An Intelligent Process to Estimate the Nonlinear Behaviors of an Elasto-Plastic Steel Coil Damper Using Artificial Neural Networks

Abstract

1. Introduction

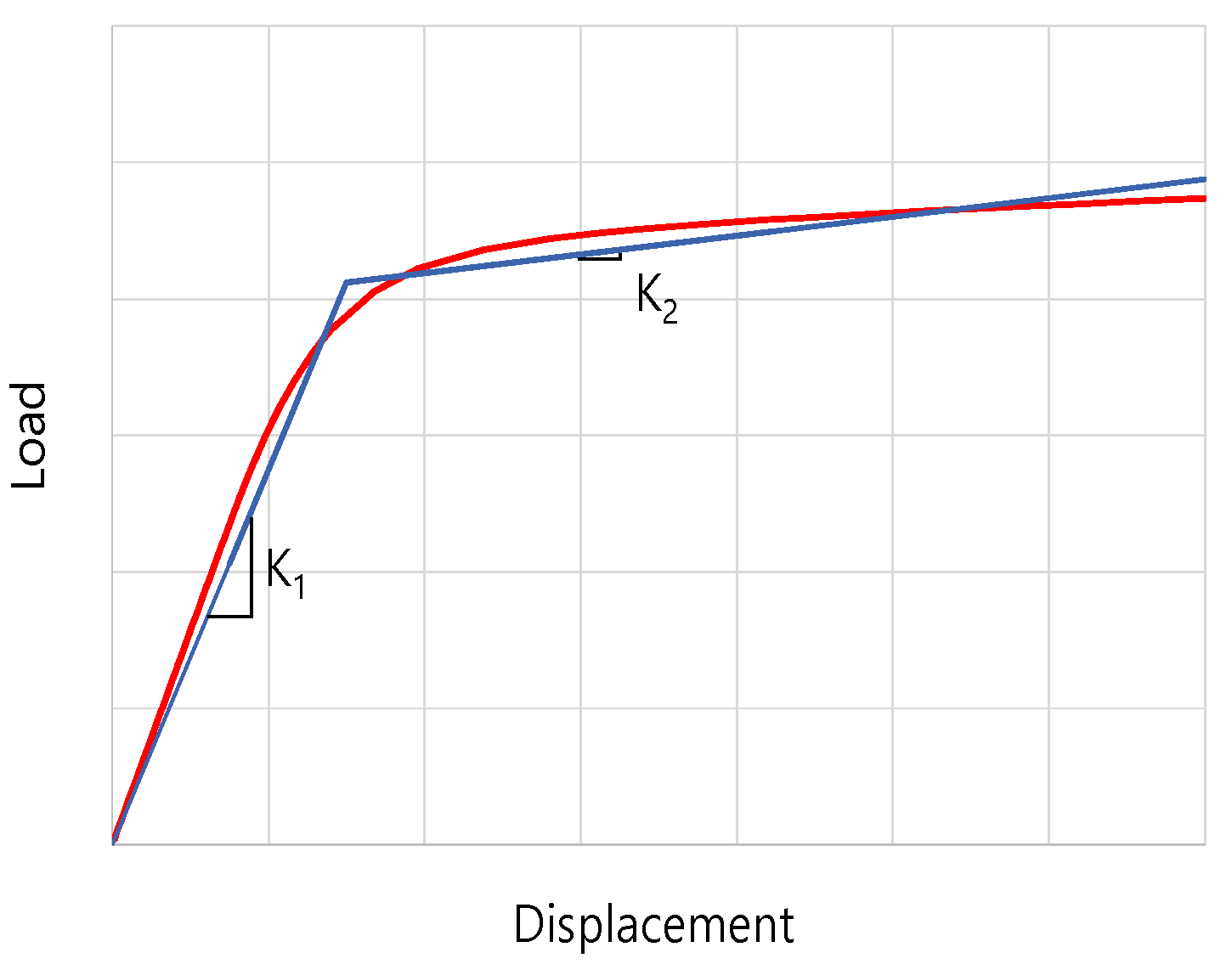

2. Analytical Model of the Elasto-Plastic SCD

2.1. Mechanical Behavior of Coil Spring

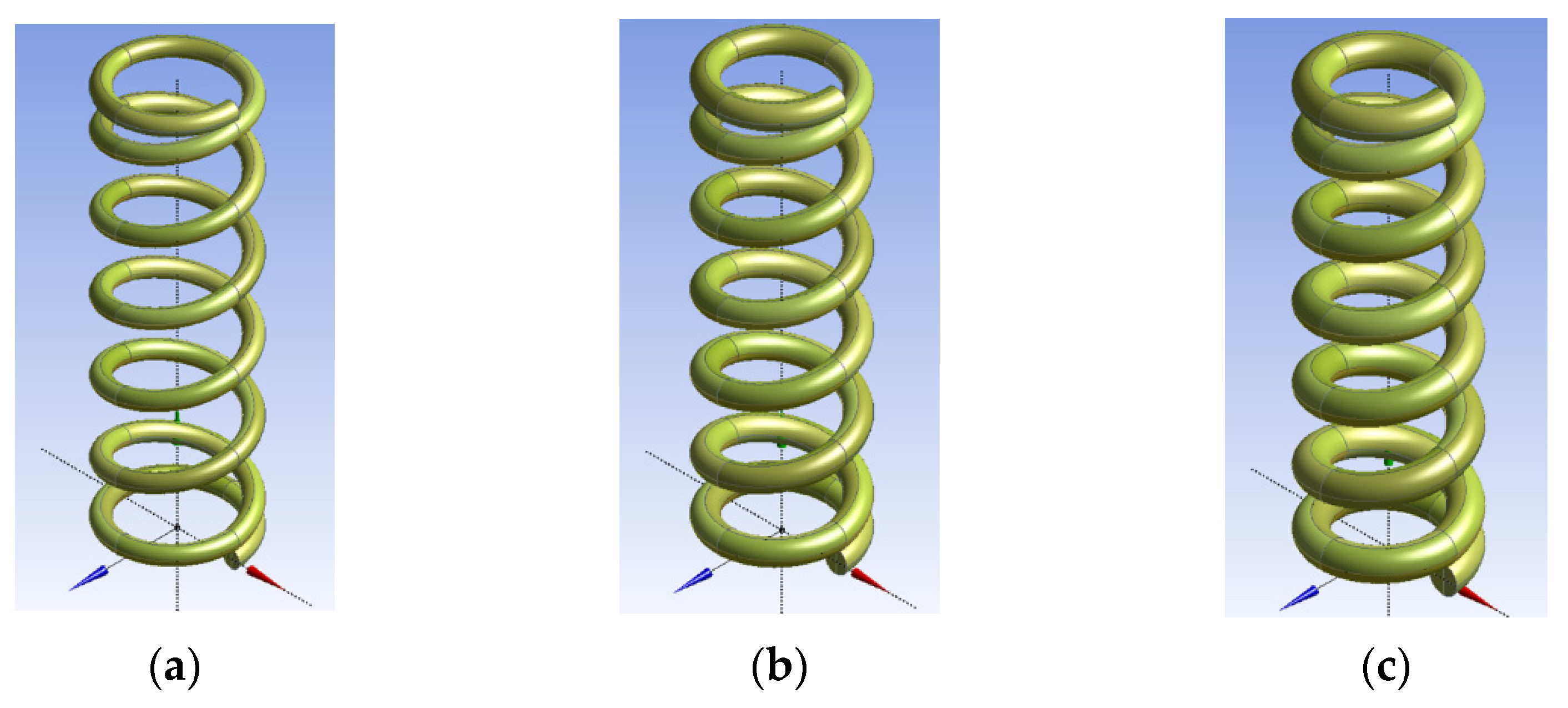

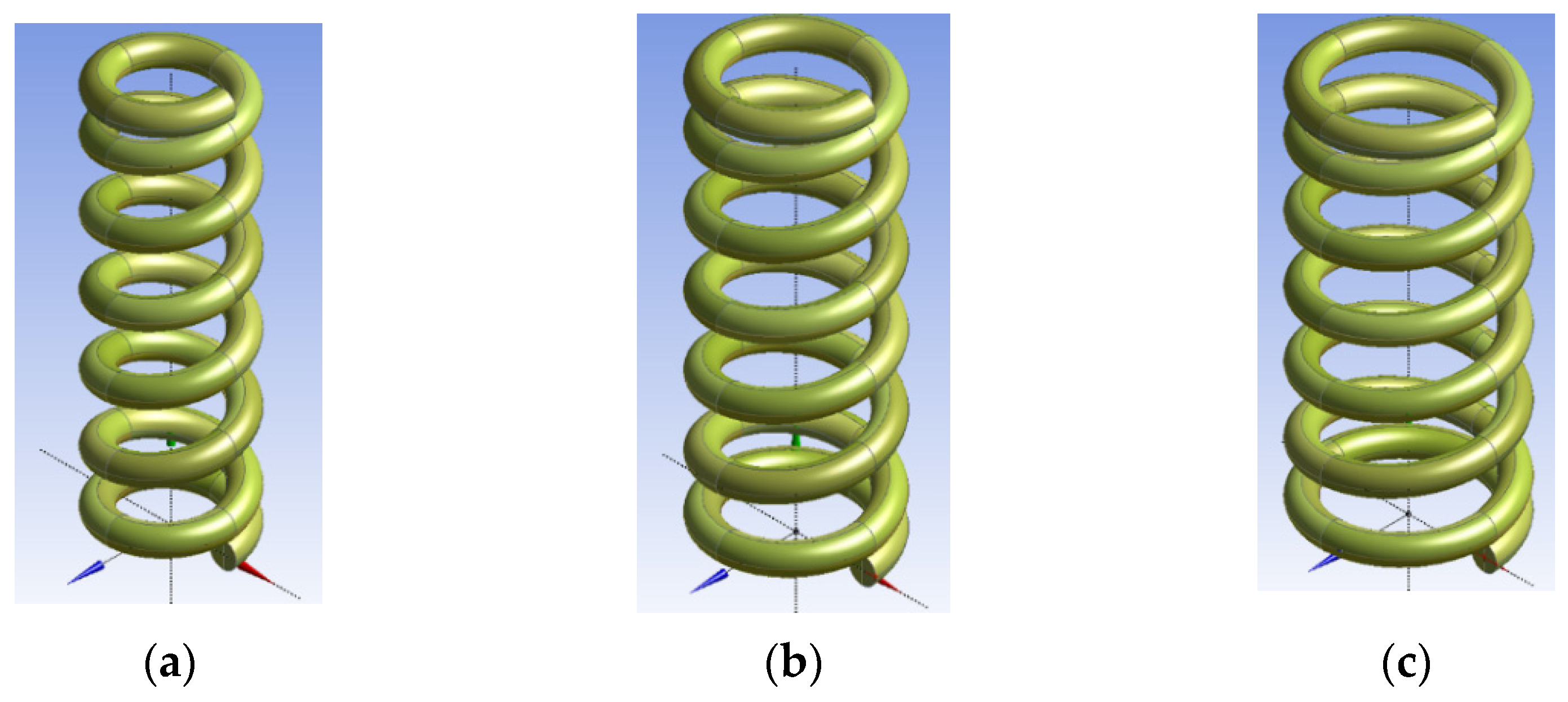

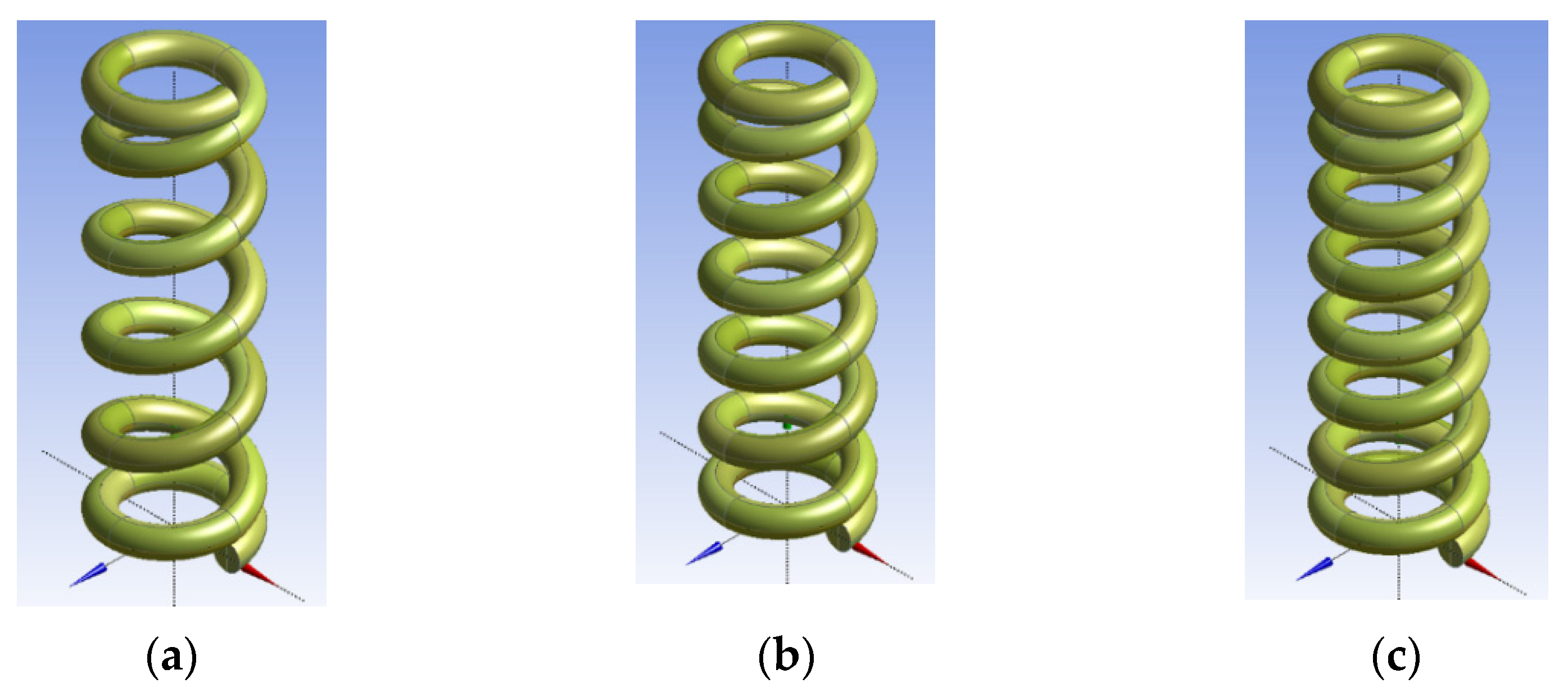

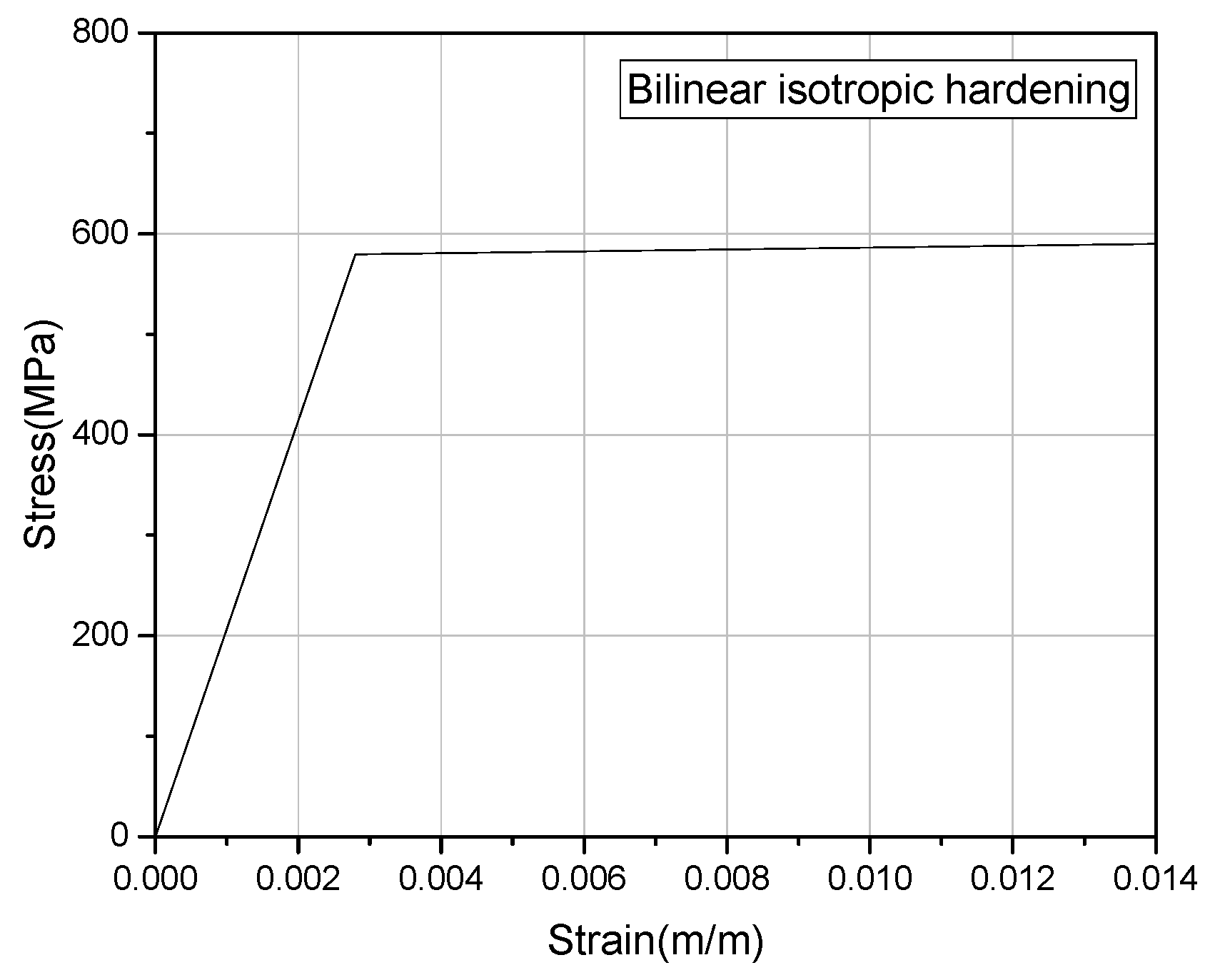

2.2. Finite Element Model

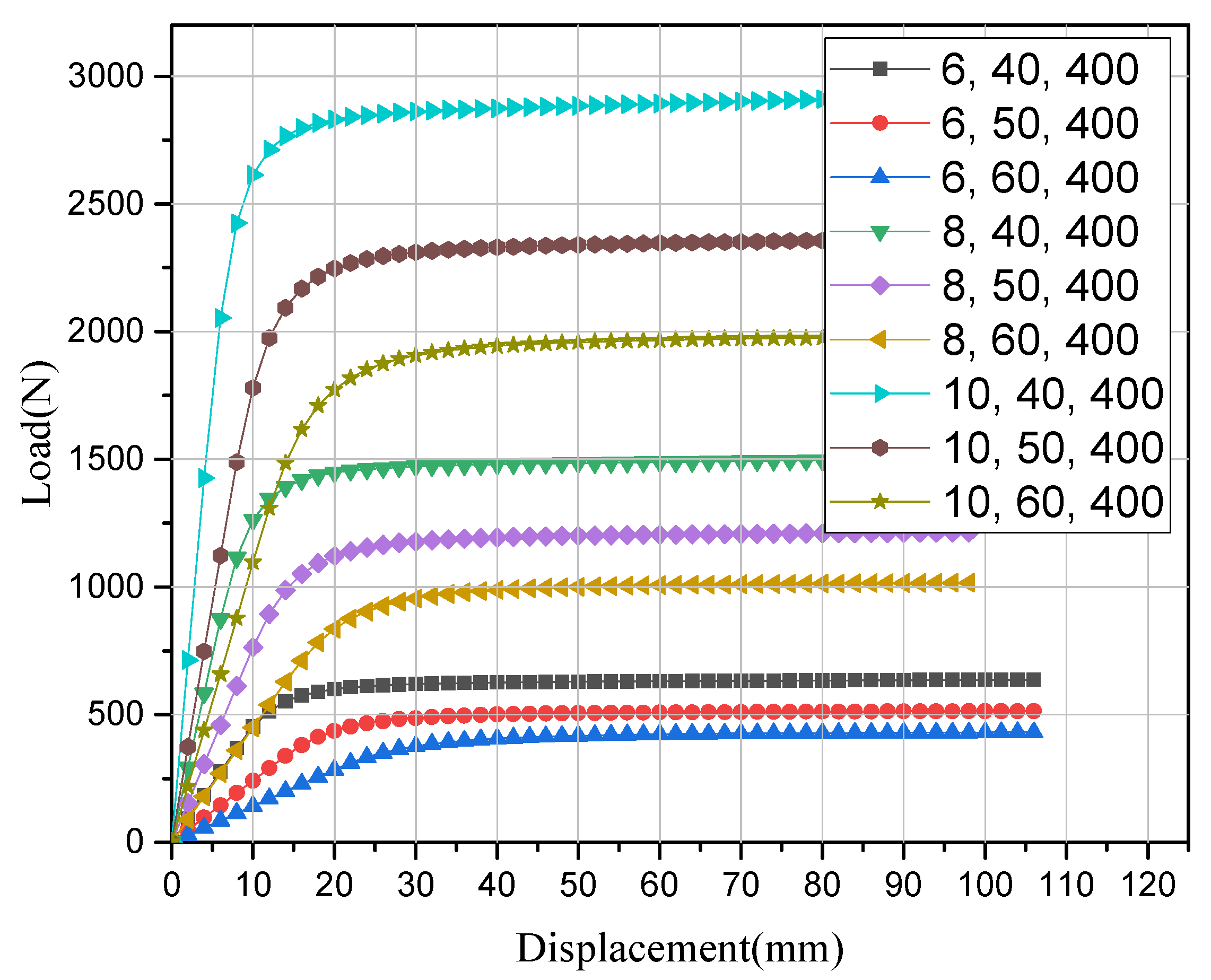

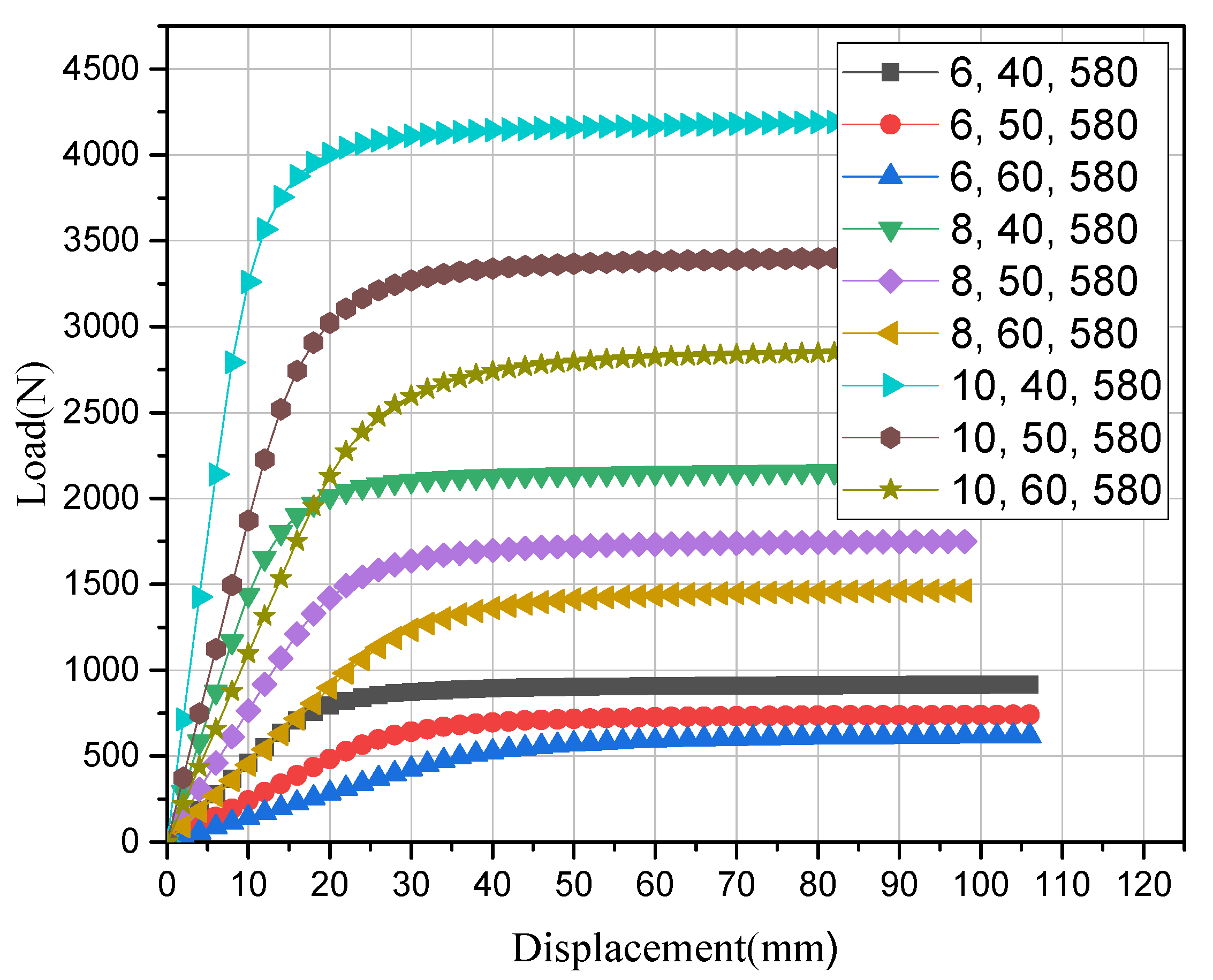

2.3. Loading Test Simulation

3. Estimation of the Elasto-Plastic Behavior of SCDs Using ANN

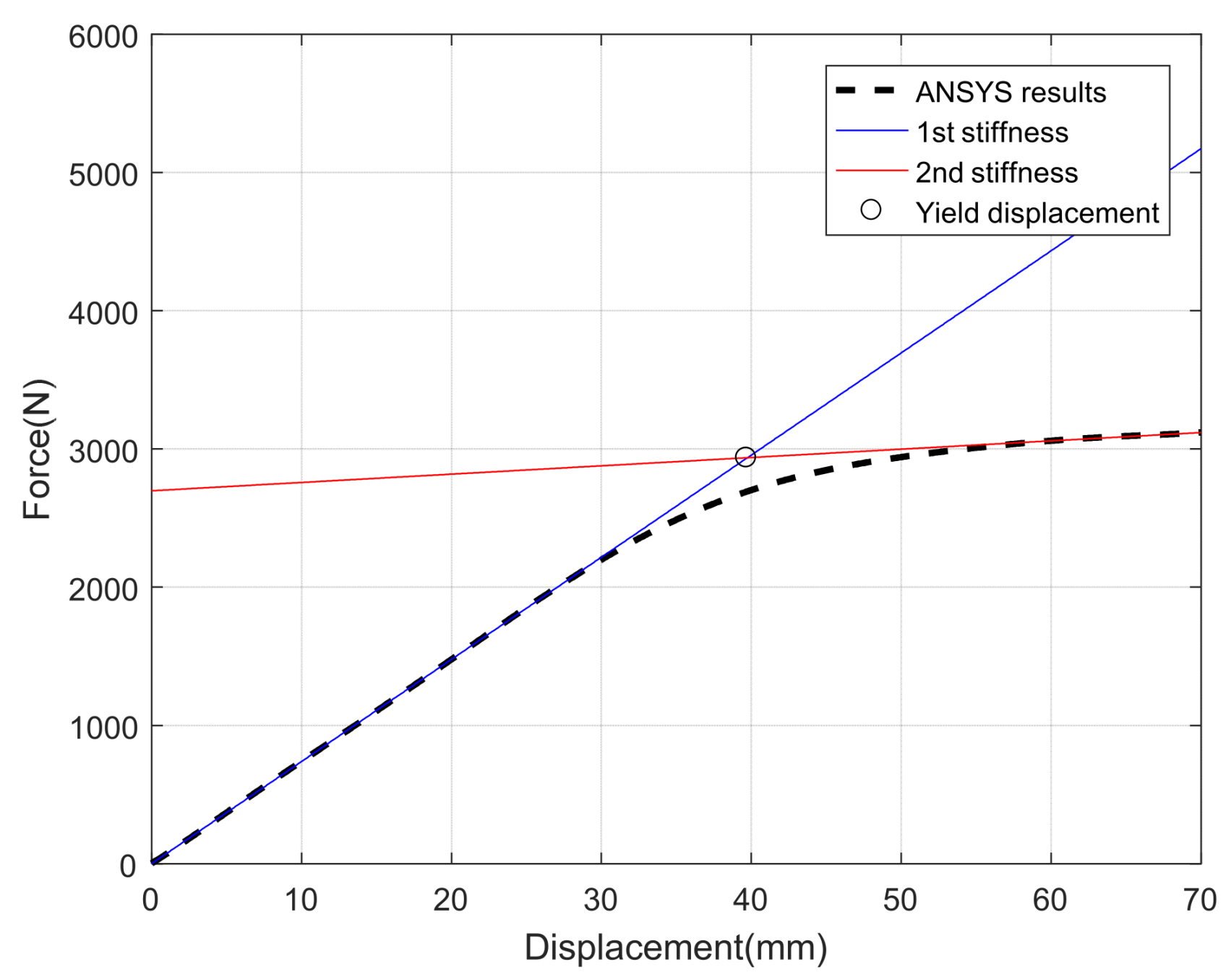

3.1. Objective of Estimation

3.2. Estimation Procedure

