Abstract

This paper presents the design, construction, and implementation of a soft robotic system comprising a continuum manipulator arm equipped with a compliant gripper. Three main objectives were pursued: (1) developing a soft silicone gripper as an alternative to expensive and rigid steel grippers, enabling safe and precise handling of delicate or irregular objects such as fruits, glassware, and irregular shapes; (2) fabricating a continuum manipulator arm with robotic joints inspired by vertebrae, allowing for smooth, non-linear motion and more excellent maneuverability compared to traditional rigid arms, enabling access to hard-to-reach areas; and (3) integrating the compliant gripper with the continuum manipulator and implementing a control system for the soft gripper and remote bending arm using a microcontroller. The soft gripper, manipulator arm vertebrae, and other components were fabricated using 3D printing with PLA material for the molds. The gripper construct used hyperelastic silicone (Ecoflex 00.30). The continuum manipulator achieved a higher degree of freedom and mobility, while simulations and experiments validated the design’s effectiveness. The comparison shows that the close agreements differ by only 2.5%. In practical experiments involving lifting objects, the gripper was able to carry items with a greater mass. The proposed soft, integrated robotic system outperformed traditional rigid approaches, offering safe and flexible handling capabilities in unstructured environments. The nature-inspired design enabled a compliant grip and enhanced maneuverability, making it suitable for various applications requiring dexterous manipulation of delicate or irregularly shaped objects.

1. Introduction

The field of robotics stands at a pivotal juncture. Traditional robotic systems, characterized by rigid links and precise but inflexible motions, have revolutionized manufacturing and industrial automation [1]. However, as robots increasingly venture into unstructured, human-centric environments, the limitations of this rigid paradigm become apparent [2,3]. It can be mentioned that tasks such as assisting the elderly, handling delicate agricultural produce, or performing minimally invasive surgery demand not just precision but also adaptability, gentleness, and the ability to safely interact with objects and beings of varying fragility and geometry [4,5,6]. In some cases, peristaltic robots mimic the wave-like movements of worms and caterpillars, enabling them to navigate through tight and complex spaces. This makes them ideal for medical applications like minimally invasive surgeries and industrial tasks such as pipe inspections [7,8].

Majidi [1], in his seminal review “Soft Robotics: A Perspective”, argues that the next frontier in robotics lies in embracing softness and flexibility. He traces the roots of soft robotics to the field of soft matter physics. He highlights how materials like elastomers, gels, and fluids can endow robots with properties hitherto unseen in engineered systems, such as extreme compliance, high toughness, and the ability to change shape. Majidi’s research sets the stage for a paradigm shift, challenging the traditional dichotomy between the “soft” biological world and “hard” artificial systems. This challenge was further underscored by Shintake et al. [2] in their comprehensive survey of robotic grippers. They categorize grippers based on their actuation mechanisms and material properties, ranging from fully rigid to soft. Their analysis reveals a stark trade-off: while rigid grippers excel in precision and payload capacity, they struggle with irregularly shaped or delicate objects.

Conversely, soft grippers, often inspired by biological graspers like tentacles or elephant trunks, can conform to diverse shapes but typically sacrifice precision and strength. The potential of soft robotics in high-stakes, human-centric applications is vividly illustrated by Cianchetti et al. [4] in their review of soft robotics in minimally invasive surgery. They argue that the inherent compliance of soft robots could revolutionize procedures by reducing the risk of tissue damage, enabling access through tortuous paths, and allowing for more intuitive control. However, the transition from concept to implementation in soft robotics is fraught with challenges. Kim et al. [9] review the materials and fabrication techniques for soft robots, highlighting the complexities of working with hyperelastic materials like silicones. Issues such as non-linear stress–strain relationships, viscoelasticity, and the Mullins effect (stress softening) complicate the design and control of soft actuators.

Moreover, controlling soft robots presents unique challenges. Unlike rigid robots, where well-established techniques like inverse kinematics are used, soft robots require new control paradigms. As Della Santina et al. [10] discuss in their survey, techniques ranging from model-based approaches (using continuum mechanics) [11,12] to data-driven methods (like reinforcement learning) are being explored. Indeed, the concept of combining soft and rigid elements is gaining traction. Kapadia et al. [13] present a tendon-driven continuum robot with extensible sections, demonstrating how tensioned cables can provide precise control over a flexible structure. This robot mirrors the manipulator design, where 3D-printed vertebrae (inspired by the research of Yirmibesoglu et al. [14] on 3D-printed soft actuators) are interconnected by soft joints and controlled by tendons. This design achieves the hyper-redundancy seen in elephant trunks [15] while maintaining a degree of precision typically associated with rigid manipulators.

The soft gripper design draws inspiration from several sources [16,17]. Shintake et al. [18] demonstrate a soft pneumatic gelatin actuator, highlighting how even edible materials can create adaptive grippers, while using silicone rather than gelatin underscores the vast material palette available in soft robotics. The multi-fingered, pneumatically actuated design was more directly influenced by Galloway et al. [19], who show how such grippers can delicately handle varied agricultural produce. By controlling air pressure, it can modulate grip force to handle everything from easily bruised tomatoes to heavier ceramic objects [20].

A key innovation in our research is using finite element analysis (FEA) to predict and optimize the behavior of our soft components. As highlighted by Jiang et al. [21], FEA can capture the non-linear, large deformations characteristic of soft robots. By validating our FEA models against experimental data, we establish a powerful tool for rapid design iteration and performance prediction.

The integration of these subsystems—a compliant, pneumatic gripper and a tendon-driven continuum manipulator—results in a robotic system that challenges traditional categorizations [22,23]. It is neither entirely soft nor fully rigid but instead harnesses the benefits of both paradigms. This hybrid approach allows us to tackle tasks that are problematic for both traditional rigid robots (due to their lack of adaptability) and purely soft systems (due to limited precision and payload) [24,25]. Our research makes several critical contributions to the field:

- Material selection and fabrication: We demonstrate that readily available, low-cost materials like PLA (for structural components) and Ecoflex silicone (for soft actuators) can create high-performance robotic systems. Our use of FDM and SLA 3D printing showcases the versatility of additive manufacturing in this domain [14,26];

- Hybrid control strategies: By combining pneumatic actuation for the gripper with tendon-driven control for the manipulator, we strike a balance between the inherent compliance of pneumatics and the precision of motor-driven systems. This approach contributes to the ongoing discussion on control strategies for soft robots [10,27,28].

- Performance prediction and validation: Through a combination of FEA for soft components and kinematic simulations for the manipulator [29], we establish a framework for predicting and validating system performance. This model-driven approach accelerates design iterations and enhances reliability;

- Quantifying soft gripper performance: Our experiments with objects varying in size, shape, weight, and fragility provide valuable data on the relationship between object properties, pneumatic pressure, and grasping success. These contribute to the nascent field of soft gripper benchmarking [19,30];

- Integrated system design: By seamlessly combining a soft gripper with a hybrid rigid–soft manipulator, we demonstrate a new class of robotic systems that are neither entirely soft nor fully rigid. These challenge taxonomies [2,31] and open new avenues for application-specific robot designs.

In the following sections, we detail our design methodology, fabrication techniques, control strategies, and experimental results. We begin with the design and manufacture of individual components—the soft gripper fingers, the continuum manipulator vertebrae, and the control systems. We then describe the integration of these components into a cohesive system, followed by a series of experiments that validate both our components and the system as a whole.

Our conclusions reflect on the broader implications of this research for the field of robotics. We argue that the future of robotics, especially in domains requiring close human interaction or environmental adaptability, lies not in choosing between soft and rigid cases but in thoughtfully blending them. By combining the gentleness and conformability of soft materials with the precision and power of traditional engineering, we can create robotic systems that are safe, adaptable, and capable—true collaborative partners in our homes, hospitals, and workplaces.

2. Continuum Manipulator with Soft Gripper Motion Analysis

The soft robotic system integrates a continuum manipulator and a compliant pneumatic gripper, offering a versatile and adaptive solution for complex tasks. This system, inspired by biological organisms, combines the flexibility of the continuum manipulator with the precision of the compliant gripper. This section covers the comprehensive design and operation of the system, in addition to the detailed kinematic and kinetic modeling.

2.1. Design and Operation

2.1.1. Continuum Manipulator

The continuum manipulator is crafted using hyperelastic materials such as silicone, which are reinforced for flexibility and strength. It comprises multiple interconnected segments, each capable of independent motion, allowing for smooth bending and twisting with embedded pneumatic or tendon-driven actuation mechanisms. Segments include reinforcement elements to maintain structural integrity while allowing flexibility.

The continuum manipulator operates by adjusting the curvature of each segment to achieve the desired shape and position. Tendons running along the length of the manipulator are pulled by actuators, causing the segments to bend in the desired direction.

The actuation of the continuum manipulator is achieved through actuators pulling on tendons running along the manipulator, adjusting the curvature of each segment.

2.1.2. Compliant Gripper

As stated, the soft gripper is a novel robotic end-effector inspired by the grasping mechanisms of biological organisms, such as the tentacles of an octopus or the trunk of an elephant. The gripper is fabricated from a highly compliant, hyperelastic silicone material, which allows for significant deformation and conformability when interacting with objects of varying shapes and sizes. The fundamental principle behind the soft gripper’s operation is the pneumatic actuation of embedded air chambers within the silicone structure. When pressurized air supplies these chambers, it induces an elongation and expansion of the chamber walls, which in turn generates a mutually opposing momentum between adjacent chamber walls. This phenomenon, governed by the laws of continuum mechanics, results in an amplified elongation effect, enabling the gripper to achieve substantial deformations and conformability.

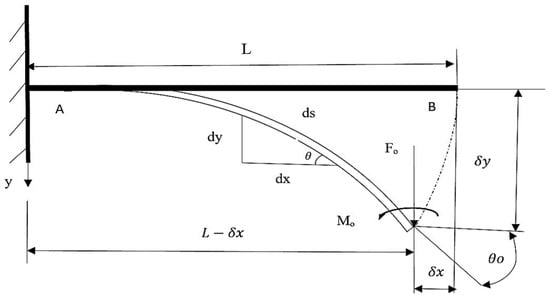

Moreover, the design of the soft gripper incorporates multiple finger-like protrusions, each containing a series of air chambers. As the chambers pressurize, the restriction of movement on one side of the finger caused by the gripper’s base leads to a downward curvature of the finger toward the restricted surface. This bending behavior is governed by the Euler–Bernoulli beam theory, which describes the relationship between the applied bending moment and the resulting deformation of a slender beam-like structure [32,33]. In a typical soft gripper configuration with three fingers, the pressurization of the air chambers induces a bending moment in each finger, causing it to curve inwards toward the center of the gripper’s base. This coordinated inward curvature facilitates the grasping and encompassing of target objects, enabling a secure and adaptive grip.

