A Real-Time Realization Method for the Pneumatic Positioning System of the Industrial Automated Production Line Using Low-Cost On–Off Valves

Abstract

:1. Introduction

2. Mathematical Modeling

2.1. Modeling of the N-MOSFET

2.2. Modeling of the Electromagnetic Components in the On–Off Valve

2.3. Modeling of the Mechanical Components and Fluid System in the On–Off Valve

2.4. Modeling of the Air Chambers in the Cylinder

2.5. Modeling of the Piston in the Cylinder

2.6. Integrated Model

3. Controller Design for the Position Tracking System

3.1. Differential Switching Method

3.2. Calculation Method of the Opening Time

3.3. Sliding Mode Controller Design

3.4. Parameters Selection and Simulation Results

4. Experimental Setup

4.1. Pneumatic and Mechanical Setup

- 1.

- Air supplier. An Outstanding (model 2200X4-160L) air compressor generates the compressed air. A 160 L high-pressure gas tank is integrated with the compressor. This compressor can provide the maximum pressure of 1.2 × 106 Pa. In order to reduce the moisture condensation, a set of filter, regulator, and lubricator (FRL) is set up between the air compressor and the valves;

- 2.

- Pneumatic control components. Four Matrix (model MX 821.103C2XX) 2/2 on–off valves are installed to control the cylinder. This kind of valve can be equipped with the officially designed acceleration circuits (model HSDB 990.012), and its price (about 229 USD) is about four times that of the valve (about 54 USD) itself. Without using the acceleration circuits, the valve opening time is about 5 ms and the closing time is about 2 ms. The valves will have a response time of 1 ms in opening and 1 ms in closing after using the acceleration circuits. The goal of the article is to achieve the best control effect with minimizing costs, so the acceleration circuits are not adopted;

- 3.

- Pneumatic actuator. An Airpel double-acting single-rod cylinder (model M24D100U) is used as the actuator. The cylinder consists of a graphite piston and a borosilicate glass shell has extremely low friction. The stroke of the cylinder is 100 mm, bore diameter is 24 mm, and the rod diameter is 6.35 mm. It can bear the pressure up to 7 × 105 Pa. It has the disadvantage of large air leakage across the piston which wastes energy.

- 4.

- Mechanical setup. The piston rod of the cylinder is connected to a customized payload platform used for carrying the payloads. A payload holding rod is placed in the center of the payload platform to hold the payloads. The payload platform is installed on a HIWIN (model MGW12C) sliding table and a HIWIN (model MGW12C300C) sliding guide. The length of the sliding guide is 300 mm.

4.2. Electrical Setup

- 1.

- Industrial Controller. An NI CompactRIO (cRIO) (model 9074) is set as the major controller. NI cRIO is a reconfigurable embedded measurement and control system. It has a robust hardware architecture, including Input/Output (I/O) boards, a chassis with a reconfigurable FPGA, and a real-time controller. The used model 9074 is a low-cost model with eight-slot chassis. A personal computer (PC) is connected to the cRIO via ethernet;

- 2.

- I/O boards. An NI digital I/O board (model 9401) and an analog input board (model 9205) are selected to generate the 5V/TTL signals for the valves and acquire the signals from the sensors. The acquisition configuration for NI 9205 is differential input mode, and the resolution is 16 bit. The nominal input ranges are ±10 V, ±5 V, ±1 V, and ±0.2 V;

- 3.

- Sensors. Three MEACON (model MIK-P300) pressure sensors are used for acquiring the pressures of air supply, chamber 1, and chamber 2. A MIRAN (model KTC-100) position transmitter is set to measure the position of the piston. The resolutions for the used sensors are both customized to 0.02 × 105 Pa and 1 × 10−5 m, respectively. The output voltage range for the sensors are both 0 V to 5 V. The effective measurement range for MIK-P300 is 0 Pa to 1 × 106 Pa and for KTC-100 is 50 mm to 150 mm;

- 4.

