A Solar Thermal Application for Mongolian Detached Houses: An Energy, Environmental, and Economic Analysis Based on Dynamic Simulations

Abstract

1. Introduction

- Electric heaters increase the electric peaks demand by a significant amount during the cold period causing frequent blackouts, which are currently one of the most relevant problems in Mongolia [4].

- The annual current expenses associated with the use of electric heaters are relatively high for people who live in a detached house, in comparison with those associated with the adoption of a coal-burning stove.

- The maximum power load for households in the Ger districts of Ulaanbaatar is generally lower than 4 kW [5]. Therefore, using a fully electric heating system would require upgrading the power level supplied by the local electric utility to the end-users.

- Centralized power plants in Mongolia use coal to produce electricity, which implies that the application of electric heaters does not contribute to the reduction of global CO2 equivalent emissions (even if it decreases the local air pollution), in comparison to distributed coal-burning stoves with a greater conversion efficiency.

- To propose an innovative solar thermal system for Mongolian applications potentially capable of mitigating the energy, environmental and economic effects of traditional Mongolian heating systems;

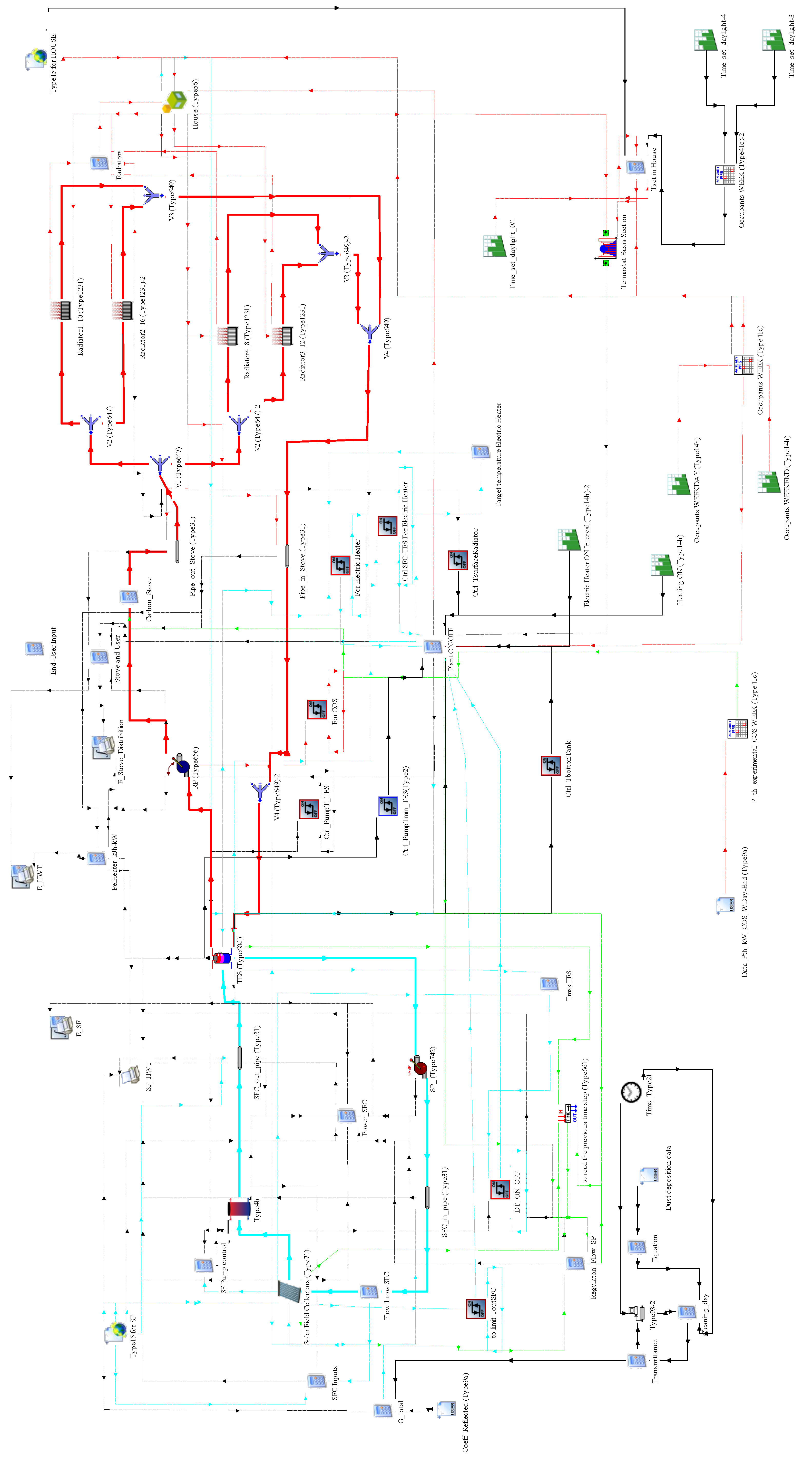

- To develop a simulation model to predict the performance of the proposed solar thermal system in Mongolia under different operating conditions and control logics;

- To assess the feasibility of using solar thermal collectors during the heating period for Mongolian applications;

