In order to dynamically adjust the stiffness and damping of the system, combined with the dynamic characteristics of the permanent and electromagnet hybrid actuator, the model of the PECVIS is established, and the nominal controller is designed.

3.1. Modeling of PECVIS

As to the complex electromechanical system of the PECVIS, many factors are ignored in order to reduce the difficulty of solving problems [

18,

19]. The magnetic flux leakage and edge effects are also ignored in this study, and it is considered that the intensity distribution of the permanent magnetic–electromagnetic hybrid magnetic field is uniform. According to the theory of the permanent magnet electromagnetic hybrid magnetic field, the equivalent magnetic circuit of the permanent and electromagnet hybrid actuator is shown in

Figure 5.

According to Ohm’s law, the entire circuit satisfies the following relationship:

In the formula, . is the number of turns of the electromagnetic coil, is the current passing through the coil of the electromagnet, is the coercive force of the NdFeB permanent magnet, is the thickness of the permanent magnet, and is the magnetic flux of the intermediate magnetic circuit of the E-type electromagnet. In addition, and are the magnetic fluxes of the left and right magnetic circuits, respectively, is the total magnetic resistance of the middle air gap and permanent magnet, is the total magnetic resistance of the left air gap and permanent magnet and is the total magnetic resistance of the right air gap and permanent magnet.

The magnetic flux of the middle magnetic circuit of the E-type electromagnet is:

In this formula, and are the vacuum permeability and the relative permeability of NdFeB permanent magnet respectively, is the magnetic pole area of the middle permanent magnet and is the gap between the permanent magnet and the armature.

The magnetic force generated by the permanent and electromagnet hybrid actuator is:

In the formula, is the magnetic force generated by the permanent and electromagnet hybrid actuator, is the magnetic pole area of the upper surface of the left permanent magnet and is the magnetic pole area of the upper surface of the right permanent magnet.

The relationship between the electromagnetic attraction force generated by the permanent and electromagnet hybrid actuator and the current and air gap can also be listed in the following form:

The specific values of

,

and

are fitted by the numerical results of the electromagnetic attraction force. The electromagnetic attraction force generated by the permanent and electromagnet hybrid actuator under different currents and different air gaps is shown in

Table 4.

According to the above

Table 4, the relationship between electromagnetic attraction force and the gap is as shown in

Figure 6.

According to the above table, the following is obtained:

, ,

The electromagnet is an inductive element, so the relationship between its voltage and current is:

