A Multidimensional Elastic–Plastic Calculation Model of the Frame Structure with Magnetorheological Damper

Abstract

1. Introduction

2. Elastic–Plastic Calculation Model of the RC Frame Structure

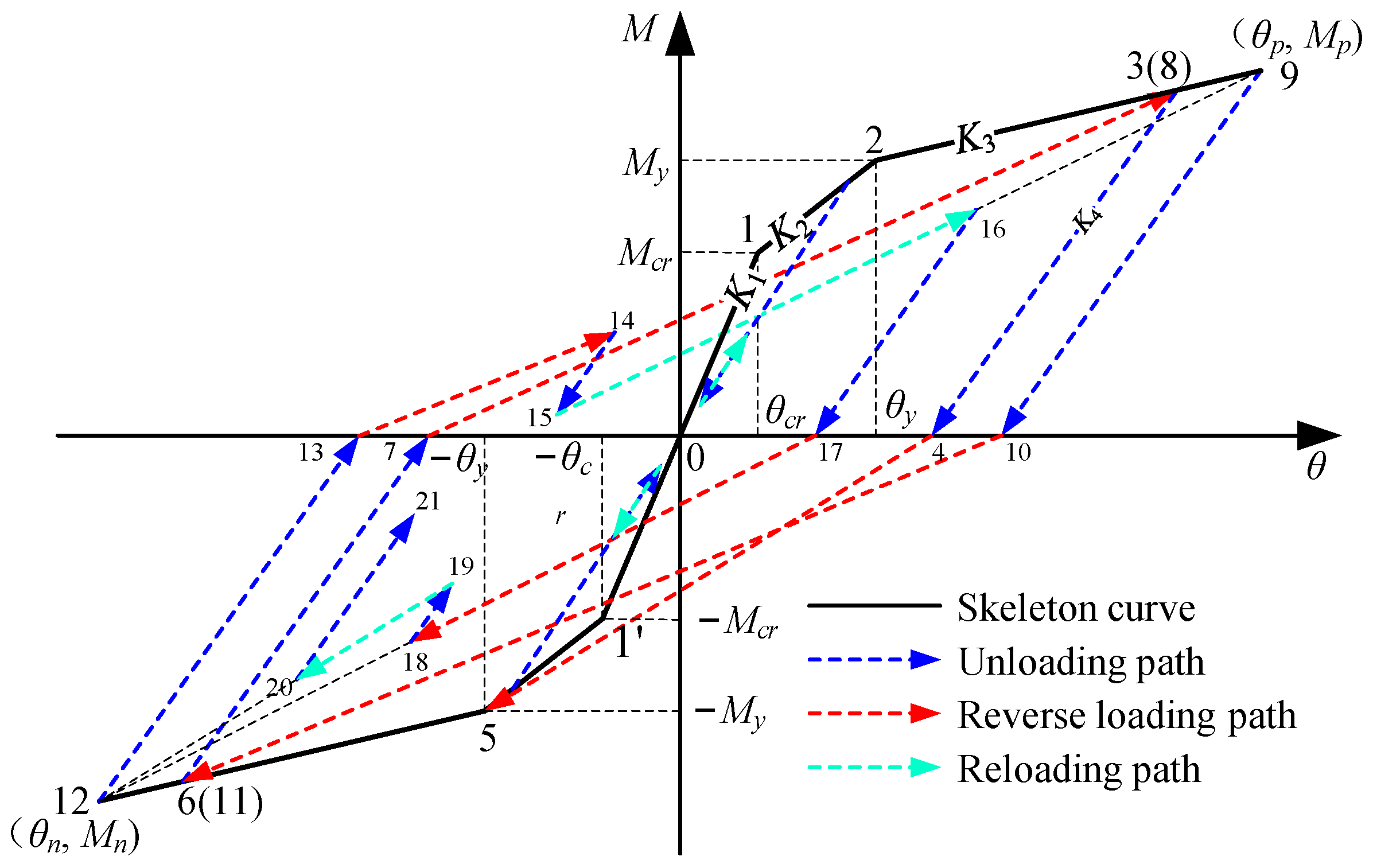

2.1. Three-Fold Line Model Considering Stiffness Degradation

- (1)

- Hysteresis path of elastic segment

- (2)

- Hysteresis path of elastic–plastic segment

- (3)

