Standalone and Interconnected Analysis of an Independent Accumulator Pressure Compressibility Hydro-Pneumatic Suspension for the Four-Axle Heavy Truck

Abstract

:1. Introduction

1.1. Introduction to Hysteresis

1.2. Literature Review

2. Modeling and Hysteresis Analysis of Various Dampers

2.1. Modeling of an Orifice

2.2. Modeling of an Accumulator

2.3. Modeling of an Chamber

3. Construction and Analysis of Pressure Independent and Velocity Dependent Hydro-Pneumatic Damper

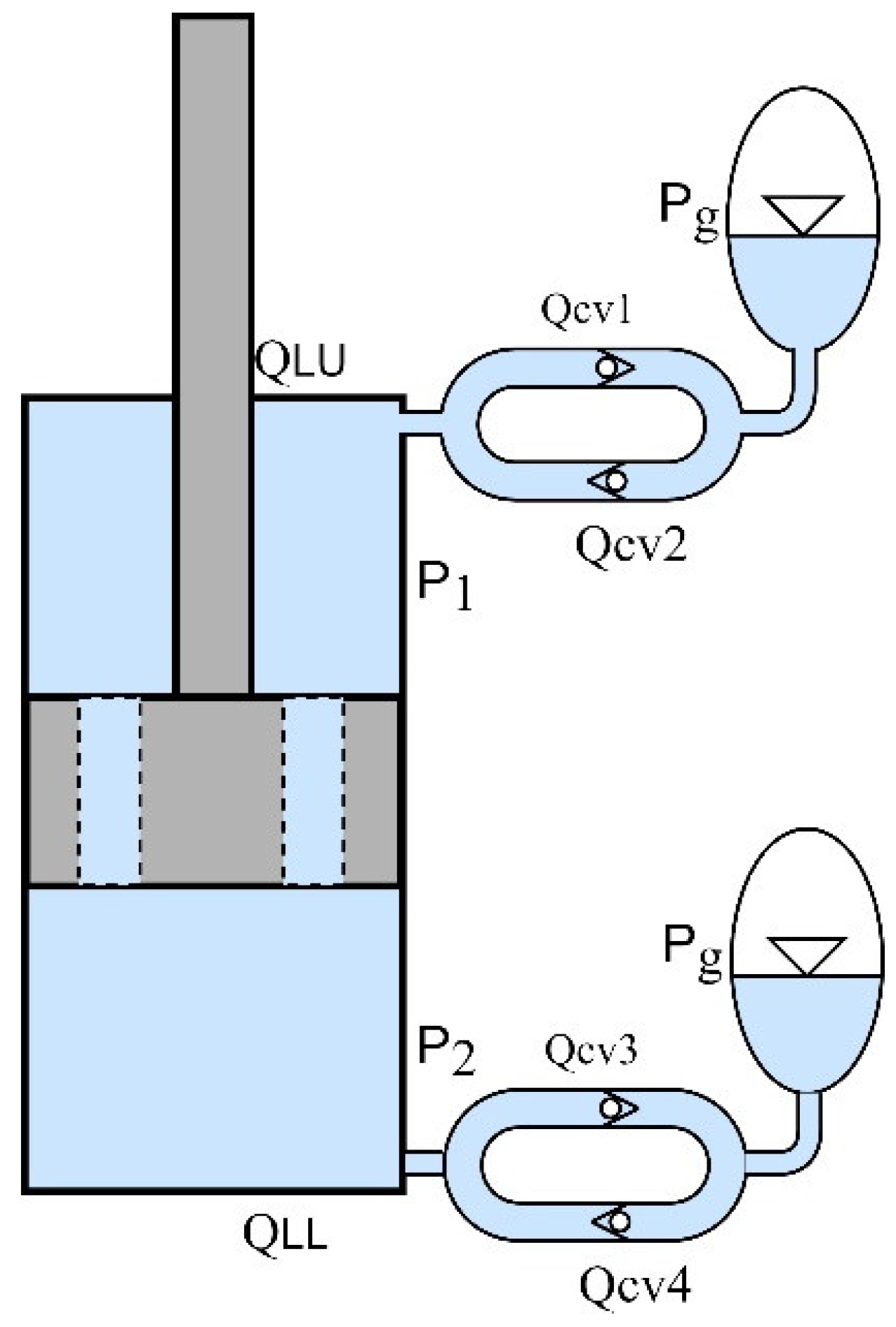

3.1. Check Valve

3.2. Working Principle

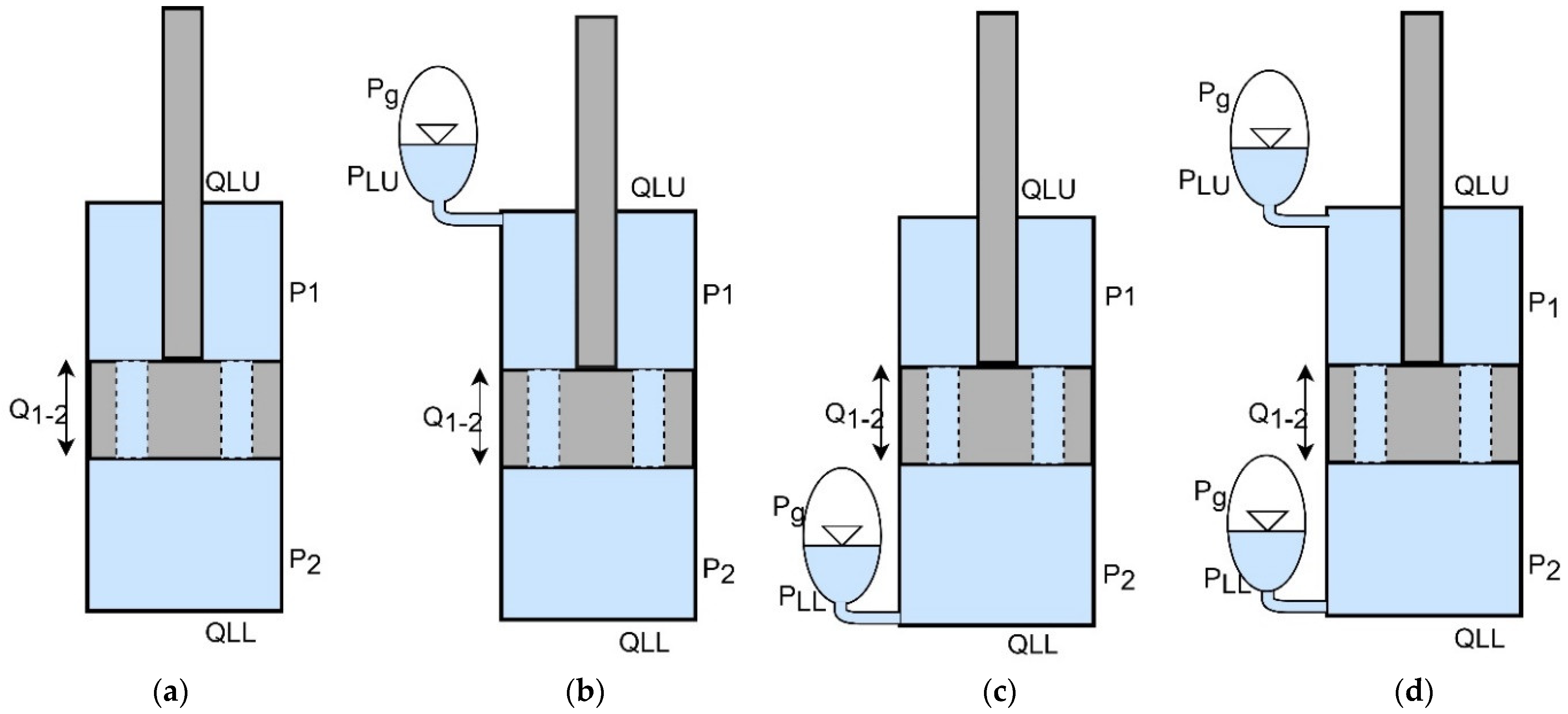

- Mode 1:

- Mode 2:

- Mode 3:

- Mode 4:

3.3. Influence of Check Valve

4. Truck Active Suspension

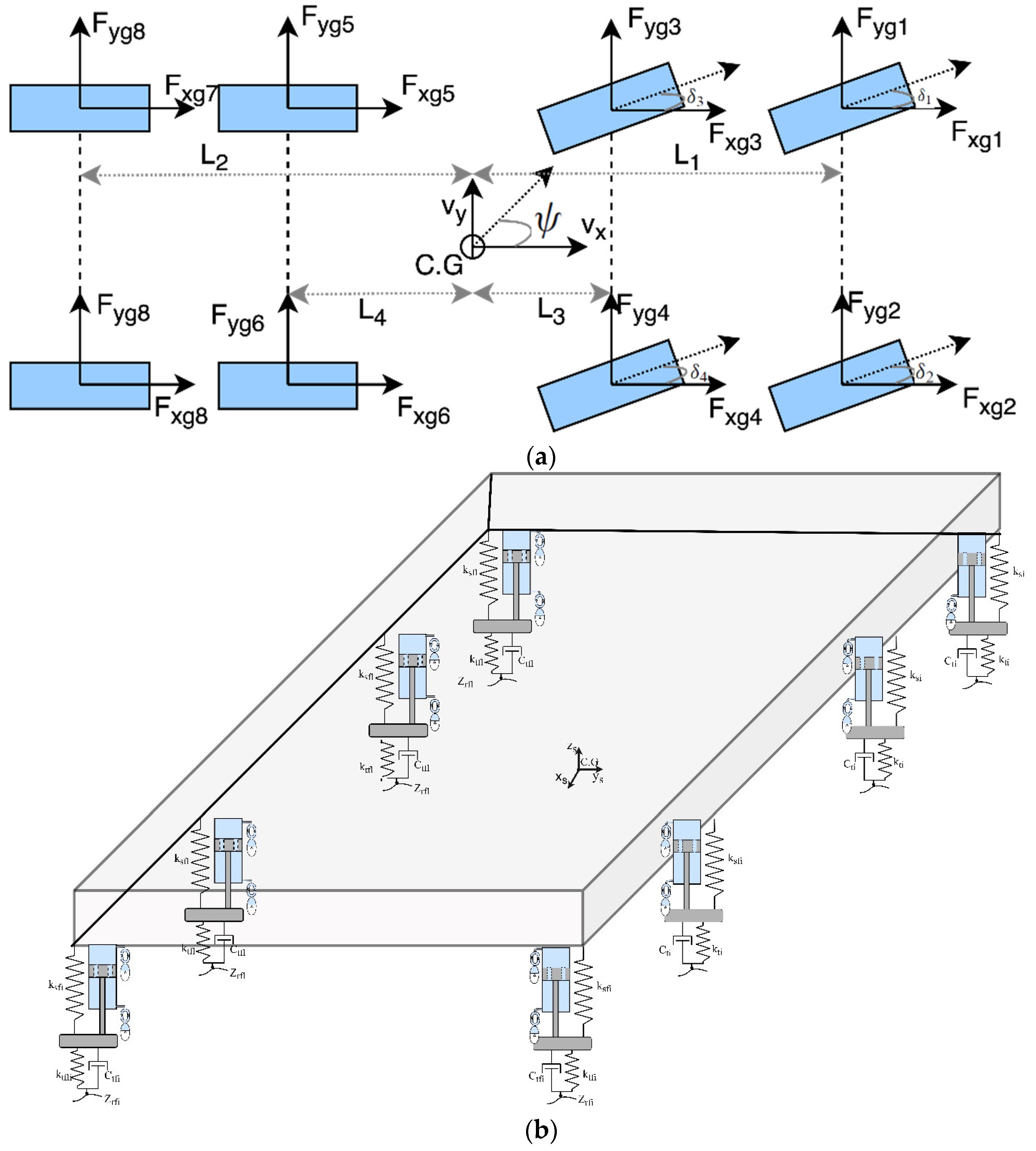

4.1. Vehicle Dynamic Truck Mathematical Model

4.2. Flow Rate through Hydraulic Control Valve

4.3. Interconnected Suspension

- Mode 1:

- Mode 2:

- Mode 3:

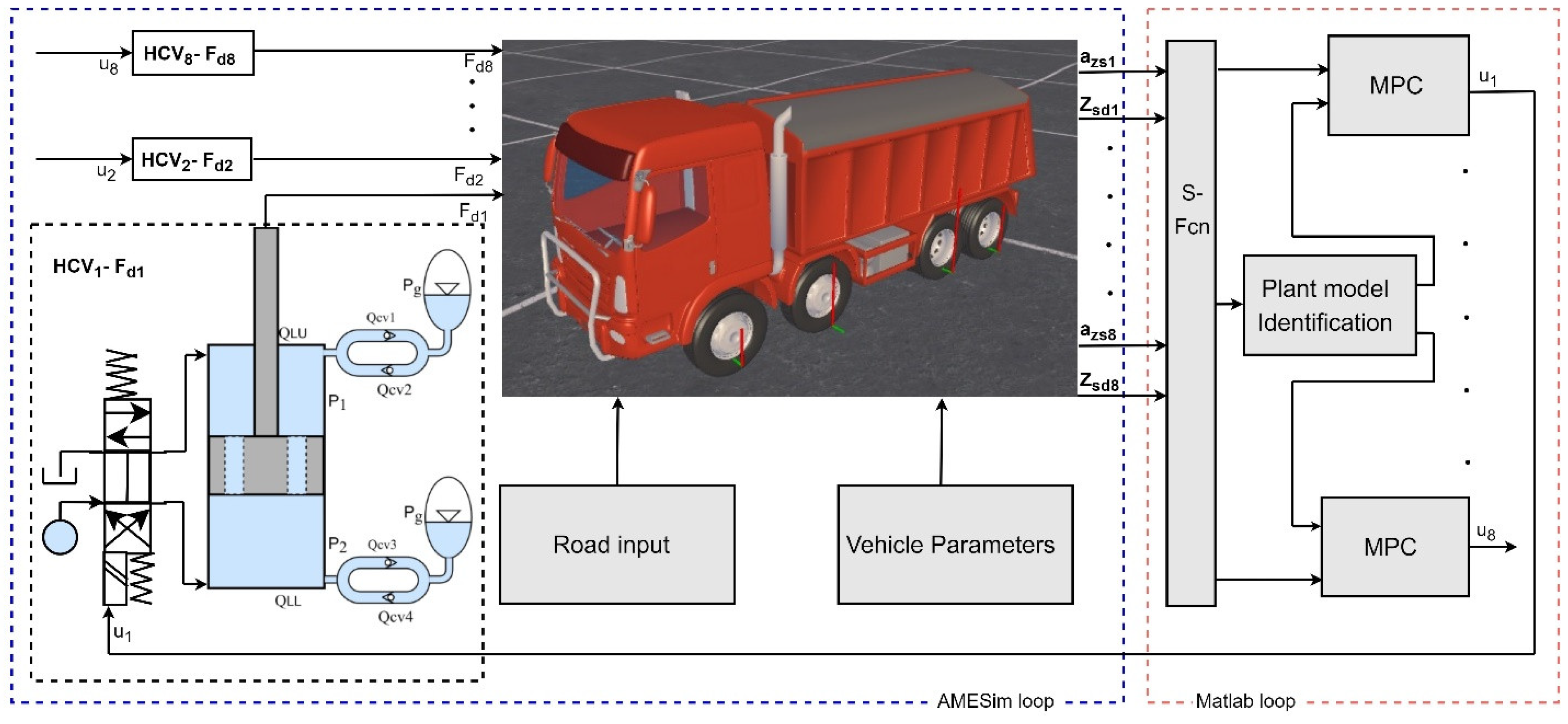

5. Identification, Control, and Co-Simulation

5.1. Co-Simulation

5.2. Identification

5.3. Controller Design

5.4. PID Controller

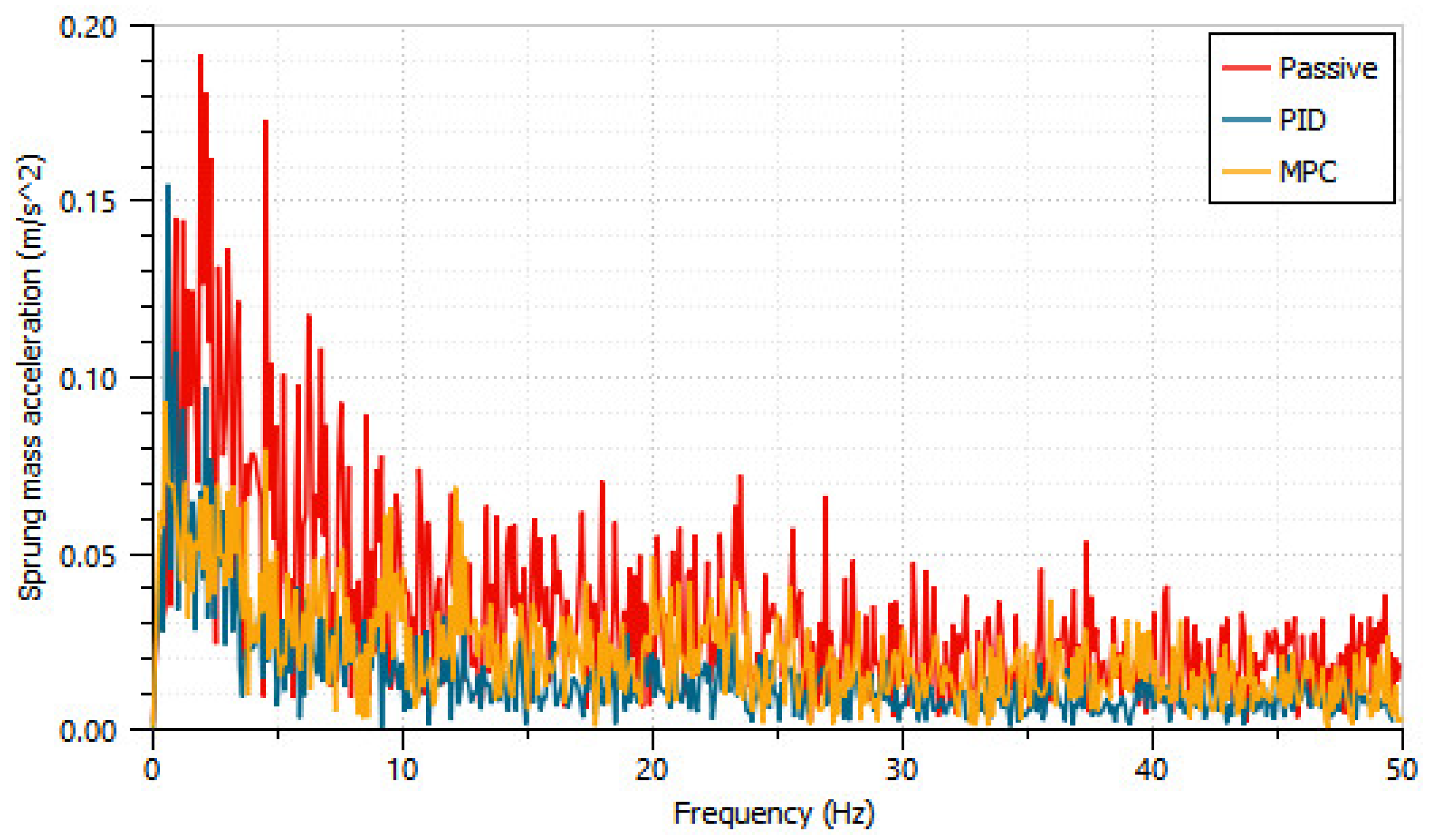

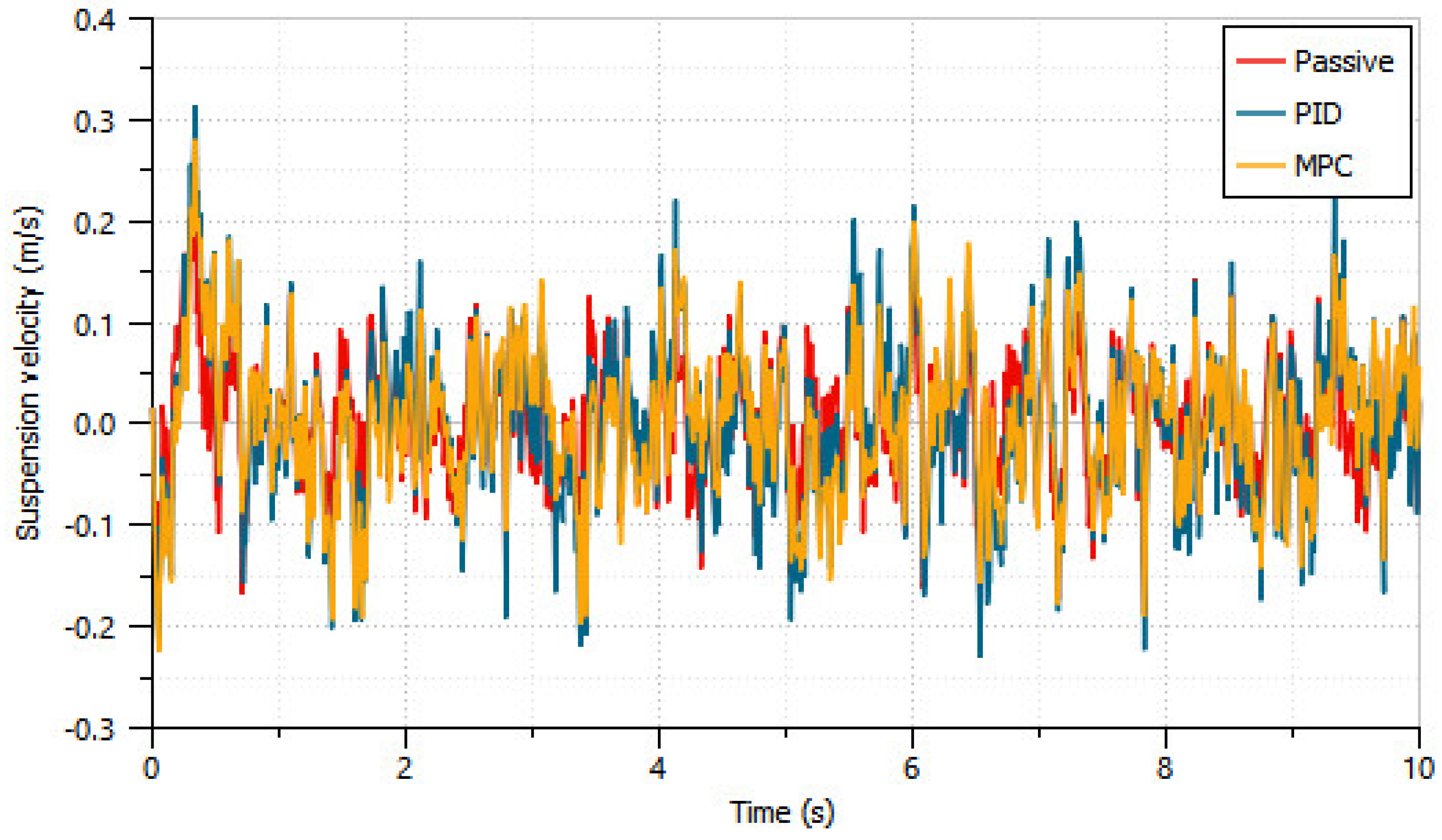

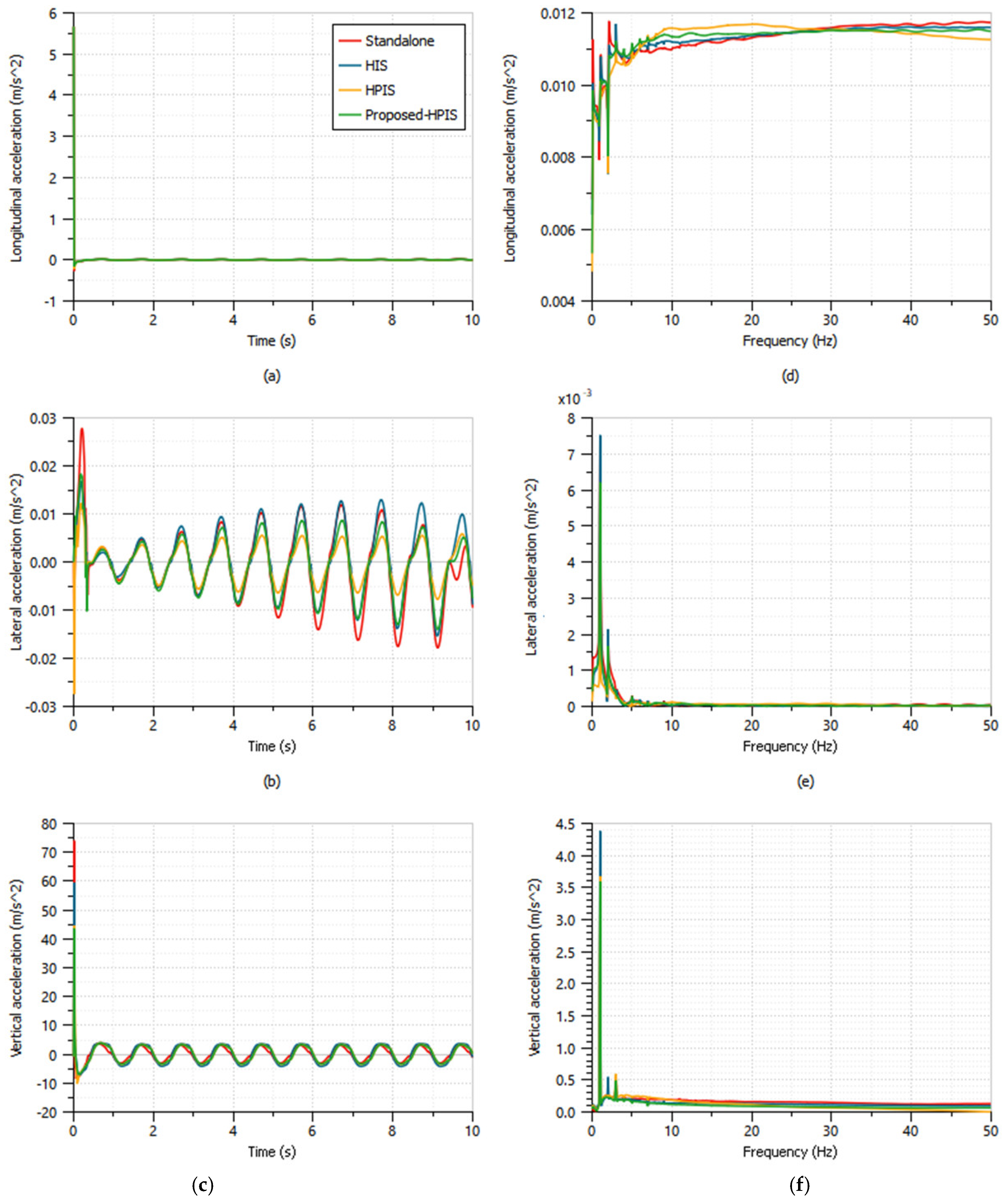

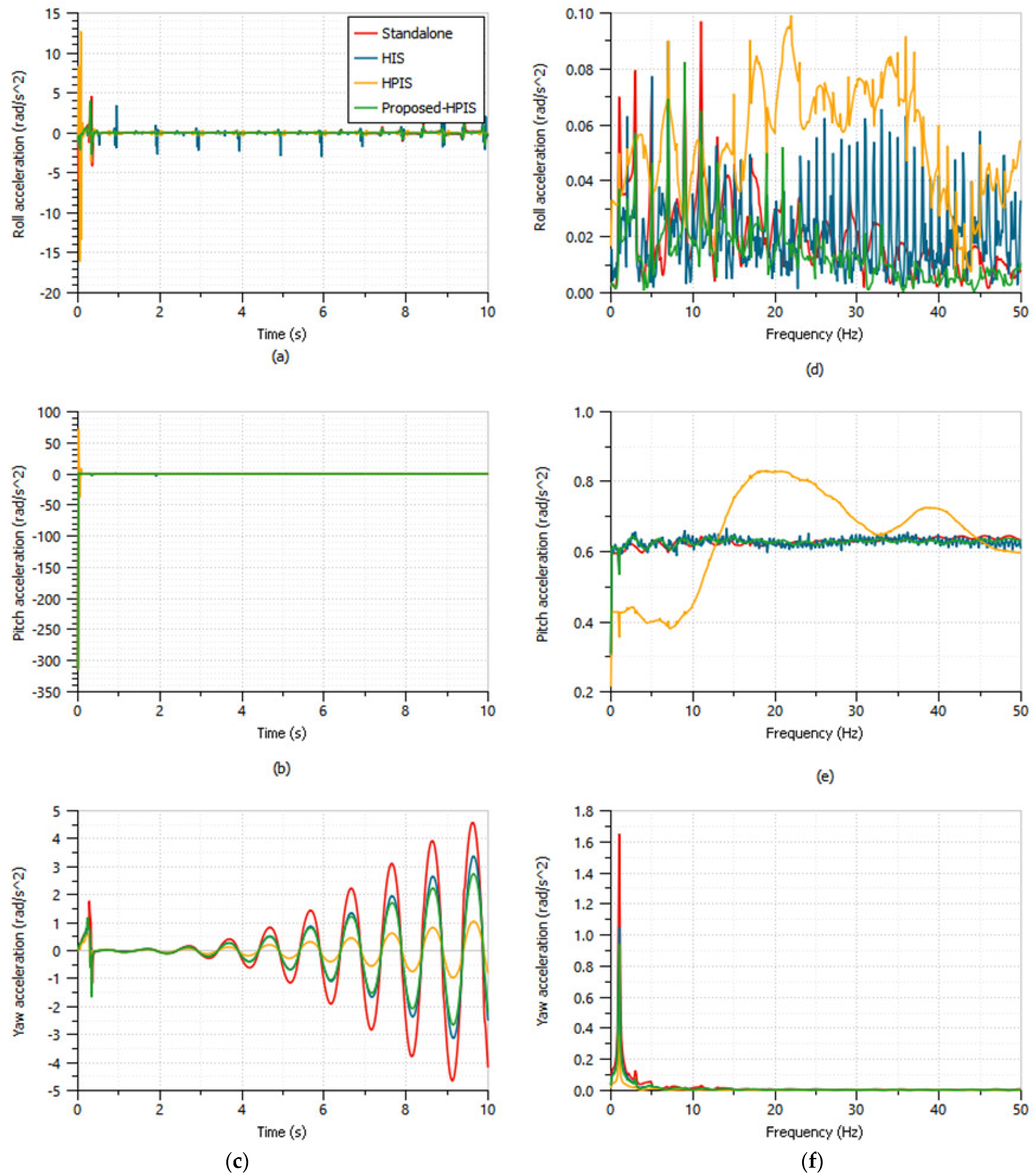

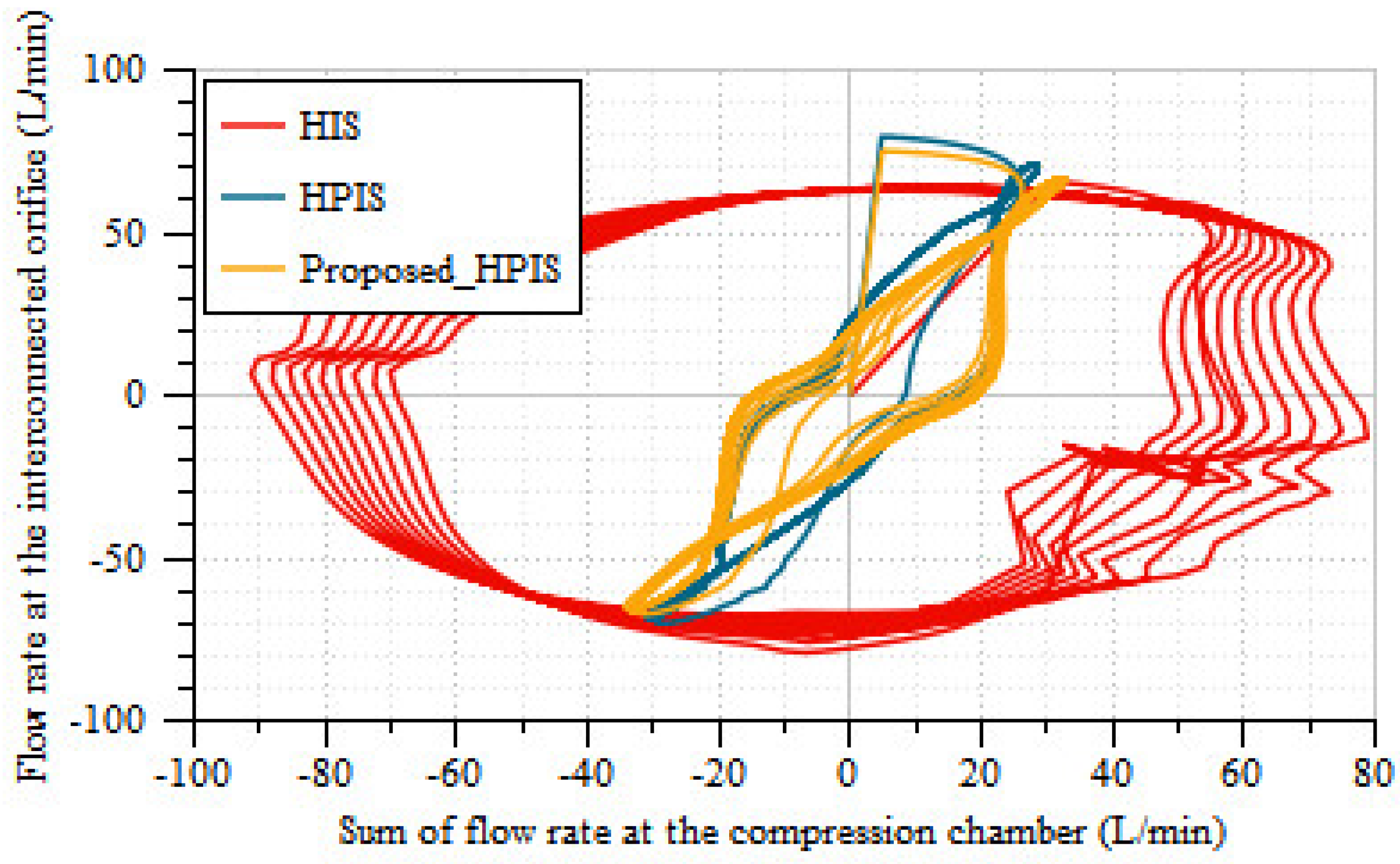

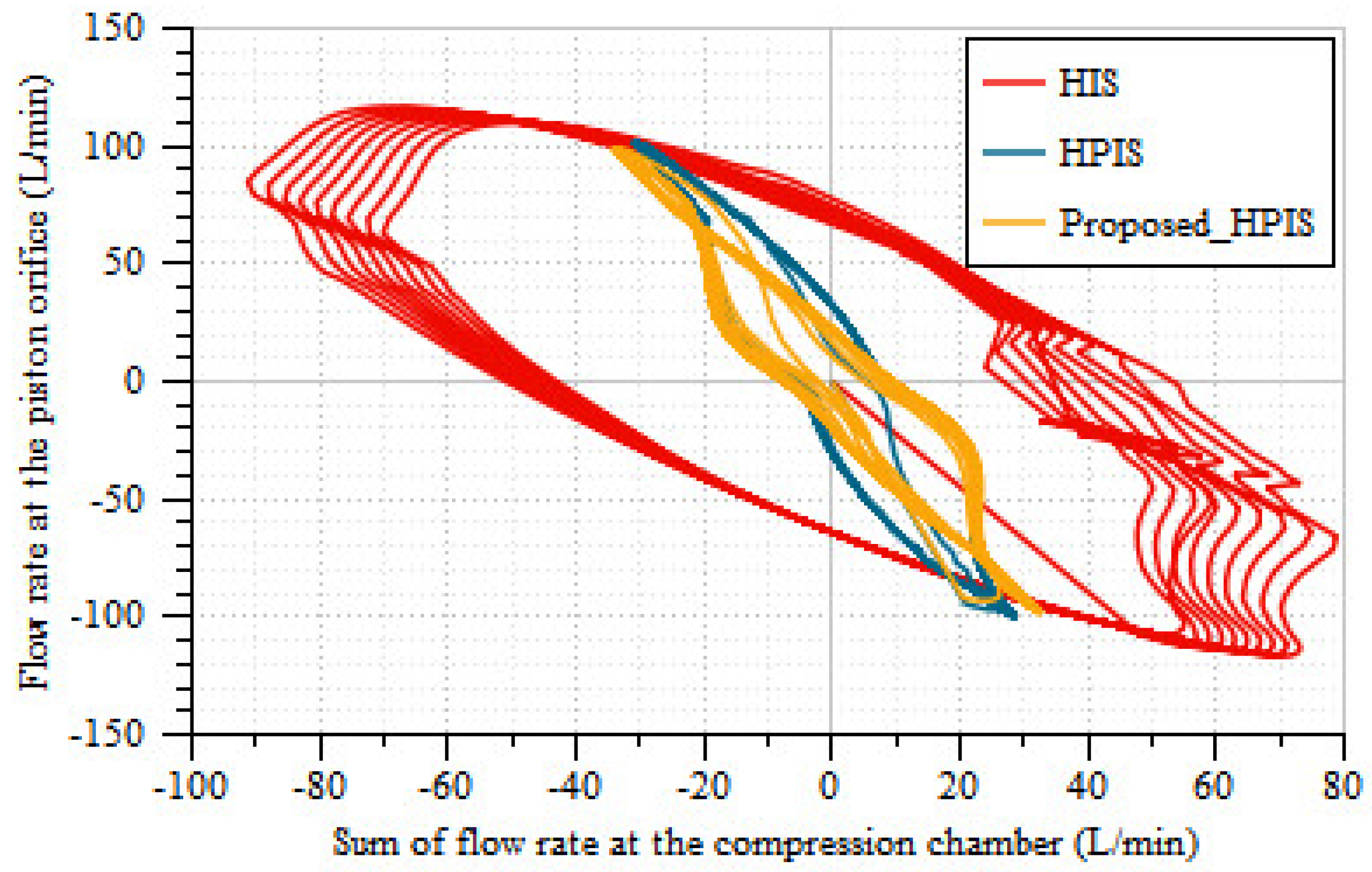

6. Results and Discussion

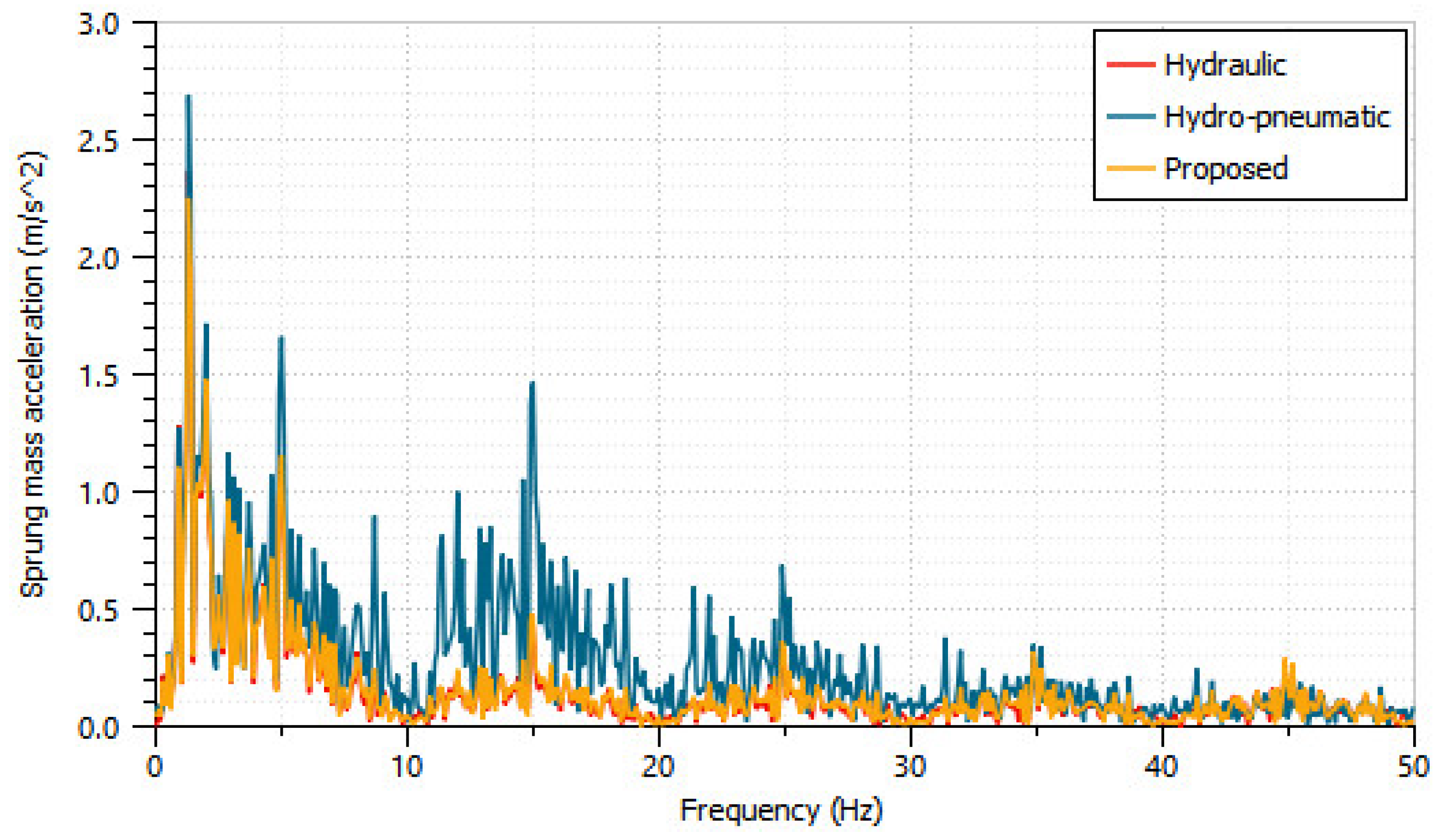

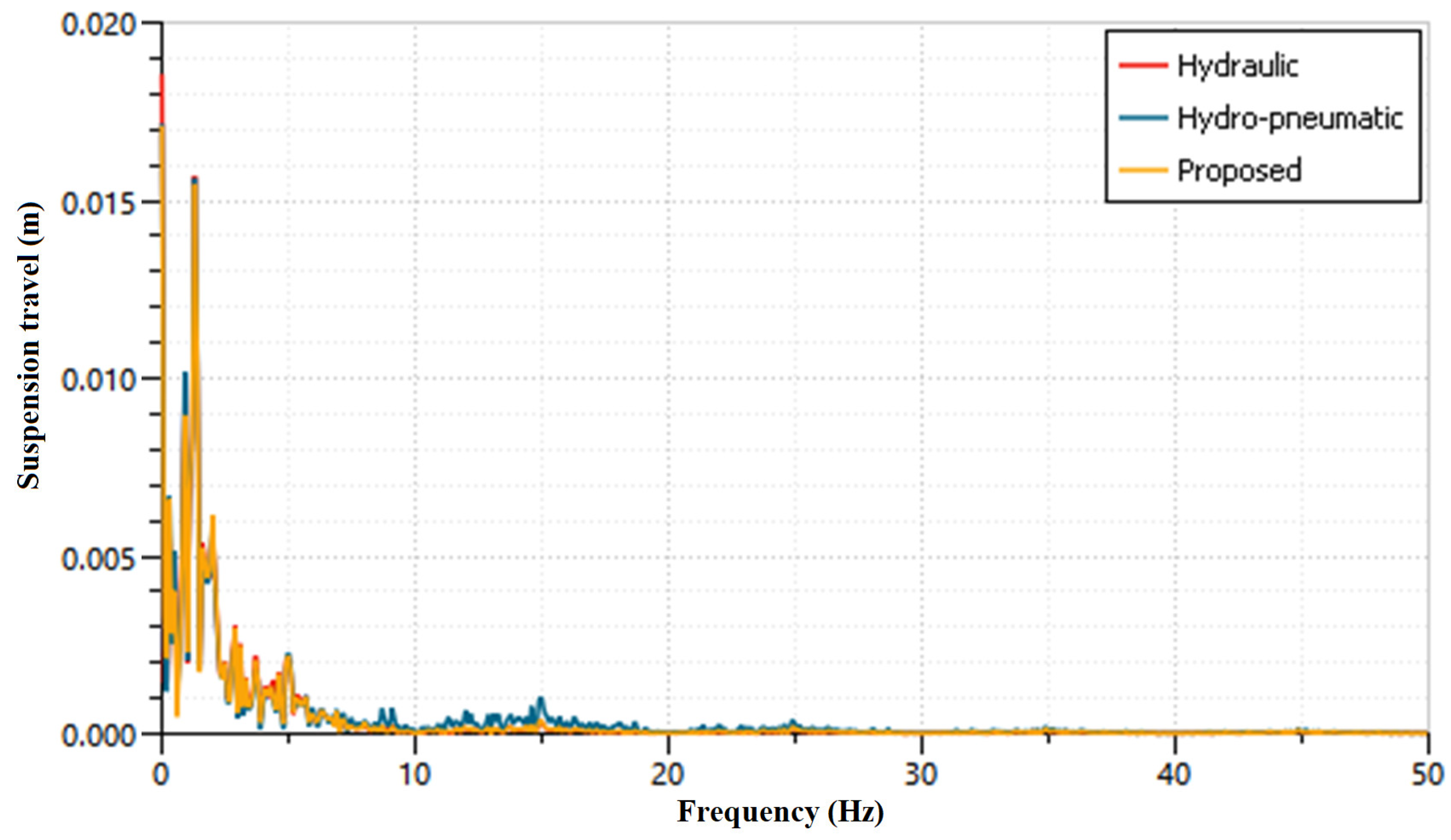

- Case 1:

- Case 2:

7. Conclusions

- From the passive systems analysis, the sprung mass acceleration of 33.64% is suppressed by the proposed HPD better than the well-known existing HPD. Also, rattle space and tire load performance improvement of the proposed HPD is more significant than the hydraulic damper.

