Tendon-Driven Gripper with Variable Stiffness Joint and Water-Cooled SMA Springs

Abstract

1. Introduction

2. Materials and Methods

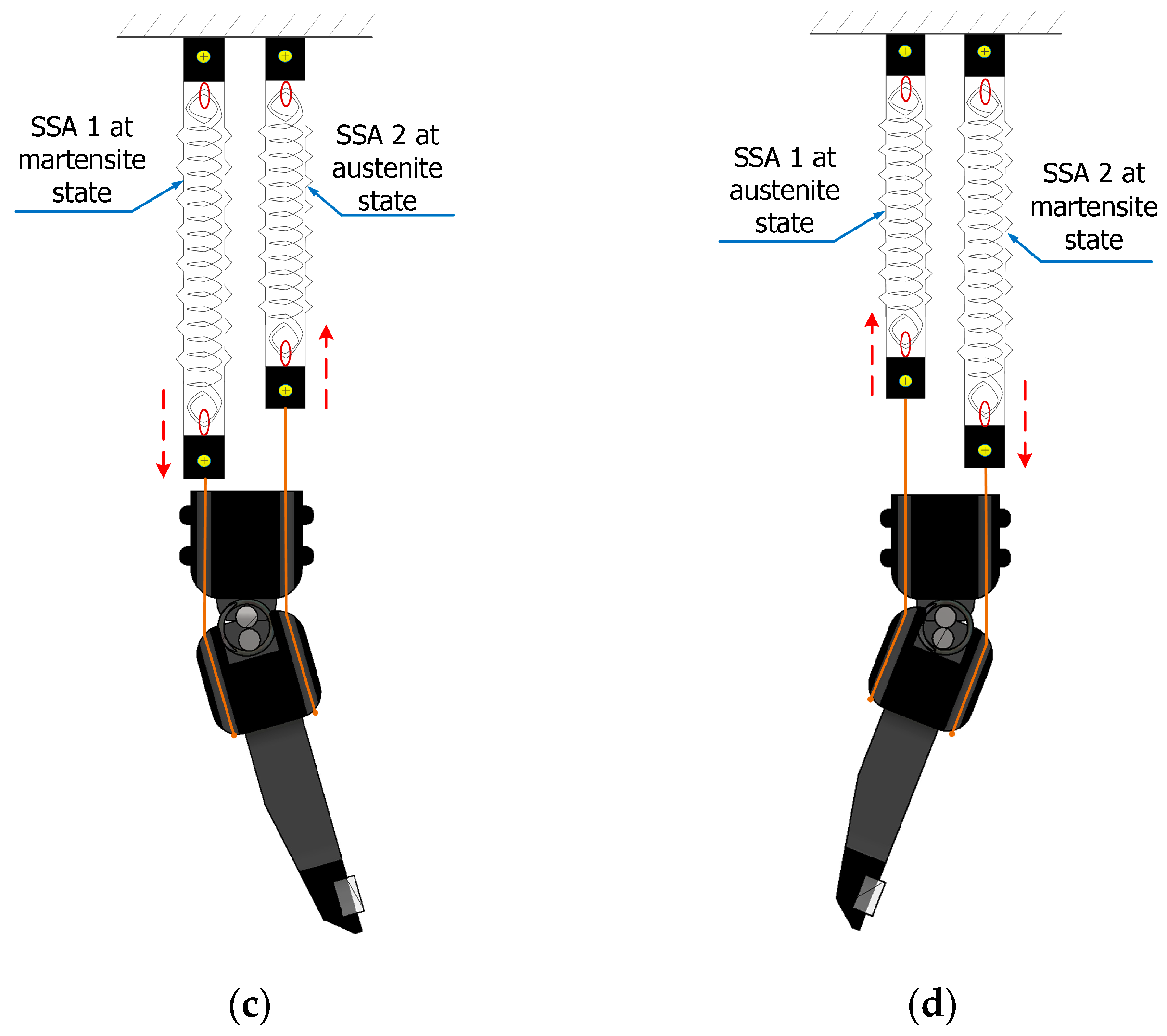

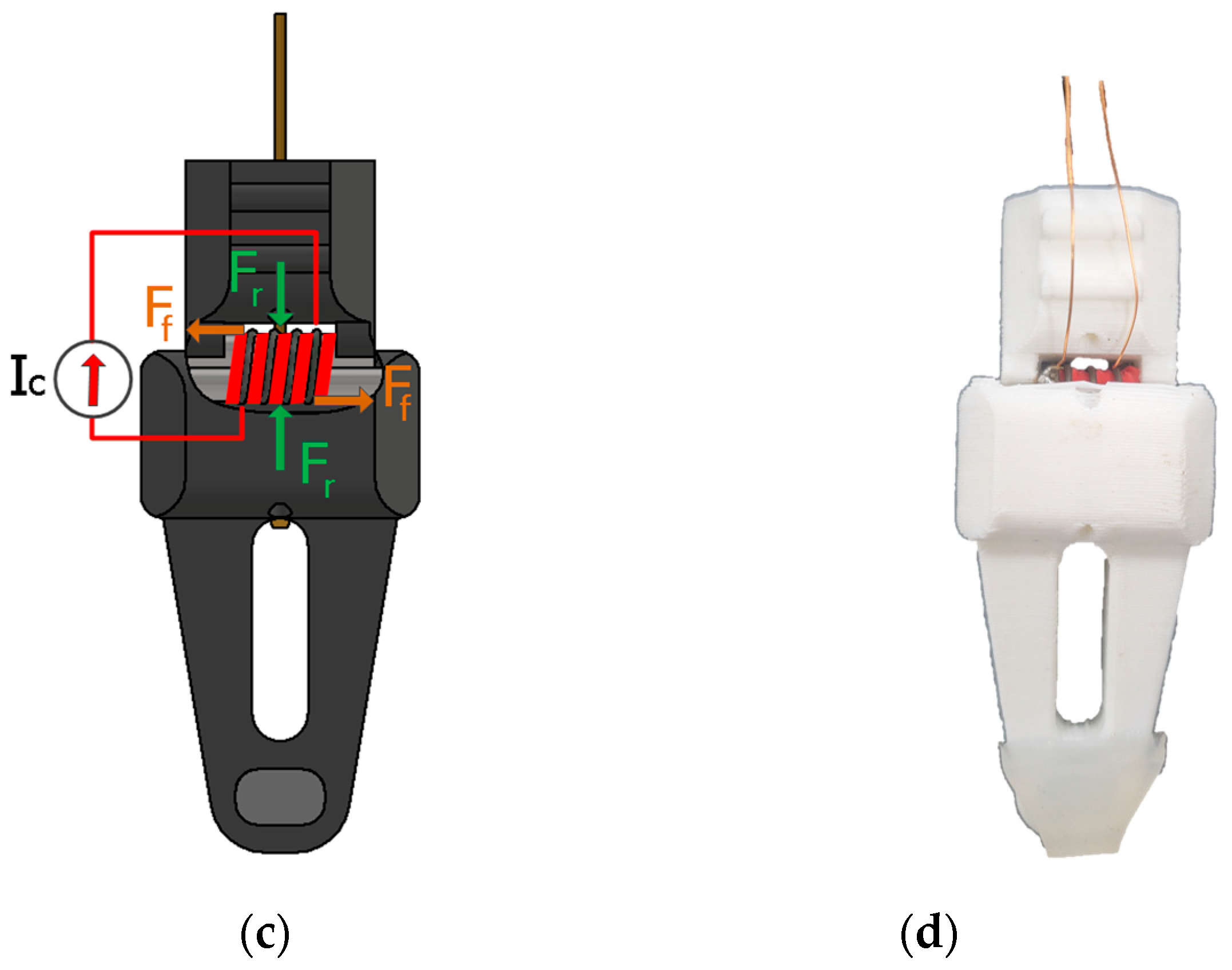

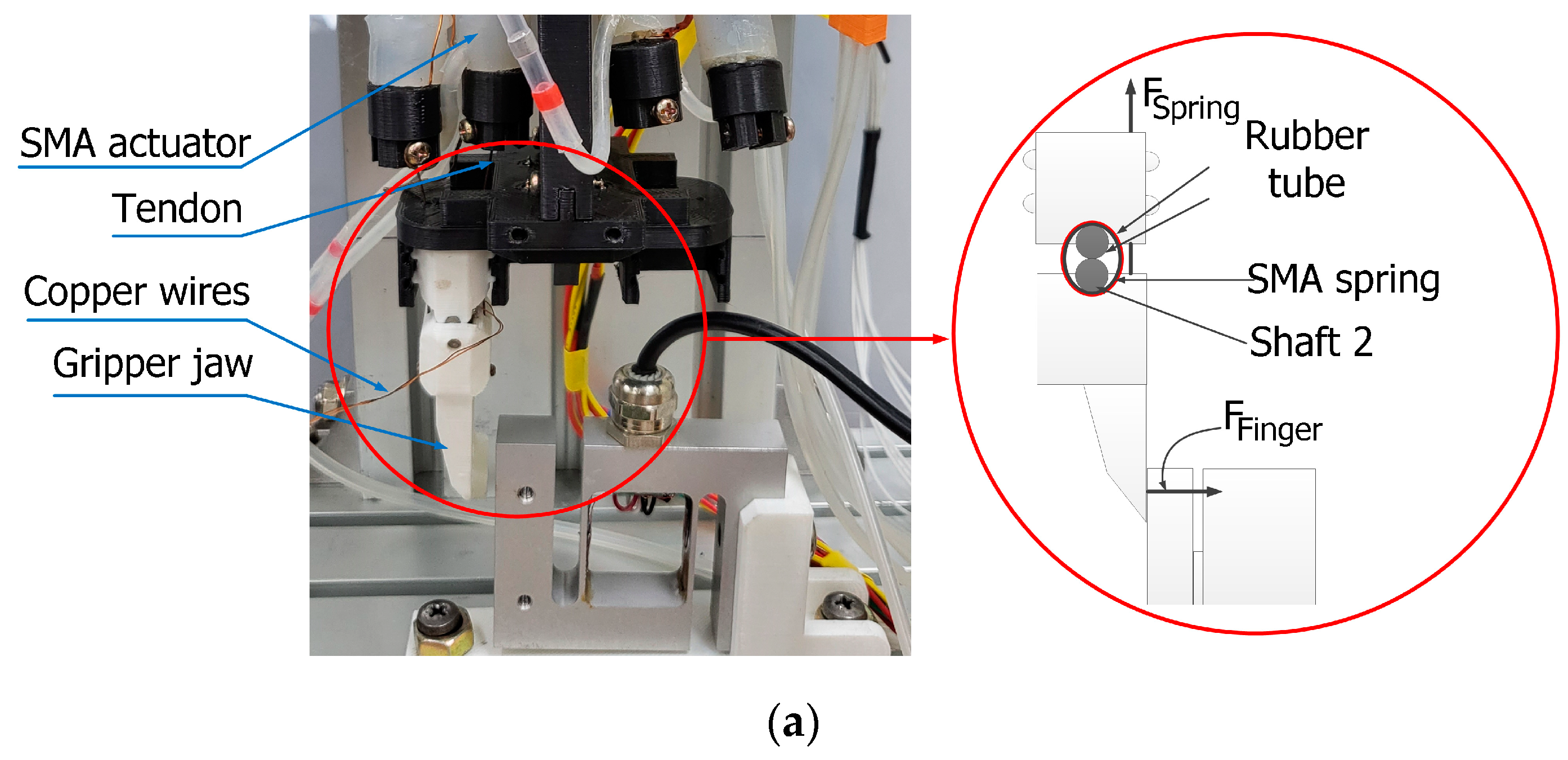

2.1. Design of the Tendon-Driven Gripper

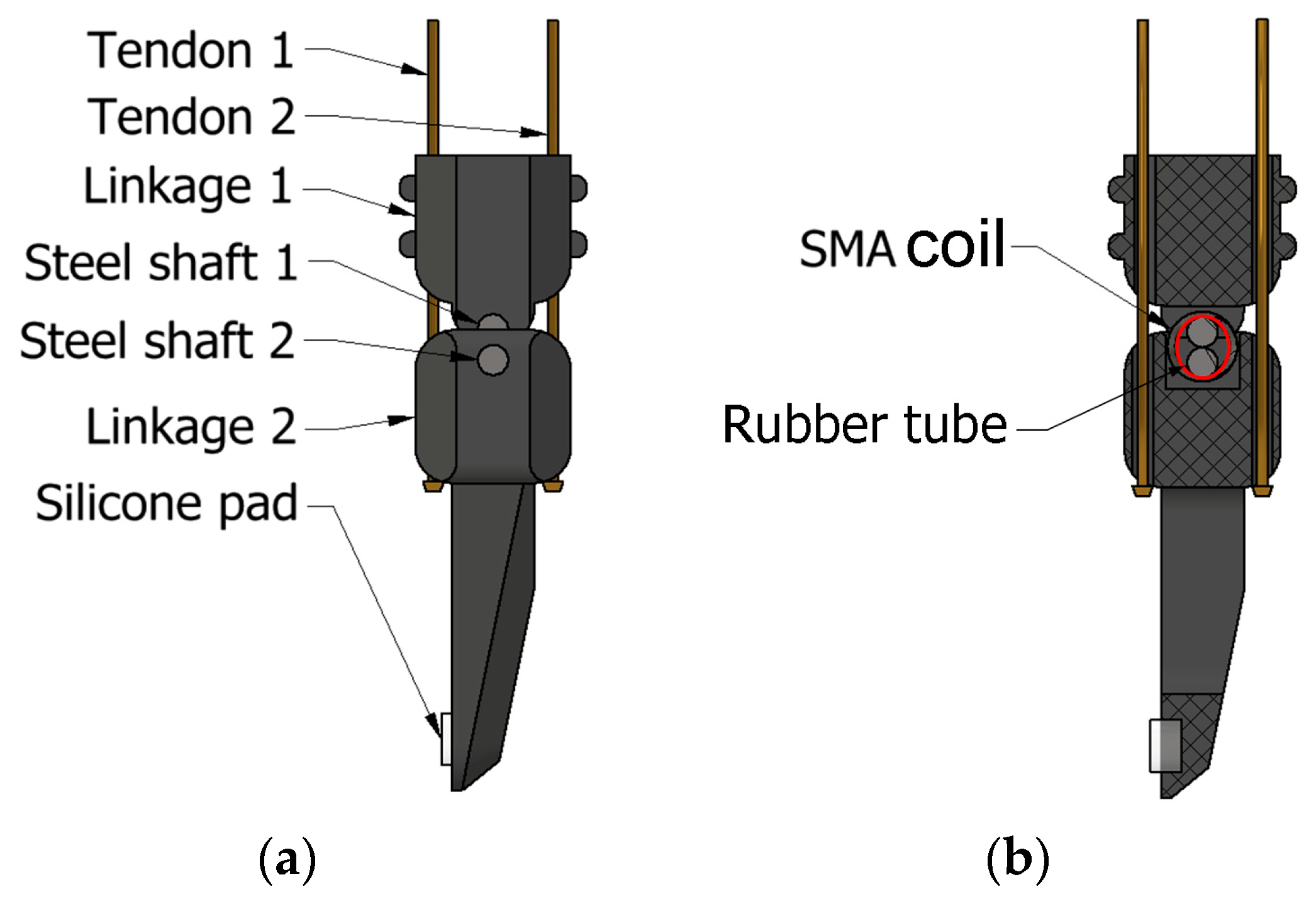

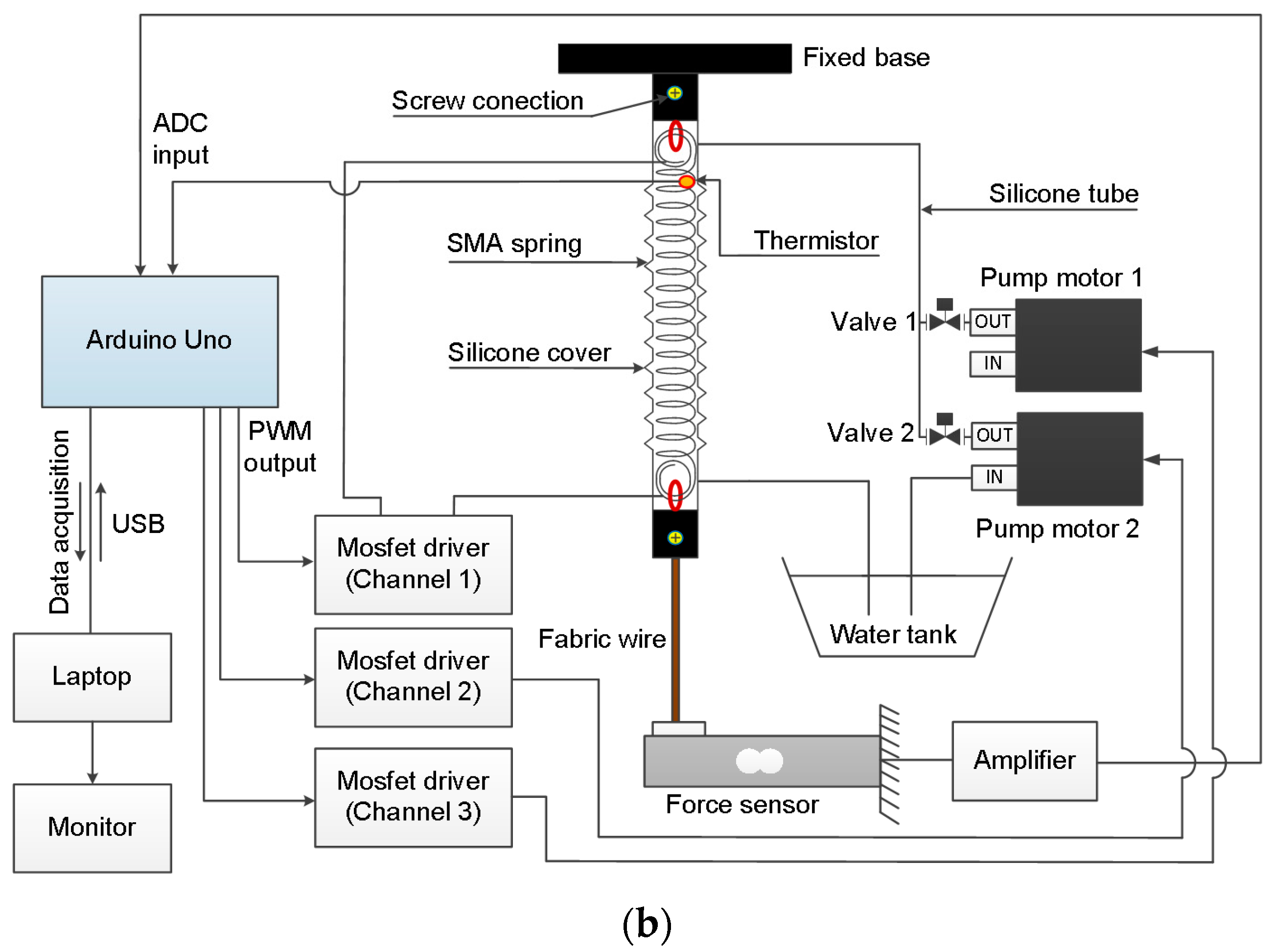

