Research on Vibration Reduction Characteristics of High-Speed Elevator with Rolling Guide Shoes Based on Hydraulic Damping Actuator

Abstract

1. Introduction

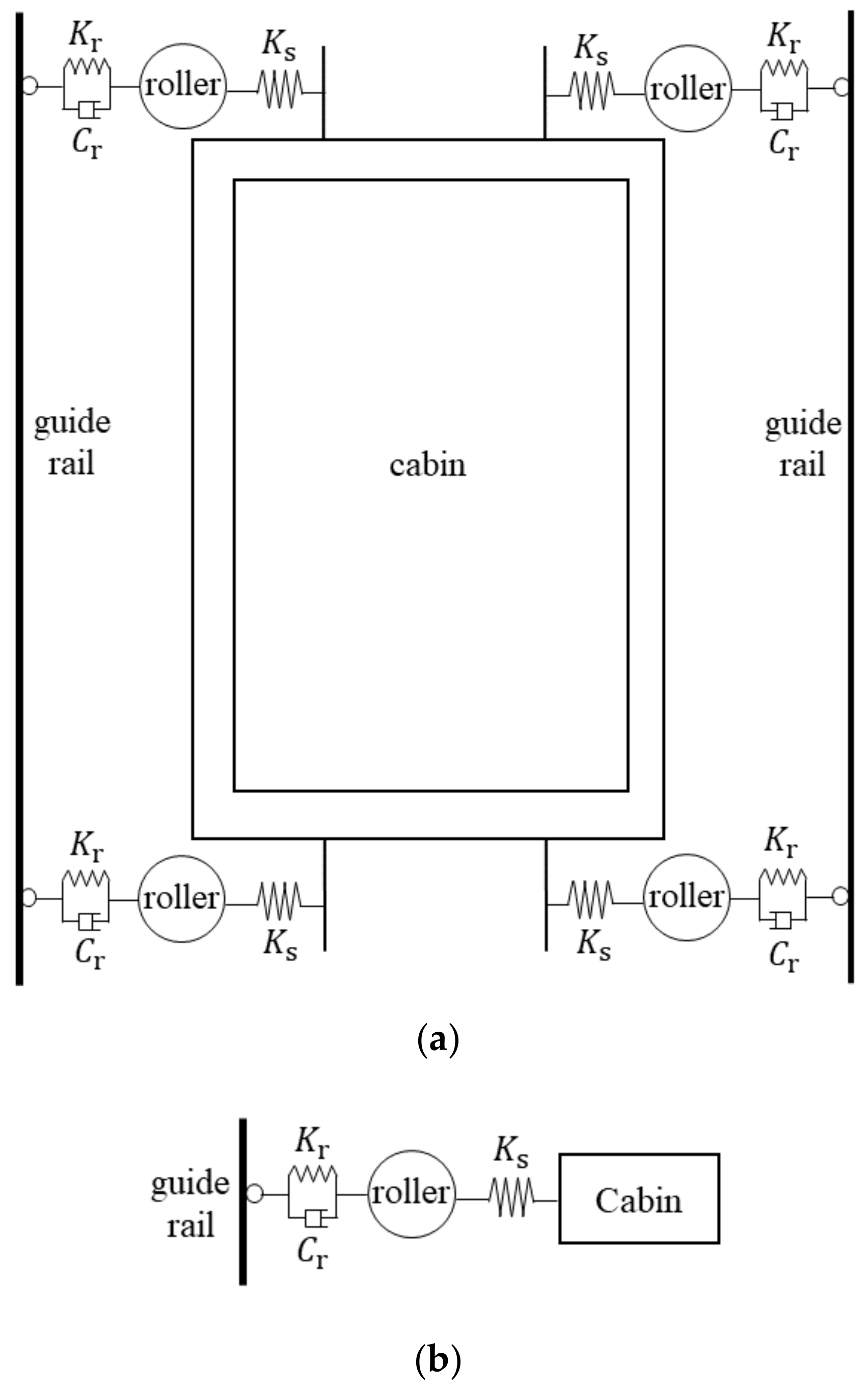

2. Overall Analysis of Elevator Horizontal Vibration

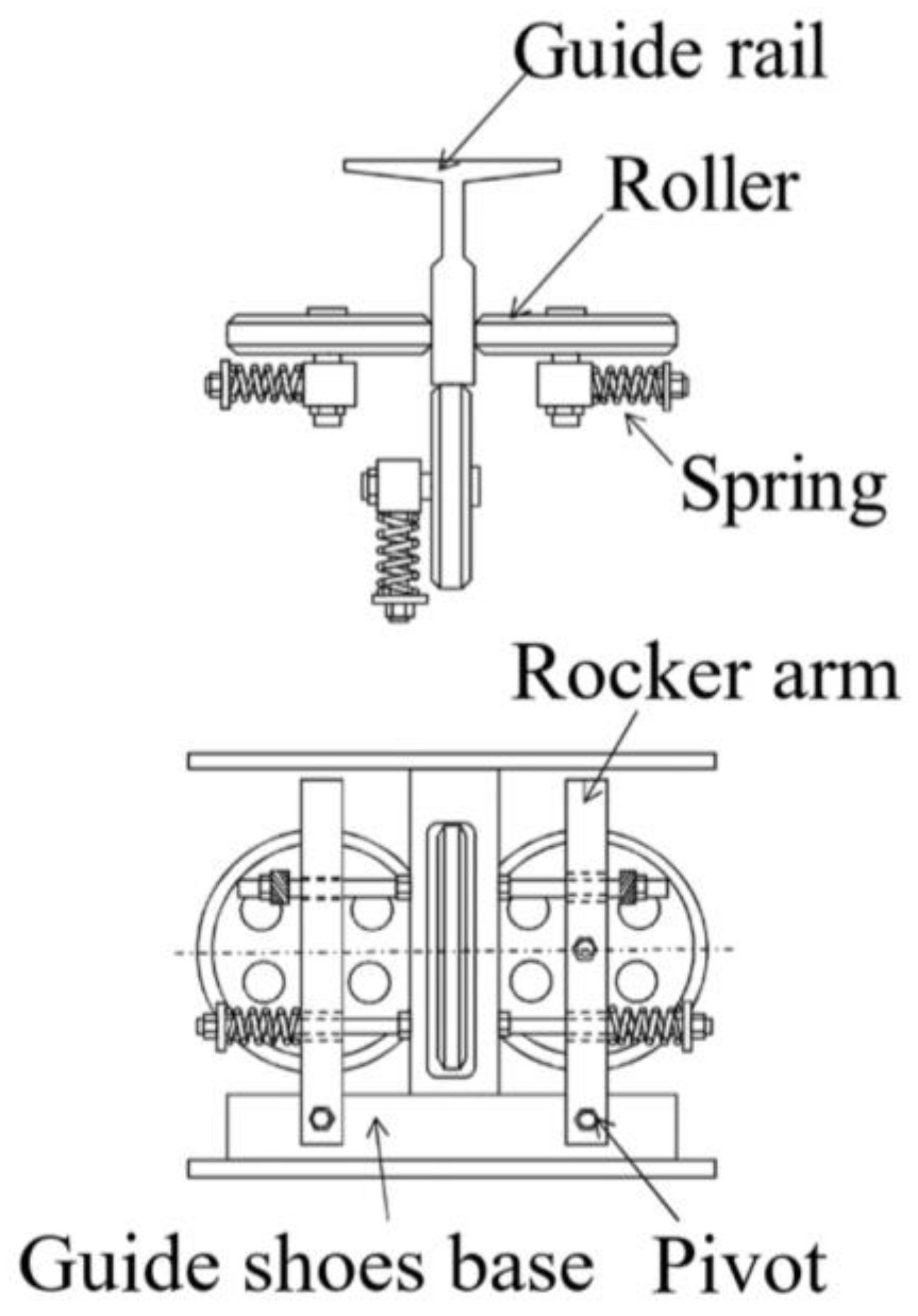

2.1. Overview of Elevator and Guide Shoes

2.2. Evaluation Standards for Elevator Vibration

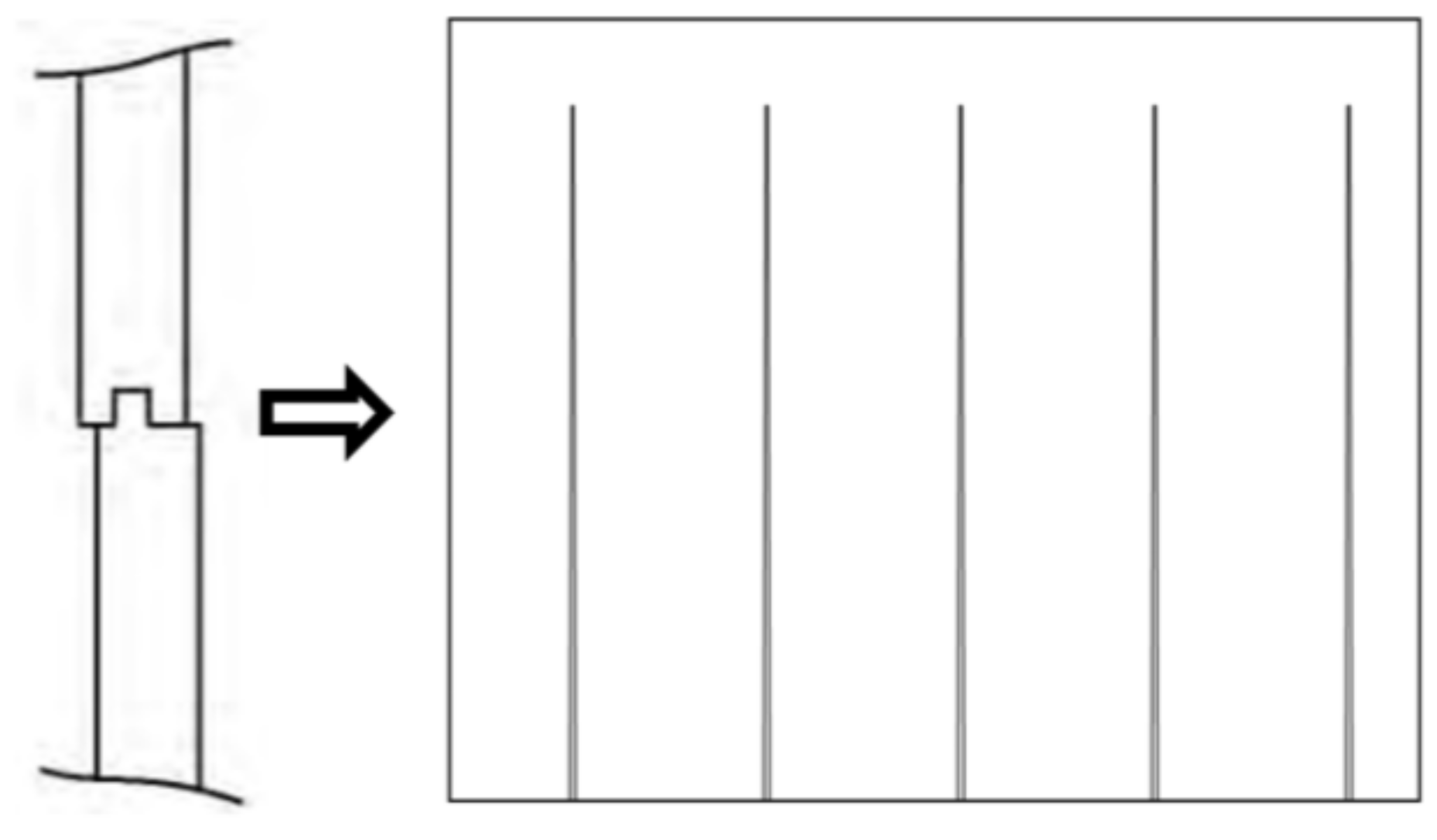

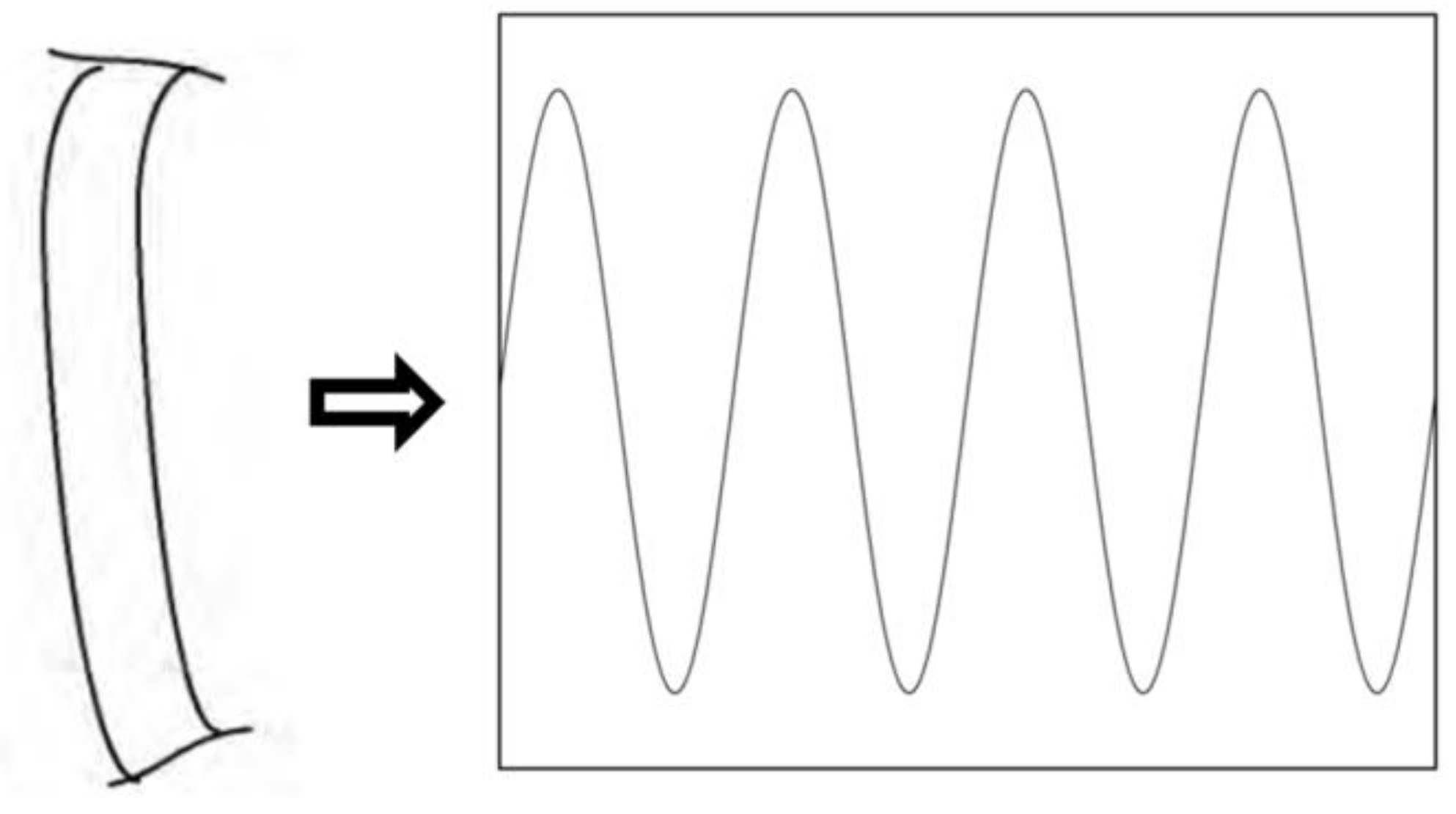

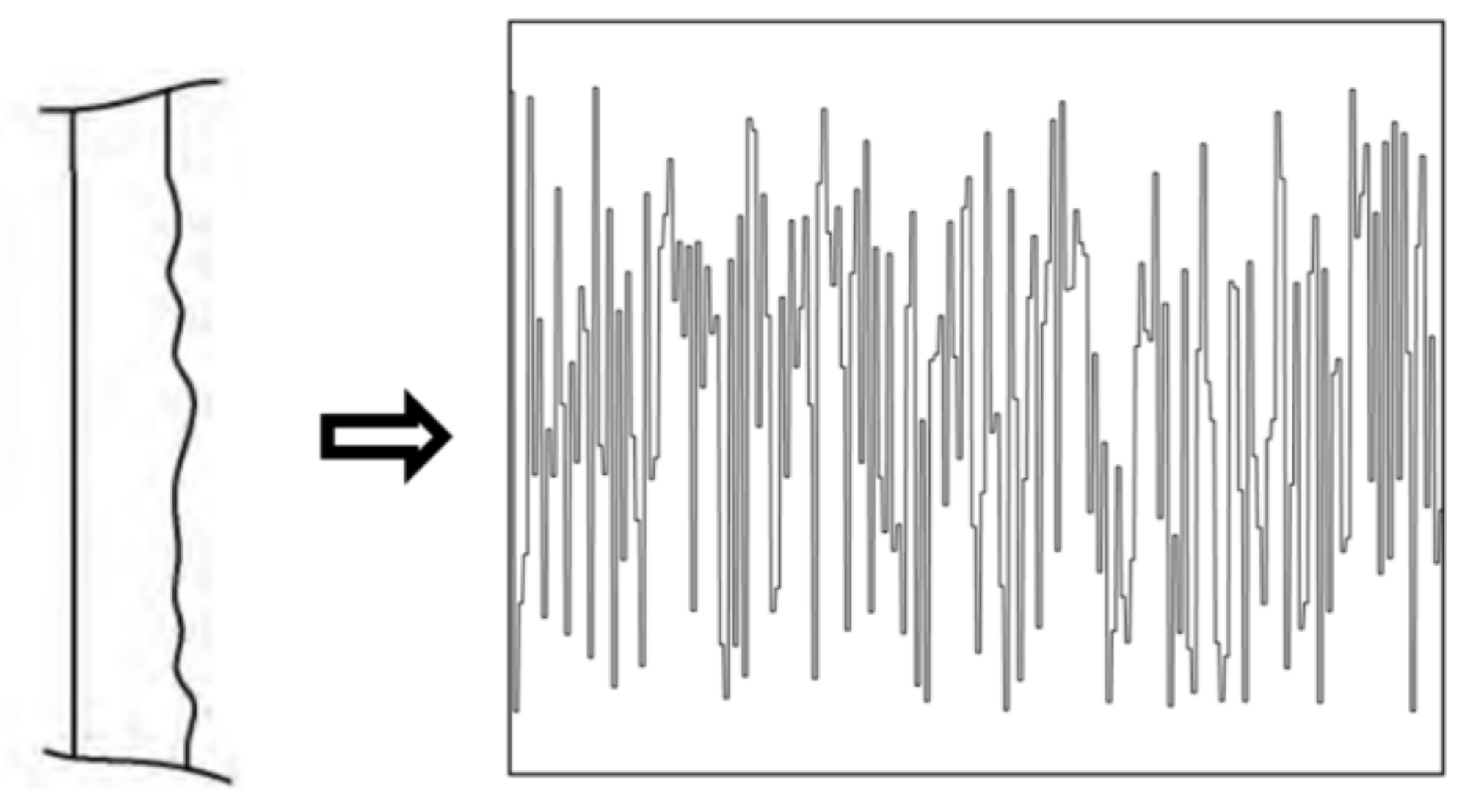