In summary, the soft robotic system with a continuum manipulator and compliant gripper is designed for versatile and adaptive manipulation, combining advanced material properties with sophisticated actuation mechanisms. Its design, performance, operation, and actuation mechanisms enable it to perform a wide range of tasks, from delicate object handling to complex navigational challenges.

2.2. Kinematic Model

The kinematics of the continuum manipulator are described using a series of parameters that define its shape and motion. These parameters include curvature, length, and bending angle. Each segment of the manipulator can be modeled as an arc with a specific radius of curvature. By adjusting the curvature and length of each segment, the overall shape and position of the manipulator can be controlled. The fundamental equations governing the kinematics of the continuum manipulator are derived from the principles of differential geometry.

where is the curvature, is the bending angle, and is the arc length along the manipulator. The position of a point along the manipulator () can be expressed in terms of as a tangent vector, and :

while . In this definition, and are the normal and binormal vectors, respectively [34,35].

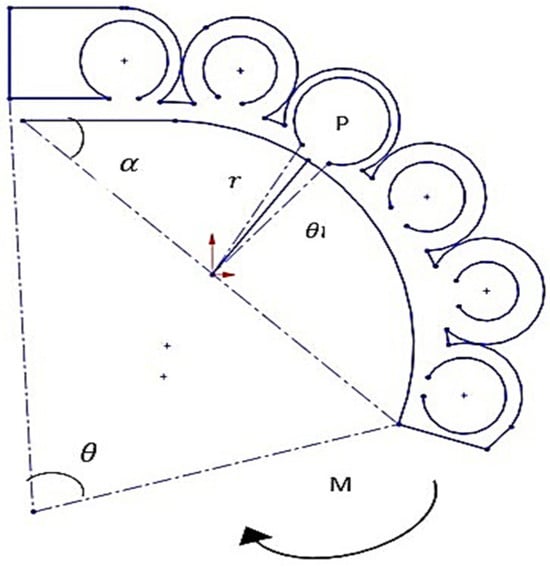

The soft gripper’s motion is characterized by the deformation of its flexible material, modeled using beam theory (Figure 1 and Figure 2). The finger curvature changes as a function of the applied pressure, which can be modeled using empirical or analytical relations. The position and orientation of the gripper’s tip (Figure 3) can be described in terms of the bending angle and the segment length :

Figure 1.

The bending angle of one finger.

Figure 2.

Cantilever beam formation under tip force.

Figure 3.

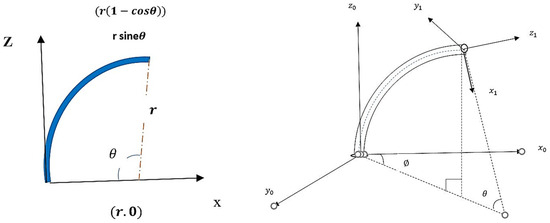

Kinematic model of the continuous manipulator at (Ø > 0). If the angle (θ) is zero, the arc is in the x and z plane; if the angle (Ø) is zero, rotate the arc out of the x–z plane.

The curvature express in terms of coordinates as

By discretizing Equation (4), the curved arc at the hinge forms the angle , and the total deformations of each finger are evaluated as

The figure above shows that the end effector has moved from the (, , ) axis to the (, , ) axis. It also rotated at an angle of () from the x-axis toward the y-axis, where is the rotation angle, and is the bending angle. The rotation matrix and transformation matrix for this motion are as follows:

The end effector operates within its own three-dimensional workspace. We can also obtain its position along the three axes (X, Y, Z) as follows:

where (, , ) represents the position vector along the three axes.

2.3. Dynamic Model

The dynamics of the continuum manipulator are derived from the principles of Lagrangian mechanics, considering the contributions of kinetic and potential energies. The manipulator’s material properties, such as elasticity and damping, are incorporated into the dynamic model to accurately predict its response to external forces and actuations.

The kinetic energy of the continuum manipulator segments is given by

where is the material density, is the cross-sectional area, and , , and are the velocities of points along the manipulator.

The potential energy consists of contributions from elastic deformation and gravitational forces:

where is the stiffness coefficient, is the mass distribution along the manipulator, is the gravitational acceleration, and is the vertical position.

The dynamic response of the soft gripper is governed by the pressure-induced forces and the material’s viscoelastic properties.

The kinetic energy is given by

where is the material density, and is the cross-sectional area.

The potential energy includes contributions from elastic deformation:

where is the stiffness coefficient, is the mass distribution along the manipulator, and is the vertical position.

The pressure-induced actuation forces are included as generalized forces in the equations of motion:

where is the internal pressure distribution.

2.4. Integration of Continuum Manipulator and Soft Gripper Model

In coupling kinematics, the end position and orientation of the continuum manipulator serve as the base for the soft gripper. The combined kinematic model accounts for the serial connection of the manipulator and the gripper, resulting in a unified description of the end effector’s position and orientation. Hence, the continuum manipulator is modeled as a series of infinitesimal segments, each with its own curvature. The gripper’s fingers are modeled using beam theory, with curvature induced by pneumatic actuation.

The combined kinematic model provides the position and orientation of the end effector (tip of the gripper) as a function of the curvatures and lengths of both the manipulator and the gripper.

The dynamic interactions between the continuum manipulator and the soft gripper are considered, including the transfer of forces and moments. As a result, the coupled dynamic model is derived by combining the Lagrangian formulations of both subsystems, leading to a comprehensive set of equations of motion.

The total Lagrangian LLL of the system is

Using the Euler–Lagrange equation for generalized coordinates ,

This results in a set of coupled differential equations that describe the motion of the entire system.

3. Experimental Setup and Methodology for Continuum Manipulator with Soft Gripper

In this section, we present the design and fabrication of our soft robotic system, focusing on the mechanical and electrical aspects. The system comprises a continuum manipulator and a compliant gripper, both pneumatically actuated. We provide detailed diagrams and explanations of the pneumatic system, power supply, and control panel.

3.1. Design Electrical and Mechanical Diagrams

The successful operation of our soft robotic system depends on the seamless integration of mechanical and electrical components. This section outlines the key design aspects through detailed diagrams and descriptions.

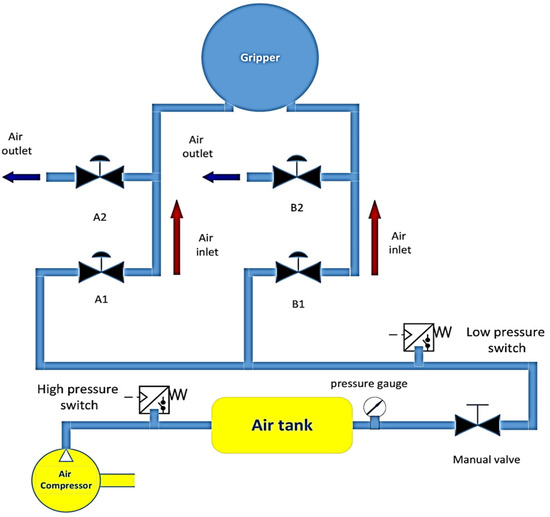

3.1.1. Mechanical Diagram of the Pneumatic System

Figure 4 illustrates the mechanical layout of our pneumatic system, which is crucial for actuating the compliant gripper. The diagram includes the following:

- Air compressor: Provides pressurized air;

- Air reservoir: Stores compressed air to maintain consistent pressure;

- Pressure regulator: Adjusts and maintains the desired air pressure;

- Solenoid valves: Control the airflow to individual pneumatic actuators;

- Pneumatic tubing: Transports pressurized air from the valves to the actuators;

- Continuum manipulator segments: Soft pneumatic chambers that enable bending and extension;

- Compliant gripper: Soft pneumatic fingers for grasping objects.

Figure 4.

Mechanical diagram of the pneumatic system.

The diagram also shows the connections between these components, highlighting the parallel arrangement of valves for independent control of each actuator.

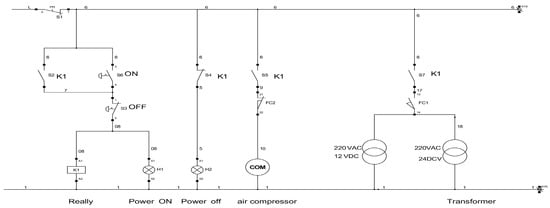

3.1.2. Electrical Diagram of the Power Supply

Figure 5 presents the electrical diagram of our power supply system. Key components include the following:

- AC power inlet: Connects to the mains electricity (110 V/220 V AC);

- Power switch: Turns the system on/off;

- Fuse: Protects against overcurrent;

- Transformer: Steps down AC voltage to a suitable level for our components;

- Bridge rectifier: Converts AC to DC;

- Voltage regulators: Provide stable DC voltages (e.g., 12 V for valves, 5 V for microcontroller);

- Capacitors: Filter and smooth the DC output;

- Power distribution bus: Distributes power to various components.

Figure 5.

Electrical diagram of the power supply.

The diagram emphasizes safety features like fuses and proper grounding, as well as the isolation between high-voltage AC and low-voltage DC circuits.

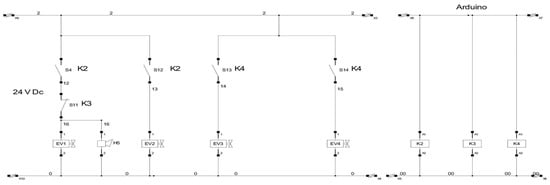

3.1.3. Electrical Diagram of the Pneumatic Control

Figure 6 shows the electrical connections for controlling the pneumatic system. Key elements are as follows:

- Microcontroller (e.g., Arduino): Processes control signals and manage valve timing;

- Pressure sensors: Monitor air pressure in the actuators for feedback control;

- Solenoid valve drivers: Amplify the microcontroller’s signals to switch the valves;

- Solenoid valves: Electrically controlled valves that direct air to the actuators;

- PWM (Pulse-Width Modulation) lines: Allow variable control of valve opening;

- Analog inputs: Read pressure sensor data;

- Digital I/O: Interface with additional sensors or indicators.

Figure 6.