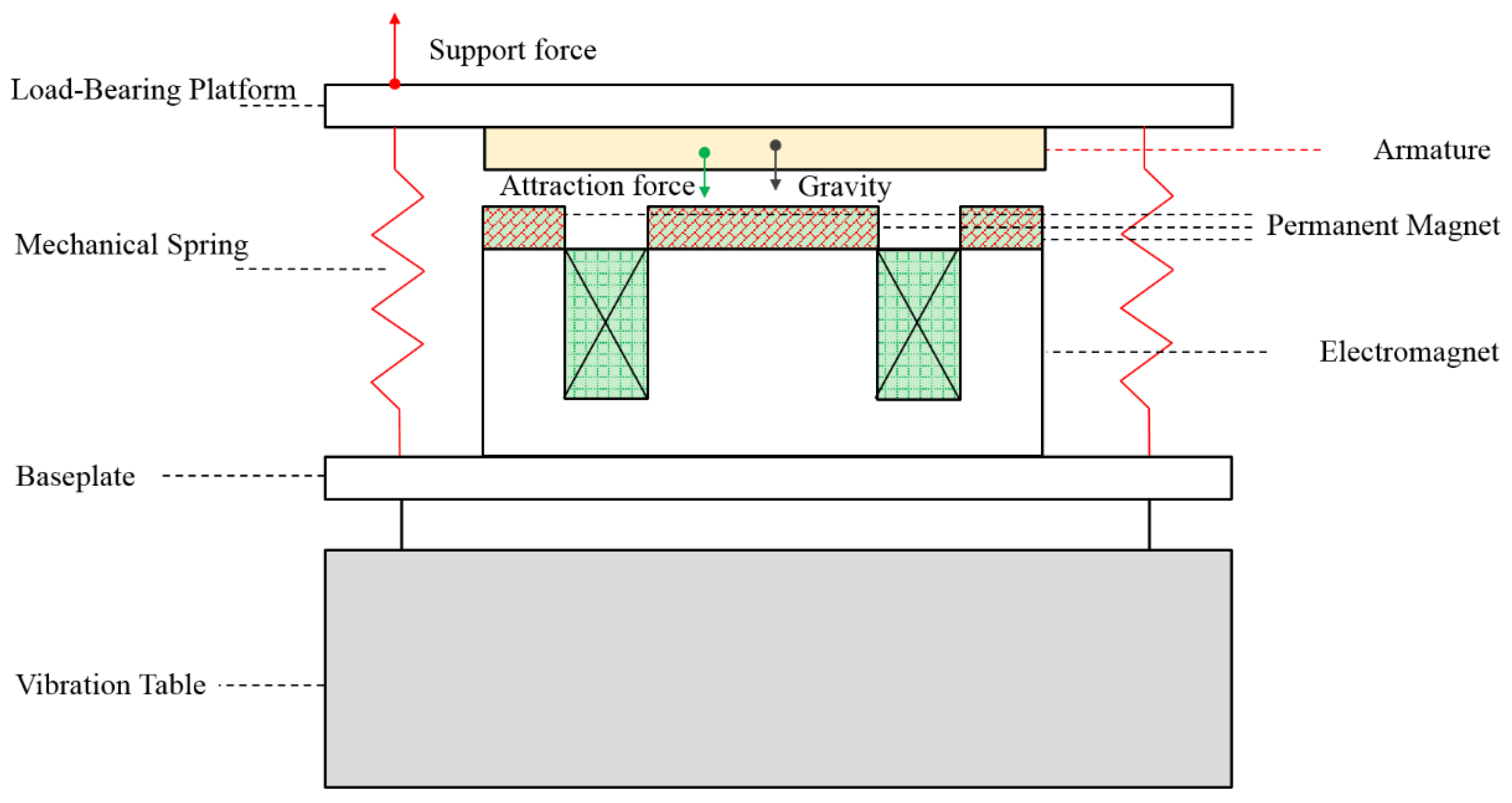

The schematic diagram of the model of the PECVIS is shown in

Figure 7.

and

represent the stiffness and damping of the spring, respectively, and

represents the stiffness of the permanent magnet–electromagnetic hybrid actuator, which includes the negative stiffness caused by the permanent magnet and the variable stiffness caused by the electromagnet.

Taking the vertical upward as the positive direction, the external excitation forces the vibration-isolated object of the system to vibrate in the vertical direction. is the vibration.

The dynamic model of the system can be expressed as:

where

is the compression amount of the spring at the equilibrium point.

The system parameter values are referred to in

Table 5.

3.2. Design of Nominal Controller

Given that the working point of the PECVIS is stable, and the operating range is concentrated around the working point, the linear analysis method can be used to analyze the systems. It is assumed that, when the system is static, the initial distance

satisfies:

Taking the state variables

, the linearized model is:

Taking the input variable

, the output variable of the system is

. Then, the system model can be represented by the following state-space equation:

The characteristic polynomial of the PECVIS does not satisfy the Hurwitz stability criterion. According to the Hartman–Grobman theorem, the system is unstable. Further analysis of the controllability of the system shows that the controllability matrix rank of the system is 3, so the PECVIS is completely controllable.

