A Survey on Autonomous Offline Path Generation for Robot-Assisted Spraying Applications

Abstract

:1. Introduction

1.1. Motivation

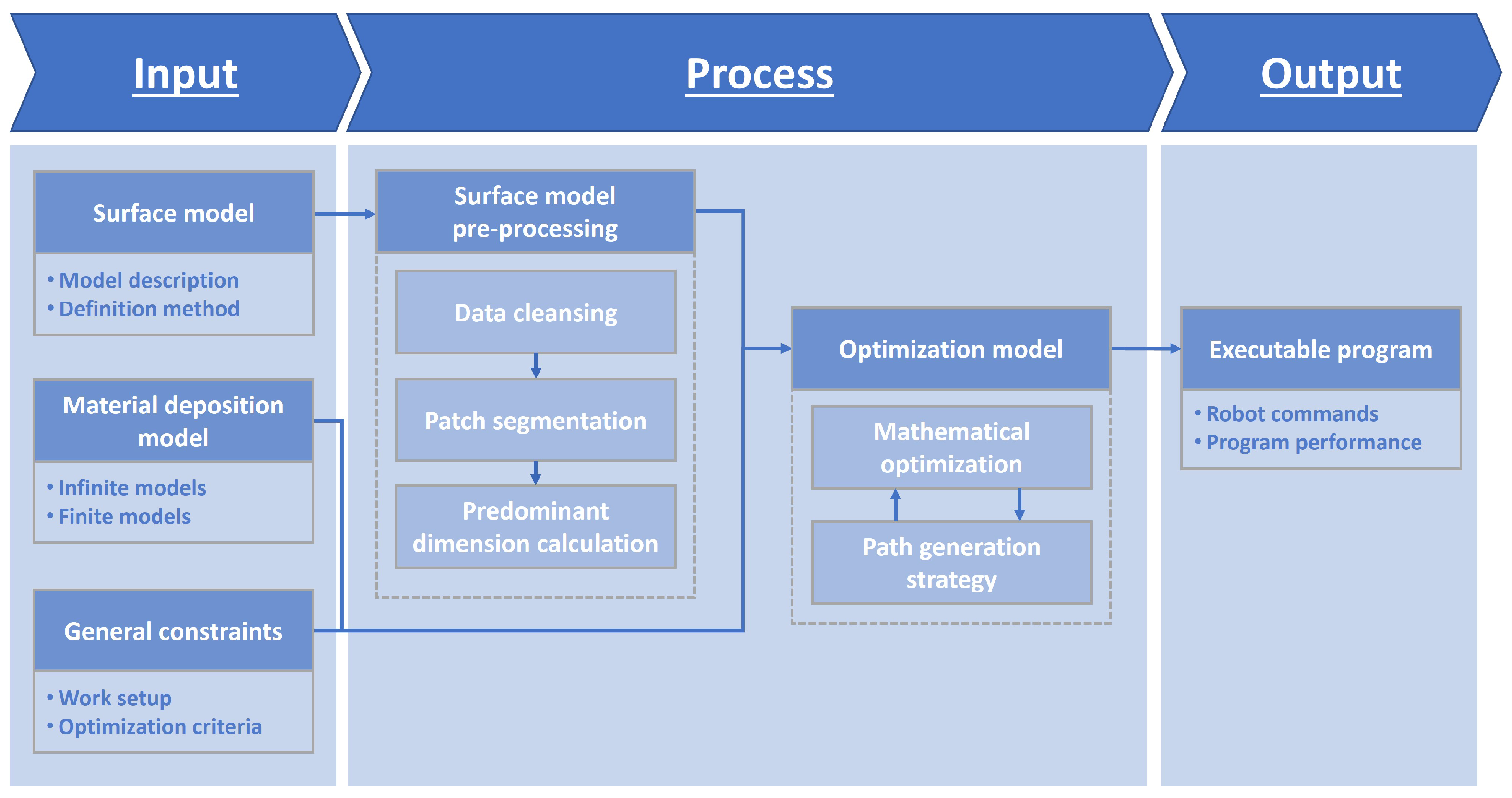

1.2. Overview

2. Input Data

2.1. Surface Model

2.1.1. Model Description

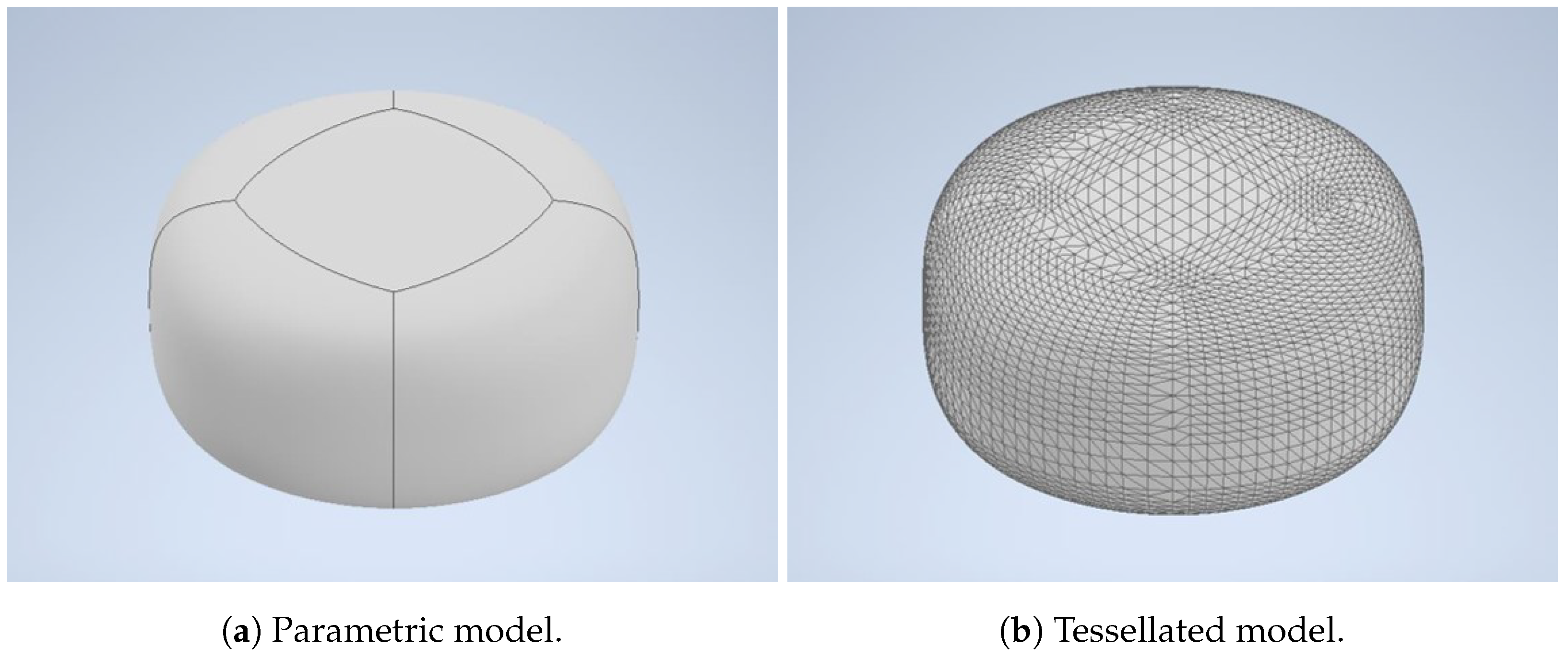

- Parametric models are a modeling paradigm based on parent–child interdependencies between features to generate a representation of the surface [10]. Parameters constitute the constraints that define the workpiece and can be dimensional, geometric, or algebraic. This modeling format constitutes the current industry standard for generating CAD-based parts and assemblies. With this format, it is possible to make a representative model while using supporting points, lines, arcs, splines, NURBS surfaces, and solid elements. This methodology guarantees a high level of accuracy in the representation of the design. However, there is much redundant information generated, a discretization step is required to calculate the spray coverage area, and each surface is interpreted independently, making an analysis of the entire surface more complex [11]. A typical example of the type of CAD file is STEP (the standard for the exchange of product model data), which is represented in Figure 2a.