Electrical diagram of the pneumatic.

This diagram highlights the closed-loop control system, where pressure feedback allows for precise and adaptive control of the soft actuators.

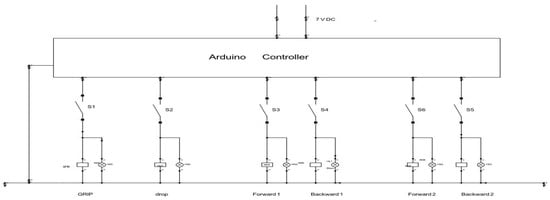

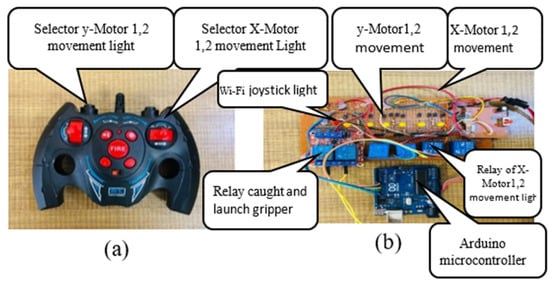

3.1.4. Electrical Diagram of the Control Panel

Figure 7 depicts the user interface for our soft robotic system. Components include the following:

- LCD display: Shows system status, pressure readings, and mode information;

- Rotary encoders: Allow manual adjustment of pressure or position setpoints;

- Pushbuttons: Select operation modes (e.g., manual, automated sequences);

- Joystick: Provides intuitive control of the continuum manipulator’s bending;

- Emergency stop button: Immediately depressurizes all actuators for safety;

- Status LEDs: Indicate power, valve states, and any error conditions;

- Communication interfaces: USB/Serial for programming and data logging.

Figure 7.

Electrical diagram of the pneumatic.

The control panel is designed for manual operation during experiments and development and for integration into automated routines for repeated tasks.

3.2. Design the Structure, Gripper Molds, and Manipulator Arm Parts

To ensure precision, reproducibility, and ease of assembly, we designed all structural and molding components using SolidWorks, a 3D CAD software. This section presents the key components and their design rationale.

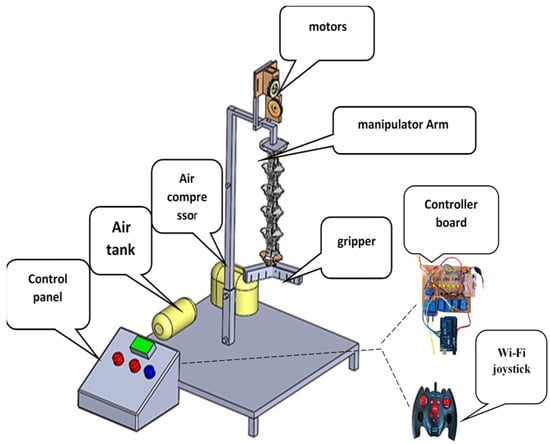

3.2.1. Overview of Designed Components

Figure 8 illustrates the complete workspace, integrating mechanical and electrical components:

- Metal structure: Forms the backbone, with provisions for mounting all subsystems;

- Manipulator arm stand: Elevates and orients the continuum arm;

- Gripper mount: Located at the manipulator’s end-effector;

- Tendon routing: Paths for strings actuating the manipulator;

- Motor mounts: Positions for tendon actuation motors;

- Control panel: User interface for system operation;

- Pneumatic components: Compressor, valves, and tubing, organized for easy access;

- Electrical enclosure: Houses power supply and control electronics.

Figure 8.

Schematic of continuum manipulator with soft gripper.

This integrated design minimizes footprint while ensuring all components are accessible for adjustment and maintenance.

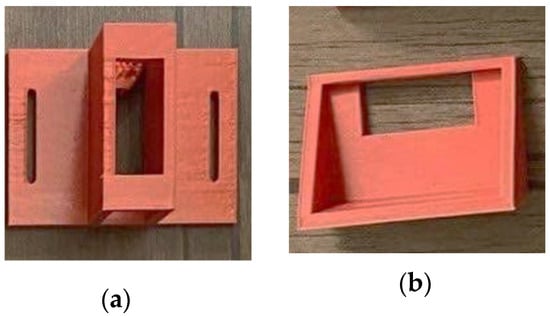

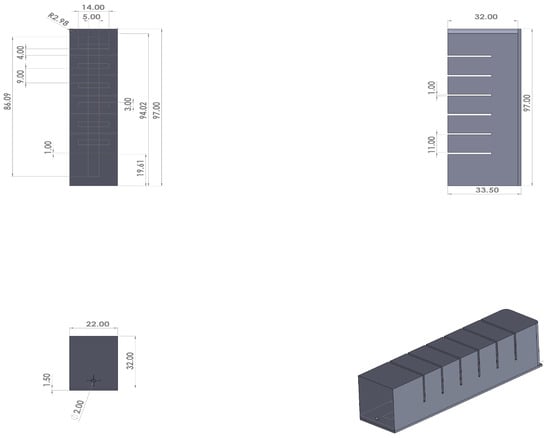

3.2.2. Single-Finger Casting Mold Design

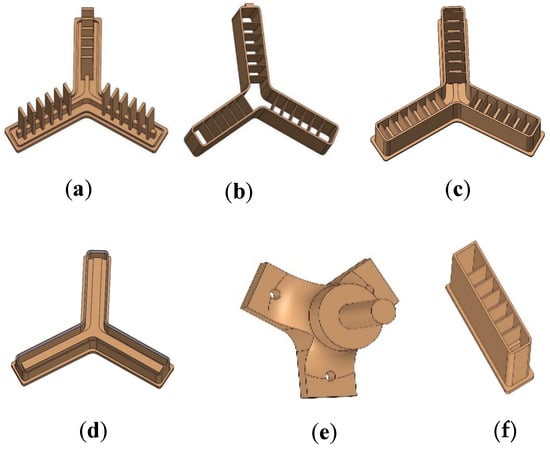

Figure 9 details the mold for a single soft gripper finger:

Figure 9.

The mold for a single soft gripper finger.

- (a)

- P1 bottom mold: Forms the lower part of the finger’s first segment;

- (b)

- P2 bottom mold: Creates the lower part of the second segment;

- (c)

- P1P2 assembly: Alignment of P1 and P2 for a seamless two-segment finger;

- (d)

- Upper mold: Forms the top of both segments, including pneumatic channels;

- (e)

- Gripper holder: Interfaces with the manipulator, securing all three fingers;

- (f)

- Single-finger casting mold design.

The two-part design (upper and lower) facilitates demolding while interlocking features ensure alignment during casting. The internal geometry is designed to create the desired bending behavior when pressurized.

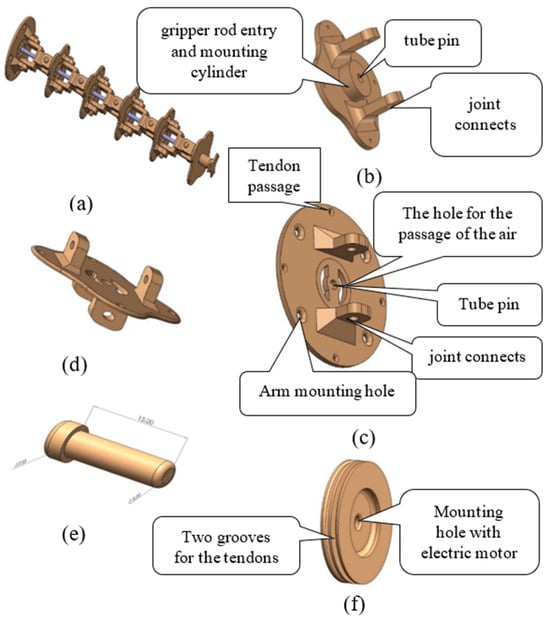

3.2.3. Continuum Manipulator Arm Components

Figure 10 showcases the vertebrae that form our continuum manipulator:

- (a)

- Vertebrae assembly: This shows how all vertebrae interlock to form the complete manipulator. The central holes align to form a conduit for pneumatic tubing or additional tendons;

- (b)

- End vertebra: A solid disc with two arms guiding tendons, which are connected to a part with a central hole. This interlocks with a hollow cylinder that secures the gripper rod.

- (c)

- Vertebra 1: Similar to the end vertebra but without the gripper mount. Its solid disc and two arms guide tendons to the next segment;

- (d)

- Vertebrae 2–5: The main body of the manipulator. Each is a solid disc with two tendon-guiding arms connected to a part with a central hole for interlocking;

- (e)

- Connecting pin;

- (f)

- Solid pulleys: There are two tracks in which for winding the strings.

Figure 10.

The mold for the continuum manipulator.

The design emphasizes the following:

- (a)

- Modularity: Each vertebra is identical except for the ends, simplifying manufacturing and assembly;

- (b)

- Tendon routing: Arms guide tendons along the manipulator’s length, minimizing friction;

- (c)

- Interlocking: Central holes allow vertebrae to connect securely while permitting flexure;

- (d)

- Customization: The number of vertebrae can be easily adjusted for different reach requirements.

In subsequent sections, we will discuss the fabrication processes for these components, including the 3D printing of molds and structural parts, the casting of soft pneumatic actuators, and the assembly and calibration of the complete soft robotic system. This modular, CAD-driven approach enables rapid prototyping and facilitates future processes. Similar molds fabricate for the second finger segment (P2) and the gripper base. Key features include the following:

- Material choice: Tough 2000 resin withstands the heat and pressure of silicone casting;

- Surface finish: Post-processing (sanding, polishing) ensures smooth finger surfaces;

- Alignment features: Pins and slots guarantee precise mold alignment;

- Venting: Small channels prevent air pockets in the cast silicone.

3.3. Fabricate Structure, Gripper Molds, and Manipulator Arm Parts

Following the design phase in SolidWorks, we proceeded to fabricate the structural components, molds for the soft gripper, and parts for the continuum manipulator. This section details our manufacturing processes, emphasizing precision, material selection, and assembly techniques.

