1. Introduction

Intelligent vehicles with high mobility, high passability, and low environmental footprint have a wide range of application prospects in the fields of resource exploration, post-disaster search, rescue, and fire extinguishing in the sustainable economy. It is difficult for vehicles with traditional passive suspensions to maintain the attitude stability of the car body, which seriously affects the comfort, safety, and sensitivity of passengers, goods, and intelligent payload.

In the past few decades, active suspension systems have been studied for improving ride comfort and handling capability [

1]. The optimal controller using integral action for the suspension deflection considerably reduced rolling, pitching, and heaving motions of the car body and at the same time adjusted the ground-grasping forces of each wheel for different road disturbances, especially on sharp corners and during braking maneuvers [

2]. The attitude tracking controller can help the car body tilt inward in cornering, lean forward when accelerating and backward when decelerating. In this way, ride comfort can be improved by eliminating the centrifugal forces acting on passengers. Along with ride comfort, the active attitude motion of the car body will enhance the road-holding capability and reduce the chance of rollover by balancing the ground grasping forces on each wheel in cornering, braking, and accelerating [

3]. In order to eliminate the unpleasant lateral and longitudinal accelerations acting on passengers, the proposed attitude control often requires large ideal roll and pitch angles that surpass the angles that can be attained in actual car body motion. Due to the limitation of suspension spaces, an active seat system is added to the car body in order to accommodate angles larger than the available body angle to further improve ride comfort [

4]. Considering the improved road-holding capability and the coupling effect of body attitude motion and yaw motion, the attitude controller combined with a steering controller to produce a synergistic effect on ride comfort, handling, and safety [

5].

Existing research of active suspension systems has shown a huge potential for attitude motion control of ground vehicles. The active system can control the body attitude according to the terrain information for eliminating large swings and vibrations of the car body in a harsh terrain situation [

6,

7,

8]. In the robotics field, research on body-level control and body motion control on unmanned multi-joints robots has been increasing [

9,

10,

11,

12,

13,

14,

15]. However, the problem of high energy consumption and low reliability of parallel active suspensions and joint-actuators still limit their utilization. As one of the limited bandwidth active suspensions, a series active suspension which includes actuators and vibrators in the form of a series has a simpler structure, lower design costs, and a larger attitude adjustment range than a parallel and hybrid active suspension. Therefore, designing an innovative vehicle with series active suspensions has good research value. Konieczny et al. investigated performances of slow and full active suspensions. Based on a quarter-vehicle model, active suspension control algorithms were analyzed [

16]. Westhuizen et al. proposed using series active suspensions to eliminate body rolling so as to reduce the possibility of a rollover. A verified ADAMS model is used to simulate the double lane change maneuver at a speed of 60 km/h. Under relatively low energy needs, it can achieve a significant reduction in body rolling [

17]. Ma et al. designed a wheel-legged all-terrain vehicle based on series active suspensions. An attitude closed-loop control strategy was verified by both the simulated model and the real vehicle. In order to reduce the impact of rough terrain on stability and ride comfort, the attitude control algorithm was further verified [

18,

19].

Many scholars have studied the control of model predictive control (MPC) on suspension and body attitude. Erik et al. propose a feasible method for analyzing the effect of the maximum force and maximum rate of change of the actuator on the attainable ride comfort. In this method, the model predictive controller is used to eliminate the influence of feedback controller performance, and the wheel load and suspension travel are constrained [

20]. Guan et al. proposed a comprehensive path and attitude control strategy for articulated vehicles for varying vehicle conditions to improve the lateral stability of articulated vehicles based on model predictive control (MPC) [

21]. In addition, A stability control system is proposed to improve vehicle stability based on model predictive control [

22,

23,

24,

25]. Alejandro et al. proposed a novel autoregressive model predictive control strategy based on exogenous input (ARX) to improve the comfort and stability of vehicles during driving and applied it to semi-active suspension with magnetorheological damper [

26]. In addition, Jimoh et al. designed a particle swarm optimization model predictive controller based on the nonlinear electro-hydraulic suspension system of semi-vehicles [

27].

One of the limiting factors for the widespread adoption of MPC in the industry is that the traditional implicit MPC can impose a huge computational load on the controller during computation. In the traditional MPC, because each sampling interval requires an optimization problem, it requires a lot of calculation. To address this problem, Johan et al. proposed a suspension system with an explicit Model Predictive controller (e-MPC), which runs the MPC optimization process offline and simplifies the online controller for functional evaluation, reducing memory usage [

28]. Shahab et al. proposed the offline RMPC method to overcome the problem of a large amount of MPC calculation through offline optimization before implementation, and extended it to the problem of uncertain parameters [

29].

Based on the above analysis and the previous research background, an MPC controller of an all-terrain vehicle acting on series active suspensions is proposed to solve the attitude control problems considering model inaccuracies and actuator constraints. The simulation and experiment results will verify the correctness of the control model and algorithm and prove that the attitude control strategy can significantly improve the attitude stability and ride comfort of the vehicle.