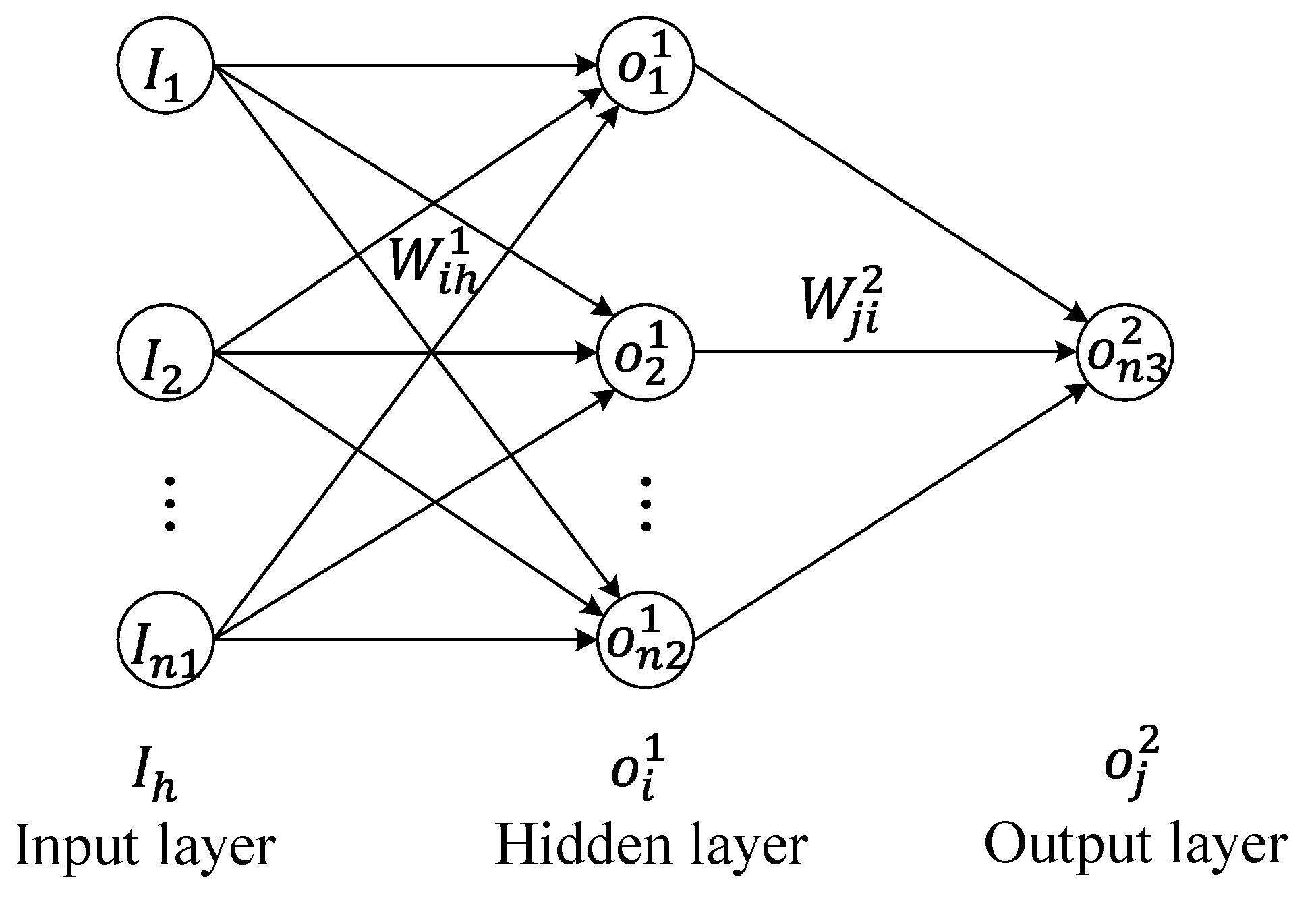

3.3. Artificial Neural Network

4. Verification of the ANN Model

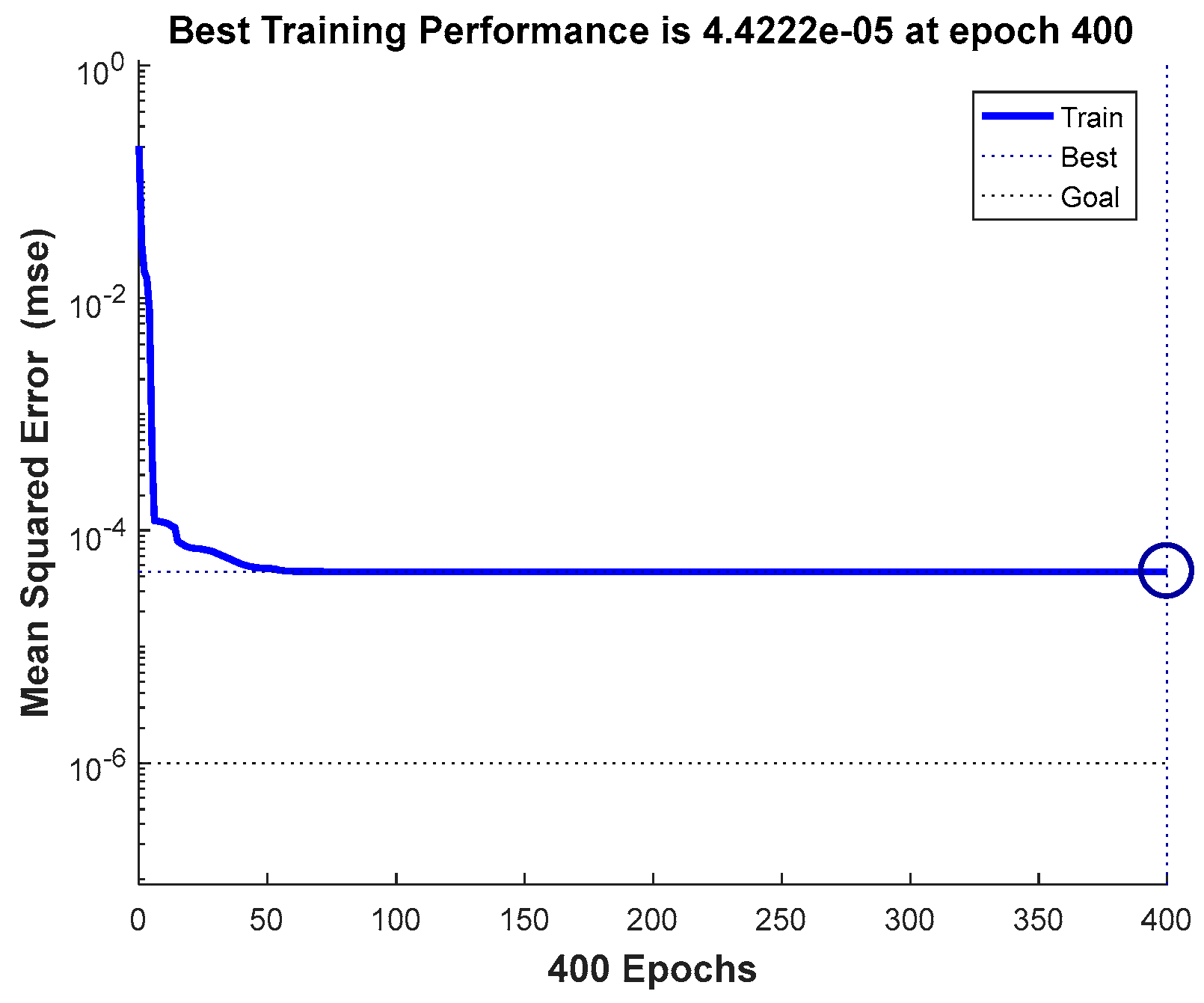

4.1. Learning Process of ANN Models

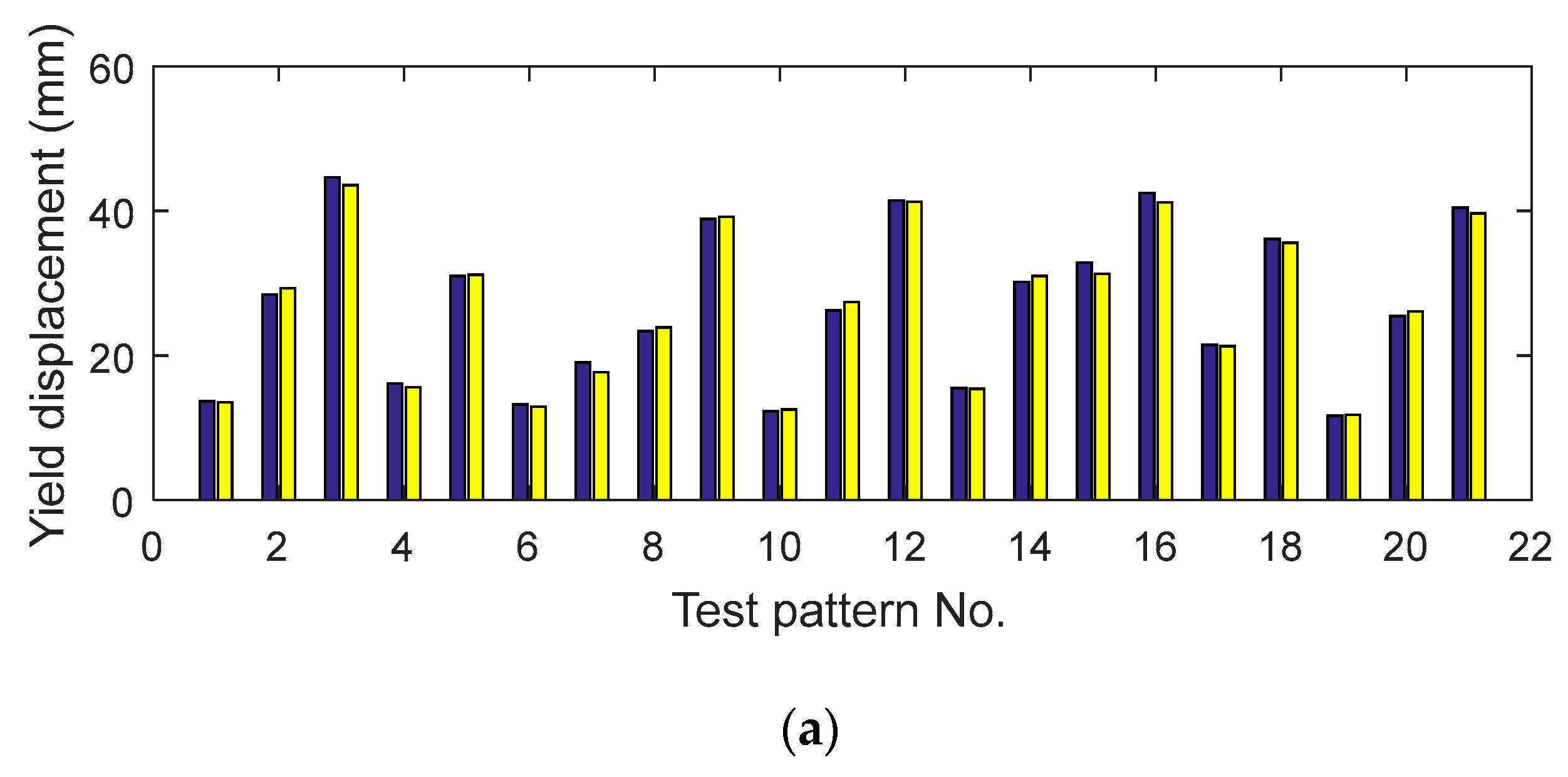

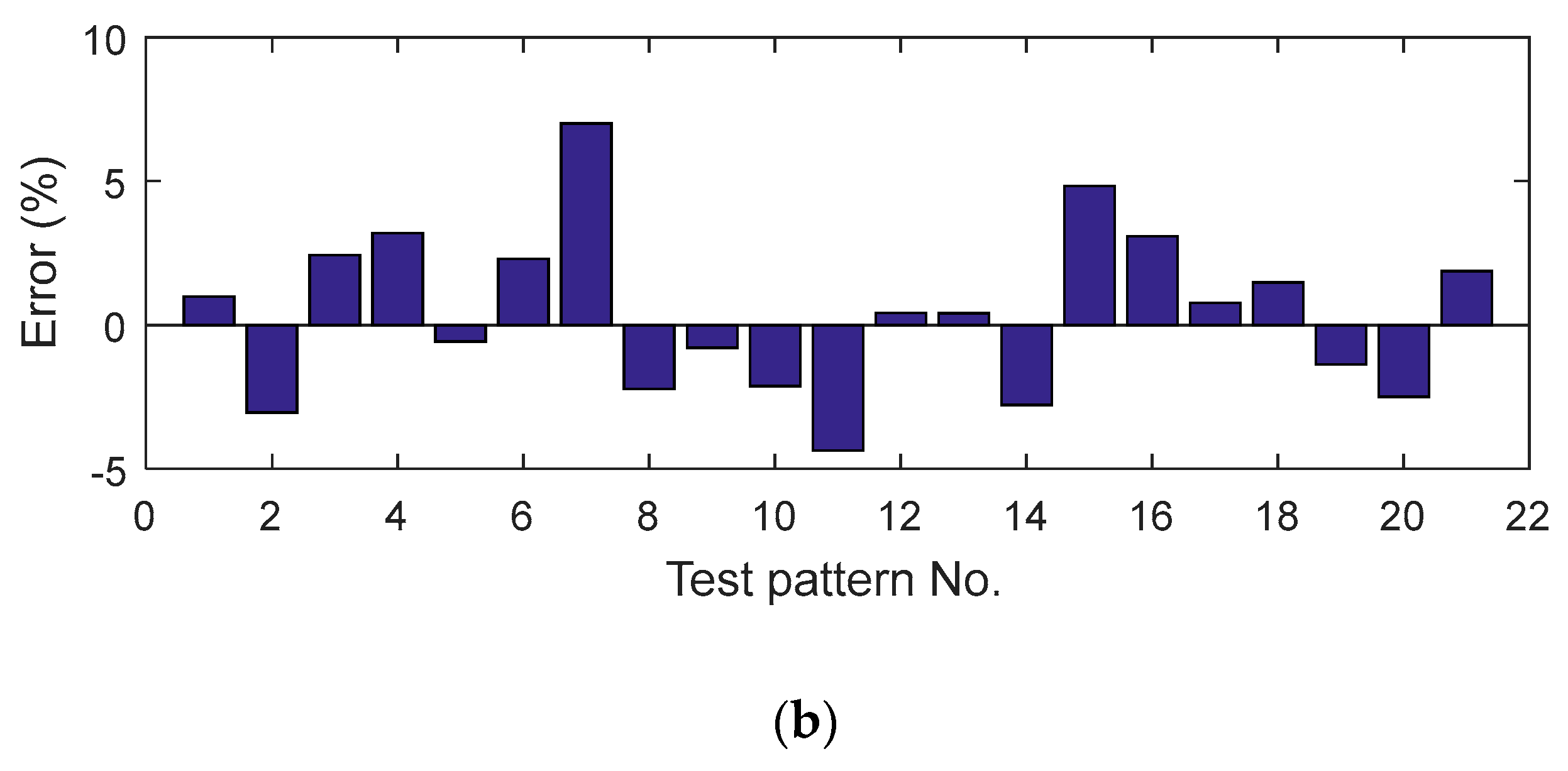

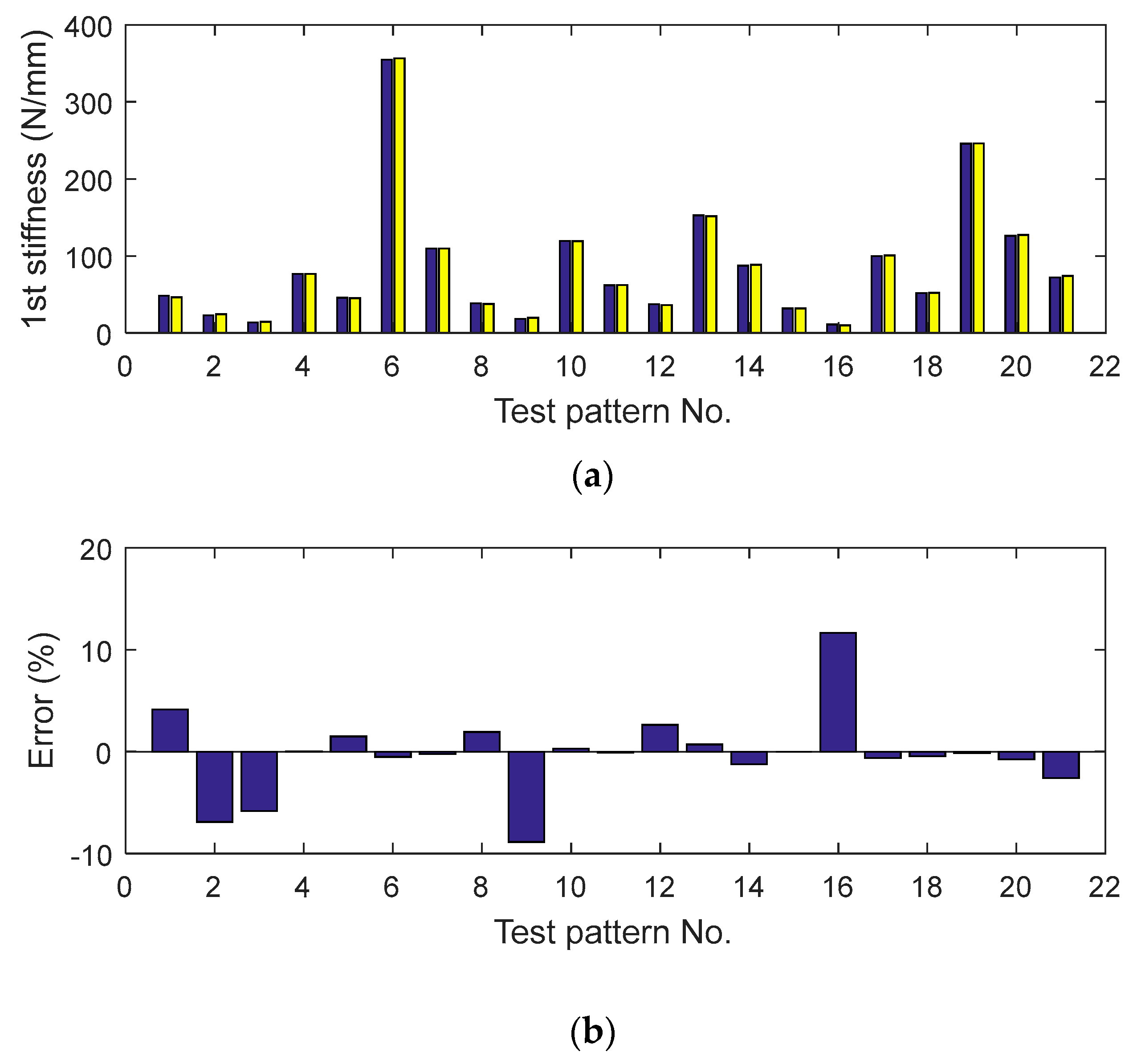

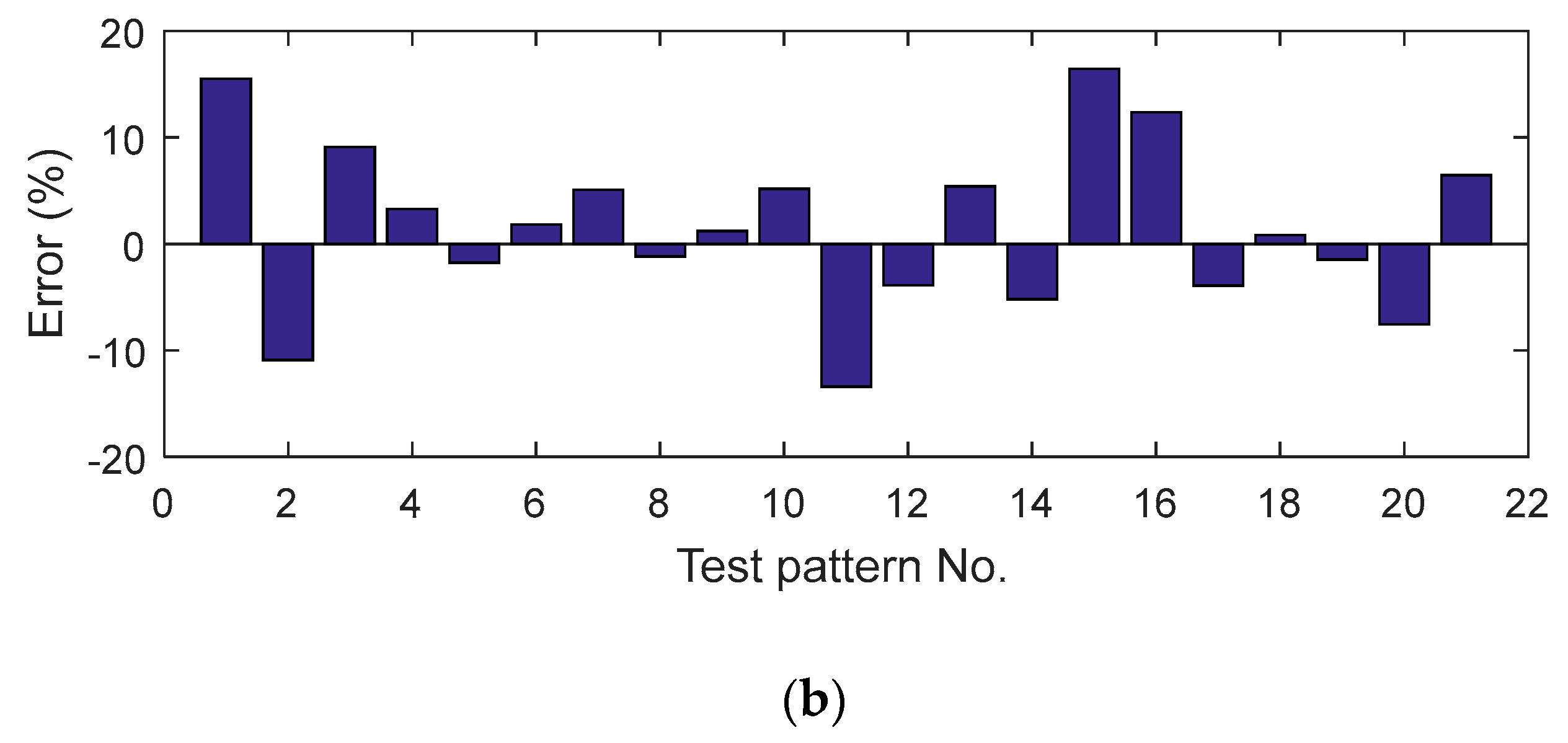

4.2. Estimation Results Obtained with the ANN Models

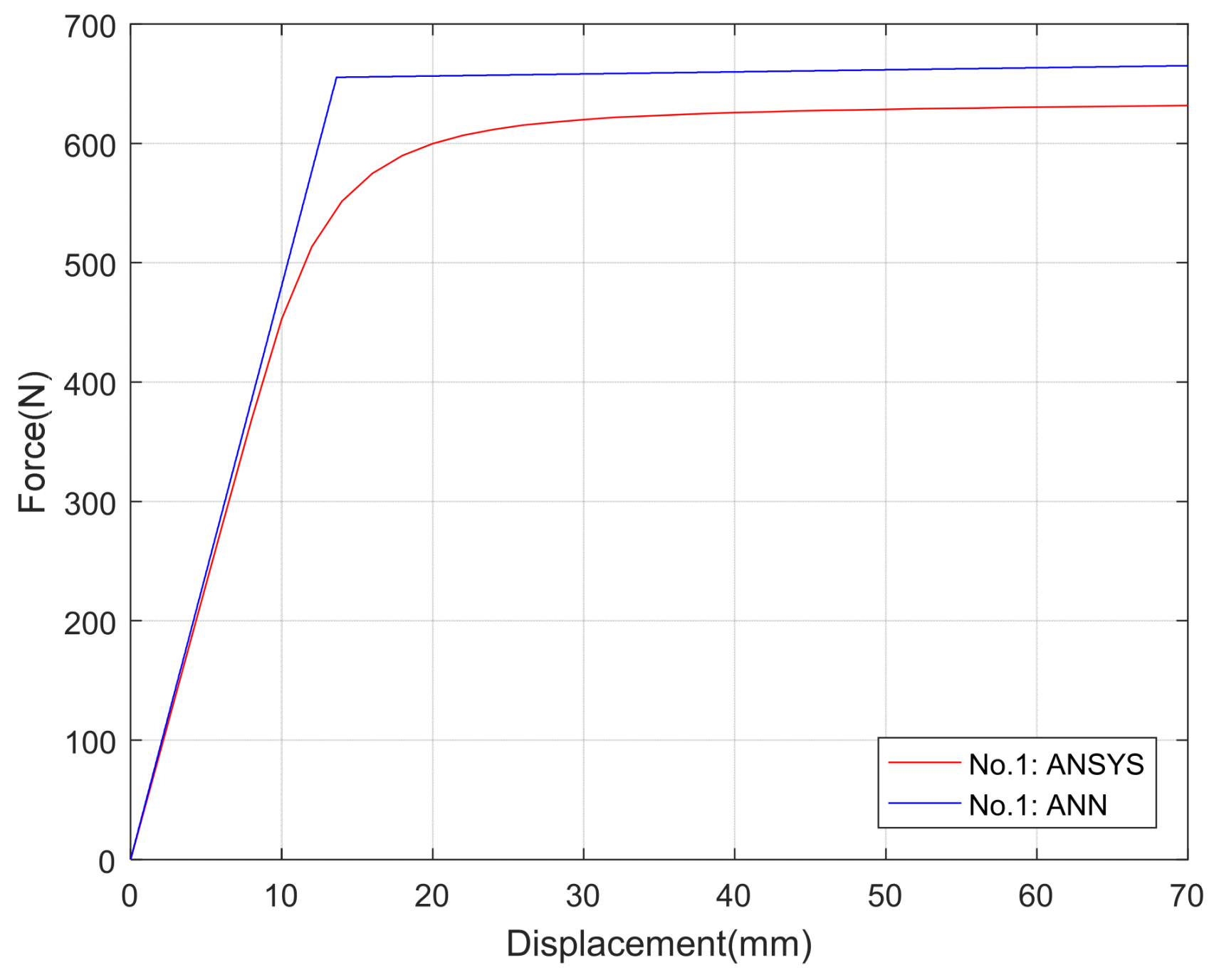

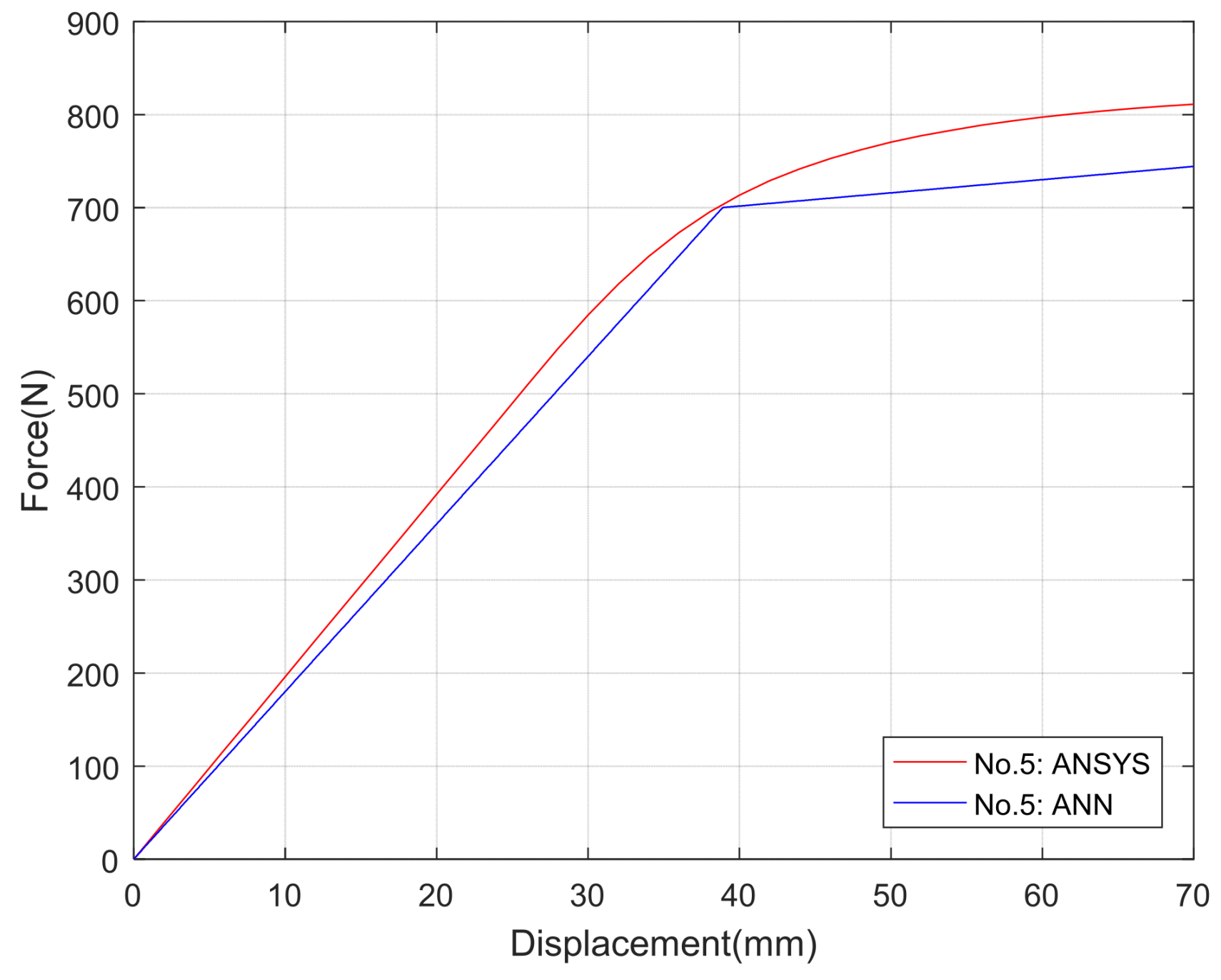

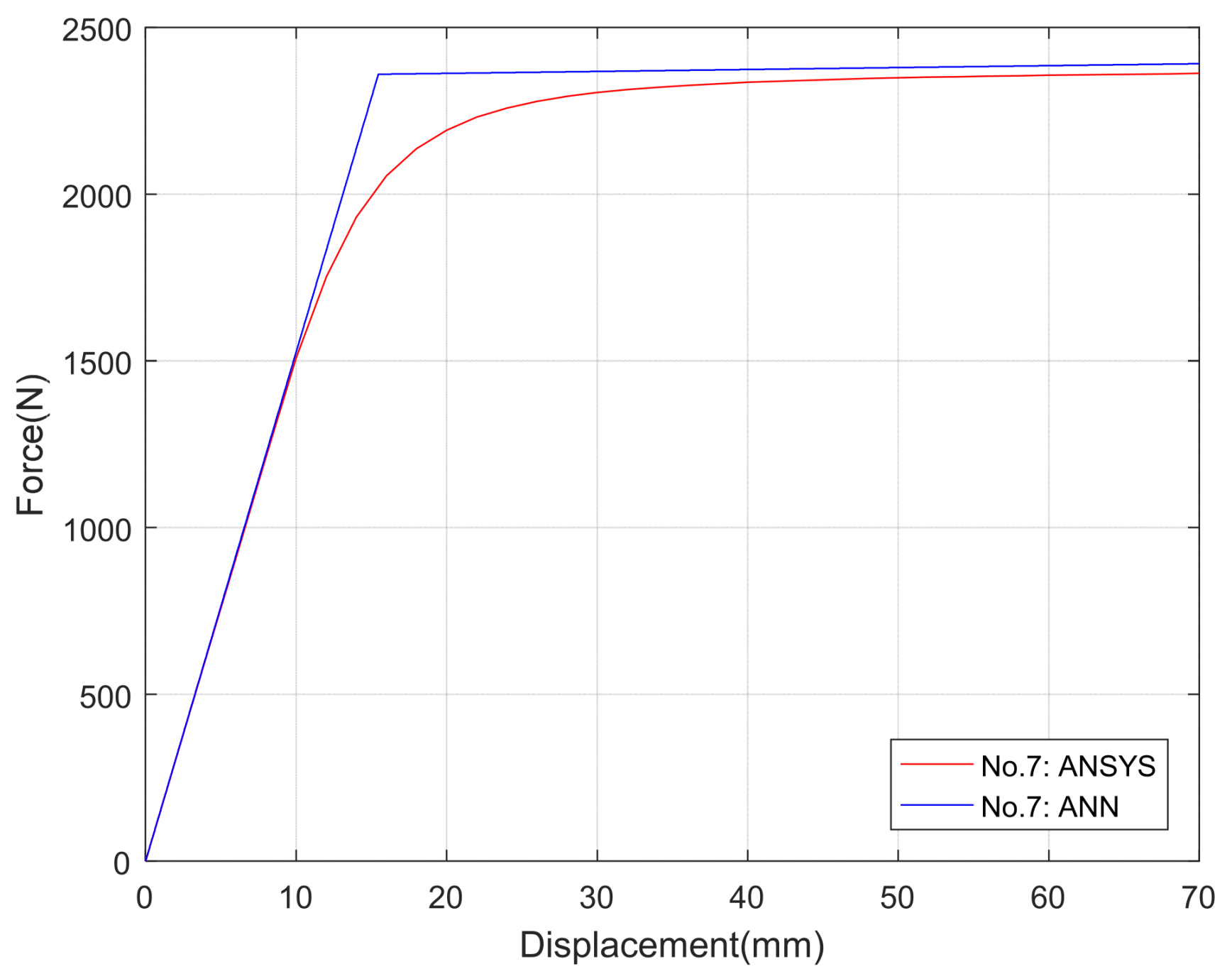

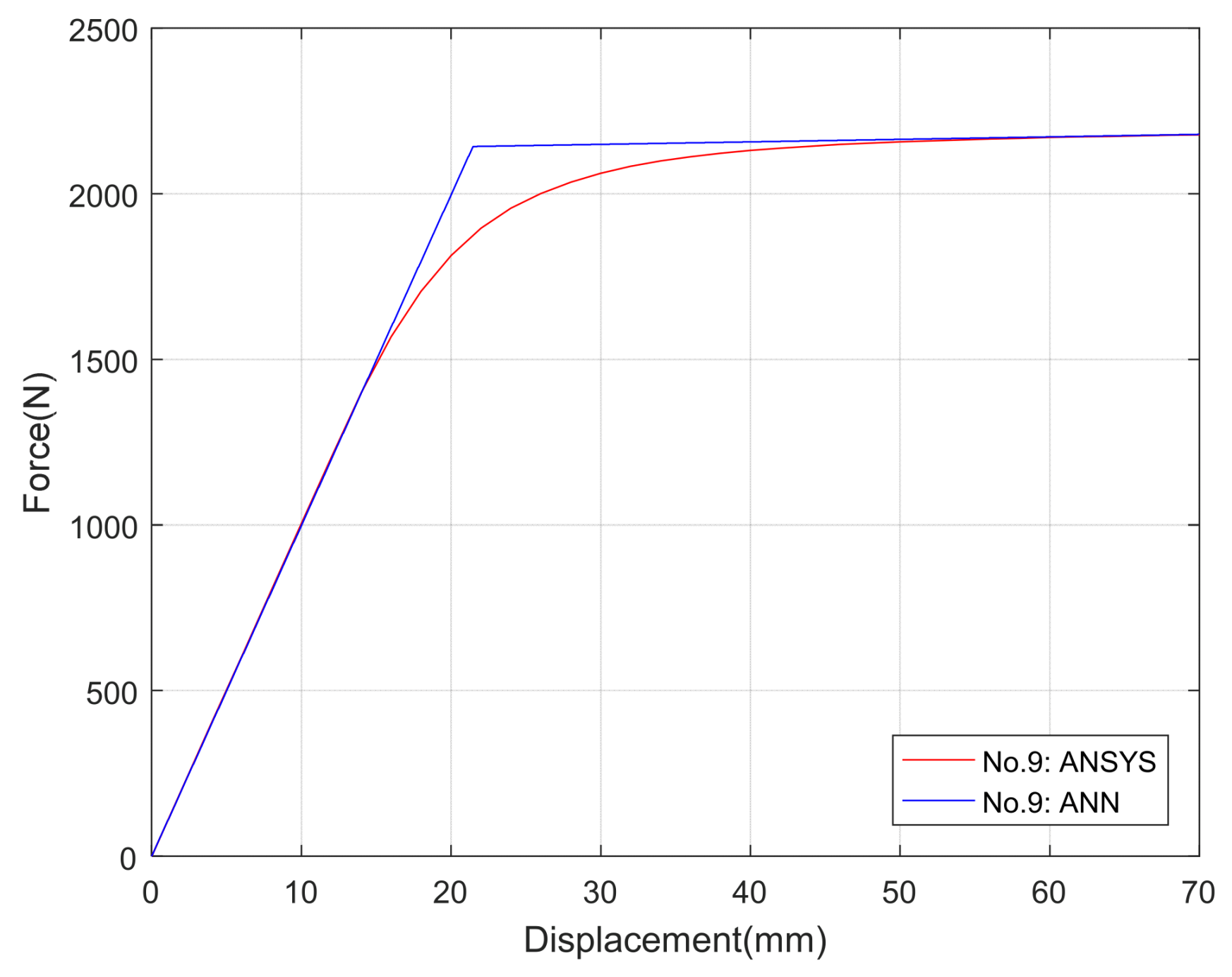

4.3. Comparison of Nonlinear Response Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- JAVIT. Overview of Vibration Technologies 2010; Japan Association for Vibration Technologies: Takanawa, Japan, 2011. [Google Scholar]