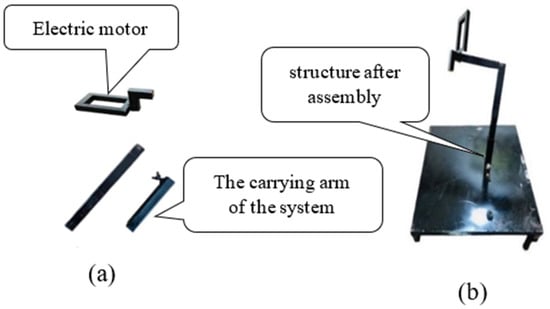

3.3.1. Fabrication of Metal Structure

The metal structure forms the backbone of our soft robotic system, providing stability and precise component placement. Figure 11 illustrates the fabrication process:

- (a)

- Manufacture of metal structure parts: Using the SolidWorks designs, we use CNC-machined aluminum alloy (6061-T6) for its high strength-to-weight ratio and corrosion resistance. Parts include the following:

- Base plate: Provides a stable foundation;

- Vertical supports: Elevate and orient the manipulator arm;

- Cross-members: Add rigidity and support for subsystems;

- Mounting brackets: For attaching motors, control panels, and pneumatics.

- (b)

- Assembling parts of the metal structure: Components were assembled using the following:

- Threaded fasteners (M5 bolts) for easy disassembly;

- Dowel pins for precise alignment;

- T-slot extrusions for adjustable component mounting.

Figure 11.

The fabrication of gripper molds.

The resulting structure offers a rigid yet reconfigurable platform critical for accurate manipulation tasks.

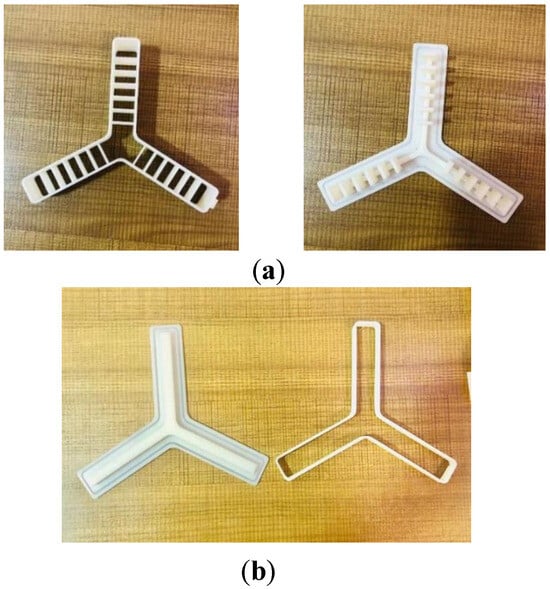

3.3.2. Fabrication of Gripper Molds

The soft gripper’s performance depends on the precision of its molding process. Figure 12 shows vital molding components:

- (a)

- Bottom casting mold for No. 1 mold: This mold forms the lower part of the first finger segment. It was 3D-printed using a high-resolution SLA printer (Form 3, Formlabs) with Tough 2000 resin for durability and detail;

- (b)

- Upper mold casting of No. 1 mold: Complementing the bottom mold, it forms the upper part of the first finger segment, including channels for pneumatic actuation. This is also 3D-printed using the same process.

Figure 12.

The fabrication of gripper molds.

3.3.3. Fabrication of Manipulator Arm Parts

Our continuum manipulator’s performance relies on the interplay of rigid vertebrae and soft pneumatic segments. Figure 13 details the fabrication of manipulator arm components:

- (a)

- Six arm vertebrae: 3D-printed using an FDM printer (Ultimaker S5) with PLA for its balance of strength and ease of printing. Each vertebra has the following:

- Two arms for tendon routing;

- A central hole for interlocking and pneumatic tubing.

- (b)

- Five joint connections: Flexible segments between vertebrae, cast from Ecoflex 00-30 silicone in 3D-printed molds. These allow omnidirectional bending;

- (c)

- Twenty connecting pins: Small PLA pins that interlock vertebrae and joint connections;

- (d)

- Assembly of parts: Vertebrae, joints, and pins are assembled in an alternating pattern to form the manipulator arm.

Figure 13.

The fabrication of gripper molds.

Figure 14 shows two pulleys for the motion motors:

- Material: Aluminum for low inertia and wear resistance;

- Features: Central bore interlocks with motor gears, secured by a set screw through a small hole;

- Function: One pulley for X-axis and one pulley for Z-axis motion to guide tendons.

Figure 14.

Two pulleys for the motion motors.

Figure 15 depicts motor mounting bases:

- (a)

- Base for Z-axis motor: CNC-milled aluminum, with slots for adjustable motor positioning;

- (b)

- Base for X-axis motor: Similar design, but it is oriented for X-axis tendon routing.

Figure 15.

Motor mounting bases.

Both bases have tapped holes for secure motor mounting and slots for attaching to the main structure.

3.3.4. Fabrication Summary

Our fabrication process leveraged several techniques:

- CNC machining: For high-precision metal parts (structure, motor mounts);

- Three-dimensional printing:

- SLA for detailed molds (gripper);

- FDM for structural parts (manipulator vertebrae).

- Silicone casting: For soft, flexible components (gripper fingers, manipulator joints);

- Assembly: Using mechanical fasteners, pins, and interlocking geometries.

This multi-material, multi-process approach allows us to tailor each component’s properties—rigidity, flexibility, and precision—to its specific role in the soft robotic system.

3.4. The Process of Pouring Silicone into Molds

One of the critical aspects of our soft robotic system is the fabrication of the compliant gripper. This section details the step-by-step process of casting silicone into the previously designed molds, ensuring high-quality, repeatable soft actuators.

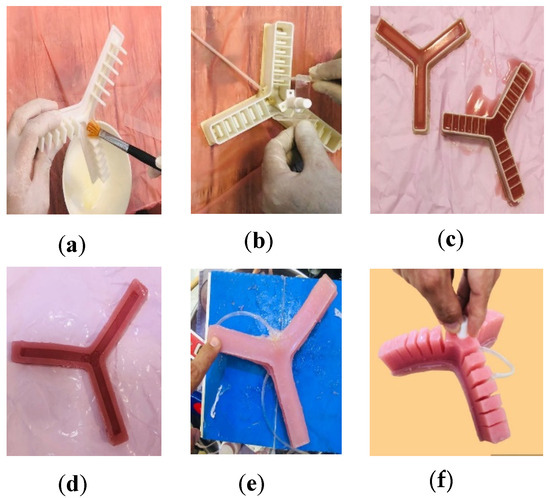

3.4.1. Casting the Soft Gripper Fingers

Figure 16 illustrates the comprehensive process of creating our soft pneumatic gripper.

Figure 16.

The comprehensive process of creating a soft pneumatic gripper.

- (a)

- Insulating the mold walls: To facilitate easy demolding, we applied a thin layer of mold-release agent (Mann Ease Release 200) to all mold surfaces. This step is crucial to prevent the silicone from bonding to the 3D-printed molds;

- (b)

- Assembling the mold: The bottom and top molds for each finger segment were carefully aligned using the built-in pins and slots. This process ensures that the pneumatic channels in the upper mold align perfectly with the finger geometry in the lower mold;

- (c)

- Pouring silicone: We used Ecoflex 00-30 silicone for its high flexibility and tear resistance. The two-part silicone was mixed in a 1:1 ratio, degassed in a vacuum chamber to remove air bubbles, and then poured slowly into the assembled mold through the provided inlet. The mold’s venting channels allow air to escape, preventing voids;

- (d)

- Gripper extraction: After curing at room temperature for 4 h (or 30 min at 60 °C for faster production), the molds carefully separate. The soft finger segment was gently removed, taking care not to tear the delicate pneumatic channels;

- (e)

- Assembling gripper parts: Two-finger segments bond using a thin layer of uncured Ecoflex, creating a seamless two-segment finger. Three fingers were then attached to the gripper base (also cast in silicone) to form the complete gripper;

- (f)

- Final gripper assembly: The completed three-fingered gripper showcases the effectiveness of our molding process. Each finger can bend independently when pressurized, allowing for adaptive grasping of various objects.

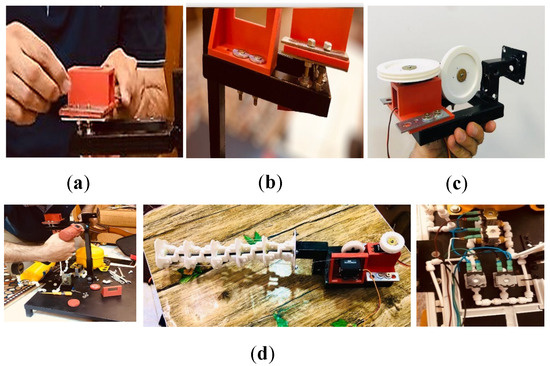

3.4.2. Assembling the Manipulator Actuation System

While the manipulator’s flexibility comes from its soft joints, precise control is achieved through tendon actuation. Figure 17 details the assembly of this system:

- (a)

- Mounting X-axis drive base: The CNC-machined aluminum base was bolted to the metal structure, with slotted holes allowing fine adjustment of the X-axis motor position;

- (b)

- Mounting Z-axis motor base: Similarly, the Z-axis motor base was mounted and oriented to guide tendons for vertical manipulator movement;

- (c)

- Motor and pulley installation: The high-torque stepper motors (NEMA 17) were secured to their respective bases. The custom aluminum pulleys were press-fit onto the motor shafts and locked with set screws, ensuring no slippage during operation;

- (d)

- Tendon routing: Dyneema fishing line (150 lb. test) was used for tendons due to its high strength and low stretch. The line was threaded through the manipulator’s vertebrae arms, over the pulleys, and finally secured to the motor shafts. Precise tendon length and tension are critical for accurate manipulator control.

Figure 17.

The manipulator actuation system.

This tendon-driven design allows our soft continuum manipulator to achieve complex, three-dimensional motions by varying the lengths of opposing tendons, much like the muscular hydrostat principle seen in octopus arms.

3.4.3. Integration of Soft and Rigid Components

The marriage of soft (gripper, manipulator joints) and rigid (vertebrae, motor mounts) components is a hallmark of our design. Key integration points include the following:

- Gripper–manipulator interface: The silicone gripper base interlocks with the end vertebra, allowing pneumatic and tendon lines to pass through;

- Vertebrae–joint connections: PLA pins lock vertebrae to soft silicone joints, balancing flexibility with the structure needed for tendon guidance;

- Tendon termination: Tendons are knotted and embedded in the end vertebra, distributing forces evenly across the manipulator;

- Pneumatic integration: Silicone tubes for gripper actuation are routed through the central channel of the manipulator vertebrae, exiting near the motor bases to connect with solenoid valves.

