Study on Buckling Characteristics of a Convex Tape-Shaped Ti-Ni Shape Memory Alloy Element for Application to Passive Vibration Isolator Devices and Force Limit Devices

Abstract

1. Introduction

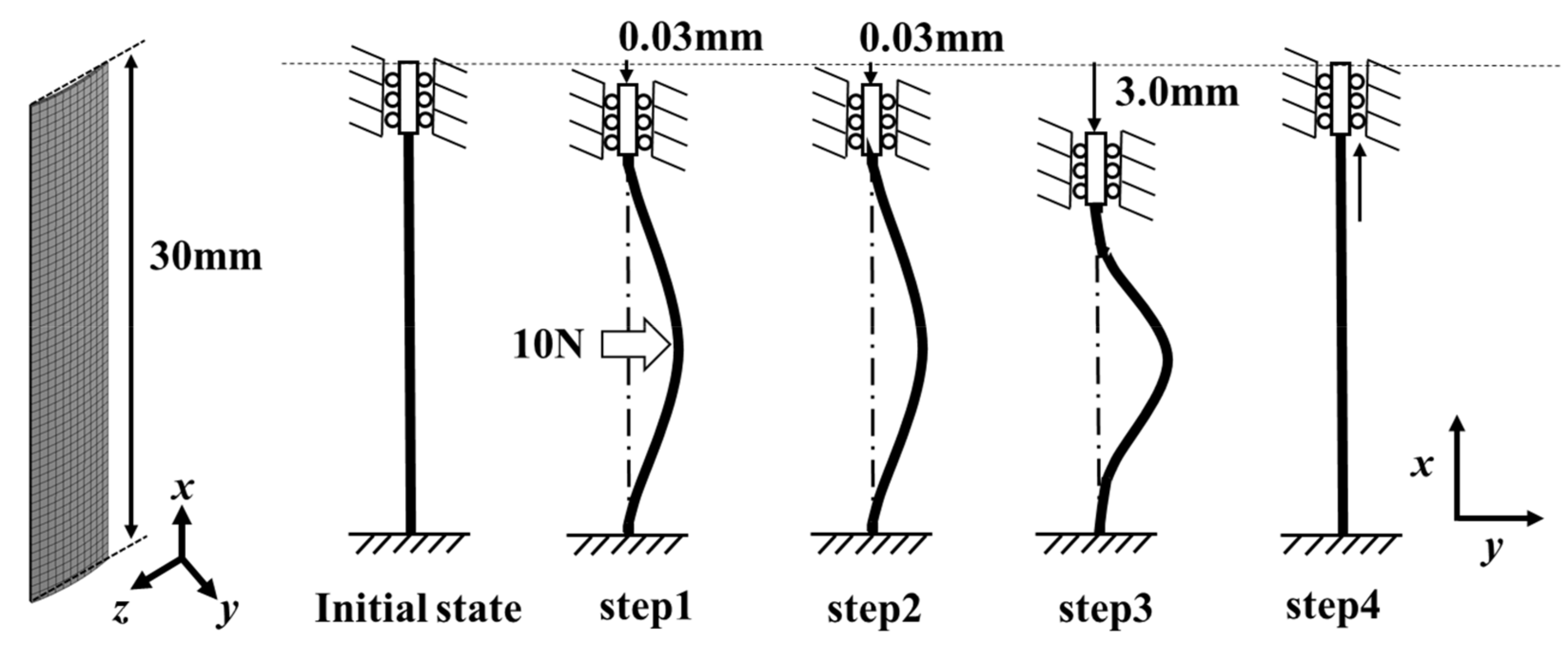

2. Materials and Methods

2.1. Convex Tape Shaped Ti-Ni Element

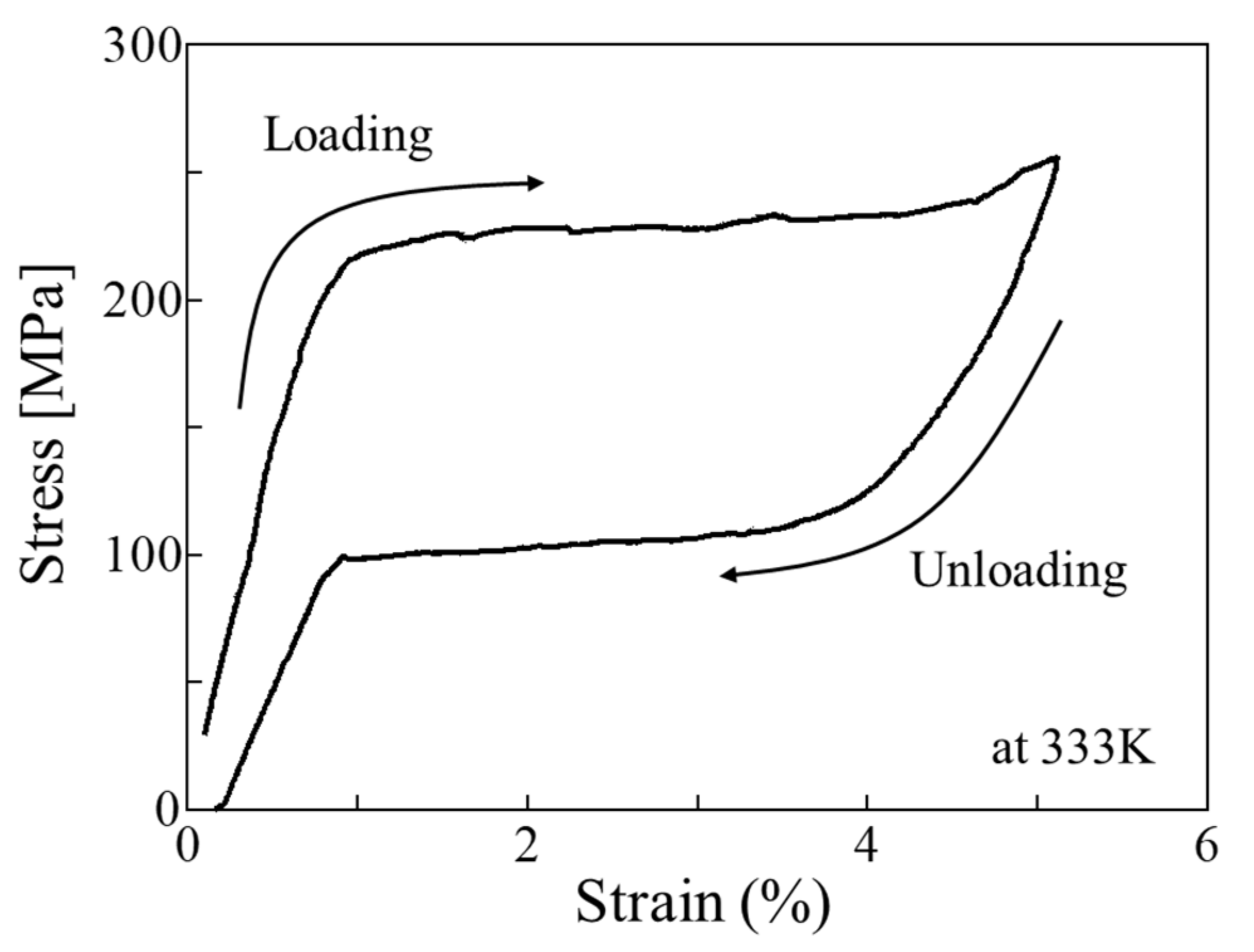

2.2. Material Testing

2.3. 3D-FEM Analyses