2.3. Excitation Source for Elevator Horizontal Vibration

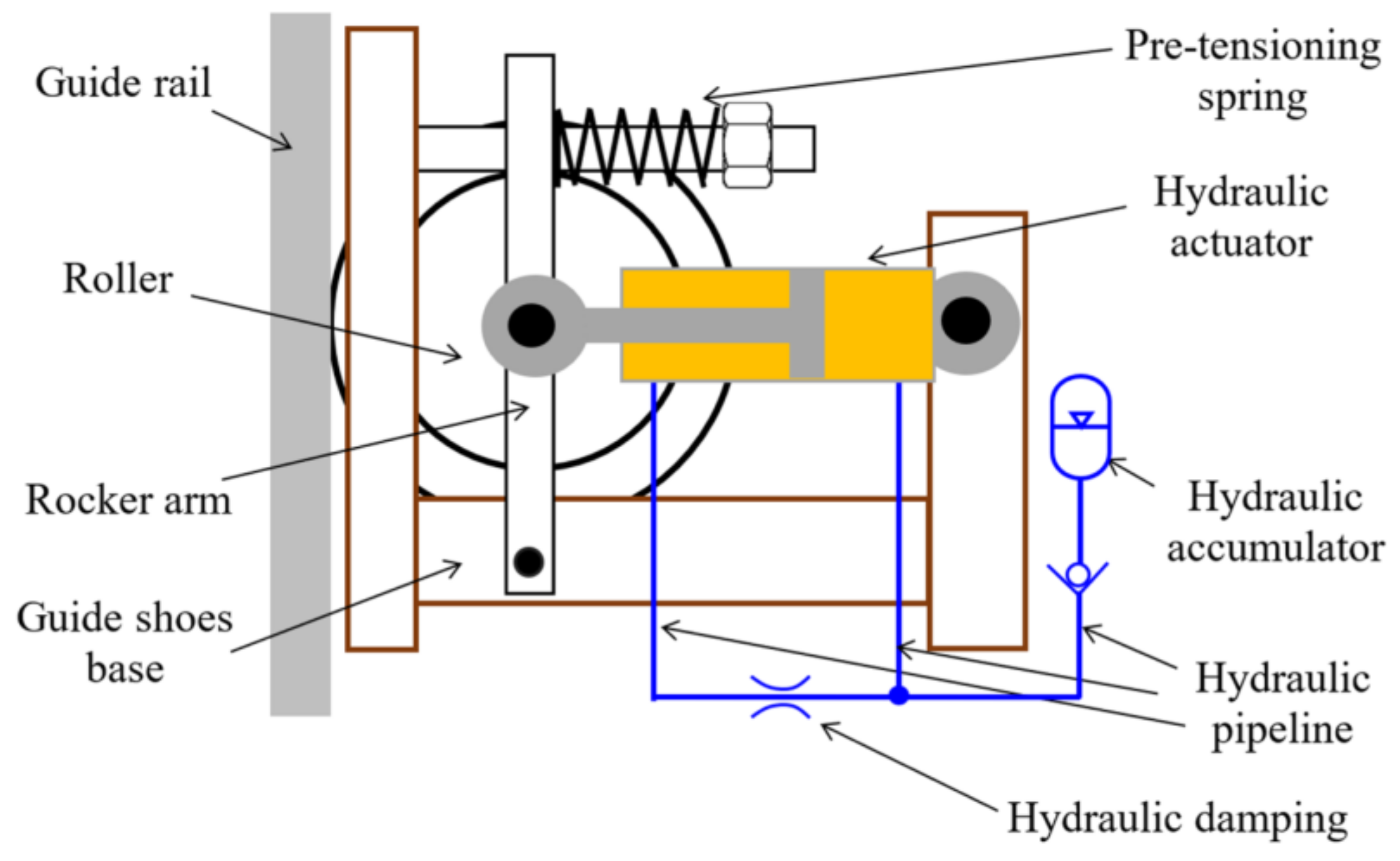

3. Working Principles

- (1)

- The system primarily comprises mechanical and hydraulic components. The mechanical components primarily include the guide shoes base, roller, rocker arm, and pre-tensioning spring. The hydraulic components primarily consist of the hydraulic actuator, hydraulic damping system, hydraulic pipelines, and hydraulic accumulator. Among these components, the rolling guide shoes are securely attached to the elevator cabin via the guide shoes’ base. The outer circular surface of the roller contacts the guide rail directly, while the roller’s center is hinged to the rocker arm. The lower end of the rocker arm is hinged to the guide shoes’ base, whereas the upper end presses the roller onto the guide rail using a pre-tensioning spring, thus ensuring a snug fit with the guide rail. The hydraulic damping component is situated between the rocker arm and the guide shoes’ base.