3. Attitude Stability Controller Design

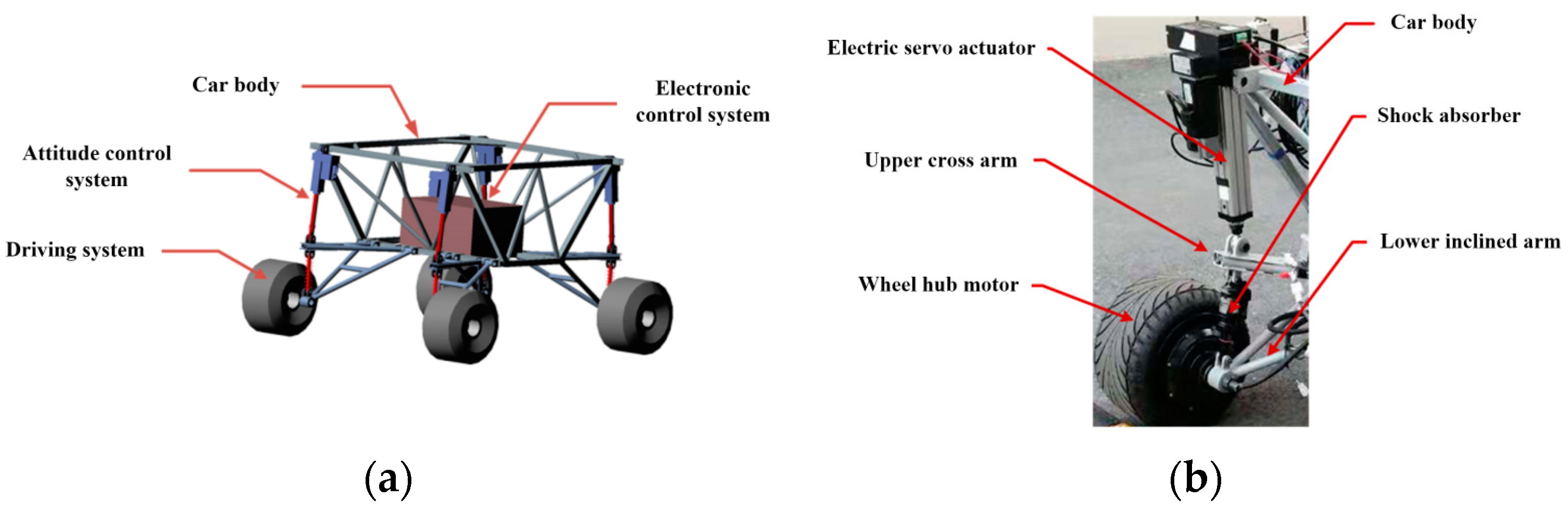

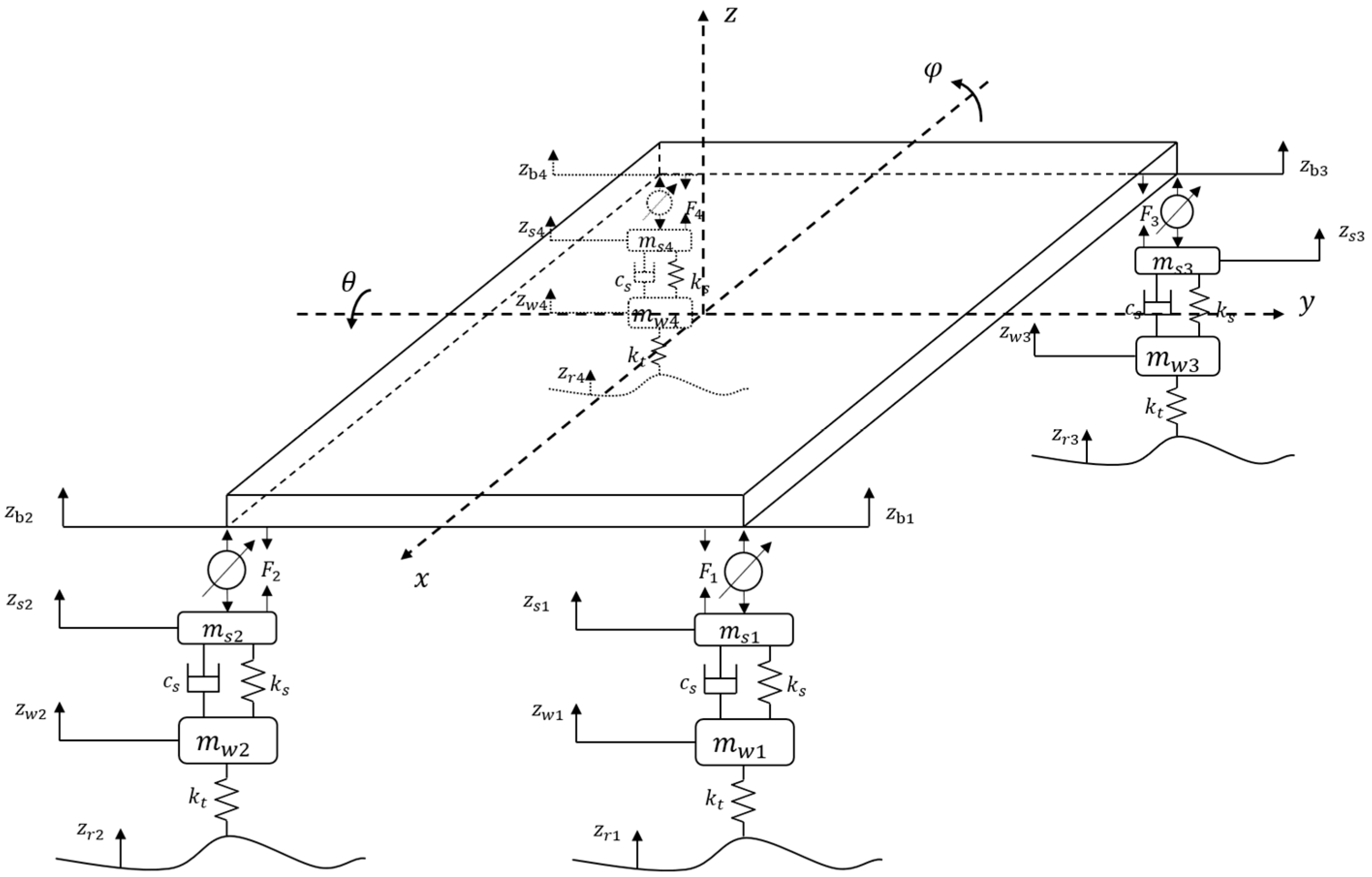

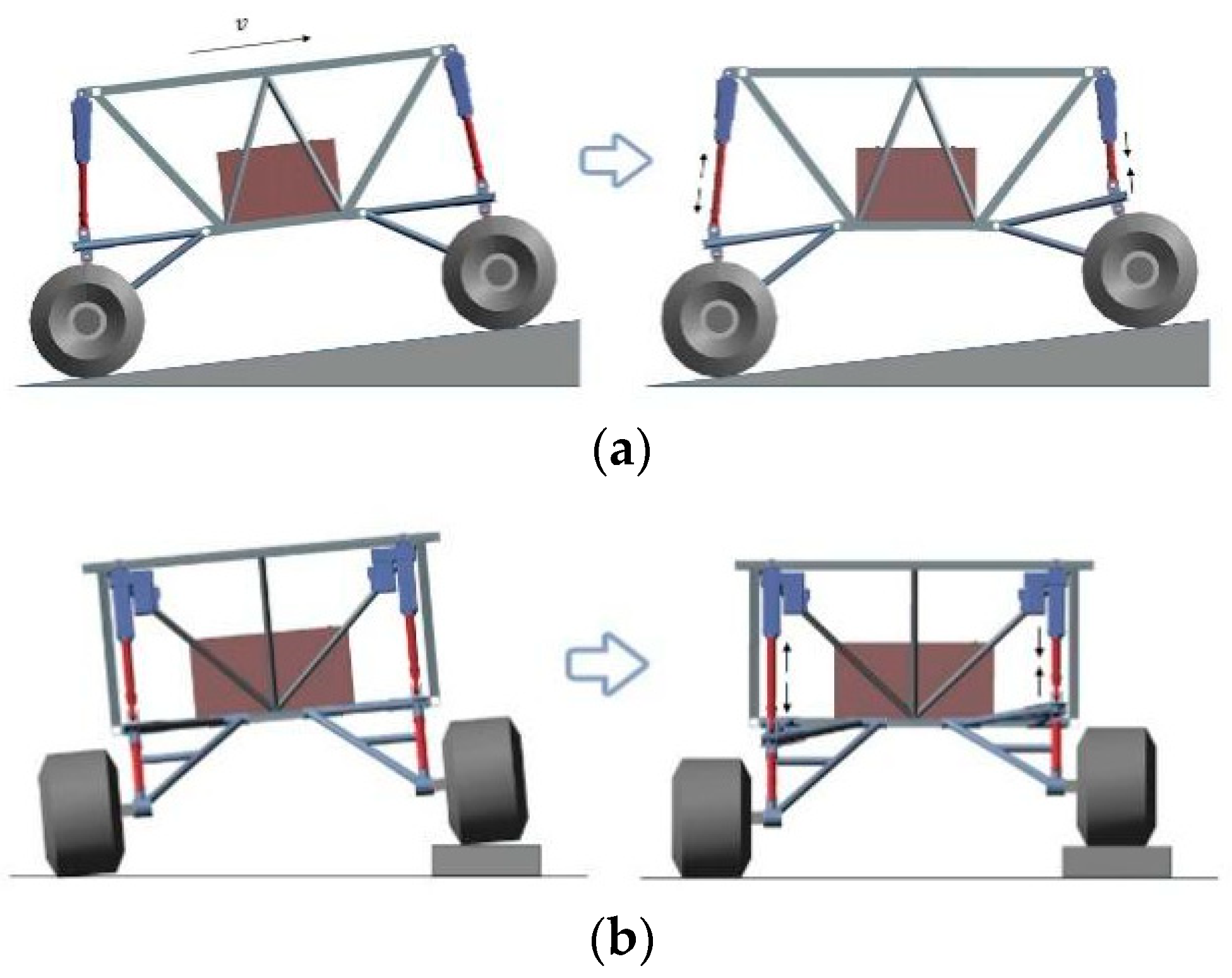

The attitude stability control of the vehicle is performed by four independent series active actuators, as shown in

Figure 1b. The series active suspension combines an electric servo actuator, which is regarded as a displacement or velocity generator, with a passive air shock absorber. The internal control loop will involve speed and displacement feedback, and the control signal of the actuator will theoretically be the desired speed or displacement. As shown in

Figure 7a, due to the height of the center of gravity and the effect of mass shift, the attitude of the car body is changed to squatting, when the vehicle is located on a slope. The proposed attitude stability control system will drive the front two actuators to shrink and the rear two actuators to extend for keeping the car body flat. In the same way, when the attitude is changed as tilting, the left actuator is extending and the right actuator is shrinking. The vehicle will always maintain a horizontal attitude, as shown in

Figure 7b. When the car body swings in pitching and rolling motions on unstructured terrain, the attitude stability control system is used to adjust four actuators by giving speed or displacement signals in real time to achieve a steady body attitude so as to improve the stability and safety of the vehicle and loaded equipment.

In this paper, the model description and control constraint are analyzed by Model Predictive Control (MPC). MPC is very effective for control problems with low model accuracy and constraints. A system inevitably has nonlinear parts. For example, (4)–(7) in

Section 2.1 simplify the nonlinearity of the vehicle and reduce the accuracy of the model. In addition, electric servo actuators also have constraints, such as speed and travel limits.

In each time interval, MPC calculates the first value of an open loop optimization problem within a finite time domain online in real-time, according to the measured value of the current system state by sensors [