- Hysteresis path of plastic segment

2.2. Elastic–Plastic Stiffness Matrix of the Variable Stiffness Space Beam Element

3. Differential Equation of Motion of the RC Structure with MRD

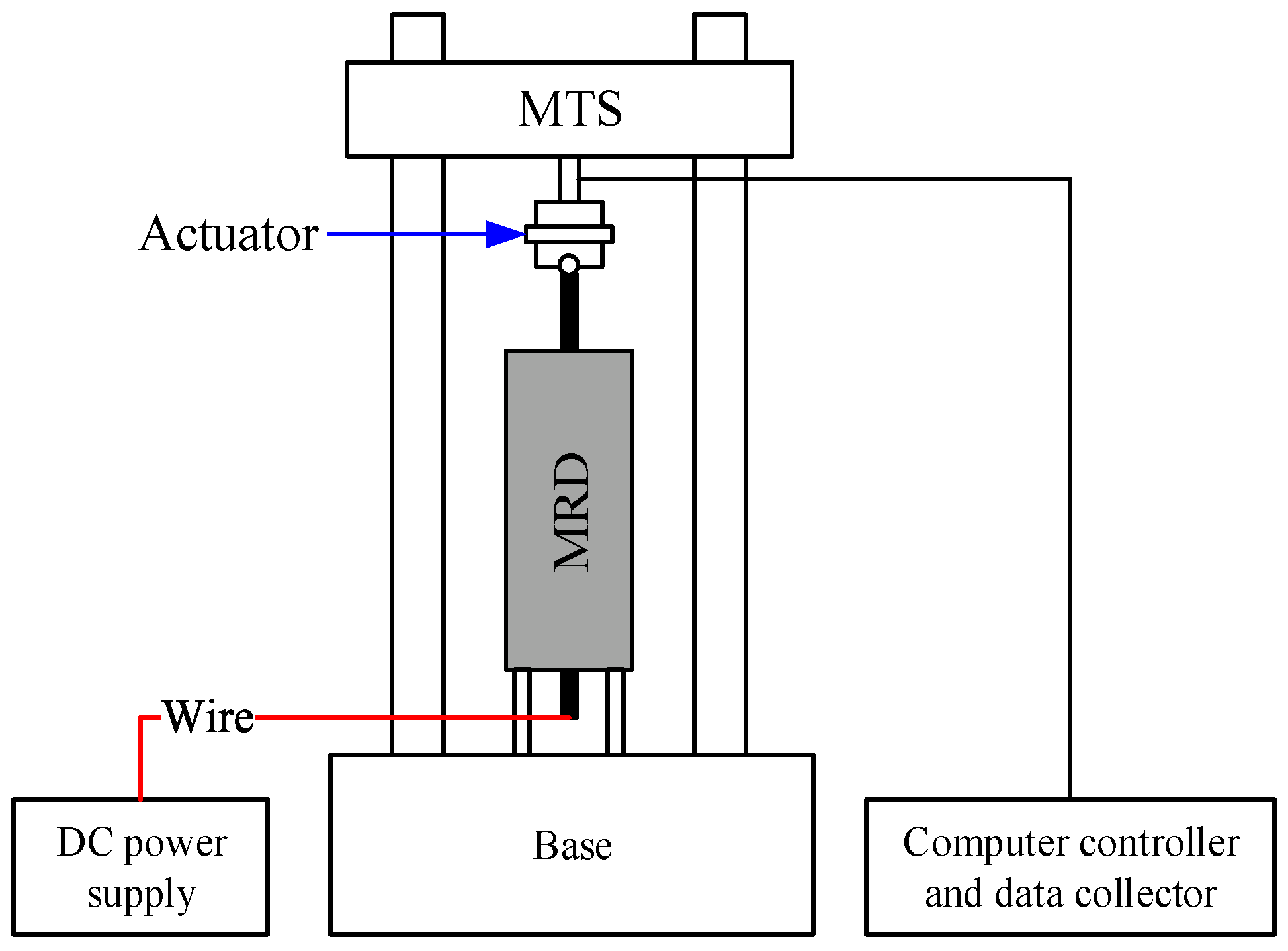

3.1. Test Results of MRD

3.2. Equilibrium Equation of the RC Structure

3.3. Semi-Active Control Algorithm

3.4. MRD Location Matrix

4. Case Analysis

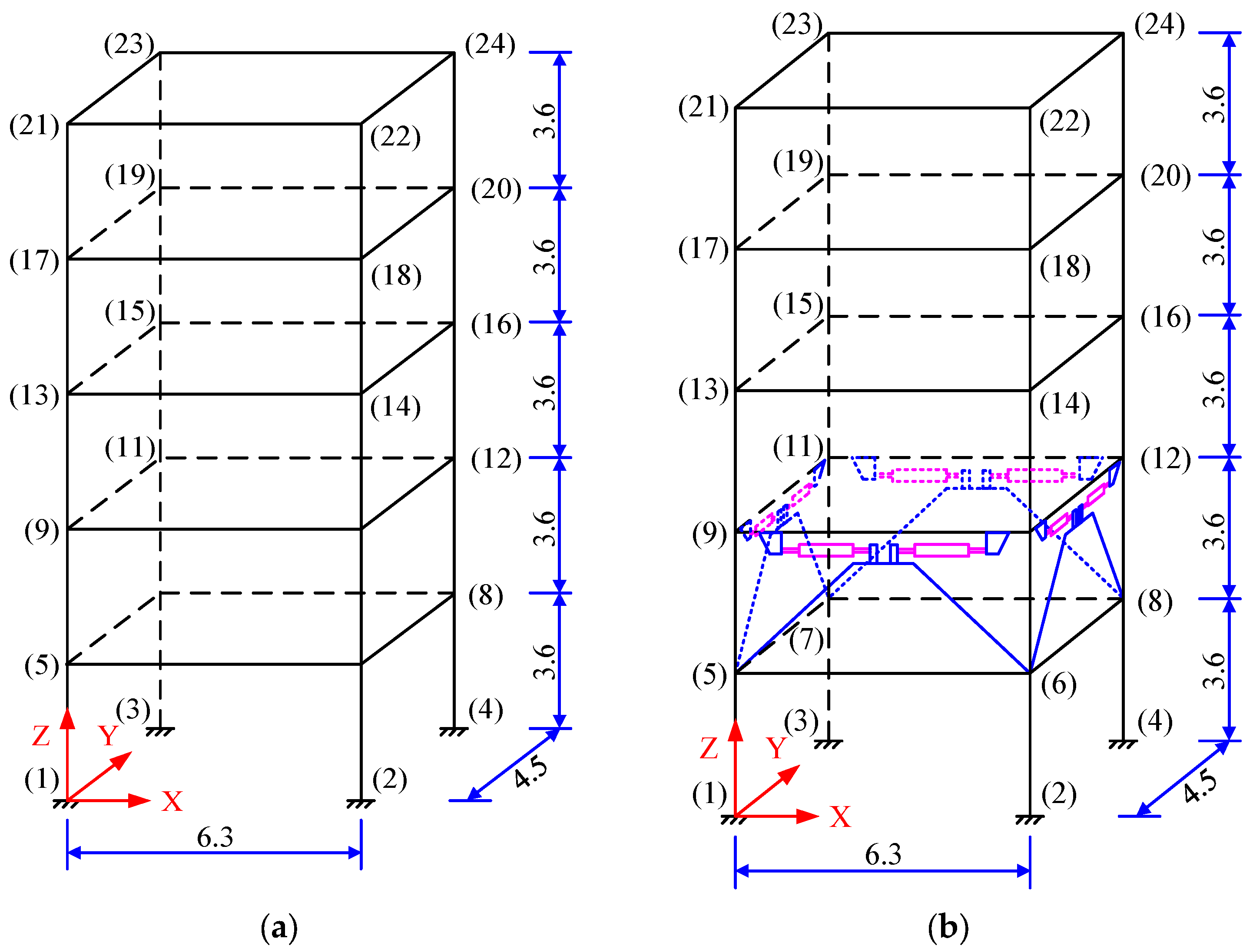

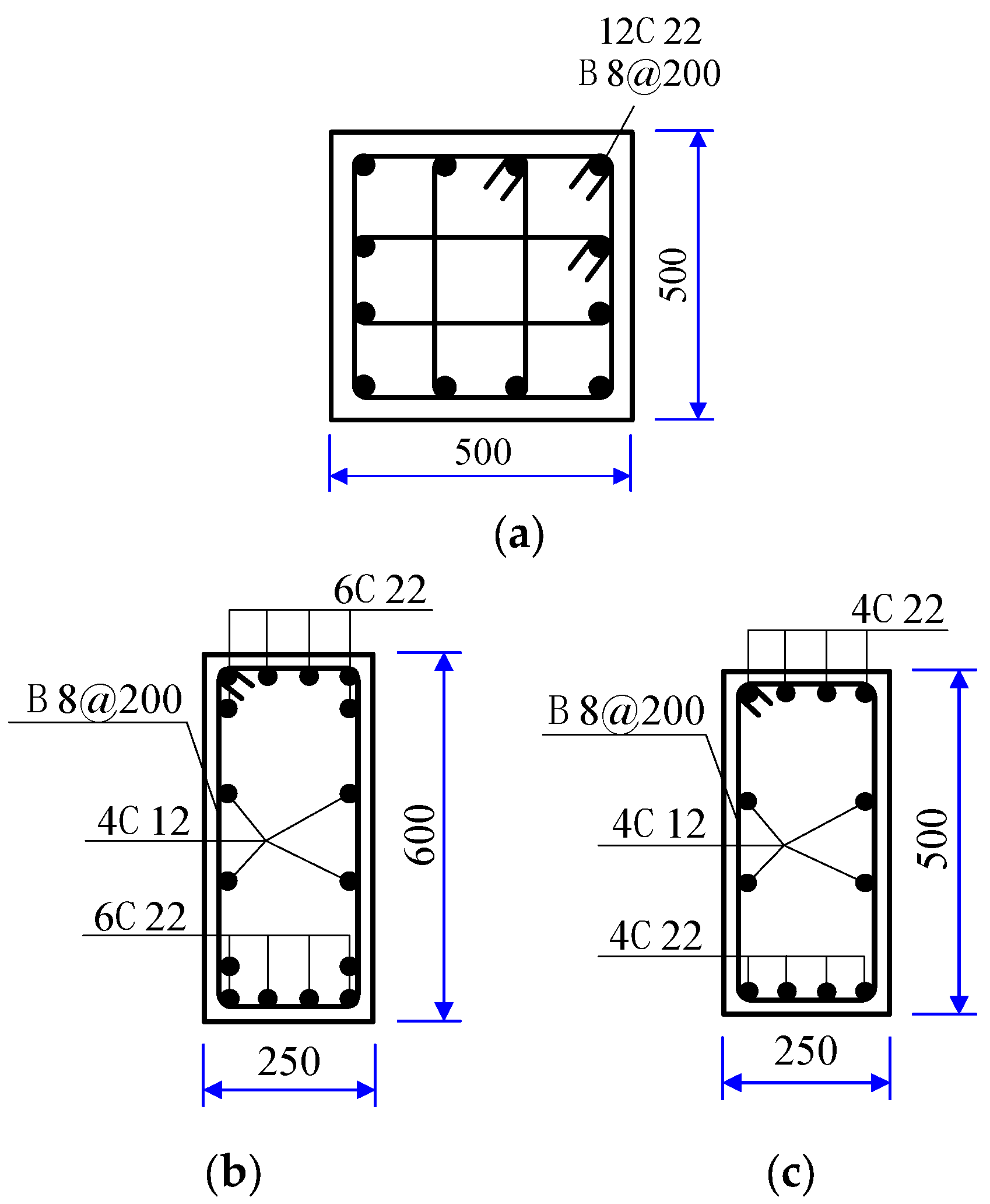

4.1. The RC Frame Structure with and without MRD

