Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke

Abstract

1. Introduction

2. Cooperative Spring-Based Long-Stroke Electrostatic Actuators

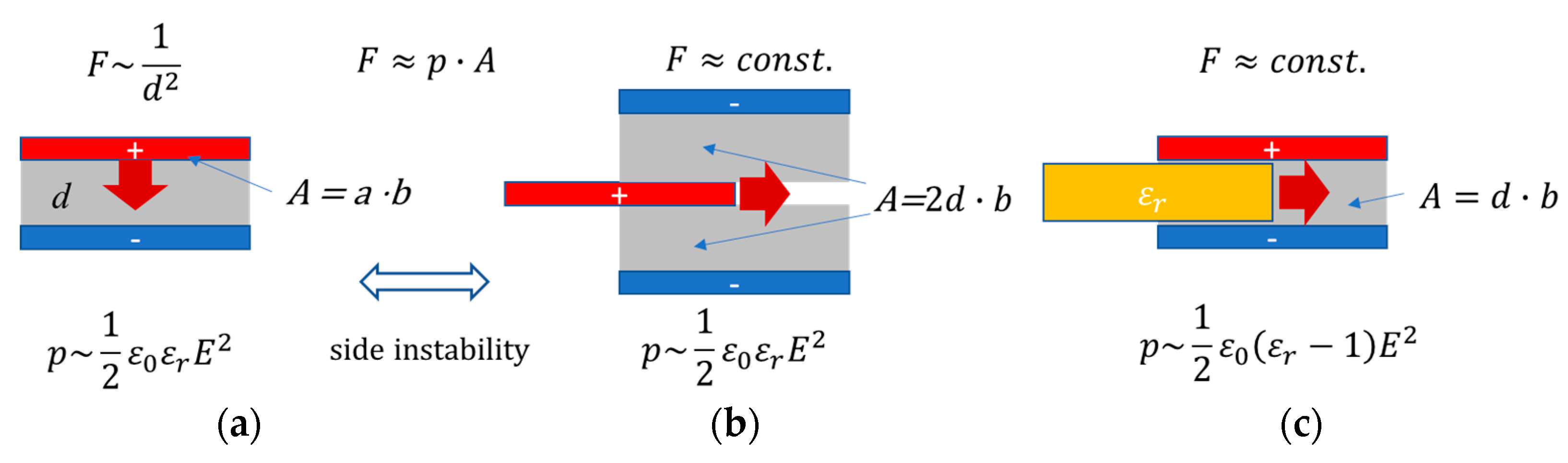

2.1. Electrostatic Vertical Attracting and Tangential Forces

- Vertical parallel-plate actuation:

- Tangential parallel-plate comb actuation:

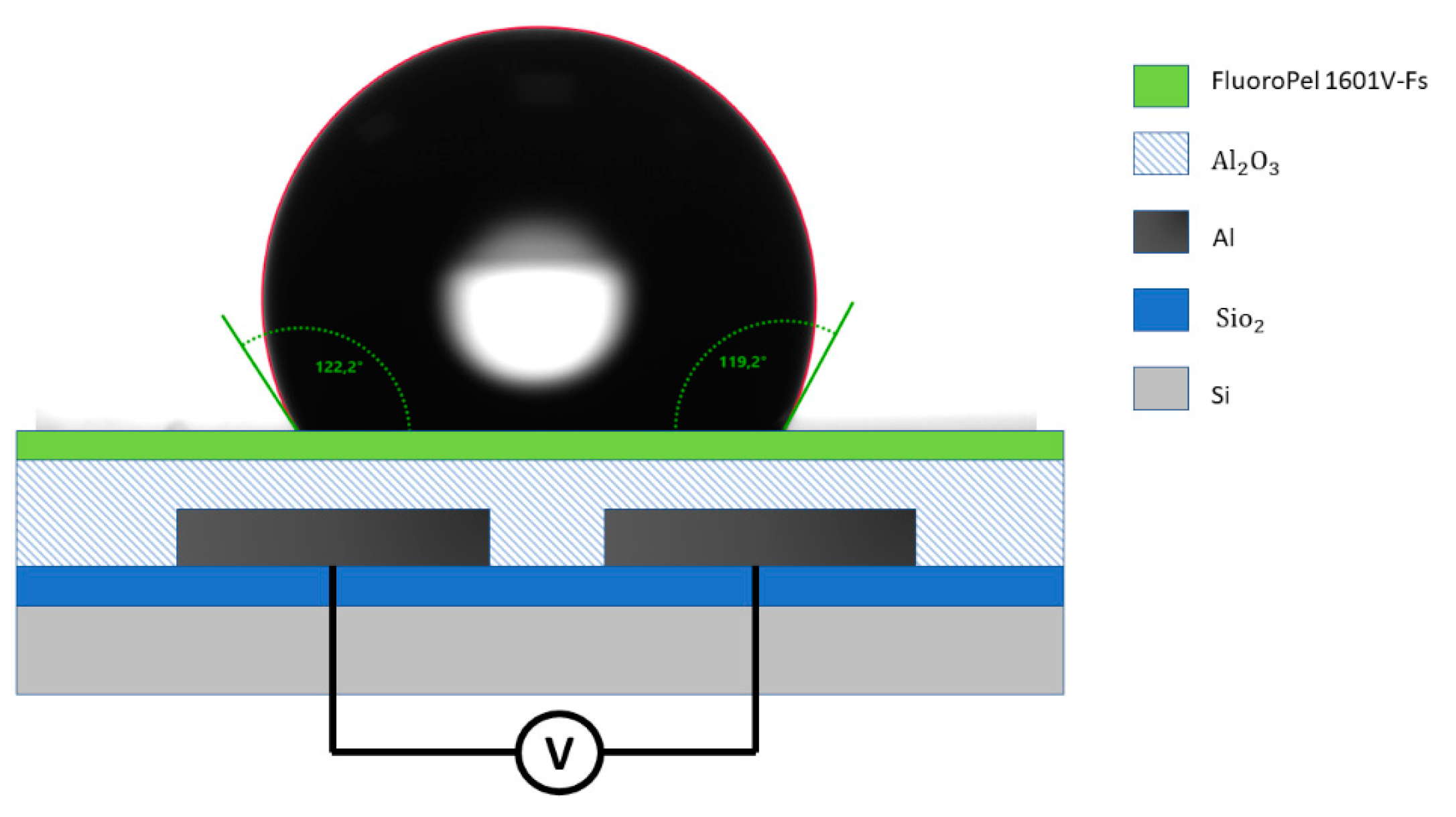

- The relevant normalization area is given using the gap area in the direction of movement: , and for standard “dry” actuators with gas-filled gap d, the dielectric constant is almost 1. As the area to which the pressure applies does not change with actuation, the resulting force is constant as long as both plates do not fully overlap. Additionally, a tangential actuation of dielectrics, particularly liquids, can be approximated in a similar way. In this case, any dielectric (dielectric constant is drawn into an air-filled capacitor (see Figure 1c). Here, the calculation of the electrostatic pressure results in a quite similar formula: ; note that this electrostatic pressure is usually much larger due to the factor and will be used for the springless long-stroke actuation.

- The electrostatic pressure is proportional to .