2.2. Conceptual Design of Silicone SSAs

2.3. Design of the Gripper Jaw with Stiffness Control

3. Gripper Modeling

3.1. Mechanical Properties of the SMA Spring

3.2. Contact Force of Single Gripper Finger

4. Experiment and Results

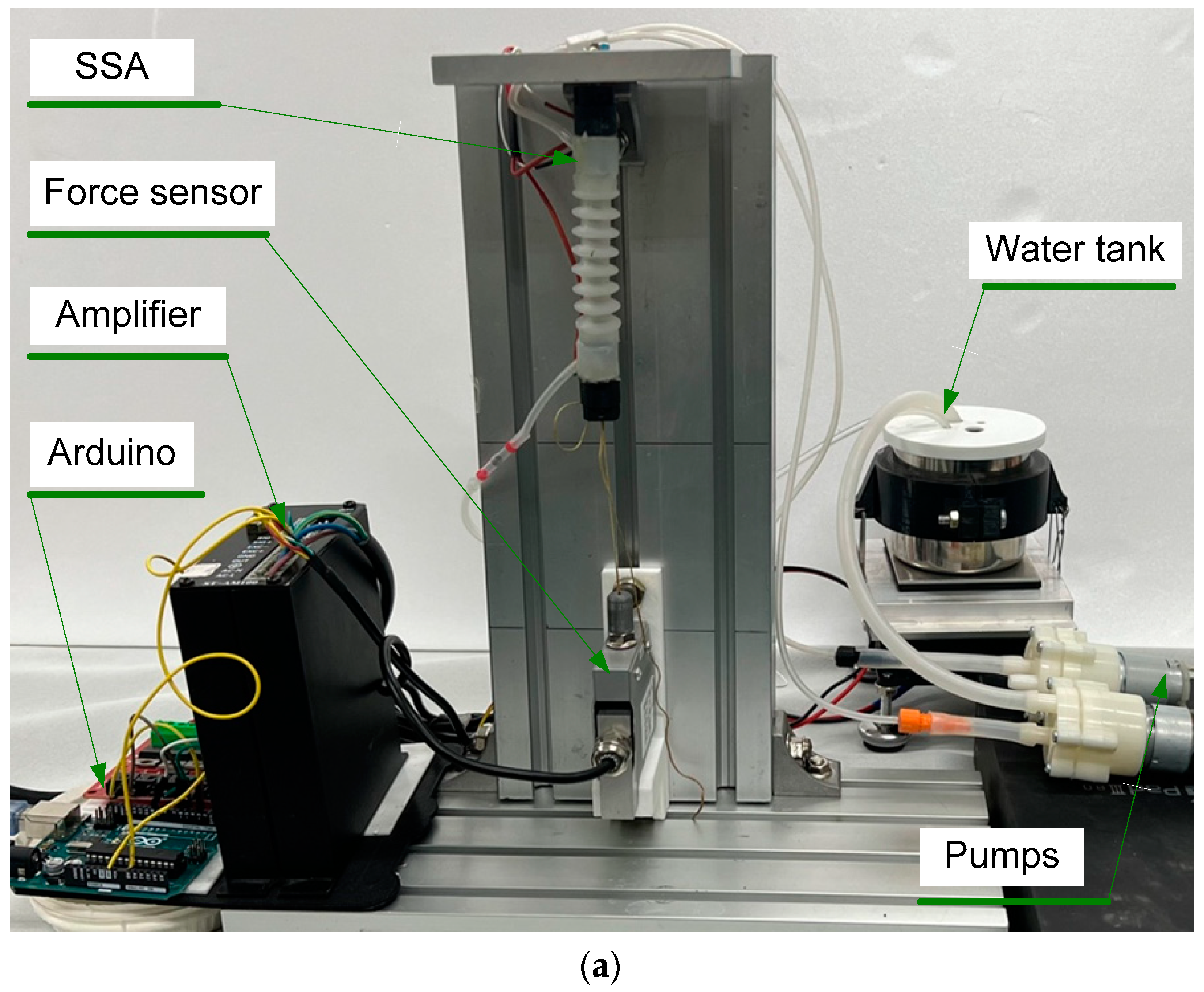

4.1. The Characteristics of the SSAs Experiment

- The first experiment aims to verify the effectiveness of the water-cooling system, so many experiments of the SSA with and without the water-cooling system are executed.

- In the second experiment, the axial force of a single SSA is measured and the shear module of the spring is then estimated.

- The general force of a single gripper is measured and the experiment results are then compared to the mathematical model in the final experiment.

