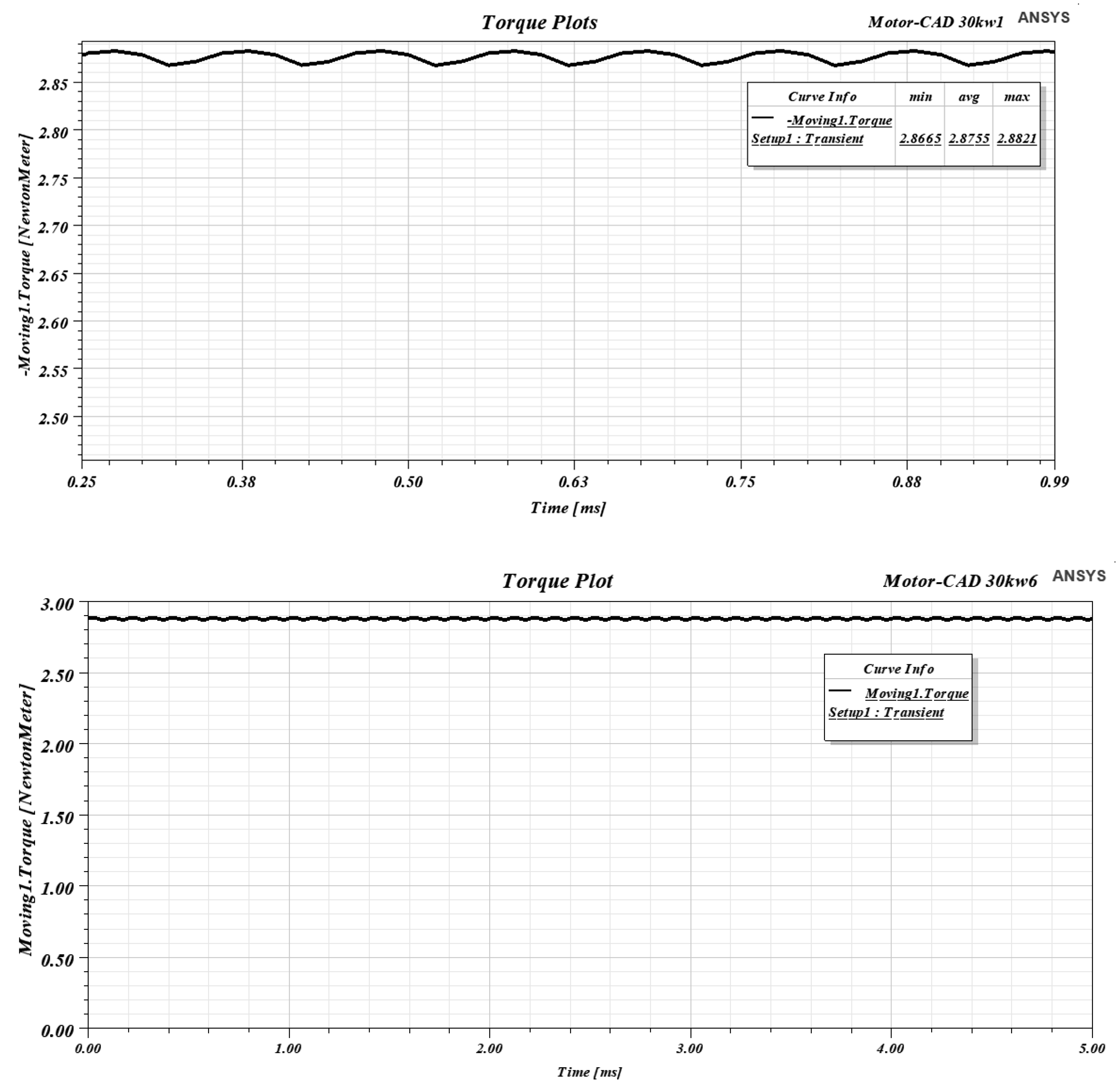

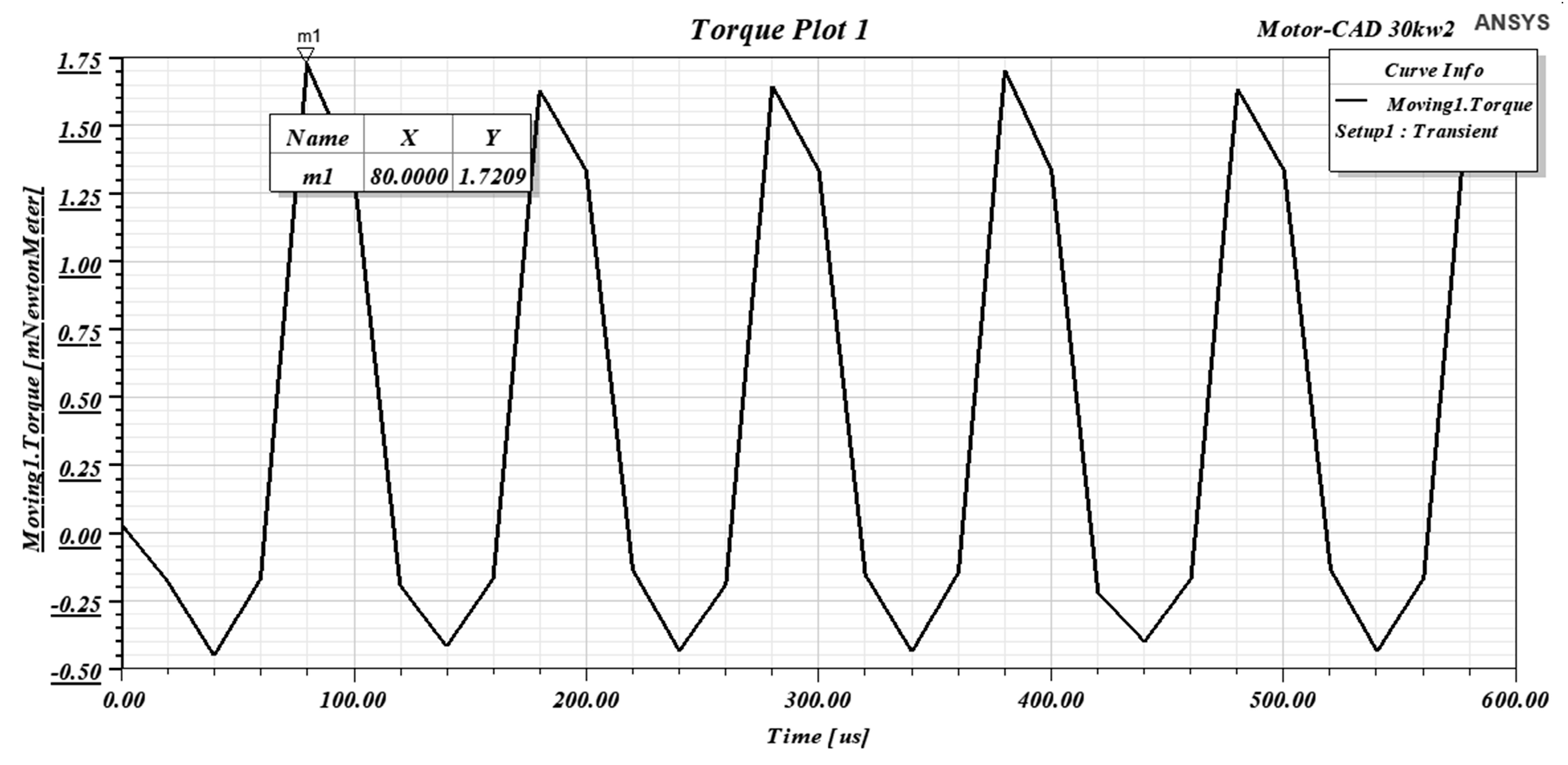

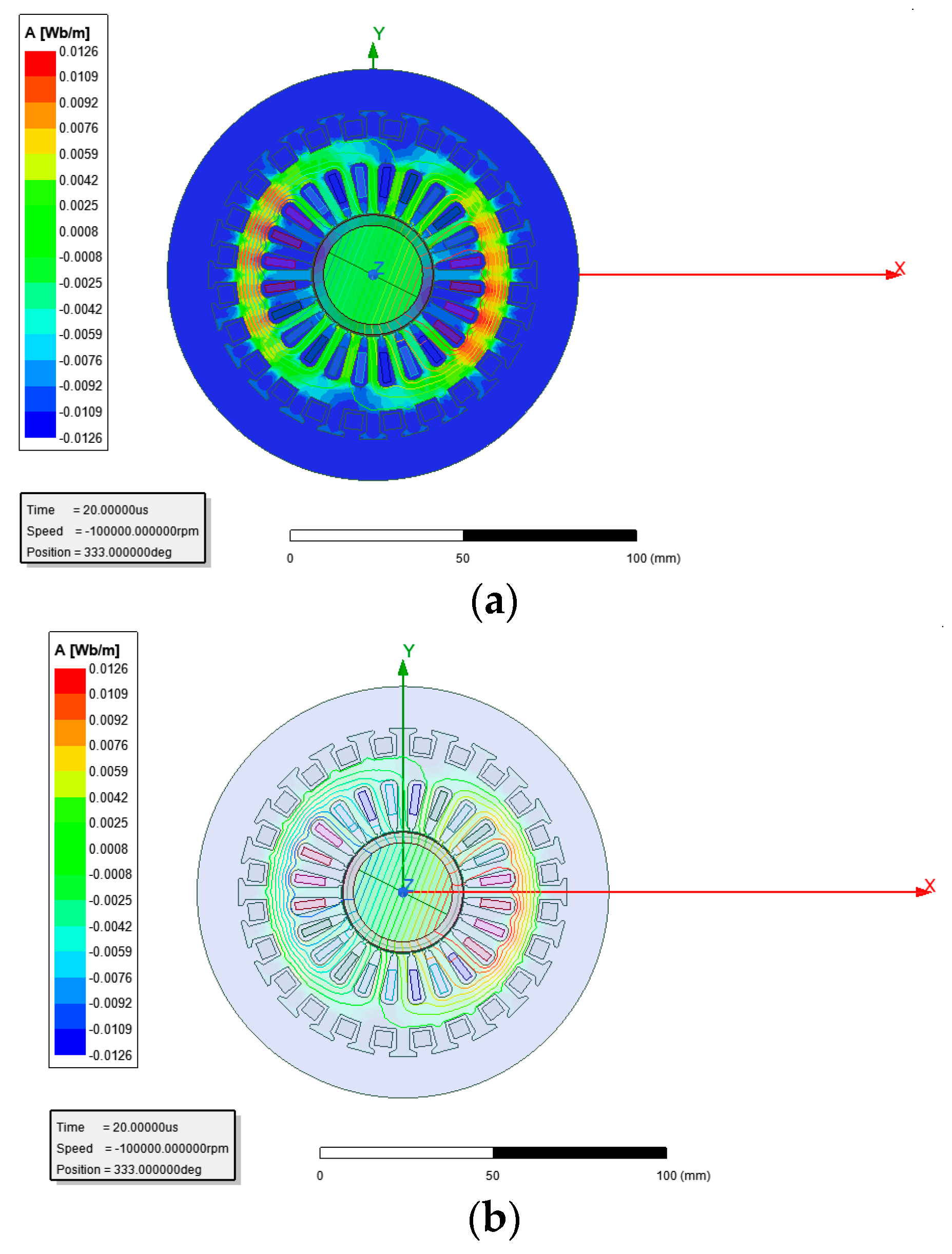

2.2.2. Finite Element Analysis of HPMSM

3. Initial Theoretical Design of 5-DOF AMB

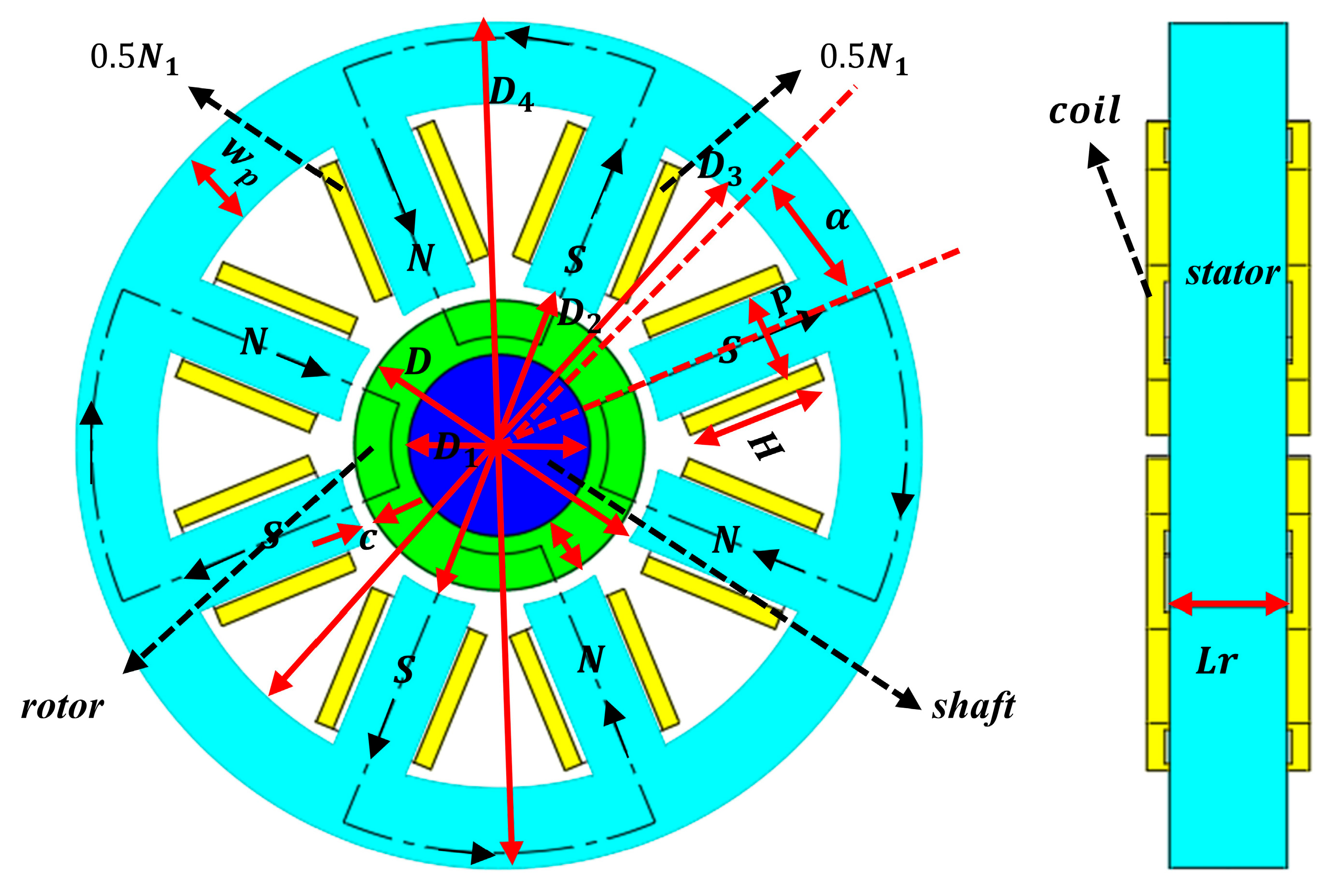

3.1. Theoretical Design of RMB

- (1)

- Determination of main design indexes of RMB

- (2)

- Selection of RMB structure, and stator and rotor core materials

- (3)