- Chang, S.; Sun, W.; Cho, S.G.; Kim, D. Vibration Control of Nuclear Power Plant Piping System Using Stockbridge Damper under Earthquakes. Sci. Technol. Nucl. Install. 2016, 2016, 5014093. [Google Scholar] [CrossRef]

- Cho, S.G.; Furuya, O.; Kurabayashi, H. Enhancement of seismic resilience of piping systems in nuclear power plants using steel coil damper. Nucl. Eng. Des. 2019, 350, 147–157. [Google Scholar] [CrossRef]

- Ge, T.; Huang, X.-H.; Guo, Y.-Q.; He, Z.-F.; Hu, Z.-W. Investigation of Mechanical and Damping Performances of Cylindrical Viscoelastic Dampers in Wide Frequency Range. Actuators 2021, 10, 71. [Google Scholar] [CrossRef]

- Hansu, O.; Güneyisi, E. Comparison of Novel Seismic Protection Devices to Attenuate the Earthquake Induced Energy. Actuators 2021, 10, 73. [Google Scholar] [CrossRef]

- Chang, S. Active Mass Damper for Reducing Wind and Earthquake Vibrations of a Long-Period Bridge. Actuators 2020, 9, 66. [Google Scholar] [CrossRef]

- Elias, S.; Matsagar, V. Seismic vulnerability of a non-linear building with distributed multiple tuned vibration absorbers. Struct. Infrastruct. Eng. 2019, 15, 1103–1118. [Google Scholar] [CrossRef]

- Elias, S.; Rupakhety, R.; De Domenico, D.; Olafsson, S. Seismic response control of bridges with nonlinear tuned vibration absorbers. Structures 2021, 34, 262–274. [Google Scholar] [CrossRef]

- Le, L.M.; Van Nguyen, D.; Chang, S.; Kim, D.; Cho, S.G.; Nguyen, D.-D. Vibration control of jacket offshore wind turbine subjected to earthquake excitations by using friction damper. J. Struct. Integr. Maint. 2019, 4, 1–5. [Google Scholar] [CrossRef]