- (2)

- The hydraulic actuator functions as a support component for the roller. When the roller experiences uneven excitation from the guide rail, it induces lateral oscillation of the rocker arm. Consequently, the piston rod of the hydraulic actuator extends or retracts, converting the vibrational energy of the roller into pressure energy within the hydraulic actuator.

- (3)

- During the extension and retraction of the piston rod, the hydraulic oil within the actuator circulates between the left and right chambers. The oil also passes through the hydraulic damping orifice, which helps to suppress and dissipate the pressure through hydraulic damping. This process ultimately serves to reduce the system’s overall energy and dynamic response.

- (4)

- The hydraulic accumulator is linked to the oil chamber and pipeline at the end of the cylinder adjacent to the hydraulic cylinder. It absorbs hydraulic pressure impacts in the pipeline, thereby further enhancing the vibration reduction performance of the rolling guide shoes.

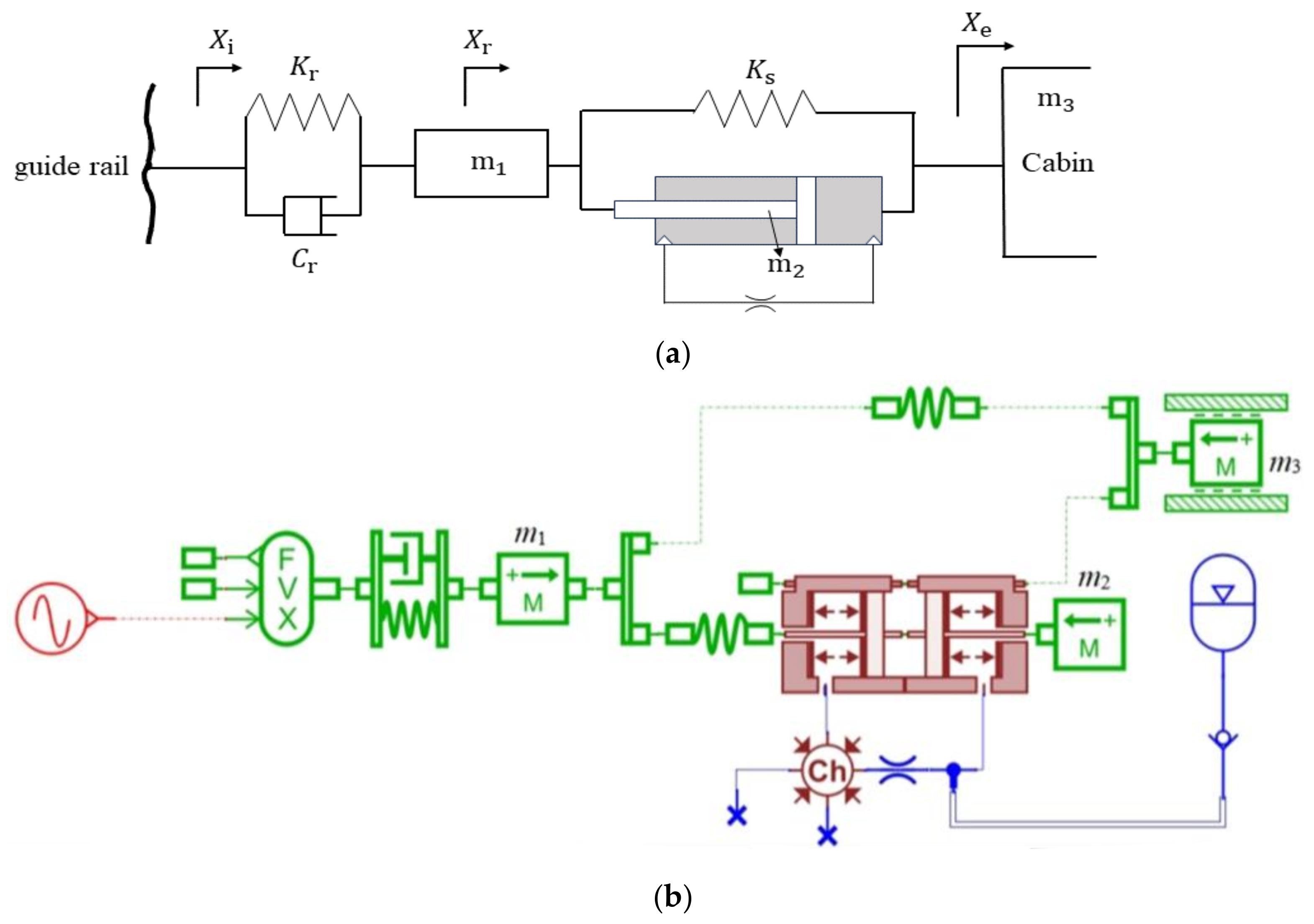

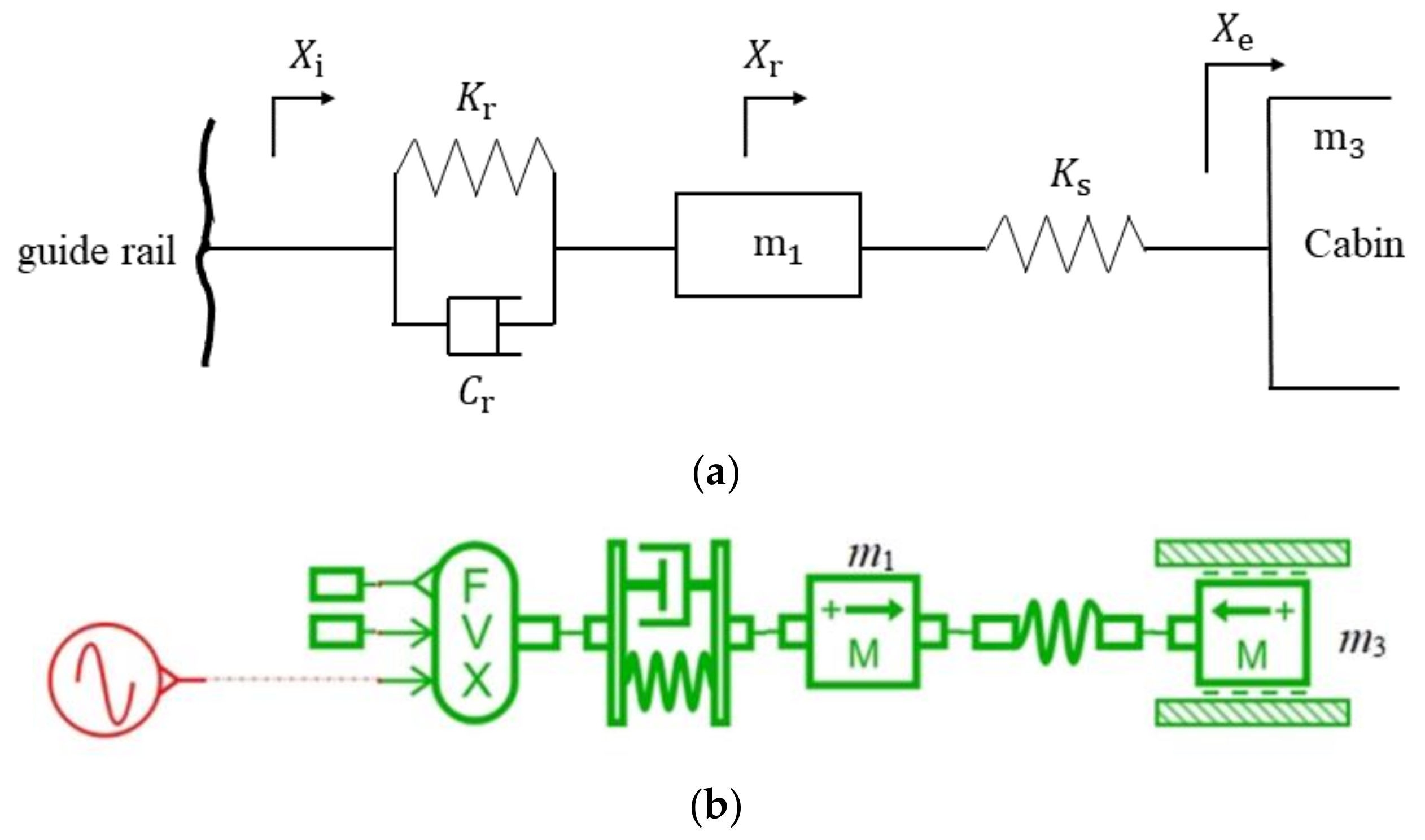

4. Simulations

4.1. Simulation Models

4.2. Key Parameters of Hydraulic Damping

4.3. Simulation Results

4.4. Impact of Other Parameters on Vibration Reduction Performance

- (1)