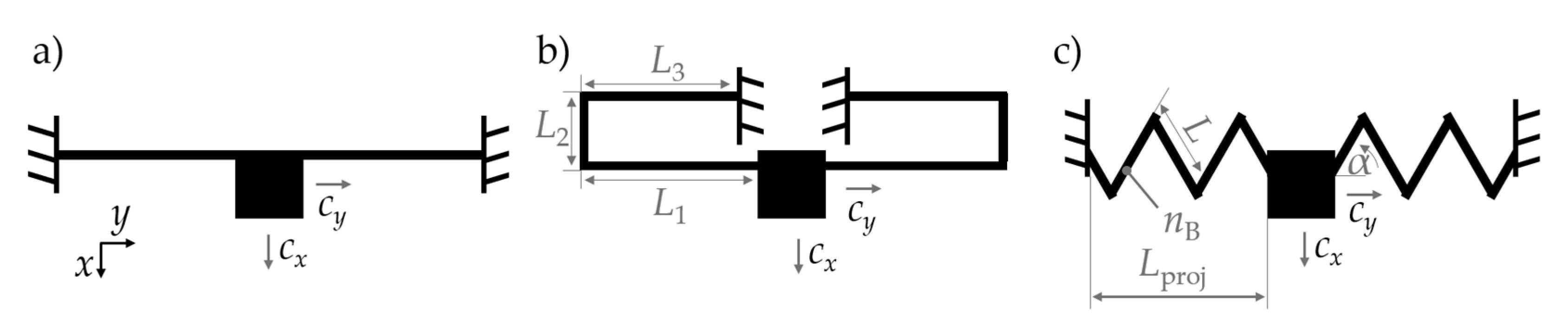

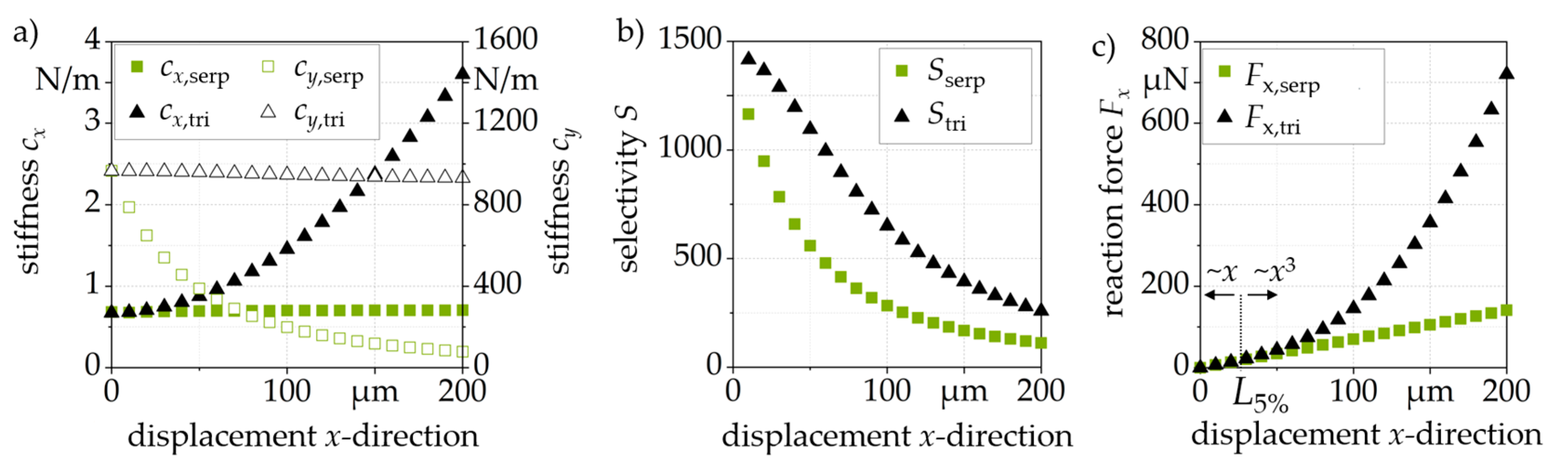

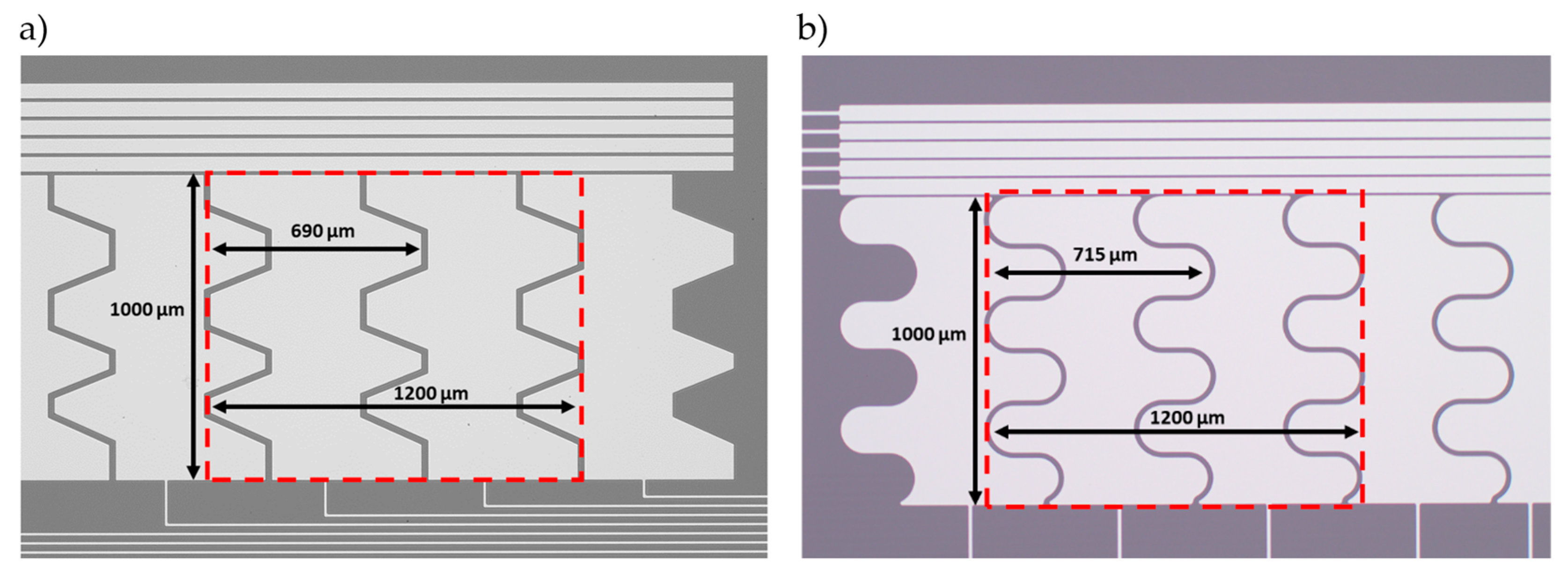

2.2. Guiding Mechanisms for Long-Stroke Actuators

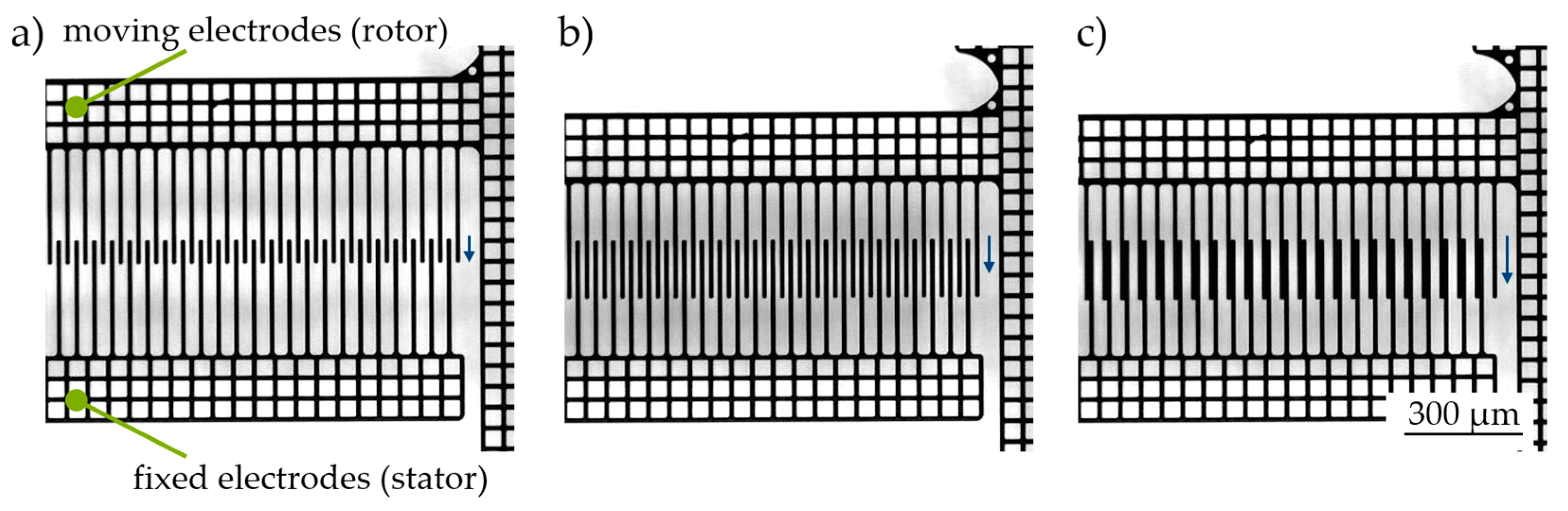

2.3. Electrostatic Comb Drives for Long-Stroke Actuation

2.4. Large Displacements Based on Parallel-Plate Actuators

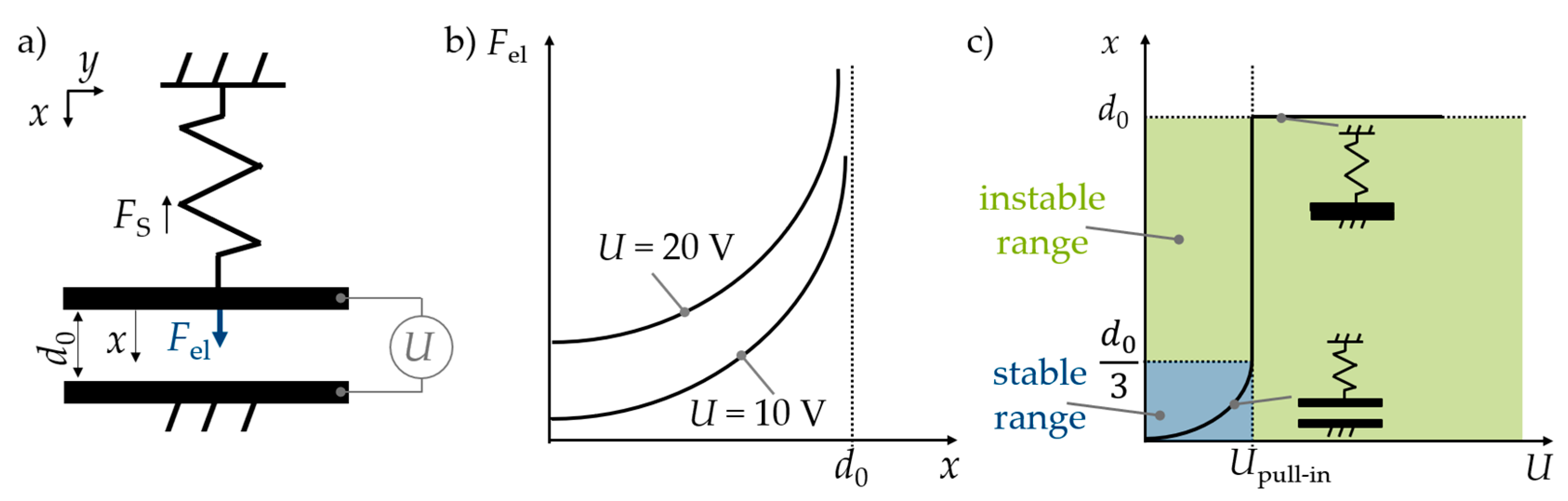

2.4.1. Electrostatic Parallel-Plate Actuators

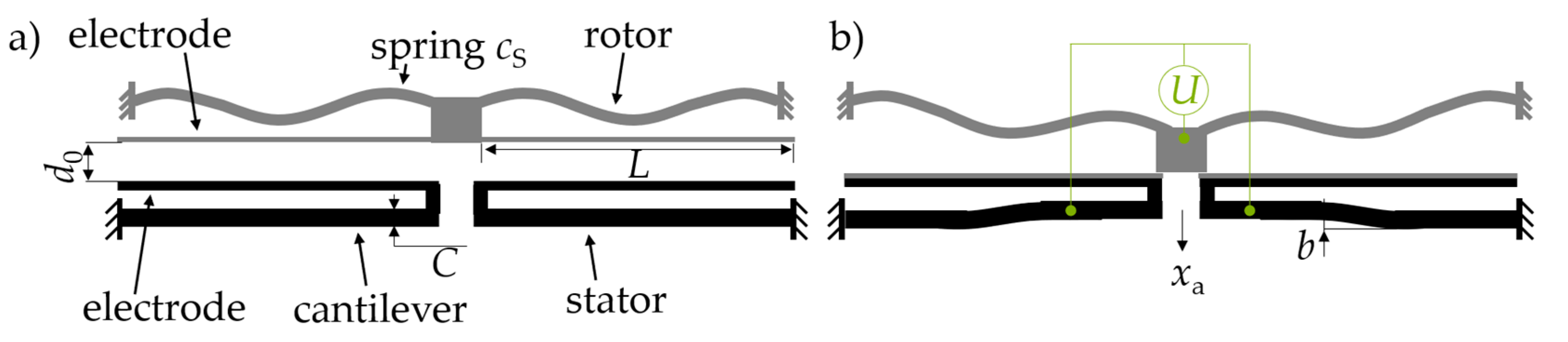

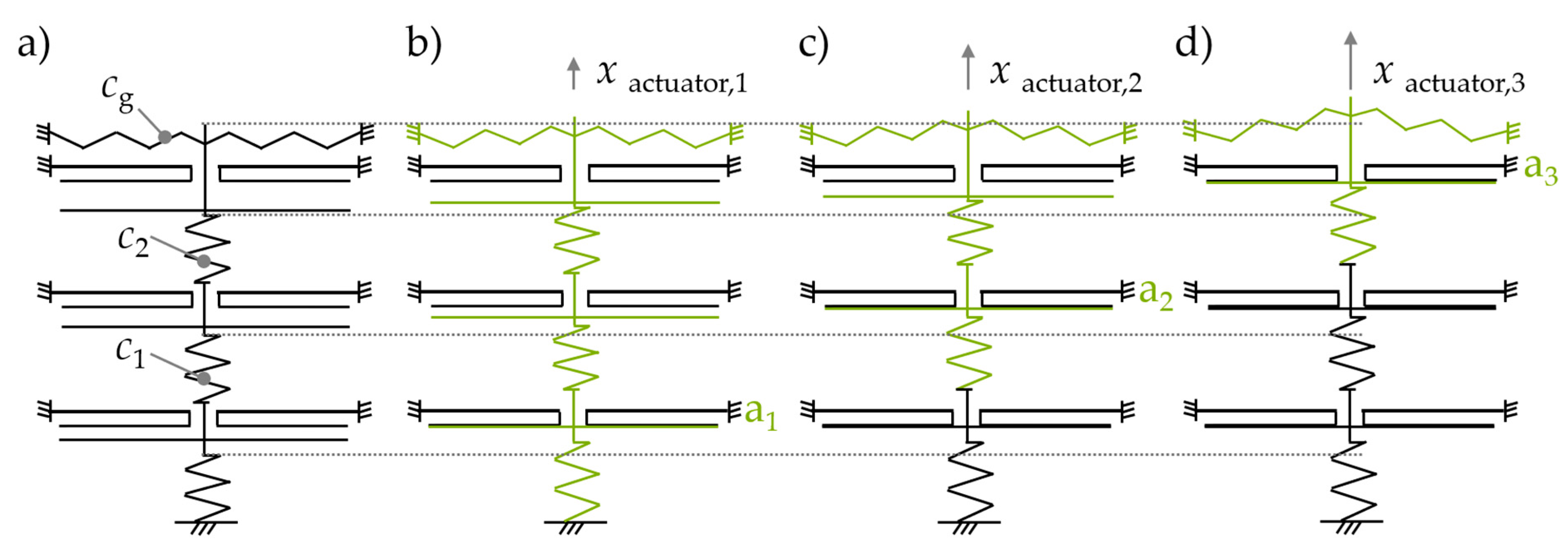

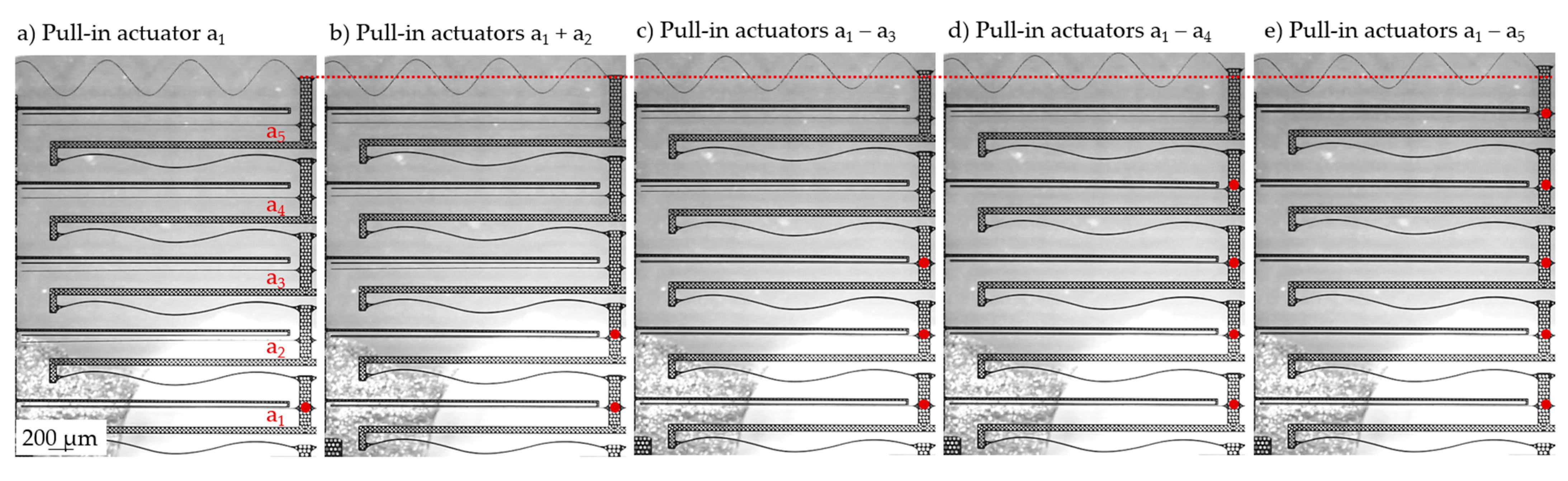

2.4.2. Electrostatic Parallel-Plate Actuators with Multiple Stable Steps

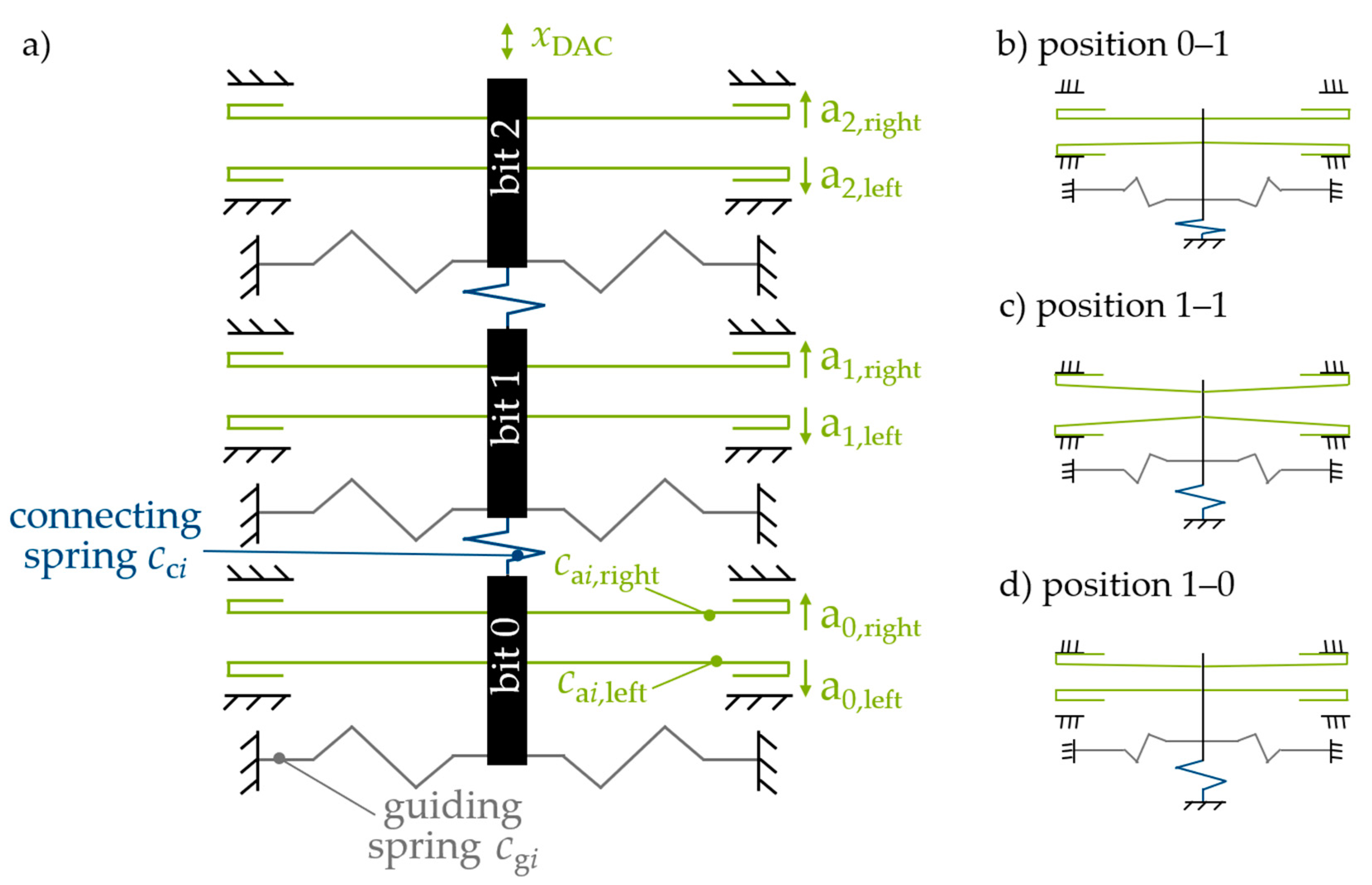

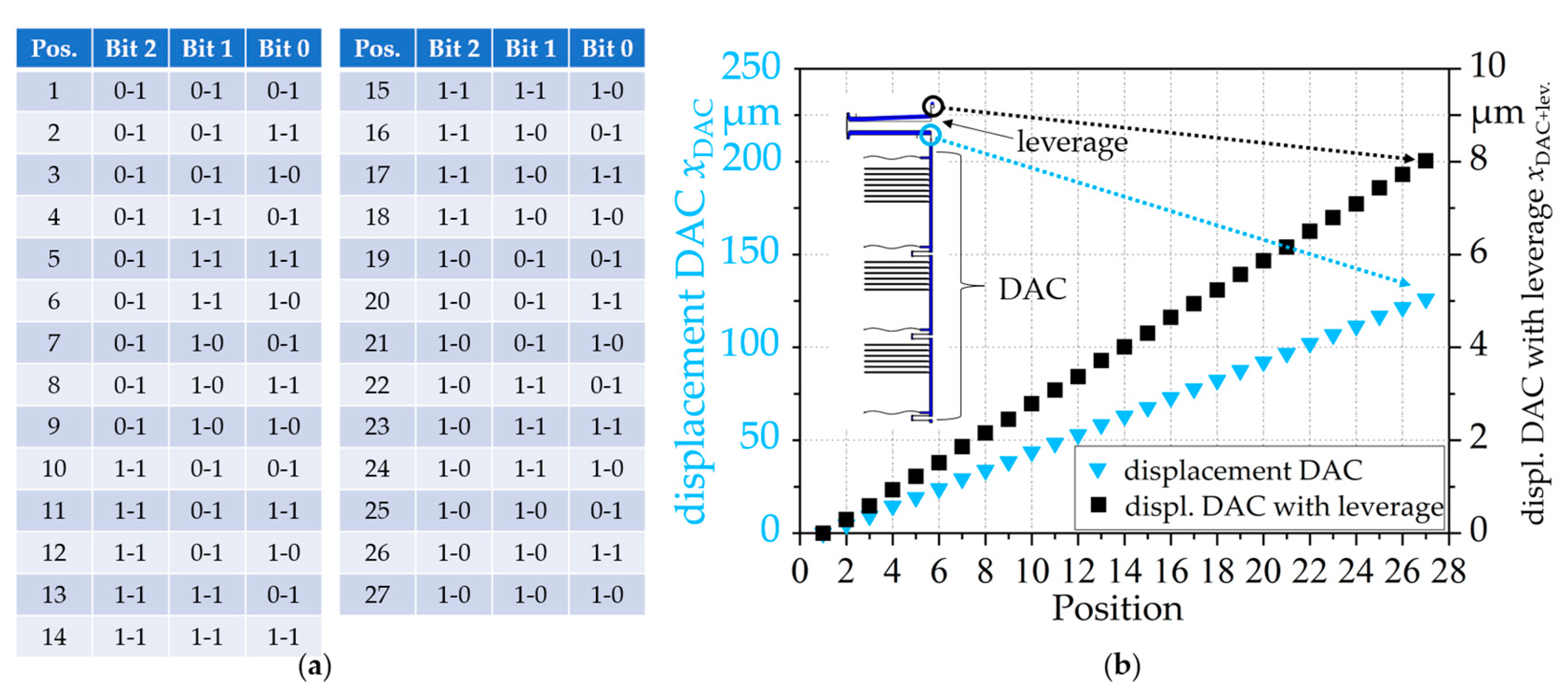

2.4.3. Digital-to-Analog Converting Actuators (DAC)

3. Springless Long Stroke/Infinite Stroke Actuators

3.1. Actuator Concept

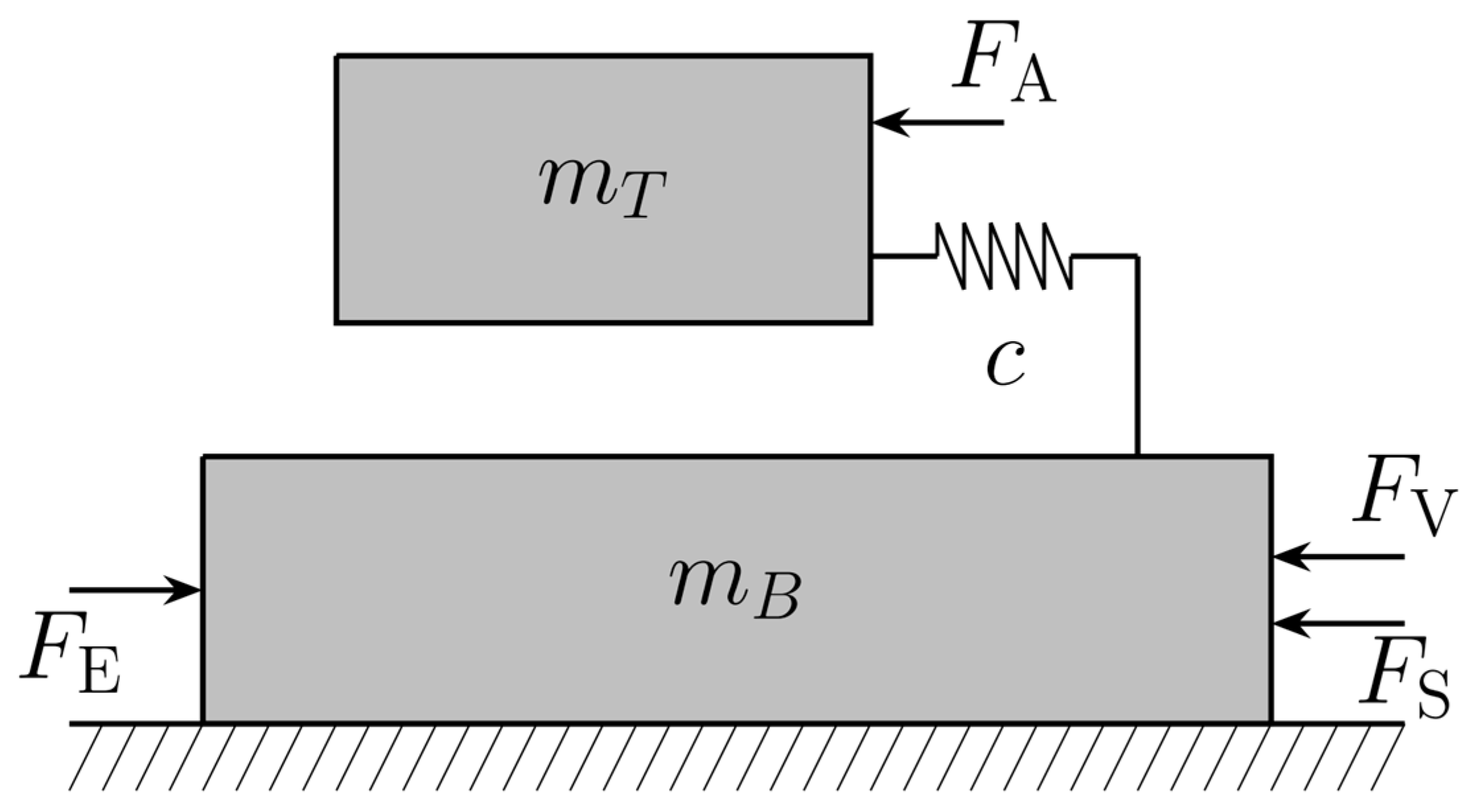

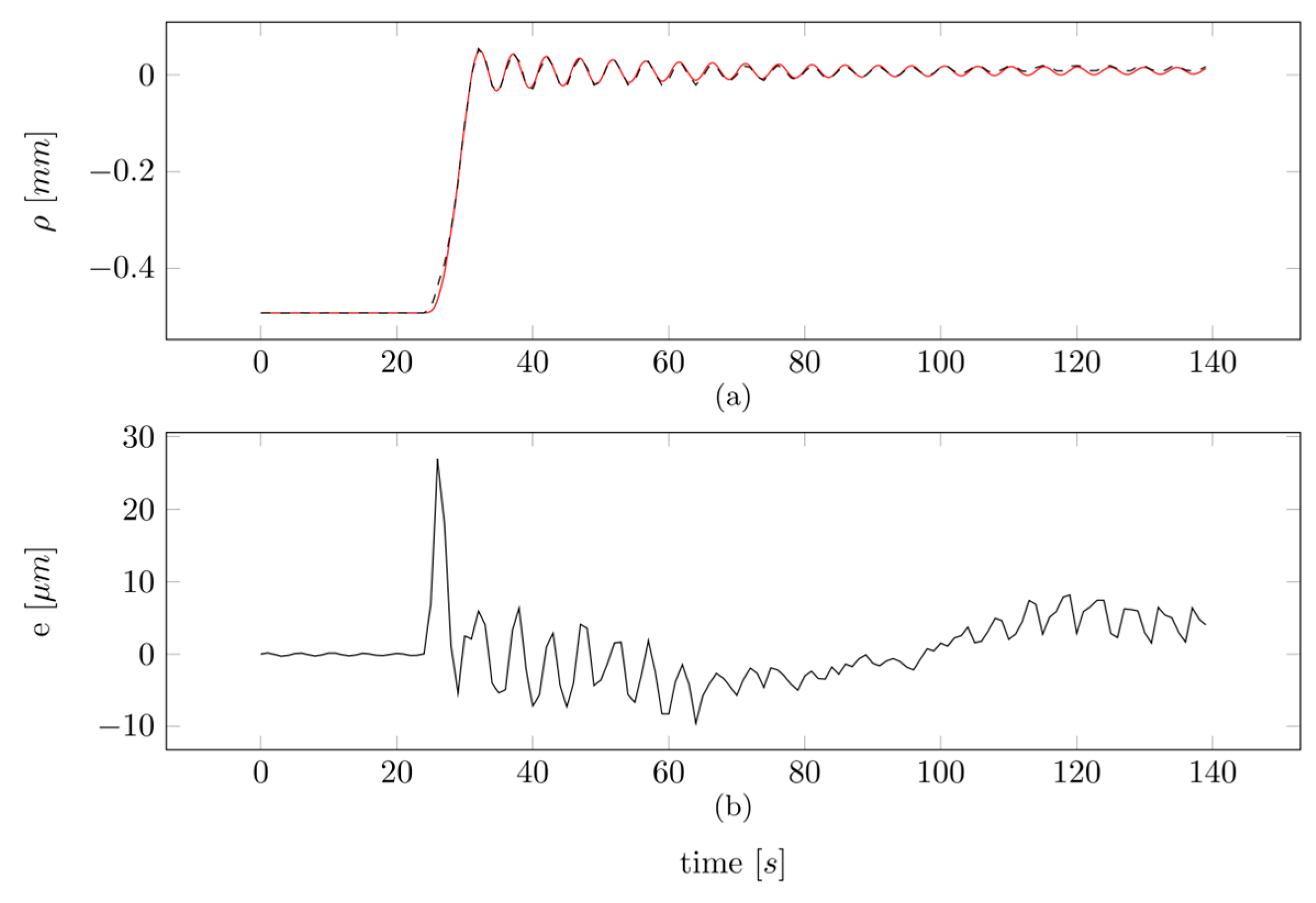

3.2. System Modelling

3.3. Experimental Results

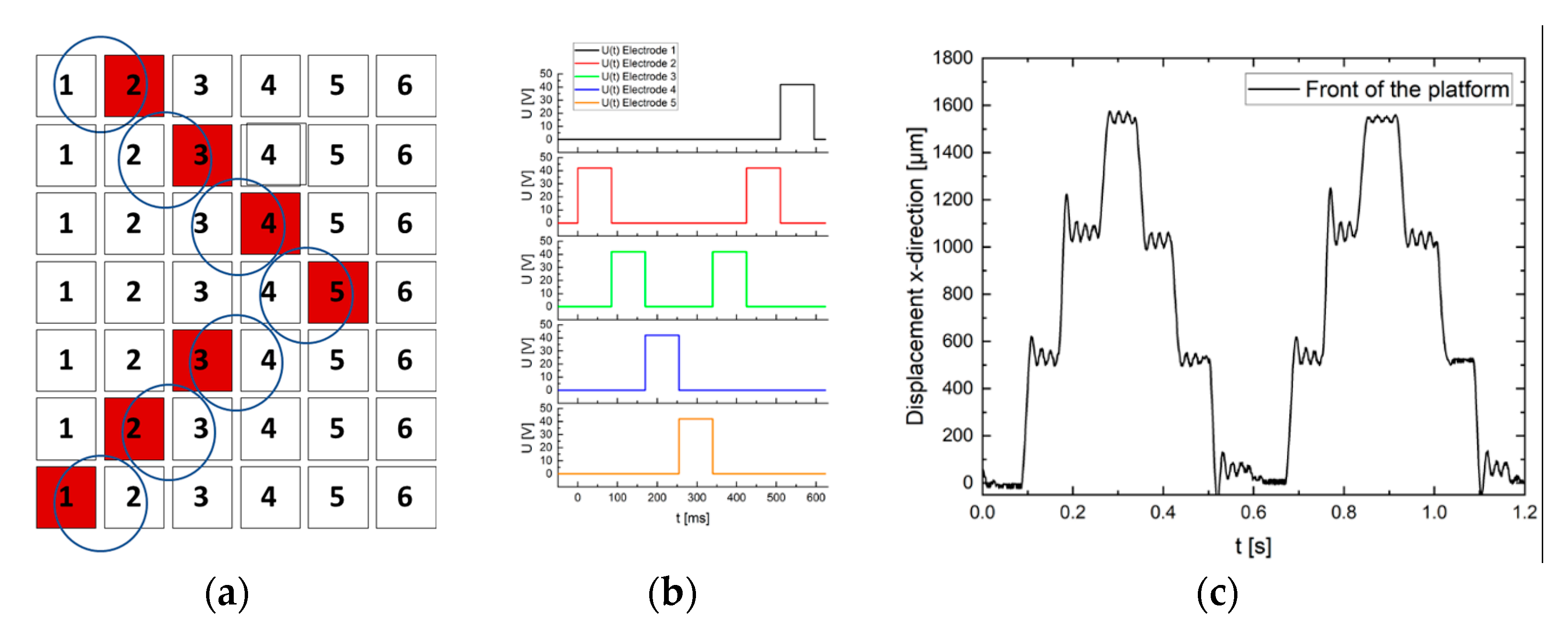

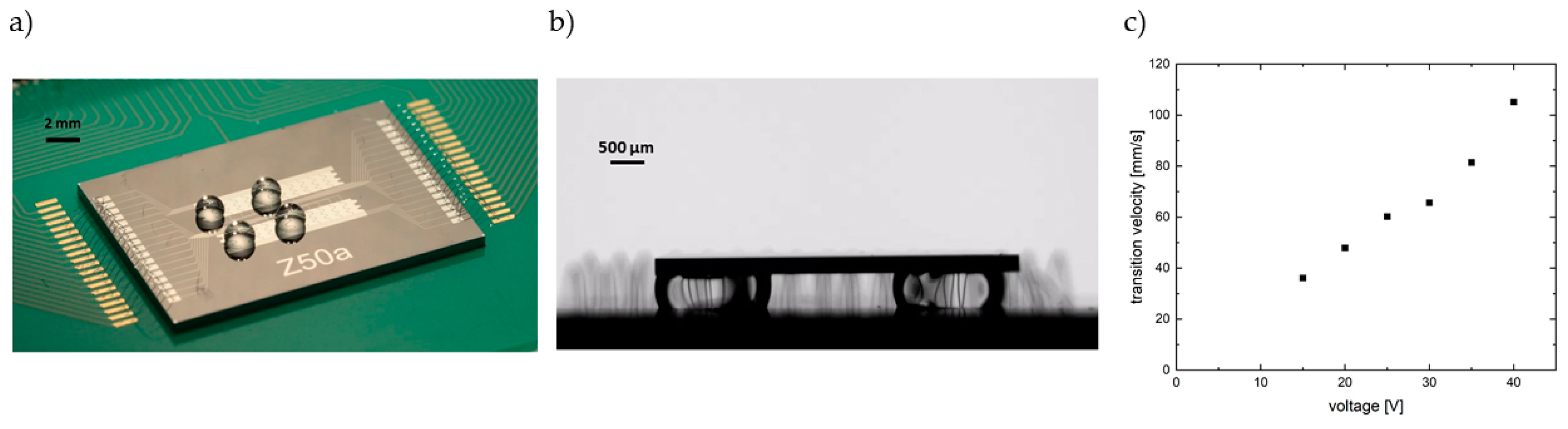

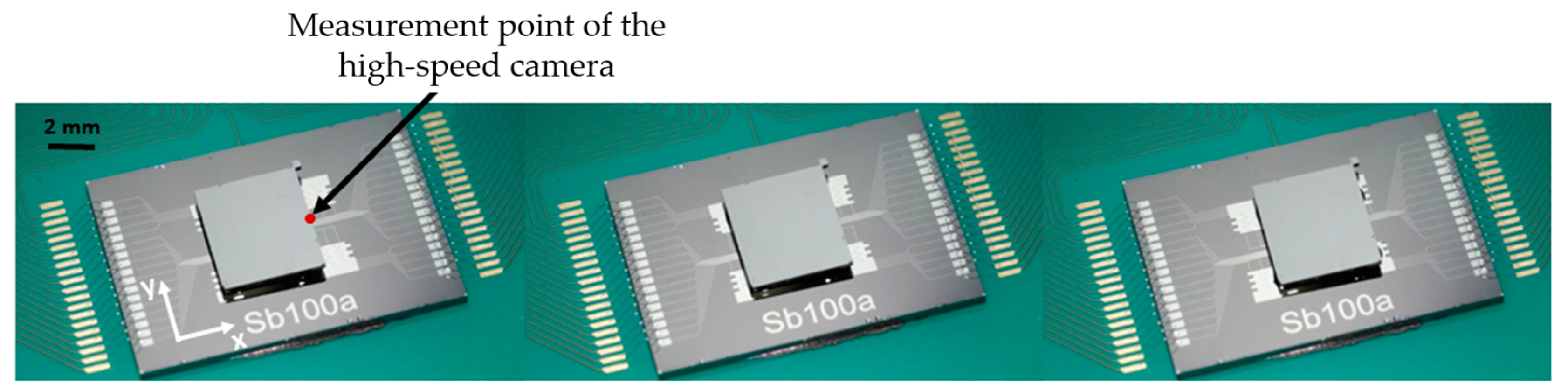

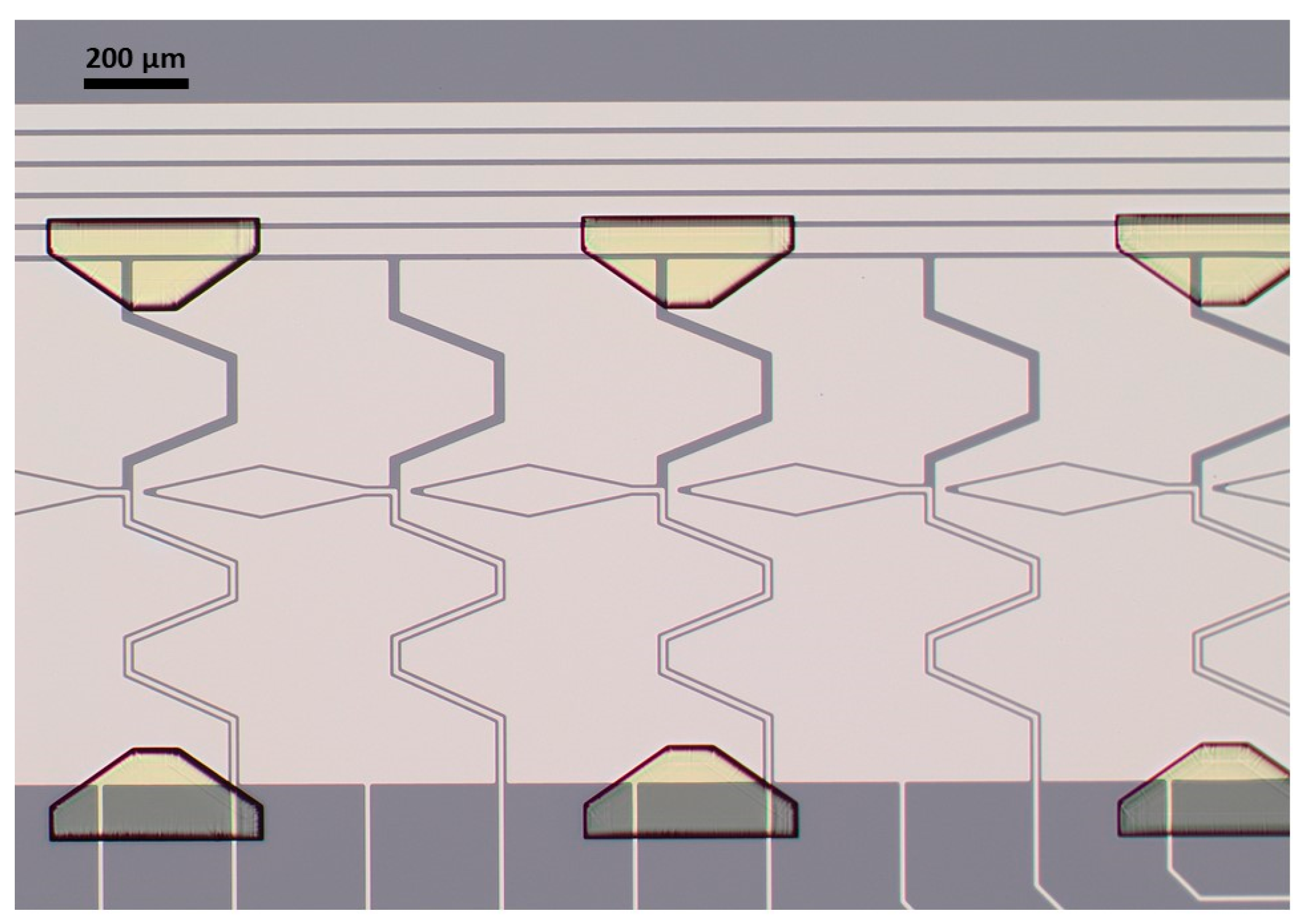

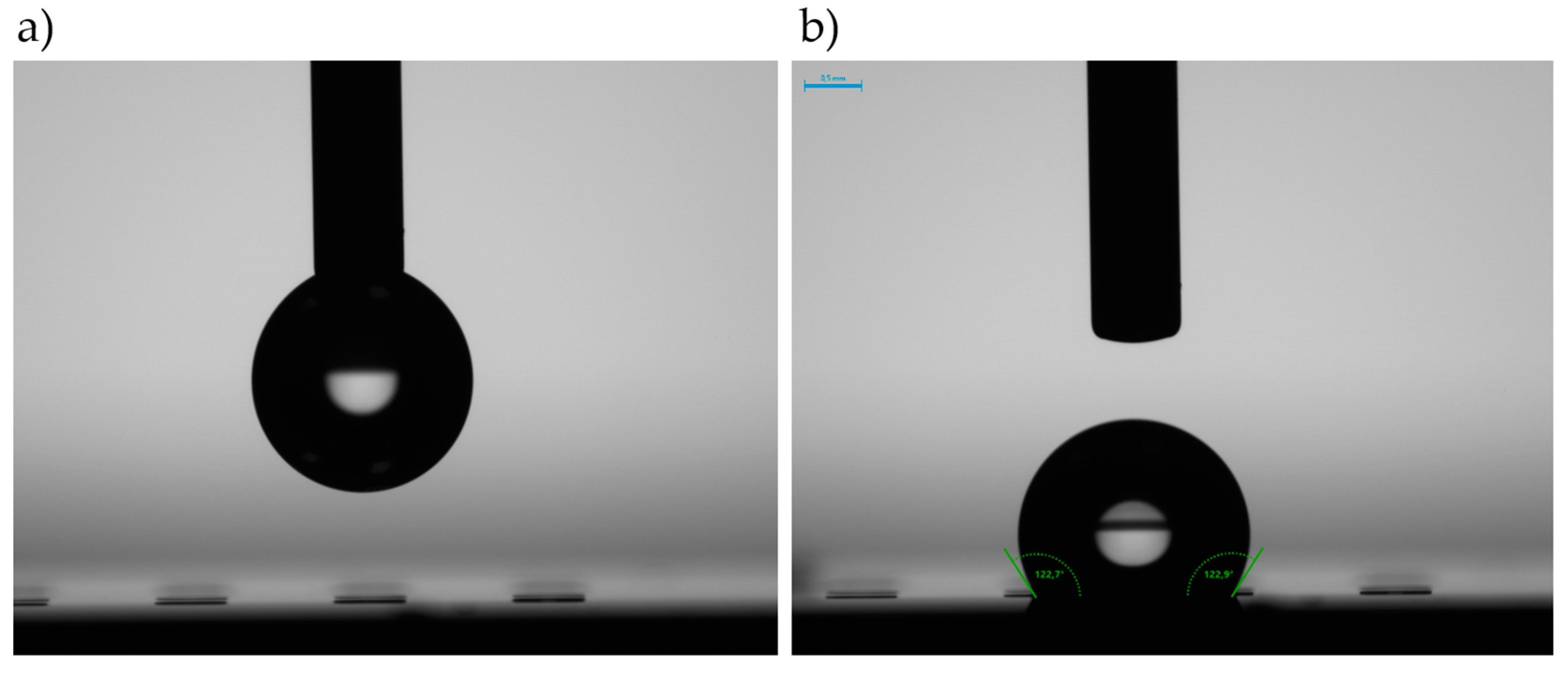

3.3.1. Coordinated Droplet Actuation for Moving Platforms

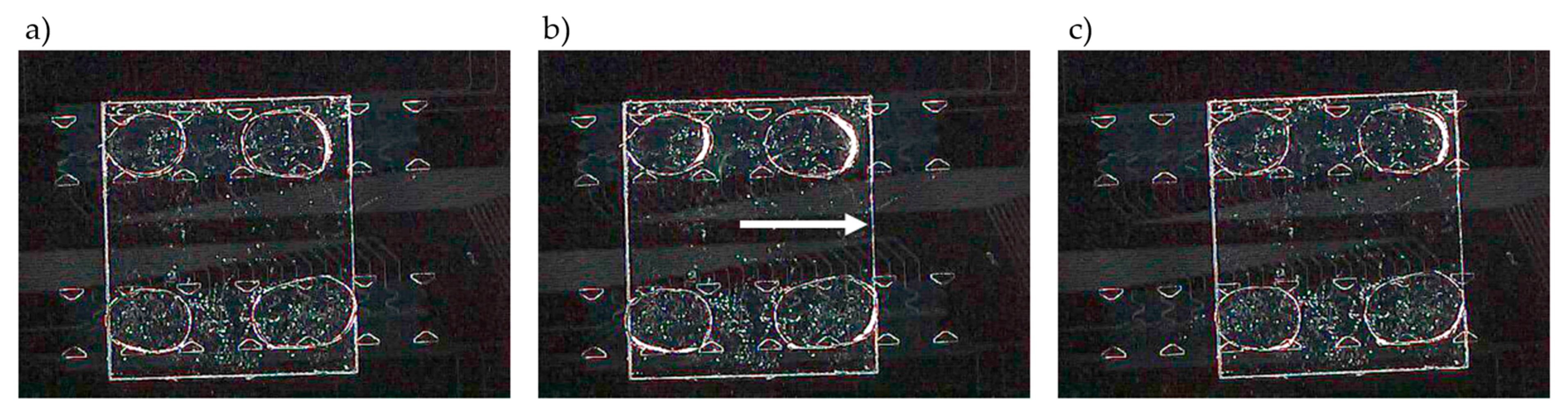