- Skinner, R.I.; Kelly, J.M.; Heine, A.J. Hysteresis dampers for earthquake resistant structures. Earthq. Eng. Struct. Dyn. 1974, 3, 287–296. [Google Scholar] [CrossRef]

- Wahl, A.M. Mechanical Springs; McGraw-Hill Book, Co.: New York, NY, USA, 1966. [Google Scholar]

- SAE Inc. Manual on Design and Application of Helical and Spiral Springs; HSJ795; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Chandeler, R.V. Direct procedure for helical spring design. Mach. Des. 1961, 131. [Google Scholar]

- Sayhor, D. Helical coil spring design. Engineering 1986, 131. [Google Scholar]

- John, R.C. Short cut for designing helical springs. Mach. Des. 1979, 22, 92–93. [Google Scholar]

- Ancker, C.J.; Goodier, J.N. Pitch and curvature corrections for helical springs. J. Appl. Mech. 1958, 25, 466–470. [Google Scholar] [CrossRef]

- Ancker, C.J.; Goodier, J.N. Theory of pitch and curvature corrections for the helical spring-Ⅰ (tension). J. Appl. Mech. 1958, 25, 471–483. [Google Scholar] [CrossRef]

- Ancker, C.J.; Goodier, J.N. Theory of pitch and curvature corrections for the helical spring-Ⅱ (torsion). J. Appl. Mech. 1958, 25, 484–495. [Google Scholar] [CrossRef]

- Sato, S.; Taguchi, K.; Adachi, R.; Nakatani, M. Strength characteristics of ceramic springs. Trans. Jpn. Soc. Spring Eng. 1997, 55–60. [Google Scholar] [CrossRef][Green Version]

- Suzuki, S.; Kamiya, S.; Imaizumi, T.; Sanada, Y. Approaches to minimizing side force of helical coil springs in suspension design. Trans. Jpn. Soc. Spring Eng. 1996, 1996, 19–26. [Google Scholar] [CrossRef]

- Bathe, K.J.; Ozdemir, H. Elasto-plastic large deformation static and dynamic analysis. Comput. Struct. 1976, 6, 81–92. [Google Scholar]

- Sawanobori, T.; Nakamura, M. The analysis of static stress in coil springs with nonlinearity. Trans. Jpn. Soc. Mech. Eng. Ser. C 1985, 51, 3105–3108. [Google Scholar] [CrossRef][Green Version]

- Kwon, H.K.; Choi, C.S.; Chung, I.S. Helical coil springs property in Cu-Zn-Al shape memory alloy. J. Korean Soc. Heat Treat. 1996, 9, 187–197. [Google Scholar]

- Lee, J.-G.; Ahn, S.-M.; Cho, K.-J.; Cho, M. The Prediction of Nonlinear behavior of Double Coil Shape Memory Alloy Spring. J. Comput. Struct. Eng. Inst. Korea 2012, 25, 347–354. [Google Scholar] [CrossRef]