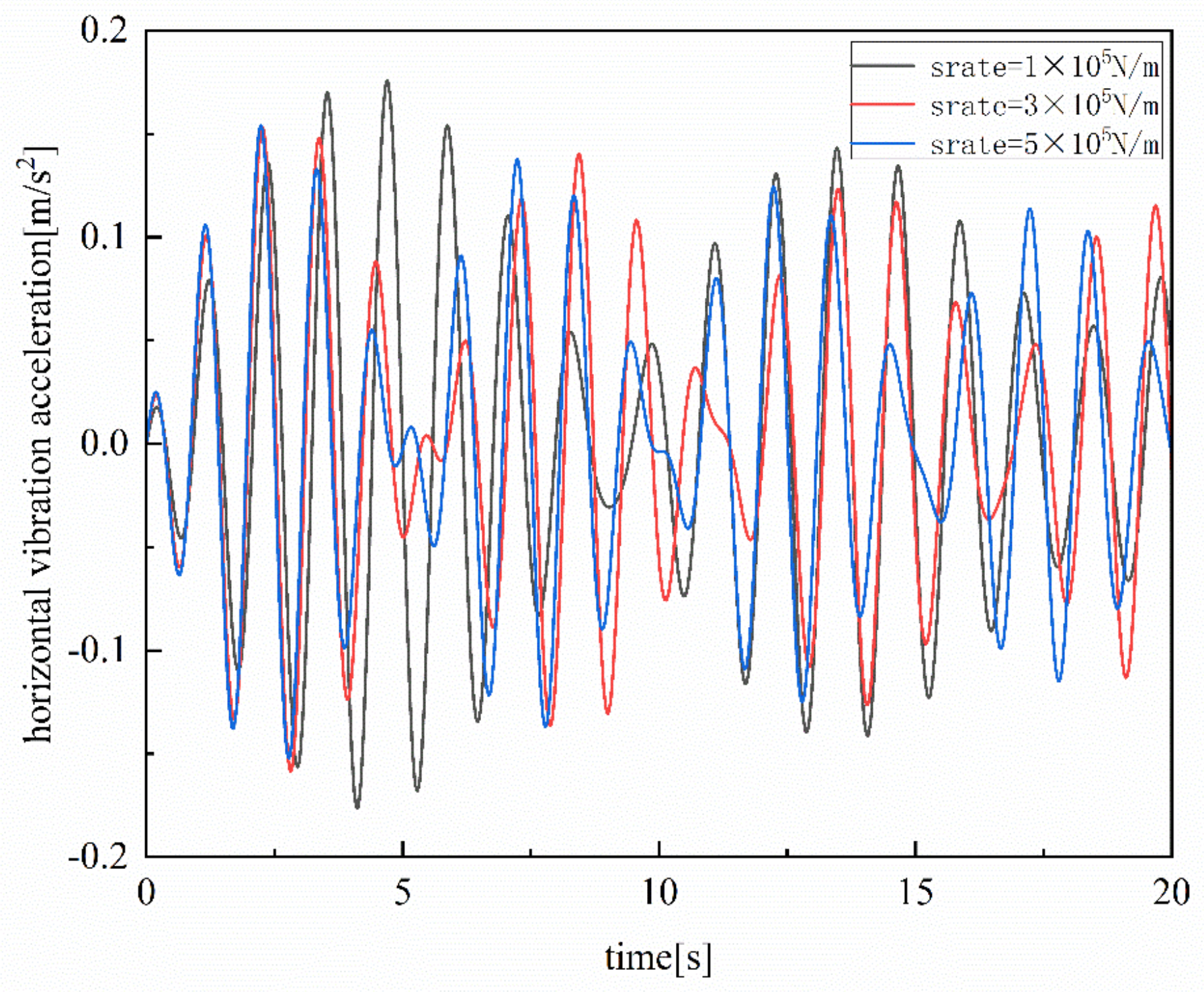

- Changing the roller stiffness coefficient

- (2)

- Changing the roller damping coefficient

- (3)

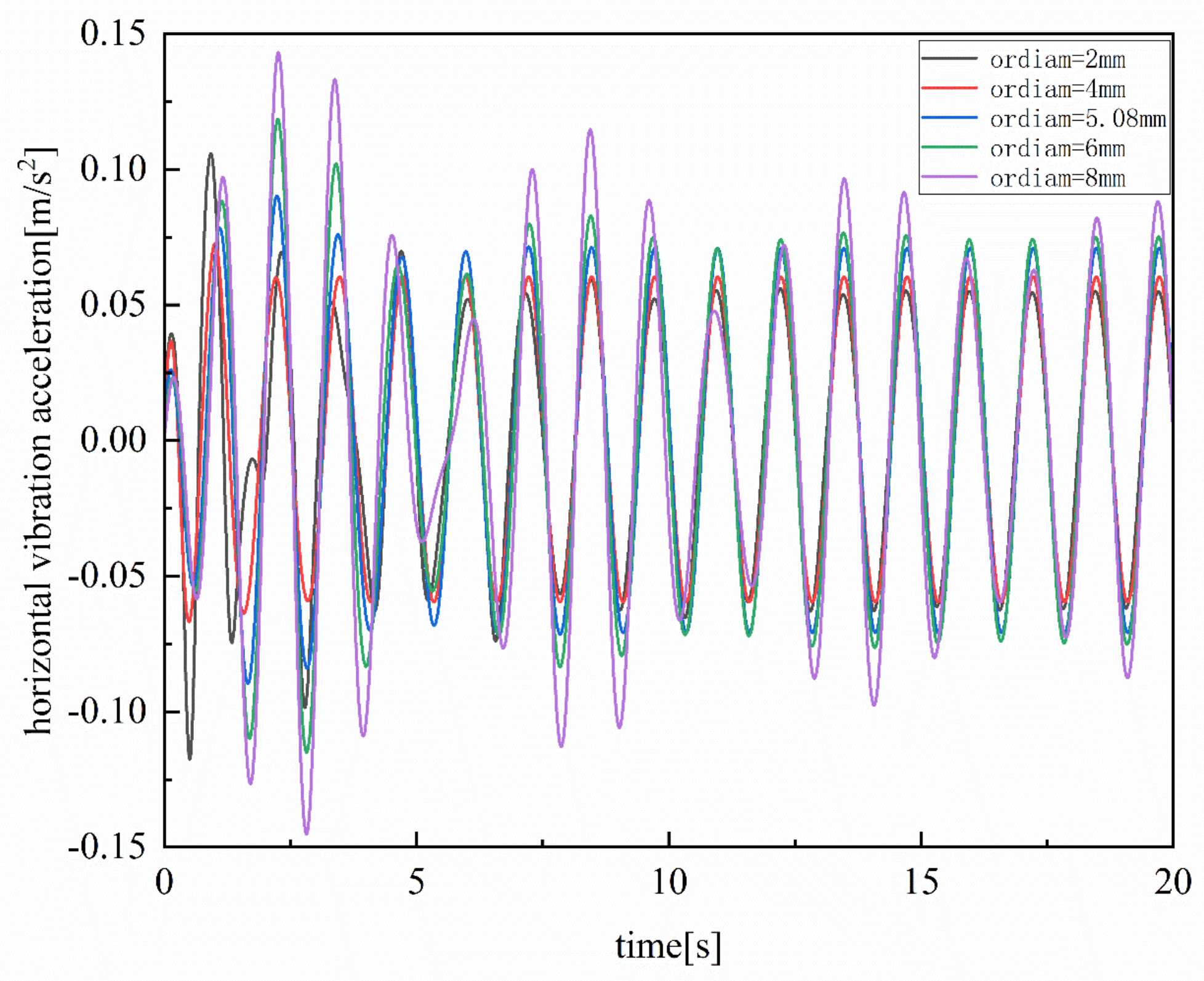

- Change in the hydraulic damping hole’s diameter

4.5. Comparison of Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.B. The Skyscraper Impulse. Build. Mater. Constr. Decor. 2014, 16–21. [Google Scholar] [CrossRef]