3.5. Assembly of Parts

After fabricating the mechanical components and soft actuators, we now focus on integrating the control systems, assembling the complete soft robotic system, and reviewing our manufacturing process. This holistic approach ensures that our system is mechanically sound but also responsive and adaptable.

3.5.1. Integration of Control Components

Effective control is paramount for the precise operation of our soft robotic system. Figure 18 illustrates key control components:

- (a)

- Remote control board (joystick): We incorporated a dual-axis joystick with additional buttons for intuitive control of the continuum manipulator. Features include the following:

- X-axis: Controls left-right bending of the manipulator;

- Y-axis: Manages forward–backward bending;

- Buttons: Activate gripper open/close functions and preset manipulator poses;

- Material: Durable ABS plastic housing for longevity;

- Interface: Connected to the Arduino via a shielded cable to minimize noise.

- (b)

- Arduino microcontroller board: At the heart of our control system is an Arduino Mega 2560, which was chosen for its ample I/O capabilities. Key aspects include the following:

- Fifty-four digital I/O pins: Sufficient for driving stepper motors, solenoid valves, and reading joystick inputs;

- Sixteen analog inputs: Used for pressure sensors in the gripper and manipulator joints;

- A 16 MHz clock: Provides adequate processing power for real-time control;

- EEPROM: Stores calibration data and preset manipulator configurations;

- USB interface: Facilitates easy programming and data logging.

Figure 18.

Integration of control components.

The integration of these components allows for a balance of manual control (via joystick) and automated sequences (programmed on the Arduino), which is essential for both experimental flexibility and repeatable task execution.

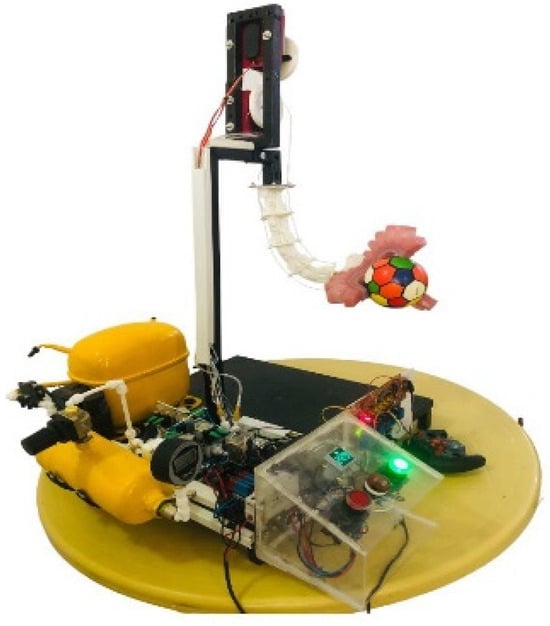

3.5.2. Final System Assembly

Figure 19 presents an image of the fully assembled soft robotic system. This image not only serves as a visual reference but also highlights the successful integration of all subsystems:

- Metal structure: Forms the rigid backbone, with all components securely mounted;

- Continuum manipulator: Vertebrae and soft joints create a flexible arm, with tendons visibly routed through guiding arms;

- Soft gripper: Mounted at the manipulator’s end, showcasing its three-fingered design;

- Motor mounts and pulleys: Positioned for optimal tendon routing, with stepper motors visible;

- Pneumatic components: Compressors, valves, and tubing are neatly organized for easy access and maintenance;

- Control panel: Houses the Arduino, power distribution, and user interface elements;

- Safety features: An emergency stop button and cable management are used to prevent entanglement.

Figure 19.

Final system assembly.

The image emphasizes the system’s modularity; each component can be accessed, replaced, or adjusted without disassembling the entire setup. This design philosophy supports ongoing development and easy troubleshooting.

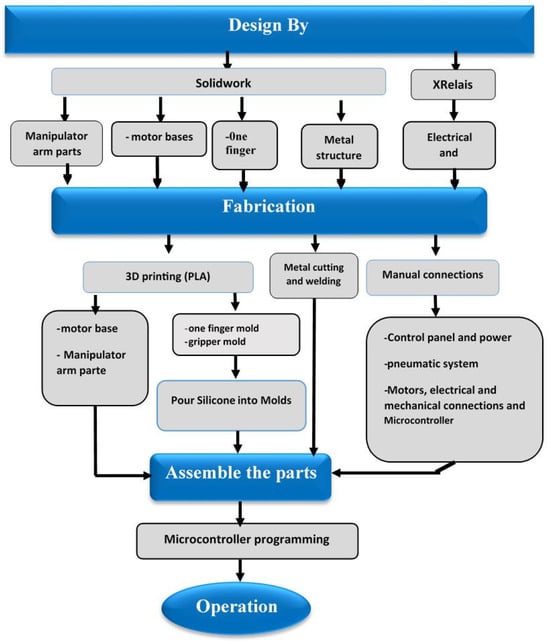

3.5.3. Manufacturing Process Overview

To encapsulate our multifaceted fabrication approach, Figure 20 presents a flowchart of the manufacturing process:

- Three-dimensional modeling (CAD):

- SolidWorks is used for all components: structure, molds, and vertebrae;

- The iterative design process is informed by simulations and preliminary tests.

- Rigid component fabrication:

- CNC machining: Aluminum parts (structure, motor mounts) for precision.

- Three-dimensional printing (FDM): PLA vertebrae and connectors;

- Three-dimensional printing (SLA): High-detail molds for soft components.

- Soft component fabrication:

- Mold preparation: Release agent application;

- Silicone mixing: Ecoflex 00-30 for gripper and joints;

- Casting: Pour silicone into molds and degas to remove bubbles;

- Curing: Room temperature or accelerated with heat;

- Demolding and assembly: Join gripper segments and attach them to the manipulator.

- Mechatronic integration:

- Motor and pulley assembly: Align and secure to mounts;

- Tendon routing: Thread through the vertebrae and over the pulleys;

- Pneumatic setup: Connect tubing, valves, and compressor;

- Sensor integration: Pressure sensors in gripper and joints.

- Control system assembly:

- Arduino setup: Mount and connect power;

- Peripheral connections: Joystick, valves, motors, and sensors;

- User interface: Assemble the control panel with display and buttons.

- Calibration and testing:

- Motor calibration: Steps-to-angle conversion for tendons;

- Pressure calibration: Map sensor readings to gripper force;

- Manipulator kinematics: Derive models for tendon lengths vs. pose;

- Functional tests: Verify all motions and fail-safes.

- Final assembly and validation:

- Component integration: Assemble all subsystems on the metal structure;

- Complete system tests: Run through a range of manipulation tasks;

- Performance metrics: Measure accuracy, repeatability, and grasp strength;

- Iterative refinement: Identify and address any shortcomings.

Figure 20.

Manufacturing process overview.

This flowchart not only guides our manufacturing but also serves as a valuable resource for others looking to replicate or adapt our soft robotic system. It underscores the interdisciplinary nature of our research, blending mechanical, electrical, and software engineering with materials science.

4. Validation and Operation of the Continuum Manipulator with Soft Gripper

After designing, fabricating, and assembling our soft robotic system, it is crucial to validate its performance. This section focuses on validating our compliant gripper, a critical component for delicate and adaptive manipulation tasks. We employ practical experiments and FEA simulations to understand and predict the gripper’s behavior under various pneumatic pressures.

4.1. Gripper Practical Experiments and Simulation by ANSYS Software

To ensure the reliability and predictability of our soft gripper, we conducted a series of experiments to measure its deformation under different pneumatic pressures. In parallel, we developed an FEA model using ANSYS software to simulate these deformations. This dual approach allows us to validate our simulation model and gain insights into the gripper’s behavior beyond what is easily measurable.

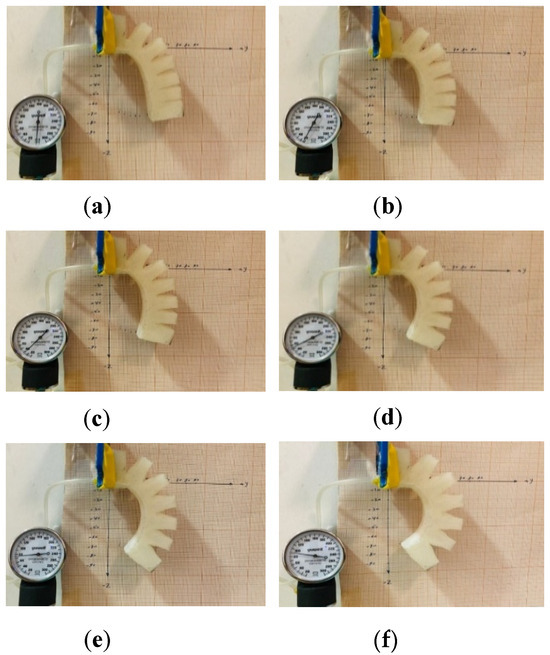

4.1.1. Practical Experiments

Figure 21 shows the experimental results of a single gripper finger’s deformation along the Y- and Z-axes (bending and extension) under increasing pneumatic pressures:

Figure 21.

Experimental results of single gripper finger’s deformation.

- (a)

- 0 kPa: The finger’s resting state, establishing the baseline for deformation measurements;

- (b)

- 3 kPa: Initial bending becomes visible, with a slight curl toward the finger’s inner channel;

- (c)

- 5 kPa: Bending increases, with the fingertip displacing notably in the negative Y direction;

- (d)

- 7 kPa: Significant bending achieved, which is suitable for grasping curved objects;

- (e)

- 10 kPa: Near-maximum bending, with the fingertip almost touching the base;

- (f)

- 12 kPa: Full actuation, showing the finger’s maximum range of motion.

These experiments reveal the following:

- Non-linear behavior: The bending rate increases with pressure due to the hyperelastic nature of the silicone;

- Anisotropic deformation: Designed channel geometry causes preferential bending (Y-axis) overextension (Z-axis);

- Repeatability: Multiple trials showed consistent deformation patterns, which is crucial for reliable grasping.

4.1.2. FEA Simulation Setup

To complement our experiments and predict behavior under varied conditions, we developed an FEA model in ANSYS 2022 R1. Key steps included the following

- Geometry import: The gripper finger’s CAD model, created in SolidWorks, was imported via STEP format;

- Material definition: Accurately modeling Ecoflex 00-30 silicone is crucial. We defined it as a hyperelastic material using the Yeoh model, which captures large, non-linear deformations. Properties include the following [36,37]:

- Density: 1.045 g/cm3;

- Yeoh third-order coefficients:

- ○

- C10 = 1.27 × 10−2;

- ○

- C20 = 4.23 × 10−4;

- ○

- C30 = −1.45 × 10−6.