3. Results and Discussions

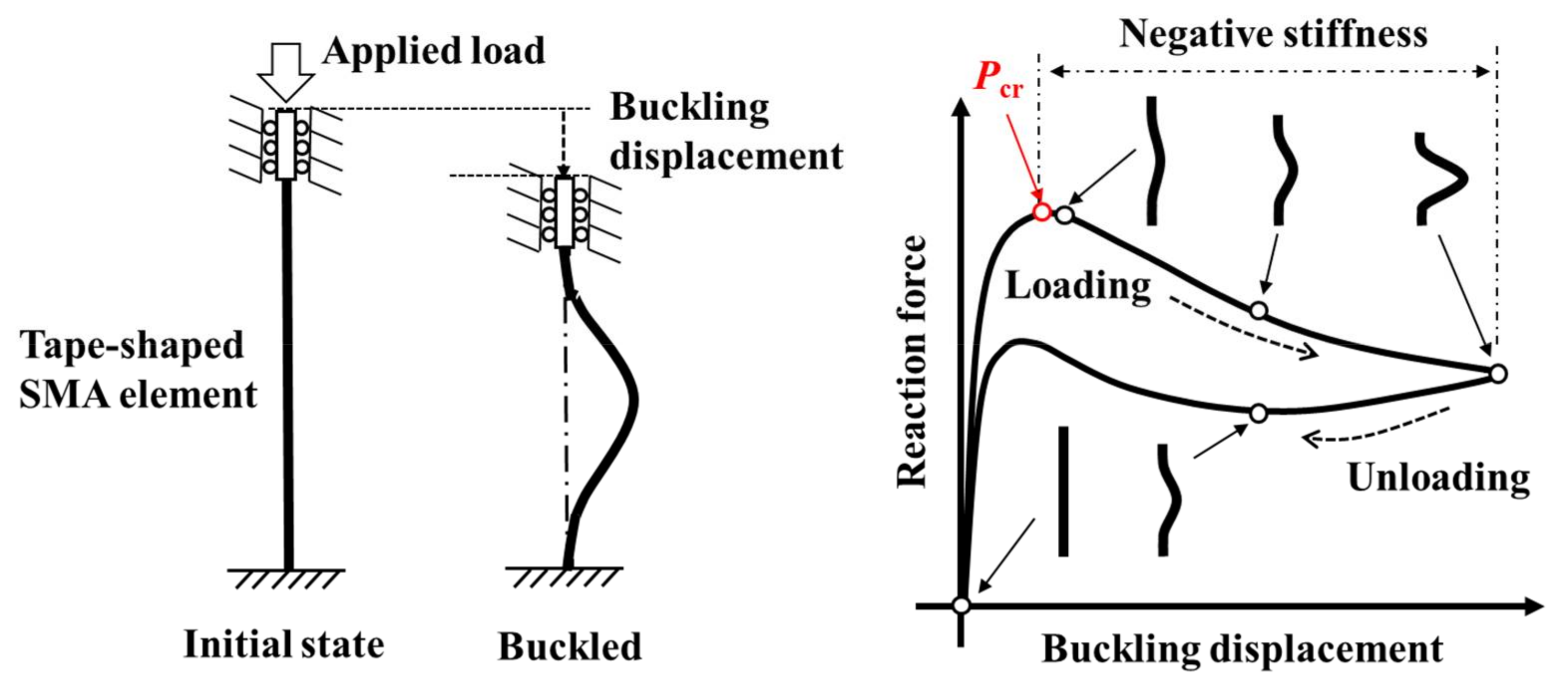

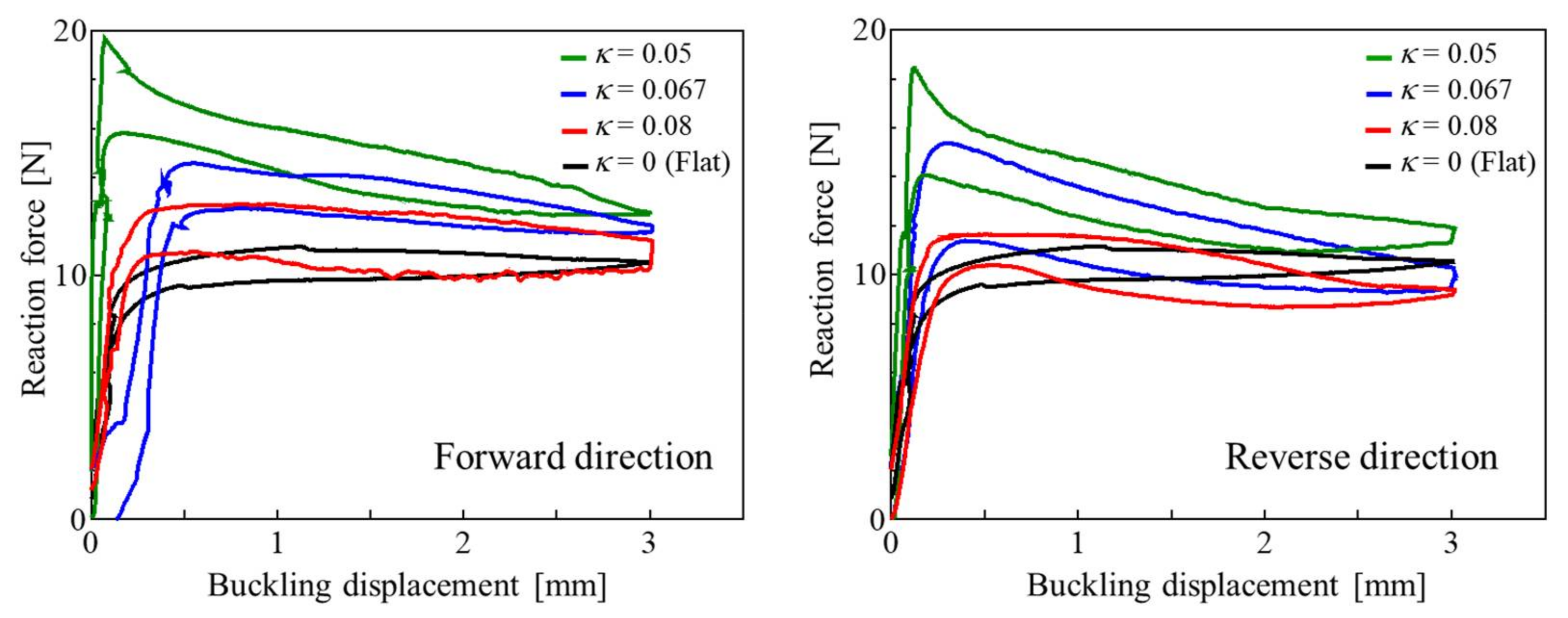

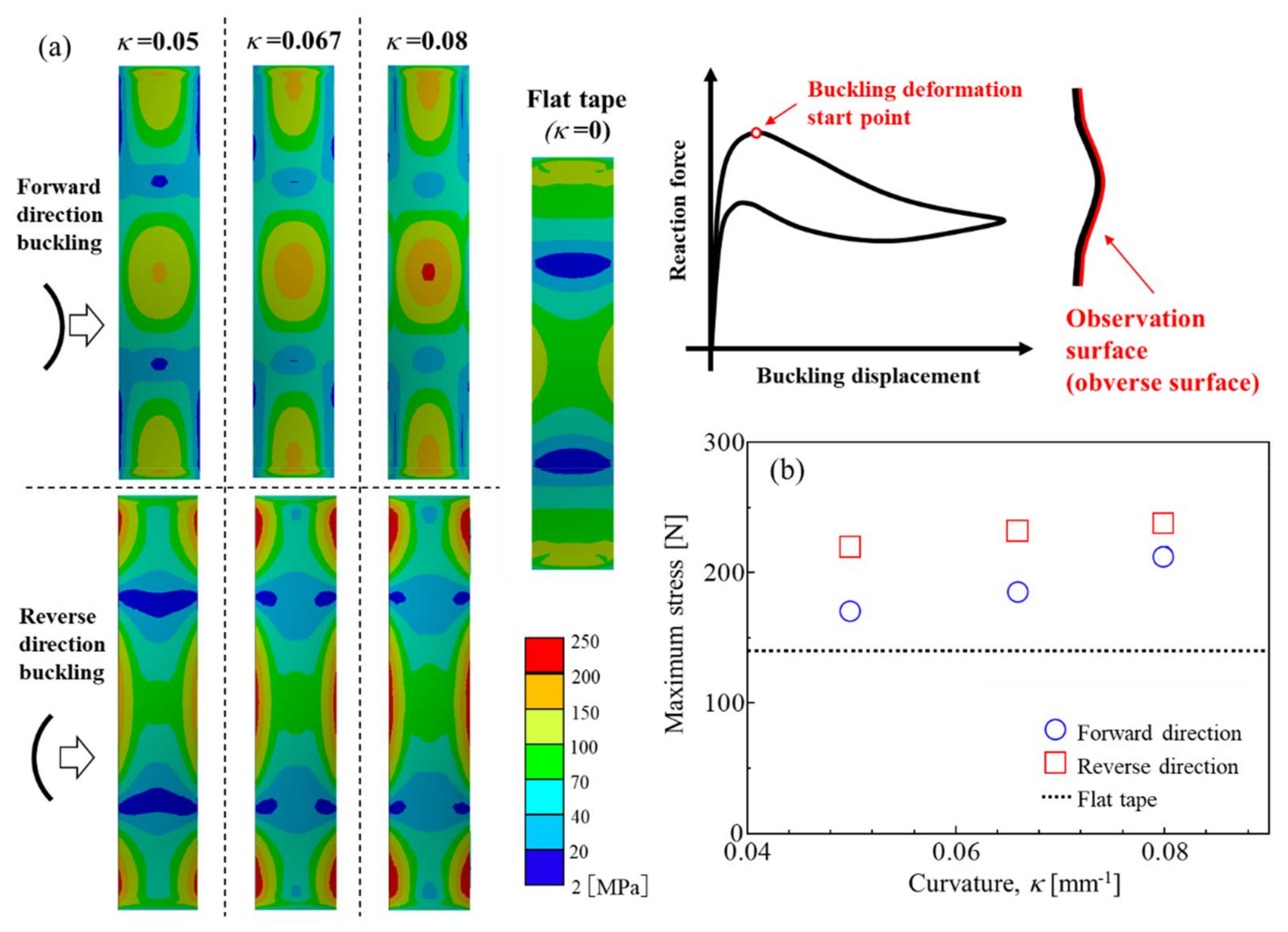

3.1. Effects of Curvature of the Cross-Section on Buckling Characteristics

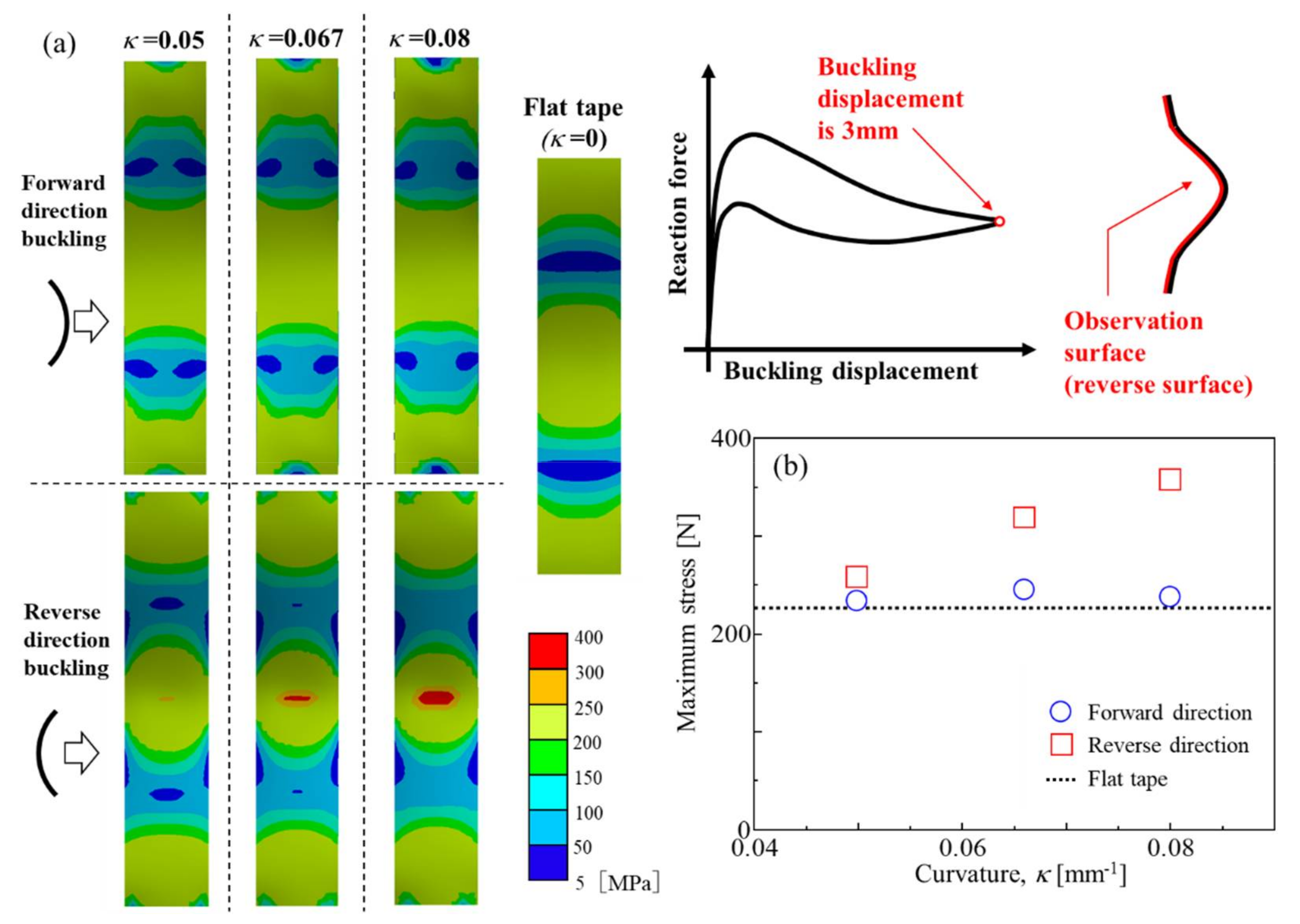

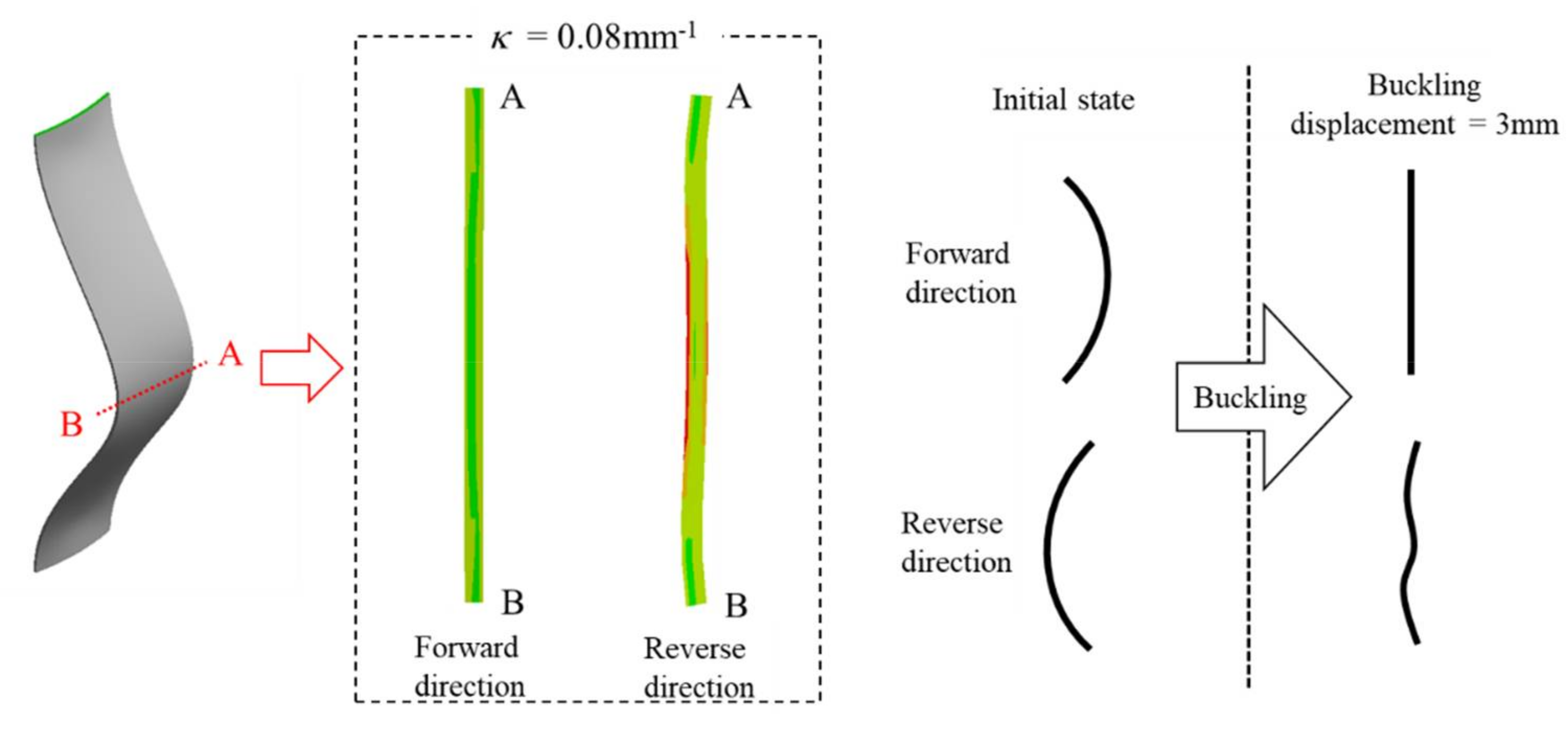

3.2. Structure and Stress Analyses

4. Conclusions

- (1)

