A Novel Control Method for Permanent Magnet Synchronous Linear Motor Based on Model Predictive Control and Extended State Observer

Abstract

1. Introduction

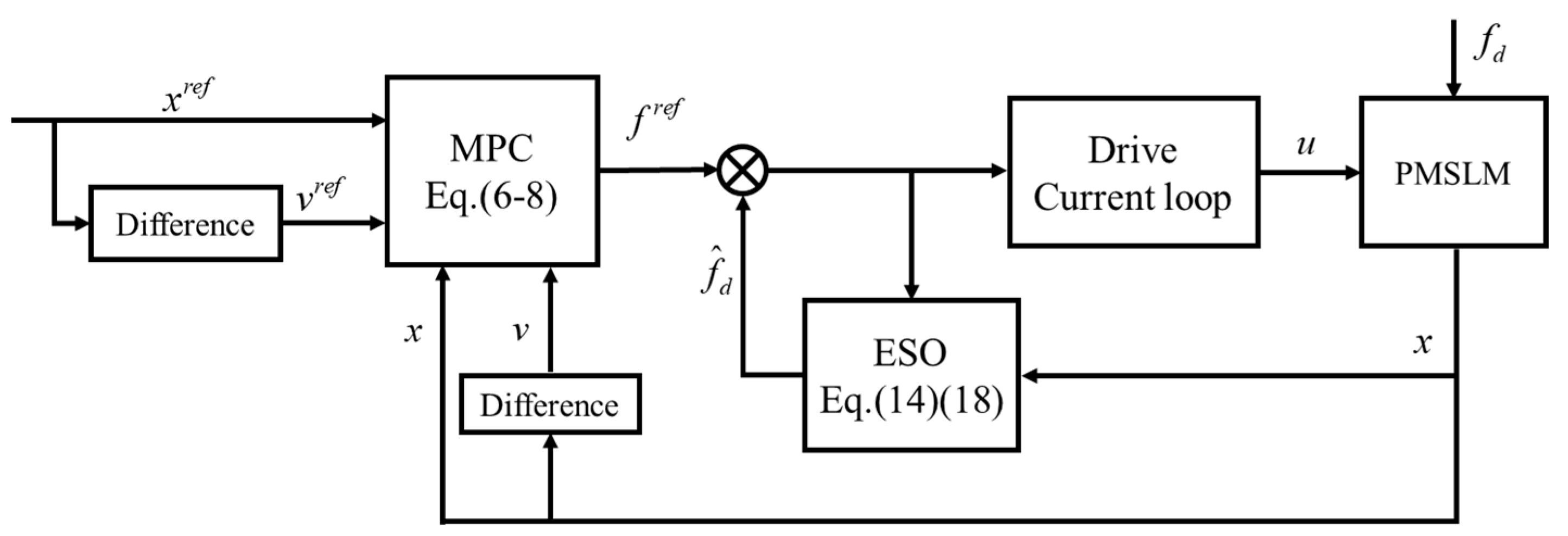

2. Model Predictive Control