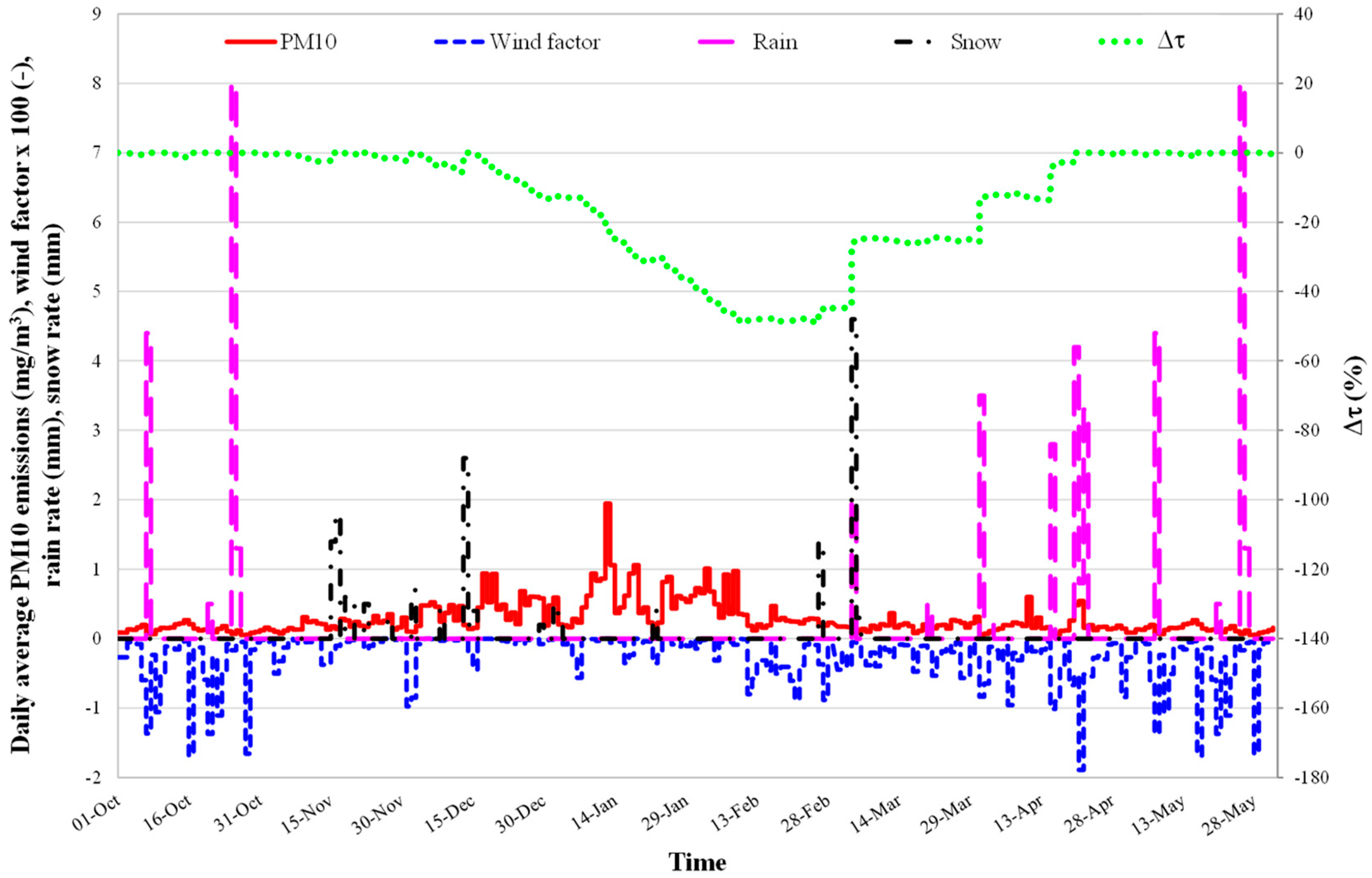

- To estimate the degrading effects of dust deposition on the glazing of solar thermal collectors on the overall performance of the proposed heating plant;

- To assess the potential benefits associated with the proposed plant with respect to the current Mongolian scenario from energy, environmental and economic points of view.