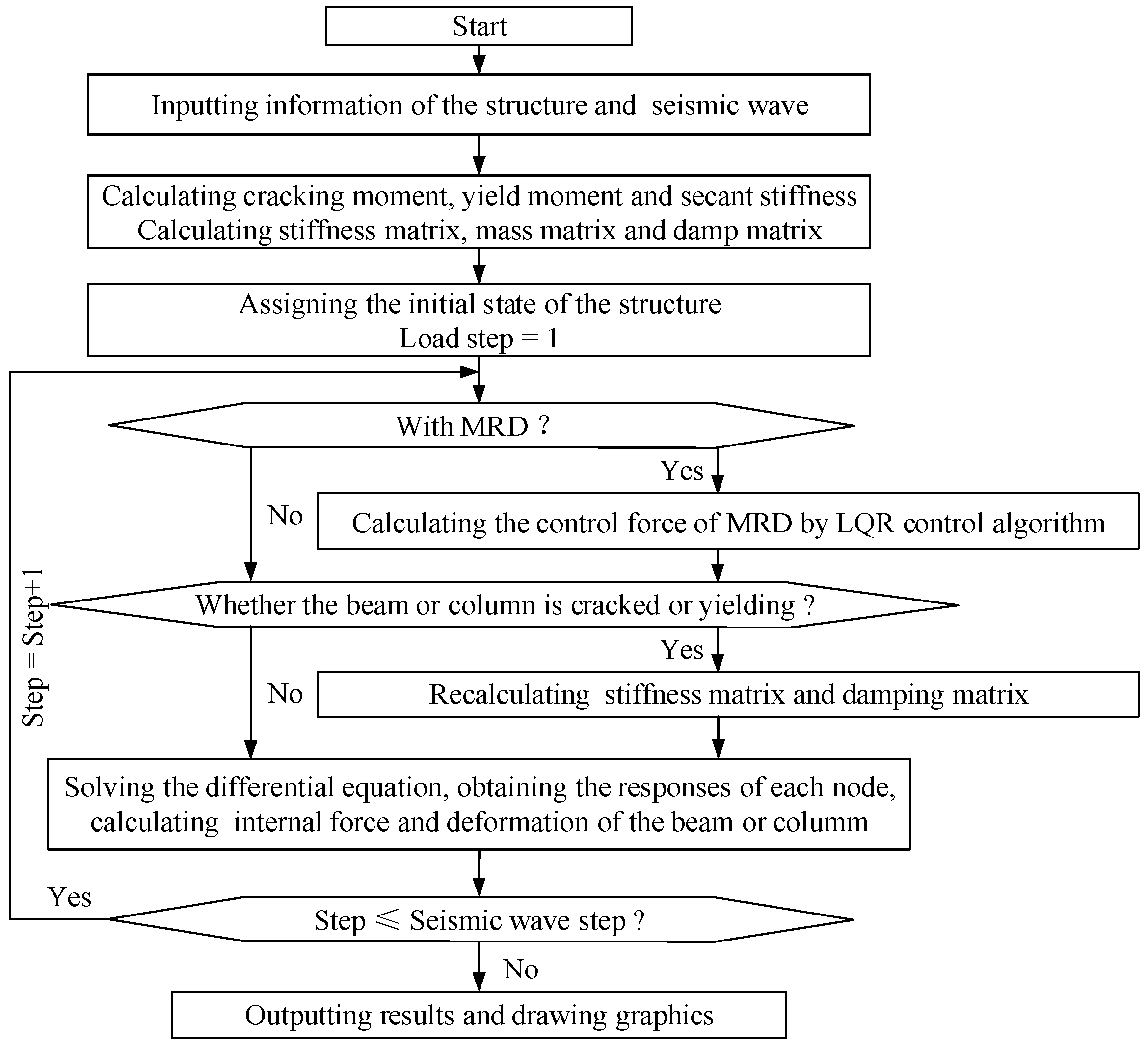

4.2. Introduction of Dynamic Time History Analysis Process

4.3. Verification of Model Validity

4.4. Analysis of Structural Damping Results

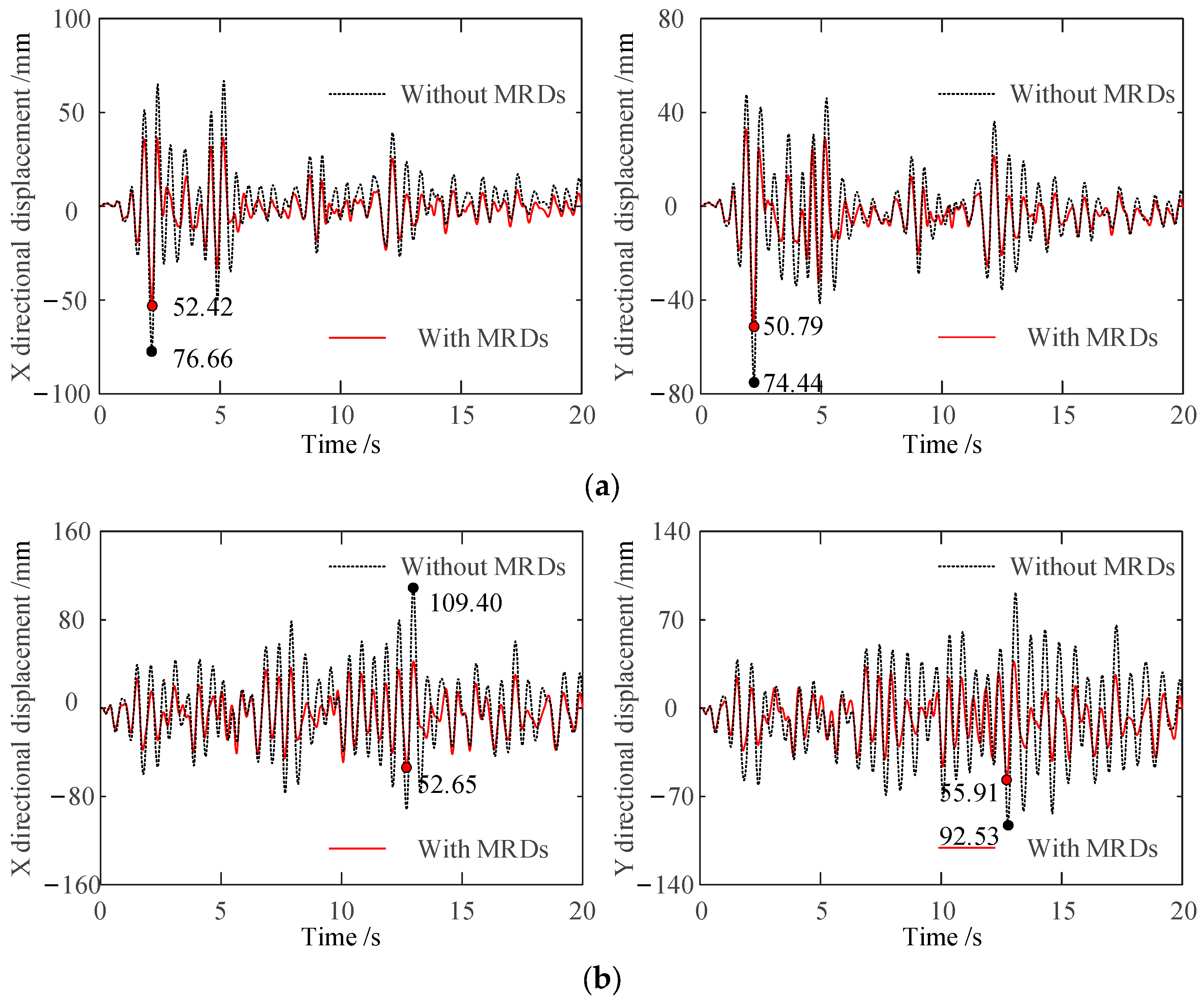

4.4.1. Comparative Analysis of Multi-Dimensional Damping Results

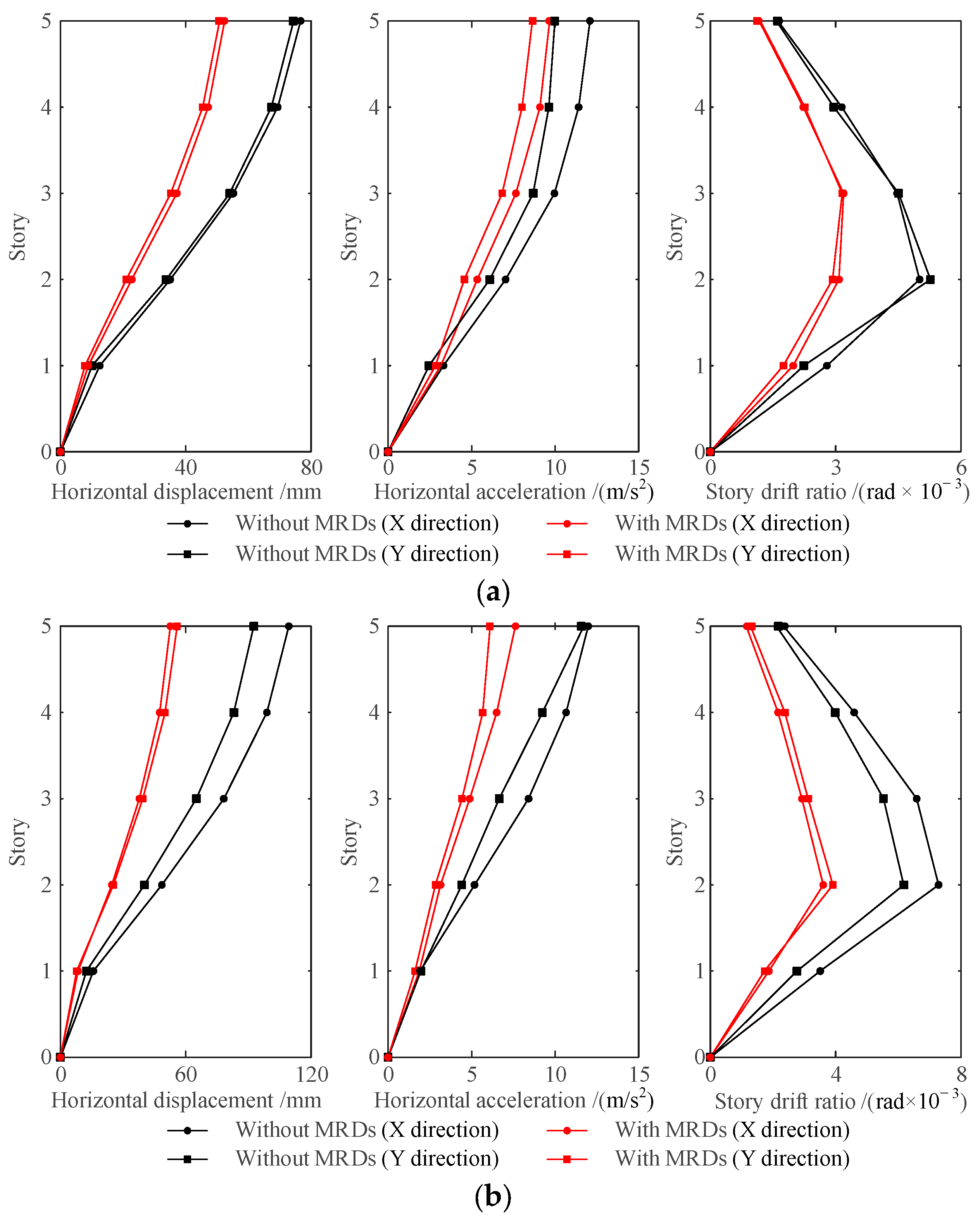

4.4.2. Comparative Analysis of Maximum Response Results of Each Story

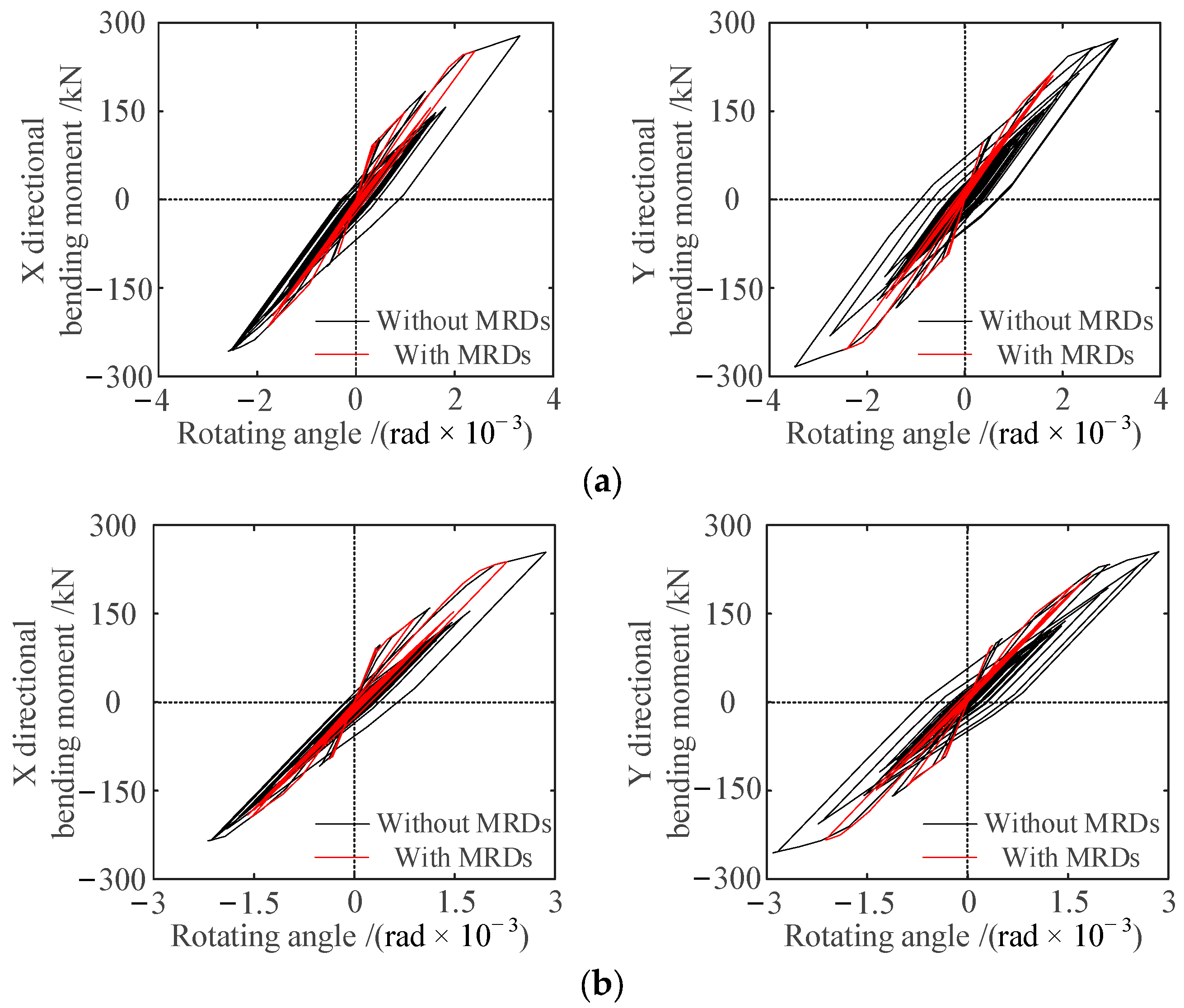

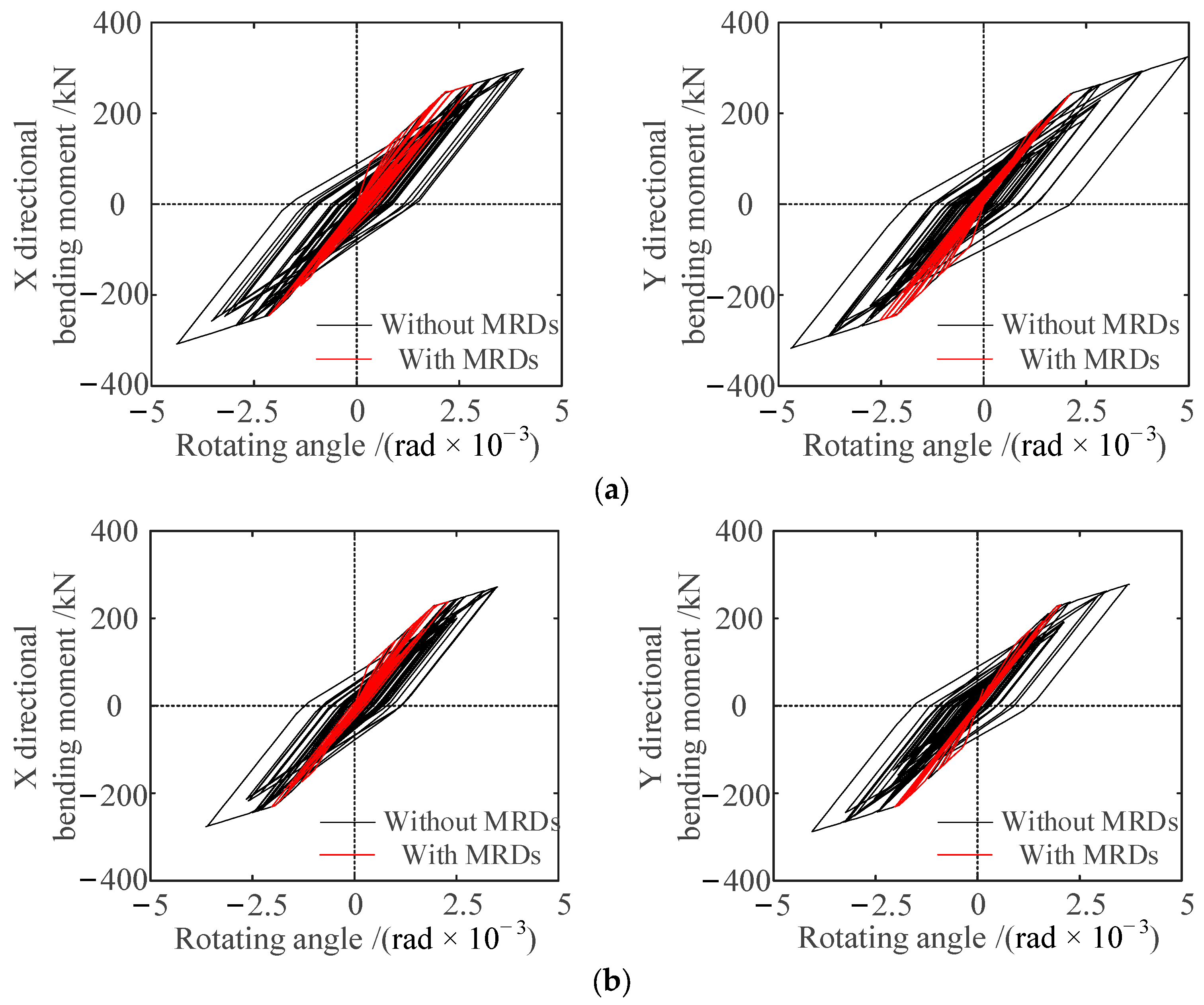