- Tessellated models consist of generating a discrete surface representation with a 3D mesh of small elements (typically triangles or other polygons) [12]. This modeling method is the simpler alternative for analysis because the normal, location, and area of each element are directly known; the tessellated part can be considered as one piece; and it can achieve a good balance between representation accuracy and computation time. On the downside, there can be a lack of information on geometrical features such as edges, and the size of the data can become quite large, especially when high resolution is required (e.g., to represent large and/or complex parts) [11,12]. A typical CAD file format type is STL (standard tessellation language), as represented in Figure 2b.

2.1.2. Definition Method

- CAD-based method: In this approach, the blueprint of the workpiece, particularly the computer-aided design (CAD) file, is directly inserted into the trajectory calculation algorithm. This approach requires that the CAD-model is available, or else it needs to be created manually starting from the workpiece that needs to be sprayed [13]. This is the most common approach employed in publications to date for the following reasons [14]: (1) its simplicity in importing directly the model into the simulated environment and algorithm; (2) no measuring inaccuracies occur, as the workpiece trajectory is calculated directly out of the flawless CAD design; (3) the ease of the CAD-software converting automatically between the tessellated and parametric models as needed; and (4) it does not require the use of gauges and sensors to determine the surface geometry. The disadvantages of employing this method are (1) manufacturing inaccuracies can no longer be compensated for with path adaptations as the trajectory is generated for the “ideal” part; and (2) the pose (i.e., position and orientation) of the workpiece needs to be determined in the workcell before starting the spraying job, either by using a bracket to always hold the workpiece in the same pose, or by the use of gauges, to determine the exact placement [3].

- Sensor-based method: The alternative approach consists of measuring the real, to-be-coated workpiece, before initiating the computation of the spraying trajectory [13]. The advantages of this type of approach are [14]: (1) its flexibility, as no CAD data are required for the particular workpiece, and (2) that the actual workpiece surface measurements are introduced into the simulated environment and algorithm instead of those of a hypothetical model. On the other hand, (1) gauges are required to perform these measurements and (2) additional computational effort is needed to reverse engineer the surface [15].Different technologies can be used to make measurements in the sensor-based method:

- (a)

- Optical barriers: Gasparetto et al. [16] propose an image acquisition based on optical barriers to determine the geometry of the surface. This type of gauge consists of a light emitter and a receiver, which have a workpiece in between. The beam of light is interrupted by the workpiece, and therefore the position of the edges and the body can be determined. On the downside, this method only works for flat (2-dimensional) surfaces and by having the surface positioned at a known distance from the camera since the created shadow does not contain any depth information.

- (b)

- Depth camera: A different approach is presented by Tadic et al. [17], which includes the use of a depth camera. This type of camera generates a point cloud, which is an unorganized set of discrete points in a three-dimensional space. There are three types of depth camera technologies: stereo vision, structured light, and time-of-flight (ToF).Stereo vision systems use two separate cameras to capture an image from two positions. By knowing the distance between the cameras and comparing both signals that were recorded from different angles, it is possible to extract the depth information [18].Structured light systems, on the other hand, use light patterns that are emitted from a projector onto the workpiece’s surface. This pattern is distorted on the reflecting surface and then recognized by a sensing camera located in a different position. Following the same principle as stereo vision systems, triangulation enables the sensor to determine the 3-dimensional position of each point [18].Finally, ToF systems work based on an emitter that sends a pulsed signal directed toward the workpiece, and a receiver that measures the reflected light. By calculating the time difference between the emitted and received signal, it is possible to define the distance between the camera and the workpiece surface, thus gaining information on the third (depth) dimension [18].With the information from the point cloud gathered, it is now possible to digitally rebuild the measured surface. However, low-resolution depth cameras can lead to the misinterpretation of complex workpiece surfaces because only discrete points are recorded. At the same time, with high-resolution depth cameras, the computational effort increases drastically due to the large amount of data processing. Therefore, it is critical to find an adequate resolution for each application so that both factors (accuracy vs. computational effort) can be balanced out.

- (c)

- LiDAR: Light detection and ranging (LiDAR) is a type of sensor used for depth perception that works under the same principle as the ToF depth camera. Fundamentally, it measures the time interval between the emission and reception of a light pulse and then converts it into a distance. This system’s components include an emitter of laser pulses, a scanning system for redirecting the light onto the to-be-measured area, a detector for capturing the reflected light, and a processing unit to analyze the data. The sensor measures the scene by redirecting the laser beam across the measured area via the scanning mechanism, thereby identifying the surface coordinates and generating a point cloud [19].

- (d)

- Coordinate measuring machine: The third system-type that can be used for digitization of the workpiece is based on a coordinate measuring machine (CMM). In this case, a contact sensor (e.g., touch trigger probe) or non-contact sensor (e.g., laser) is attached to a robot, which moves the gauge in relation to the probe, thereby defining the point cloud coordinates [15]. Although a workpiece surface reconstruction can be created based on the information gained from a touch-trigger probe-based system, it is uncommon due to the data-acquisition time necessary for each coordinate and simultaneously the quantity of data-points required to recreate the surface with sufficient accuracy. Therefore, it is more common (and appropriate) to use non-contact sensors, as documented in the literature [13,20,21].