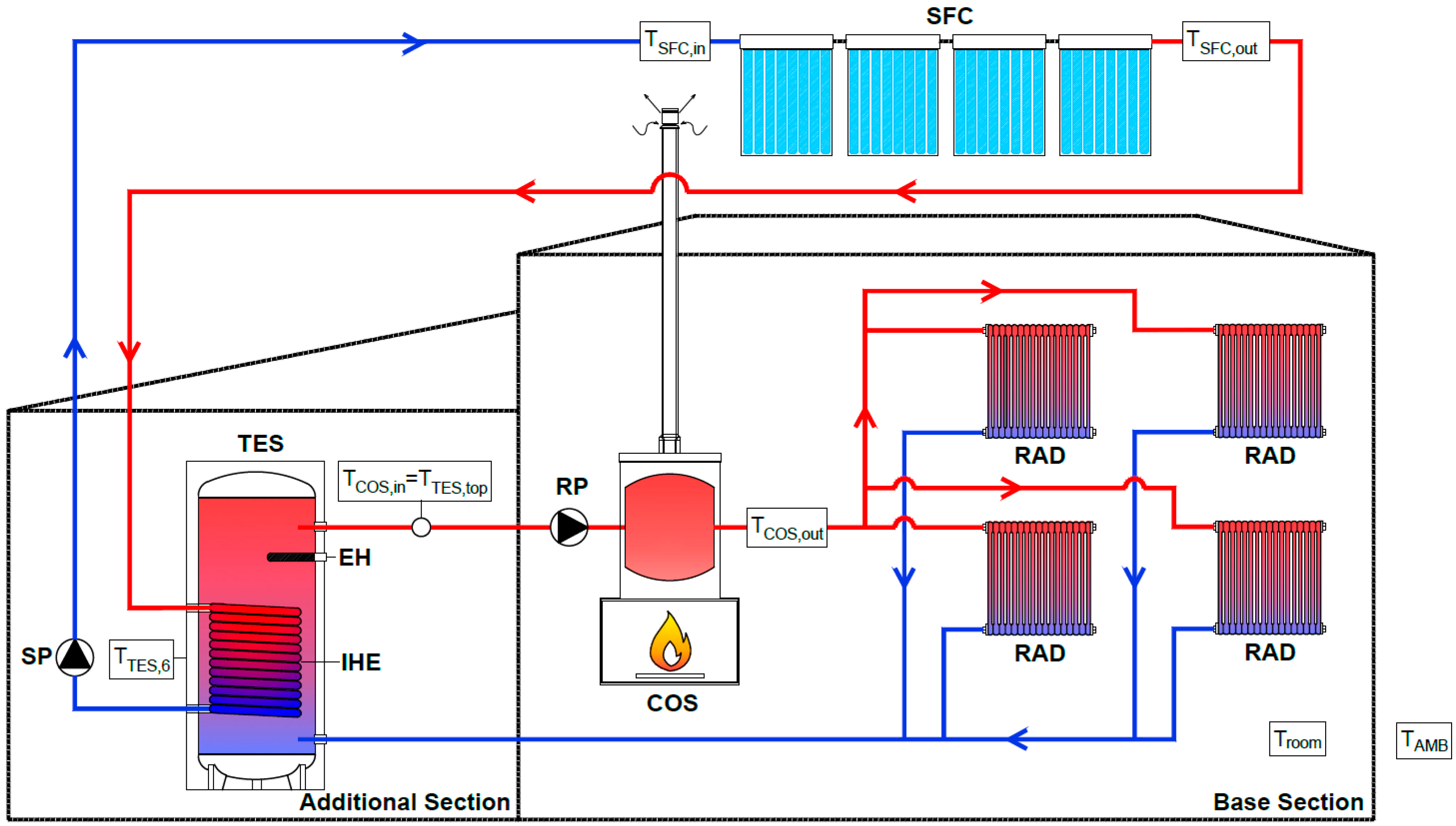

2. Description of the Proposed Plant

- The solar thermal collectors circuit (including the solar thermal panels, the solar circuit pump and the heat exchanger immersed into the storage);

- The space heating circuit (including the tank, the coal stove, the radiators circuit pump as well as the radiators).

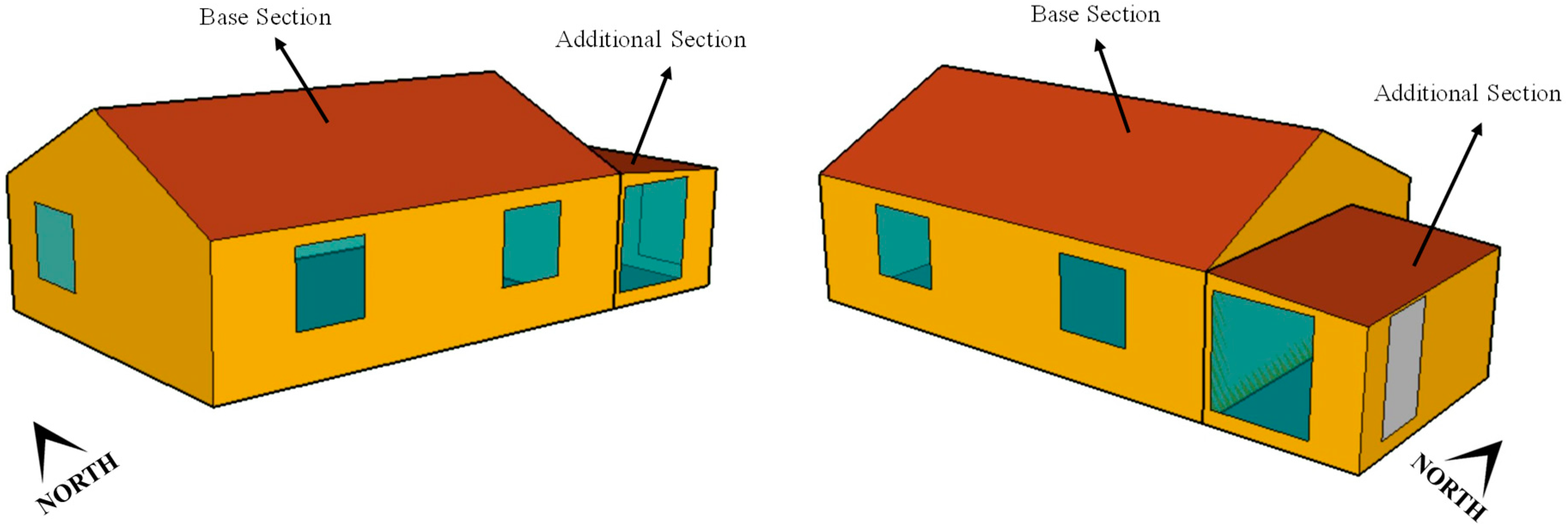

2.1. Description of the Detached House

- A base section, with a total floor area of 48 m2 and a volume of 144.0 m3;

- An additional section, with a total floor area of 10 m2 and a volume of 22.1 m3.