- Power supply and other circuits. A DC power supply is used for powering the entire system. Power and sensor circuits are designed to connect various electronic components. A SANWO DC SSR (model KYOTTO KF0604D) is installed to drive the on–off valves. No acceleration circuits are used for the valves.

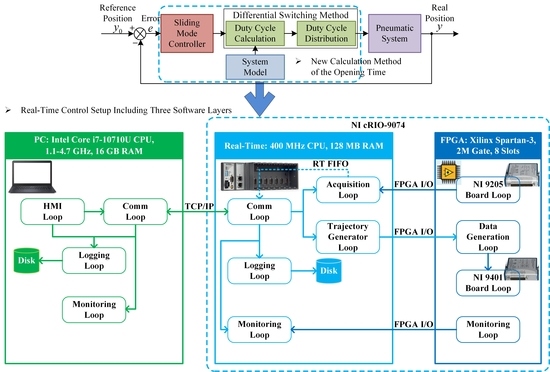

4.3. Software Platform and Real-Time Control Setup

- 1.

- Monitoring layer on PC. Since Microsoft Windows is not a real-time operating system, the LabVIEW programs running on PC cannot achieve precise timing. Therefore, the program on the PC is only for monitoring. The monitoring part is the top level of the software system, consisting of the human machine interface (HMI) loop, communication (comm) loop, logging loop, and monitoring loop. The HMI loop is only responsible for the input and output of the user, and the cycle time for the loop is 100 ms. The comm loop carries out data exchange with cRIO through Transmission Control Protocol/Internet Protocol (TCP/IP), and the cycle time can be set to the fastest to ensure real-time data transmission. The logging loop saves the data to the hard disk. Only some user operation data is saved, and sensor data is not saved here. The monitoring loop displays the data on the screen, and the cycle time can be set to 200 ms. The programming environment on PC is NI LabVIEW Professional Development System 11.0;

- 2.

- Calculation layer on NI RT. By downloading the program into NI RT which is a real-time operating system in Linux, the real-time performance of the program can be guaranteed. The calculation part is the middle level of the software system, consisting of the comm loop, trajectory generator loop, acquisition loop, logging loop, and monitoring loop. The comm loop is used to send data to PC or receive data from PC corresponding to the comm loop on PC, and the cycle time for the loop is set to the fastest. The trajectory generator loop includes the calculation of the algorithm and the model. This part is set to 20 ms. The setting of cycle time balances the computing consumption and real-time requirements. The acquisition loop is set separately. After receiving the command from the comm loop, this loop will use the RT First Input First Output (FIFO) for data collection. The RT FIFO function is used to send and receive data in a deterministic manner between VIs which represent subprograms in LabVIEW. The deterministic data transfer of the RT FIFO function does not add jitter to the cycle time of the loop. The cycle time of this loop is set to 1 ms. The logging loop will record all the acquiring data to the hard disk on cRIO, and its cycle time is 1 ms, too. The monitoring loop is the display output of the cRIO itself. Since it does not need to be used, it is disabled here. The programming environment on NI RT is NI LabVIEW Real-Time Module 11.0;

- 3.

- I/O layer on FPGA. Using FPGA as the bottom layer of the program further ensures real-time performance. I/O part consists of the NI 9205 board loop, data generation loop, NI 9401 board loop, and monitoring loop. Among them, the NI 9205 board loop is responsible for collecting the data, directly using FPGA I/O to transmit the data to the acquisition loop on NI RT. The signal generates by the NI 9401 board is from the data generation loop which works with the trajectory generator loop on NI RT. The programming environment on FPGA is NI LabVIEW FPGA Module 11.0.

4.4. Overall Setup

5. Experimental Results and Discussion

5.1. Comparative Experiments between Four Controllers

5.2. Dynamic Response Experiments

5.3. Step Response Experiments under Different Payloads

- 1.