- Initial theoretical parameter design

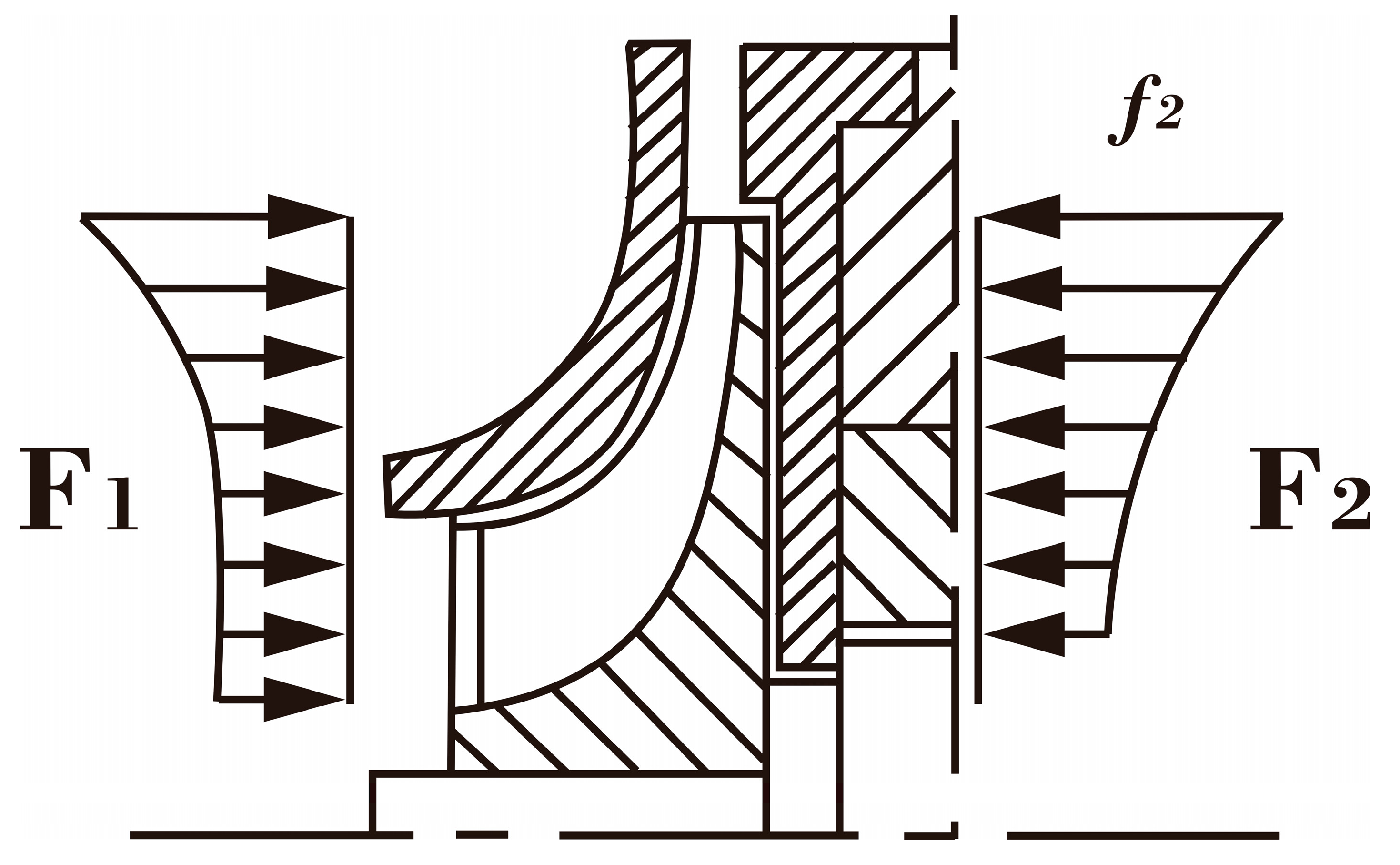

3.2. Theoretical Design of TMB

- (1)

- Determination of main design indexes of TMB

- (2)

- Selection of TMB structure, and stator and rotor core materials

- (3)

- Initial theoretical parameter design

4. Structural Parameter Optimization of 5-DOF AMB

4.1. Mogwo Principles

4.2. Objective Function

- (1)

- Objective function of RMB

- (2)