2.2. Description of the Thermal Energy Storage

2.3. Description of the Solar Thermal Collectors Circuit

2.4. Description of the Solar Thermal Collectors Circuit

- -

- PCOS,th is the thermal power produced by the stove;

- -

- , ρw, cw and vw represent, respectively, the volumetric flow rate, the density, the specific heat and the velocity of the heat carrier fluid flowing inside the stove;

- -

- A is the area of cross section of the tube inside which the heat carrier fluid is flowing;

- -

- TCOS,out and TCOS,in are, respectively, the temperature of the heat carrier fluid at the inlet and outlet of the stove.

2.5. Description of Radiators

2.6. Description of Auxiliaries

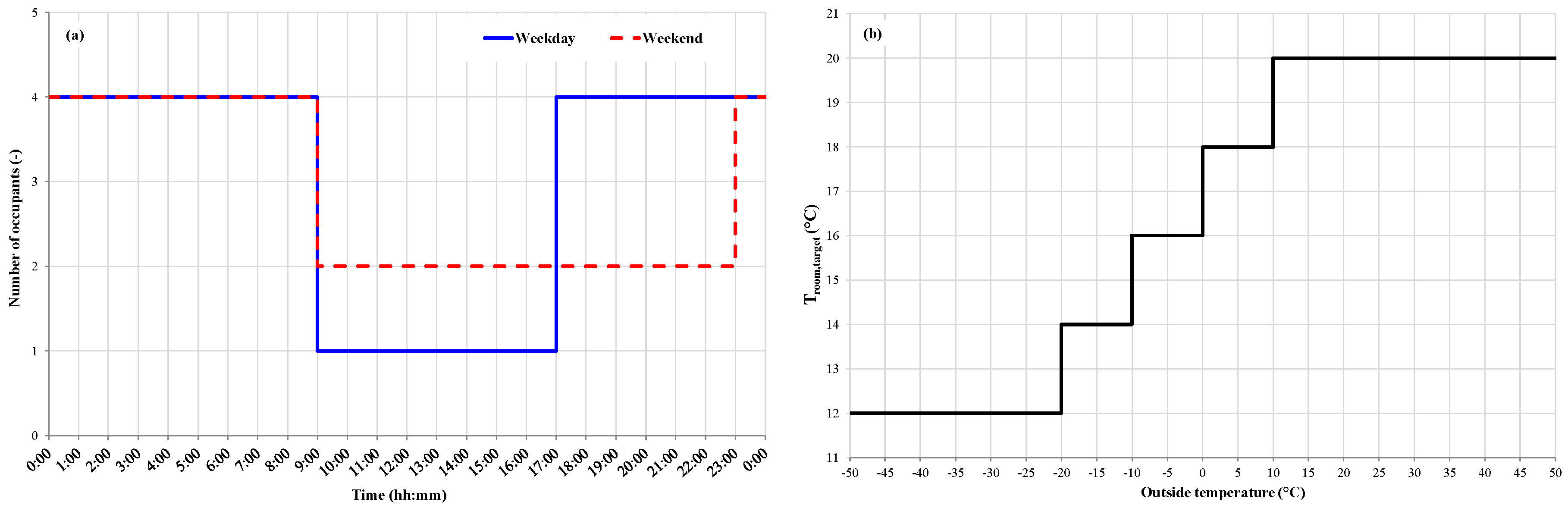

2.7. Description of Control Logics

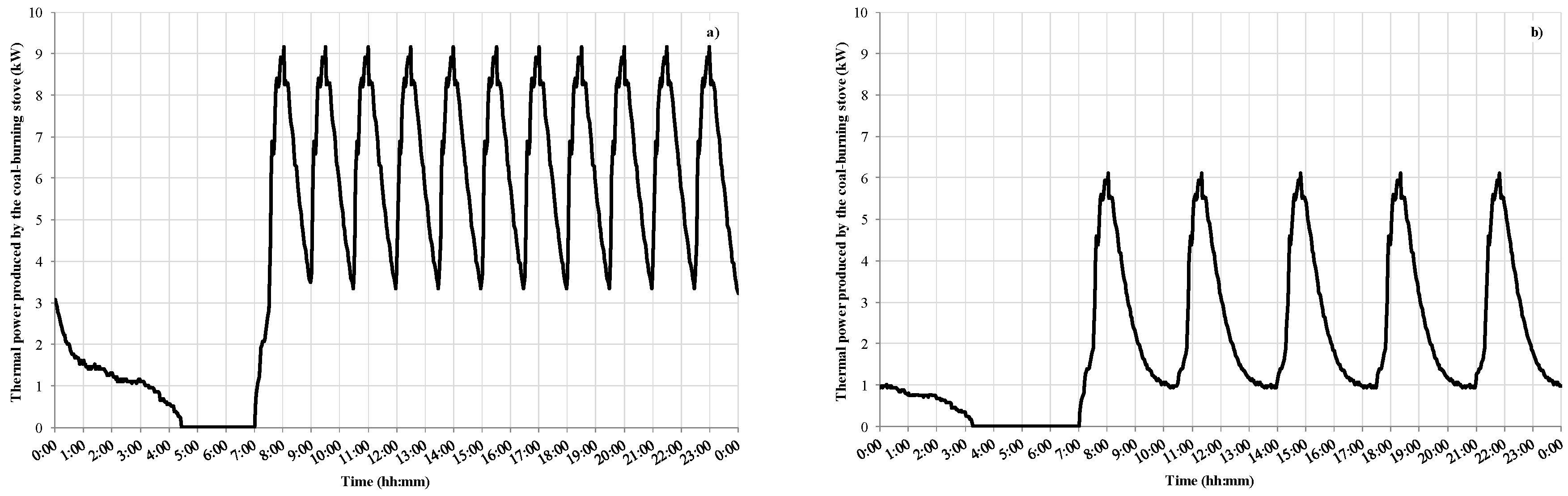

- 7.00 a.m., 4.00 p.m., 8.00 p.m. (in the case of the soiling effects are neglected);

- 7.00 a.m., 10.00 a.m., 4.00 p.m., 8.00 p.m. (in the case of the soiling effects are taken into account).