2.1. Linear Motor State Equation

2.2. Design of the MPC

2.3. Stability Analysis of the MPC

3. Extended State Observer

3.1. Construction of ESO

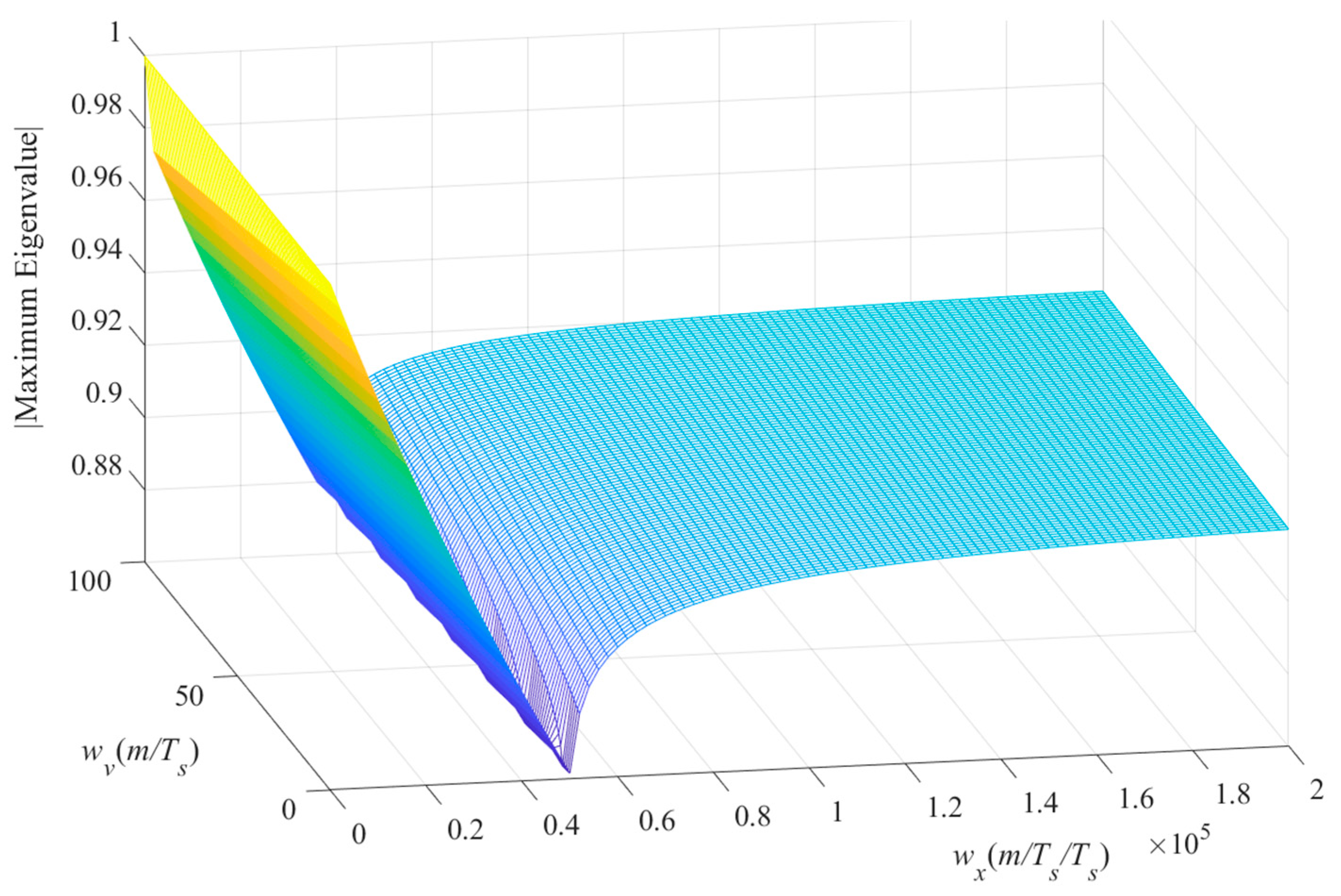

3.2. Gains Tuning and Stability Analysis