2.2. Material Deposition Model

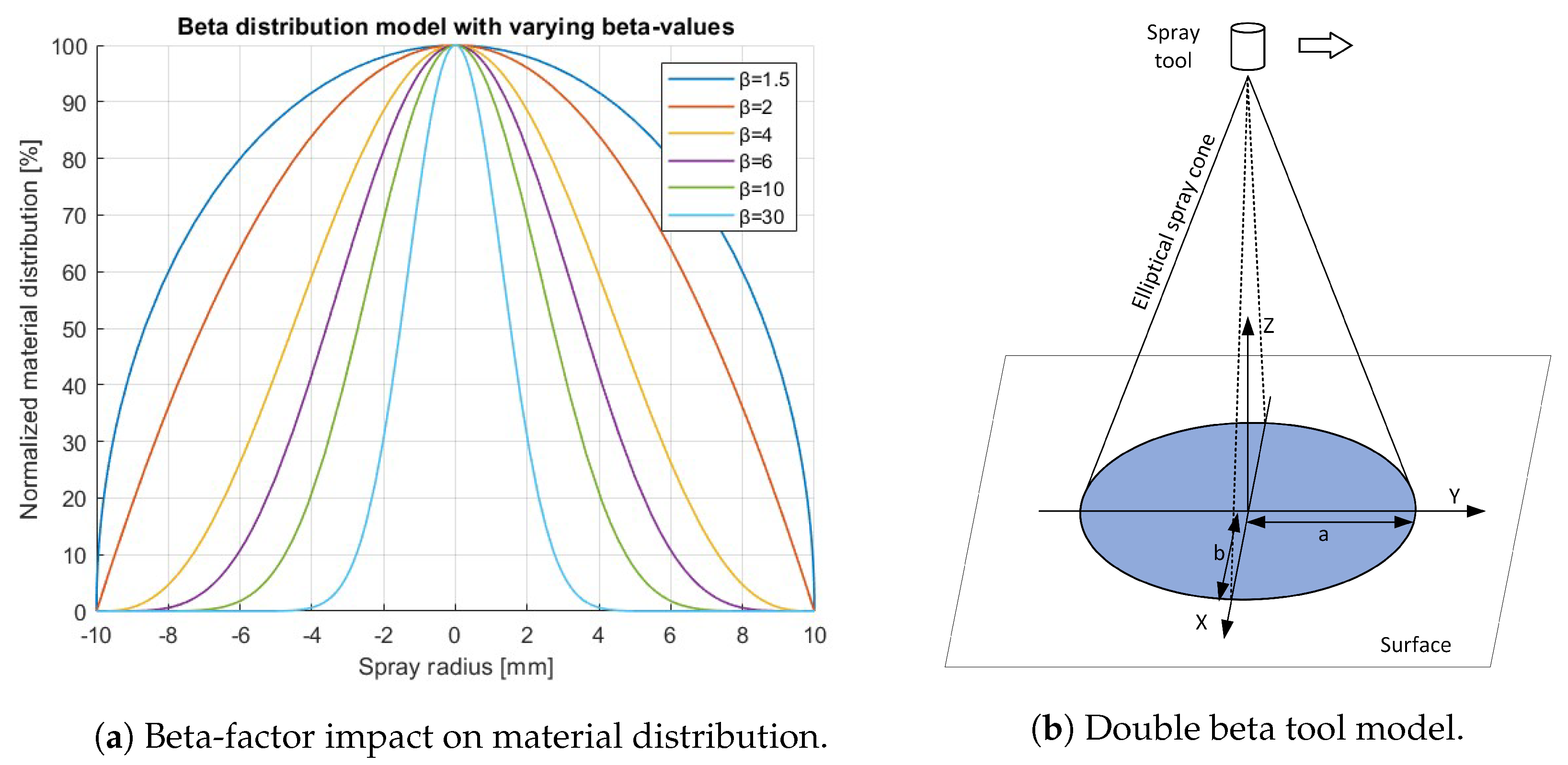

- Infinite-range models: This type of model has non-zero values outside the range R. This means that the surface area outside the spray cone always has a very small amount of material deposited, which decreases further with the distance from point O. It includes, e.g., the Gaussian model and the Cauchy model.

- Finite-range models: Unlike the former, this type of model does not have material deposition outside the area delimited by the range R. It includes, e.g., the trigonometric model, the piecewise model, the ellipse model, the parabolic model, the beta model, and the elliptic double beta model.

2.2.1. Beta Distribution Model

2.2.2. Elliptic Double Beta Distribution Model

2.3. General Constraints

2.3.1. Work Setup

- Robot type: As was stated in the previous example, the robot or robots (when used in tandem as proposed in [14,26]) have an important impact on the compatibility of the generated path. Particularly the technical specifications of the robot, its configuration, its reach, and its kinematic behavior may require some program adaptations for the suggested path to be compatible with the existing setup. Although industrial robots are the most common type of system used for moving the spraying tool to cover the surface in an industrial setting, there are also alternative systems such as unmanned aerial vehicles (UAVs) for painting surfaces directly from the air [27,28].

- Coating tools: This input also restricts how the path needs to be calculated. The technical specifications of the coating tools, their type, their volumetric flow rate, and the tank pressure are examples of inputs that must be considered.

- Workpiece properties: Besides the surface model, there are also other properties related to the workpiece that limit the path compatibility. The surface roughness, the workpiece temperature, and its material are criteria that ultimately influence how well the sprayed coating material adheres to the workpiece surface.

- Coating material: With respect to the adherence of the coating material, not only the workpiece itself but also the coating material must be considered. The chemical composition, its physical state, its temperature, and its viscosity are examples of relevant factors.

- Environmental conditions: Finally, the workcell conditions, including the temperature, humidity, and atmospheric pressure, also condition the general coating process.

2.3.2. Optimization Criteria

- Operational requirements: This type of criterion focuses on improving the overall performance of the spraying process. The length of the trajectory and the cycle time needed to perform the job [9,29], and wasted materials [30] are key performance indicators (KPIs) evaluated in the literature to reach the (semi-)optimal trajectory.

- Machine behavior: Finally, the parameters related to the machine behavior should also be considered to optimize the recommended path. Depending on the kinematic and dynamic behavior of the robot [32], and on the energy consumption of the system [33] a better path can be generated to spray a particular workpiece.

3. Processing Algorithm

3.1. Surface Model Pre-Processing

3.1.1. Data Cleansing

- Outlier elimination: Invalid data points and gross outliers must be identified and filtered out. A statistical filter can be used to remove unnecessary and noisy data, e.g., by computing the mean and standard deviation of the closest neighbors and pruning those values that lie outside a threshold criterion [17].

- Data merging: If multiple sensors are used, all datapoint information should be merged into one common coordinate system so that the workpiece can be analyzed as a whole [14].

- Data compression: A compression (or simplification) of the amount of data is required when the accuracy of the surface representation can be ensured [13]. This is an important step because depending on the resolution of the hardware used to generate the point cloud, large amounts of data-points can be defined, which will drastically increase the computational effort.

- Format conversion: And finally, a surface reconstruction should take place to bring the point cloud information to the right format for further processing by the following algorithms [14].