- The buckling load (Pcr) and the negative stiffness gradient of the convex tape-shaped SMA element increased with increasing κ. The increase of Pcr was mainly due to the increase of the second moment of area with increasing κ. On the other hand, regardless of the κ or the buckling direction, the overall buckling shape will approach approximately the same shape when the buckling deformation is sufficiently advanced. Therefore, the reaction force for maximum buckling in this study was approximately constant regardless of the κ and buckling direction. Since the negative stiffness gradient was determined by the difference between the Pcr and reaction force for maximum buckling in this study, the negative stiffness gradient increased with increasing κ.

- (2)

- The numerical analysis results show that stress was not concentrated during buckling deformation in the case of the forward-buckled convex tape-shaped specimen and the flat tape-shaped specimen. On the other hand, in the case the reverse-buckled convex tape-shaped specimen, stress concentration was observed in the center of the specimen. Investigation of the cross-sectional shape of the center of the specimen in each buckling direction showed that the cross-sectional shape of the forward-buckled convex tape-shaped specimen during buckling had a uniformly deformed and near-linear shape. However, the cross-sectional shape of the reverse-buckled convex tape-shaped specimen during buckling was a cosine curve shape with a bending deformation in the opposite direction to the convex at the center. Hence, stress concentration occurred in the center of the specimen.