4.4.3. Comparative Analysis of Moment Rotation Hysteretic Curve Results

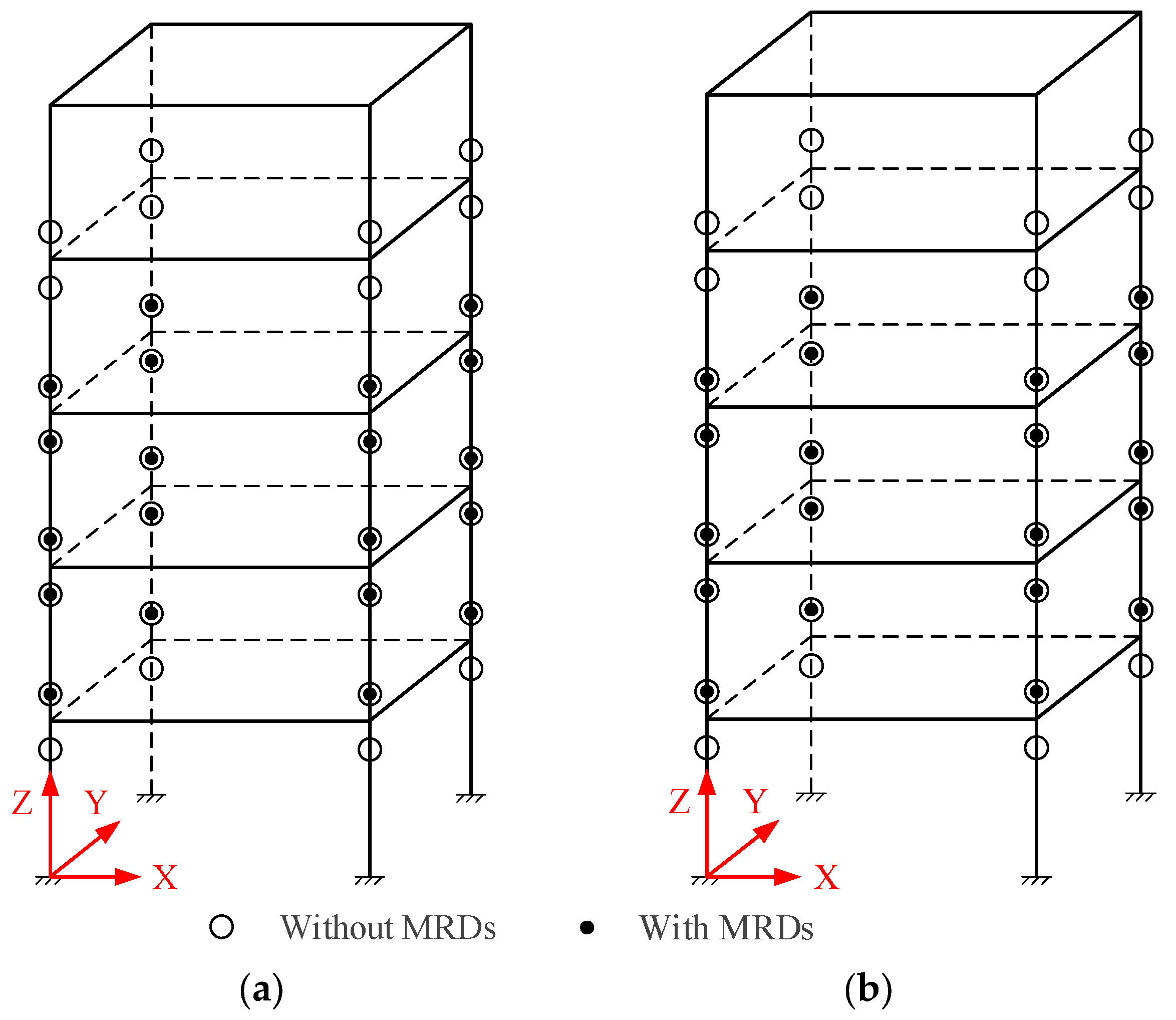

4.4.4. Cracking and Yield of Each Member of Structure

5. Conclusions

- (1)

- The multi-dimensional elastoplastic calculation model of the MRD frame’s structure was established, and the elastoplastic dynamic time history analysis program was developed by using MATLAB software, which could accurately calculate the multi-dimensional elastoplastic response of the structure under a strong earthquake.

- (2)

- After the MRD is set in the frame structure, the maximum horizontal displacement and acceleration of each story decreases. The maximum displacement and acceleration of the top node 24 on the structure in the X direction and Y direction decreased by 51.87%, 39.59%, 36.67%, and 47.86%, respectively; the decrease in the acceleration is not very significant.

- (3)

- For the frame structure with an MRD, the offset of the displacement time history curve of the column in the third story is weakened and the hysteretic loop area of the structural members is significantly reduced. The maximum residual displacement angle in the X and Y directions of the column in the third story decreased from 1.628 × 10−3 rad and 2.101 × 10−3 rad to 0.511 × 10−3 rad and 0.297 × 10−3 rad, indicating that the MRD can effectively consume the vibration energy of the incoming structure and significantly improve the seismic performance of the structure.