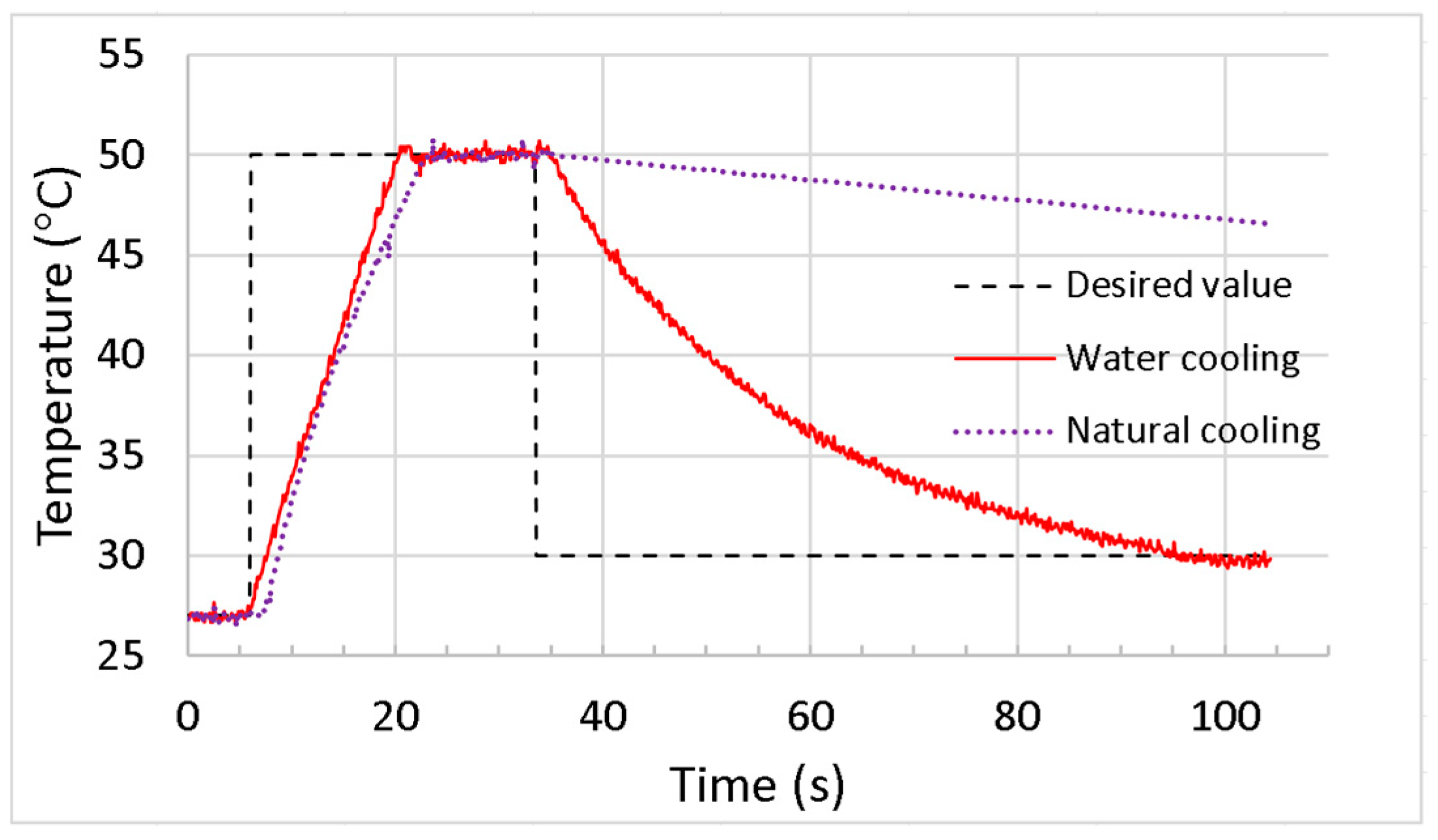

4.1.1. The Response Time of the Cooling System

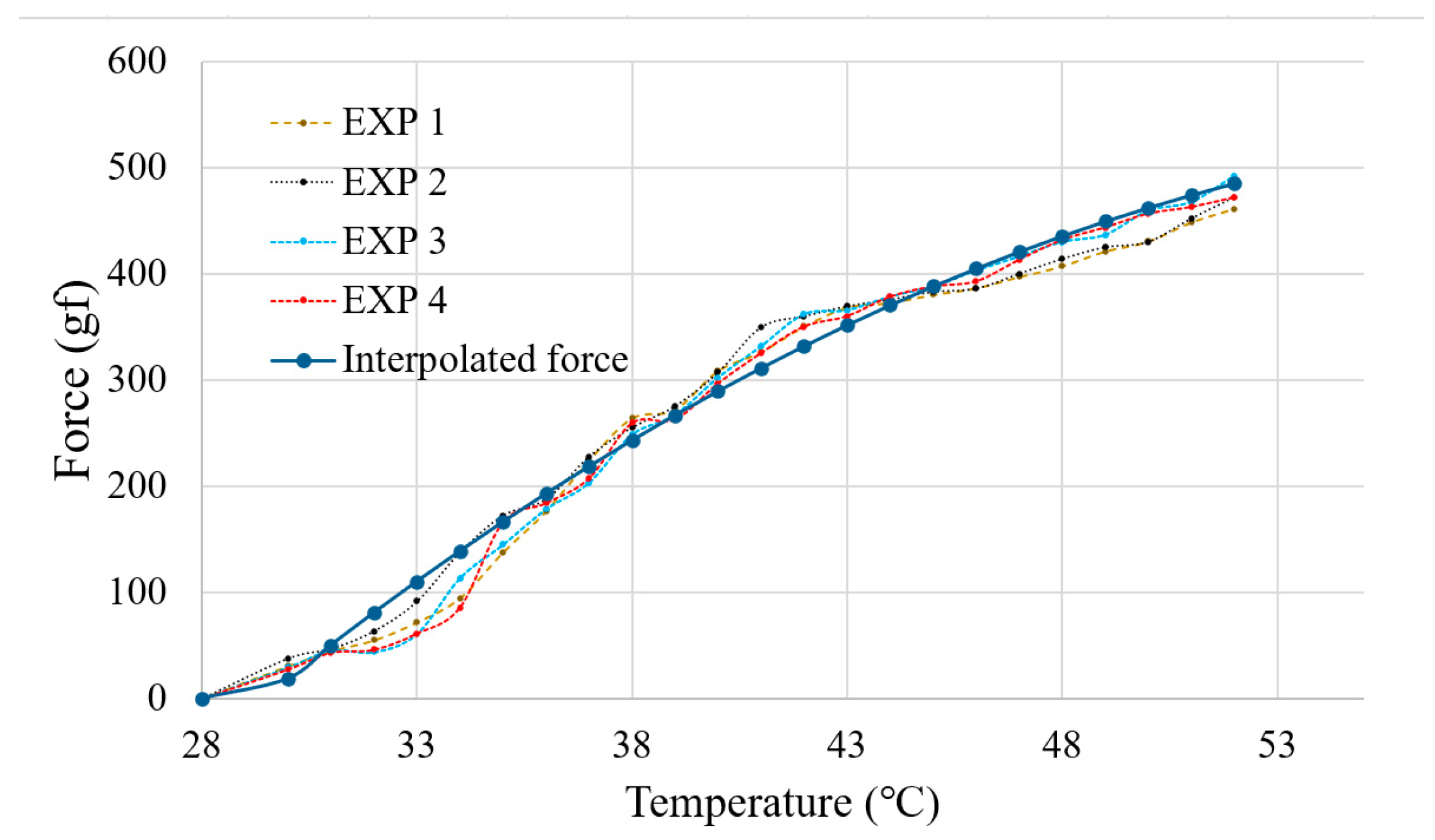

4.1.2. Shear Modulus Estimation

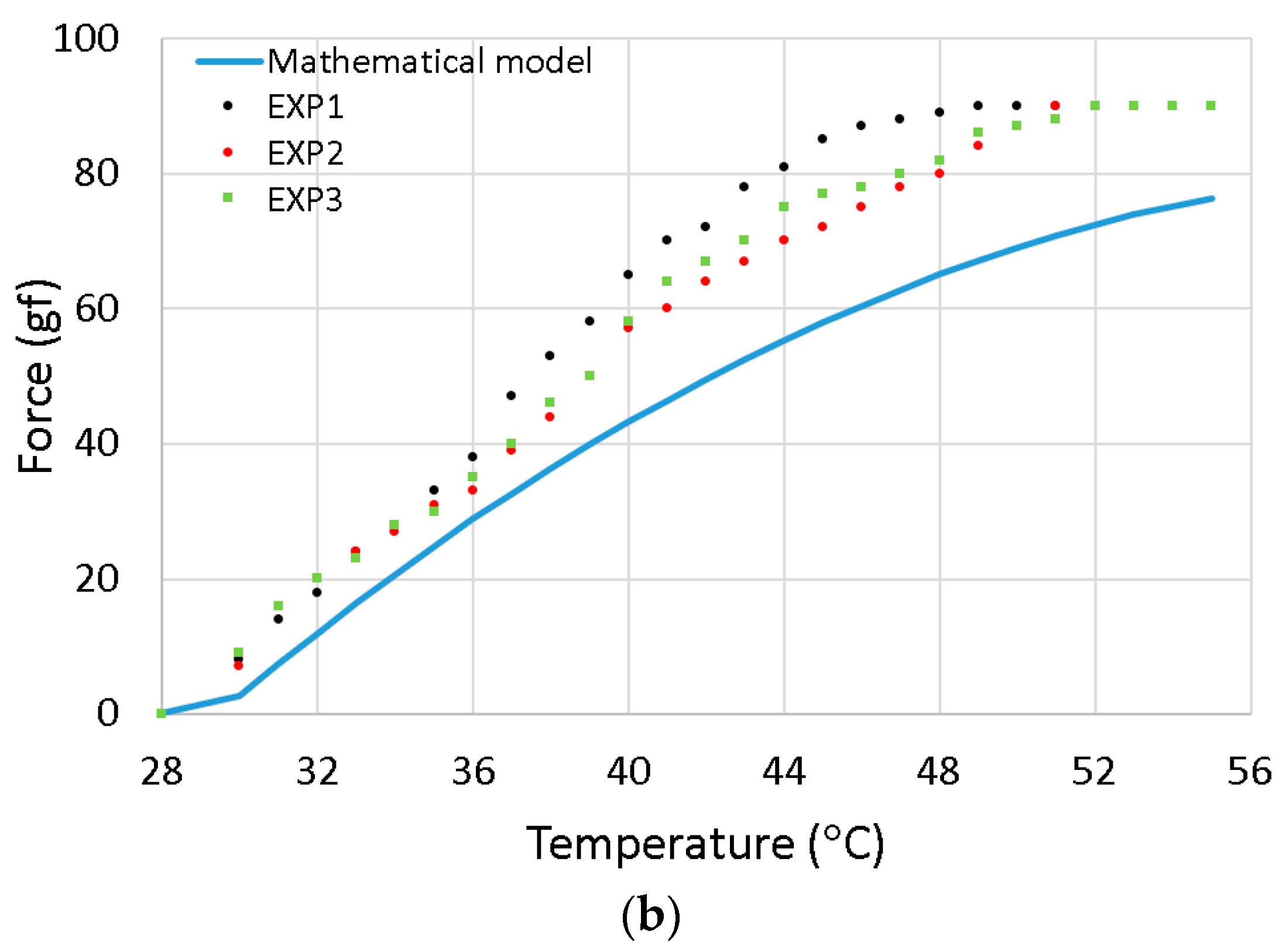

4.1.3. Survey the Contact Force of a Gripper Finger

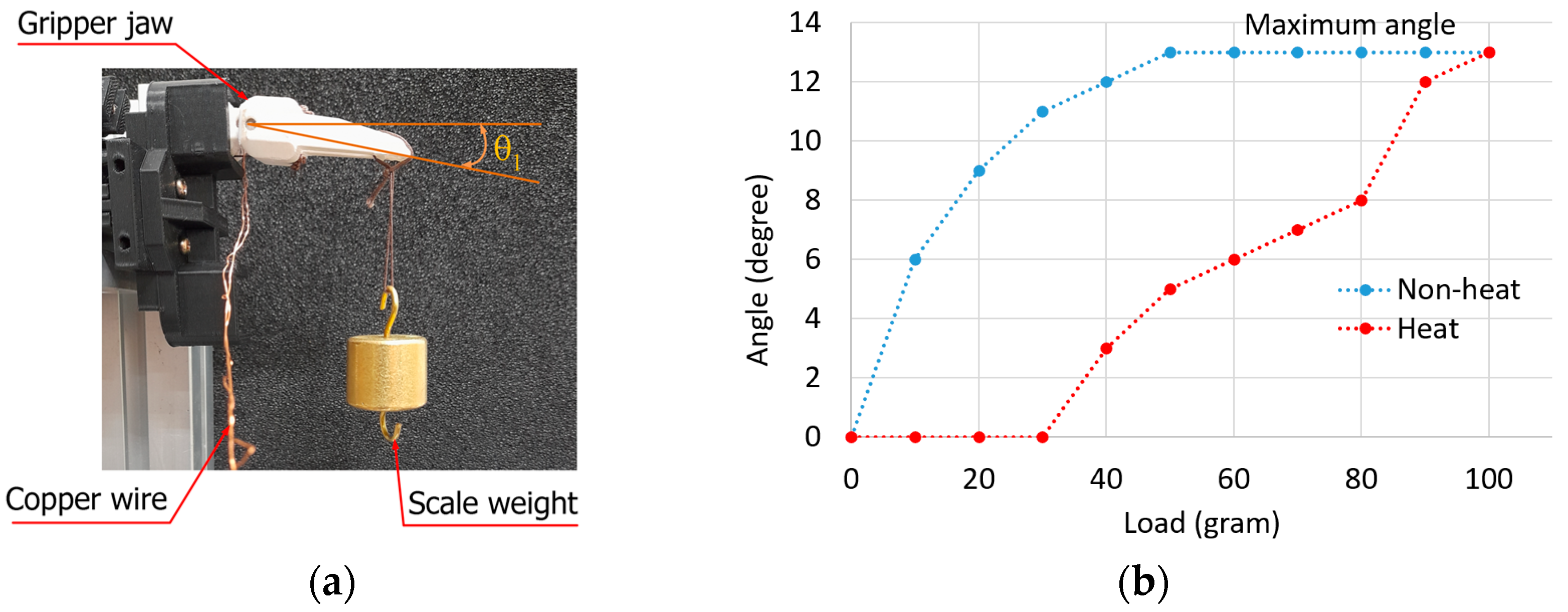

4.2. The Characteristics of the Joint Stiffness

4.3. Gripper Experiment

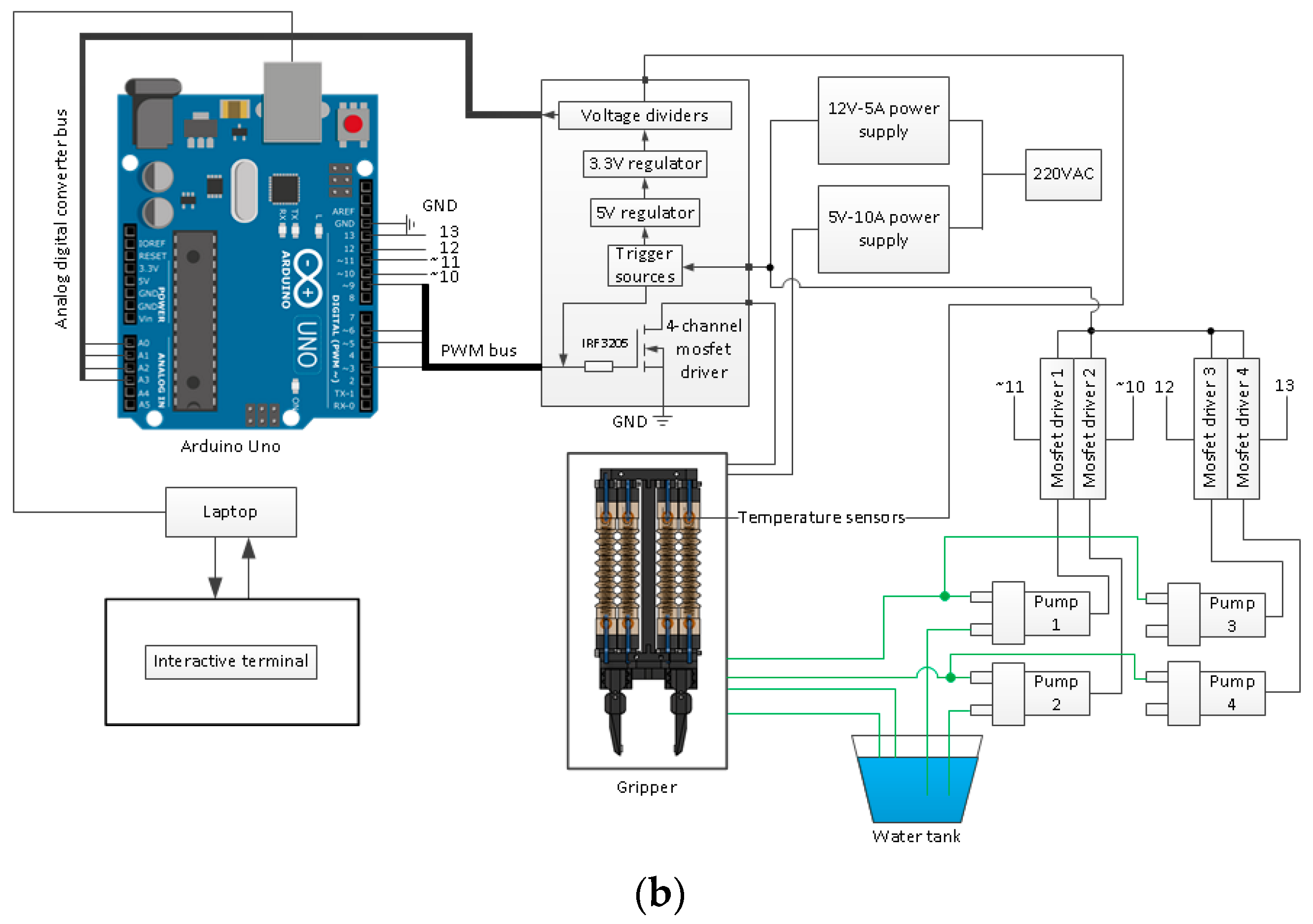

4.3.1. Experimental Setup

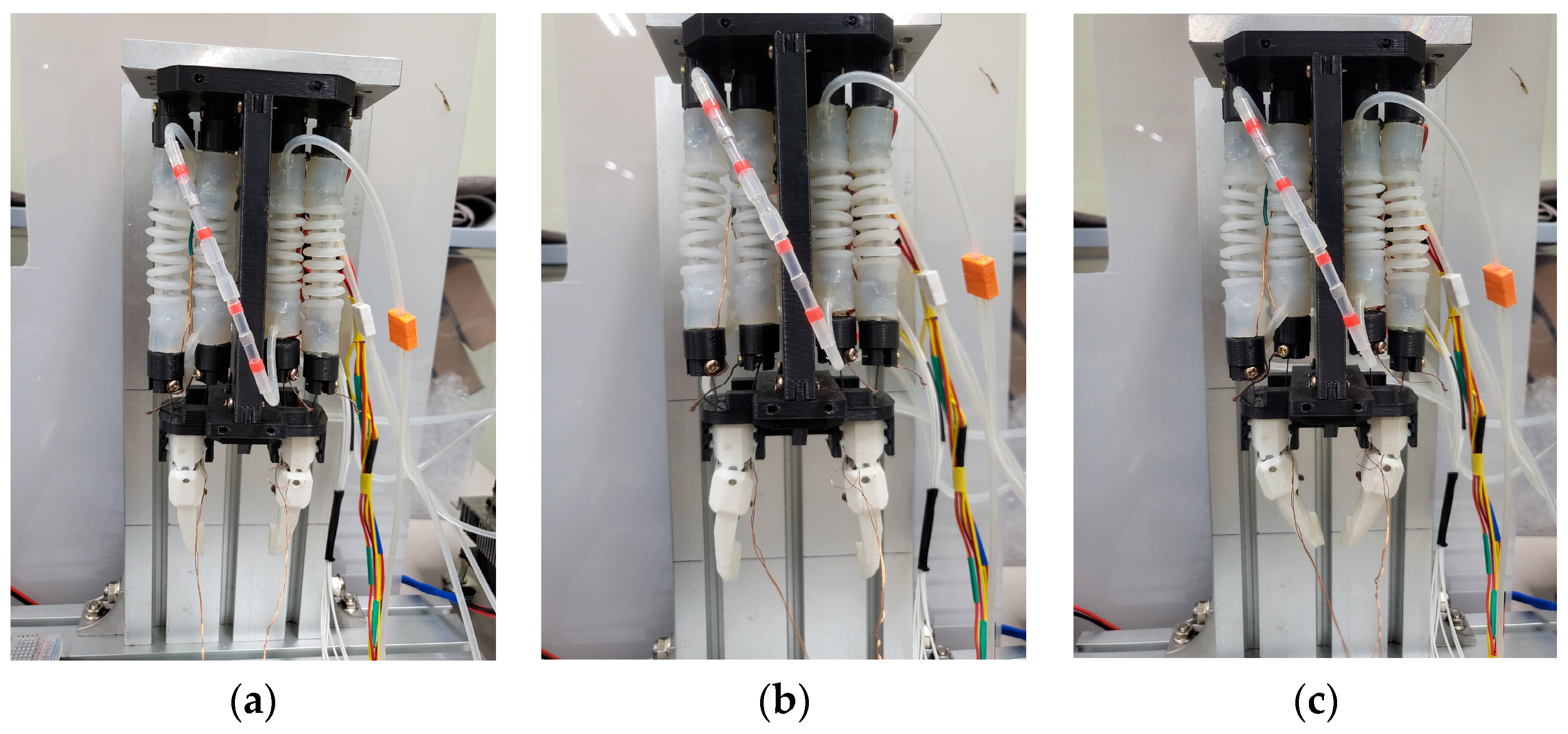

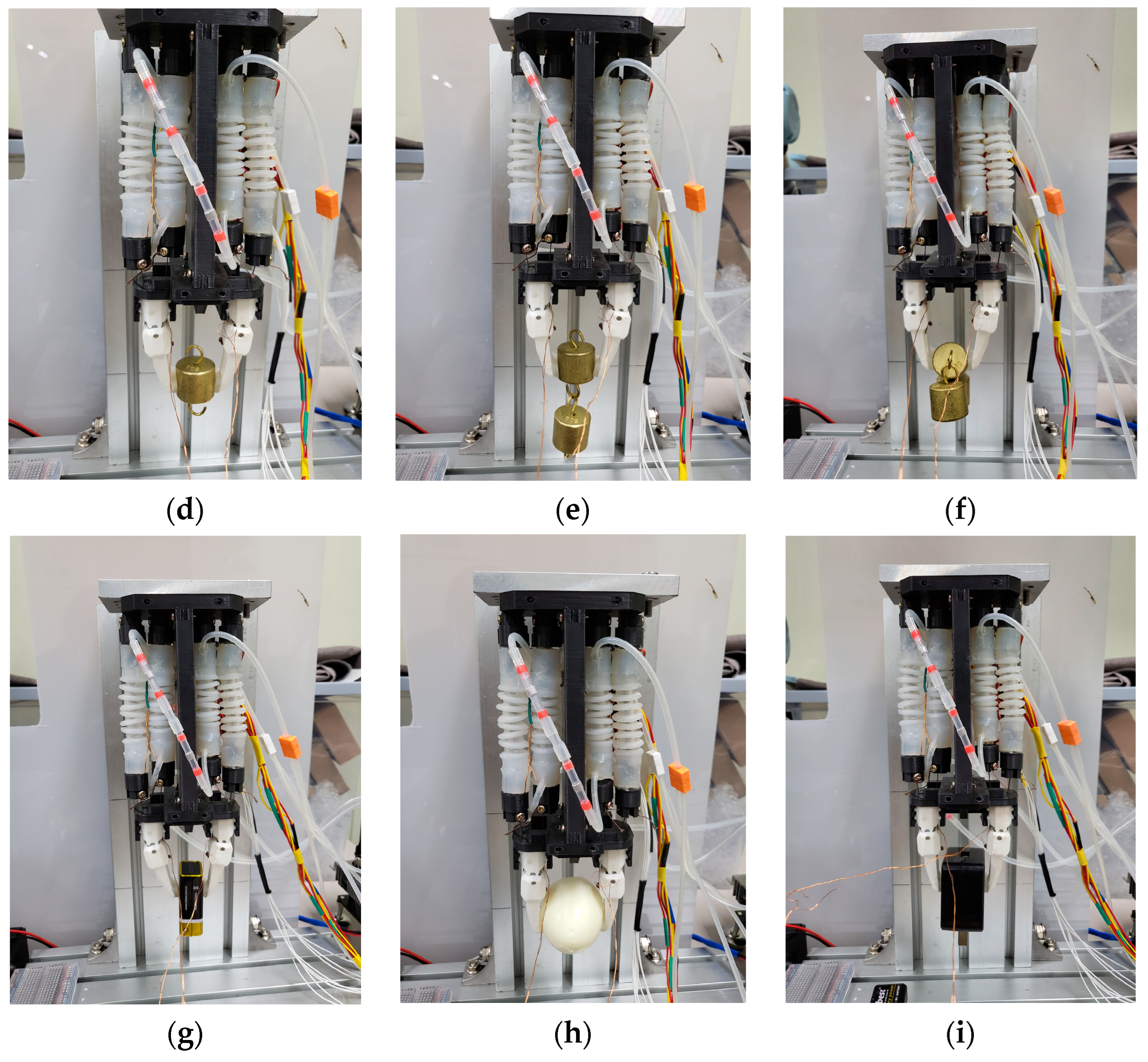

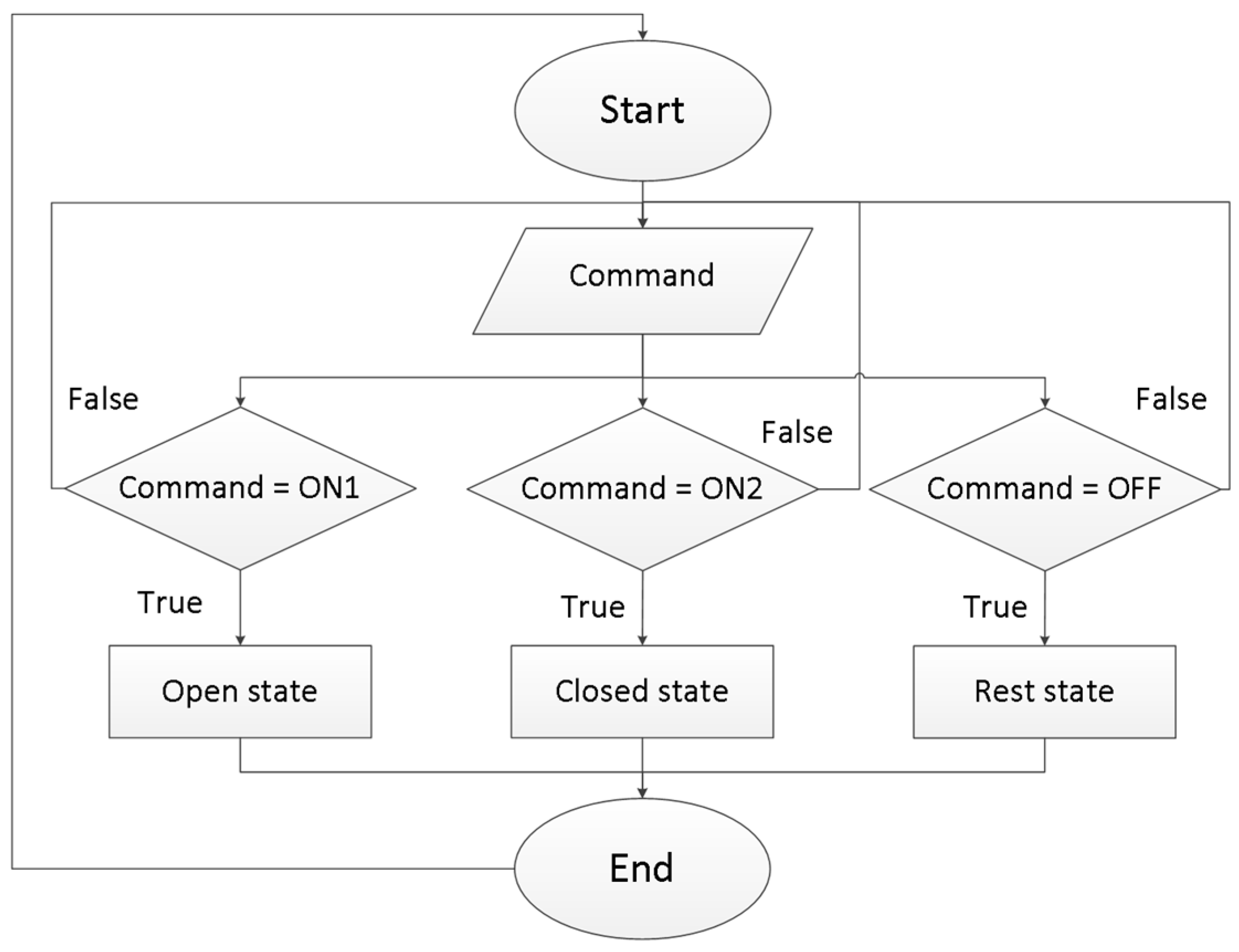