- Chen, J.W.; Zhang, X.Z.; Li, X. Principle and Control of Elevator Structure; Chemical Industry Press: Beijing, China, 2017. [Google Scholar]

- Chen, H.Y. Discussion about Elevator Vibration Reasons and Damping Methods. Mech. Eng. 2014, 1, 250–252. [Google Scholar]

- Yin, J.C. Research on the Vibration in Traction System Medium-high Speed Elevator. Master’s Thesis, SuZhou University, Suzhou, China, 2011. [Google Scholar]

- Ye, J. Analysis of the Causes of Elevator Operation Vibration and Discussion on Countermeasure. China Plant Eng. 2019, 16, 81–83. [Google Scholar]

- Zhang, Y. Research on the ride comfort of elevator monitoring using smartphone. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Portland, OR, USA, 25–29 March 2017. [Google Scholar]

- Hamdy, A. Active damping of vibrations in elevator cars. Struct. Control. Health Monit. 1999, 6, 53–100. [Google Scholar] [CrossRef]

- Schmulling, B.; Effing, O.; Hameyer, K. State control of an electromagnetic guiding system for ropeless elevators. In Proceedings of the in 2007 European Conference on Power Electronics and Applications, Aalborg, Denmark, 2–5 September 2007; pp. 1–10. [Google Scholar]

- Appunn, R.; Schmülling, B.; Hameyer, K. Electromagnetic Guiding of Vertical Transportation Vehicles: Experimental Evaluation. IEEE Trans. Ind. Electron. 2009, 57, 335–343. [Google Scholar] [CrossRef]

- Schmulling, B.; Hameyer, K. Decoupling and adjustment of forces in an electromagnetic guiding system with six degrees of freedom. COMPEL Electr. Electron. Eng. 2011, 30, 1011–1018. [Google Scholar] [CrossRef]

- Noguchi, N.; Arakawa, A.; Miyata, K.; Yoshimura, T.; Shin, S. Study on Active Vibration Control for High-Speed Elevators. J. Syst. Des. Dyn. 2011, 5, 164–179. [Google Scholar] [CrossRef]

- Noguchi, N.; Arakawa, A.; Miyoshi, K.; Kawamura, Y.; Yoshimura, T. Active vibration control technology for elevator cars considering controllability. Transact. Japan Soc. Mech. Eng. Series C 2013, 79, 3192–3205. [Google Scholar] [CrossRef]

- Hu, D.M.; Gao, X.C.; Wang, Q.B. Passive control Elevator Rolling Guide Shoes with Hydraulic Damping. Chinese Patent ZL 2022 2 2696572.0, 13 October 2022. [Google Scholar]

- Song, D.; Bai, Y.; Zhang, X.; Cui, Y.; Liu, K.; Lu, X. Analysis and optimization of horizontal vibration isolation performance of elevator rolling guide shoes. J. Mach. Des. 2021, 38, 34–41. [Google Scholar]

- Mei, D.Q.; Du, X.Q.; Chen, Z.C. Vibration analysis of high-speed traction elevator based on guide roller-rail contact model. J. Mech. Eng. 2009, 45, 264–270. [Google Scholar] [CrossRef]

- Wu, H. Study on Dynamic Characteristics of High-Speed Traction Elevator. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2013. [Google Scholar]

- Feng, Y.H. Active Control of Horizontal Vibrations for High—Speed Elevator. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2008. [Google Scholar]

- GB/T10058-2009; Specification for Electric Lifts. National Standard of the People’s Republic of China: Beijing, China, 2009.

- GB/T 24474.1-2020; Measurement of Ride Quality Part 1: Lifts (Elevators). National Standard of the People’s Republic of China: Beijing, China, 2020.

- Zhang, P. Research on Nonlinear Control of Lateral Vibration in High Speed Elevator Car System. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2022. [Google Scholar]

- GB/T22562-2008; Guide Rails for Lifts—T-Type. National Standard of the People’s Republic of China: Beijing, China, 2008.

- Fu, Y.; Qi, X. AMESim System Modeling and Simulation—From Beginner to Proficient; Beihang University Press: Beijing, China, 2006. [Google Scholar]

- Zhou, C. Design and Theory of Automotive Hydraulic Cylinder Shock Absorber; Peking University Press: Beijing, China, 2012. [Google Scholar]

- High-Speed Elevator Operation Test Report; Sicher Elevator Co., Ltd.: Huzhou, China, 2023.

- Gao, X.C. Research on Vibration Reduction Characteristics of High-Speed Elevator Guide Shoes Based on Passive Hydraulic Damping Control. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2022. [Google Scholar]

| Grade | Qualified | First Grade | Excellent |

|---|---|---|---|

| Acceleration (m/s2) | ≤0.20 | ≤0.10 | ≤0.07 |

| Signals Type | Pulse | Sine Wave 1 (2 Guide Rails/Cycle) | Sine Wave 2 (4 Guide Rails/Cycle) | Sine Wave 3 (6 Guide Rails/Cycle) | White Noise | |

|---|---|---|---|---|---|---|

| Characteristics | ||||||

| Frequency (Hz) | 1.6 | 0.8 | 0.4 | 0.267 | random | |

| Amplitudes (mm) | 2 | 2 | 2 | 2 | 0.75 | |

| Nomenclature | |||

|---|---|---|---|

| A0 | The flow area of the hydraulic damping hole (mm2) | m3 | Mass of cabin (value no-load 2000 kg, half load 2500 kg, and full load 3000 kg respectively) |

| A | Action area of hydraulic oil in the hydraulic actuator (mm2) | ∆P | Pressure difference between both sides of the hydraulic actuator piston (MPa) |

| Cq | Hydraulic flow coefficient (value 0.62) | q0 | Flow rate of damping hole (L/min) |

| Cr | Damping coefficient of the roller (value 920 N/(m/s)) | qs | Flow rate of hydraulic actuator (L/min) |

| Cs | Optimal damping coefficient | rk | Stiffness ratio of roller to the spring on guide shoes |

| d | Diameter of piston rod (value 22 mm) | rm | Mass ratio of cabin to roller |

| D | Diameter of piston (value 40 mm) | vs | Running speed of hydraulic actuator piston (m/s) |

| d0 | Diameter of hydraulic damping hole (mm) | ω0 | Natural frequency of the cabin under the action of spring on rolling guide shoes (rad/s) |

| F | Damping force (N) | ρ | Density of hydraulic oil (value 850 kg/m3) |

| kr | Stiffness coefficient of the roller (value 3 × 105 N/m) | ξ0 | Optimal damping ratio |

| ks | Stiffness coefficient of the spring on rolling guide shoes (value 7 × 104 N/m) | Xi | Input vibration displacement caused by uneven excitation of guide rail (mm) |

| m1 | Mass of guide roller (value 5 kg) | Xr | Displacement of the rocker arm at the center of the roller (mm) |

| m2 | Mass of piston in hydraulic cylinder (value 1 kg) | Xe | Displacement of guide shoe base and elevator cabin (mm) |

