Unbalance Vibration Suppression of Maglev High-Speed Motor Based on the Least-Mean-Square

Abstract

1. Introduction

2. Mechanism of Rotor Unbalance of Maglev Motor

3. Unbalance Vibration Control of Maglev Motor Based on LMS

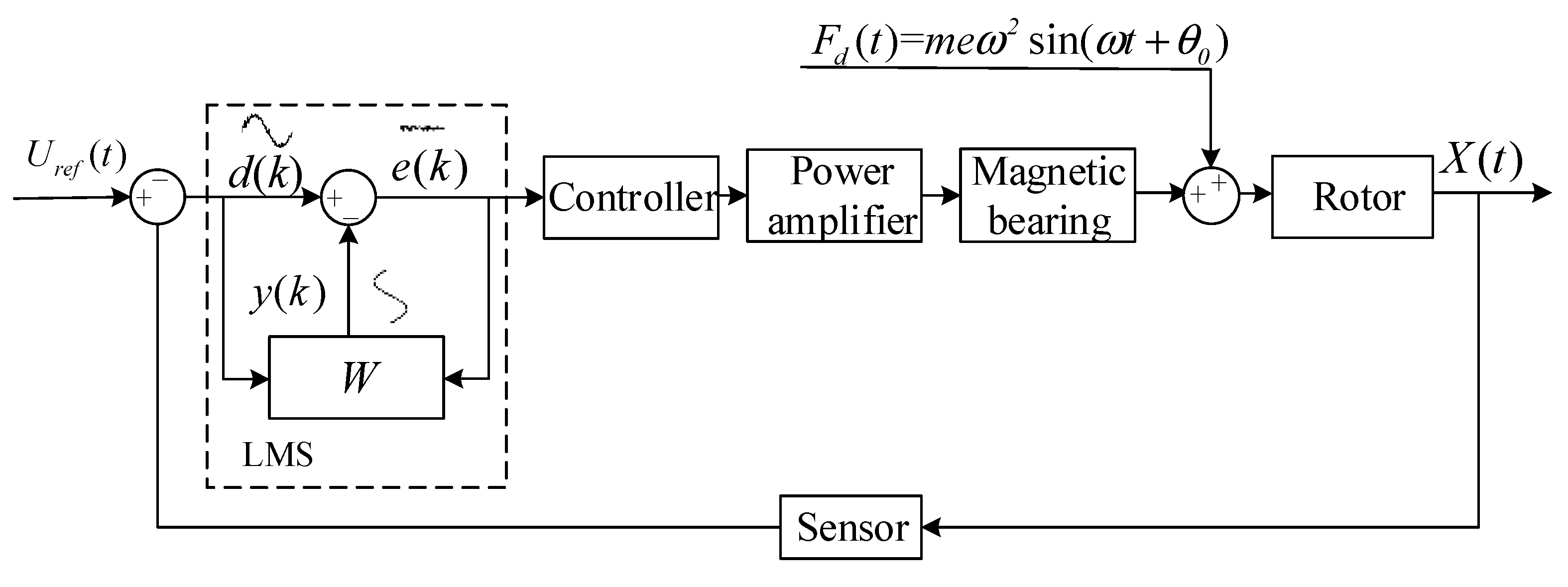

3.1. Unbalance Vibration Control Model of Maglev Motor Rotor

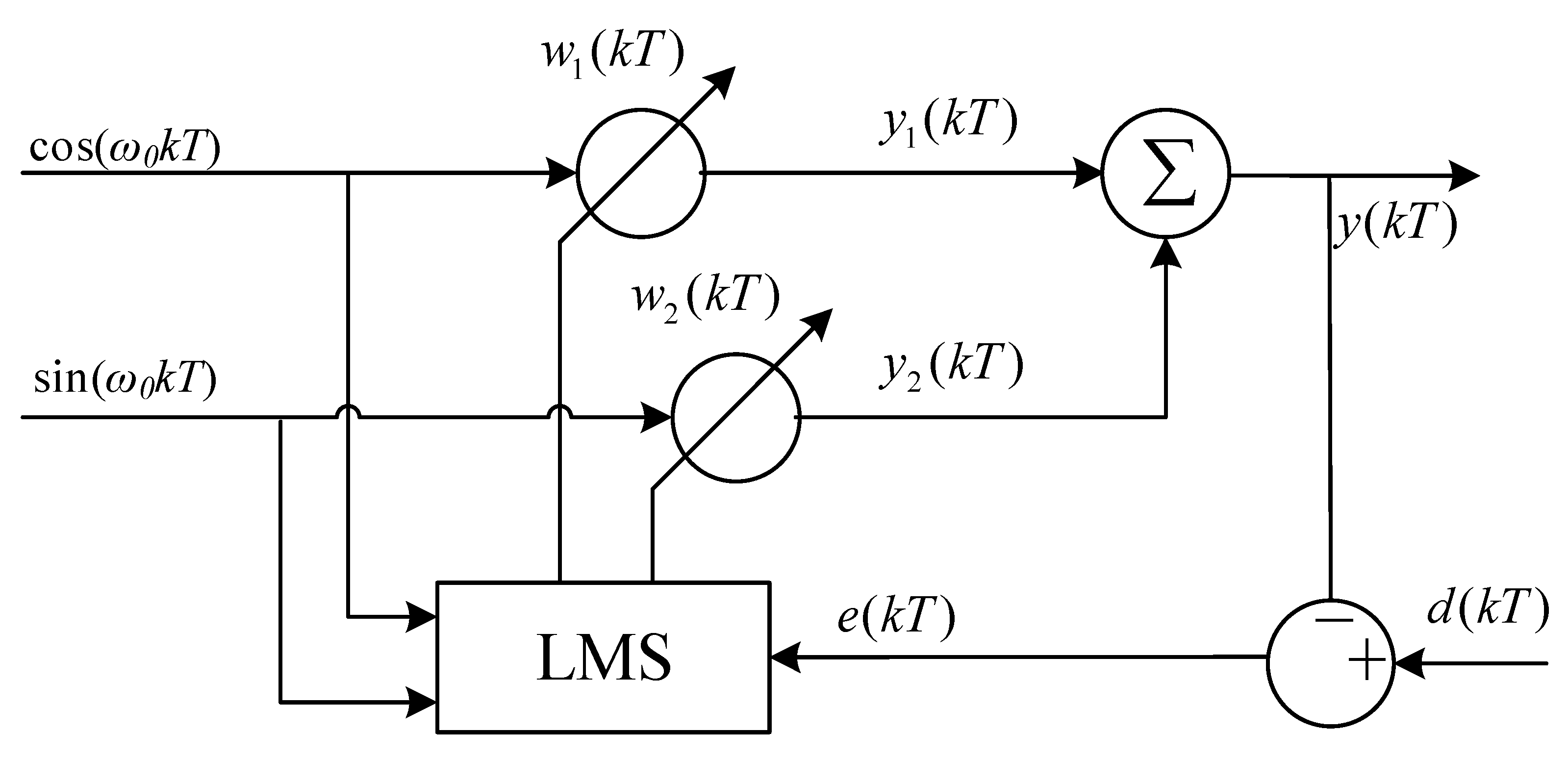

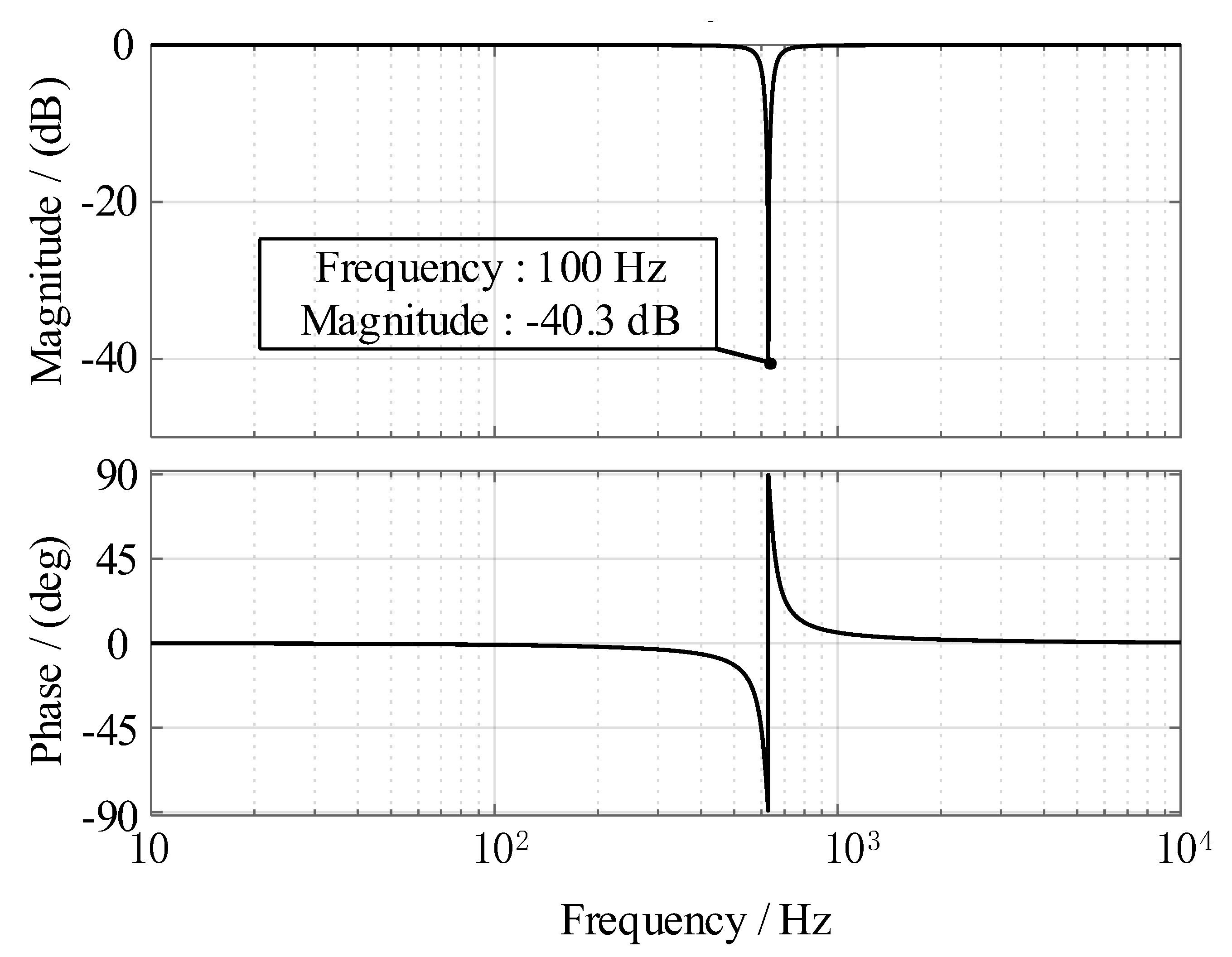