- (4)

- The column end of the frame structure without an MRD appears to be more of a plastic hinge, which is the yield mechanism of the column hinge. Compared with the frame structure without the MRD, after setting the MRD in the structure, the number of plastic hinges in the X direction and Y direction were all reduced by 37.50%. Although some structural members still yield, it will not endanger the safety of the whole structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.C.; Zhang, X.; Zhao, Y.X.; Zhao, J.; Xu, Z. Experimental and numerical studies on a composite MR damper considering magnetic saturation effect. Eng. Struct. 2017, 132, 576–585. [Google Scholar] [CrossRef]

- Xu, Z.D.; Huang, X.H.; Xu, F.H.; Yuan, J. Parameters optimization of vibration isolation and mitigation system for precision platforms using non-dominated sorting genetic algorithm. Mech. Syst. Signal Process. 2019, 128, 191–201. [Google Scholar] [CrossRef]

- Wang, W.X.; Hua, X.G.; Chen, Z.Q.; Wang, X.; Song, G. Modeling, simulation, and validation of a pendulum-pounding tuned mass damper for vibration control. Struct. Control Health Monit. 2019, 26, e2326. [Google Scholar] [CrossRef]

- Sakurai, T.; Morishita, S. Seismic response reduction of a three-storey building by an MR grease damper. Front. Mech. Eng. 2017, 12, 224–233. [Google Scholar] [CrossRef]

- Xu, Z.D.; Jia, D.H.; Zhang, X.C. Performance tests and mathematical model considering magnetic saturation for magnetorheological damper. J. Intell. Mater. Syst. Struct. 2012, 23, 1331–1349. [Google Scholar] [CrossRef]

- Lv, H.Z.; Zhang, S.S.; Sun, Q.; Chen, R.; Zhang, W.J. The dynamic models, control strategies and applications for magnetorheological damping systems: A systematic review. J. Vib. Eng. Technol. 2020, 9, 131–147. [Google Scholar] [CrossRef]

- Parlak, Z.; Engin, T. Time-dependent CFD and quasi-static analysis of magnetorheological fluid dampers with experimental validation. Int. J. Mech. Sci. 2012, 64, 22–31. [Google Scholar] [CrossRef]

- Xu, Z.D.; Sha, L.F.; Zhang, X.C.; Ye, H.-H. Design, performance test and analysis on magnetorheological damper for earthquake mitigation. Struct. Control Health Monit. 2013, 20, 956–970. [Google Scholar] [CrossRef]

- Zemp, R.; De la Llera, J.C.; Weber, F. Experimental analysis of large capacity MR dampers with short- and long-stroke. Smart Mater. Struct. 2014, 23, 125028. [Google Scholar] [CrossRef]

- Zhang, X.C.; Xu, Z.D. Testing and modeling of a CLEMR damper and its application in structural vibration reduction. Nonlinear Dynamics 2012, 70, 1575–1588. [Google Scholar] [CrossRef]

- Jiang, R.L.; Rui, X.T.; Zhu, W.; Yang, F.; Zhang, Y.; Gu, J. Design of multi-channel bypass magnetorheological damper with three working modes. Int. J. Mech. Mater. Des. 2022, 18, 155–167. [Google Scholar] [CrossRef]

- Raju, K.R.; Jame, A.; Gopalakrishnan, N.; Muthumani, K.; Iyer, N.R. Experimental studies on seismic performance of three-storey steel moment resisting frame model with scissor-jack-magnetorheological damper energy dissipation systems. Struct. Control Health Monit. 2014, 21, 741–755. [Google Scholar] [CrossRef]

- Cruze, D.; Gladston, H.; Farsangi, E.N.; Banerjee, A.; Loganathan, S.; Solomon, S.M. Seismic performance evaluation of a recently developed magnetorheological damper: Experimental investigation. Pract. Period. Struct. Des. Constr. 2021, 26, 04020061. [Google Scholar] [CrossRef]

- Rakshita, R.; Daniel, C.; Hemalatha, G.; Sarala, L.; Tensing, D.; Manoharan, S.S. Studies on modeling and control of RCC frame with MR damper. Smart Technol. Sustain. Dev. 2021, 78, 223–234. [Google Scholar]

- Chae, Y.; Ricles, J.M.; Sause, R. Large-scale real-time hybrid simulation of a three-story steel frame building with magneto-rheological dampers. Earthq. Eng. Struct. Dyn. 2014, 43, 1915–1933. [Google Scholar] [CrossRef]

- Aggumus, H.; Cetin, S. Experimental investigation of semiactive robust control for structures with magnetorheological dampers. J. Low Freq. Noise Vib. Act. Control 2018, 37, 216–234. [Google Scholar] [CrossRef]

- Eltahawy, W.; Ryan, K.; Cesmeci, S.; Gordaninejad, F. Displacement/velocity-based control of a liquid spring—MR damper for vertical isolation. Struct. Control Health Monit. 2019, 26, e2363. [Google Scholar] [CrossRef]

- Bhaiya, V.; Shrimali, M.K.; Bharti, S.D.; Datta, T.K. Modified semi-active control with MR dampers for partially observed systems. Eng. Struct. 2019, 191, 129–147. [Google Scholar] [CrossRef]

- Li, L.Y.; Liang, H.Z. Semiactive control of structural nonlinear vibration considering the MR damper model. J. Aerosp. Eng. 2018, 31, 04018095. [Google Scholar] [CrossRef]

- Zafarani, M.M.; Halabian, A.M. Supervisory adaptive nonlinear control for seismic alleviation of inelastic asymmetric buildings equipped with MR dampers. Eng. Struct. 2018, 176, 849–858. [Google Scholar] [CrossRef]

- Zhao, J.; Li, K.; Zhang, X.C.; Sun, Y.; Xu, Z. Multidimensional vibration reduction control of the frame structure with magnetorheological damper. Struct. Control Health Monit. 2020, 27, e2572. [Google Scholar] [CrossRef]

- Xu, F.H.; Xu, Z.D.; Zhang, X.C. Study on the space frame structures incorporated with magnetorheological dampers. Smart Struct. Syst. 2017, 19, 279–288. [Google Scholar] [CrossRef]

- Xu, L.H.; Li, Z.X.; Lv, Y. Nonlinear seismic damage control of steel frame-steel plate shear wall structures using MR dampers. Earthq. Struct. 2014, 7, 937–953. [Google Scholar] [CrossRef]

- Xu, L.H.; Xie, X.S.; Li, Z.X. Seismic performances of magnetorheological flag-shaped damping braced frame structures. Smart Mater. Struct. 2020, 29, 075032. [Google Scholar] [CrossRef]

- Dai, J.; Xu, Z.D.; Gai, P.P.; Hu, Z.-W. Optimal design of tuned mass damper inerter with a Maxwell element for mitigating the vortex-induced vibration in bridges. Mech. Syst. Signal Process. 2021, 148, 107180. [Google Scholar] [CrossRef]

- Xu, Z.D.; Yang, Y.; Miao, A.N. Dynamic analysis and parameter optimization of pipelines with multidimensional vibration isolation and mitigation device. J. Pipeline Syst. Eng. Pract. 2021, 12, 04020058. [Google Scholar] [CrossRef]

- Lu, H.; Xu, Z.D.; Iseley, T.; Matthews, J.C. Novel data-driven framework for predicting residual strength of corroded pipelines. J. Pipeline Syst. Eng. Pract. 2021, 12, 04021045. [Google Scholar] [CrossRef]