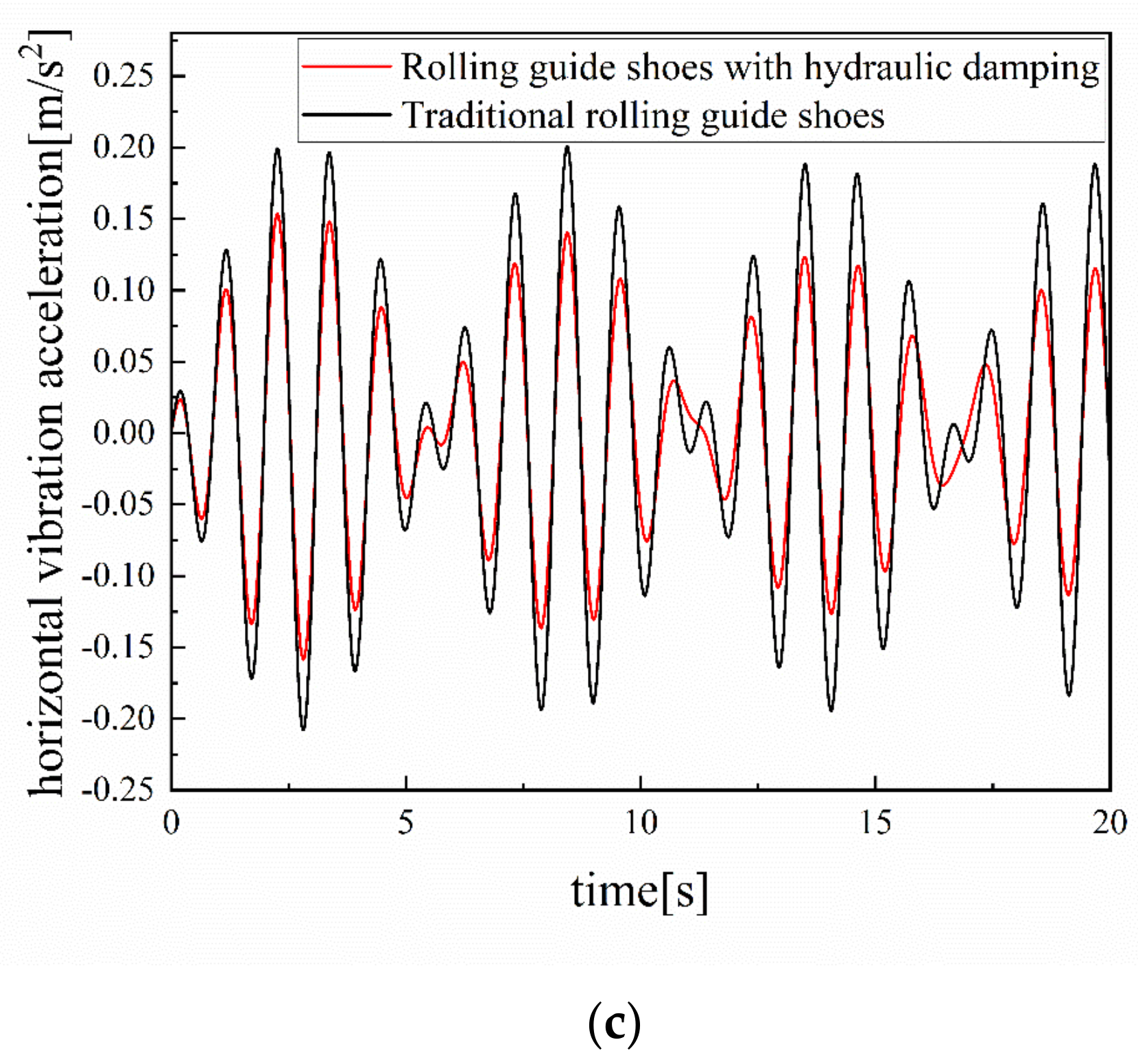

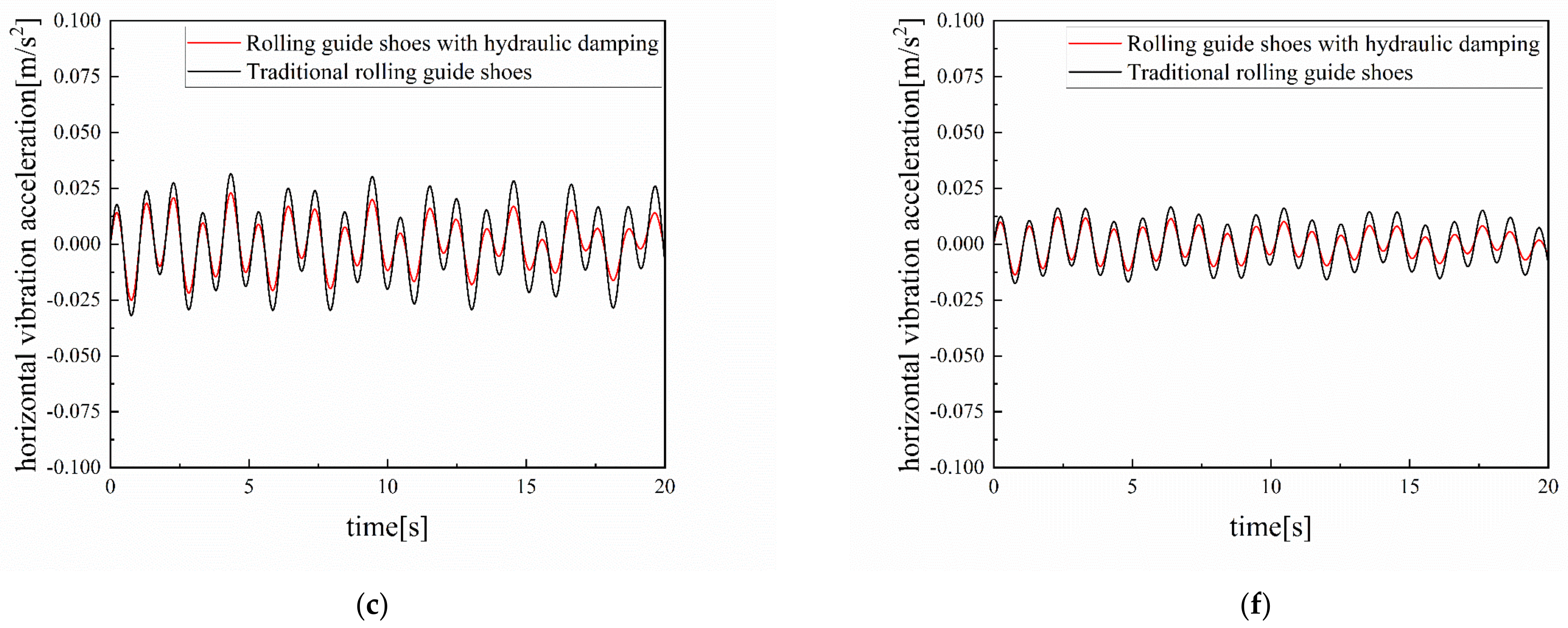

| Running Conditions | Sine Wave Excitation (0.8 Hz) | Sine Wave Excitation (0.4 Hz) | Sine Wave Excitation (0.267 Hz) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Horizontal Acceleration | 2000 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg | 3000 kg | |

| Rolling guide shoes with hydraulic damping (m/s2) | 0.105 | 0.125 | 0.158 | 0.0260 | 0.0262 | 0.0251 | 0.0154 | 0.0144 | 0.0137 | |

| Traditional rolling guide shoes (m/s2) | 0.135 | 0.162 | 0.208 | 0.0347 | 0.0334 | 0.0319 | 0.0197 | 0.0184 | 0.0175 | |

| Reduction amplitude | 22.2% | 22.8% | 24.1% | 25.1% | 21.6% | 21.3% | 21.2% | 21.7% | 21.7% | |