3.3.2. Multistability

4. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grade, J.; Jerman, H.; Kenny, T. Design of large deflection electrostatic actuators. J. Microelectromechanical Syst. 2003, 12, 335–343. [Google Scholar] [CrossRef]

- Jerman, J.H.; Grade, J.D.; Drak, J.D. Electrostatic Microactuator and Method for Use Thereof. U.S. Patent 5,998,906, 7 December 1999. [Google Scholar]

- Zhou, G.; Dowd, P. Tilted folded-beam suspension for extending the stable travel range of comb-drive actuators. J. Micromechanics Microengineering 2002, 13, 178–183. [Google Scholar] [CrossRef]

- Chen, C.; Lee, C. Design and modeling for comb drive actuator with enlarged static displacement. Sens. Actuators A Phys. 2004, 115, 530–539. [Google Scholar] [CrossRef]

- Xue, G.; Toda, M.; Li, X.; Wang, X.; Ono, T. Assembled Comb-Drive XYZ-Microstage With Large Displacements and Low Crosstalk for Scanning Force Microscopy. J. Microelectromechanical Syst. 2021, 31, 54–62. [Google Scholar] [CrossRef]

- Olfatnia, M.; Sood, S.; Gorman, J.J.; Awtar, S. Large Stroke Electrostatic Comb-Drive Actuators Enabled by a Novel Flexure Mechanism. J. Microelectromechanical Syst. 2012, 22, 483–494. [Google Scholar] [CrossRef]