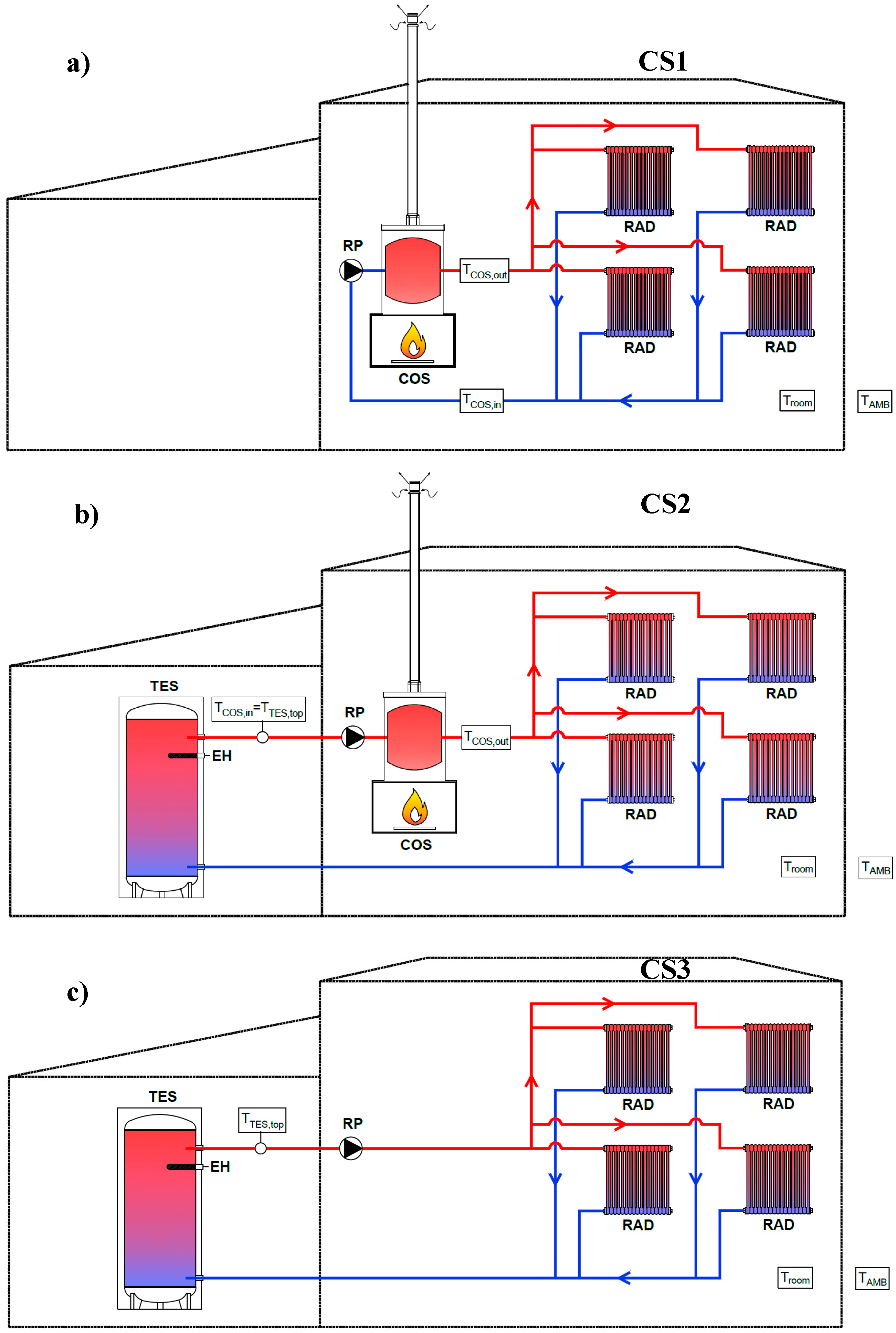

3. Reference Systems

4. Methods of Analysis

4.1. Energy Analysis

4.2. Environmental Analysis

4.3. Economic Analysis

- CCPS is the capital cost of the proposed system;

- CCCS represents the capital costs of the conventional systems;

- OCPS is the operating cost of the proposed system due to the consumption of electricity and coal Equation (21);

- OCCS represents the operating costs of the conventional systems (Equation (22) for CS1, Equation (23) for CS2, Equation (24) for CS3).

- CCSFC is the capital cost of the four series-connected evacuated tube heat pipe collectors (assumed equal to 12 €/tube, according to the values suggested by Ramos et al. [56], for a total cost of the entire solar field equal to 1440 €);

- CCTES is the capital cost of the thermal energy storage (assumed equal to 1000 €, according to manufacturer data [57]);

- CCCOS_6kW represents the capital cost of the 6 kWth coal-burning stove (assumed equal to 190 €, according to manufacturer data [44]);

- CCCOS_9kW represents the capital cost of the 9 kWth coal-burning stove (assumed equal to 250 €, according to manufacturer data [44]);

- CCEH_3kW is the capital cost of the 3 kWel electric heater (assumed equal to 200 €, according to manufacturer data [57]);

- CCEH_9kW is the capital cost of the 9 kWel electric heater (assumed equal to 250 €, according to manufacturer data [57]);

- CCSP is the capital cost of the solar pump and controller (assumed equal to 360 €, according to the values suggested by Ramos et al. [56]);

- CCRP is the capital cost of the radiators pump (assumed equal to 167 €, according to the values suggested by Ramos et al. [56]).