- (3)

- The results of this study show that the Pcr and negative stiffness gradient of the tape-shaped SMA element during buckling deformation can be adjusted without changing the dimensions of the material by adding curvature of the cross-section. Moreover, when forward-buckled convex tape-shaped SMA elements are applied to passive vibration isolator devices and force limit devices, it is expected that they will have an equivalent product lifespan to that of devices that employ a flat tape-shaped SMA element. This is because the loading stress of forward-buckled convex tape-shaped specimens is approximately equal to that of flat tape-shaped specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miyazaki, S.; Otsuka, K.; Suzuki, Y. Transformation pseudoelasticity and deformation behavior in a Ti-50.6at%Ni alloy. Scr. Metall. 1981, 15, 287–292. [Google Scholar] [CrossRef]

- Miyazaki, S.; Ohmi, Y.; Otsuka, K.; Suzuki, Y. Characteristics of deformation and transformation pseudoelasticity in Ti-Ni alloy. J. Phys. Colloq. 1982, 43, C4-255–C4-260. [Google Scholar] [CrossRef]

- Miyazaki, S.; Sakuma, T.; Shibuya, T. Properties and Application Development of Shape Memory Alloy; CMC: Yokohama, Japan, 2001; pp. 233–260. [Google Scholar]

- Strnadel, B.; Ohashi, S.; Miyazaki, S.; Ishihara., T. Effect of mechanical cycling on the pseudoelasticity characteristics of Ti-Ni and Ti-Ni-Cu alloys. Mater. Sci. Eng. A 1995, 203, 187–196. [Google Scholar] [CrossRef]

- Rondelli, G.; Vicentini, B.; Cigada, A. The corrosion behaviour of nickel titanium shape memory alloys. Corros. Sci. 1990, 30, 805–812. [Google Scholar] [CrossRef]

- Shabalovskaya, S.A. On the nature of the biocompatibility and on medical applications of NiTi shape memory and superelastic alloys. Biomed. Mater. Eng. 1996, 6, 267–289. [Google Scholar] [CrossRef] [PubMed]

- Duerig, T.W.; Pelton, A.R. An Overview of Superelastic Stent Design. Mater. Sci. Forum 2002, 394–395, 1–8. [Google Scholar] [CrossRef]

- Kitamura, K.; Tobushi, H.; Yoshimi, Y.; Date, K.; Miyamoto, K. Fatigue Properties of Cast TiNi Shape Memory Alloy Brain Spatula. J. Solid Mech. Mater. Eng. 2010, 4, 796–805. [Google Scholar] [CrossRef]

- Takaoka, S.; Horikawa, H.; Kobayashi, J.; Shimizu, K. Applications and Development of Shape-Memory and Superelastic Alloys in Japan. Mater. Sci. Forum 2002, 394–395, 61–68. [Google Scholar] [CrossRef]

- Haptic Device. Available online: http://www.tgk-jp.com/english/products/haptic_device/index.html (accessed on 3 March 2022).

- Tobushi, H.; Kimura, K.; Iwanaga, H.; Cahoon, J.R. Basic Research on Shape Memory Alloy Heat Engine (Output Power Characteristics and Problems in Development). JSME Int. J. Ser. 1990, 33, 263–267. [Google Scholar] [CrossRef]

- Cho, H.; Takeda, Y.; Sakuma, T. Fabrication and Output Power Characteristics of Heat-Engines Using Tape-Shaped SMA Element. In Advances in Shape Memory Materials; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–15. [Google Scholar]

- Kumar, P.; Kishore, R.A.; Maurya, D.; Stewart, C.J.; Mirzaeifar, R.; Quandt, E.; Priya, S. Shape memory alloy engine for high efficiency low-temperature gradient thermal to electrical conversion. Appl. Energy 2019, 251, 113277. [Google Scholar] [CrossRef]

- Ma, N.; Song, G.; Lee, H.J. Position control of shape memory alloy actuators with internal electrical resistance feedback using neural networks. Smart Mater. Struct. 2004, 13, 777–783. [Google Scholar] [CrossRef]

- Tung, A.T.; Park, B.H.; Liang, D.H.; Niemeyer, G. Laser-machined shape memory alloy sensors for position feedback in active catheters. Sens. Actuators A Phys. 2008, 147, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Yamamoto, T.; Takeda, Y.; Suzuki, A.; Sakuma, T. Exploitation of shape memory alloy actuator using resistance feedback control and its development. Prog. Nat. Sci. Mater. Int. 2010, 20, 97–104. [Google Scholar] [CrossRef]

- Superelastic Tire. Available online: https://technology.nasa.gov/patent/LEW-TOPS-99 (accessed on 12 January 2022).