- Zhang, W.-M.; Yan, H.; Peng, Z.-K.; Meng, G. Electrostatic pull-in instability in MEMS/NEMS: A review. Sens. Actuators A Phys. 2014, 214, 187–218. [Google Scholar] [CrossRef]

- Legtenberg, R.; Gilbert, J.; Senturia, S.D.; Elwenspoek, M. Electrostatic curved electrode actuators. J. Microelectromechanical Syst. 1997, 6, 257–265. [Google Scholar] [CrossRef]

- Preetham, B.S.; Lake, M.A.; Hoelzle, D.J. A curved electrode electrostatic actuator designed for large displacement and force in an underwater environment. J. Micromechanics Microengineering 2017, 27, 095009. [Google Scholar] [CrossRef]

- Preetham, B.S.; Mangels, J.A. Performance evaluation of a curved electrode actuator fabricated without gold/chromium conductive layers. Microsyst Technol 2018, 24, 3479–3485. [Google Scholar]

- Hoffmann, M.; Nüsse, D.; Voges, E. Electrostatic parallel-plate actuators with large deflections for use in optical moving-fibre switches. J. Micromechanics Microengineering 2001, 11, 323–328. [Google Scholar] [CrossRef]

- Schmitt, L.; Hoffmann, M. Large Stepwise Discrete Microsystem Displacements Based on Electrostatic Bending Plate Actuation. Actuators 2021, 10, 272. [Google Scholar] [CrossRef]

- Sun, Q.; He, Y.; Liu, K.; Fan, S.; Parrott, E.P.J.; Pickwell-MacPherson, E. Recent advances in terahertz technology for biomedical applications. Quant. Imaging Med. Surg. 2017, 7, 345–355. [Google Scholar] [CrossRef]