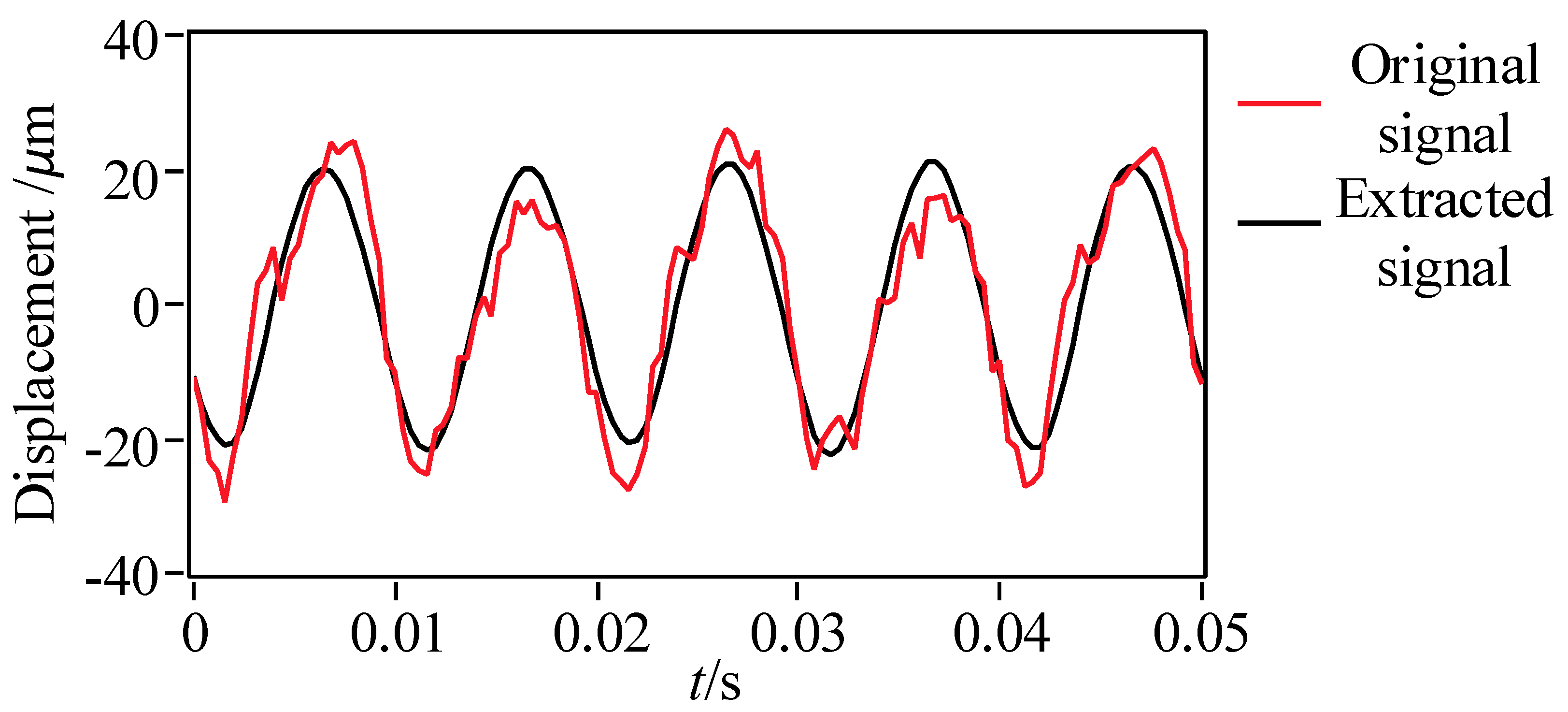

3.2. LMS Filtering Performance Analysis

4. Experimental Verification

4.1. Experimental Installation

4.2. Experimental Result

5. Conclusions

- (1)

- The LMS algorithm can effectively filter out the sine wave with a specified frequency in the signal, which is introduced into the unbalance compensation process of the maglev rotor to realize the unbalance vibration suppression of the maglev rotor.

- (2)