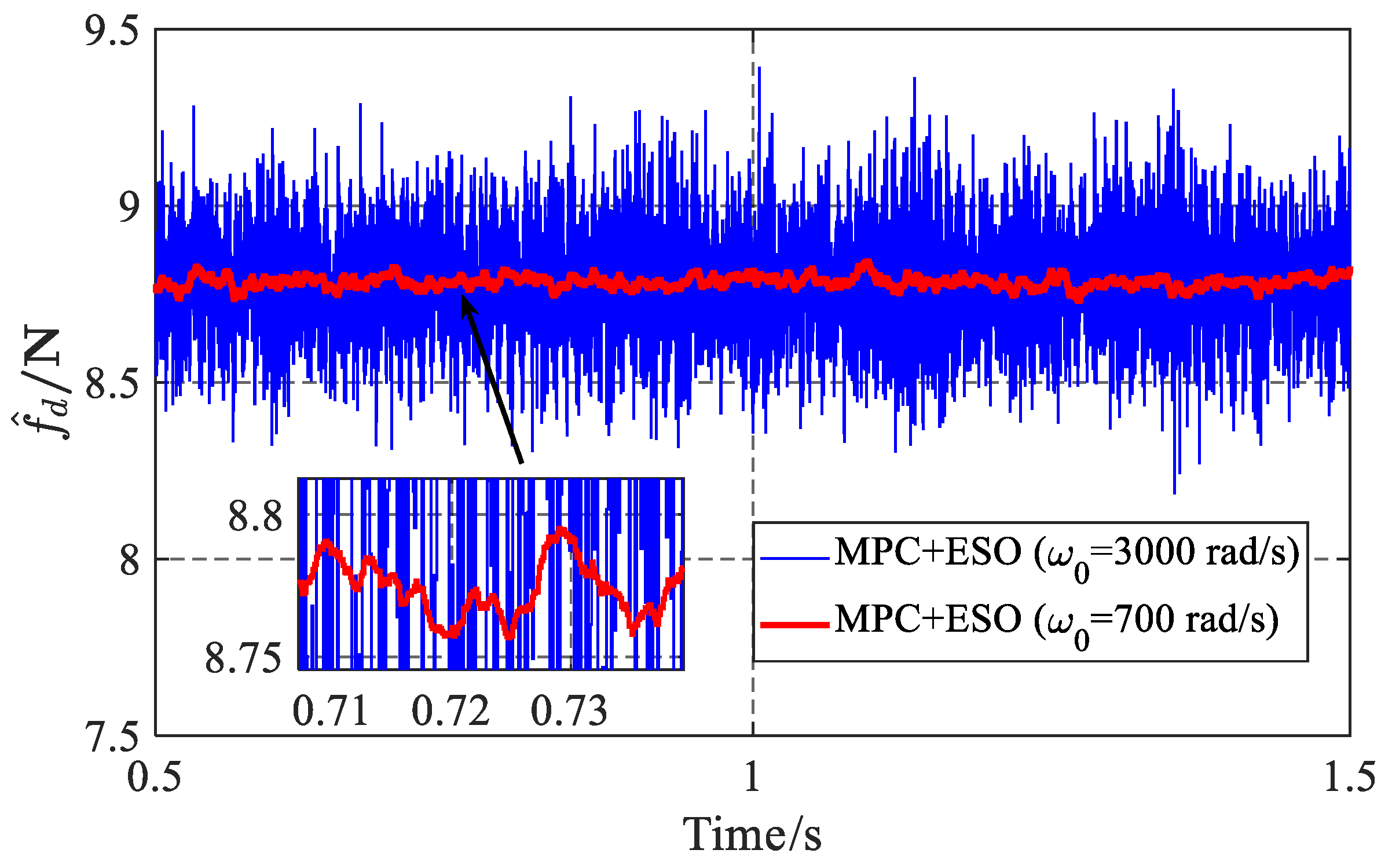

3.3. Noise Sensitivity Analysis of ESO

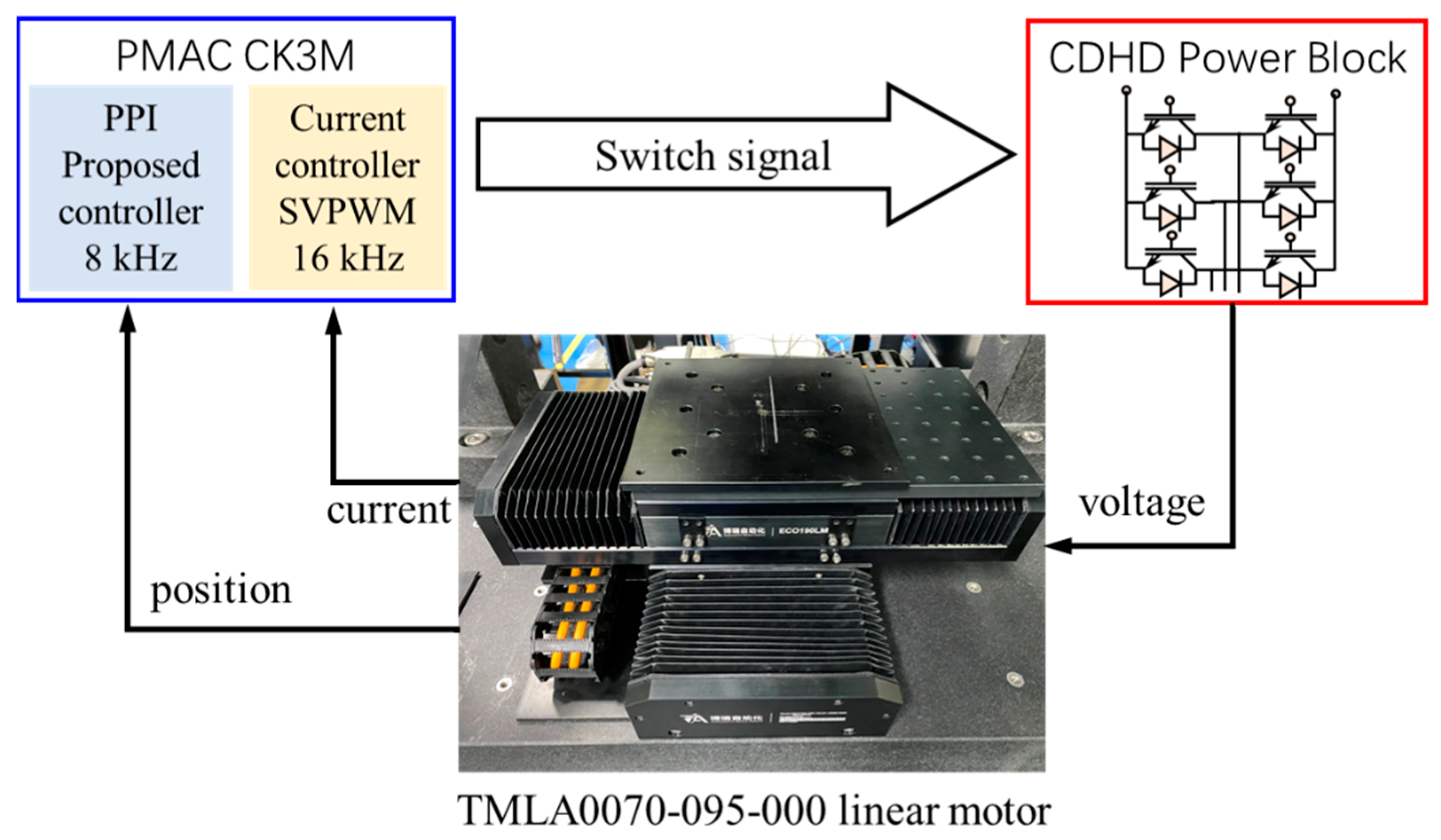

4. Experimental Verification

4.1. Setup of Test Bench

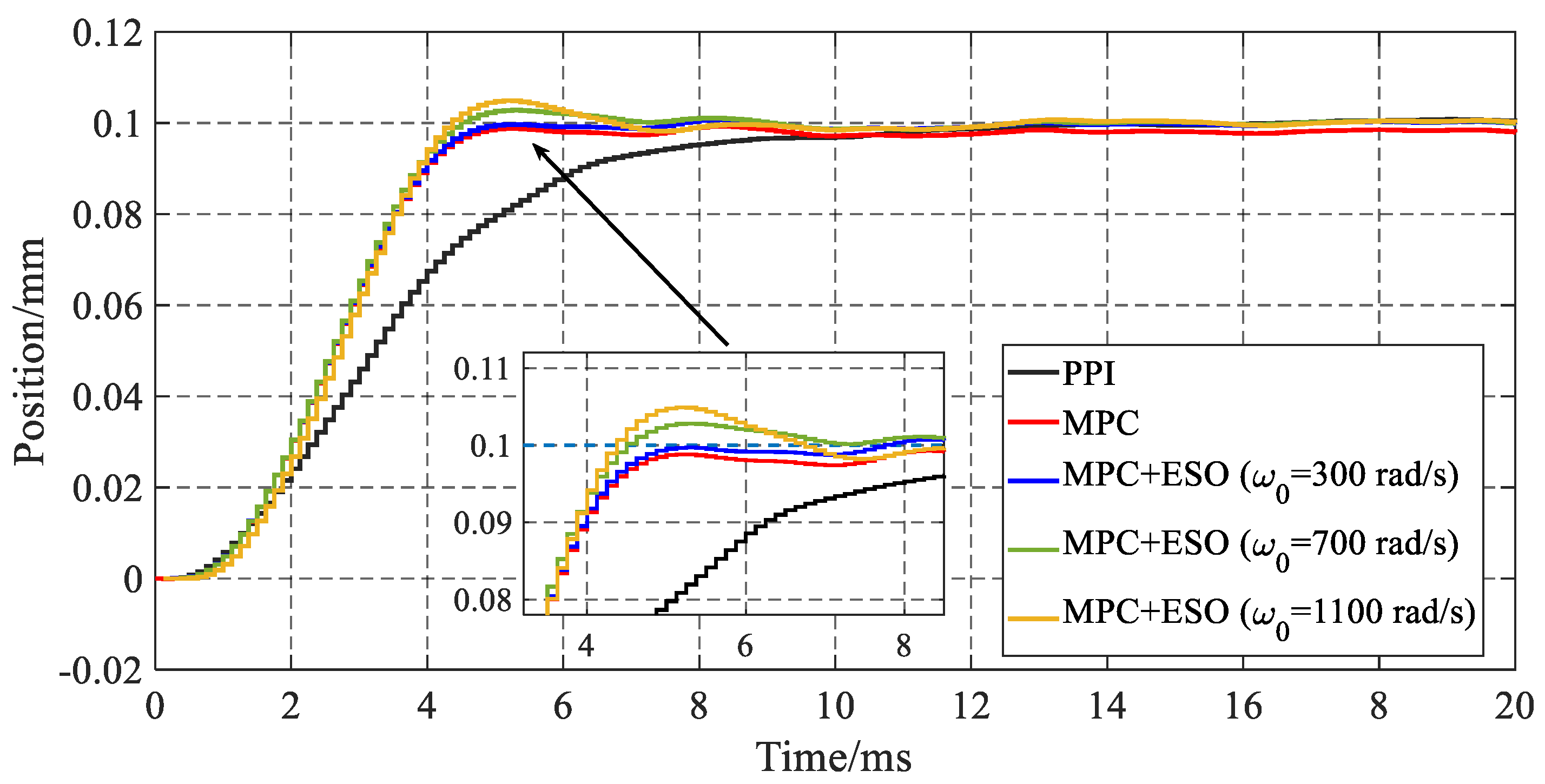