- Bakri-Kassem, M.; Mansour, R.R. High Tuning Range Parallel Plate MEMS Variable Capacitors with Arrays of Supporting Beams. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 666–669. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Z.; Lee, Y.C.; Bright, V.M.; Neff, J. Design and invention of multi-level digitally positioned micromirror for open-loop controlled applications. Sens. Actuators A Phys. 2003, 103, 271–283. [Google Scholar] [CrossRef]

- Spencer, M.; Chen, F.; Wang, C.C.; Nathanael, R.; Fariborzi, H.; Gupta, A.; Kam, H.; Pott, V.; Jeon, J.; Liu, T.-J.K.; et al. Demonstration of Integrated Micro-Electro-Mechanical Relay Circuits for VLSI Applications. IEEE J. Solid-State Circuits 2010, 46, 308–320. [Google Scholar] [CrossRef]

- Velosa-Moncada, L.A.; Aguilera-Cortés, L.A.; González-Palacios, M.A.; Raskin, J.-P.; Herrera-May, A.L. Design of a Novel MEMS Microgripper with Rotatory Electrostatic Comb-Drive Actuators for Biomedical Applications. Sensors 2018, 18, 1664. [Google Scholar] [CrossRef]

- Kostsov, E.; Alexei, S. Fast-response electrostatic actuator based on nano-gap. Micromachines 2017, 8, 78. [Google Scholar] [CrossRef]