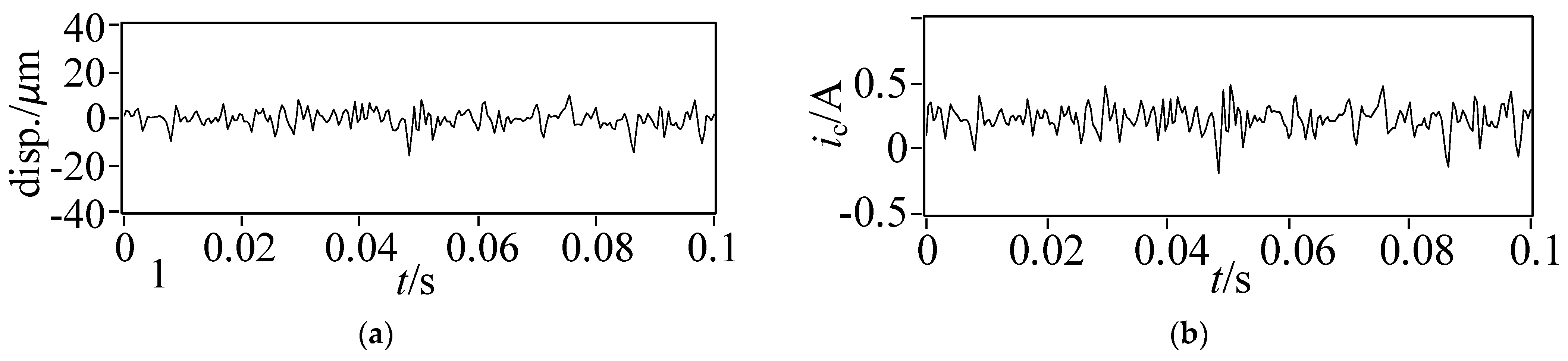

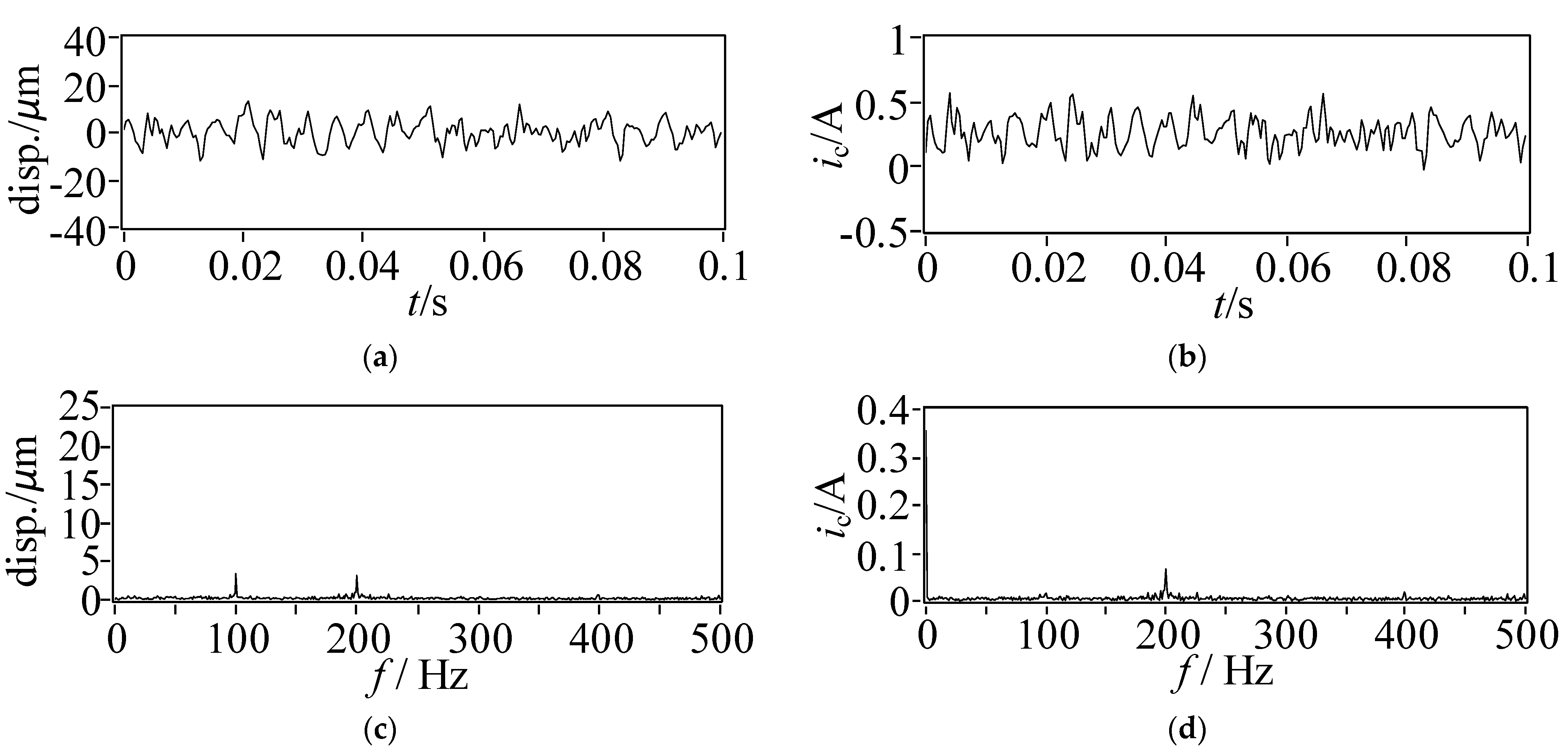

- Using the LMS algorithm control in this paper, after filtering the unbalanced signal of the synchronous frequency of 100 Hz, the synchronous frequency displacement of the maglev rotor and the synchronous frequency control current of the magnetic bearing is reduced by 87% and 92%, respectively. Further filtering the harmonic signal of the maglev rotor can effectively reduce the harmonic control current of the magnetic bearing. Further reduction of unbalanced control of rotors by magnetic bearings to better realize the unbalanced vibration control of the rotor.

- (3)