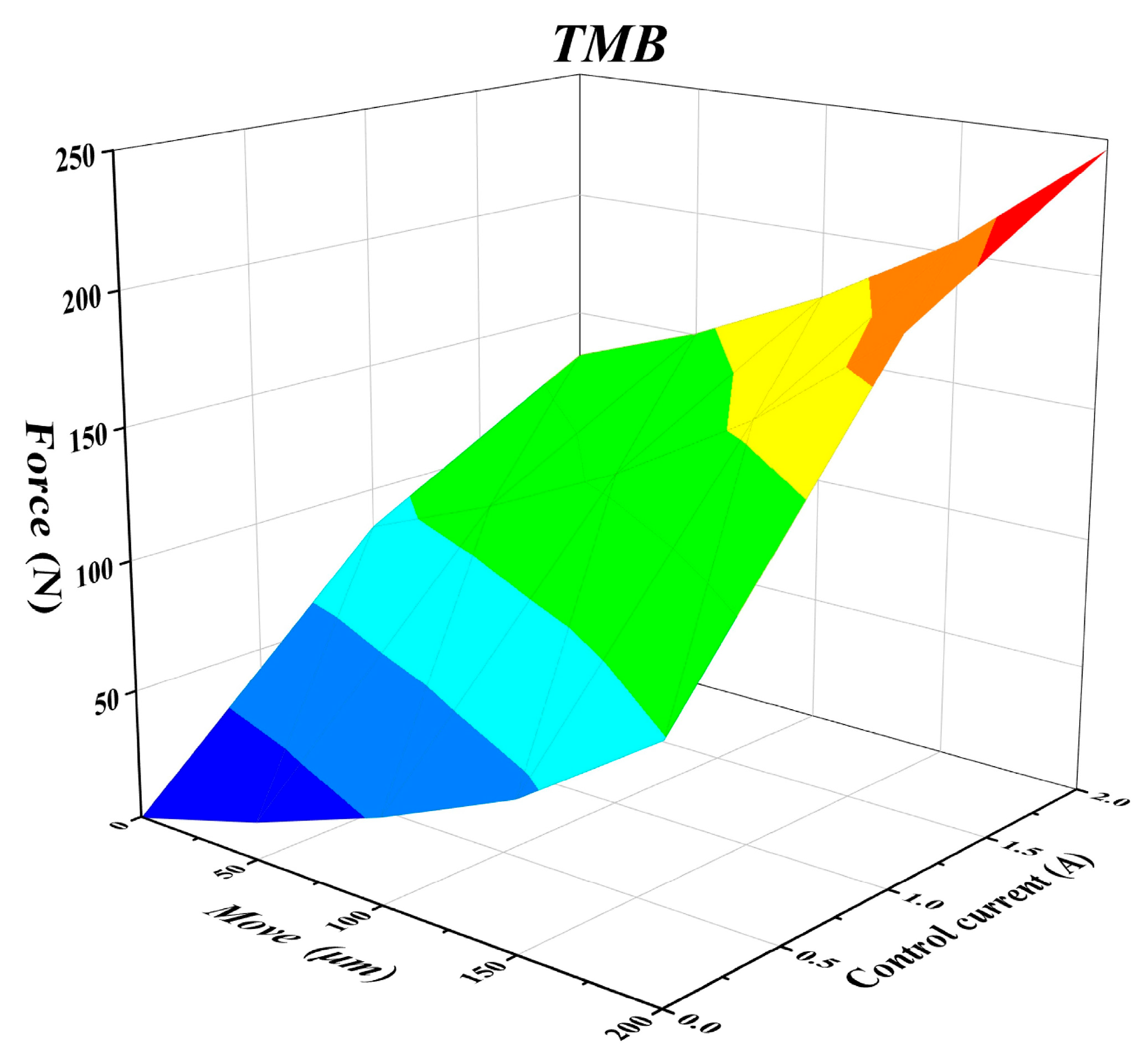

- Objective function of TMB

4.3. Optimization Variables

4.4. Constraints

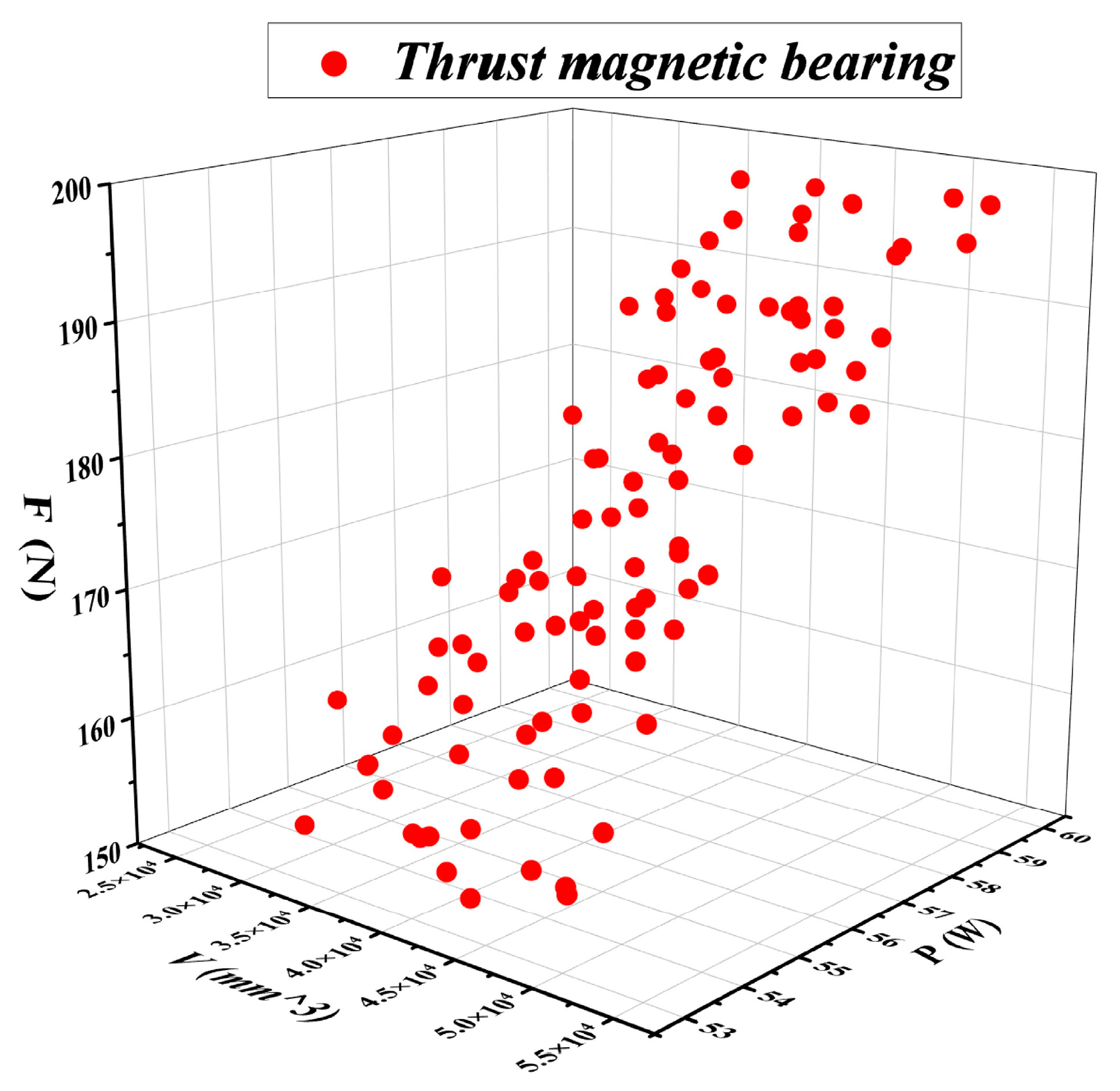

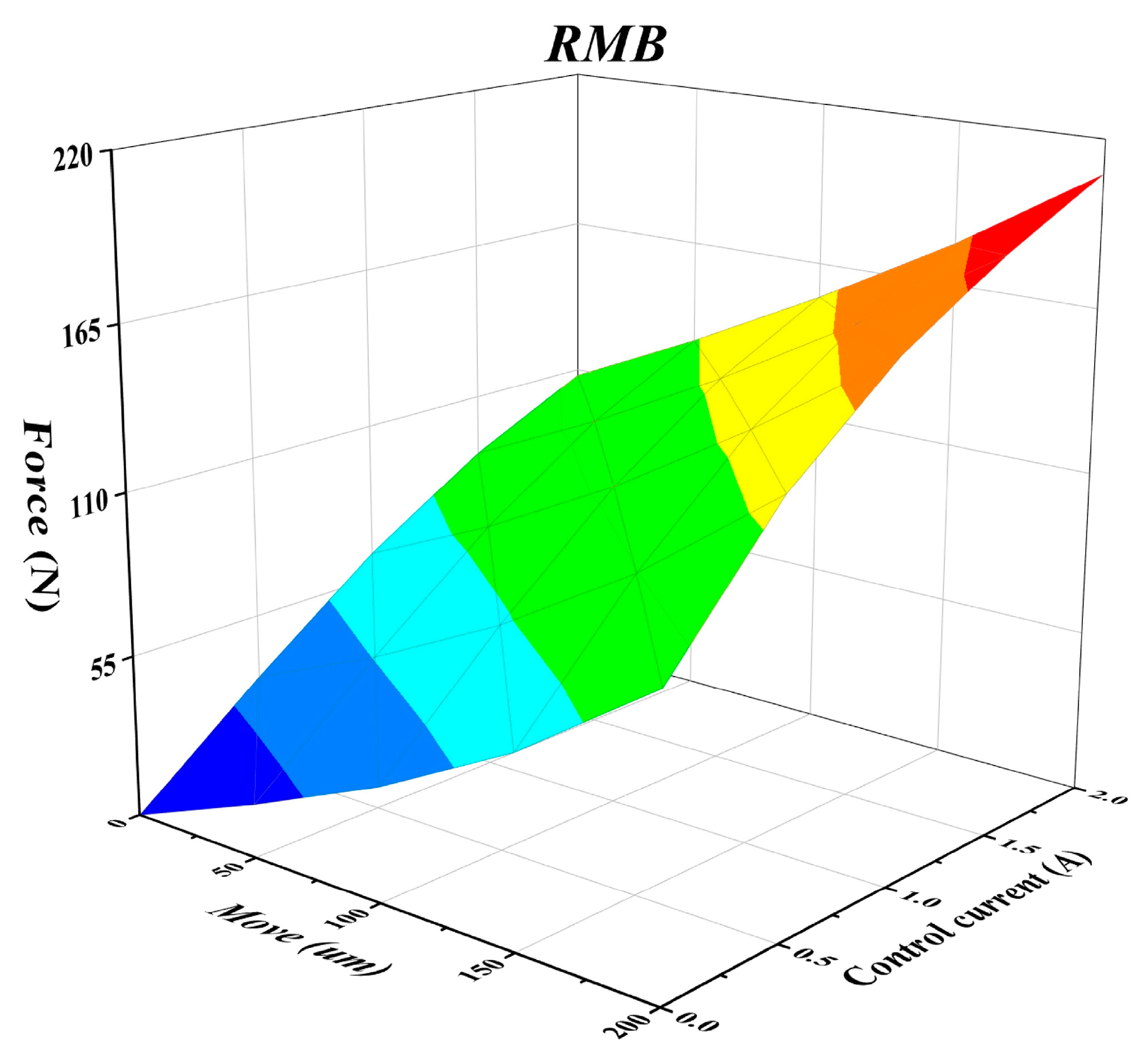

4.5. Optimization Results

5. Multi-Physics Field Analysis of Optimization Results