- Leroy, E.; Hinchet, R.; Shea, H. Multimode Hydraulically Amplified Electrostatic Actuators for Wearable Haptics. Adv. Mater. 2020, 32, 2002564. [Google Scholar] [CrossRef]

- Toda, R.; Yang, E.-H. A normally latched, large-stroke, inchworm microactuator. J. Micromechanics Microengineering 2007, 17, 8. [Google Scholar] [CrossRef]

- Kloub, H. Design Concepts of Multistage Multistable Cooperative Electrostatic Actuation System with Scalable Stroke and Large Force Capability. In Proceedings of the ACTUATOR—International Conference and Exhibition on New Actuator Systems and Applications, Online, 17–19 February 2021; pp. 1–4. [Google Scholar]

- Teal, D.; Gomez, H.C.; Schindler, C.B.; Pister, K.S.J.; Teal, D. Robust electrostatic inchworm motors for macroscopic manipulation and movement. In Proceedings of the 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), online virtual conference, 20–25 June 2021. [Google Scholar]

- Romasanta, L.J.; López-Manchado, M.A.; Verdejo, R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Schomburg, W.K. Introduction to Microsystem Design; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Gao, Y.; You, Z.; Zhao, J. Electrostatic comb-drive actuator for MEMS relays/switches with double-tilt comb fingers and tilted parallelogram beams. J. Micromechanics Microengineering 2015, 25, 45003. [Google Scholar] [CrossRef]