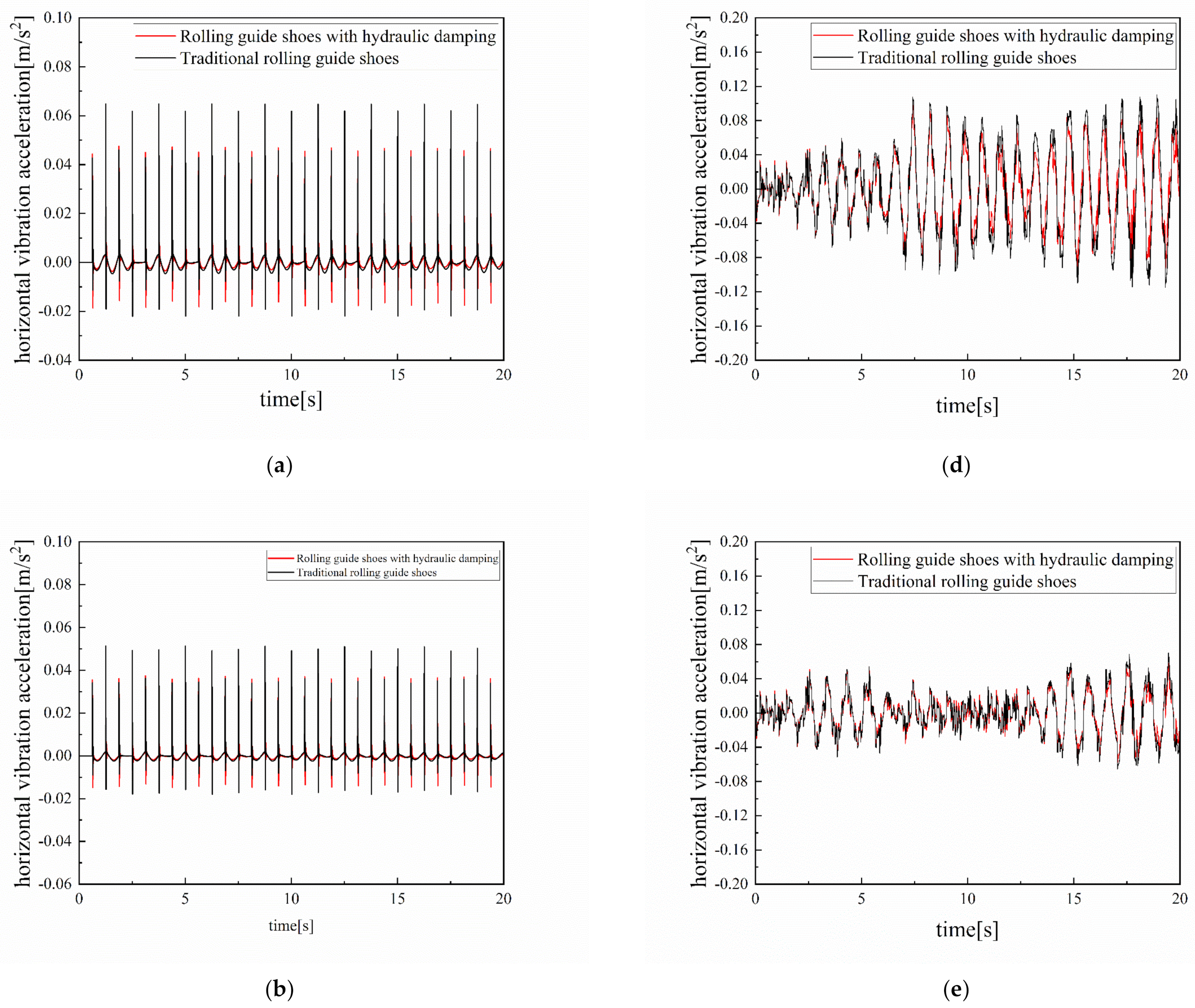

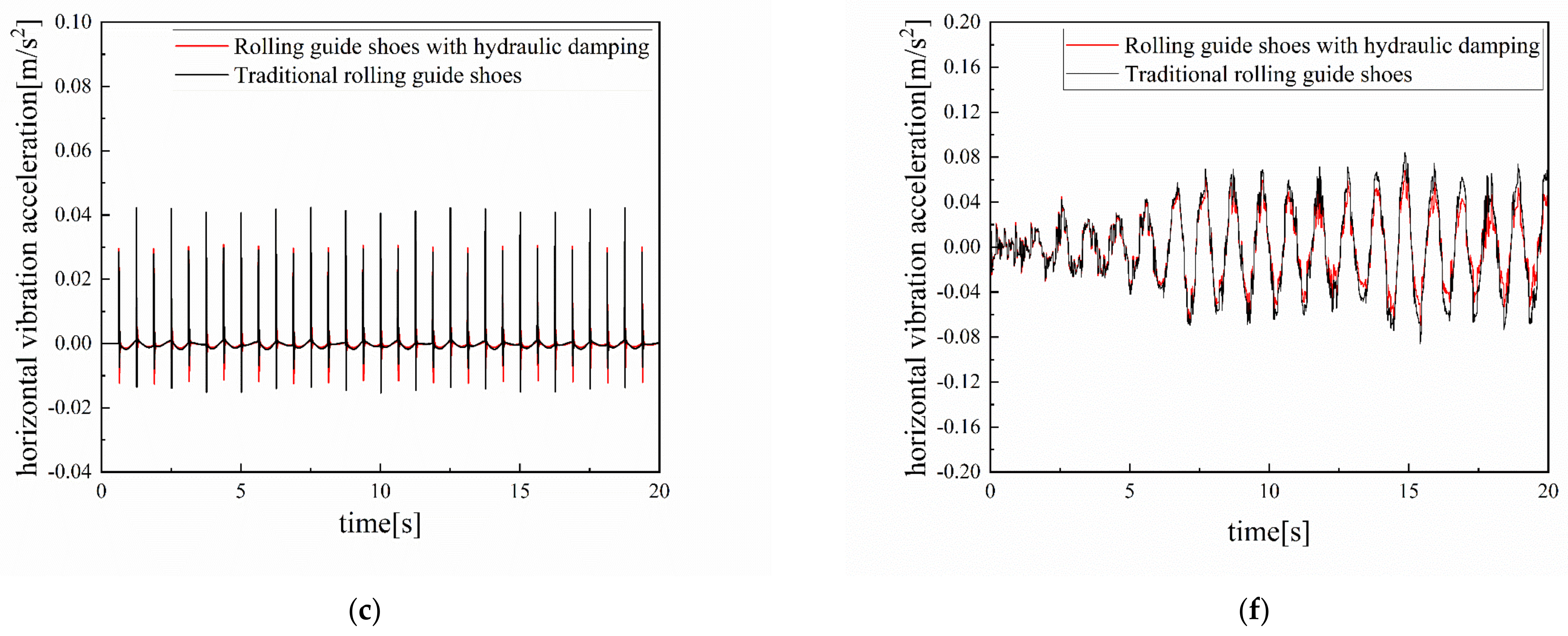

| Running Conditions | Pulse Excitation | Sine Wave Excitation (0.8 Hz) | White Noise Excitation | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Horizontal Acceleration | 2000 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg | 3000 kg | 2000 kg | 2500 kg | 3000 kg | |

| Rolling guide shoes with hydraulic damping (m/s2) | 0.048 | 0.037 | 0.031 | 0.105 | 0.125 | 0.158 | 0.098 | 0.060 | 0.068 | |

| Traditional rolling guide shoes (m/s2) | 0.065 | 0.051 | 0.042 | 0.135 | 0.162 | 0.208 | 0.115 | 0.070 | 0.082 | |

| Reduction amplitude | 26.2% | 27.5% | 26.2% | 22.2% | 22.8% | 24.1% | 14.7% | 14.3% | 17.1% | |

| Cost | Maintenance | Effectiveness | |

|---|---|---|---|

| Traditional passive-control rolling guide shoes | low | easy | Moderate |

| Passive-control rolling guide shoes with hydraulic damping | relatively low | relatively easy | Notable |

| Active-control rolling guide shoes | high | difficult | Significant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, D.; Wang, Q.; Zhan, J. Research on Vibration Reduction Characteristics of High-Speed Elevator with Rolling Guide Shoes Based on Hydraulic Damping Actuator. Actuators 2024, 13, 356. https://doi.org/10.3390/act13090356

Hu D, Wang Q, Zhan J. Research on Vibration Reduction Characteristics of High-Speed Elevator with Rolling Guide Shoes Based on Hydraulic Damping Actuator. Actuators. 2024; 13(9):356. https://doi.org/10.3390/act13090356

Chicago/Turabian StyleHu, Dongming, Qibing Wang, and Jianming Zhan. 2024. "Research on Vibration Reduction Characteristics of High-Speed Elevator with Rolling Guide Shoes Based on Hydraulic Damping Actuator" Actuators 13, no. 9: 356. https://doi.org/10.3390/act13090356

APA StyleHu, D., Wang, Q., & Zhan, J. (2024). Research on Vibration Reduction Characteristics of High-Speed Elevator with Rolling Guide Shoes Based on Hydraulic Damping Actuator. Actuators, 13(9), 356. https://doi.org/10.3390/act13090356