- From the active suspension investigation, simply designed MPC and PID mitigate the sprung mass acceleration of the heavy truck of 39.8% and 50.4%, respectively. In addition, the conflict parameter of suspension deflection of the standalone active system was improved to 22% more than the passive HPD vehicle. It is evident that the proposed active HPD is capable of working in a truck active suspension scheme.

- Moreover, from the interconnected investigation, it was illustrated that there is a marginal improvement in heave and pitch acceleration of the proposed HPIS system over existing HIS and HPIS. In addition, roll acceleration is improved to 70.1% more than the existing HPIS with the compromise of 62.4% in yaw acceleration. Hence, the proposed HPD can be implemented into practical scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Simulation Parameters | ||

| 5.3 | MPa | |

| 50 | cm3 | |

| 12 | L/min | |

| 0.5 | MPa | |

| 1 | L/min/bar | |

| 7 | MPa | |

| 16,000 | kg | |

| 500 | kg | |

| 100,000 | Ns/m | |

| 74,000 (F), 82,000 (R) | N/m | |

| 400,000 | N/m | |

| 80,000 | Nm/rad | |

| 2160 | mm | |

| 2900 | mm | |

| 3200 | mm | |

| 1170 | mm | |

| 1820 | mm | |

| Nomenclature | ||

| Parameters | Units | Description |

| , | m2 | cross sectional area of piston in compression and rebound chamber side |

| , | MPa | rebound and compression chamber pressure |

| , | MPa | Gas pressure of upper and lower accumulator |

| , | m3 | Volume of the gas in compression and rebound chamber side accumulator |

| , | m3 | Volume of the accumulator in compression and rebound chamber side |

| MPa | check valve saturation pressure | |

| MPa | check valve cracking pressure | |

| % | Fractional valve opening of the valve | |

| MPa | Pressure drop of check valve | |

| L/min | Flow rate from source and tank orifice | |

| m | Hydraulic diameter of orifice | |

| m | Wet perimeter of orifice | |

| m2 | cross sectional area of orifice | |

| - | flow co-efficient | |

| - | flow number | |

| m2/s | kinematic viscosity | |

| - | critical flow number | |

| kg/m3 | density | |

| m2 | Valve area gradient | |

| , | N | Longitudinal, lateral and vertical forces of tire-ground contact forces |

| ,, | N | Longitudinal, lateral and vertical force transferred to the sprung mass at suspension mounting |

| ,, | N | longitudinal, lateral and vertical tire force |

| kg. m2 | Moment of inertia of the wheel | |

| N | Vertical of load of wheel | |

| - | Rolling resistance | |

| m | Wheel radius | |

| Nm | Braking torque | |

| rad | Wheel steer angle | |

| , | N/m, Ns/m | tire stiffness and damping constant |

| m | tire deflection | |

| m/s | vertical velocity of tire-ground contact forces | |

| kg | Truck sprung mass | |

| m/s | Longitudinal, lateral and vertical velocity | |

| , | m, m/s | Relative displacement and velocity of sprung and unsprung mass at suspension mounting |

References

- Quaglia, G.; Sorli, M. Air Suspension Dimensionless Analysis and Design Procedure. Veh. Syst. Dyn. 2003, 35, 443–475. [Google Scholar] [CrossRef]