- Legtenberg, R.; Groeneveld, A.W.; Elwenspoek, M. Comb-drive actuators for large displacements. J. Micromech. Microeng. 1996, 6, 320–329. [Google Scholar] [CrossRef]

- Leadenham, S.; Erturk, A. M-shaped asymmetric nonlinear oscillator for broadband vibration energy harvesting: Harmonic balance analysis and experimental validation. J. Sound Vib. 2014, 333, 6209–6223. [Google Scholar] [CrossRef]

- Schmitt, P.; Schmitt, L.; Tsivin, N.; Hoffmann, M. Highly Selective Guiding Springs for Large Displacements in Surface MEMS. J. Microelectromechanical Syst. 2021, 30, 597–611. [Google Scholar] [CrossRef]

- Qiu, J.; Lang, J.; Slocum, A. A centrally-clamped parallel-beam bistable MEMS mechanism. Technical Digest. MEMS 2001. In Proceedings of the 14th IEEE International Conference on Micro Electro Mechanical Systems, Interlaken, Switzerland, 25–25 January 2001. [Google Scholar] [CrossRef]

- Qiu, J.; Lang, J.; Slocum, A. A Curved-Beam Bistable Mechanism. J. Microelectromechanical Syst. 2004, 13, 137–146. [Google Scholar] [CrossRef]

- Vysotskyi, B.; Parrain, F.; Aubry, D.; Gaucher, P.; Le Roux, X.; Lefeuvre, E. Engineering the Structural Nonlinearity Using Multimodal-Shaped Springs in MEMS. J. Microelectromechanical Syst. 2017, 27, 40–46. [Google Scholar] [CrossRef]