The strain energy potential () is given by

where is the first stress invariant. This model captures the non-linear stress–strain behavior of Ecoflex.

- 3.

- Mesh and boundary conditions:

- Fine tetrahedral mesh to capture the finger’s complex internal channels;

- Fixed constraint at the finger base to mimic actual mounting;

- Pressure is applied to the internal surfaces of pneumatic channels.

4.1.3. Simulation Results and Validation

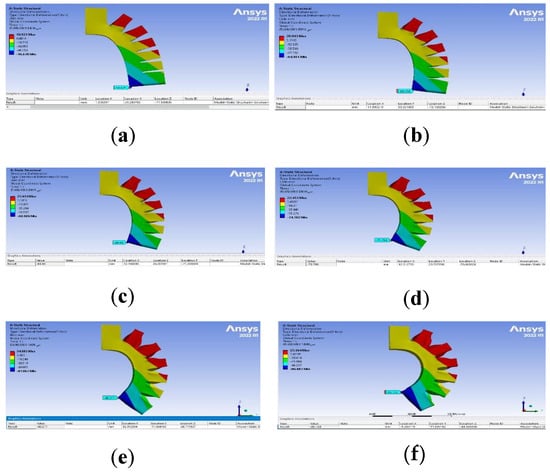

Figure 22 illustrates the multifaceted nature of the FEA:

Figure 22.

Multifaceted nature of the FEA.

- (a)

- Complete finger mesh;

- (b)

- Section view showing internal channels;

- (c)

- Deformation contour plot.

Figure 23 presents simulation results mirroring the experimental conditions:

Figure 23.

Simulation results mirroring the experimental conditions.

- (a)

- 0 kPa: Undeformed state, matching the physical finger;

- (b)

- 3 kPa: Slight bending, with deformation concentrated near the tip;

- (c)

- 5 kPa: Increased bending, closely matching experimental results;

- (d)

- 7 kPa: Substantial bending, with high strain regions visible;

- (e)

- 10 kPa: Near-maximum bending, validating the accuracy of our material model.

Key findings:

- Quantitative validation: Simulated displacements were within 8% of experimental values across all pressures, validating our FEA model;

- Stress distribution: Simulations revealed higher stresses near channel intersections, guiding future design iterations to enhance durability;

- Predictive power: With a validated model, we can now simulate gripper performance under conditions challenging to test experimentally, such as grasping irregular objects or under varied temperature conditions.

4.1.4. Discussion

The close agreement between experiments and simulations underscores the effectiveness of our design and material choices. The Yeoh hyperelastic model accurately captures the silicone’s behavior, a critical factor given the large deformations in soft robotics.

Moreover, this validation process provides several benefits:

- Design optimization: We can rapidly iterate finger designs in silico, minimizing the need for physical prototypes;

- Failure prediction: By identifying high-stress regions, we can reinforce critical areas or adjust actuation pressures to extend the gripper’s lifespan;

- Generalization: The validated modeling approach can be extended to our continuum manipulator, facilitating whole-system optimization.

4.2. Operation and Performance Testing

After validating individual components like the soft gripper, it is essential to evaluate the performance of the complete soft robotic system. This section details the operation of our system using the custom control interface and assesses its performance in handling various objects, demonstrating its adaptability and precision.

4.2.1. System Operation

We used a remote control (joystick) to operate the system, focusing on tasks that require a combination of reach, precision, and gentle handling. To quantify these aspects, we set up a target task: placing a ball into a basket at coordinates (200, 112, 245) mm along the X-, Y-, and Z-axes, respectively, relative to the manipulator’s base (0, 0, 0). The operational steps are as follows:

- Power-up and initialization:

- Pressing the power button activates the system, indicated by a green LED;

- This step energizes the microcontroller, motor drivers, and pneumatic valves.

- Object grasping:

- Place the target object (initially a ball) at the manipulator’s base (0, 0, 0);

- Press the “pickup” button on the joystick to initiate grasping;

- Valve A1 opens, pressurizing the upper chambers of the gripper fingers;

- Simultaneously, valve B2 opens to vent the lower chambers;

- An audible alarm and flashing red LED indicate the grasping process;

- A pressure regulator maintains a constant 30 kPa in the chambers, ensuring a secure but gentle grip.

- Manipulator control:

- Using the joystick’s rotary switches for actuators 1 and 2 (corresponding to X- and Z-axes), guide the manipulator;

- The controller coordinates stepper motor rotations to achieve smooth, three-dimensional motion along X-, Y-, and Z-axes;

- This step showcases the manipulator’s dexterity in navigating to the target (200, 112, 245) mm.

- Object release:

- Upon reaching the target, press the “release” button;

- Valve A2 opens to vent the upper finger chambers;

- Valve B1 pressurizes the lower chambers, actively extending the fingers;

- This controlled release ensures the ball is placed, not dropped, into the basket.

The operation demonstrates the synergy between soft (pneumatic gripper) and rigid (tendon-driven manipulator) elements, all orchestrated by our intuitive control system.

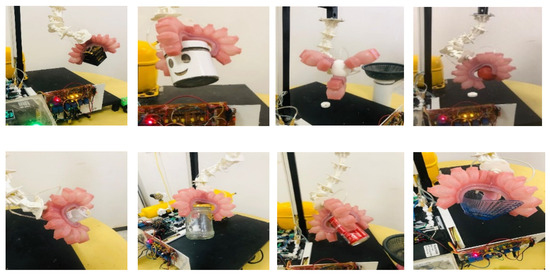

4.2.2. Grasping Performance

To assess the versatility of our soft gripper, we tested it with a variety of objects, as shown in Figure 24. These tests challenged the gripper’s adaptability, grip strength, and gentleness as the manipulator arm (505 g) lifted the maximum load.

Figure 24.

The test results with a variety of objects.

- Spherical objects:

- Ball (Ø 100 mm, 100 g): Successfully grasped and manipulated, validating the target task.

- Fragile objects:

- Chicken egg (60 g): Grasped and released without damage, showcasing the gripper’s delicacy;

- Tomato (100 g): Handled without bruising, demonstrating suitability for soft produce.

- Irregular shapes:

- Glass mug (150 g): Securely grasped despite non-uniform shape and fragility;

- Ceramic mug (slightly < 150 g): Easier to handle due to its more regular shape.

- Maximum payload test:

- Ceramic case (255 g): Heaviest item successfully manipulated;

- Total system capacity: 505 g (255 g payload + 250 g gripper mass).

- Shape variety:

- Additional tests with cylindrical and square objects (5–10 g) further validated the gripper’s morphological adaptability.

4.2.3. Discussion and Insights

- Adaptive grasping: The success with varied objects (spheres, cylinders, squares) validates our design goal of a universally adaptive gripper. The pneumatic actuation allows fingers to conform to object contours;

- Gentle manipulation: Handling eggs and tomatoes without damage is a significant achievement. It suggests that our system could be valuable in agricultural, food processing, or even healthcare applications where gentle touch is paramount;

- Payload capacity: A 505 g total capacity is impressive for a soft gripper. It suggests that our choice of Ecoflex 00-30 silicone and the internal channel design provide a good balance of compliance and strength;

- Control precision: Successfully placing objects (like the ball) at specific coordinates demonstrates the efficacy of our tendon-driven manipulator and intuitive joystick control;

- Human–robot interaction: Using visual (LEDs) and auditory (alarm) feedback during grasping makes the system more user-friendly, a crucial factor for collaborative robotics;

- Design validation: The gripper’s performance corroborates our earlier FEA simulations (Section 6.1). The ability to handle various objects without recalibration suggests that our models capture the essential behaviors of the soft materials;

- Future directions: While impressive, the current setup has room for improvement. Integrating force sensors could allow for even more delicate handling. Computer vision could enable automated object recognition and grasping strategy selection.

In conclusion, our soft robotic system demonstrates remarkable versatility, from the precise placement of objects to the gentle handling of fragile items. These results not only validate our design and fabrication processes but also highlight the potential of soft robotics in scenarios requiring both dexterity and delicacy.

5. Simulation Results and Analysis

In this section, we present and analyze the results of our experimental trials and computational simulations. Our focus is on validating the design and performance of the soft pneumatic gripper and the continuum manipulator. By comparing empirical data with FEA predictions and kinematic simulations, we not only demonstrate the efficacy of our system but also establish a foundation for model-based design in soft robotics.

5.1. Soft Gripper Performance: Deflection and Grasping Force

A critical aspect of our soft gripper’s performance is its ability to deform predictably under pneumatic actuation. This deformation directly influences its grasping capabilities. We conducted both physical experiments and FEA simulations to characterize this behavior.

5.1.1. Experimental Setup

We fabricated a single gripper finger from Ecoflex 00-30 silicone using the molds. The finger was mounted vertically, and its tip position was recorded using a high-resolution camera for various pneumatic pressures (0 to 30 kPa in 5 kPa increments).

5.1.2. FEA Simulation

In parallel, we simulated the finger’s deformation in ANSYS using the Yeoh hyperelastic model with parameters C₁₀ = 1.27 × 10−2, C₂₀ = 4.23 × 10−4, and C₃₀ = −1.45 × 10−6, as described. The model replicated the experimental conditions, including fixed base and applied pressures.

5.1.3. Deflection Results

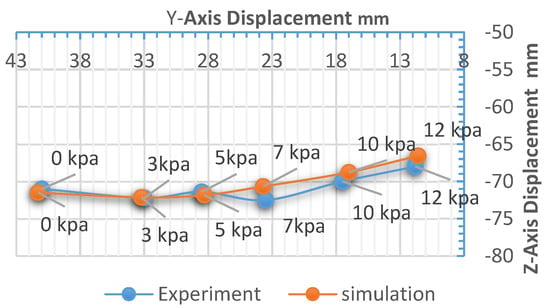

Figure 25 presents a comparison of the experimental and simulated finger deflections:

Figure 25.

Comparison of the experimental and simulated finger deflections.

Key observations:

- Non-linear deflection: Both curves show increasing deflection rates at higher pressures, which is characteristic of hyperelastic materials.

- Close agreement: The experimental and simulated results differ by only 2.5% in both Y (bending)- and Z (extension)-axes across all pressures.

- Bending dominance: The Y-axis deflection is significantly larger than the Z-axis, confirming our design intent for a curling, enveloping grasp.