5.1. Electromagnetic Characterization

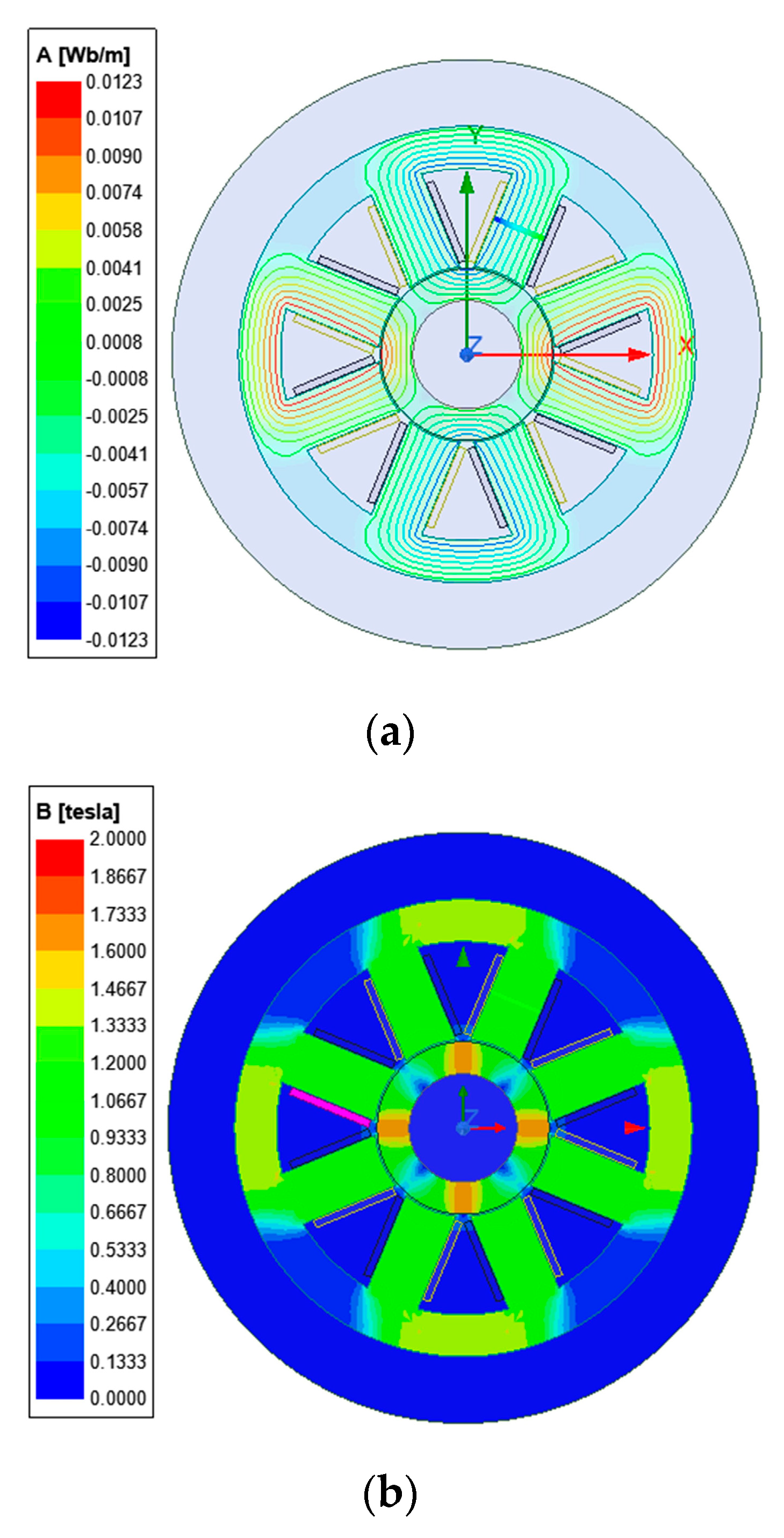

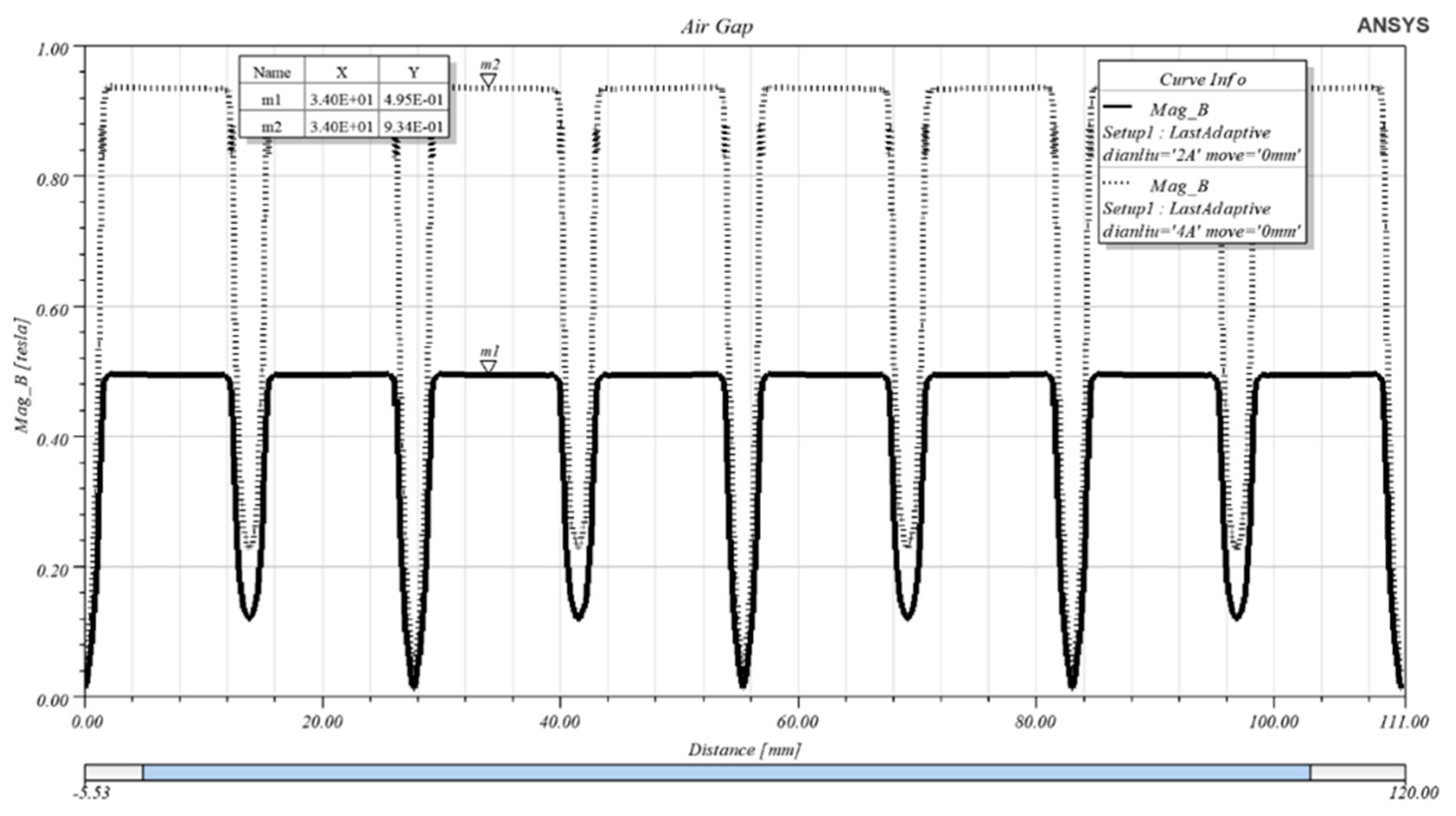

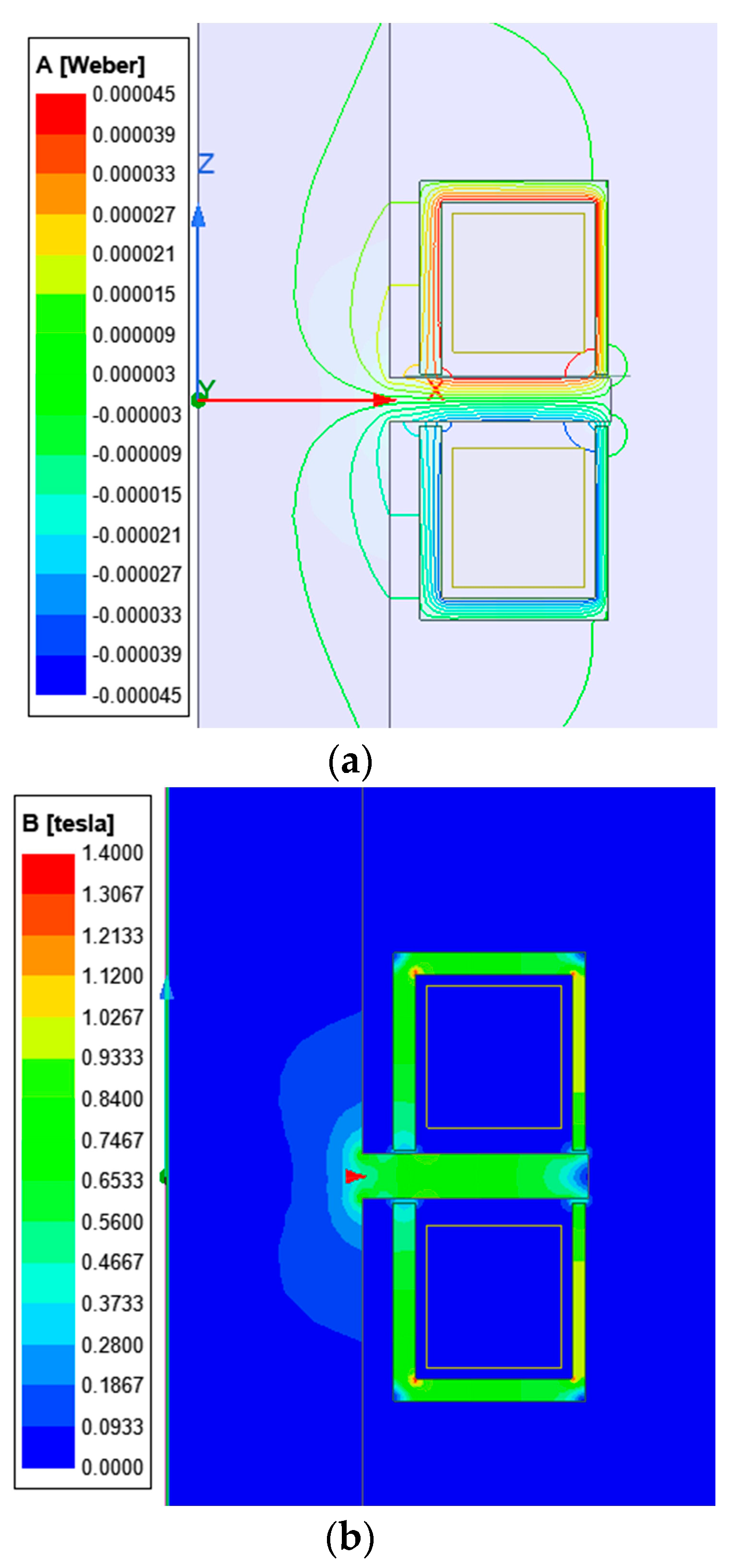

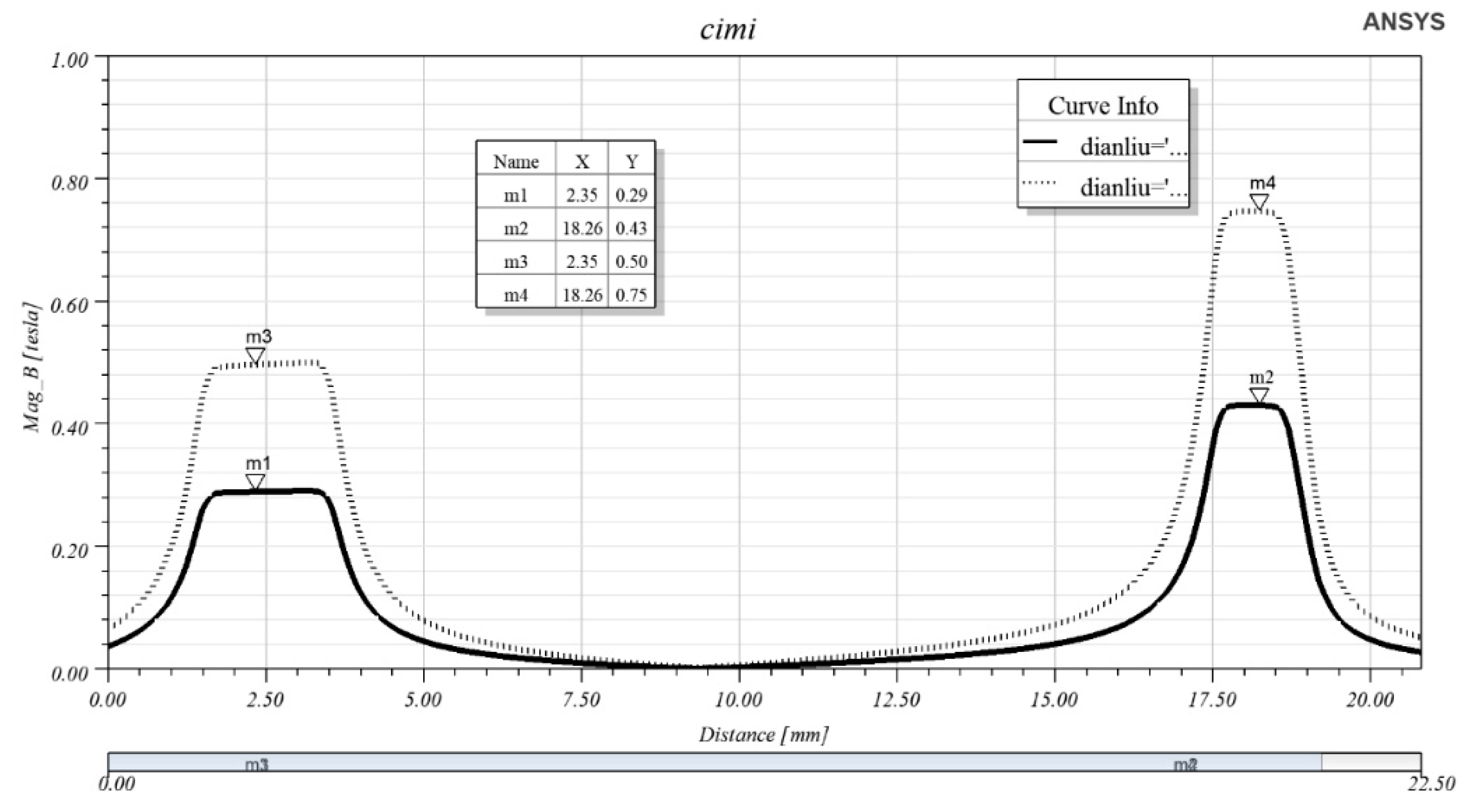

5.1.1. Electromagnetic Characterization of RMB