4.3.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Farooq, M.U.; Seong, Y.K. A Decade of MRI Compatible Robots: Systematic Review. IEEE Trans. Robot. 2022, 1–23. [Google Scholar] [CrossRef]

- Kim, Y.; Cheng, S.S.; Desai, J.P. Active Stiffness Tuning of a Spring-Based Continuum Robot for MRI-Guided Neurosurgery. IEEE Trans. Robot. 2017, 34, 18–28. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Cheng, S.S.; Diakite, M.; Gullapalli, R.P.; Simard, J.M.; Desai, J.P. Toward the Development of a Flexible Mesoscale MRI-Compatible Neurosurgical Continuum Robot. IEEE Trans. Robot. 2017, 33, 1386–1397. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.S.; Kim, Y.; Desai, J.P. New Actuation Mechanism for Actively Cooled SMA Springs in a Neurosurgical Robot. IEEE Trans. Robot. 2017, 33, 986–993. [Google Scholar] [CrossRef] [PubMed]

- Monfaredi, R.; Cleary, K.; Sharma, K. MRI Robots for Needle-Based Interventions: Systems and Technology. Ann. Biomed. Eng. 2018, 46, 1479–1497. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Zareinia, K.; Janabi-Sharifi, F. A Brief Review on Robotic Grippers Classifications. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; IEEE: New York, NY, USA, 2019; pp. 1–4. [Google Scholar]

- Gabriel, F.; Fahning, M.; Meiners, J.; Dietrich, F.; Dröder, K. Modeling of vacuum grippers for the design of energy efficient vacuum-based handling processes. Prod. Eng. 2020, 14, 545–554. [Google Scholar] [CrossRef]

- Zhang, H.; Peeters, J.; Demeester, E.; Kellens, K. A CNN-Based Grasp Planning Method for Random Picking of Unknown Objects with a Vacuum Gripper. J. Intell. Robot. Syst. 2021, 103, 64. [Google Scholar] [CrossRef]