3.1.2. Patch Segmentation

3.1.3. Predominant Dimension Calculation

3.2. Optimization Model

3.2.1. Trajectory Optimization

3.2.2. Processing Time and Surface Finish Optimization

3.2.3. Robotic Arm Kinematic and Dynamic Optimization

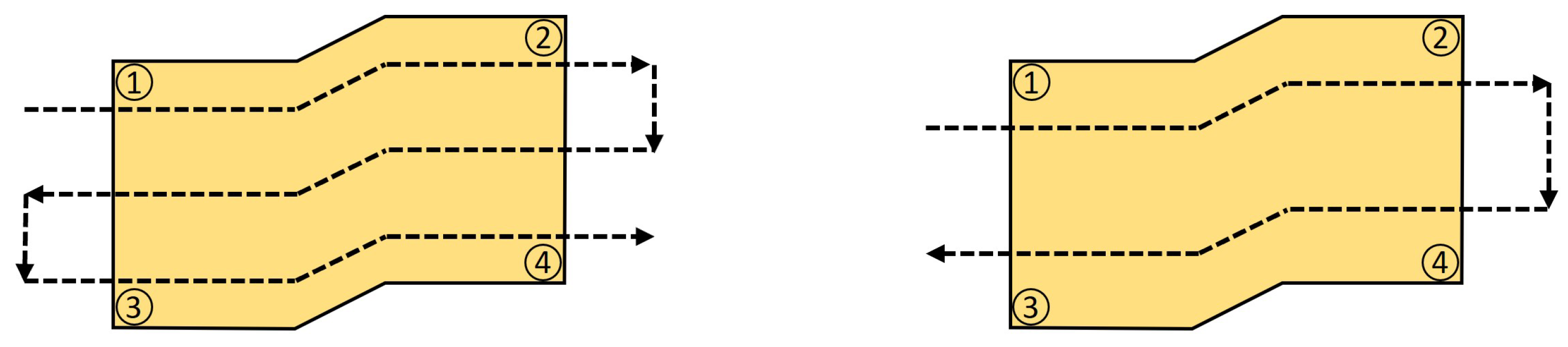

3.3. Path Generation Strategy

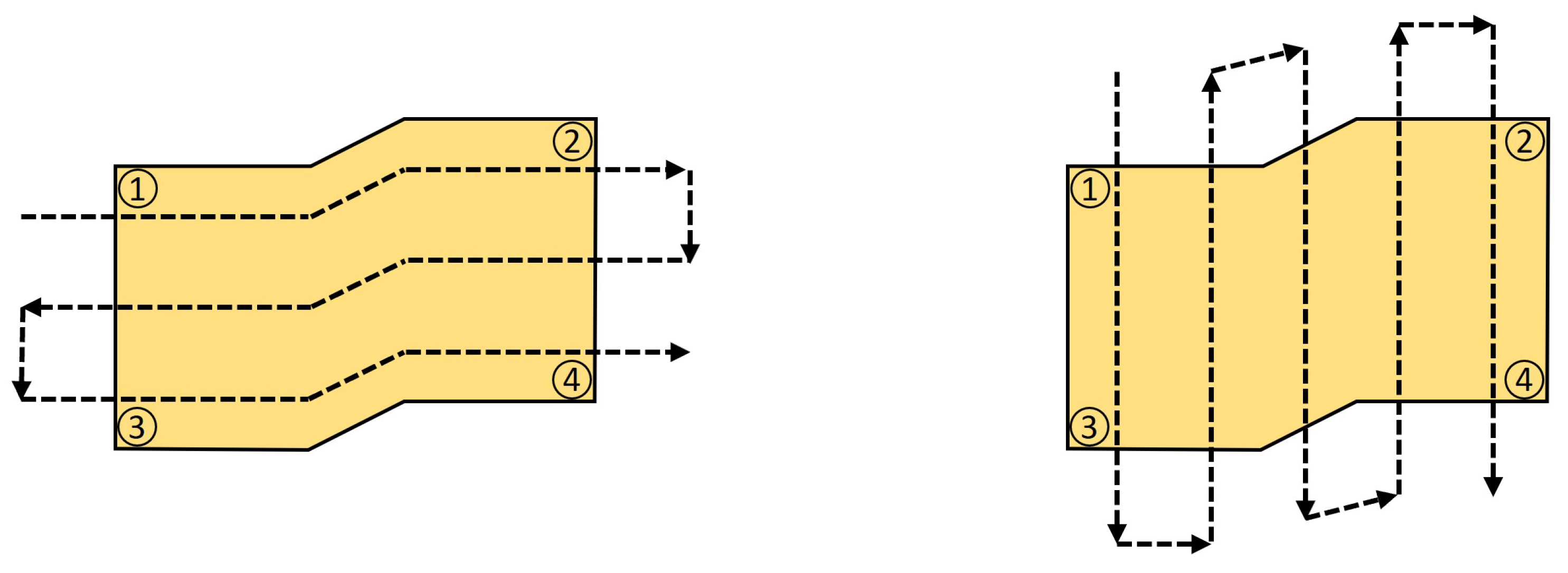

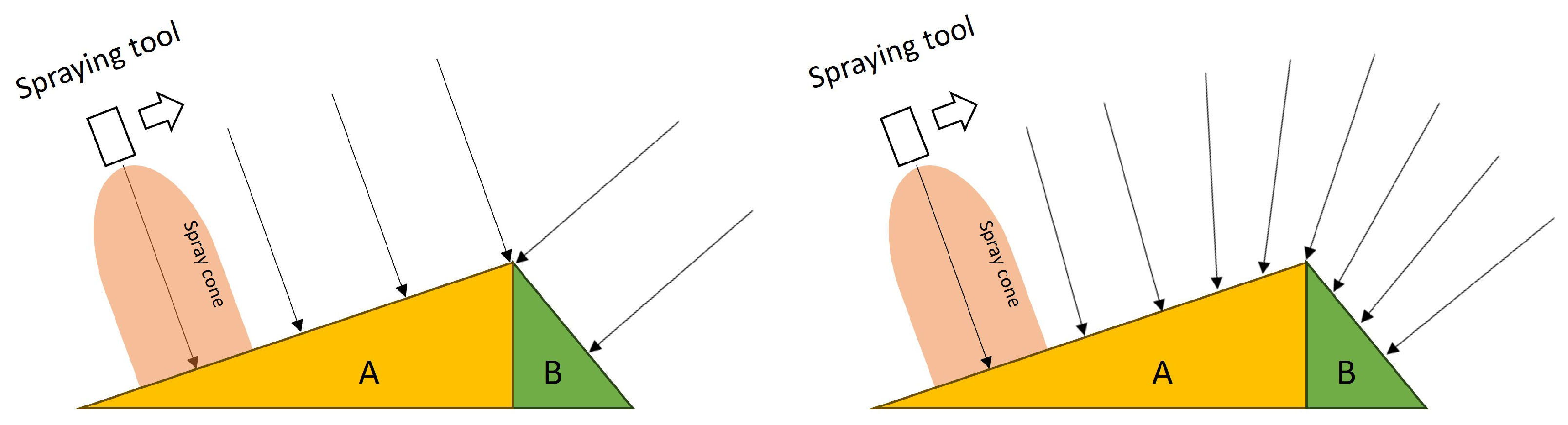

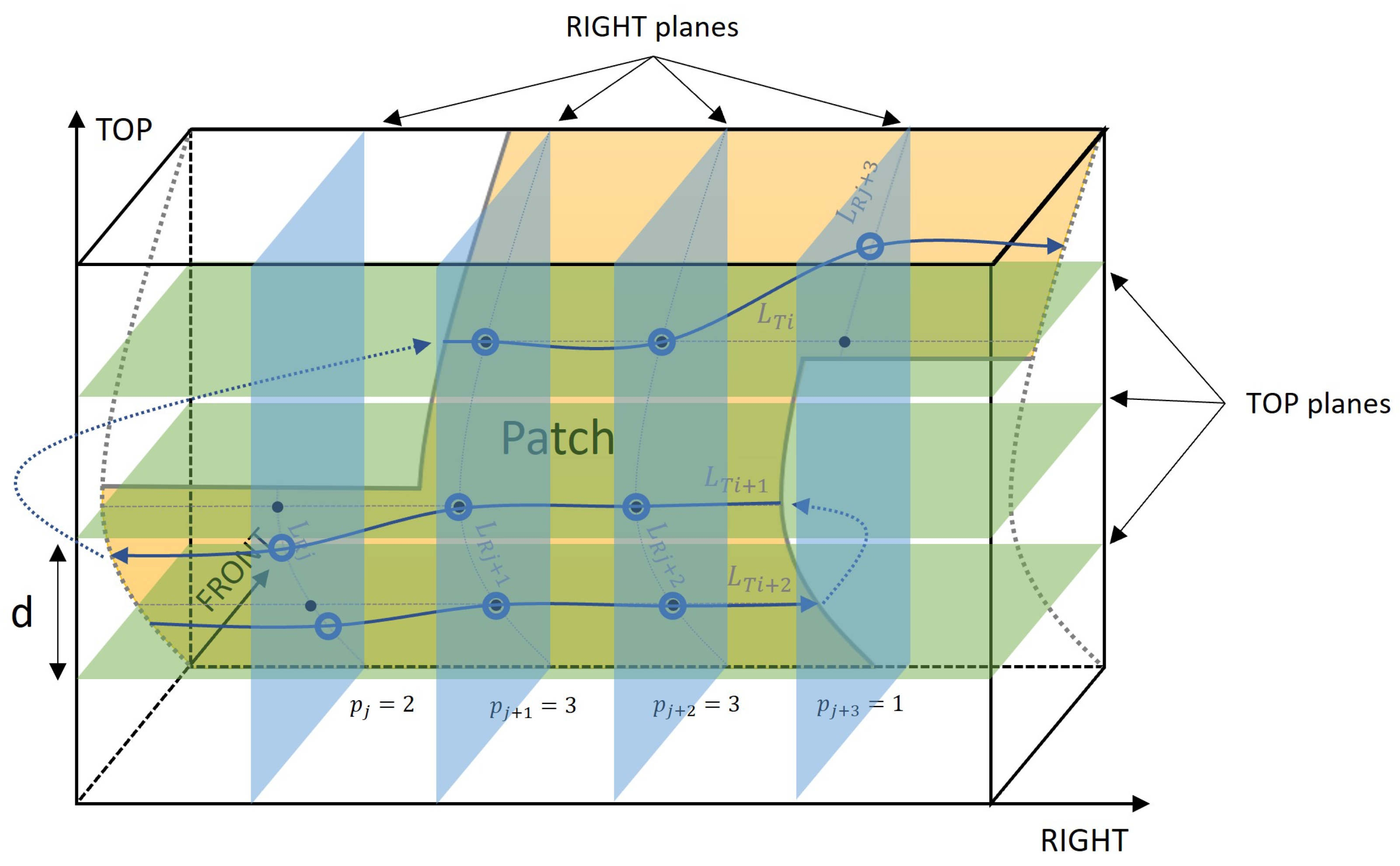

3.3.1. Slicing-Based Models

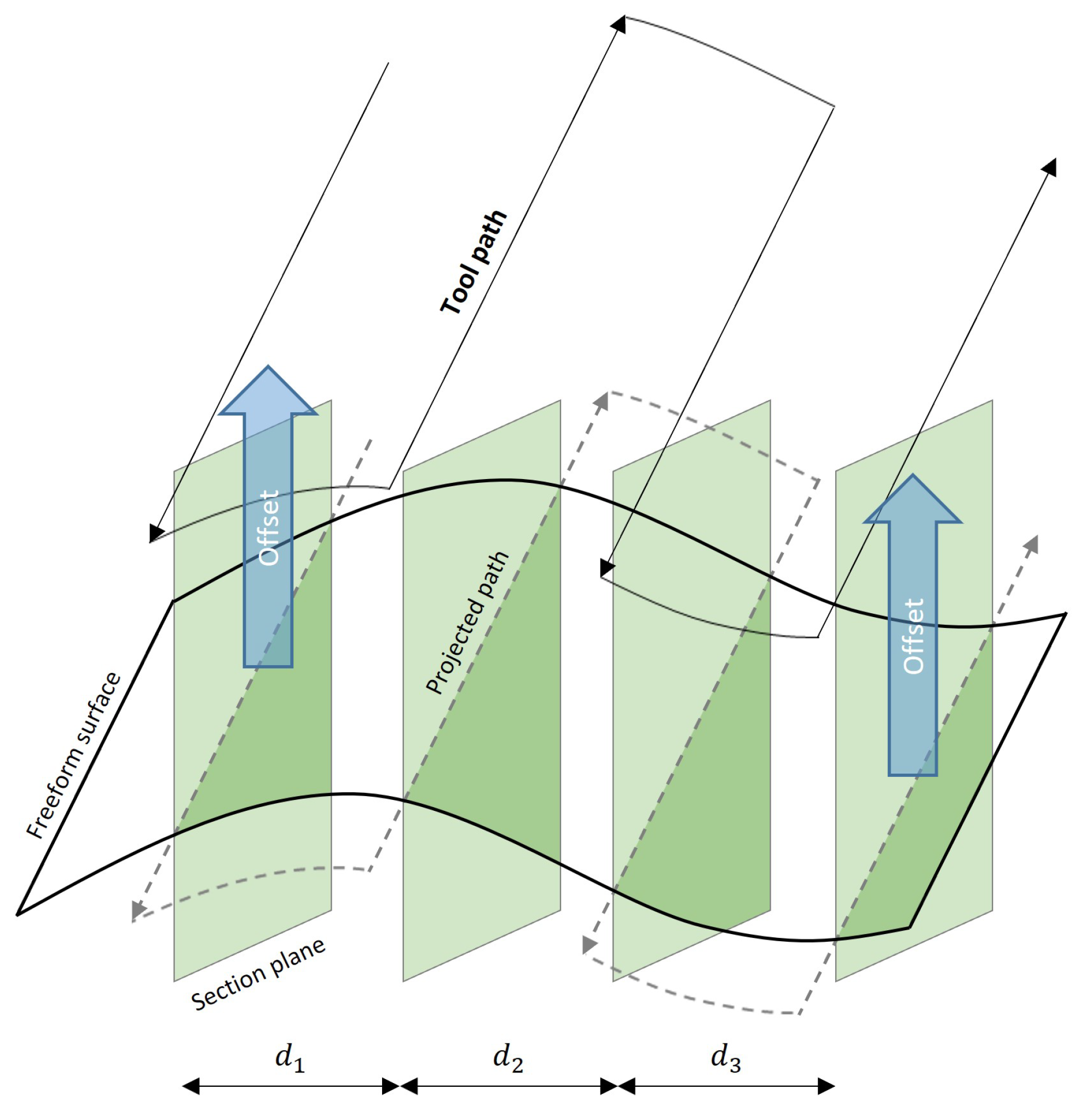

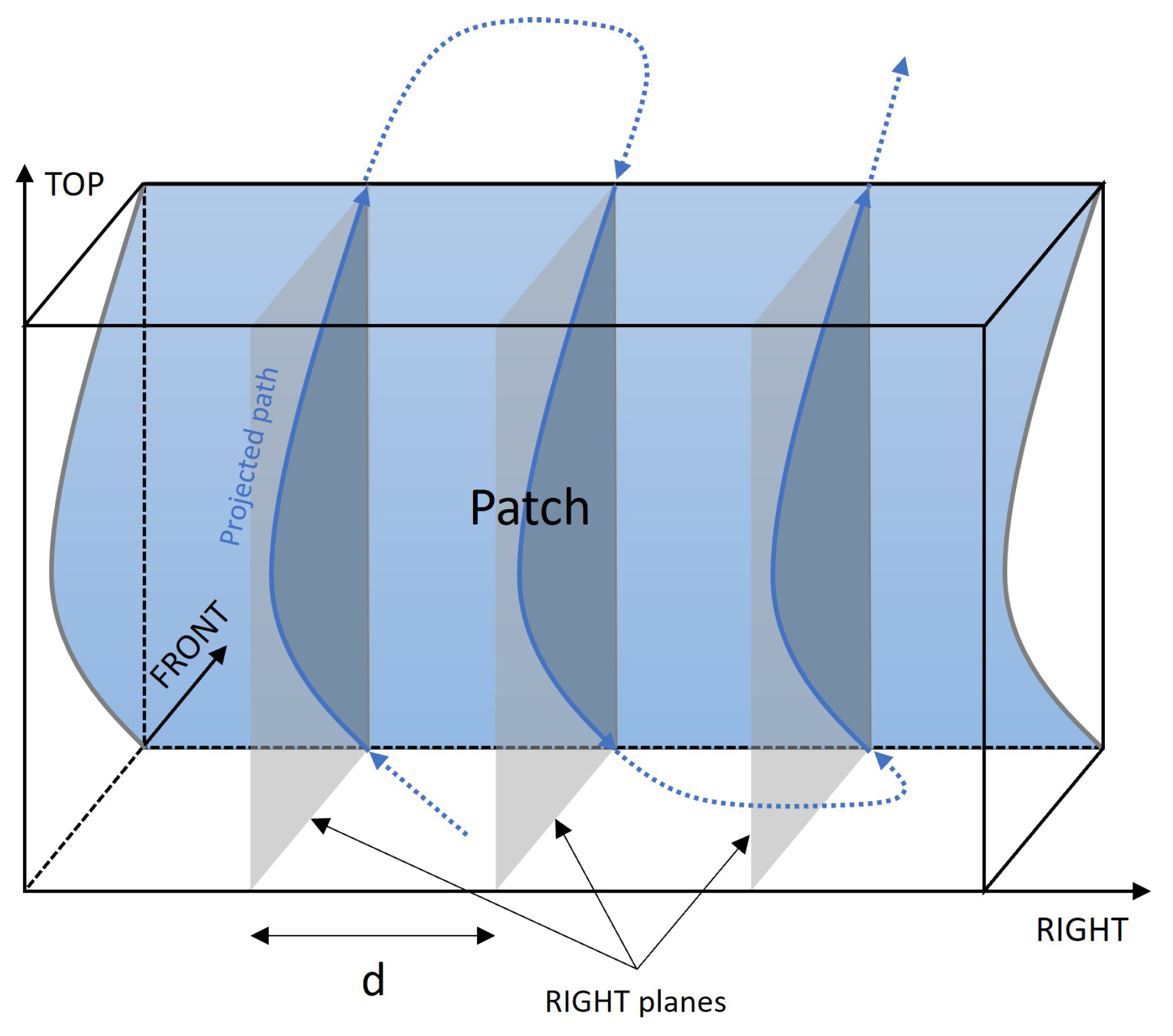

3.3.2. Section-Based Models

3.3.3. Differential Geometry Based Models

4. Computation Output

4.1. Robot Commands

- Waypoint coordinates: These are specific positions through which the spraying tool must pass to properly coat the workpiece [48]. It is the first component of the pose and must include the Cartesian coordinates, which unambiguously define how the workpiece, robot, and tool are placed in relation to each other.

- Waypoint speed: The speed is also an important component of the calculation because it affects the amount of coating material deposited at each point of the workpiece surface. Although most models assume a constant speed for the entire path, in the case of varying speeds, it is necessary for the machine commands to include the particular speed-value for each waypoint [13].

- Waypoint acceleration: Analogously to the waypoint speed, the acceleration is also required to ensure the uniform deposition of the coating material on the surface [39]. This information will support minimizing sudden changes in the deposition rate and ensure the good adherence of the coating material to the workpiece surface.

- Spraying tool angle: The orientation of the spraying tool is the second component of the pose and complements the waypoint coordinate information. Only by defining how the tool is oriented with respect to the workpiece is it possible to guarantee that the coating material is correctly aimed at the surface, thus adhering to the surface efficiently and minimizing material waste [49].