- Differential switching method. In the proposed method, the flow difference generated by the charging and discharging valve of the single-sided chamber is used to create the pressure difference. The opening time of the four valves is strictly regulated, and calculation method of the opening time are given. The innovative method can replace the traditional PWM method and be applied with the nonlinear controller.

- 2.

- Real-time control setup. The control program is reasonably divided into three layers including monitoring layer on PC, calculation layer on NI RT, and I/O layer on FPGA. Suggested values of the cycle time for all programs are given. Assigning different cycle time to different tasks and using RT FIFO for important tasks ensure the timely response of each program and the real-time of the overall program.

6. Conclusions

- 1.

- The main limitations of the research and the future work are summarized as: The embedded control system used in this research is NI cRIO-9074. It is an expensive platform, and the price of the total platform and digital boards is about 4500 USD. Compared with other components in the system, the price of the platform can be further reduced, such as using some commercial products or developing an embedded system ourselves. To reduce the costs, MangoTree AtomRIO controller which is based on Intel Core CPU and Xilinx Spartan-LX75 FPGA is recommended for this system. The price of this plan is about 1200 USD. Since the real-time operating system (RTOS) and FPGA are needed, it is recommended to use ARM (Advanced RISC Machine) and FPGA design on the hardware architecture. A typical design is to used XILINX Zynq-7000 SoC (System on Chip). The hardware design and production costs will be reduced to about 1000 USD. So, the next step for the research is to design an embedded control system based on Zynq-7000 SoC to further reduce the costs.

- 2.

- The proposed control method is extremely dependent on the accuracy of the system model. If it needs to be used in the real engineering project, it is necessary to solve the problem that the parameters of the real system model are difficult to determine. Therefore, in the next step, we will explore how to use field-collected data for modeling, such as neural networks or deep learning methods, to ensure the performance of the controller.

- 3.

- In this research, the error value is just subtracting from the analog-to-digital converter (ADC) reading and then getting a mean value. A better way to perform the measurements is through a specialized device which is calibrated. A dial indicator is usually used in this task with adequate resolution and range. In the next step, we will carry out these measurements with a dial indicator and then trace the error curve where the error behaviour over the measurement range can be seen.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Load current of the MOSFET (A) | |

| Drivability factor of the MOSFET | |

| Drain-source voltage of the MOSFET (V) | |

| Power supply output | |

| Saturation drain-source voltage of the MOSFET (V) | |

| Gate-source voltage of the MOSFET (V) | |

| Threshold voltage of the MOSFET (V) | |

| Twice the length of the magnetic circuit in the air gap (m) | |

| Length of the magnetic circuit inside the fixed core (m) | |

| Total length of the magnetic circuit (m) | |

| Relative permeability of the fixed core | |

| Permeability of the fixed core (H/m) | |

| Permeability of the air (H/m) | |

| Number of the solenoid turns | |

| Current through the solenoid (A) | |

| Magnetic field intensity (A/m) | |

| Length of the magnetic circuit (m) | |

| Magnetic flux density (T) | |

| Permeability of the medium (H/m) | |

| Magnetic flux (Wb) | |

| Cross-sectional area of the flux path (m2) | |

| Magnetic flux of the magnetic circuit (Wb) | |

| Effective cross-sectional area of the flux path (m2) | |

| Solenoid resistance (Ω) | |

| Solenoid inductance (H) | |

| Moving distance of the spool (m) | |

| Maximum moving distance of the spool (m) | |

| Magnetic attraction force of the solenoid (N) | |

| Mass of the spool (kg) | |

| Damping coefficient of the spool ((N·s)/m) | |

| Force affected by the input and output pressure of the valve (N) | |

| and | Effective area differences of the input and output port in the valve (m2) |