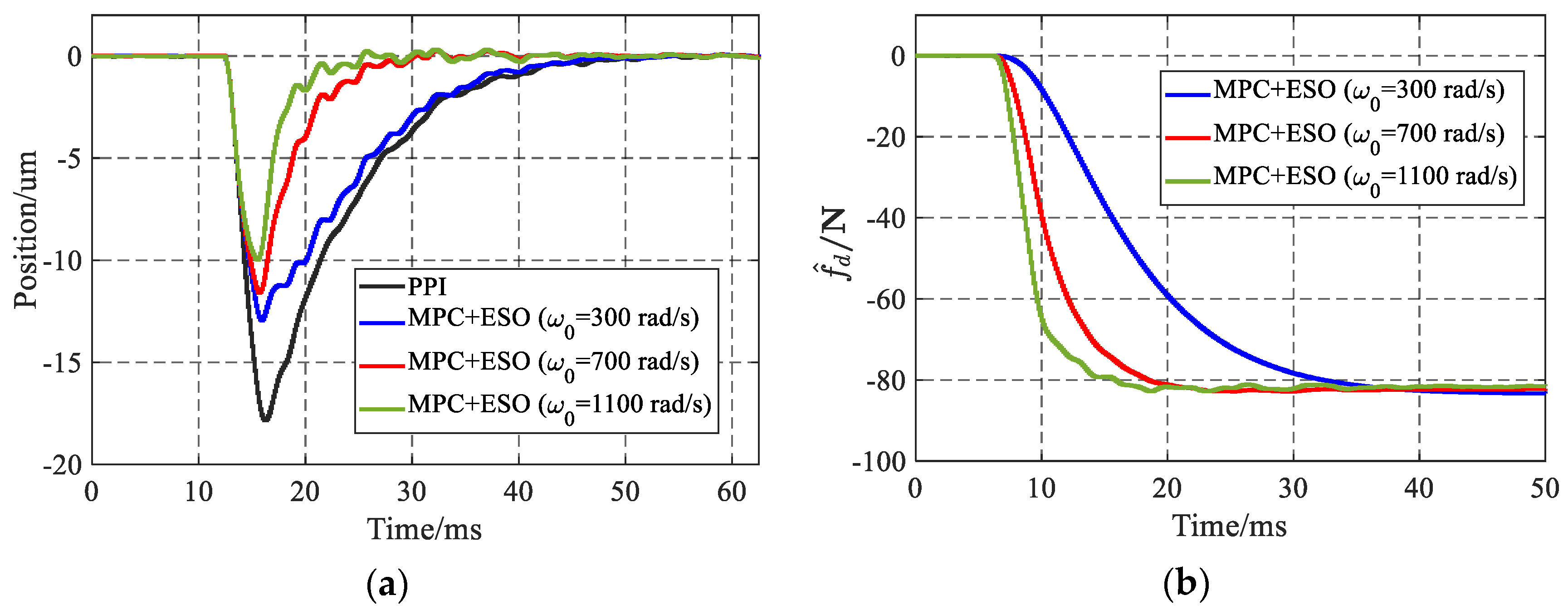

4.2. Experimental Verification of Tracking Performance

4.3. Experimental Verification of Anti-Disturbance Performance

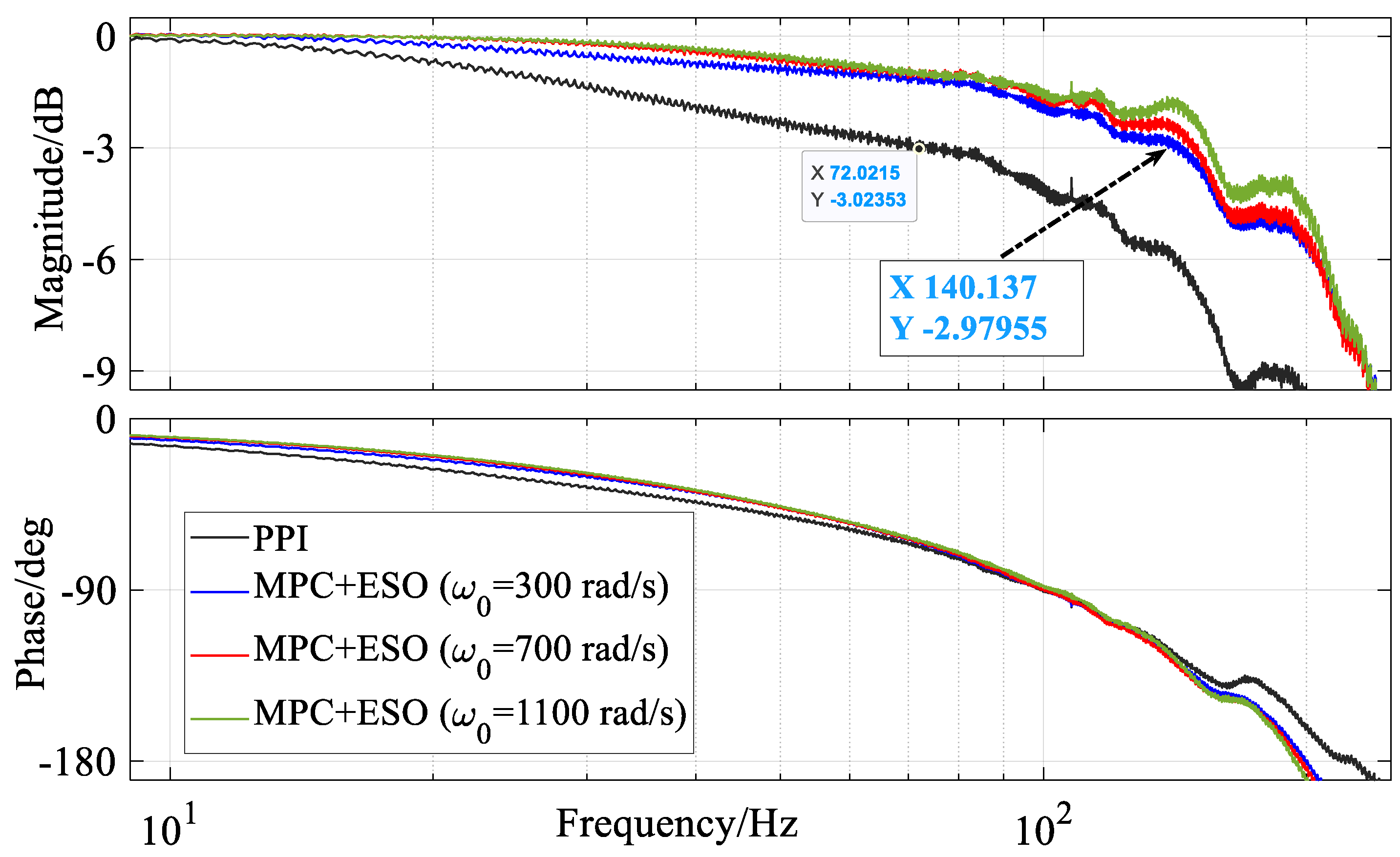

4.4. Experimental Verification in the Frequency Domain

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pritschow, G. A comparison of linear and conventional electromechanical dives. CIRP Ann. Manuf. Technol. 1998, 47, 541–548. [Google Scholar] [CrossRef]

- Du, H.B.; Chen, X.P.; Wen, G.H.; Yu, X.H.; Lü, J.H. Discrete-Time Fast Terminal Sliding Mode Control for Permanent Magnet Linear Motor. IEEE Trans. Ind. Electron. 2018, 65, 9916–9927. [Google Scholar] [CrossRef]