33]. At the next moment, the new open loop optimization problem is refreshed by the latest measured value. It realizes the purpose of real-time online optimization.

The design process of the model predictive controller includes three steps: prediction model, rolling optimization, and feedback correction. Firstly, the continuous system (17) is discretized [

34] as:

After discretization, the equation of state of the system is:

where

is a discrete time of the system, and

,, , and are the coefficient matrix of the discrete system under

sampling period. The detail of matrix,

A, B, D is in

Appendix A.

In this section, the MPC is solved by converting the cost function into the form of quadratic programming. The general form of quadratic programming [

35] is as follows:

Then, it is as defined here:

With the all-terrain vehicle as an attitude control object, control constraints of the electric servo actuator are as follows: maximum speed is the positive maximum speed that the actuator can achieve, minimum speed is the negative maximum speed, maximum displacement is half of the positive maximum travel, and minimum displacement is half of the negative maximum travel.

According to the system output, actuator input and weight factors, the performance index can be expressed in forms of the matrices and the vectors which represent the system states, disturbance inputs, and control forces as:

The symmetric positive definite constant matrix , , and are the weights of the output, input, and terminal error, respectively.

Therefore, the predicted values of system state x at time k can be expressed as:

According to (24)–(26) and (28), the system can be expressed in matrix form as follows:

where

According to (24)–(26), the cost function can be simplified to:

where

By substituting (29) into (30), the quadratic programming form of the cost function can be obtained through simplification as follows:

In (31), is solved based on the minimum of the quadratic programming form of the cost function. According to the above analysis and the system state, ,, and can be calculated as follows:

The first item, as input to the current system, can be expressed as:

At the end of this cycle, the optimal solution

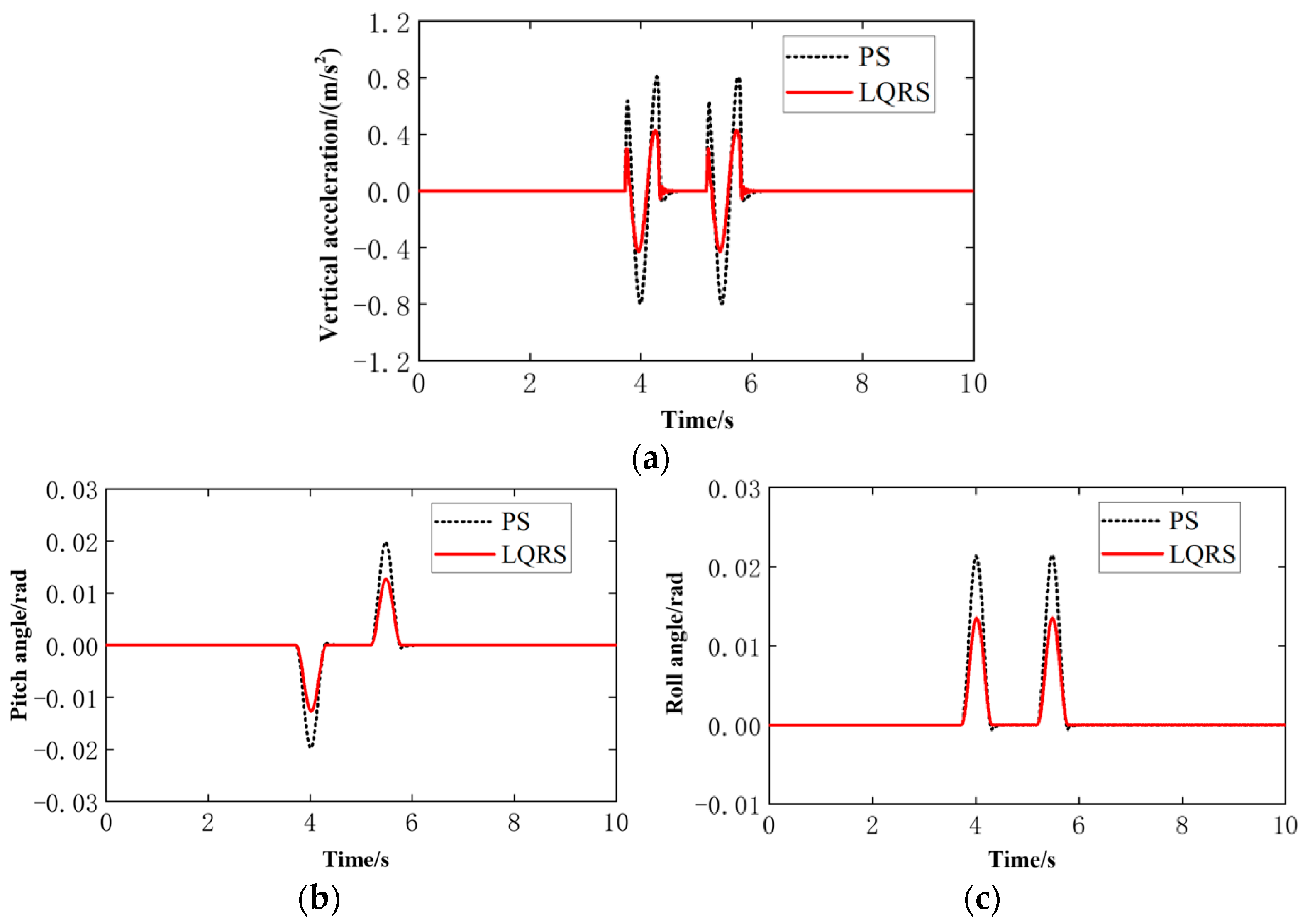

is obtained and applied to the system. The calculation process is repeated to the next time interval. In this way, the whole process of model prediction, rolling optimization, and feedback correction is completed. The attitude controller will drive the four series active suspension to achieve the reference attitude for keeping stability and improving ride comfort and safety. For further verifying the accuracy of vehicle modeling and performance of proposed controller, a LQR controller [

36] is also derived by the above dynamic equations. The detail derivation of LQR method can be found in [

3]. The corresponding programs can be found in the online data repository.