| and | Input and output pressure of the valve (Pa) |

| Spring force in the valve (N) | |

| Spring coefficient in the valve (N/m) | |

| Spring pre-tension in the valve (m) | |

| Mass flow rate constant(kg/(Pa·s)) | |

| Atmospheric temperature (K) | |

| Air-supply temperature (K) | |

| Pressure ratio | |

| Air-supply pressure (Pa) | |

| Atmosphere pressure (Pa) | |

| Specific heat ratio | |

| Ideal gas constant (kJ/(kg·K)) | |

| , , , and | Mass flow rate through the four valves (kg/s) |

| , , , and | Control signals of the four valves (V) |

| and | Mass flow rate for chambers 1 and 2 (kg/s) |

| and | Pressure of the chamber (Pa) |

| and | Volume of the chamber (m3) |

| and | Mass of the gas in the chamber (kg) |

| and | Temperature inside the chamber (K) |

| Half of the cylinder stroke (m) | |

| Piston displacement (m) | |

| and | Effective area of the left and right chambers (m2) |

| Total mass of the piston and the payloads (kg) | |

| Damping coefficient of the cylinder piston ((N·s)/m) | |

| Stiction force (N) | |

| External force produced by the atmosphere acted on the piston rod (N) | |

| Duration of the control pulse (s) | |

| PWM period (s) | |

| PWM duty cycle | |

| Synchronized opening time (s) | |

| Differential opening time (s) | |

| Stable pressure of the chamber (Pa) | |

| and | Minimum opening and closing times of the valve (s) |

| Total pressure variation of each PWM cycle (Pa) | |

| Displacement error of the cylinder piston (m) | |

| Desired piston displacement (m) | |

| Sliding function | |

| Sliding function parameter | |

| and | Exponential approaching parameters |

| Output of the controller | |

| Lyapunov-like function | |

| PID control output | |

| , , and | Proportional, integral, and derivative parameters |

| Minimum absolute error (m) |

References

- Hadi, H.H.; Sallom, M.Y. Pneumatic Control System of Automatic Production Line Using SCADA Implement PLC. In Proceedings of the 2019 4th Scientific International Conference Najaf (SICN), Al-Najef, Iraq, 29–30 April 2019; pp. 37–42. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y. PLC Control System of Pneumatic Manipulator Automatic Assembly Line Based on Cloud Computing Platform. J. Phys. Conf. Ser. 2021, 1744, 022011. [Google Scholar] [CrossRef]

- Zhao, S.; Li, D.; Zhou, J.; Sha, E. Numerical and Experimental Study of a Flexible Trailing Edge Driving by Pneumatic Muscle Actuators. Actuators 2021, 10, 142. [Google Scholar] [CrossRef]

- Cantoni, C.; Gobbi, M.; Mastinu, G.; Meschini, A. Brake and pneumatic wheel performance assessment—A new test rig. Measurement 2019, 150, 107042. [Google Scholar] [CrossRef]

- Lu, S.; Chen, D.; Hao, R.; Luo, S.; Wang, M. Design, fabrication and characterization of soft sensors through EGaIn for soft pneumatic actuators. Measurement 2020, 164, 107996. [Google Scholar] [CrossRef]

- Belforte, G.; Mauro, S.; Mattiazzo, G. A method for increasing the dynamic performance of pneumatic servosystems with digital valves. Mechatronics 2004, 14, 1105–1120. [Google Scholar] [CrossRef]

- Carneiro, J.F.; De Almeida, F.G. Accurate motion control of a servopneumatic system using integral sliding mode control. Int. J. Adv. Manuf. Technol. 2014, 77, 1533–1548. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Najafi, F.; Ghaffari, A. Multimodel PD-control of a pneumatic actuator under variable loads. Int. J. Adv. Manuf. Technol. 2009, 48, 655–662. [Google Scholar] [CrossRef]

- Systems, Solutions and Expertise for the Automotive and Tier 1 Supplier Industry. Available online: https://www.festo.com/net/SupportPortal/Files/467715/PO-for-the-automotive-Tier1-supplier-industry_EN_2016-07c.pdf (accessed on 1 July 2016).