The close match validates our FEA model and material characterization. It suggests we can reliably predict gripper behavior for various object sizes and required grasping forces, streamlining future designs.

To quantify the agreement between experimental and simulated results, we calculated the Root Mean Square Error (RMSE) and the coefficient of determination (R2) for both Y-axis (bending) and Z-axis (extension) deflections. The results indicate that for the Y-axis, RMSE = 0.73 mm, and R2 = 0.998; and for the Z-axis, RMSE = 0.31 mm, and R2 = 0.997. These values indicate a strong correlation between our experimental and simulated results, with less than a 3% average deviation across all pressure points.

5.1.4. Grasping Performance

Using the validated model, we estimated grasping forces and conducted trials with various objects:

- Fragile objects:

- Chicken egg (60 g): Grasped at 10 kPa without damage;

- Tomato (100 g): Held securely at 20 kPa without bruising.

- Irregular shapes:

- Glass mug (150 g): Stable grasp at 25 kPa;

- Ceramic mug (180 g): Held at 30 kPa.

- Maximum payload:

- Ceramic object: 255 g at 40 kPa;

- Total system capacity: 505 g (payload + 250 g gripper).

These results demonstrate our gripper’s wide operating range (10–40 kPa) and ability to adapt grasping force to object properties, which is a key advantage over rigid grippers.

5.1.5. Gripper Versatility: Object Diversity

To further characterize our gripper’s adaptability, we tested it with a wide range of objects. Table 1 summarizes these tests:

Table 1.

Types of loads the gripper handles with different shapes, weights, thicknesses, and thinnesses.

These results highlight several key capabilities:

- Pressure sensitivity: From 2 kPa for paper to 15 kPa for metal, showcasing fine force control;

- Morphological adaptation: Conforms to shapes from spherical to cubic without reconfiguration;

- Material invariance: Effectively grasps porous (sponge), rigid (metal), and brittle (glass) materials;

- Size range: Handles objects from a few grams to over 300 g, indicating utility across various tasks.

After comparing our gripper with the one described in reference [38], we observed that our design demonstrated greater versatility and strength. Our gripper successfully manipulated objects of various weights and shapes, with the heaviest being a ceramic container weighing 255 g. In contrast, the gripper in reference [38] had a maximum lifting capacity of 107 g, which was demonstrated by lifting a water-filled cup. This comparison reveals that our gripper achieved a lifting capacity more than twice that of the reference design, highlighting a significant improvement in performance (Table 2).

Table 2.

Comparisons of loads of the gripper handle with different shapes, weights, thicknesses, and thinnesses with Ref. [38].

5.1.6. Gripper Load Capacity

Through our experimental trials, we have quantified the maximum load capacity of our soft pneumatic gripper:

- Maximum load: The highest weight successfully lifted and manipulated by our gripper was a ceramic case weighing 255 g. This was achieved at a pneumatic pressure of 40 kPa;

- Total system capacity: Considering the weight of the gripper itself (250 g), the total system demonstrated a capacity of 505 g (255 g payload + 250 g gripper mass);

- Optimal load range: While the gripper successfully handled loads up to 255 g, we observed that the optimal performance, balancing grip security and object safety, was achieved in the range of 60–180 g. Within this range, the gripper demonstrated consistent performance across various object shapes and materials, requiring pressures between 10 and 30 kPa.

It is important to note that the maximum load capacity may vary depending on the object’s shape, material, and surface properties. For instance, while we successfully manipulated a 255 g ceramic case, a 180 g ceramic mug was handled with greater ease and stability due to its more graspable form factor.

5.1.7. Error Analysis of Grasping Performance

We conducted a series of 20 trials for each object type listed in Table 1 to assess the reliability and repeatability of our gripper’s performance. The success rate and standard deviation of applied pressure were calculated in Table 3.

Table 3.

Success rate and standard deviation of applied pressure of gripper handled.

These results demonstrate high repeatability for most objects, with slightly lower success rates for the heaviest (can) and most fragile (glass) items. The low standard deviations in applied pressure indicate consistent performance across trials.

5.2. Continuum Manipulator Performance

5.2.1. Workspace and Precision

Using the tendon-driven control system, we mapped the manipulator’s workspace:

- Reach: Maximum extension of 400 mm vertically (Z-axis) and 300 mm horizontally (X-axis).

- Bending angle: Up to 180° in any direction, allowing the gripper to face back toward the base.

- Placement precision: Within ±2 mm, tested by repeatedly placing the 100 g ball in the target basket at (200, 112, 245) mm.

5.2.2. Obstacle Avoidance

We introduced obstacles in the manipulator’s path to test its flexibility:

- Vertical pole: The manipulator curved around it without contact.

- Overhanging shelf: It dipped below and then up, showcasing actual 3D motion.

These tests highlight the manipulator’s ability to navigate cluttered spaces that would challenge traditional rigid-link robots.

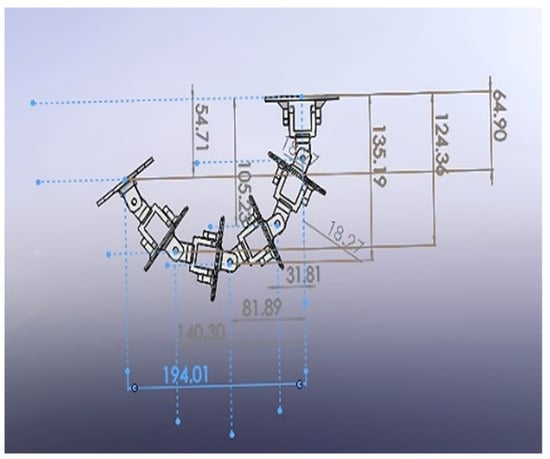

5.2.3. Continuum Manipulator Simulation by SolidWorks

To further understand and predict the manipulator’s behavior, we conducted kinematic simulations in SolidWorks. Figure 26 illustrates the simulated motion.

Figure 26.

The continuum manipulator simulation motion.

Key features of the simulation:

- Each vertebra (V1 through V6) is modeled as a rigid body;

- Joints between vertebrae were modeled as spherical, allowing omnidirectional bending;

- Tendons were simulated as distance constraints, shortening to induce bending.

Table 4 presents the simulated positions of each vertebra for three key manipulator configurations.

Table 4.

The position of movement of the manipulator vertebrae (in mm).

Insights from the simulation:

- Non-constant curvature: Unlike traditional models, our manipulator does not follow a constant curvature;

- Variable segment contribution: In the 45° bend, segments closer to the base (V2, V3) contribute more to the deflection, distributing strain;

- Workspace validation: Simulated positions align with our experimental reach, confirming the model’s accuracy.

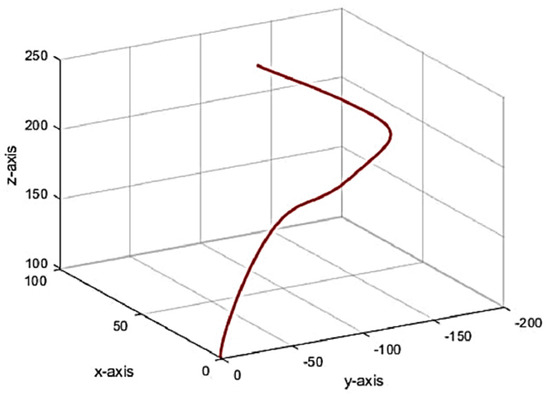

Figure 27 demonstrates the path tracked by the gripper.

Figure 27.

The continuum manipulator simulation motion.

5.3. Discussion

Our results validate several critical aspects of our soft robotic system:

- Predictive design: The gripper’s FEA and the manipulator’s kinematic models closely match experimental results, enabling model-driven design iterations;

- Unmatched adaptability: The gripper handles objects varying in weight by 70×, in size from millimeters to centimeters, and in rigidity from paper to metal, all without hardware changes;

- Bioinspired dexterity: The manipulator’s non-constant curvature and omnidirectional bending replicate the complex motions of biological limbs, promising unmatched adaptability in unstructured environments;

- Safety and delicacy: Handling eggs and paper structures underscores the system’s suitability for environments where traditional robots are too risky, like assisted living or surgical settings;

- Scalability: With validated models for both the gripper and manipulator, scaling this system for different payloads or workspaces becomes primarily a computational task.

However, challenges remain. The current payload limit and the reliance on open-loop pressure control for grasping suggest avenues for future research, such as the following:

- Variable stiffness materials to increase payload without sacrificing gentleness;

- Closed-loop force control using embedded tactile sensors;

- Learning algorithms to automatically select grasping pressures based on object properties.

In summary, these results demonstrate that our soft robotic system successfully marries the compliance and adaptability of biological systems with the precision required for practical robotic applications. The synergy of hyperelastic materials, pneumatic actuation, tendon-driven control, and predictive modeling opens new frontiers in robotics, blurring the line between the adaptability of life and the precision of machines. As we move forward, the insights gained here will guide us toward robots that do not just manipulate their environment but interact with it in fundamentally more harmonious ways.

6. Conclusions and Future Research

In this paper, we embarked on a journey to bridge the gap between the adaptability of biological systems and the precision of traditional robotics. We focused on developing a soft robotic system that combines a continuum manipulator with a compliant gripper, aiming to achieve both dexterous manipulation and gentle interaction with a wide range of objects. This endeavor traversed the realms of materials science, mechanical design, pneumatic actuation, tendon-driven control, and empirical validation.

We began by identifying the limitations of conventional rigid robotic systems, particularly in tasks requiring adaptability to unstructured environments or interaction with delicate objects. Inspired by octopus tentacles and elephant trunks, we turned to soft robotics as a promising solution. The challenge was to create a system that not only mimics the compliance and adaptability of these natural systems but also maintains the precision and controllability expected in robotic applications.

Our journey through this paper reflects the multifaceted approach required to meet this challenge:

- We delved into the design phase, using SolidWorks to craft every component, from the gripper’s pneumatic chambers to the manipulator’s vertebrae. This digital-first approach allowed for rapid iteration and optimization;

- In fabrication, we explored the capabilities of hyperelastic materials like Ecoflex 00-30 silicone. Through a combination of 3D-printed molds and careful casting techniques, we created soft pneumatic actuators that form the heart of our adaptive gripper;

- The integration of these soft components with more traditional elements—a tendon-driven continuum manipulator, stepper motors, and a structured control interface—marked a pivotal phase. This hybrid approach aimed to harness the strengths of both soft and rigid paradigms;

- Validation was crucial to our scientific approach. We employed finite element analysis (FEA) to predict the behavior of our soft components under varying pneumatic pressures. The strong correlation between these simulations and our physical experiments not only validated our models but also provided insights for future designs;

- Finally, we put our system to the test with a series of manipulation tasks. From the precise placement of objects to the gentle handling of fragile items like eggs and tomatoes, our experiments demonstrated the system’s versatility and finesse.