- Nieto, A.J.; Morales, A.L.; González, A.; Chicharro, J.M.; Pintado, P. An Analytical Model of Pneumatic Suspensions Based on an Experimental Characterization. J. Sound Vib. 2008, 313, 290–307. [Google Scholar] [CrossRef]

- Porumamilla, H.; Kelkar, A.G.; Vogel, J.M. Modeling and Verification of an Innovative Active Pneumatic Vibration Isolation System. J. Dyn. Syst. Meas. Control 2008, 130, 031001. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Wang, R.; Yang, L.; Thiyagarajan, J. Trajectory Control for Tire Burst Vehicle Using the Standalone and Roll Interconnected Active Suspensions with Safety-Comfort Control Strategy. Mech. Syst. Signal Process. 2020, 142, 106776. [Google Scholar] [CrossRef]

- Yin, Z.; Khajepour, A.; Cao, D.; Ebrahimi, B.; Guo, K. A New Pneumatic Suspension System with Independent Stiffness and Ride Height Tuning Capabilities. Veh. Syst. Dyn. 2012, 50, 1735–1746. [Google Scholar] [CrossRef]

- Nieto, A.J.; Morales, A.L.; Chicharro, J.M.; Pintado, P. An Adaptive Pneumatic Suspension System for Improving Ride Comfort and Handling. JVC J. Vib. Control 2016, 22, 1492–1503. [Google Scholar] [CrossRef]

- Chen, Y.; Peterson, A.W.; Ahmadian, M. Achieving Anti-Roll Bar Effect through Air Management in Commercial Vehicle Pneumatic Suspensions. Veh. Syst. Dyn 2019, 57, 1775–1794. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, Y.; Peterson, A.; Ahmadian, M. Failure Mode and Effects Analysis of Dual Levelling Valve Airspring Suspensions on Truck Dynamics. Veh. Syst. Dyn. 2019, 57, 617–635. [Google Scholar] [CrossRef]

- Bauer, W. Hydropneumatic Suspension Systems; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-15146-0. [Google Scholar]

- Shi, J.W.; Li, X.W.; Zhang, J.W. Feedback Linearization and Sliding Mode Control for Active Hydropneumatic Suspension of a Special-Purpose Vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2010, 224, 41–53. [Google Scholar] [CrossRef]

- Yin, C.; Zhai, X.; Sun, X.; Wang, S.; Wong, P.K. Design and Performance Research of a Hydro-Pneumatic Suspension with Variable Damping and Stiffness Characteristics. J. Mech. Sci. Technol. 2022, 36, 4913–4923. [Google Scholar] [CrossRef]

- Calvo, J.A.; López-Boada, B.; Román, J.L.S.; Gauchía, A. Influence of a Shock Absorber Model on Vehicle Dynamic Simulation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2009, 223, 189–202. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J. Nonlinear Dynamic Responses of Twin-Tube Hydraulic Shock Absorber. Mech. Res. Commun. 2002, 29, 359–365. [Google Scholar] [CrossRef]

- Łuczko, J.; Ferdek, U. Non-Linear Analysis of a Quarter-Car Model with Stroke-Dependent Twin-Tube Shock Absorber. Mech. Syst. Signal Process. 2019, 115, 450–468. [Google Scholar] [CrossRef]

- Tan, B.; Lin, X.; Zhang, B.; Zhang, N.; Qi, H.; Zheng, M. Nonlinear Modeling and Experimental Characterization of Hydraulically Interconnected Suspension with Shim Pack and Gas-Oil Emulsion. Mech. Syst. Signal Process. 2023, 182, 109554. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Zhan, M.; Guo, K. Study on a Novel Hydraulic Pumping Regenerative Suspension for Vehicles. J. Frankl. Inst. 2015, 352, 485–499. [Google Scholar] [CrossRef]

- Westhuizen, S.F.; Els, P.S. Comparison of Different Gas Models to Calculate the Spring Force of a Hydropneumatic Suspension. J. Terramechanics 2015, 57, 41–59. [Google Scholar] [CrossRef]

- Lin, D.; Yang, F.; Li, R. Experimental Modelling and Analysis of Compact Hydro-Pneumatic Interconnected Suspension Strut Considering Pneumatic Thermodynamics and Hydraulic Inertial Properties. Mech. Syst. Signal Process. 2022, 172, 108988. [Google Scholar] [CrossRef]

- Spelta, C.; Previdi, F.; Savaresi, S.M.; Bolzern, P.; Cutini, M.; Bisaglia, C.; Bertinotti, S.A. Performance Analysis of Semi-Active Suspensions with Control of Variable Damping and Stiffness. Veh. Syst. Dyn. 2011, 49, 237–256. [Google Scholar] [CrossRef]

- Abd-EI-Tawwab, A.M. Twin Accumulator Semi Active Suspension System with Preview Control. J. Low Freq. Noise Vib. Act. Control 2008, 26, 283–294. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Du, H.; Hu, Z. Modelling and Analysis of Full-Vehicle Hydro-Pneumatic Suspension System Considering Real-Gas Polytropic Process. Mech. Syst. Signal Process. 2022, 165, 108406. [Google Scholar] [CrossRef]

- Sang, Z.; Dong, M.; Gu, L. Numerical Analysis of a Dual-Chamber Hydro-Pneumatic Suspension Using Nonlinear Vibration Theory and Fractional Calculus. Adv. Mech. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, H.; Deng, Y.; Wang, Q. Multi-Objective Optimization for Ride Comfort of Hydro-Pneumatic Suspension Vehicles with Mechanical Elastic Wheel. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 233, 2714–2728. [Google Scholar] [CrossRef]

- Smith, W.A.; Zhang, N.; Jeyakumaran, J. Hydraulically Interconnected Vehicle Suspension: Theoretical and Experimental Ride Analysis. Veh. Syst. Dyn. 2010, 48, 41–64. [Google Scholar] [CrossRef]

- Zhang, N.; Smith, W.A.; Jeyakumaran, J. Hydraulically Interconnected Vehicle Suspension: Background and Modelling. Veh. Syst. Dyn. 2010, 48, 17–40. [Google Scholar] [CrossRef]

- Ding, F.; Zhang, N.; Liu, J.; Han, X. Dynamics Analysis and Design Methodology of Roll-Resistant Hydraulically Interconnected Suspensions for Tri-Axle Straight Trucks. J. Frankl. Inst. 2016, 353, 4620–4651. [Google Scholar] [CrossRef]

- Ding, F.; Han, X.; Zhang, N.; Luo, Z. Characteristic Analysis of Pitch-Resistant Hydraulically Interconnected Suspensions for Two-Axle Vehicles. J. Vib. Control 2015, 21, 3167–3188. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, N.; Roser, H.M. Roll and Pitch Independently Tuned Interconnected Suspension: Modelling and Dynamic Analysis. Veh. Syst. Dyn. 2015, 53, 1830–1849. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, N. Characteristic Analysis of Roll and Pitch Independently Controlled Hydraulically Interconnected Suspension. SAE Int. J. Commer. Veh 2014, 7, 170–175. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, J.; Zhang, Y. Modeling and Optimization for Pneumatically Pitch-Interconnected Suspensions of a Vehicle. J. Sound Vib. 2018, 432, 290–309. [Google Scholar] [CrossRef]

- Tang, C.; Goodarzi, A.; Khajepour, A. A Novel Integrated Suspension Tilting System for Narrow Urban Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 1970–1981. [Google Scholar] [CrossRef]

- Cao, D.; Rakheja, S.; Su, C.Y. Dynamic Analyses of Roll Plane Interconnected Hydro-Pneumatic Suspension Systems. Int. J. Veh. Des. 2015, 47, 51. [Google Scholar] [CrossRef]

- Palanisamy, S.; Thangaraj, M.; Elsheikh, A.H. A review of flexible printed sensors for automotive infotainment systems. Arch. Civ. Mech. Eng. 2023, 23, 67. [Google Scholar] [CrossRef]

- Palanisamy, S.; Thangaraj, M. Fabrication and Performance Evolution of AgNP Interdigitated Electrode Touch Sensor for Automotive Infotainment. Sensors 2021, 21, 7961. [Google Scholar] [CrossRef]

- Palanisamy, S.; Thangaraj, M.; Moiduddin, K.; Al-Ahmari, A.M. Fabrication and Performance Analysis of 3D Inkjet Flexible Printed Touch Sensor Based on AgNP Electrode for Infotainment Display. Coatings 2022, 12, 416. [Google Scholar] [CrossRef]