- Angular speed: The angular speed with which the spraying tool changes its orientation should also be defined as an input. With limitations to this parameter, gradual angle changes can be implemented, which results in the better kinematic behavior of the robot and leads to a more uniform layer of the coating material [42].

- Tool status: The tool status defines in every waypoint if the spraying tool is active (meaning emitting spraying material) or disabled (the opposite). This information is used to reduce material waste, which is generated when the spraying tool is active while being aimed away from the workpiece surface (e.g., when moving to the first waypoint or changing the stroke direction) [13].

4.2. Program Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAD | Computer-aided design |

| CAM | Computer-aided manufacturing |

| CMM | Coordinate measuring machine |

| CNC | Computer numerical control |

| IPO | Input–process–output |

| KPI | Key performance indicators |

| LiDAR | Light detection and ranging |

| ML | Machine learning |

| MSA | Minimal sum of altitudes |

| NURBS | Non-uniform rational B-splines |

| OLP | Offline robot programming |

| PCA | Principal component analysis |

| ROS | Robot operating system |

| STEP | Standard for the exchange of product model data |

| STL | Stereolithography |

| ToF | Time-of-flight |

| TSP | Traveling salesman problem |

| UAV | Unmanned aerial vehicle |

References

- Quintino, L. Overview of coating technologies. In Surface Modification by Solid State Processing; Elsevier: Amsterdam, The Netherlands, 2014; Chapter 1; pp. 1–24. [Google Scholar] [CrossRef]

- Fauchais, P.L.; Heberlein, J.V.; Boulos, M.I. Thermal Spray Fundamentals; Springer: Boston, MA, USA, 2014. [Google Scholar] [CrossRef]