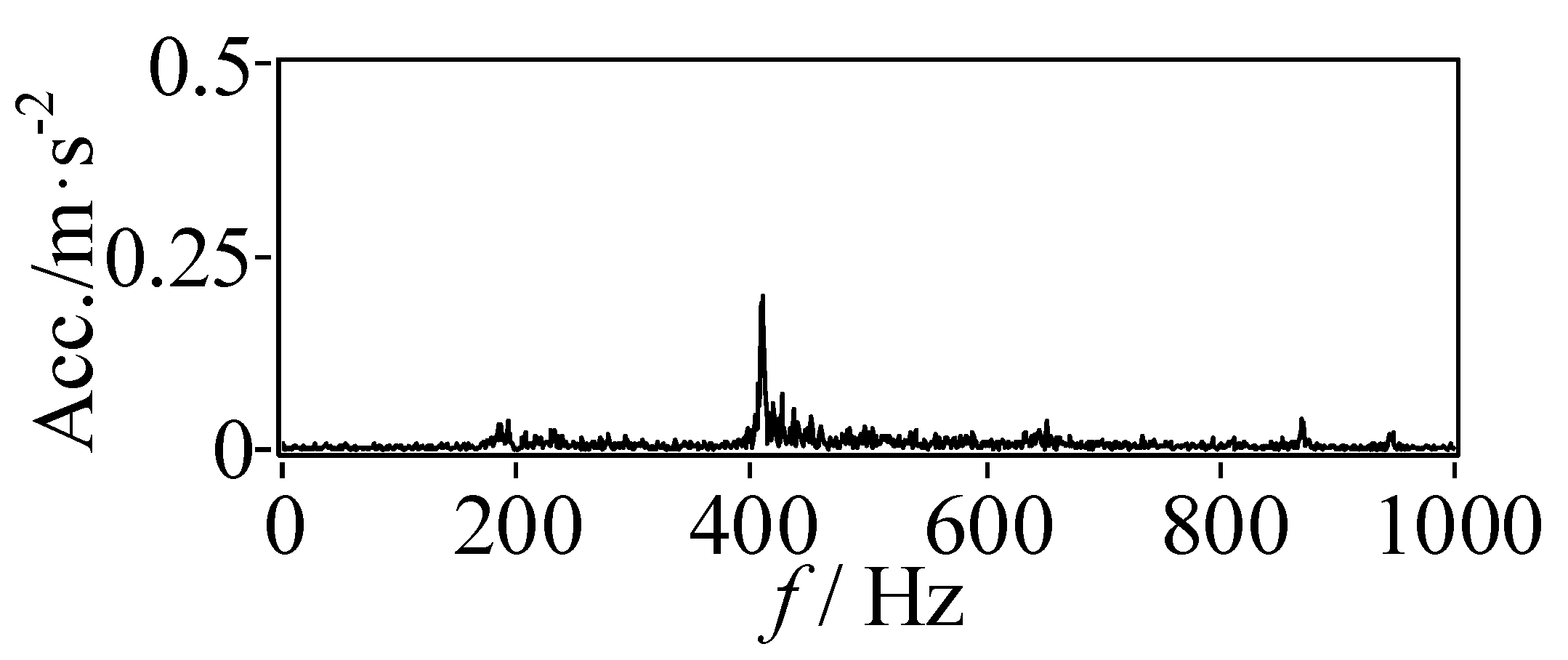

- The final compensation results show that the peak-to-peak mean value of rotor displacement decreases by 67.4% and the peak-to-peak mean value of control current decreases by 31% after using the LMS-based fundamental frequency and harmonic vibration control algorithm. Compared with the displacement and control current in static suspension, they only increase by 32.6% and 6.5%, respectively. At the same time, the vibration amplitude of the synchronous frequency with the base speed is attenuated by 80.4%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, F.; Jin, J.J.; Oka, K. Permanent Magnetic Suspension System-Principle, Model, Simulation and Experiment; Beijing Science Press: Beijing, China, 2018. [Google Scholar]

- Zhao, C.; Sun, F.; Jin, J.J.; Tang, H.J.; Xu, F.; Li, Q.; Oka, K. Analysis of quasi-zero power characteristic for a permanent magnetic levitation system with a variable flux path control mechanism. IEEE-ASME Trans. Mechatron. 2021, 26, 1416–1420. [Google Scholar] [CrossRef]

- Zhou, R.; Yan, M.Y.; Sun, F.; Jin, J.; Li, Q.; Xu, F.; Zhang, M.; Zhang, X.; Nakano, K. Experimental validations of a magnetic energy-harvesting suspension and its potential application for self-powered sensing. Energy 2022, 239, 122205. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, H.; Guan, X. Unbalance Suppression for AMB Rotor System Using APF-SRF Algorithm. Shock. Vib. 2020, 1–10. [Google Scholar] [CrossRef]

- Mohamed, M.E.; Bonello, P. The efficient inclusion of rotation-induced inertia effects in a shaft-blisk assembly model using zero-speed modes. J. Sound Vib. 2020, 479, 115357. [Google Scholar] [CrossRef]