- Vysotskyi, B.; Parrain, F.; Aubry, D.; Gaucher, P.; Lefeuvre, E. Innovative Energy Harvester Design Using Bistable Mechanism With Compensational Springs In Gravity Field. J. Physics Conf. Ser. 2016, 773, 012064. [Google Scholar] [CrossRef]

- Li, B.; Li, G.; Lin, W.; Xu, P. Design and constant force control of a parallel polishing machine. In Proceedings of the 2014 4th IEEE International Conference on Information Science and Technology, Shenzhen, China, 26–28 April 2014; pp. 324–328. [Google Scholar]

- Erlbacher, E. Method for Applying Constant Force with Nonlinear Feedback Control and Constant Force Device using Same. US Patent 5,448,146, 5 September 1995. [Google Scholar]

- Boudaoud, M.; Haddab, Y.; Le Gor, Y. Modeling and optimal force control of a nonlinear electrostatic microgripper. IEEE/ASME Trans. Mechatron. 2012, 18, 1130–1139. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Q. Design and simulation of a passive-type constant-force MEMS microgripper. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 1100–1105. [Google Scholar] [CrossRef]

- Wang, P.; Xu, Q. Design and modeling of constant-force mechanisms: A survey. Mech. Mach. Theory 2018, 119, 1–21. [Google Scholar] [CrossRef]

- Shahan, D.; Fulcher, B.; Seepersad, C.C. Robust design of negative stiffness elements fabricated by selective laser sintering. In Proceedings of the 2011 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011. [Google Scholar]

- Thewes, A.C.; Schmitt, P.; Löhler, P.; Hoffmann, M. Design and Characterization of an Electrostatic Constant-Force Actuator Based on a Non-Linear Spring System. Actuators 2021, 10, 192. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, G.; Xu, Q. Design, Analysis and Testing of a New Compliant Compound Constant-Force Mechanism. Actuators 2018, 7, 65. [Google Scholar] [CrossRef]

- Guo; Tatar, E.; Fedder, G.K. Large-displacement parametric resonance using a shaped comb drive. In Proceedings of the IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013. [Google Scholar]

- Engelen, J.B.C.; Abelmann, L.; Elwenspoek, M.C. Optimized comb-drive finger shape for shock-resistant actuation. J. Micromechanics Microengineering 2010, 20, 105003. [Google Scholar] [CrossRef]

- Ye, W.; Mukherjee, S.; MacDonald, N. Optimal shape design of an electrostatic comb drive in microelectromechanical systems. J. Microelectromechanical Syst. 1998, 7, 16–26. [Google Scholar] [CrossRef]

- Schmitt, L.; Schmitt, P.; Hoffmann, M. Optimization of Electrostatic Bending-Plate Actuators: Increasing the Displacement and Adjusting the Actuator Stiffness. In Proceedings of the ACTUATOR 2022: International Conference and Exhibition on New Actuator Systems and Applications, Mannheim, Germany, 29–30 June 2021. [Google Scholar]

- Toshiyoshi, H. Electrostatic Actuation. In Comprehensive Microsystems; Yogesh, B., Ed.; Gianchandani, Osamu Tabata, Hans Zappe: Paris, France, 2008; pp. 1–38. [Google Scholar]

- Schmit, L.; Schmitt, P.; Barowski, J.; Hoffmann, J. Stepwise Electrostatic Actuator System for THz Reflect Arrays, GMM-Fachbericht 98: ACTUATOR 2021. In Proceedings of the International Conference and Exhibition on New Actuator Systems and Applications, Online, 17–19 February 2021. [Google Scholar]

- Sarajlic, E.; Collard, D.; Toshiyoshi, H.; Fujita, H. 12-bit microelectromechanical digital-to-analog converter of displacement: Design, fabrication and char-acterization. In Proceedings of the IEEE 20th International Conference on Micro Electro Mechanical Systems (MEMS), Kyoto, Japan, 21–25 January 2007. [Google Scholar]

- Toshiyoshi, H.; Kobayashi, D.; Mita, M.; Hashiguchi, G.; Fujita, H.; Endo, J.; Wada, Y. Microelectromechanical digital-to-analog converters of displacement for step motion actuators. J. Microelectromechanical Syst. 2000, 9, 218–225. [Google Scholar] [CrossRef]

- Sarajlic, E.; Collard, D.; Toshiyoshi, H.; Fujita, H. Design and modeling of compliant micromechanism for mechanical digital-to-analog conversion of displacement. In Proceedings of the IEEJ Transactions on Electrical and Electronic Engineering, Online, 15–20 June 2007; pp. 357–364. [Google Scholar]

- Schmitt, L.; Schmitt, P.; Hoffmann, M. Mechanischer 3-Bit Digital-Analog-Wandler (DAC) mit großem Stellweg. In Proceedings of the MikroSystemTechnik Kongress, Germany, Ludwigsburg, 8–10 November 2021; VDE-Verlag: Stuttgart-Ludwigsburg, Germany, 2021; ISBN 978-3-8007-5656-8. [Google Scholar]

- Schmitt, L.; Schmitt, P.; Hoffmann, M. 3-Bit Digital-to-Analog Converter with Mechanical Amplifier for Binary Encoded Large Displacements. Actuators 2021, 10, 182. [Google Scholar] [CrossRef]

- Schmitt, L.; Liu, X.; Schmitt, P.; Czylwik, A.; Hoffmann, M. Large Displacement Actuators With Multi-Point Stability for a MEMS-Driven THz Beam Steering Concept. J. Microelectromechanical Syst. 2023, 1–13. [Google Scholar] [CrossRef]

- Cho, S.K.; Moon, H.; Kim, C.-J. Creating, transporting, cutting, and merging liquid droplets by electrowetting-based actuation for digital microfluidic circuits. J. Microelectromech. Syst. 2003, 12, 70–80. [Google Scholar] [CrossRef]

- Berthier, J. Electrowetting Theory. In Micro and Nano Technologies, Micro-Drops and Digital Microfluidics, 2nd ed.; William Andrew Publishing: Waltham, MA, USA, 2013; pp. 162–222. [Google Scholar] [CrossRef]

- Samiei, E.; Tabrizian, M.; Hoorfar, M. A review of digital microfluidics as portable platforms for lab-on a-chip applications. Lab Chip 2016, 16, 2376–2396. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y. Advances in integrated digital microfluidic platforms for point-of-care diagnosis: A review. Sensors Diagn. 2022, 1, 648–672. [Google Scholar] [CrossRef]

- Berthier, J. EWOD Microsystems. In Micro and Nano Technologies, Micro-Drops and Digital Microfluidics, 2nd ed.; William Andrew Publishing: Waltham, MA, USA, 2013; pp. 225–324. [Google Scholar] [CrossRef]

- Mugele, F.; Baret, J.-C. Electrowetting: From basics to applications. J. Physics: Condens. Matter 2005, 17, R705–R774. [Google Scholar] [CrossRef]

- Jones, T. An electromechanical interpretation of electrowetting. J. Micromech. Microeng. 2005, 15, 1184–1187. [Google Scholar] [CrossRef]

- Chan, M.L.; Yoxall, B.; Park, H.; Kang, Z.; Izyumin, I.; Chou, J.; Megens, M.M.; Wu, M.C.; Boser, B.E.; Horsley, D.A. Design and characterization of MEMS micromotor supported on low friction liquid bearing. Sensors Actuators A Phys. 2012, 177, 1–9. [Google Scholar] [CrossRef]

- Takei, A.; Binh-Khiem, N.; Iwase, E.; Matsumoto, K.; Shimoyama, I. Liquid motor driven by electrowetting. In Proceedings of the in IEEE 21st International Conference on Micro Electro Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008. [Google Scholar]

- Kang, H.-H.; Kim, J. EWOD (Electrowetting-on-Dielectric) Actuated Optical Micromirror. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006. [Google Scholar]

- Kopp, A.; Conrad, P.; Hoffmann, M.; Ament, C. System level modeling and closed loop control for a droplet-based micro-actuator. In Proceedings of the SICE International Symposium on Control Systems 2023 (Part of the 10th SICE Multi-Symposium on Control Systems), Kusatsu, Japan, 9–11 March 2023. [Google Scholar]

- Conrad, P.; Berdnykov, A.; Hoffmann, M. Design of a Liquid Dielectrophoresis-driven Platform with Cooperative Actuation. In Proceedings of the ACTUATOR 2022, International Conference and Exhibition on New Actuator Systems and Applications, Mannheim, Germany, 28–30 June 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmitt, L.; Conrad, P.; Kopp, A.; Ament, C.; Hoffmann, M. Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke. Actuators 2023, 12, 150. https://doi.org/10.3390/act12040150

Schmitt L, Conrad P, Kopp A, Ament C, Hoffmann M. Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke. Actuators. 2023; 12(4):150. https://doi.org/10.3390/act12040150

Chicago/Turabian StyleSchmitt, Lisa, Peter Conrad, Alexander Kopp, Christoph Ament, and Martin Hoffmann. 2023. "Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke" Actuators 12, no. 4: 150. https://doi.org/10.3390/act12040150

APA StyleSchmitt, L., Conrad, P., Kopp, A., Ament, C., & Hoffmann, M. (2023). Non-Inchworm Electrostatic Cooperative Micro-Stepper-Actuator Systems with Long Stroke. Actuators, 12(4), 150. https://doi.org/10.3390/act12040150