5. Conclusions

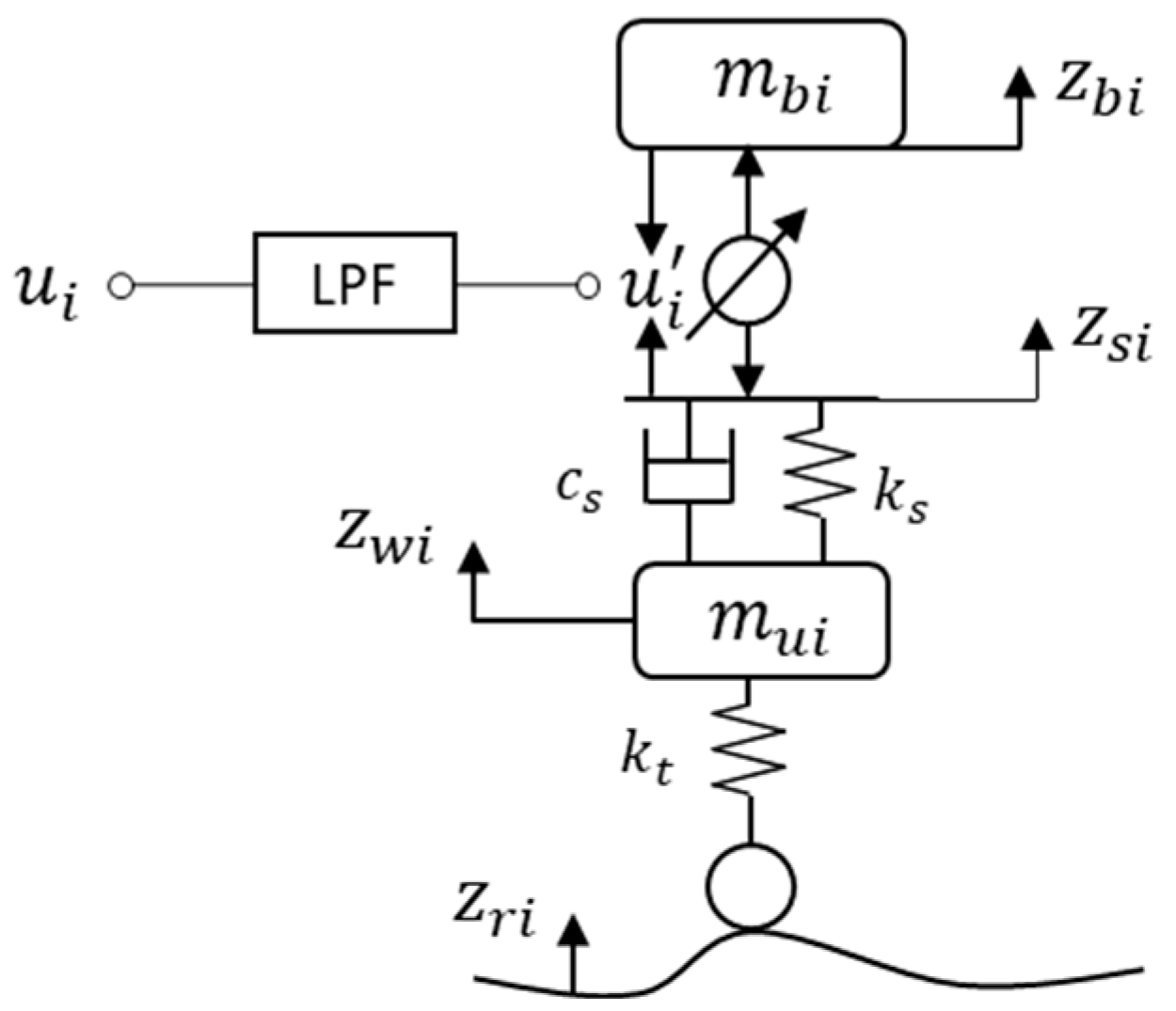

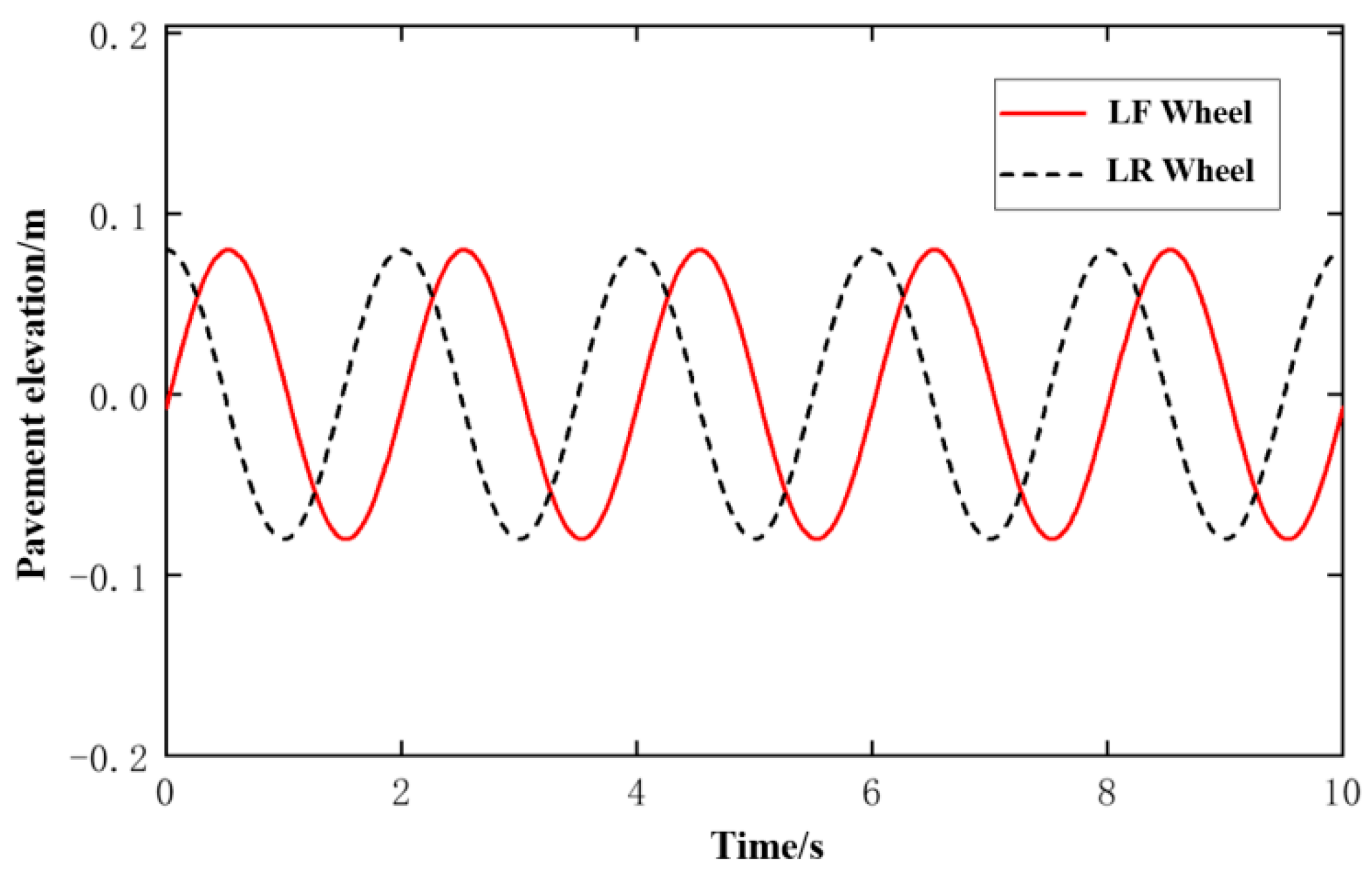

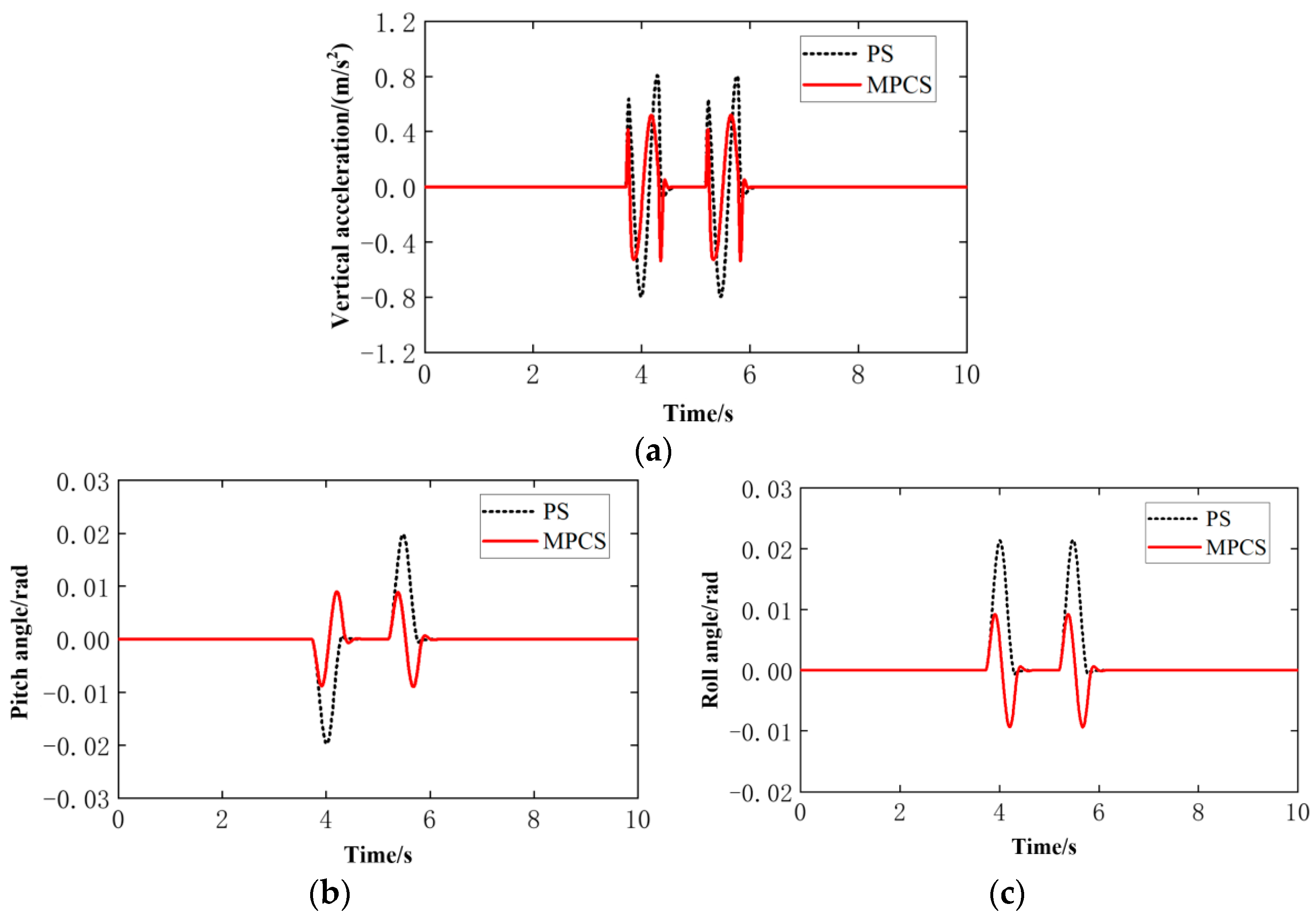

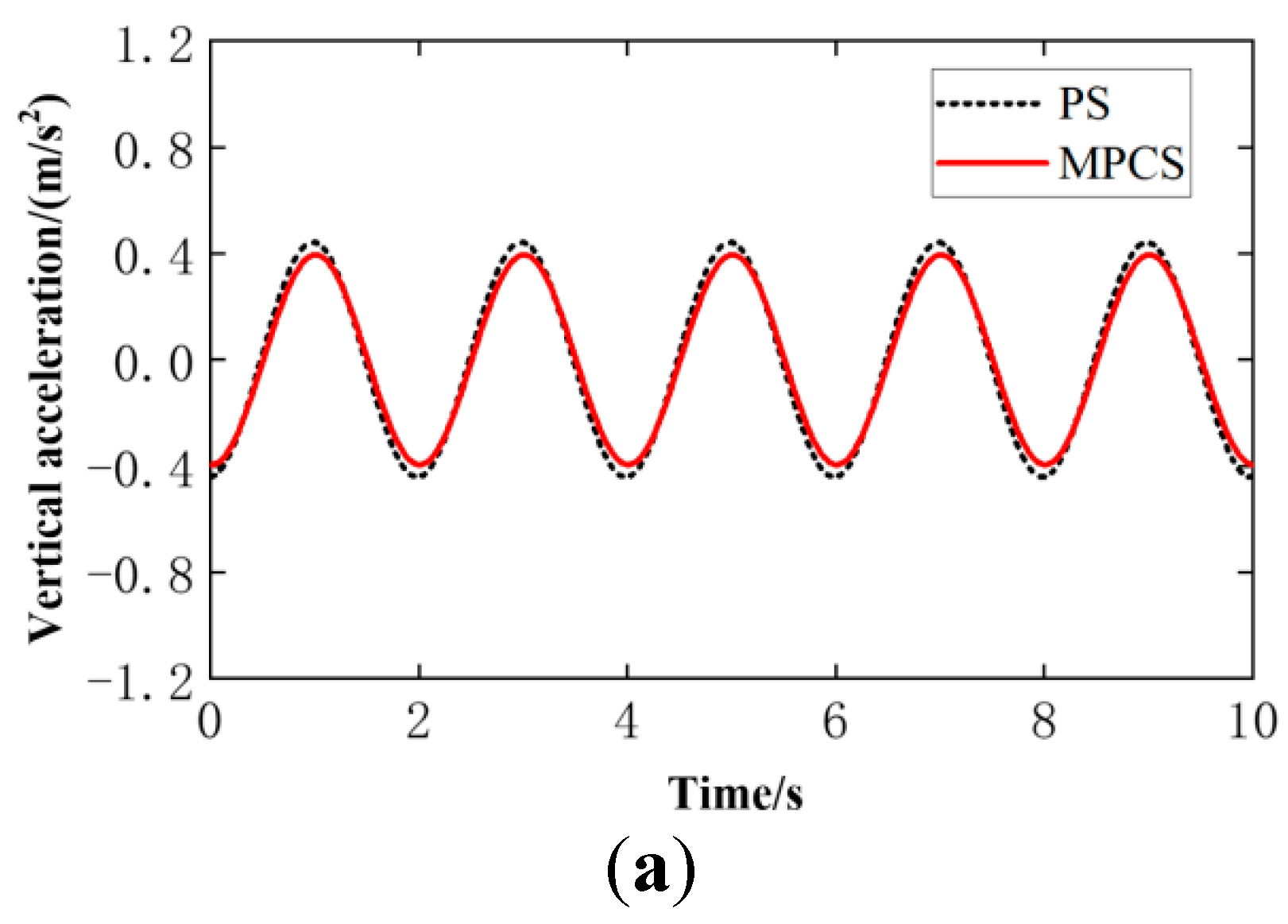

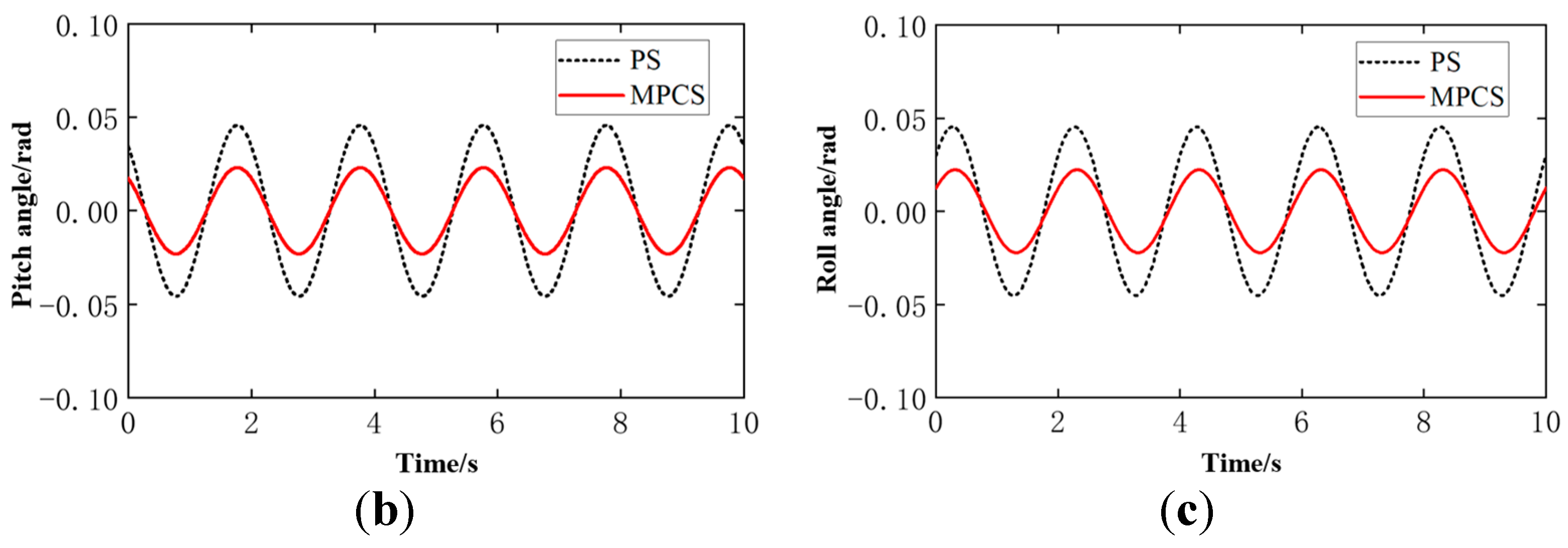

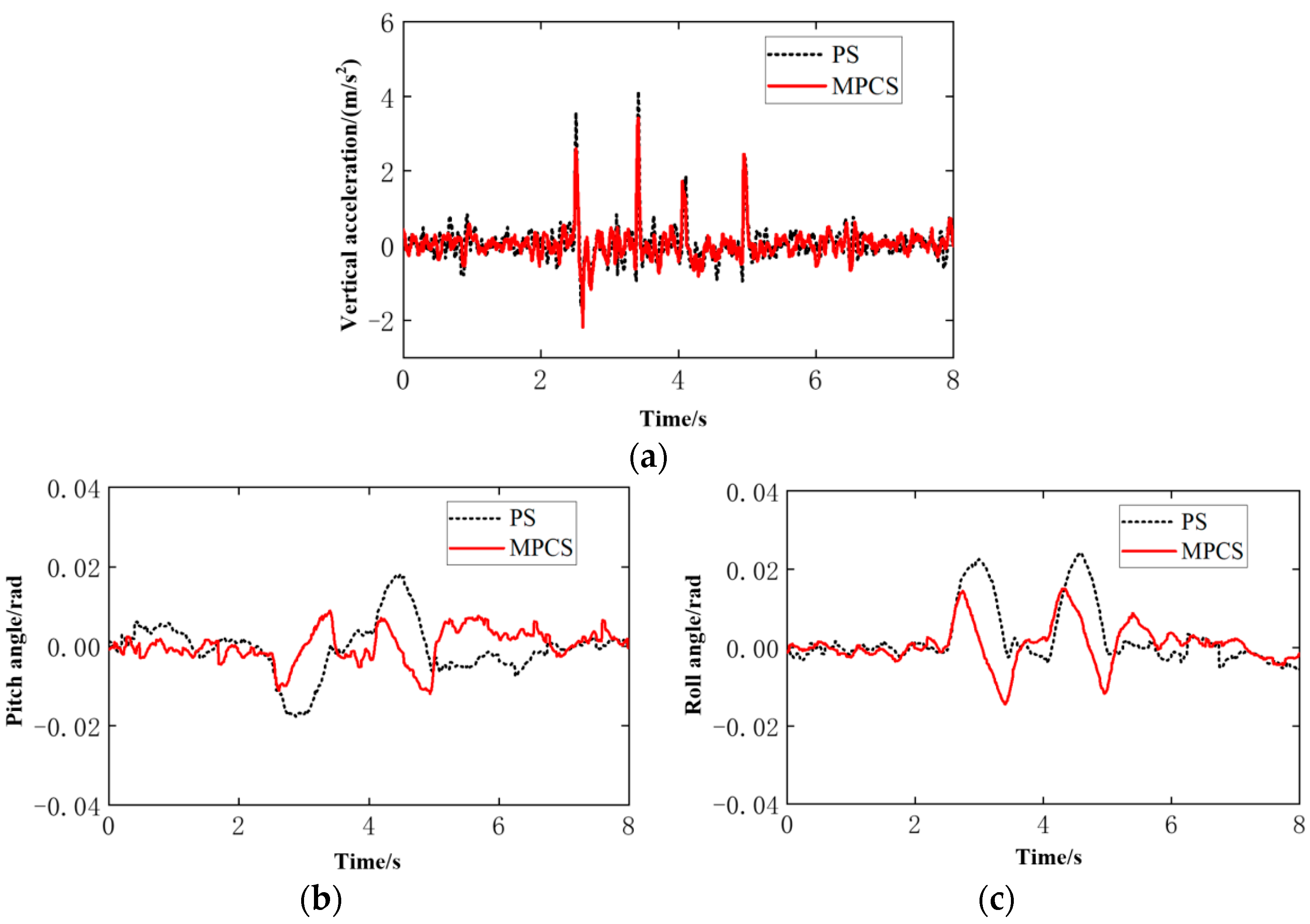

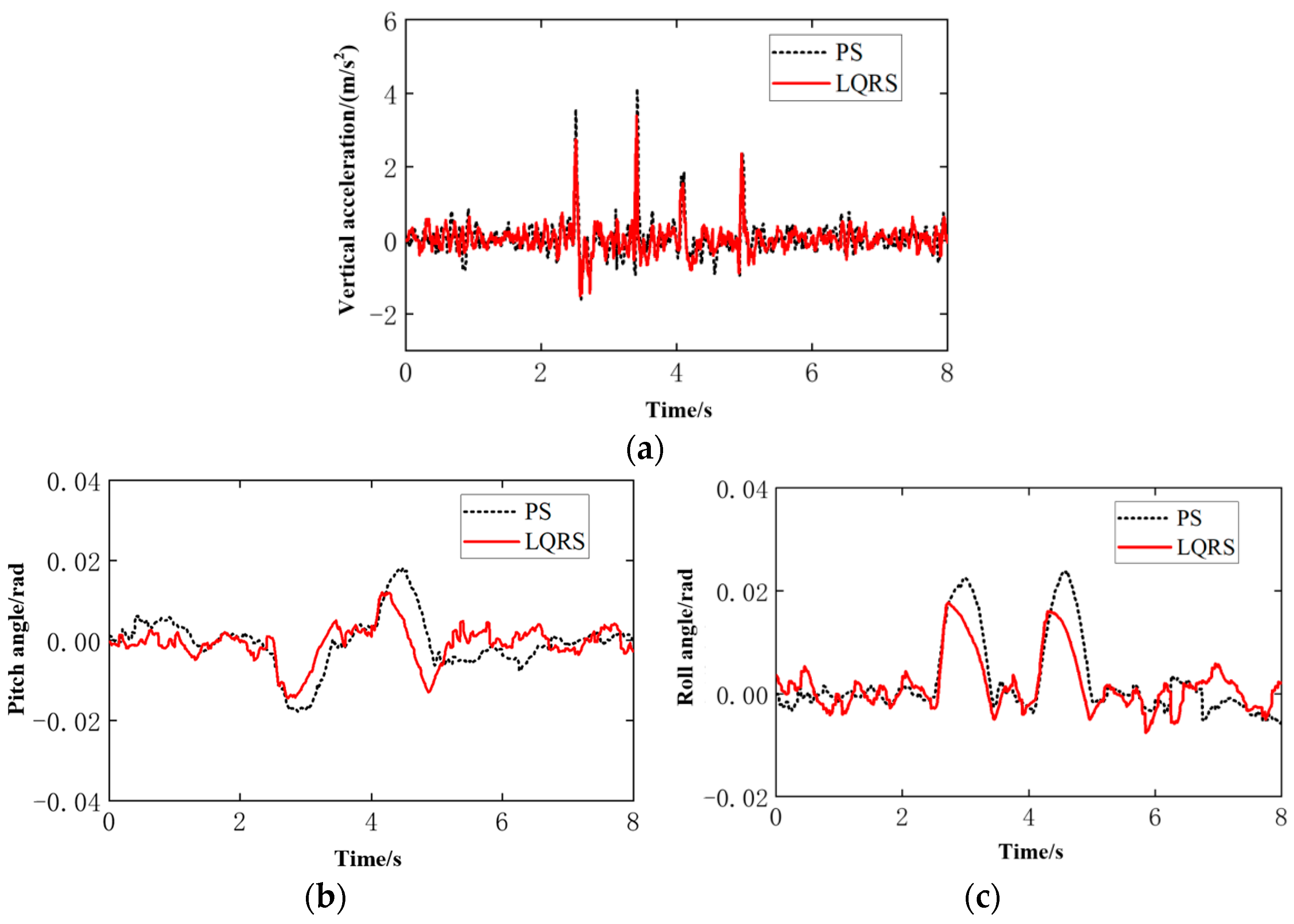

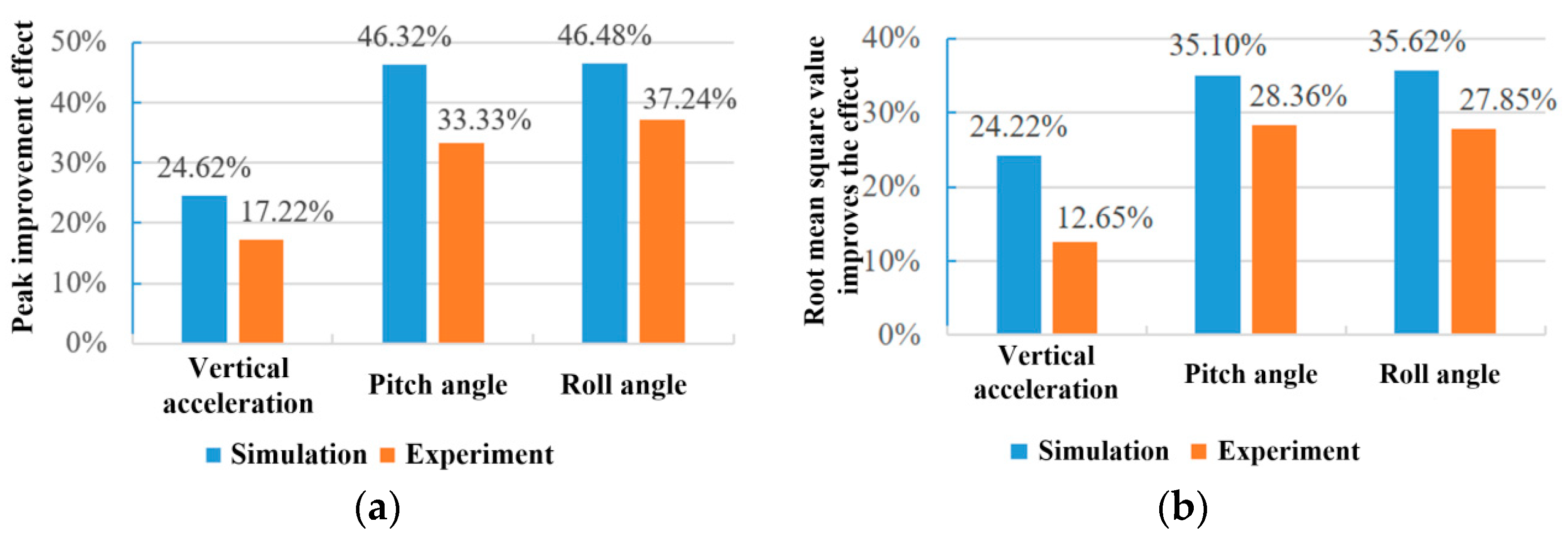

In order to improve the attitude stability and ride comfort by the series active suspensions in the case of unstructured terrain, this research builds a full car model for the innovative all-terrain vehicle and analyzes the kinematics and dynamics of each machine based on the series active suspensions. A second-order low-pass filter is introduced into the series active suspension for solving the difficulty of speed control modeling of the electric servo actuator. The transient, steady, and random response characteristics of the MPC attitude control system are verified, respectively, under various road disturbances.

Considering the bump, sinusoidal, and random road disturbances, the attitude controller designed in this paper reduces unexpected angular motions and acceleration of car body by more than 46% and 24% in the simulation environment while meeting the actuator constraints. The real tests show that unexpected angular motions and acceleration of car body are also reduced by more than 33% and 12%. Finally, the attitude controller on the self-designed ATV can obviously reduce the pitching, rolling angle, and heaving acceleration of the car body on different road conditions so as to achieve design goals and improve both attitude stability and ride comfort of the vehicle.