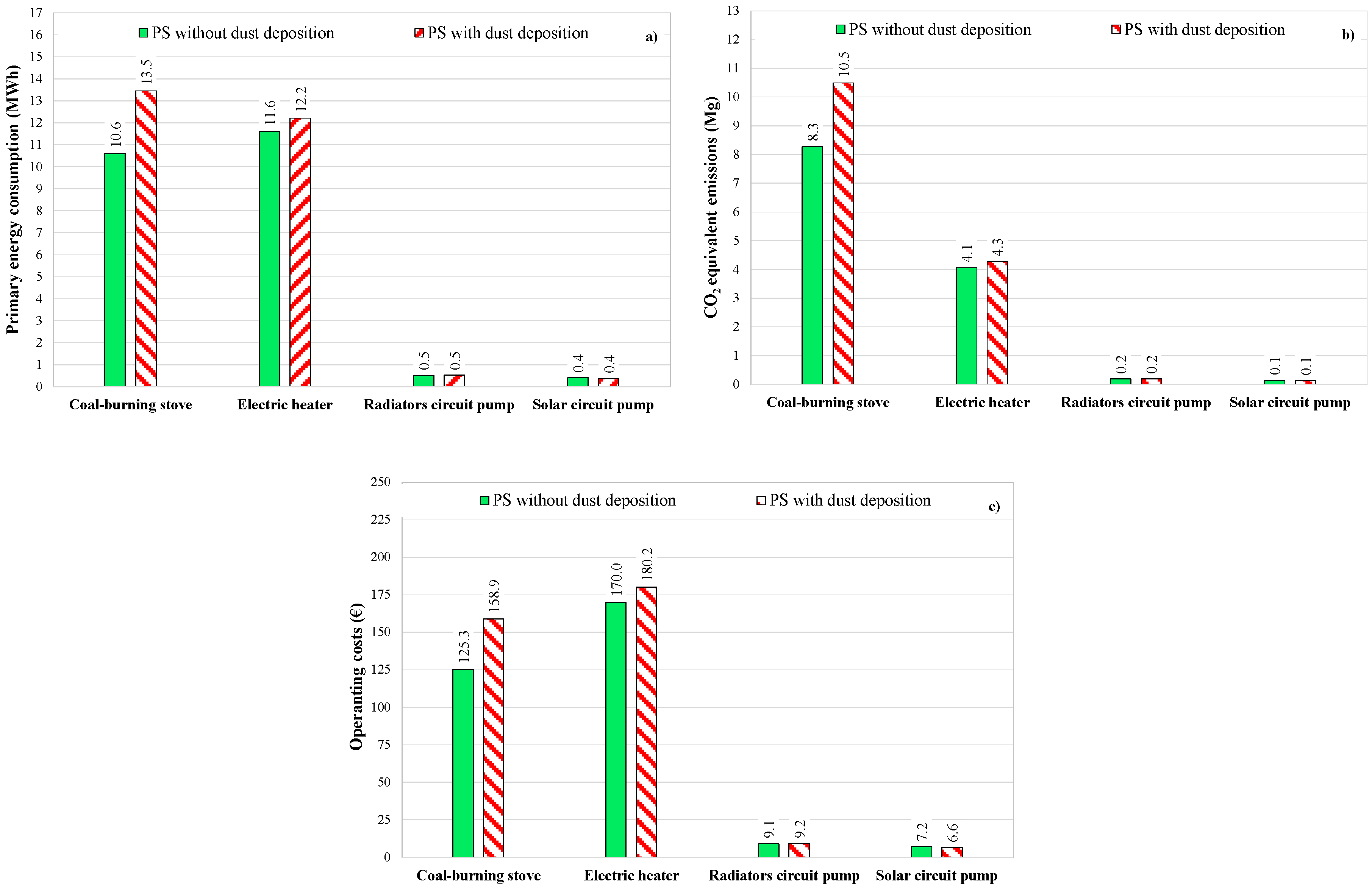

5. Results and Discussion

- case (1)

- The dust deposition effects on the performance of the solar thermal collectors are neglected by assuming the glass tubes perfectly clean during the whole heating season;

- case (2)

- The dust deposition effects on the performance of the solar thermal collectors are taken into account by means of Equation (2) as a function of the operating conditions.