- Noritsugu, T. Development of PWM mode electro-pneumatic servomechanism. I: Speed control of a pneumatic cylinder. J. Fluid Control 1986, 17, 65–80. [Google Scholar]

- Zhang, J.; Lv, C.; Yue, X.; Li, Y.; Yuan, Y. Study on a linear relationship between limited pressure difference and coil current of on/off valve and its influential factors. ISA Trans. 2013, 53, 150–161. [Google Scholar] [CrossRef] [PubMed]

- Van Varseveld, R.; Bone, G. Accurate position control of a pneumatic actuator using on/off solenoid valves. IEEE/ASME Trans. Mechatron. 1997, 2, 195–204. [Google Scholar] [CrossRef]

- Ming-Chang, S.; Ming-An, M. Position Control of a Pneumatic Rodless Cylinder Using Sliding Mode M-D-PWM Control the High Speed Solenoid Valves. JSME Int. J. Ser. C 1998, 41, 236–241. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Zhang, T.; Xie, Q. Intelligent real-time pressure tracking system using a novel hybrid control scheme. Trans. Inst. Meas. Control 2017, 40, 3744–3759. [Google Scholar] [CrossRef]

- Thanh, T.D.C.; Ahn, K.K. Nonlinear PID control to improve the control performance of 2 axes pneumatic artificial muscle manipulator using neural network. Mechatronics 2006, 16, 577–587. [Google Scholar] [CrossRef]

- Lin, Z.; Wei, Q.; Ji, R.; Huang, X.; Yuan, Y.; Zhao, Z. An Electro-Pneumatic Force Tracking System using Fuzzy Logic Based Volume Flow Control. Energies 2019, 12, 4011. [Google Scholar] [CrossRef] [Green Version]

- Hodgson, S.; Le, M.Q.; Tavakoli, M.; Pham, M.T. Improved tracking and switching performance of an electro-pneumatic positioning system. Mechatronics 2012, 22, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Hodgson, S.; Tavakoli, M.; Pham, M.T.; Lelevé, A. Nonlinear Discontinuous Dynamics Averaging and PWM-Based Sliding Control of Solenoid-Valve Pneumatic Actuators. IEEE/ASME Trans. Mechatron. 2014, 20, 876–888. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.; Leavitt, J.; Jabbari, F.; Bobrow, J.E. Accurate Sliding-Mode Control of Pneumatic Systems Using Low-Cost Solenoid Valves. IEEE/ASME Trans. Mechatron. 2007, 12, 216–219. [Google Scholar] [CrossRef]

- Lin, C.-J.; Sie, T.-Y.; Chu, W.-L.; Yau, H.-T.; Ding, C.-H. Tracking Control of Pneumatic Artificial Muscle-Activated Robot Arm Based on Sliding-Mode Control. Actuators 2021, 10, 66. [Google Scholar] [CrossRef]

- dos Santos, M.P.S.; Ferreira, J.A.F. Novel intelligent real-time position tracking system using FPGA and fuzzy logic. ISA Trans. 2014, 53, 402–414. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, T.; Xie, Q.; Wei, Q. Electro-pneumatic position tracking control system based on an intelligent phase-change PWM strategy. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 512. [Google Scholar] [CrossRef]

- Sakurai, T.; Newton, A. Alpha-power law MOSFET model and its applications to CMOS inverter delay and other formulas. IEEE J. Solid-State Circuits 1990, 25, 584–594. [Google Scholar] [CrossRef] [Green Version]

- Taghizadeh, M.; Ghaffari, A.; Najafi, F. Modeling and identification of a solenoid valve for PWM control applications. Comptes Rendus Mec. 2009, 337, 131–140. [Google Scholar] [CrossRef]

- Beater, P. Pneumatic Drives: System Design, Modelling and Control, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 11–39. [Google Scholar] [CrossRef]

- Richer, E.; Hurmuzlu, Y. A High Performance Pneumatic Force Actuator System: Part I—Nonlinear Mathematical Model. J. Dyn. Syst. Meas. Control. 1999, 122, 416–425. [Google Scholar] [CrossRef]