- Jin, H.Y.; Zhao, X.M. Approach Angle-Based Saturation Function of Modified Complementary Sliding Mode Control for PMLSM. IEEE Access 2019, 7, 126014–126024. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, M.; Tang, Y.; Zhou, C.; Li, L. Super Twisting-Based Position Control of PMLSM with Load Force Observer. In Proceedings of the 22nd International Conference on Electrical Machines and Systems, Harbin, China, 11–14 August 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Jin, H.Y.; Zhao, X.M.; Wang, T.H. Modified complementary sliding mode control with disturbance compensation for permanent magnet linear synchronous motor servo system. IET Electr. Power App. 2020, 14, 2128–2135. [Google Scholar] [CrossRef]

- Fu, D.X.; Zhao, X.M.; Zhu, J.G. A Novel Robust Super-Twisting Nonsingular Terminal Sliding Mode Controller for Permanent Magnet Linear Synchronous Motors. IEEE Trans. Power Electr. 2022, 37, 2936–2945. [Google Scholar] [CrossRef]

- Huang, Y.S.; Sung, C.C. Function-Based Controller for Linear Motor Control Systems. IEEE Trans. Ind. Electron. 2010, 57, 1096–1105. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chiang, H.H.; Liu, T.S.; Chang, C.H. Precision Motion Control of Permanent Magnet Linear Synchronous Motors Using Adaptive Fuzzy Fractional-Order Sliding-Mode Control. IEEE-Asme Trans. Mechatron. 2019, 24, 741–752. [Google Scholar] [CrossRef]

- Li, J.; Du, H.B.; Cheng, Y.Y.; Wen, G.H.; Chen, X.P.; Jiang, C.H. Position tracking control for permanent magnet linear motor via fast nonsingular terminal sliding mode control. Nonlinear Dyn. 2019, 97, 2595–2605. [Google Scholar] [CrossRef]

- Li, M.; Zhao, J.; Hu, Y.; Wang, Z. Active disturbance rejection position servo control of PMSLM based on reduced-order extended state observer. Chin. J. Electr. Eng. 2020, 6, 30–41. [Google Scholar] [CrossRef]

- Gao, W.; Li, S.; Wang, Y.F.; Wu, Z.S.; Ran, Z.Q.; Zhou, M.L. Phase-lead Linear Active Disturbance Rejection Controller of Permanent Magnet Synchronous Linear Motor Platform. In Proceedings of the Chinese Automation Congress, Shanghai, China, 6–8 November 2020; pp. 392–397. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, C.; Shen, L.Y.; Zhao, F.; Zhang, Y.L.; Zhang, S.C. Parameters Identification and Adaptive Feedforward Control of Permanent Magnent Linear Synchronous Motor. In Proceedings of the IEEE 11th Conference on Industrial Electronics and Applications, Hefei, China, 5–7 June 2016; pp. 1898–1903. [Google Scholar] [CrossRef]

- Huang, W.L.; Wang, Y.H.; Kuo, F.C.; Yen, J.Y.; Kuo, F.C.; Chou, S.C.; Chung, T.T.; Wang, F.C. Integrating time-optimal motion profiles with position control for a high-speed permanent magnet linear synchronous motor planar motion stage. Precis. Eng. 2021, 68, 106–123. [Google Scholar] [CrossRef]

- Kwon, W.H.; Han, S.H. Receding Horizon Control: Model Predictive Control for State Models; Springer: London, UK, 2005. [Google Scholar] [CrossRef]

- Errouissi, R.; Ouhrouche, M. Nonlinear predictive controller for a permanent magnet synchronous motor drive. Math. Comput. Simul. 2010, 81, 394–406. [Google Scholar] [CrossRef]

- Errouissi, R.; Ouhrouche, M.; Chen, W.H.; Trzynadlowski, A.M. Robust Nonlinear Predictive Controller for Permanent-Magnet Synchronous Motors With an Optimized Cost Function. IEEE Trans. Ind. Electron. 2012, 59, 2849–2858. [Google Scholar] [CrossRef]

- Chai, S.; Wang, L.P.; Rogers, E. Model predictive control of a permanent magnet synchronous motor with experimental validation. Control. Eng. Pract. 2013, 21, 1584–1593. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.D.; Zhang, Q. Predictive Speed-Control Algorithm Based on a Novel Extended-State Observer for PMSM Drives. Appl. Sci. 2019, 9, 2575. [Google Scholar] [CrossRef]