- Cao, D.; Rakheja, S.; Su, C.Y. Roll- and Pitch-Plane-Coupled Hydro-Pneumatic Suspension. Part 2: Dynamic Response Analyses. Veh. Syst. Dyn. 2010, 48, 507–528. [Google Scholar] [CrossRef]

- Lallart, M.; Li, K.; Yang, Z.; Wang, W. System-Level Modeling of Nonlinear Hysteretic Piezoelectric Actuators in Quasi-Static Operations. Mech. Syst. Signal Process 2019, 116, 985–996. [Google Scholar] [CrossRef]

- Palomares, E.; Nieto, A.J.; Morales, A.L.; Chicharro, J.M.; Pintado, P. Dynamic Behaviour of Pneumatic Linear Actuators. Mechatronics 2017, 45, 37–48. [Google Scholar] [CrossRef]

- GP, S.; MM, K. A Contemporary Adaptive Air Suspension Using LQR Control for Passenger Vehicles. ISA Trans. 2019, 93, 244–254. [Google Scholar] [CrossRef]

- Yin, Y.; Rakheja, S.; Yang, J.; Boileau, P. Characterization of a Hydro-Pneumatic Suspension Strut with Gas-Oil Emulsion. Mech. Syst. Signal Process. 2018, 106, 319–333. [Google Scholar] [CrossRef]

- Graczykowski, C.; Pawłowski, P. Exact Physical Model of Magnetorheological Damper. Appl. Math. Model. 2017, 47, 400–424. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, H.; Luo, X.; Xiao, J. Adaptive Sliding Fault Tolerant Control for Nonlinear Uncertain Active Suspension Systems. J. Frankl. Inst. 2016, 353, 180–199. [Google Scholar] [CrossRef]

- Zeng, X.; Li, G.; Yin, G.; Song, D.; Li, S.; Yang, N. Model Predictive Control-Based Dynamic Coordinate Strategy for Hydraulic Hub-Motor Auxiliary System of a Heavy Commercial Vehicle. Mech. Syst. Signal Process. 2018, 101, 97–120. [Google Scholar] [CrossRef]

- Zou, J.; Guo, X.; Abdelkareem, M.A.A.; Xu, L.; Zhang, J. Modelling and Ride Analysis of a Hydraulic Interconnected Suspension Based on the Hydraulic Energy Regenerative Shock Absorbers. Mech. Syst. Signal Process. 2019, 127, 345–369. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Kaldas, M.M.S.; Kamal Ahmed Ali, M.; Xu, L. Analysis of the Energy Harvesting Potential–Based Suspension for Truck Semi-Trailer. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 2955–2969. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Makrahy, M.M.; Abd-El-Tawwab, A.M.; El-Razaz, A.S.A.; Ali, M.K.A.; Moheyeldein, M.M. An Analytical Study of the Performance Indices of Articulated Truck Semi-Trailer during Three Different Cases to Improve the Driver Comfort. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2018, 232, 84–102. [Google Scholar] [CrossRef]

- Yuan, H.B.; Na, H.C.; Kim, Y.B. Robust MPC–PIC Force Control for an Electro-Hydraulic Servo System with Pure Compressive Elastic Load. Control Eng. Pract. 2018, 79, 170–184. [Google Scholar] [CrossRef]

- Yuan, H.B.; Na, H.C.; Kim, Y.B. System Identification and Robust Position Control for Electro-Hydraulic Servo System Using Hybrid Model Predictive Control. J. Vib. Control 2018, 24, 4145–4159. [Google Scholar] [CrossRef]

- Garriga, J.L.; Soroush, M. Model Predictive Control Tuning Methods: A Review. Ind. Eng. Chem. Res. 2010, 49, 3505–3515. [Google Scholar] [CrossRef]

- Mustafa, G.I.Y.; Wang, H.P.; Tian, Y. Vibration Control of an Active Vehicle Suspension Systems Using Optimized Model-Free Fuzzy Logic Controller Based on Time Delay Estimation. Adv. Eng. Softw. 2019, 127, 141–149. [Google Scholar] [CrossRef]

- Wang, H.P.; Mustafa, G.I.Y.; Tian, Y. Model-Free Fractional-Order Sliding Mode Control for an Active Vehicle Suspension System. Adv. Eng. Softw. 2018, 115, 452–461. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, K.; Wang, D.; Chen, C.; Li, X. Energy Conversion Mechanism and Regenerative Potential of Vehicle Suspensions. Energy 2017, 119, 961–970. [Google Scholar] [CrossRef]

- Muthuramalingam, T.; Rabik, M.M.; Saravanakumar, D.; Jaswanth, K. Sensor integration based approach for automatic fork lift trucks. IEEE Sens. 2018, 18, 736–740. [Google Scholar] [CrossRef]

- Rabik, M.M.; Muthuramalingam, T. Tracking and locking system for shooter with sensory noise cancellation. IEEE Sens. 2018, 18, 732–735. [Google Scholar] [CrossRef]

- Jayaraman, T.; Palanisamy, S.; Thangaraj, M. Hydraulic control valve integrated novel semi active roll resistant interconnected suspension with vertical and roll coordinated control scheme. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 237, 98–111. [Google Scholar] [CrossRef]

| Parameters | Hydraulic | Hydro-Pneumatic | Proposed |

|---|---|---|---|

| Sprung mass acceleration (m/s2) | 4.37 | 6.57 | 4.36 |

| Sprung mass displacement (m) | 0.11 | 0.11 | 0.11 |

| Suspension travel (m) | 0.03 | 0.03 | 0.03 |

| Tire load (kN) | 2.92 | 2.91 | 2.91 |

| Unsprung mass acceleration × 103 (m/s2) | 2.10 | 2.10 | 2.10 |

| Parameter | Passive | PID | MPC | PID % of Improvement than Passive | MPC % of Improvement than Passive | MPC % of Improvement than PID |

|---|---|---|---|---|---|---|

| Sprung mass acceleration (m/s2) | 0.69 | 0.34 | 0.42 | 50.72 | 39.13 | −23.52 |

| Left suspension deflection (m) | 0.022 | 0.022 | 0.018 | - | 18.18 | 18.18 |

| Right suspension deflection (m) | 0.022 | 0.022 | 0.017 | - | 22.72 | 22.72 |

| Suspension velocity (m/s) | 0.06 | 0.08 | 0.07 | −33.33 | −16.67 | 12.5 |

| Parameters | Standalone | HIS | HPIS | Proposed-HPIS |

|---|---|---|---|---|

| Longitudinal acceleration (m/s2) | 0.18 | 0.18 | 0.18 | 0.18 |

| Lateral acceleration (m/s2) | 0.01 | 0.01 | 0.01 | 0.01 |

| Vertical acceleration (m/s2) | 3.37 | 3.73 | 3.30 | 3.02 |

| Roll acceleration (rad/s2) | 0.39 | 0.40 | 0.90 | 0.27 |

| Pitch acceleration (rad/s2) | 9.94 | 9.94 | 10.43 | 9.94 |

| Yaw acceleration (rad/s2) | 1.71 | 1.11 | 0.36 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayaraman, T.; Thangaraj, M. Standalone and Interconnected Analysis of an Independent Accumulator Pressure Compressibility Hydro-Pneumatic Suspension for the Four-Axle Heavy Truck. Actuators 2023, 12, 347. https://doi.org/10.3390/act12090347

Jayaraman T, Thangaraj M. Standalone and Interconnected Analysis of an Independent Accumulator Pressure Compressibility Hydro-Pneumatic Suspension for the Four-Axle Heavy Truck. Actuators. 2023; 12(9):347. https://doi.org/10.3390/act12090347

Chicago/Turabian StyleJayaraman, Thiyagarajan, and Muthuramalingam Thangaraj. 2023. "Standalone and Interconnected Analysis of an Independent Accumulator Pressure Compressibility Hydro-Pneumatic Suspension for the Four-Axle Heavy Truck" Actuators 12, no. 9: 347. https://doi.org/10.3390/act12090347

APA StyleJayaraman, T., & Thangaraj, M. (2023). Standalone and Interconnected Analysis of an Independent Accumulator Pressure Compressibility Hydro-Pneumatic Suspension for the Four-Axle Heavy Truck. Actuators, 12(9), 347. https://doi.org/10.3390/act12090347