- Lin, W.; Anwar, A.; Li, Z.; Tong, M.; Qiu, J.; Gao, H. Recognition and Pose Estimation of Auto Parts for an Autonomous Spray Painting Robot. IEEE Trans. Ind. Inform. 2019, 15, 1709–1719. [Google Scholar] [CrossRef]

- Andulkar, M.V.; Chiddarwar, S.S. Incremental approach for trajectory generation of spray painting robot. Ind. Robot. 2015, 42, 228–241. [Google Scholar] [CrossRef]

- Posada, J.R.; Meissner, A.; Hentz, G.; D’Agostino, N. Machine learning approaches for offline-programming optimization in robotic painting. In Proceedings of the 52nd International Symposium on Robotics, ISR 2020, Munich, Germany, 17–18 June 2020; pp. 280–286. [Google Scholar]

- Sahir Arikan, M.A.; Balkan, T. Process modeling, simulation, and paint thickness measurement for robotic spray painting. J. Robot. Syst. 2000, 17, 479–494. [Google Scholar] [CrossRef]

- Conner, D.C.; Greenfield, A.; Atkar, P.N.; Rizzi, A.A.; Choset, H. Paint deposition modeling for trajectory planning on automotive surfaces. IEEE Trans. Autom. Sci. Eng. 2005, 2, 381–391. [Google Scholar] [CrossRef]

- Chen, H.; Thomas, F.; Xiongzi, L. Automated industrial robot path planning for spray painting a process: A review. In Proceedings of the 4th IEEE Conference on Automation Science and Engineering, CASE 2008, Mexico City, Mexico, 20–24 August 2008; pp. 522–527. [Google Scholar] [CrossRef]

- Chen, H. A General Framework for Automated Cad-Guided Optimal Tool Planning in Surface Manufacturing. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2003. [Google Scholar]

- Camba, J.D.; Contero, M.; Company, P. Parametric CAD modeling: An analysis of strategies for design reusability. CAD Comput. Aided Des. 2016, 74, 18–31. [Google Scholar] [CrossRef]

- Chen, H.; Fuhlbrigge, T.; Li, X. A review of CAD-based robot path planning for spray painting. Ind. Robot. 2009, 36, 45–50. [Google Scholar] [CrossRef]