5.1.2. Electromagnetic Characterization of TMB

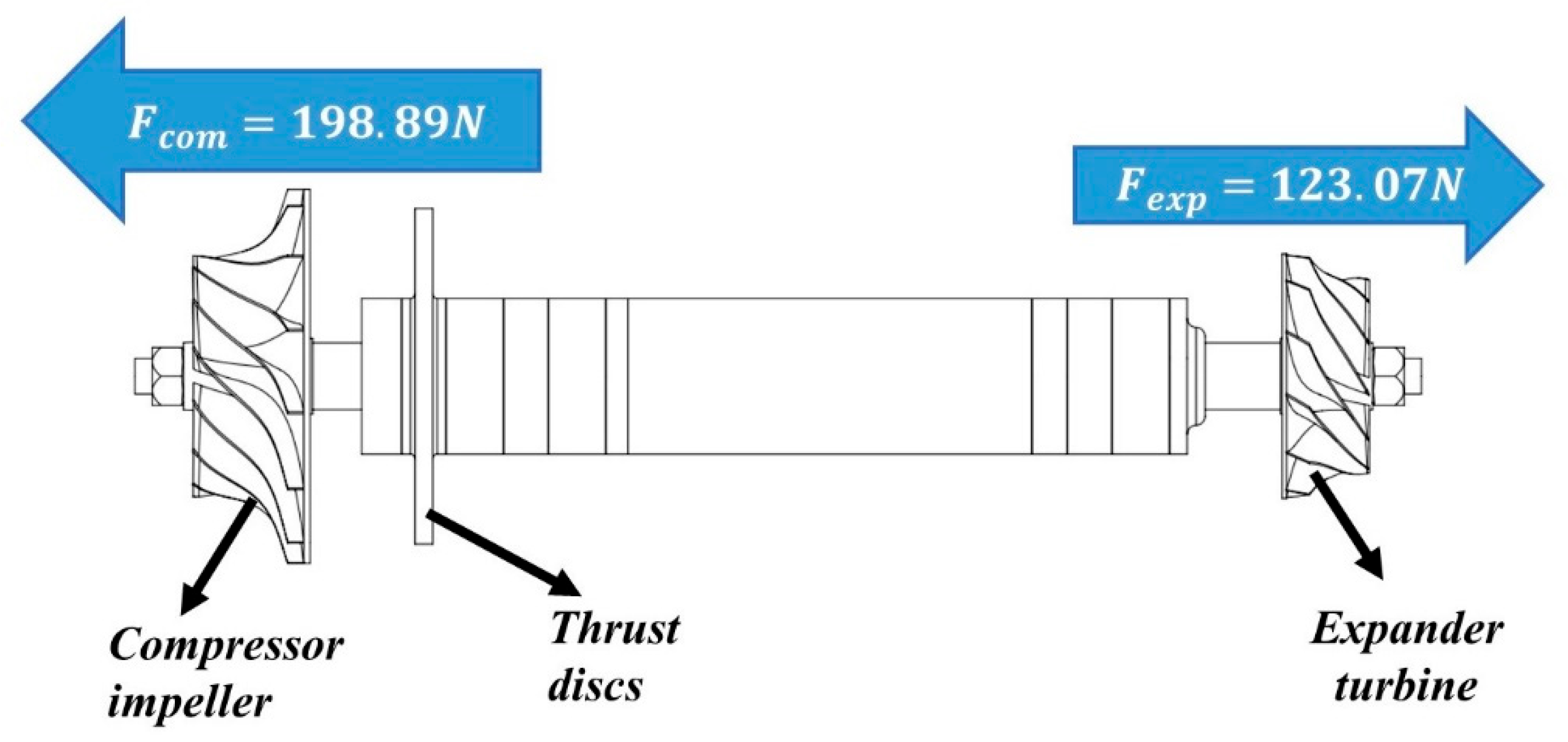

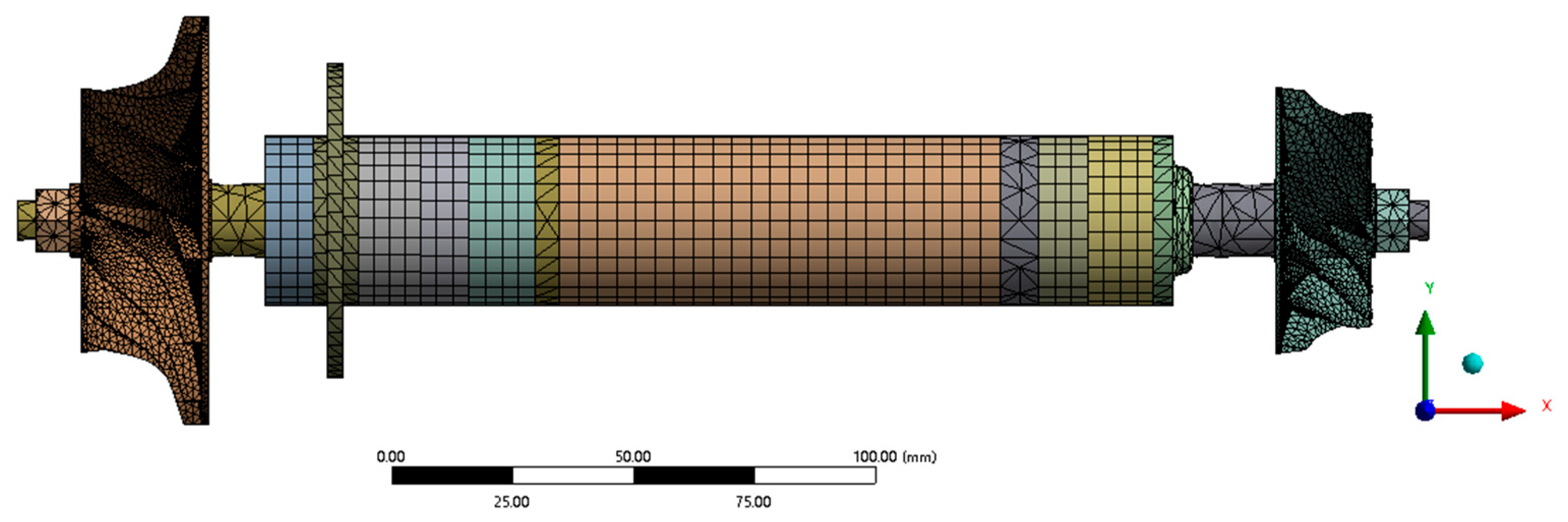

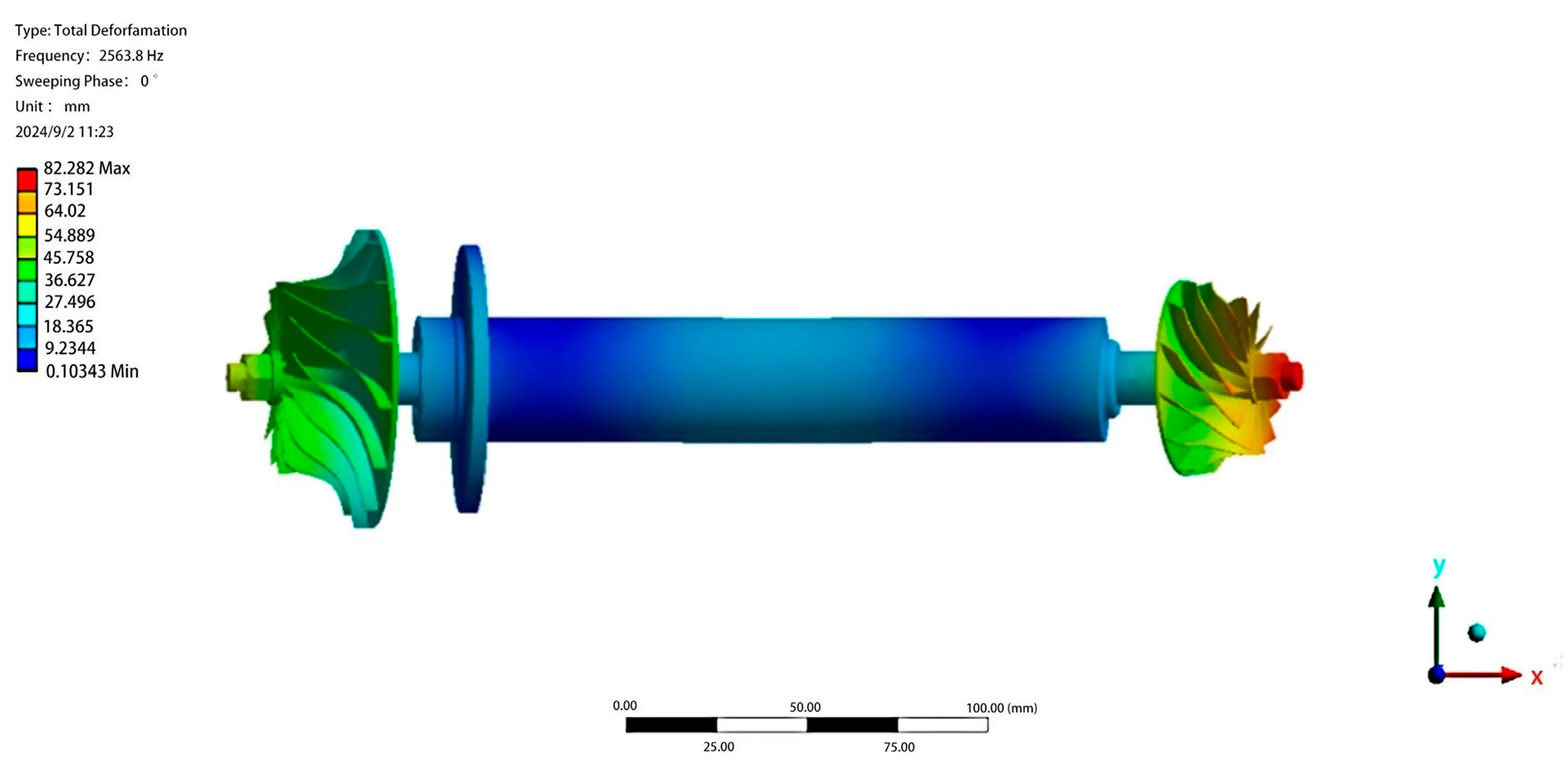

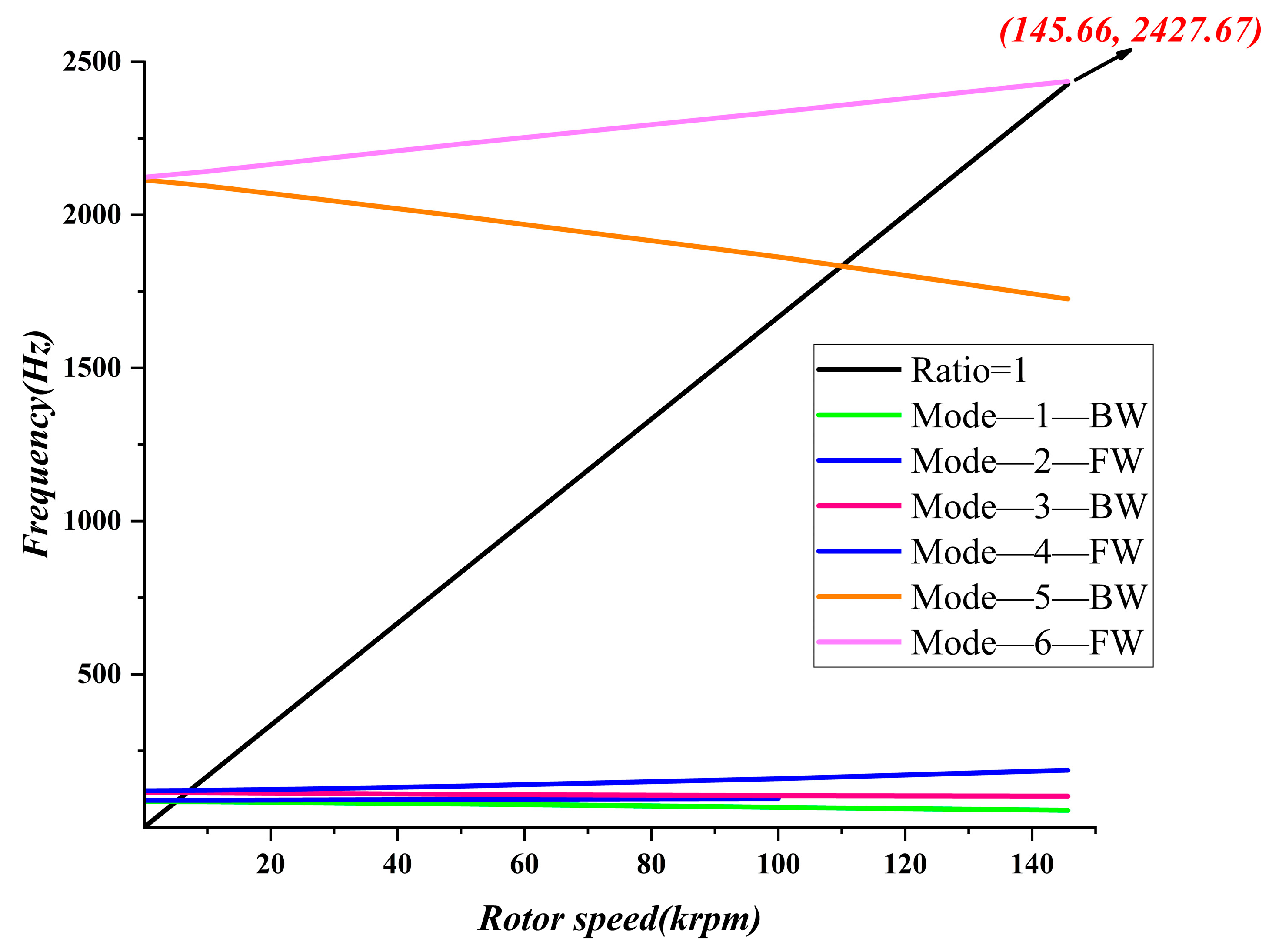

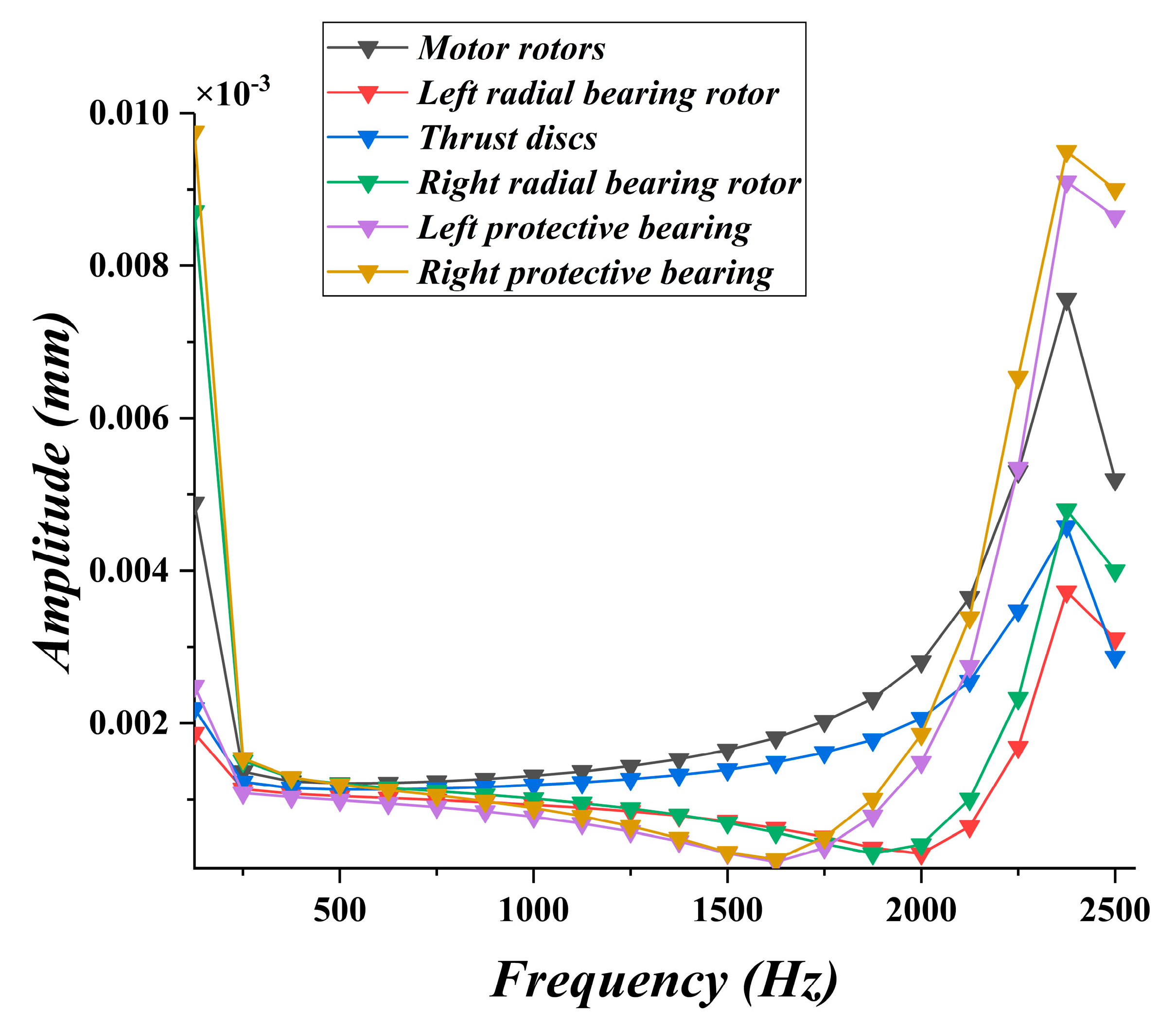

5.2. Rotor Dynamics Analysis

5.2.1. Analysis of Critical Rotor Speed

5.2.2. Analysis of Rotor Unbalance Response

6. Conclusions

- (1)

- The integrated and optimized design of HPMSM was carried out considering multi-physics fields such as rotor dynamics.