- Herzog, R.; Buhler, P.; Gahler, C.; Larsonneur, R. Unbalance compensation using generalized notch filters in the multivariable feedback of magnetic bearings. IEEE Trans. Control. Syst. Technol. 1996, 4, 580–586. [Google Scholar] [CrossRef]

- Lum, K.Y.; Coppola, V.T.; Bernstein, D.S. Adaptive auto-centering control for an active magnetic bearing supporting a rotor with unknown mass imbalance. IEEE Trans. Control. Syst. Technol. 1996, 4, 587–597. [Google Scholar]

- Setiawan, J.; Mukherjee, R.; Maslen, E. Synchronous Disturbance Compensation in Active Magnetic Bearings Using Bias Current Excitation. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Como, Italy, 8–12 July 2001; pp. 707–712. [Google Scholar]

- Matras, A.; Flowers, G.; Fuentes, R.; Balas, M.; Fausz, J. Suppression of persistent rotor vibrations using adaptive techniques. J. Vib. Acoust. 2003, 128, 682–689. [Google Scholar] [CrossRef]

- Chiacchiarini, H.; Mandolesi, P. Unbalance compensation for active magnetic bearings using ILC. In Proceedings of the IEEE International Conference on Control Applications, Mexico City, Mexico, 7 September 2001; pp. 58–63. [Google Scholar]

- Betschon, F.; Knospe, C.R. Reducing magnetic bearing currents via gain scheduled adaptive control. IEEE/ASME Trans. Mechatron. 2001, 6, 437–443. [Google Scholar] [CrossRef]

- Zheng, S.; Feng, R. Feedforward compensation control of rotor imbalance for high-speed magnetically suspended centrifugal compressors using a novel adaptive notch filter. J. Sound Vib. 2016, 366, 1–14. [Google Scholar] [CrossRef]

- Nonami, K.; Qifu, F.; Ueyama, H. Unbalance vibration control of magnetic bearing systems using an adaptive algorithm with disturbance frequency estimation. JSME Int. J. 2008, 41, 220–226. [Google Scholar] [CrossRef][Green Version]