- Ge, T.; Xu, Z.D.; Yuan, F.G. Predictive model of dynamic mechanical properties of VE damper based on acrylic rubber–graphene oxide composites considering aging damage. J. Aerosp. Eng. 2022, 35, 04021132. [Google Scholar] [CrossRef]

- Sun, B.; Liu, X.; Xu, Z.D. A Multiscale Bridging Material Parameter and Damage Inversion Algorithm from Macroscale to Mesoscale Based on Ant Colony Optimization. J. Eng. Mech. 2022, 148, 04021150. [Google Scholar] [CrossRef]

- Li, H.; Xu, Z.D.; Gomez, D.; Gai, P.; Wang, F.; Dyke, S.J. A modified fractional-order derivative zener model for rubber-like devices for structural control. J. Eng. Mech. 2022, 148, 04021119. [Google Scholar] [CrossRef]

- You, J.T.; Yang, Y.; Fan, Y.F.; Zhang, X. Seismic response study of L-shaped frame structure with magnetorheological dampers. Appl. Sci. 2022, 12, 5976. [Google Scholar] [CrossRef]

- Xu, Z.D.; Guo, Y.Q. Fuzzy control method for earthquake mitigation structures with magnetorheological dampers. J. Intell. Mater. Syst. Struct. 2006, 17, 871–881. [Google Scholar] [CrossRef]

- Panagiotakos, T.B.; Fardis, M.N. Deformations of reinforced concrete members at yielding and ultimate. ACI Struct. J. 2001, 98, 135–148. [Google Scholar]

- Rao, S.S. The Finite Element Method in Engineering, 6th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Vaiana, N.; Rosati, L. Classification and unified phenomenological modeling of complex uniaxial rate-independent hysteretic responses. Mech. Syst. Signal Process. 2022, 182, 1132. [Google Scholar] [CrossRef]

- Vaiana, N.; Sessa, S.; Marmo, F.; Rosati, L. A class of uniaxial phenomenological models for simulating hysteretic phenomena in rate-independent mechanical systems and materials. Nonlinear Dyn. 2018, 93, 1647–1669. [Google Scholar] [CrossRef]

- Vaiana, N.; Sessa, S.; Rosati, L. A generalized class of uniaxial rate-independent models for simulating asymmetric mechanical hysteresis phenomena. Mech. Syst. Signal Process. 2021, 146, 2162. [Google Scholar] [CrossRef]

- Yang, H.X.; Shen, T.; Yao, J.G. Study on Earthquake Response Analysis of Reinforced Concrete Masonry Structure. Adv. Mater. Res. 2011, 1336, 244–248. [Google Scholar] [CrossRef]

- Vaiana, N.; Sessa, S.; Marmo, F.; Rosati, L. Nonlinear dynamic analysis of hysteretic mechanical systems by combining a novel rate-independent model and an explicit time integration method. Nonlinear Dyn. 2019, 98, 2879–2901. [Google Scholar] [CrossRef]

- Vaiana, N.; Sessa, S.; Paradiso, M.; Marmo, F.; Rosati, L. An Efficient Computational Strategy for Nonlinear Time History Analysis of Seismically Base-Isolated Structures. In Proceedings of the AIMETA 2019 XXIV Conference, Rome, Italy, 15–19 September 2019; Springer: Cham, Switzerland, 2020; pp. 1340–1353, Lecture Notes in Mechanical Engineering. [Google Scholar]

- Motra, G.B.; Mallik, W.; Chandiramani, N.K. Semi-active vibration control of connected buildings using magnetorheological dampers. J. Intell. Mater. Syst. Struct. 2011, 22, 1811–1827. [Google Scholar] [CrossRef]

- Ubaidillah, H.K.; Kadir, F.A.A. Modelling, characterisation and force tracking control of a magnetorheological damper under harmonic excitation. Int. J. Model. Identif. Control 2011, 13, 9–21. [Google Scholar] [CrossRef]

- Russo, R.; Terzo, M. Modelling, parameter identification, and control of a shear mode magnetorheological device. Proc. Inst. Mech. Eng. Part I-J. Syst. Control. Eng. 2011, 225, 549–562. [Google Scholar] [CrossRef]

- Weber, F. Robust force tracking control scheme for MR dampers. Struct. Control Health Monit. 2015, 22, 1373–1395. [Google Scholar] [CrossRef]

| Natural Frequencies | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th |

|---|---|---|---|---|---|---|---|---|---|---|

| ANSYS | 0.759 | 0.823 | 0.896 | 2.371 | 2.559 | 2.777 | 4.322 | 4.441 | 4.940 | 6.352 |

| MATLAB | 0.749 | 0.810 | 0.881 | 2.348 | 2.524 | 2.749 | 4.255 | 4.487 | 4.877 | 6.315 |

| Relative error (%) | 1.29 | 1.59 | 0.95 | 0.97 | 1.36 | 1.00 | 1.54 | −1.03 | 1.28 | 0.58 |

| Story (Node) | El-Centro Wave | Tangshan Wave | ||||||

|---|---|---|---|---|---|---|---|---|

| Without MRD | With MRD | Without MRD | With MRD | |||||

| X-Direction | Y-Direction | X-Direction | Y-Direction | X-Direction | Y-Direction | X-Direction | Y-Direction | |

| 1(4) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2(8) | 0.412 | 0.828 | 0.014 | 0.017 | 1.137 | 1.686 | 0.031 | 0.069 |

| 3(12) | 0.923 | 0.914 | 0.205 | 0.188 | 1.628 | 2.101 | 0.511 | 0.297 |

| 4(16) | 0.648 | 0.672 | 0.241 | 0.141 | 1.217 | 1.562 | 0.264 | 0.065 |

| 5(20) | 0.205 | 0.133 | 0 | 0 | 0.561 | 0.620 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Mou, C.; Zhao, J.; Guo, Y.; Song, Y.; You, J. A Multidimensional Elastic–Plastic Calculation Model of the Frame Structure with Magnetorheological Damper. Actuators 2022, 11, 362. https://doi.org/10.3390/act11120362

Zhang X, Mou C, Zhao J, Guo Y, Song Y, You J. A Multidimensional Elastic–Plastic Calculation Model of the Frame Structure with Magnetorheological Damper. Actuators. 2022; 11(12):362. https://doi.org/10.3390/act11120362

Chicago/Turabian StyleZhang, Xiangcheng, Changchi Mou, Jun Zhao, Yingqing Guo, Youmin Song, and Jieyong You. 2022. "A Multidimensional Elastic–Plastic Calculation Model of the Frame Structure with Magnetorheological Damper" Actuators 11, no. 12: 362. https://doi.org/10.3390/act11120362

APA StyleZhang, X., Mou, C., Zhao, J., Guo, Y., Song, Y., & You, J. (2022). A Multidimensional Elastic–Plastic Calculation Model of the Frame Structure with Magnetorheological Damper. Actuators, 11(12), 362. https://doi.org/10.3390/act11120362