- (2)

- The initial theoretical design of the 5-DOF AMB was optimized in terms of structural parameters based on MOGWO, with the objective function of maximizing the bearing capacity of the 5-DOF AMB and minimizing its volume and windage loss.

- (3)

- Through the finite element software, the feasibility and reliability of the system design were verified by analyzing the electromagnetism, rotor dynamics, and unbalanced responses.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, Y.Y. Application of Proton Exchange Membrane Fuel Cells in Electric Vehicle. Mod. Veh. Power 2024, 2, 6–9+23. [Google Scholar]

- Fang, S.Y. Research on Control Method of Air Supply System for Vehicle Fuel Cells. Master’s Thesis, Dalian University of Technology, Dalian, China, 2019. [Google Scholar]

- Wu, Y.; Bao, H.; Fu, J.; Wang, X.; Liu, J. Review of recent developments in fuel cell centrifugal air compressor: Comprehensive performance and testing techniques. Int. J. Hydrogen Energy 2023, 48, 32039–32055. [Google Scholar] [CrossRef]

- Guo, A.; Li, Q.; Chen, W.R.; Liu, Z.X. Characteristics of Cathode System in Fuel Cells for Electric Vehicles. J. Southwest Jiao Tong Univ. 2013, 48, 1052–1058. [Google Scholar] [CrossRef]

- Pei, F.L.; Hou, M.T.; He, J.L.; Wu, B.; Chen, F.X. Modeling of air compressor for proton exchange membrane fuel cell. Energy Storage Sci. Technol. 2019, 8, 1247–1252. [Google Scholar] [CrossRef]

- Gao, Z.W.; Li, X.G.; Liu, Z.X.; Rao, J. Development trend and research status of the hydrogen fuel cell vehicle. Mater. Rep. 2022, 36, 74–81. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Gaillard, P. Emissions reduction by using e-components in 48 V mild hybrid trucks under dual-mode dual-fuel combustion. Appl. Energy 2021, 299, 117305. [Google Scholar] [CrossRef]

- Zhang, Y.; Bao, P.; Wan, Y.; Xu, S. Modeling and analysis of air supply system of polymer electrolyte membrane fuel cell system. Energy Procedia 2017, 142, 1053–1058. [Google Scholar] [CrossRef]

- Li, H.Q. Design and Research of High-Speed Centrifugal Compressor for Hydrogen Fuel Cell Vehicle. Master’s Thesis, Zhejiang University, Zhejiang, China.

- Yu, W.; Sichuan, X.; Ni, H. Air Compressors for Fuel Cell Vehicles: A Systematic Review. SAE Int. J. Altern. Powertrains 2015, 4, 115–122. [Google Scholar] [CrossRef]

- Zhang, Y. Analysis of the development status and trend of air compressors for the fuel cell vehicle. Intern. Combust. Engine Parts 2019, 2, 201–202. [Google Scholar]

- Bao, P.L.; Zhang, D.B.; Xu, S.C.; Fang, Y. Development status and trend of air compressor for fuel cell vehicles. Chin. J. Power Sources 2016, 40, 1731–1734. [Google Scholar] [CrossRef]

- Meng, H.K. High-speed permanent Magnet Synchronous Motor Control System for Hydrogen Fuel Cell Centrifugal Fans. Master’s Thesis, Jiangsu University of Science and Technology, Zhenjiang, China, 2023. [Google Scholar]

- Xiong, W.L.; Wang, J.; Chen, Z.Y.; Sun, W.B.; Xue, H.N.; Tang, X.Q. Review of Research Status and Development of Foil Air Bearings. J. Mech. Eng. 2022, 58, 92–113. [Google Scholar] [CrossRef]

- Sun, S. Collaborative Control Study of the Air-Magnetic Suspension Drive System for Fuel Cell Compressors. Master’s Thesis, Yangzhou University, Yangzhou, China, 2023. [Google Scholar]

- Peng, C.; He, J.; Zhu, M.; Deng, Z.; Zhen, Z.; Liu, Q. Optimal synchronous vibration control for magnetically suspended centrifugal compressor. Mech. Syst. Signal Process. 2023, 2, 776–789. [Google Scholar] [CrossRef]

- Zhou, J.Y.; Zhu, H.Q. Development and Research Summary of Magnetic Bearings. Micromotors 2022, 55, 93–98. [Google Scholar] [CrossRef]

- Zhang, J. Structure Design and Performance Analysis of Gas Magnetic Bearing. Master’s Thesis, Yangzhou University, Yangzhou, China, 2020. [Google Scholar]

- Cao, Z. Research On Key Problems Of active Magnetic Bearing Aring System for High-Speed Motors. Master’s Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar]

- Ravikovich, Y.A.; Ermilov, Y.I.; Kholobtsev, D.P.; Sukhomlinov, I.Y.; Golovin, M.V. Experience of improving rotor system having petal-shaped gas-dynamic bearings for centrifugal refrigeration compressor. Chem. Pet. Eng. 2016, 51, 838–843. [Google Scholar] [CrossRef]

- Su, H.N.; Song, J.S.; Zhang, T.X.; Tian, Y.; Liu, Z.H. Research progress of magnetic bearings. J. Shanghai Electr. Technol. 2023, 16, 60–63. [Google Scholar] [CrossRef]

- Fang, Q.H. Analysis of Loss and Temperature Field of High-Speed Maglev Permanent Magnet Motor. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2021. [Google Scholar]

- Xiao, L.J.; Zhang, X.S.; Chang, L.; Guo, H. Design and Optimization of Magnetic Bearings Based on ANSYS and ISIGHT. Bearing 2012, 5, 5–8. [Google Scholar] [CrossRef]

- Huang, Z.; Han, B. Effective approach for calculating critical speeds of high-speed permanent magnet motor rotor-shaft assemblies. IET Electr. Power Appl. 2015, 9, 628–633. [Google Scholar] [CrossRef]

- Zhang, S.S.; Zhou, J.; Zhang, F.P. Structural Optimization Design for Magnetic Bearings Based on Multi-objective Genetic Algorithm. Mach. Electron. 2013, 08, 3–6. [Google Scholar] [CrossRef]

- Smirnov, A.; Uzhegov, N.; Sillanpää, T.; Pyrhonen, J.; Pyrhonen, O. High-speed electrical machine with active magnetic bearing system optimization. IEEE Trans. Ind. Electron. 2017, 64, 9876–9885. [Google Scholar] [CrossRef]

- Shelke, S.N.; Chalam, R.V. Optimum power loss in eight poles radial magnetic bearing: Multi-objective genetic algorithm. In Proceedings of the International Conference on Computational Intelligence and Information Technology, Surat, India, 7–8 November 2011; Springer: Berlin/Heidelberg, Germany; pp. 72–77. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, T.Y.; Dong, J.Y.; Chen, Y.; Gao, S.M. Optimal Design for Structure of Radial Magnetic Bearings Based on ISIGHT. Bearing 2018, 7, 6–11. [Google Scholar]

- Zhou, Y.; Zhou, J.; Zhang, Y. Optimum Structural Design of Active Magnetic Bearing Based on RBF Approximation Model. J. Southwest Jiao Tong Univ. 2022, 57, 682–692. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhang, D.Z.; Gao, P. Multi-variable and Multi-objective Optimization Design of Active Radial Magnetic Bearing Based on Fruit Fly Optimization Algorithm. Mot. Technol. 2017, S1, 174–181. [Google Scholar]

- Wang, X.; Xu, Y. Multi-Physics Multi-Objective Optimal Design of 5-DOF Magnetic Bearing System with High-speed Permanent Magnet Synchronous Motor. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 457–461. [Google Scholar] [CrossRef]

- Feng, C. Optimized Design and Performance Analysis of Active Electromagnetic Bearings for Flywheel Batteries. Master’s Thesis, Shandong University of Technology, Zibo, China, 2023. [Google Scholar]

- Betancor, J.; Sahinkaya, M.N.; Zweiri, Y.H. Radial active magnetic bearing design optimization. In Proceedings of the 10th International Conference on Rotor Dynamics–IFToMM: Vol.1 10; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 321–334. [Google Scholar] [CrossRef]

- Yadav, V.K.; Kumar, P.; Bhushan, G. A novel approach for design optimization of radial active magnetic bearing. Aust. J. Mech. Eng. 2023, 21, 1461–1473. [Google Scholar] [CrossRef]