As we conclude this paper, we find ourselves at an exciting juncture. Our research has not only resulted in a functional soft robotic system but has also opened myriad avenues for future research and development. The following sections will crystallize our key findings and chart the course for the next wave of advancements in this burgeoning field.

6.1. Conclusions: Soft Robotics for Adaptive and Gentle Manipulation

Our research in designing, fabricating, and implementing a soft robotic system with a continuum manipulator and compliant gripper has yielded several key insights:

- Material selection for soft robotics: We demonstrated that highly elastic materials like Ecoflex 00-30 silicone can effectively create flexible, pneumatically actuated components. This material choice enables low-cost manufacturing of soft grippers capable of adapting to various object geometries;

- Gentle and versatile manipulation: Our gripper successfully manipulated various objects, from fragile items like eggs and tomatoes to irregularly shaped objects like mugs, without damage. This versatility stems from the gripper’s ability to conform to object contours, distributing forces evenly;

- Tunable grasping force: We found that grasping force depends on object material, weight, and rigidity. By controlling air pressure in the gripper’s chambers, we can modulate the grasping force, making our system adaptable to a wide range of objects. This tunability is a significant advantage over rigid grippers;

- Efficacy of multi-fingered design: The three-fingered design proved highly effective for grasping spherical, cylindrical, and asymmetric objects. This configuration provides robust, enveloping grasps, enhancing stability and adaptability;

- Tendon-driven continuum manipulation: Our tendon-driven approach to continuum manipulator control offers advantages in payload capacity and precision. We successfully manipulated objects up to 255 g (505 g, including gripper mass) with millimeter-level placement accuracy;

- Hyperredundant manipulation: The continuum manipulator, with its theoretically infinite degrees of freedom, demonstrated superior workspace coverage and obstacle avoidance compared to traditional rigid-link manipulators. This flexibility is crucial in cluttered or human-centric environments;

- Integrated design and validation: The close agreement between our FEA simulations and experimental results validates our modeling approach. This enables rapid design iterations and predictive performance analysis, accelerating the development cycle.

In summary, our research demonstrates that by thoughtfully combining soft materials, pneumatic actuation, and tendon-driven control, we can create robotic systems that are inherently safe, highly adaptable, and surprisingly precise. This paradigm opens new possibilities in fields ranging from minimally invasive surgery to assistive robotics.

6.2. Future Research: Toward More Capable and Ubiquitous Soft Robots

While our current system demonstrates the potential of soft robotics for adaptive manipulation, several avenues for improvement and expansion exist:

- Enhanced payload capacity: By exploring stiffer silicone formulations (e.g., Ecoflex 00-50) and variable pneumatic pressures, we aim to increase the gripper’s payload beyond 2 kg. This would broaden the application domains to include heavier industrial or domestic objects;

- Modular continuum manipulator: Future designs could segment the manipulator into two or three independently controlled sections. This would enhance dexterity, allowing more complex maneuvers like reaching around obstacles or self-reconfiguration for compact storage;

- Hybrid soft–rigid design: Integrating rigid components (e.g., aluminum vertebrae or reinforced tendons) could improve load-bearing capacity and precision without sacrificing the benefits of a soft exterior. High-torque motors could further increase payload while maintaining smooth motion control;

- Advanced sensing and control: Incorporating distributed tactile sensors, force/torque sensors, and vision systems would enable the following:

- Closed-loop force control for more delicate manipulation;

- Visual serving for automated object recognition and grasping;

- Proprioceptive sensing to estimate manipulator shape for model-based control.

- Learning-based control: Employing machine learning algorithms (e.g., reinforcement learning) could allow the system to adapt to varying object properties and task constraints autonomously, reducing the need for manual tuning;

- Human–robot interaction (HRI): Expanding our intuitive joystick control to include haptic feedback or gesture recognition could make the system more accessible to non-expert users, which is crucial for assistive or collaborative applications;

- Durability and field testing: Long-term studies on material fatigue, especially in the pneumatic chambers and high-stress points identified by FEA, are needed. Additionally, field trials in targeted environments (e.g., agri-food processing, elderly care) would validate the system’s real-world efficacy;

- Toward soft robotic ecosystems: Integrating our soft manipulator with other soft systems (e.g., mobile bases, wearable interfaces) could lead to entirely new paradigms in robotics, where adaptability and safety are inherent at every level;

- Expanded sample sizes for all experiments to increase statistical power;

- Analysis of variance (ANOVA) to examine the effects of different factors (e.g., object properties, pressure) on grasping performance;

- Development of predictive models for grasping success based on object and gripper parameters;

- Rigorous uncertainty quantification for all measured and derived quantities.

In conclusion, this paper is more than a description of a novel robotic system; it is a testament to the potential of interdisciplinary, bio-inspired engineering. As we stand on the cusp of a new era in robotics, we hope that this research contributes to a future where robots seamlessly integrate into human environments, assisting and interacting with a gentleness and adaptability hitherto unseen. The path forward is clear. By continuing to blend the compliance of soft materials with the precision of modern control, we can create robotic systems that are not just tools but collaborative partners in our daily lives.

Author Contributions

Conceptualization, S.F.D.; Methodology, S.F.D.; Software, S.Q.F.; Validation, S.F.D.; Formal analysis, S.Q.F.; Investigation, S.F.D.; Resources, S.Q.F.; Data curation, S.Q.F.; Writing—original draft, S.Q.F. and S.F.D.; Writing—review & editing, S.F.D.; Visualization, S.F.D.; Supervision, S.F.D.; Project administration, S.F.D.; Funding acquisition, S.F.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Council of Shahid Chamran University of Ahvaz (grant no. SCU.EM1402.72111).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

S.F. Dehkordi is grateful to the Research Council of Shahid Chamran University of Ahvaz for its financial support (grant no. SCU.EM1402.72111).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Majidi, C. Soft Robotics: A Perspective—Current Trends and Prospects for the Future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft Robotics: Technologies and Systems Pushing the Boundaries of Robot Abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef] [PubMed]

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical Applications of Soft Robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, Fabrication and Control of Soft Robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Bao, G.; Fang, H.; Chen, L.; Wan, Y.; Xu, F.; Yang, Q.; Zhang, L. Soft Robotics: Academic Insights and Perspectives Through Bibliometric Analysis. Soft Robot. 2018, 5, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Nabae, H.; Funabora, Y.; Suzumori, K. Controlling a Peristaltic Robot Inspired by Inchworms. Biomim. Intell. Robot. 2024, 4, 100146. [Google Scholar] [CrossRef]

- Peng, Y.; Nabae, H.; Funabora, Y.; Suzumori, K. Peristaltic Transporting Device Inspired by Large Intestine Structure. Sens. Actuators A Phys. 2024, 365, 114840. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft Robotics: A Bioinspired Evolution in Robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Della Santina, C.; Piazza, C.; Gasparri, G.M.; Bonilla, M.; Catalano, M.G.; Grioli, G.; Garabini, M.; Bicchi, A. The Quest for Natural Machine Motion: An Open Platform to Fast-Prototyping Articulated Soft Robots. IEEE Robot. Autom. Mag. 2017, 24, 48–56. [Google Scholar] [CrossRef]

- Bamdad, M.; Bahri, M.M. Kinematics and Manipulability Analysis of a Highly Articulated Soft Robotic Manipulator. Robotica 2019, 37, 868–882. [Google Scholar] [CrossRef]

- Dou, W.; Zhong, G.; Cao, J.; Shi, Z.; Peng, B.; Jiang, L. Soft Robotic Manipulators: Designs, Actuation, Stiffness Tuning, and Sensing. Adv. Mater. Technol. 2021, 6, 2100018. [Google Scholar] [CrossRef]

- Kapadia, A.D.; Walker, I.D.; Dawson, D.M.; Tatlicioglu, E. A Model-Based Sliding Mode Controller for Extensible Continuum Robots. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; pp. 1–3. [Google Scholar]

- Yirmibesoglu, O.D.; Morrow, J.; Walker, S.; Gosrich, W.; Canizares, R.; Kim, H.; Daalkhaijav, U.; Fleming, C.; Branyan, C.; Menguc, Y. Direct 3D Printing of Silicone Elastomer Soft Robots and Their Performance Comparison with Molded Counterparts. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 295–302. [Google Scholar]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Zaidi, S.; Maselli, M.; Laschi, C.; Cianchetti, M. Actuation Technologies for Soft Robot Grippers and Manipulators: A Review. Curr. Robot. Rep. 2021, 2, 355–369. [Google Scholar] [CrossRef]

- Sun, J.; Chen, C.; Wang, L.; Liang, Y.; Chen, G.; Xu, M.; Xi, R.; Shao, H. Design and Simulation Experiment of Rigid-Flexible Soft Humanoid Finger. Machines 2022, 10, 448. [Google Scholar] [CrossRef]

- Shintake, J.; Sonar, H.; Piskarev, E.; Paik, J.; Floreano, D. Soft Pneumatic Gelatin Actuator for Edible Robotics. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6221–6226. [Google Scholar]

- Galloway, K.C.; Becker, K.P.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R.J.; Gruber, D.F. Soft Robotic Grippers for Biological Sampling on Deep Reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Fatahillah, M.; Oh, N.; Rodrigue, H. A Novel Soft Bending Actuator Using Combined Positive and Negative Pressures. Front. Bioeng. Biotechnol. 2020, 8, 472. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Chen, D.; Liu, P.; Jiao, X.; Ping, Z.; Xu, Z.; Li, J.; Xu, Y. Fishbone-Inspired Soft Robotic Glove for Hand Rehabilitation with Multi-Degrees-of-Freedom. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 394–399. [Google Scholar]

- Mishra, A.K.; Del Dottore, E.; Sadeghi, A.; Mondini, A.; Mazzolai, B. SIMBA: Tendon-Driven Modular Continuum Arm with Soft Reconfigurable Gripper. Front. Robot. AI 2017, 4, 4. [Google Scholar] [CrossRef]