- Rundell, A.; Drakunov, S.; Decarlo, R. A sliding mode observer and controller for stabilization of rotational motion of a vertical shaft magnetic bearing. IEEE Trans. Control. Syst. Technol. 1996, 4, 598–608. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.; Ilene, B. Imbalance compensation and automatic balancing in magnetic bearing systems using the Q-parameterization theory. In Proceedings of the American Control Conference, Baltimore, MD, USA, 30 June–2 July 1994; pp. 2952–2957. [Google Scholar]

- Han, B.; Cui, H.; Tang, E. Vibration suppression of magnetic bearing based on sliding mode disturbance observer. Opt. Precis. Eng. 2012, 20, 563–570. [Google Scholar]

- Zhang, Y.; Zhou, J.; Han, X.; Zhou, Y. Adaptive odd repetitive control for magnetically suspended rotor harmonic currents suppression. J. Vib. Control. 2022, 89, 510–526. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, Q.; Yang, K.; Zhou, J.; Guo, Q. A novel ultra-high-resolution inclination sensor based on diamagnetic levitation. Sens. Actuators A Phys. 2022, 343, 113686. [Google Scholar] [CrossRef]

- Ashkezari-Toussi, S.; Sabzevari, V.R. Early arrhythmia prediction based on Hurst index and ECG prediction using robust LMS adaptive filter. Signal Image Video Process. 2021, 15, 1813–1820. [Google Scholar] [CrossRef]

- Nishikawa, K. The LMS-Type Adaptive Filter Based on the Gaussian Model for Controlling the Variances of Coefficients. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2020, E103.A, 1494–1502. [Google Scholar] [CrossRef]

- Zhang, H.; JLiu Zhu, R.; Chen, H.; Yuan, H. Nonlinear adaptive harmonics vibration control for an active magnetic bearing system with rotor unbalance and sensor runout. IEEE Sens. J. 2021, 21, 12245–12254. [Google Scholar] [CrossRef]

- Soni, T.; Dutt, J.K.; Das, A.S. Parametric Stability Analysis of Active Magnetic Bearing Supported Rotor System With a Novel Control Law Subject to Periodic Base Motion. IEEE Trans. Ind. Electron. 2020, 67, 1160–1170. [Google Scholar] [CrossRef]

- Wang, M.; Han, Q.; Wen, B.; Zhang, H.; Guan, T. Modal characteristics and unbalanced responses of fan rotor system with flexible support structures in aero-engine. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 231, 1686–1705. [Google Scholar] [CrossRef]

- Gao, H.; Song, L. Modified LMS algorithm applied to maglev flywheel’s vibration compensation problem. Int. J. Appl. Electromagn. Mech. 2017, 53, 359–369. [Google Scholar] [CrossRef]

| Peak-Peak Mean Value | ||

|---|---|---|

| Displacement (μm) | Current (A) | |

| static levitation | 9.32 | 0.46 |

| 100 Hz rotation, no compensation | 38.77 | 0.71 |

| 100 Hz rotation, after compensation | 12.63 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Yu, M.; Song, C.; Wang, N. Unbalance Vibration Suppression of Maglev High-Speed Motor Based on the Least-Mean-Square. Actuators 2022, 11, 348. https://doi.org/10.3390/act11120348

Wu H, Yu M, Song C, Wang N. Unbalance Vibration Suppression of Maglev High-Speed Motor Based on the Least-Mean-Square. Actuators. 2022; 11(12):348. https://doi.org/10.3390/act11120348

Chicago/Turabian StyleWu, Huachun, Mengying Yu, Chunsheng Song, and Nianxian Wang. 2022. "Unbalance Vibration Suppression of Maglev High-Speed Motor Based on the Least-Mean-Square" Actuators 11, no. 12: 348. https://doi.org/10.3390/act11120348

APA StyleWu, H., Yu, M., Song, C., & Wang, N. (2022). Unbalance Vibration Suppression of Maglev High-Speed Motor Based on the Least-Mean-Square. Actuators, 11(12), 348. https://doi.org/10.3390/act11120348