- Matsuo, I.; Shimizu, T.; Nakai, Y.; Kakimoto, M.; Sawasaki, Y.; Mori, Y.; Sugano, T.; Ikemoto, S.; Miyamoto, T. Q-bot: Heavy object carriage robot for in-house logistics based on universal vacuum gripper. Adv. Robot. 2020, 34, 173–188. [Google Scholar] [CrossRef]

- Schaffrath, R.; Jäger, E.; Winkler, G.; Doant, J.; Todtermuschke, M. Vacuum gripper without central compressed air supply. Procedia CIRP 2021, 97, 76–80. [Google Scholar] [CrossRef]

- Jamaludin, A.S.; Razali, M.N.M.; Jasman, N.; Ghafar, A.N.A.; Hadi, M.A. Design of Spline Surface Vacuum Gripper for Pick and Place Robotic Arms. J. Mod. Manuf. Syst. Technol. 2020, 4, 48–55. [Google Scholar] [CrossRef]

- Tahir, A.M.; Zoppi, M.; Naselli, G.A. PASCAV Gripper: A Pneumatically Actuated Soft Cubical Vacuum Gripper. In Proceedings of the 2018 International Conference on Reconfigurable Mechanisms and Robots (ReMAR), Delft, The Netherlands, 20–22 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–6. [Google Scholar]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Pancheri, F.; Lueth, T.C. LARG: A Lightweight Robotic Gripper With 3-D Topology Optimized Adaptive Fin-gers. IEEEASME Trans. Mechatron. 2022, 27, 2026–2034. [Google Scholar] [CrossRef]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft Robot Review. Int. J. Control Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Miriyev, A.; Stack, K.; Lipson, H. Soft material for soft actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.; Kim, Y.; Cheng, S.S.; Gullapalli, R.; Desai, J.P. Design, development, and evaluation of an MRI-guided SMA spring-actuated neurosurgical robot. Int. J. Robot. Res. 2015, 34, 1147–1163. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Desai, J.P. Design and kinematic analysis of a neuro- surgical spring-based continuum robot using SMA spring ac-tuators. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1428–1433. [Google Scholar]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; De Falco, I.; Laschi, C.; Menciassi, A. STIFF-FLOP surgical manipulator: Mechanical design and experimental characterization of the single module. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 3576–3581. [Google Scholar] [CrossRef]

- Mohd-Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Sobrinho, J.M.; Filho, F.; Emiliavaca, A.; Cunha, M.F.; Souto, C.R.; Silva, S.; Ries, A. Experimental and numerical analyses of a rotary motor using shape memory alloy mini springs. Sens. Actuators A Phys. 2020, 302, 111823. [Google Scholar] [CrossRef]

- Choudhary, N.; Kaur, D. Shape memory alloy thin films and heterostructures for MEMS applications: A review. Sens. Actuators A Phys. 2016, 242, 162–181. [Google Scholar] [CrossRef]

- Singh, R.K.; Murigendrappa, S.M.; Kattimani, S. Investigation on Properties of Shape Memory Alloy Wire of Cu-Al-Be Doped with Zirconium. J. Mater. Eng. Perform. 2020, 29, 7260–7269. [Google Scholar] [CrossRef]

- Wu, Y.; Wan, Y. The low-velocity impact and compression after impact (CAI) behavior of foam core sandwich panels with shape memory alloy hybrid face-sheets. Sci. Eng. Compos. Mater. 2019, 26, 517–530. [Google Scholar] [CrossRef]

- Roshan, U.; Amarasinghe, R.; Dayananda, N. Design and Fabrication of a Minimally Invasive Surgical Device with Customized Shape Memory Alloy Spring Actuator. J. Robot. Netw. Artif. Life 2018, 5, 194–198. [Google Scholar] [CrossRef]

- Cheng, S.S.; Kim, Y.; Desai, J.P. Modeling and characterization of shape memory alloy springs with water cooling strategy in a neurosurgical robot. J. Intell. Mater. Syst. Struct. 2017, 28, 2167–2183. [Google Scholar] [CrossRef] [PubMed]

- Liao, B.; Zang, H.; Liu, Y.; Wang, Y.; Lang, X.; Jin, J.; Zhu, N.; Yin, Q. Programmable Design of Soft Actuators and Robots. In Proceedings of the 2019 WRC Symposium on Advanced Robotics and Automation (WRC SARA), Beijing, China, 21–22 August 2019; IEEE: New York, NY, USA, 2019; pp. 222–227. [Google Scholar]

- Digumarti, K.M.; Conn, A.T.; Rossiter, J. Euglenoid-Inspired Giant Shape Change for Highly Deformable Soft Robots. IEEE Robot. Autom. Lett. 2017, 2, 2302–2307. [Google Scholar] [CrossRef]

- Tawk, C.; Alici, G. Finite Element Modeling in the Design Process of 3D Printed Pneumatic Soft Actuators and Sensors. Robotics 2020, 9, 52. [Google Scholar] [CrossRef]

- Miron, V.M.; Lämmermann, S.; Çakmak, U.; Major, Z. Material Characterization of 3D-printed Silicone Elastomers. Procedia Struct. Integr. 2021, 34, 65–70. [Google Scholar] [CrossRef]

- Jeon, H.; Le, Q.N.; Jeong, S.; Jang, S.; Jung, H.; Chang, H.; Pandya, H.J.; Kim, Y. Towards a Snake-Like Flexible Robot with Variable Stiffness Using an SMA Spring-Based Friction Change Mechanism. IEEE Robot. Autom. Lett. 2022, 7, 6582–6589. [Google Scholar] [CrossRef]

- Ma, J.; Huang, H.; Huang, J. Characteristics Analysis and Testing of SMA Spring Actuator. Adv. Mater. Sci. Eng. 2013, 2013, 823594. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Material | NiTi-45 | Nitinol |

| Spring diameter | D | 6.5 mm |

| Wire diameter | d | 0.75 mm |

| Original length | Lmin | 20 mm |

| Maximum length stretch | Lmax | 150 mm |

| Number of coils | n | 21 |

| Elastic modulus at room temperature | E | 50 GPa |

| Austenite temperature | 45–50 °C |

| Target | Weight [g] | Size [mm] | Temperature [°C] |

|---|---|---|---|

| A scale weight | 50 | ϕ22 × 19 | 35 |

| 2 scale weights | 100 | ϕ22 × 19 | 45 |

| 3 scale weights | 150 | ϕ22 × 19 | 55 |

| A battery | 45 | 25 × 40 × 18 | 35 |

| An egg | 45 | Null | 35 |

| A charger | 60 | 60 × 60 × 30 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, P.T.; Le, Q.N.; Luong, Q.V.; Kim, H.-H.; Park, H.-M.; Kim, Y.-J. Tendon-Driven Gripper with Variable Stiffness Joint and Water-Cooled SMA Springs. Actuators 2023, 12, 160. https://doi.org/10.3390/act12040160

Do PT, Le QN, Luong QV, Kim H-H, Park H-M, Kim Y-J. Tendon-Driven Gripper with Variable Stiffness Joint and Water-Cooled SMA Springs. Actuators. 2023; 12(4):160. https://doi.org/10.3390/act12040160

Chicago/Turabian StyleDo, Phuoc Thien, Quang Ngoc Le, Quoc Viet Luong, Hyun-Ho Kim, Hyeong-Mo Park, and Yeong-Jin Kim. 2023. "Tendon-Driven Gripper with Variable Stiffness Joint and Water-Cooled SMA Springs" Actuators 12, no. 4: 160. https://doi.org/10.3390/act12040160

APA StyleDo, P. T., Le, Q. N., Luong, Q. V., Kim, H.-H., Park, H.-M., & Kim, Y.-J. (2023). Tendon-Driven Gripper with Variable Stiffness Joint and Water-Cooled SMA Springs. Actuators, 12(4), 160. https://doi.org/10.3390/act12040160