- Oh, S.H.; Choi, B.L. Analytical and Experimental Study for Development of Composite Coil Springs. Trans. Korean Soc. Mech. Eng. A 2014, 38, 31–36. [Google Scholar] [CrossRef][Green Version]

- Mcculloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Darsey, J.A.; Griffin, W.O.; Joginipelli, S.; Melapu, V.K. Architecture and Biological Applications of Artificial Neural Networks: A Tuberculosis Perspective. Methods Mol. Biol. 2015, 1260, 269–283. [Google Scholar] [CrossRef] [PubMed]

- Calvo-Pardo, H.F.; Mancini, T.; Olmo, J. Neural Network Models for Empirical Finance. J. Risk Financial Manag. 2020, 13, 265. [Google Scholar] [CrossRef]

- Lin, Y.-K.; Su, M.-C.; Hsieh, Y.-Z. The Application and Improvement of Deep Neural Networks in Environmental Sound Recognition. Appl. Sci. 2020, 10, 5965. [Google Scholar] [CrossRef]

- Wang, P.-H.; Lin, G.-H.; Wang, Y.-C. Application of Neural Networks to Explore Manufacturing Sales Prediction. Appl. Sci. 2019, 9, 5107. [Google Scholar] [CrossRef]

- Drywień, M.; Górnicki, K.; Górnicka, M. Application of Artificial Neural Network to Somatotype Determination. Appl. Sci. 2021, 11, 1365. [Google Scholar] [CrossRef]

- Bistron, M.; Piotrowski, Z. Artificial Intelligence Applications in Military Systems and Their Influence on Sense of Security of Citizens. Electronics 2021, 10, 871. [Google Scholar] [CrossRef]

- Feng, M.Q.; Bahng, E.Y. Damage assessment of jacketed RC columns using vibration tests. J. Struct. Eng. 1999, 125, 265–271. [Google Scholar] [CrossRef]

- Ghaboussi, J.; Joghataie, A. Active Control of Structures Using Neural Networks. J. Eng. Mech. 1995, 121, 555–567. [Google Scholar] [CrossRef]

- Adeli, H.; Park, H.S. A neural dynamics model for structural optimization—Theory. Comput. Struct. 1995, 57, 383–390. [Google Scholar] [CrossRef]

- Ranjithan, S.; Eheart, J.W.; Garrett, J.H. Neural network-based screening for groundwater reclamation under uncertainty. Water Resour. Res. 1993, 29, 563–574. [Google Scholar] [CrossRef]

- Chen, H.M.; Tsai, K.H.; Qi, G.Z.; Yang, J.C.S.; Amini, F. Neural Network for Structure Control. J. Comput. Civ. Eng. 1995, 9, 168–176. [Google Scholar] [CrossRef]

- Chang, S.; Sung, D. Modal-Energy-Based Neuro-Controller for Seismic Response Reduction of a Nonlinear Building Structure. Appl. Sci. 2019, 9, 4443. [Google Scholar] [CrossRef]

- Mase, H.; Sakamoto, M.; Sakai, T. Neural Network for Stability Analysis of Rubble-Mound Breakwaters. J. Waterw. Port, Coastal, Ocean Eng. 1995, 121, 294–299. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, W.S. Neural network for design and reliability analysis of rubble mound breakwaters. Ocean Eng. 2005, 32, 1332–1349. [Google Scholar] [CrossRef]

- Kim, J.-I.; Kim, D.K.; Feng, M.Q.; Yazdani, F. Application of Neural Networks for Estimation of Concrete Strength. J. Mater. Civ. Eng. 2004, 16, 257–264. [Google Scholar] [CrossRef]

- Kim, D.K.; Lee, J.J.; Lee, J.H.; Chang, S.K. Application of prediction of probabilistic neural networks of concrete strength. J. Mater. Civ. Eng. 2005, 17, 353–362. [Google Scholar] [CrossRef]

- Dorofki, M.; Elshafie, A.H.; Jaafar, O.; Karim, O.A.; Mastura, S. Comparison of artificial neural network transfer functions abilities to simulate extreme runoff data. Int. Proc. Chem. Biol. Environ. Eng. 2012, 2012, 39–44. [Google Scholar]

| Parameters | Symbols | Values | ||

|---|---|---|---|---|

| Wire diameter | d (mm) | 6 | 8 | 10 |

| Spring diameter | D (mm) | 40 | 50 | 60 |

| Yield strength | fy (MPa) | 400 | 580 | 650 |

| Number of effective windings | n (number) | 4 | 5 | 6 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | Yield Displacement (mm) |

|---|---|---|---|---|

| 6 | 40 | 580 | 4 | 19.5 |

| 8 | 40 | 400 | 4 | 10.1 |

| 8 | 60 | 650 | 4 | 34.4 |

| 10 | 60 | 580 | 4 | 25.3 |

| 6 | 60 | 400 | 5 | 35.4 |

| 8 | 50 | 650 | 5 | 30.4 |

| 10 | 50 | 580 | 5 | 22.0 |

| 6 | 50 | 400 | 6 | 30.2 |

| 8 | 40 | 650 | 6 | 23.7 |

| 10 | 40 | 580 | 6 | 17.0 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | First Stiffness (n/mm) |

|---|---|---|---|---|

| 6 | 40 | 580 | 4 | 46.1 |

| 8 | 40 | 400 | 4 | 145.8 |

| 8 | 60 | 650 | 4 | 44.9 |

| 10 | 60 | 580 | 4 | 109.7 |

| 6 | 60 | 400 | 5 | 11.5 |

| 8 | 50 | 650 | 5 | 61.9 |

| 10 | 50 | 580 | 5 | 151.5 |

| 6 | 50 | 400 | 6 | 16.4 |

| 8 | 40 | 650 | 6 | 100.4 |

| 10 | 40 | 580 | 6 | 246.0 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | Second Stiffness (n/mm) |

|---|---|---|---|---|

| 6 | 40 | 580 | 4 | 0.28 |

| 8 | 40 | 400 | 4 | 0.36 |

| 8 | 60 | 650 | 4 | 1.93 |

| 10 | 60 | 580 | 4 | 1.47 |

| 6 | 60 | 400 | 5 | 0.51 |

| 8 | 50 | 650 | 5 | 1.59 |

| 10 | 50 | 580 | 5 | 1.35 |

| 6 | 50 | 400 | 6 | 0.38 |

| 8 | 40 | 650 | 6 | 1.11 |

| 10 | 40 | 580 | 6 | 1.10 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | Yield Displacement (mm) | ||

|---|---|---|---|---|---|---|

| Target | Estimation | Error (%) | ||||

| 6 | 40 | 400 | 4 | 13.50 | 13.64 | −1.0 |

| 6 | 60 | 650 | 4 | 43.60 | 44.68 | −2.5 |

| 8 | 60 | 580 | 4 | 31.20 | 31.02 | 0.6 |

| 10 | 60 | 400 | 4 | 17.70 | 19.03 | −7.5 |

| 6 | 50 | 650 | 5 | 39.20 | 38.89 | 0.8 |

| 8 | 50 | 580 | 5 | 27.40 | 26.25 | 4.2 |

| 10 | 50 | 400 | 5 | 15.40 | 15.46 | −0.4 |

| 6 | 40 | 650 | 6 | 31.30 | 32.89 | −5.1 |

| 8 | 40 | 580 | 6 | 21.30 | 21.46 | −0.8 |

| 10 | 40 | 400 | 6 | 11.80 | 11.64 | 1.3 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | 1st Stiffness (n/mm) | ||

|---|---|---|---|---|---|---|

| Target | Estimation | Error (%) | ||||

| 6 | 40 | 400 | 4 | 46.06 | 48.06 | −4.3 |

| 6 | 60 | 650 | 4 | 14.24 | 13.45 | 5.5 |

| 8 | 60 | 580 | 4 | 44.90 | 45.58 | −1.5 |

| 10 | 60 | 400 | 4 | 109.66 | 109.42 | 0.2 |

| 6 | 50 | 650 | 5 | 19.60 | 18.00 | 8.1 |

| 8 | 50 | 580 | 5 | 61.94 | 61.87 | 0.1 |

| 10 | 50 | 400 | 5 | 151.47 | 152.58 | −0.7 |

| 6 | 40 | 650 | 6 | 31.71 | 31.71 | 0.0 |

| 8 | 40 | 580 | 6 | 100.43 | 99.81 | 0.6 |

| 10 | 40 | 400 | 6 | 246.00 | 245.64 | 0.1 |

| Wire Diameter (mm) | Internal Diameter (mm) | Yield Strength (MPa) | Number of Active Coils | 2nd Stiffness (n/mm) | ||

|---|---|---|---|---|---|---|

| Target | Estimation | Error (%) | ||||

| 6 | 40 | 400 | 4 | 0.15 | 0.17 | −18.3 |

| 6 | 60 | 650 | 4 | 1.75 | 1.93 | −10.0 |

| 8 | 60 | 580 | 4 | 1.27 | 1.25 | 1.7 |

| 10 | 60 | 400 | 4 | 0.53 | 0.56 | −5.4 |

| 6 | 50 | 650 | 5 | 1.40 | 1.42 | −1.2 |

| 8 | 50 | 580 | 5 | 1.07 | 0.94 | 11.8 |

| 10 | 50 | 400 | 5 | 0.55 | 0.58 | −5.7 |

| 6 | 40 | 650 | 6 | 0.87 | 1.04 | −19.7 |

| 8 | 40 | 580 | 6 | 0.79 | 0.76 | 3.8 |

| 10 | 40 | 400 | 6 | 0.66 | 0.65 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Cho, S.G. An Intelligent Process to Estimate the Nonlinear Behaviors of an Elasto-Plastic Steel Coil Damper Using Artificial Neural Networks. Actuators 2022, 11, 9. https://doi.org/10.3390/act11010009

Chang S, Cho SG. An Intelligent Process to Estimate the Nonlinear Behaviors of an Elasto-Plastic Steel Coil Damper Using Artificial Neural Networks. Actuators. 2022; 11(1):9. https://doi.org/10.3390/act11010009

Chicago/Turabian StyleChang, Seongkyu, and Sung Gook Cho. 2022. "An Intelligent Process to Estimate the Nonlinear Behaviors of an Elasto-Plastic Steel Coil Damper Using Artificial Neural Networks" Actuators 11, no. 1: 9. https://doi.org/10.3390/act11010009

APA StyleChang, S., & Cho, S. G. (2022). An Intelligent Process to Estimate the Nonlinear Behaviors of an Elasto-Plastic Steel Coil Damper Using Artificial Neural Networks. Actuators, 11(1), 9. https://doi.org/10.3390/act11010009