- Guo, J.; Ding, F.; Jia, X.; Yan, D.M. Automatic and high-quality surface mesh generation for CAD models. CAD Comput. Aided Des. 2019, 109, 49–59. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, Z.; Zhang, Y.; Ou, L. point cloud modeling and slicing algorithm for trajectory planning of spray painting robot. Robotica 2021, 39, 2246–2267. [Google Scholar] [CrossRef]

- Bi, Z.M.; Lang, S.Y. A framework for CAD and scanner-based robotic coating automation. IEEE Trans. Ind. Inform. 2007, 3, 84–91. [Google Scholar] [CrossRef]

- Mian, S.H.; Al-Ahmari, A. Comparative analysis of different digitization systems and selection of best alternative. J. Intell. Manuf. 2019, 30, 2039–2067. [Google Scholar] [CrossRef]

- Gasparetto, A.; Vidoni, R.; Pillan, D.; Saccavini, E. Optimal path planning for spray painting robots. In Proceedings of the ASME, Calgary, AB, Canada, 27 September–1 October 2010. [Google Scholar]

- Tadic, V.; Odry, A.; Burkus, E.; Kecskes, I.; Kiraly, Z.; Klincsik, M.; Sari, Z.; Vizvari, Z.; Toth, A.; Odry, P. Painting path planning for a painting robot with a realsense depth sensor. Appl. Sci. 2021, 11, 1467. [Google Scholar] [CrossRef]

- Zanuttigh, P.; Marin, G.; Dal Mutto, C.; Dominio, F.; Minto, L.; Cortelazzo, G.M. Time-of-Flight and Structured Light Depth Cameras; Springer: Cham, Switzerland, 2016; p. 355. [Google Scholar] [CrossRef]

- Raj, T.; Hashim, F.H.; Huddin, A.B.; Ibrahim, M.F.; Hussain, A. A Survey on LiDAR Scanning Mechanisms. Electronics 2020, 9, 741. [Google Scholar] [CrossRef]

- Candel, A.; Gadow, R. Trajectory generation and coupled numerical simulation for thermal spraying applications on complex geometries. J. Therm. Spray Technol. 2009, 18, 981–987. [Google Scholar] [CrossRef]

- Vincze, M.; Pichler, A.; Biegelbauer, G.; Hausler, K.; Andersen, H.; Madsen, O.; Kristiansen, M. Automatic robotic spray painting of low volume high variant parts. Int. Symp. Robot. 2002, 7, 11. [Google Scholar]

- Chen, Y.; Chen, W.; Li, B.; Zhang, G.; Zhang, W. Paint thickness simulation for painting robot trajectory planning: A review. Ind. Robot. 2017, 44, 629–638. [Google Scholar] [CrossRef]

- Andulkar, M.V.; Chiddarwar, S.S.; Marathe, A.S. Novel integrated offline trajectory generation approach for robot assisted spray painting operation. J. Manuf. Syst. 2015, 37, 201–216. [Google Scholar] [CrossRef]

- Zhou, B.; Fang, F.; Shao, Z.; Meng, Z.; Dai, X. Fast and templatable path planning of spray painting robots for regular surfaces. Chin. Control. Conf. 2015, 9, 5925–5930. [Google Scholar] [CrossRef]

- Chen, H.; Xi, N.; Sheng, W.; Chen, Y. General framework of optimal tool trajectory planning for free-form surfaces in surface manufacturing. J. Manuf. Sci. Eng. 2005, 127, 49–59. [Google Scholar] [CrossRef]

- Zbiss, K.; Kacem, A.; Santillo, M.; Mohammadi, A. Automatic Collision-Free Trajectory Generation for Collaborative Robotic Car-Painting. IEEE Access 2022, 10, 9950–9959. [Google Scholar] [CrossRef]

- Vempati, A.S.; Kamel, M.; Stilinovic, N.; Zhang, Q.; Reusser, D.; Sa, I.; Nieto, J.; Siegwart, R.; Beardsley, P. PaintCopter: An Autonomous UAV for Spray Painting on Three-Dimensional Surfaces. IEEE Robot. Autom. Lett. 2018, 3, 2862–2869. [Google Scholar] [CrossRef]

- Vazquez-Carmona, E.V.; Vasquez-Gomez, J.I.; Herrera-Lozada, J.C.; Antonio-Cruz, M. Coverage path planning for spraying drones. Comput. Ind. Eng. 2022, 168, 108125. [Google Scholar] [CrossRef]

- Chen, H.; Xi, N.; Sheng, W.; Dahl, J.; Li, Z. Optimal tool trajectory integration in surface manufacturing. IFAC Proc. Vol. 2005, 16, 211–216. [Google Scholar] [CrossRef]

- Atkar, P.N.; Conner, D.C.; Greenfield, A.; Choset, H.; Rizzi, A.A. Hierarchical segmentation of piecewise pseudoextruded surfaces for uniform coverage. IEEE Trans. Autom. Sci. Eng. 2009, 6, 107–120. [Google Scholar] [CrossRef]

- Chen, W.; Liu, J.; Tang, Y.; Huan, J.; Liu, H. Trajectory Optimization of Spray Painting Robot for Complex Curved Surface Based on Exponential Mean Bézier Method. Math. Probl. Eng. 2017, 2017, 4259869. [Google Scholar] [CrossRef]

- Hegels, D.; Wiederkehr, T.; Muller, H. Simulation based iterative post-optimization of paths of robot guided thermal spraying. Robot. Comput. Integr. Manuf. 2015, 35, 1–15. [Google Scholar] [CrossRef]

- Helou, M.E.; Mandt, S.; Krause, A.; Beardsley, P. Mobile robotic painting of texture. IEEE Int. Conf. Robot. Autom. 2019, 5, 640–647. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Kim, J.; Lee, Y.; Ahmed, N.; Lee, S. Accurate and fast extraction of planar surface patches from 3D point cloud. In Proceedings of the 7th International Conference on Ubiquitous Information Management and Communication, ICUIMC 2013, Bali, Indonesia, 8–10 January 2013. [Google Scholar] [CrossRef]

- Galceran, E.; Carreras, M. A survey on coverage path planning for robotics. Robot. Auton. Syst. 2013, 61, 1258–1276. [Google Scholar] [CrossRef]

- Choset, H.; Pignon, P. Coverage Path Planning: The Boustrophedon Cellular Decomposition. Field Serv. Robot. 1998, 1, 203–209. [Google Scholar] [CrossRef]

- Huang, W.H. Optimal line-sweep-based decompositions for coverage algorithms. IEEE Int. Conf. Robot. Autom. 2001, 1, 27–32. [Google Scholar] [CrossRef]

- Wang, G.; Cheng, J.; Li, R.; Chen, K. A new point cloud slicing based path planning algorithm for robotic spray painting. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 2 December 2015; pp. 1717–1722. [Google Scholar] [CrossRef]

- Atkar, P.N.; Greenfield, A.; Conner, D.C.; Choset, H.; Rizzi, A.A. Uniform Coverage of Automotive Surface Patches. Int. J. Robot. Res. 2005, 24, 883–898. [Google Scholar] [CrossRef]

- Andersson, J. A Survey of Multiobjective Optimization in Engineering Design; Technical Report January 2000; Department of Mechanical Engineering, Linktjping University: Linktjping, Sweden, 2000. [Google Scholar]

- Trigatti, G.; Boscariol, P.; Scalera, L.; Pillan, D.; Gasparetto, A. A new path-constrained trajectory planning strategy for spray painting robots. Int. J. Adv. Manuf. Technol. 2018, 98, 2287–2296. [Google Scholar] [CrossRef]