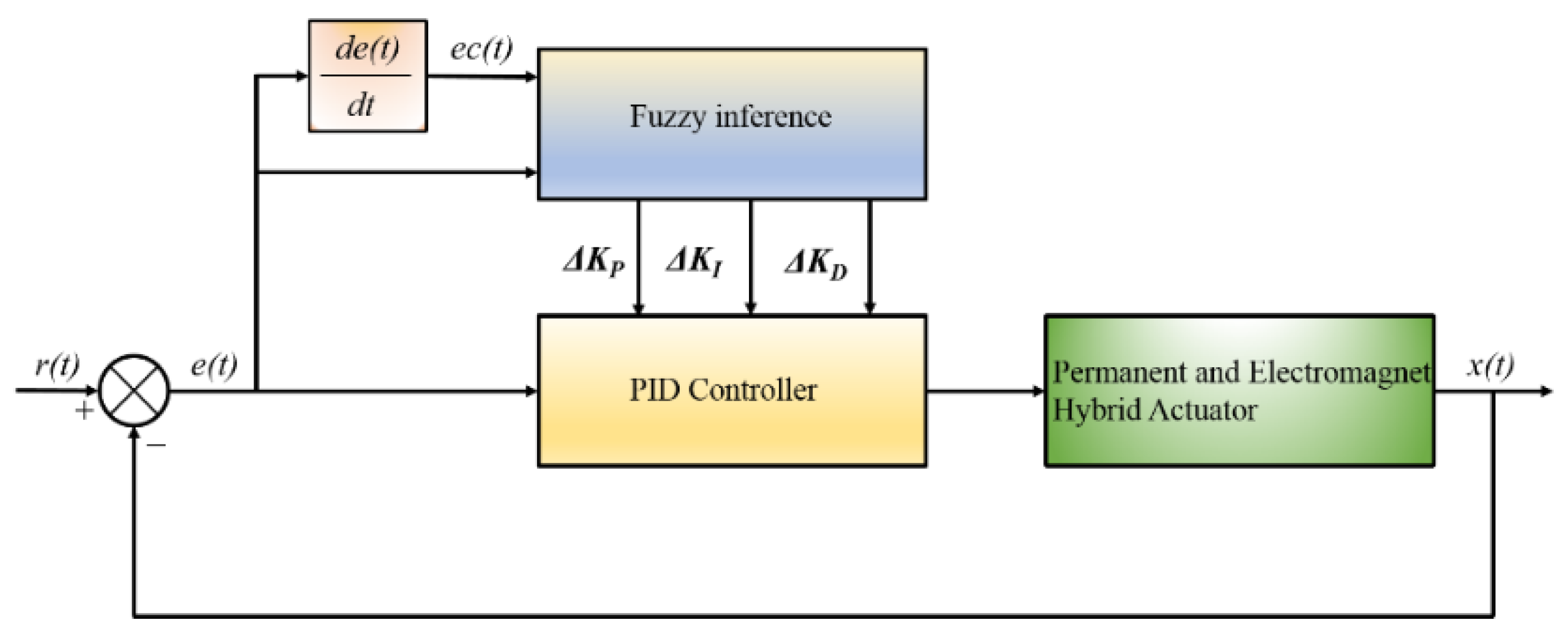

Based on the thought of cascade control, the control algorithm is usually divided into two parts, including the inner loop (also called the current loop) and the outer loop (also called the position loop) [

20,

21,

22]. When the electromagnet works in the equilibrium position, due to the small variation range of inductance, its inductance can be considered as a constant. Therefore, close to the operating point, the transfer function of the relationship between the voltage and the current of the levitating electromagnet is:

The transfer functions of the electromagnet voltage and current show that the electromagnet is a typical inertial link, and the response speed of the output current seriously lags behind the changing speed of the input voltage. Therefore, current negative feedback is introduced in the design of the control algorithm.

is the preamplification factor, and

is the negative feedback coefficient, as shown in

Figure 8.

The input voltage before the introduction of current feedback is

, then the voltage directly acting on the electromagnet is:

When the input voltage is a unit step signal, the response curve after introducing the current loop is as shown in

Figure 9.

After introducing the current negative feedback, the output current can track the change of the input voltage in time, and the order of the system is decreased from 3 to 2. After the design of the current loop is completed, the design of the position loop adopts the PID control algorithm:

where

is the proportional coefficient,

is the integral coefficient and

is the differential coefficient. In the PECVIS, the

deviation is the displacement

of the vibration-isolated object in the vertical direction. Initially, the vibration-isolated object is at the equilibrium point, and its initial value is

. Therefore, the PID control law of the system is:

In summary, after the control law design is completed, it is brought into the PECVIS, which satisfies:

At this time, the equivalent stiffness and equivalent damping of the PECVIS are:

The PECVIS designed in this paper can realize the dynamic adjustment of the stiffness and damping of the system by adjusting the three parameters , and .