- Li, S.H.; Liu, H.X.; Fu, W.S. Predictive functional control of PMSM based on a composite prediction model. In Proceedings of the IEEE International Symposium on Sensorless Control for Electrical Drives and Predictive Control of Electrical Drives and Power Electronics, Munich, Germany, 17–19 October 2013. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, W.J.; Shi, J.; Ji, H.; Huang, S.R. A High Performance Permanent Magnet Synchronous Motor Servo System Using Predictive Functional Control and Kalman Filter. J. Power Electron. 2015, 15, 1547–1558. [Google Scholar] [CrossRef]

- Shao, M.; Deng, Y.T.; Li, H.W.; Liu, J.; Fei, Q. Robust Speed Control for Permanent Magnet Synchronous Motors Using a Generalized Predictive Controller With a High-Order Terminal Sliding-Mode Observer. IEEE Access 2019, 7, 121540–121551. [Google Scholar] [CrossRef]

- Wei, Y.; Wei, Y.J.; Sun, Y.N.; Qi, H.H.; Guo, X.Q. Prediction Horizons Optimized Nonlinear Predictive Control for Permanent Magnet Synchronous Motor Position System. IEEE Trans. Ind. Electron 2020, 67, 9153–9163. [Google Scholar] [CrossRef]

- Li, L.; Pei, G.; Liu, J.; Du, P.; Pei, L.; Zhng, C. 2-DOF Robust H Speed Control for Permanent Magnet Synchronous Motor with Disturbance Observer. IEEE Trans. Power Electron. 2020, 36, 3462–3472. [Google Scholar] [CrossRef]

- Chen, P.C.; Luo, Y. A Two-Degree-of-Freedom Controller Design Satisfying Separation Principle With Fractional-Order PD and Generalized ESO. IEEE-ASME Trans. Mechatron. 2022, 27, 137–148. [Google Scholar] [CrossRef]

- Xia, C.; Ji, B.; Shi, T.; Yan, Y. Two-degree-of-freedom proportional integral speed control of electrical drives with Kalman-filter-based speed estimation. IET Electric. Power Appl. 2016, 10, 18–24. [Google Scholar] [CrossRef]

- Peng, H.; Yang, Z.J.; Xue, W.C.; Huang, R.R.; Huang, Y. The Design and Control of a Rigid-Flexible Coupling Positioning Stage for Enhanced Settling Performance. J. Dyn. Syst. Meas. Control. 2021, 143, 111003. [Google Scholar] [CrossRef]

| Parameters | Parameter Value | Parameters | Parameter Value |

|---|---|---|---|

| /Ω | 2.8 | , /mH | 6.8 |

| /A | 9.5 | /A | 2.5 |

| /V | 300 | /V·m−1·s−1 | 21.4 |

| /N·A−1 | 32 | m/kg | 6 |

| MPC | PPI | |||

|---|---|---|---|---|

| Weight Coefficient | Value | Control Gain | Value | Unit |

| 1 | ||||

| Controller | Position Error/μm | Settling Time/ms |

|---|---|---|

| PPI | 17.8 | 35.7 |

| ) | 12.9 | 35.8 |

| ) | 11.6 | 18.1 |

| ) | 10.0 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Z.; Sun, Z.; Sun, H.; Wang, W.; Mei, X. A Novel Control Method for Permanent Magnet Synchronous Linear Motor Based on Model Predictive Control and Extended State Observer. Actuators 2024, 13, 34. https://doi.org/10.3390/act13010034

Dong Z, Sun Z, Sun H, Wang W, Mei X. A Novel Control Method for Permanent Magnet Synchronous Linear Motor Based on Model Predictive Control and Extended State Observer. Actuators. 2024; 13(1):34. https://doi.org/10.3390/act13010034

Chicago/Turabian StyleDong, Zhuobo, Zheng Sun, Hao Sun, Wenjun Wang, and Xuesong Mei. 2024. "A Novel Control Method for Permanent Magnet Synchronous Linear Motor Based on Model Predictive Control and Extended State Observer" Actuators 13, no. 1: 34. https://doi.org/10.3390/act13010034

APA StyleDong, Z., Sun, Z., Sun, H., Wang, W., & Mei, X. (2024). A Novel Control Method for Permanent Magnet Synchronous Linear Motor Based on Model Predictive Control and Extended State Observer. Actuators, 13(1), 34. https://doi.org/10.3390/act13010034