- Deng, S.H.; Cai, Z.H.; Fang, D.D.; Liao, H.L.; Montavon, G. Application of robot offline programming in thermal spraying. Surf. Coatings Technol. 2012, 206, 3875–3882. [Google Scholar] [CrossRef]

- Moe, S.; Gravdahl, J.T.; Pettersen, K.Y. Set-Based Control for Autonomous Spray Painting. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1785–1796. [Google Scholar] [CrossRef]

- Sheng, W.; Xi, N.; Song, M.; Chen, Y.; MacNeille, P. Automated CAD-guided robot path planning for spray painting of compound surfaces. IEEE Int. Conf. Intell. Robot. Syst. 2000, 3, 1918–1923. [Google Scholar] [CrossRef]

- Atkar, P.; Choset, H.; Rizzi, A. Towards optimal coverage of 2-dimensional surfaces embedded in R3: Choice of start curve. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No.03CH37453), Las Vegas, NV, USA, 27–28 October 2003; pp. 3581–3587. [Google Scholar] [CrossRef]

- Chen, H.; Xi, N. Automated tool trajectory planning of industrial robots for painting composite surfaces. Int. J. Adv. Manuf. Technol. 2008, 35, 680–696. [Google Scholar] [CrossRef]

- Mineo, C.; Pierce, S.G.; Nicholson, P.I.; Cooper, I. Introducing a novel mesh following technique for approximation-free robotic tool path trajectories. J. Comput. Des. Eng. 2017, 4, 192–202. [Google Scholar] [CrossRef]

- Cai, Z.; Liang, H.; Quan, S.; Deng, S.; Zeng, C.; Zhang, F. Computer-Aided Robot Trajectory Auto-generation Strategy in Thermal Spraying. J. Therm. Spray Technol. 2015, 24, 1235–1245. [Google Scholar] [CrossRef]

- Bidanda, B.; Narayanan, V.; Rubinovitz, J. Computer-aided-design-based interactive off-line programming of spray-glazing robots. Int. J. Comput. Integr. Manuf. 1993, 6, 357–365. [Google Scholar] [CrossRef]

- Siciliano, B.; Khatib, O. Springer Handbook of Robotics; Springer: Cham, Switzerland, 2016; pp. 1–222. [Google Scholar] [CrossRef]

- Russell, S.; Norvig, P. Artificial Intelligence: A Modern Approach, 4th ed.; Pearson: London, UK, 2021. [Google Scholar]

- Wu, H.; Xie, X.; Liu, M.; Chen, C.; Liao, H.; Zhang, Y.; Deng, S. A new approach to simulate coating thickness in cold spray. Surf. Coatings Technol. 2020, 382, 125151. [Google Scholar] [CrossRef]

- Chen, H.; Sheng, W. Transformative industrial robot programming in surface manufacturing. In Proceedings of the IEEE International Conference on Robotics and Automation, Yokohama, Japan, 13–17 May 2011; pp. 6059–6064. [Google Scholar] [CrossRef]

- Fang, D.; Zheng, Y.; Zhang, B.; Li, X.; Ju, P.; Li, H.; Zeng, C. Automatic robot trajectory for thermal-sprayed complex surfaces. Adv. Mater. Sci. Eng. 2018, 2018, 8697056. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, C.; Xiao, H.; Zhou, B.; Zeng, Y. Planning Method of Offset Spray Path for Patch considering Boundary Factors. Math. Probl. Eng. 2018, 2018, 6067391. [Google Scholar] [CrossRef]

- Garbev, A.; Atanassov, A. Comparative Analysis of RoboDK and Robot Operating System for Solving Diagnostics Tasks in Off-Line Programming. In Proceedings of the 2020 International Conference Automatics and Informatics (ICAI), Varna, Bulgaria, 1–3 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Kout, A.; Muller, H. Tool-adaptive offset paths on triangular mesh workpiece surfaces. CAD Comput. Aided Des. 2014, 50, 61–73. [Google Scholar] [CrossRef]

- Chen, H.; Xi, N.; Chen, Y. Multi-objective Optimal Robot Path Planning in Manufacturing. IEEE Int. Conf. Intell. Robot. Syst. 2003, 2, 1167–1172. [Google Scholar] [CrossRef]

- Berenson, D.; Abbeel, P.; Goldberg, K. A robot path planning framework that learns from experience. In Proceedings of the IEEE International Conference on Robotics and Automation, St. Paul, MN, USA, 14–18 May 2012; pp. 3671–3678. [Google Scholar] [CrossRef]

| Input | Category | Subcategory |

|---|---|---|

| Surface model | Model description | Parametric model |

| Tessellated model | ||

| Definition method | CAD-based | |

| Sensor-based | ||

| Material deposition model | Infinite models | Gaussian model |

| Cauchy model | ||

| Finite models | Trigonometric model | |

| Piecewise model | ||

| Ellipse model | ||

| Parabolic model | ||

| Beta model | ||

| Elliptical double beta model | ||

| General constraints | Work setup | Robot type |

| Coating tool | ||

| Workpiece properties | ||

| Coating material | ||

| Environmental conditions | ||

| Optimization criteria | Operational requirements | |

| Coating quality | ||

| Machine behavior |

| Process | Category | Subcategory |

|---|---|---|

| Surface model pre-processing | Data cleansing | Outlier elimination |

| Surface smoothing | ||

| Data merging | ||

| Data compression | ||

| Format conversion | ||

| Patch segmentation | Surface normal clustering | |

| Watershed segmentation | ||

| Trapezoidal decomposition | ||

| Boustrophedon decomposition | ||

| Morse-based cellular decomposition | ||

| Landmark-based topological coverage | ||

| Minimal sum of altitudes (MSA) decomposition | ||

| Predominant dimension calculation | Principal component analysis (PCA) | |

| Optimization model | Mathematical optimization | Trajectory optimization |

| Processing time optimization | ||

| Coating quality optimization | ||

| Kinematic and dynamic behavior optimization | ||

| Path generating strategy | Slicing-based models | |

| Section-based models | ||

| Differential geometry-based models |

| Output | Category | Subcategory |

|---|---|---|

| Executable program | Robot commands | Waypoints coordinates |

| Waypoint speed | ||

| Waypoint acceleration | ||

| Spraying tool angle | ||

| Angular speed | ||

| Tool status | ||

| Program performance | Processing time | |

| Coating uniformity | ||

| Coating coverage | ||

| Spraying material wastage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weber, A.M.; Gambao, E.; Brunete, A. A Survey on Autonomous Offline Path Generation for Robot-Assisted Spraying Applications. Actuators 2023, 12, 403. https://doi.org/10.3390/act12110403

Weber AM, Gambao E, Brunete A. A Survey on Autonomous Offline Path Generation for Robot-Assisted Spraying Applications. Actuators. 2023; 12(11):403. https://doi.org/10.3390/act12110403

Chicago/Turabian StyleWeber, Alexander Miguel, Ernesto Gambao, and Alberto Brunete. 2023. "A Survey on Autonomous Offline Path Generation for Robot-Assisted Spraying Applications" Actuators 12, no. 11: 403. https://doi.org/10.3390/act12110403

APA StyleWeber, A. M., Gambao, E., & Brunete, A. (2023). A Survey on Autonomous Offline Path Generation for Robot-Assisted Spraying Applications. Actuators, 12(11), 403. https://doi.org/10.3390/act12110403