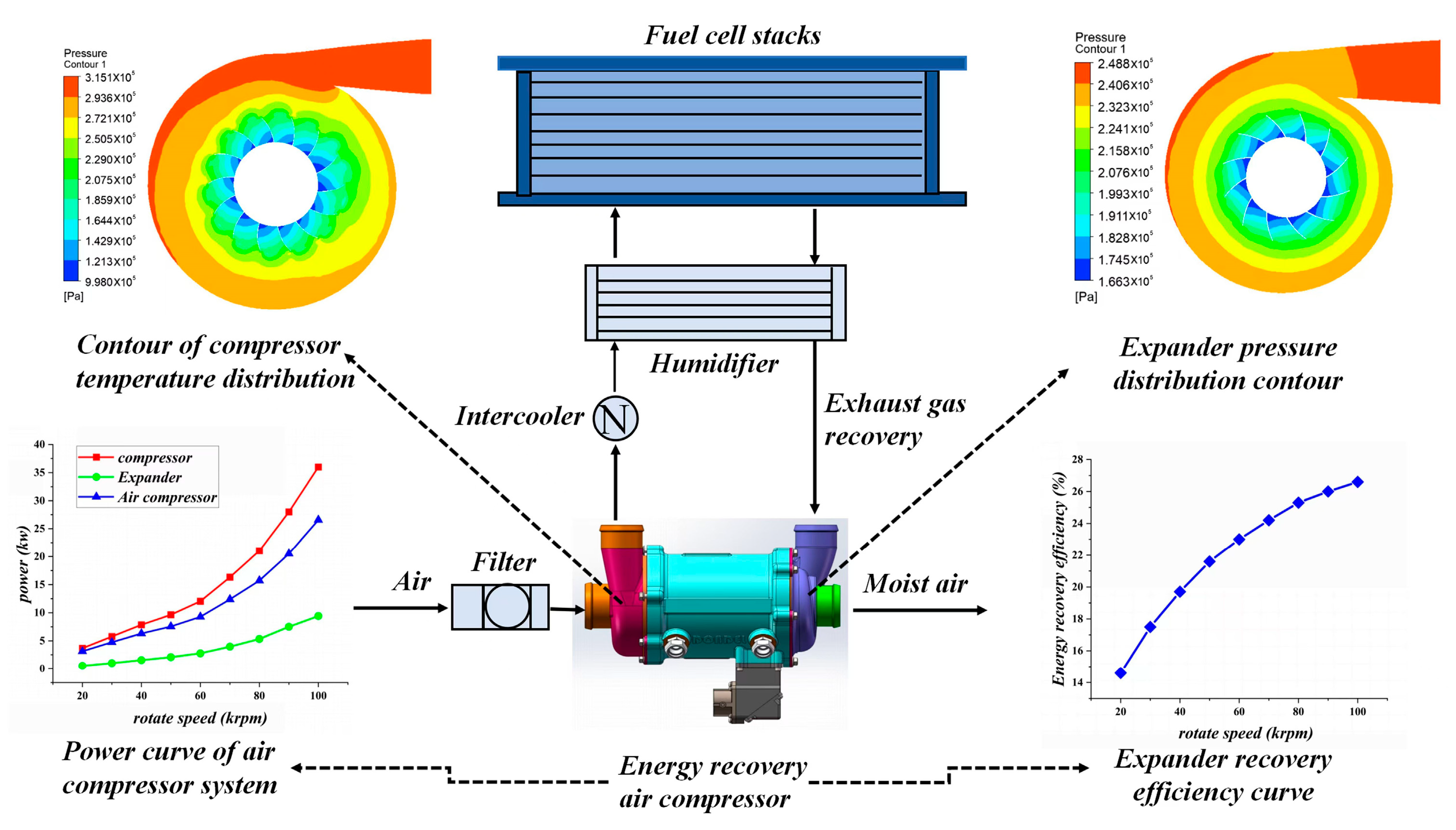

- Liu, F.Y. Design and Performance Analysis of Key Components for Fuel Cell Centrifugal Air Compressor with Energy Recovery. Master’s Thesis, Yantai University, Yantai, China, 2024. [Google Scholar]

- Fu, Z.S. Research and Design of Active Magnetic Bearing for High-Speed Motors. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2017. [Google Scholar]

- Yu, Z.J. Design and Optimization of High-Speed Permanent Magnet Synchronous Motor for Air Compressor. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Qiu, M.S.; Hua, Q.S. Electromagnetic optimization design of high-speed permanent magnet synchronous motor based on Taguchi iterative method. J. Beijing Norm. Univ. (Nat. Sci.) 2022, 58, 713–719. [Google Scholar] [CrossRef]

- Chen, M.X. Design and Magnetocaloric Coupling Analysis of High-Speed Permanent Magnet DRIVE Motor. Master’s Thesis, Shandong University of Technology, Zibo, China, 2023. [Google Scholar]

- Gao, T.Y. Research on the Design and Comprehensive Optimization Technology of Maglev High-Speed Permanent Magnet Generator. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Zhu, L.F. Design and Optimization of a Gramme-Ring-Winding High-Speed Slot Less Permanent-Magnet Motor. Master’s Thesis, Nanjing University of Science & Technology, Nanjing, China, 2021. [Google Scholar]

- Zhang, M.X. Design and Rotor Loss Optimization of the High-Speed Permanent Magnet Machine for Compressor. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2023. [Google Scholar]

- Zhong, Y. Design and Research of High-Speed Permanent Magnet Synchronous Motor for Aeration Fan. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2022. [Google Scholar]

- Shao, Y.Y. Design of Ultra-High-Speed Permanent Magnet Synchronous Motor. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2020. [Google Scholar]

- Du, K.L. DESIGN and Experimental Study of Toroidal Winding Flywheel Energy STORAGE motor. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2023. [Google Scholar]

- Voigt, A.J. Towards Identification of Rotor Dynamic Properties for Seals in Multiphase Flow Using Active Magnetic Bearings. Design and Commissioning of a Novel Test Facility. Ph. D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2016. Available online: https://findit.dtu.dk/en/catalog/581cbeaac1ff02154f00008b (accessed on 1 October 2024).

- Du, Y.H. Design and Research of Radial Magnetic Bearing Structure for High-Speed Motor. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. [Google Scholar]

- Wang, Y. Design and Control of Magnetic Bearing for Flywheel Battery. Master’s Thesis, Shandong University of Technology, Zibo, China, 2022. [Google Scholar]

- Su, H. Research on Vibration and Control Caused by Thermal Bending of Magnetic Levitation Rotor. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2022. [Google Scholar]

- Yan, X. Study on the Mechanism of the Morton Effect of Magnetic Bearings. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2020. [Google Scholar]

- Liu, B.; Yu, Z.J.; Fu, J. Cooling Design and Temperature Field Analysis of Radial-axial Magnetic Bearings. Proc. CSEE 2024, 44, 4945–4956. [Google Scholar] [CrossRef]

- Xu, Z.Y. Research on Key Technologies of Rotor of High-Speed Permanent Magnet Motor. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Han, B.; Liu, X.; Huang, Z.; Zhang, X.; Zhou, Y. Loss calculation, thermal analysis, and measurement of magnetically suspended PM machine. IEEE Trans. Ind. Electron. 2017, 65, 4514–4523. [Google Scholar] [CrossRef]

- Li, H.; Xu, X.B.; Chen, S.; Bi, Z.W. Research on dynamic analysis of three-stage rotor of high-speed magnetic levitation motor. Small Spec. Electr. Mach. 2024, 52, 6–10. [Google Scholar] [CrossRef]

- Wang, M.Y. Design and Characteristic Analysis of Ultra-High-Speed Flywheel Energy Storage Rotor and Its Support System. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2022. [Google Scholar]

- Hu, Z.D. Research on the Control System of Active Magnetic Bearing. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2020. [Google Scholar]

- Yang, J.C. Research on Key Components of Active Magnetic Bearing CONTROL system. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2022. [Google Scholar]

- Wang, C.T.; Guo, H.; Sun, F. Simulation analysis of the automatic balance of unbalanced magnetic levitation rotor. Mech. Eng. Autom. 2021, 5, 60–62. [Google Scholar] [CrossRef]

- Ge, Y.Z.; Lei, X.M.; Zhang, Y.C.; Fang, Z.X.; Lu, Z. Analysis and test of the allowable residual unbalance of the rotor. J. Vib. Meas. Diagn. 2023, 43, 371–377+414–415. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rated power | 30 kw |

| DC bus voltage | 470 V |

| Rated rotational speed | 100,000 rpm |

| Efficiency | >96% |

| Power factor | >0.9 |

| Winding Structure | End Length (mm) |

|---|---|

| Double-layer short-pitch distributed winding | 27 |

| Toroidal winding | 17 |

| Type | Parameter | Type | Parameter |

|---|---|---|---|

| 32 | Stator outer diameter (mm) | 96 | |

| 3.5 | Axial length (mm) | 61 | |

| Pole pairs | 1 | Number of stator slots | 24 |

| Permanent magnet material | Smco30 | Stator core material | B20AT1500 |

| Sheath material | GH4169 | Winding structure | Toroidal winding |

| Parameter | Value |

|---|---|

| Rated rotational speed n | |

| Winding heat dissipation conditions | Natural air cooling |

| Outer diameter of stator D4 | ≤110 mm |

| Outer diameter of rotor D | 35 mm |

| Stator thickness Lr | ≤16 mm |

| 4 A |

| Parameter | Value |

|---|---|

| 8 | |

| 21 mm | |

| Outer diameter of rotor D | 35 mm |

| 0.4 mm | |

| 35.8 mm | |

| 84.8 mm | |

| 100.3 mm | |

| 7.03 mm | |

| 7.73 mm | |

| 14 mm | |

| 94.5 mm2 | |

| 290 mm2 | |

| 190 | |

| 1.12 mm | |

| 4 A | |

| 2 A | |

| 1.2 T | |

| 100 N |

| Parameter | Value |

|---|---|

| ≥152 N | |

| Rated rotational speed n | |

| Winding heat dissipation conditions | Natural air-cooling |

| ≤80 mm | |

| Outer diameter of rotor D | 35 mm |

| 4 A |

| Parameter | Value |

|---|---|

| Outer diameter of rotor D | 35 mm |

| Single-side air gap | 0.4 mm |

| 41 mm | |

| 45 mm | |

| 74.8 mm | |

| 77 mm | |

| 77.5 mm | |

| 14.9 mm | |

| Magnetic yoke thickness h | 2.5 mm |

| Thrust disc thickness L | 5 mm |

| 264.4 mm2 | |

| 221.7 mm2 | |

| 135 | |

| 1.12 mm | |

| 4 A | |

| 2 A | |

| 0.85 T | |

| 152 N |

| Parameter | Initial Value | Optimized Value |

|---|---|---|

| 7.03 mm | 8.6 mm | |

| 7.73 mm | 8.6 mm | |

| 21 mm | 22 mm | |

| 24.5 mm | 20 mm | |

| 14 mm | 12 mm | |

| Parameter | Initial Value | Optimized Value |

|---|---|---|

| 41 mm | 40.6 mm | |

| 45 mm | 44.7 mm | |

| 77 mm | 75 mm | |

| 14.9 mm | 14 mm | |

| 2.5 mm | 2 mm | |

| Name of Material | Application Components | |||

|---|---|---|---|---|

| 7750 | 196 | 0.28 | Spindle | |

| 7700 | 197 | 0.26 | Radial magnetic bearing rotor core | |

| 8240 | 199 | 0.3 | Motor rotor sheath | |

| 7840 | 210 | 0.278 | Thrust disc | |

| 4510 | 110 | 0.34 | Pressure sleeve, expander impeller, lock nut | |

| 2810 | 71 | 0.33 | Compressor impeller, inspection ring, baffle | |

| 8400 | 120 | 0.24 | Permanent magnet |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, E.; Gao, Q.; Dong, Y.; Bai, W. Design and Optimization of Support and Drive System for Magnetic Levitation Air Compressor for Fuel Cells. Actuators 2025, 14, 26. https://doi.org/10.3390/act14010026

Xing E, Gao Q, Dong Y, Bai W. Design and Optimization of Support and Drive System for Magnetic Levitation Air Compressor for Fuel Cells. Actuators. 2025; 14(1):26. https://doi.org/10.3390/act14010026

Chicago/Turabian StyleXing, Enhui, Qi Gao, Yuanqi Dong, and Wenxin Bai. 2025. "Design and Optimization of Support and Drive System for Magnetic Levitation Air Compressor for Fuel Cells" Actuators 14, no. 1: 26. https://doi.org/10.3390/act14010026

APA StyleXing, E., Gao, Q., Dong, Y., & Bai, W. (2025). Design and Optimization of Support and Drive System for Magnetic Levitation Air Compressor for Fuel Cells. Actuators, 14(1), 26. https://doi.org/10.3390/act14010026