- Tobe, H.; Matsuki, U.; Takeuchi, S.; Sato, E. Deployable Rocket Nozzle Utilizing Superelastic Titanium Alloy Sheet. Mater. Trans. 2020, 61, 68–71. [Google Scholar] [CrossRef]

- Torra, V.; Auguet, C.; Isalgue, A.; Carreras, G.; Terriault, P.; Lovey, F.C. Built in dampers for stayed cables in bridges via SMA. The SMARTeR-ESF project: A mesoscopic and macroscopic experimental analysis with numerical simulations. Eng. Struct. 2013, 49, 43–57. [Google Scholar] [CrossRef]

- Rahman, M.S.; Qiu, J.; Tani, J. Buckling and postbuckling characterristics of the superelastic SMA columns. Int. J. Solid Struct. 2001, 38, 9253–9265. [Google Scholar] [CrossRef]

- Pereiro-Barceló, J.; Bonet, J.L. Ni-Ti SMA bars behaviour under compression. Constr. Build. Mater. 2017, 155, 348–362. [Google Scholar] [CrossRef]

- Urusiyama, Y.; Lewinnek, D.; Qiu, J.; Tani, J. Buckling of Shpee Memory Alloy Columns (1st Report, Buckling of Curved Column and Twinning Deformation Effect). Trans. JSME A 2001, 67, 1132–1138. [Google Scholar] [CrossRef][Green Version]

- Urusiyama, Y.; Qiu, J.; Osanai, D.; Tani, J. Buckling Suppression of the Column by Using Shape Memory Alloy. Trans. JSME A 2003, 69, 873–879. [Google Scholar] [CrossRef]

- Park, S.T.; Luu, T.T. Techniques for optimizing parameters of negative stiffness. Proc. Inst. Mech. Eng. C 2007, 221, 505–510. [Google Scholar] [CrossRef]

- Ibrahim, R.A. Recent advances in nonlinear passive vibration isolators. J. Sound Vib. 2008, 314, 371–452. [Google Scholar] [CrossRef]

- Sasaki, T.; Kimura, Y. Experimental Study on a Passive Vibration Isolator Utilizing Dynamic Characteristics of a Post-Buckled Shape Memory Alloy. Vib. Eng. A Sustain. Future 2021, 2, 115–120. [Google Scholar]

- Noda, S. Proposal of Leaf Spring Buckling for Forceps Force Limiter—Confirmation of Basic Principle. In Proceedings of the Robotics and Mechatronics Conference 2018 in Kitakyushu, Kitakyushu, Japan, 4 June 2018. [Google Scholar]

- Ishii, T.; Cho, H.; Urakawa, A.; Sasaki, T. FEM Analysis of Effect of Thickness on Post-buckling Behavior of Tape-shaped Ti-Ni Shape Memory Alloy. Sens. Mater. 2020, 32, 2841–2849. [Google Scholar]

- Doi, Y.; Ishii, T.; Cho, H.; Sasaki, T. Effects of the Volume Fraction of Martensitic-phase during Buckling Deformation on Post-buckling Behavior of Tape-shaped Ti-Ni Shape Memory Alloy Element. Trans. MRS-J. 2021, 46, 3–8. [Google Scholar] [CrossRef]

- Miyazaki, Y.; Inoue, S.; Tamura, A. Analytical solution of the bending of a bi-convex boom. Mech. Eng. J. 2015, 2, 15-00465. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, H.; Nagamatsu, S.; Sasaki, T. Study on Buckling Characteristics of a Convex Tape-Shaped Ti-Ni Shape Memory Alloy Element for Application to Passive Vibration Isolator Devices and Force Limit Devices. Actuators 2022, 11, 88. https://doi.org/10.3390/act11030088

Cho H, Nagamatsu S, Sasaki T. Study on Buckling Characteristics of a Convex Tape-Shaped Ti-Ni Shape Memory Alloy Element for Application to Passive Vibration Isolator Devices and Force Limit Devices. Actuators. 2022; 11(3):88. https://doi.org/10.3390/act11030088

Chicago/Turabian StyleCho, Hiroki, Sho Nagamatsu, and Takumi Sasaki. 2022. "Study on Buckling Characteristics of a Convex Tape-Shaped Ti-Ni Shape Memory Alloy Element for Application to Passive Vibration Isolator Devices and Force Limit Devices" Actuators 11, no. 3: 88. https://doi.org/10.3390/act11030088

APA StyleCho, H., Nagamatsu, S., & Sasaki, T. (2022). Study on Buckling Characteristics of a Convex Tape-Shaped Ti-Ni Shape Memory Alloy Element for Application to Passive Vibration Isolator Devices and Force Limit Devices. Actuators, 11(3), 88. https://doi.org/10.3390/act11030088