- Ioannou, P.; Sun, J. Robust Adaptive Control, 1st ed.; Prentice Hall PTR: Hoboken, NJ, USA, 1996; pp. 75–76. [Google Scholar]

- Lin, Z.; Zhang, T.; Xie, Q.; Wei, Q. Intelligent Electro-Pneumatic Position Tracking System Using Improved Mode-Switching Sliding Control With Fuzzy Nonlinear Gain. IEEE Access 2018, 6, 34462–34476. [Google Scholar] [CrossRef]

| Symbol | System Parameters | Value |

|---|---|---|

| / | Ode solver | Ode-45 (Dormand–Prince) |

| / | Variable step | 1 × 10−4 s to 2 × 10−4 s |

| Air-supply pressure | 3 × 105 Pa | |

| Atmosphere pressure | 1 × 105 Pa | |

| Air-supply temperature | 293.15 K | |

| Specific heat ratio | 1.4 | |

| Ideal gas constant | 0.287 kJ/(kg·K) | |

| Mass flow rate constant | 3.4 × 10−9 kg/(Pa·s) | |

| Pressure ratio | 0.528 | |

| Number of the solenoid turns | 1.05 × 104 | |

| Solenoid resistance | 10 Ω | |

| Length of the magnetic circuit inside the fixed core | 0.1 m | |

| Relative permeability of the fixed core | 110 | |

| Effective cross-sectional area of the flux path | 8.5 × 10−5 m2 | |

| Maximum moving distance of the spool | 3.2 × 10−4 m | |

| Damping coefficient of the spool | 0.21 (N·s)/m | |

| Spring coefficient in the valve | 1 × 104 N/m | |

| Spring pre-tension in the valve | 0.001 m | |

| and | Effective area of the left and right chambers | 4.53 × 10−4 m2 and 4.03 × 10−4 m2 |

| Damping coefficient of the cylinder piston | 46 (N·s)/m | |

| Half of the cylinder stroke | 0.05 m |

| Forward | Stop | Backward | |

|---|---|---|---|

| Valve 1 | 0 | ||

| Valve 2 | 0 | ||

| Valve 3 | 0 | ||

| Valve 4 | 0 |

| SMC+DS | PID+DS | PID+PWM | MBC7 | |

|---|---|---|---|---|

| Rising time (average) | 0.31 s | 0.35 s | 0.36 s | 0.33 s |

| Overshoot (average) | 0.83% | 3.33% | 5.57% | 2.93% |

| Steady-state error (average) | 0.18 mm | 0.25 mm | 0.28 mm | 0.21 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Xie, Q.; Qian, Q.; Zhang, T.; Zhang, J.; Zhuang, J.; Wang, W. A Real-Time Realization Method for the Pneumatic Positioning System of the Industrial Automated Production Line Using Low-Cost On–Off Valves. Actuators 2021, 10, 260. https://doi.org/10.3390/act10100260

Lin Z, Xie Q, Qian Q, Zhang T, Zhang J, Zhuang J, Wang W. A Real-Time Realization Method for the Pneumatic Positioning System of the Industrial Automated Production Line Using Low-Cost On–Off Valves. Actuators. 2021; 10(10):260. https://doi.org/10.3390/act10100260

Chicago/Turabian StyleLin, Zhonglin, Qi Xie, Qiang Qian, Tianhong Zhang, Jiaming Zhang, Jiaquan Zhuang, and Weixiong Wang. 2021. "A Real-Time Realization Method for the Pneumatic Positioning System of the Industrial Automated Production Line Using Low-Cost On–Off Valves" Actuators 10, no. 10: 260. https://doi.org/10.3390/act10100260

APA StyleLin, Z., Xie, Q., Qian, Q., Zhang, T., Zhang, J., Zhuang, J., & Wang, W. (2021). A Real-Time Realization Method for the Pneumatic Positioning System of the Industrial Automated Production Line Using Low-Cost On–Off Valves. Actuators, 10(10), 260. https://doi.org/10.3390/act10100260