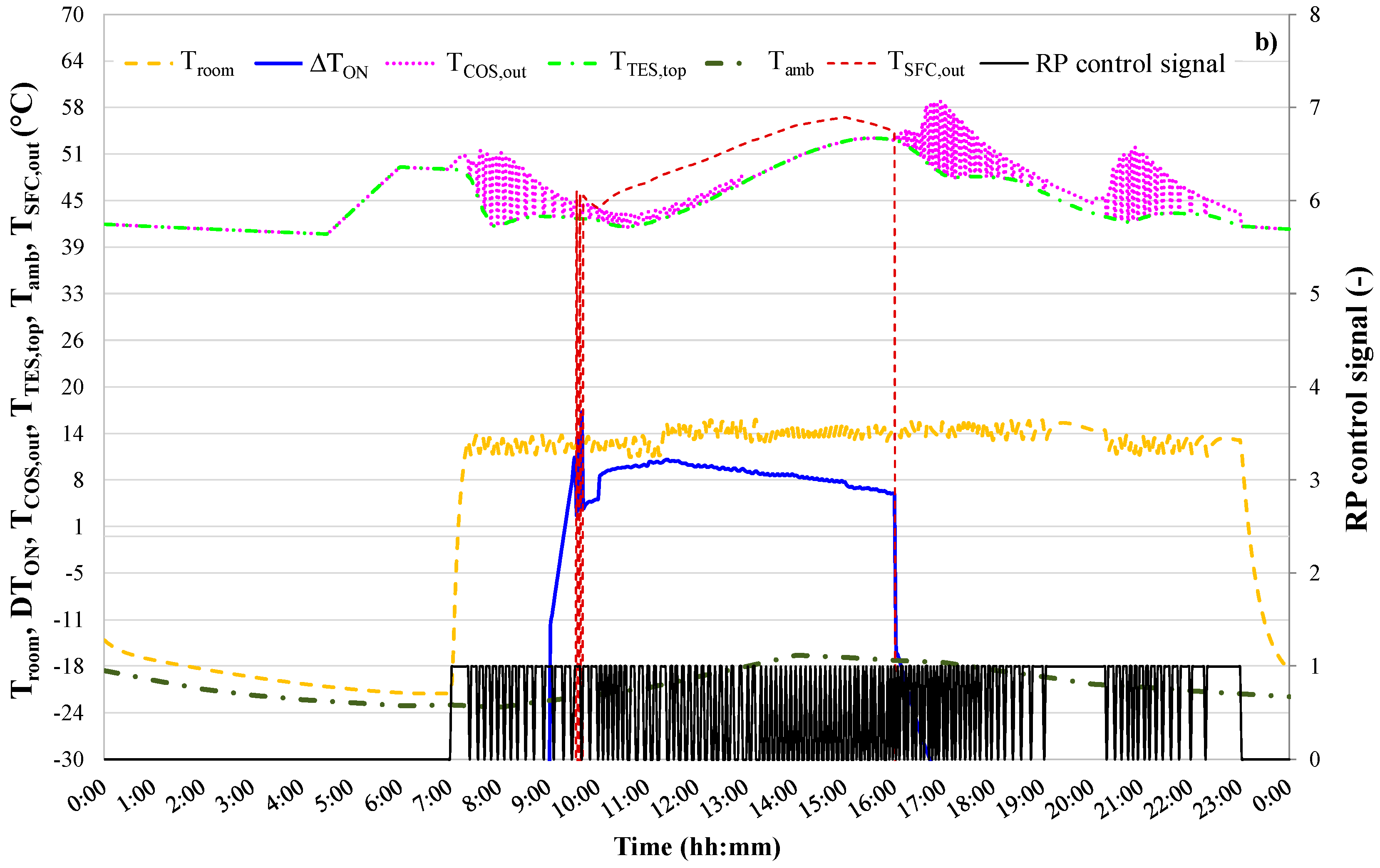

- The indoor air temperature Troom is generally within the desirable thermal comfort levels indicated in Figure 4b as a function of Tamb;

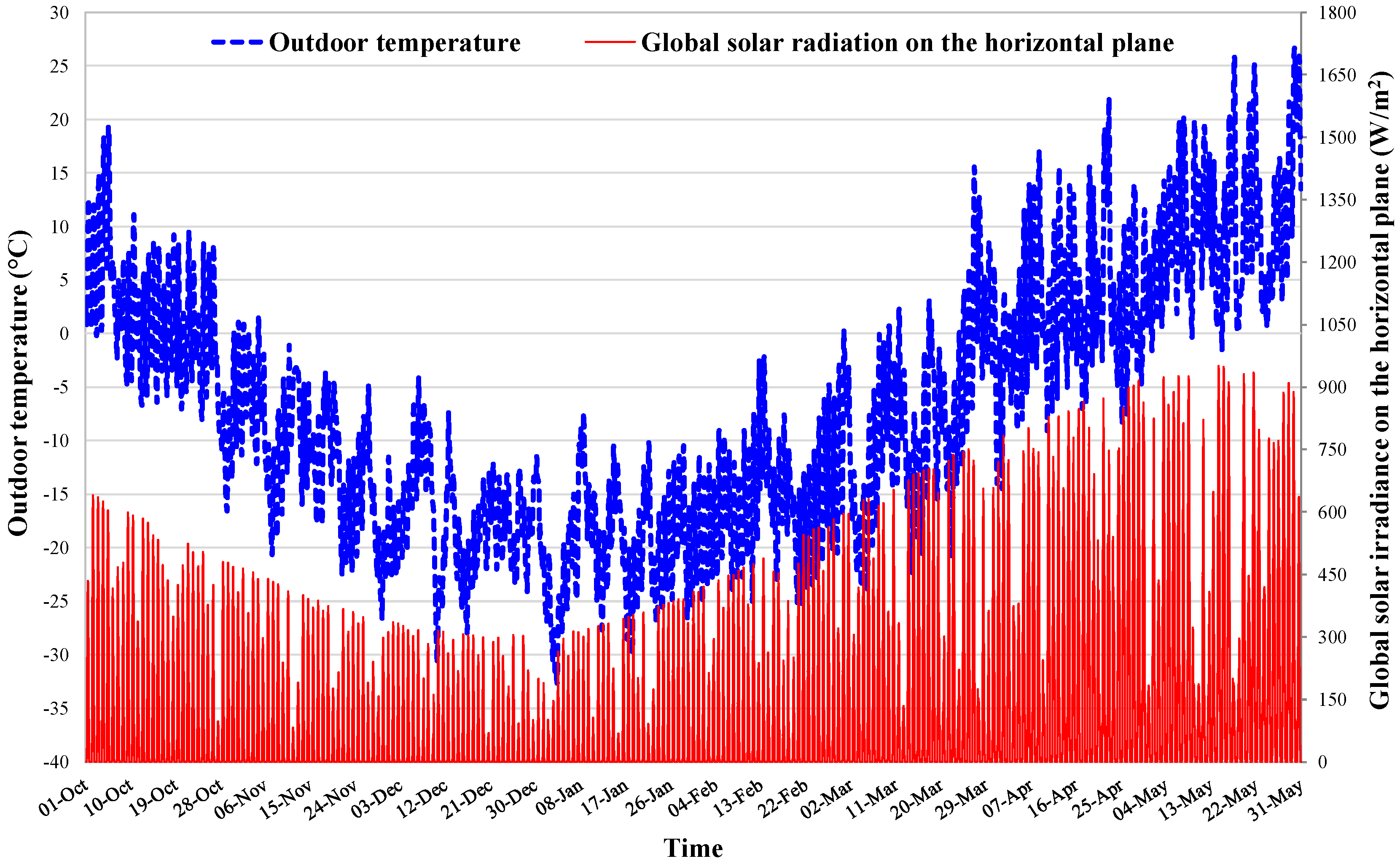

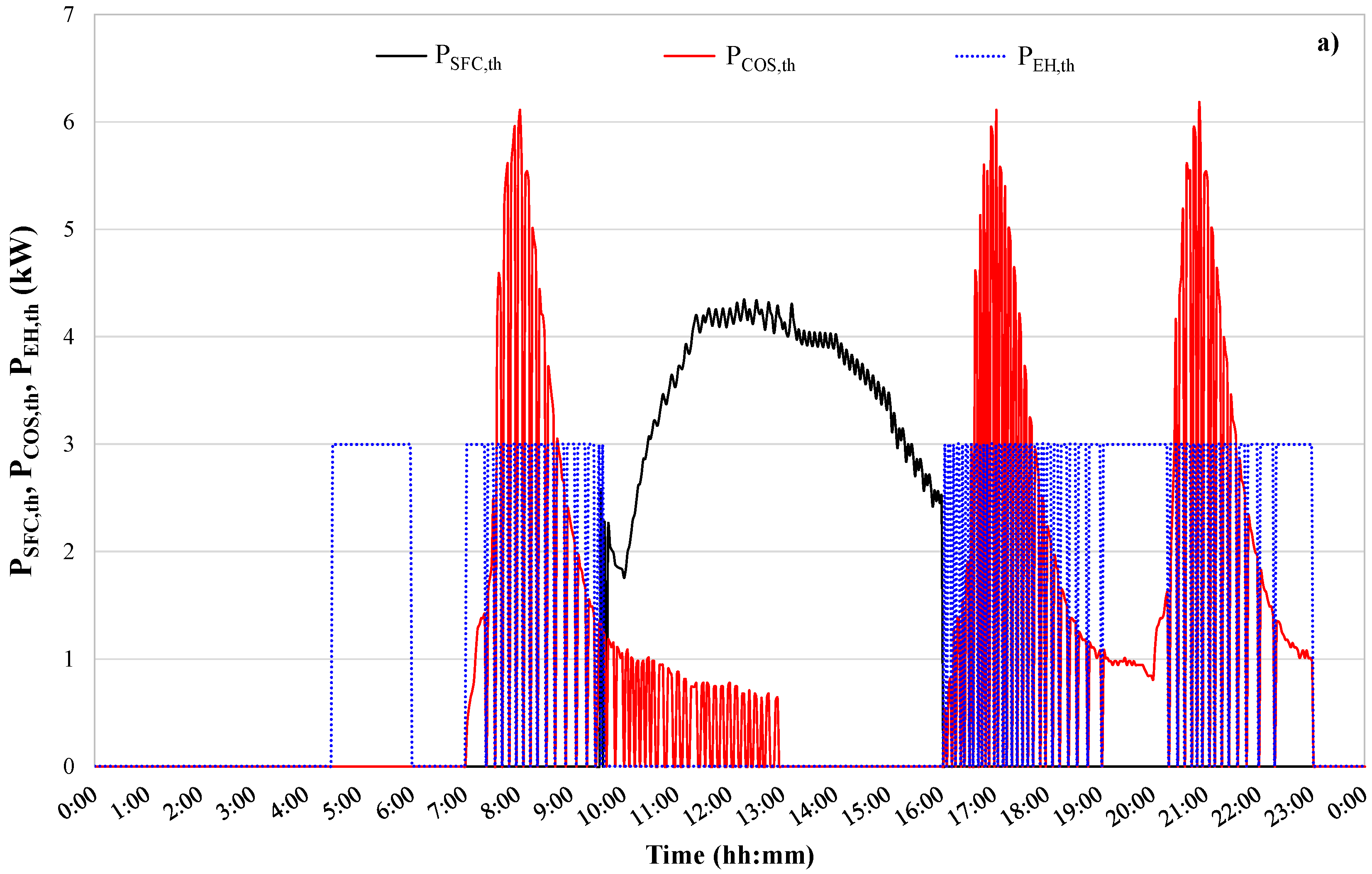

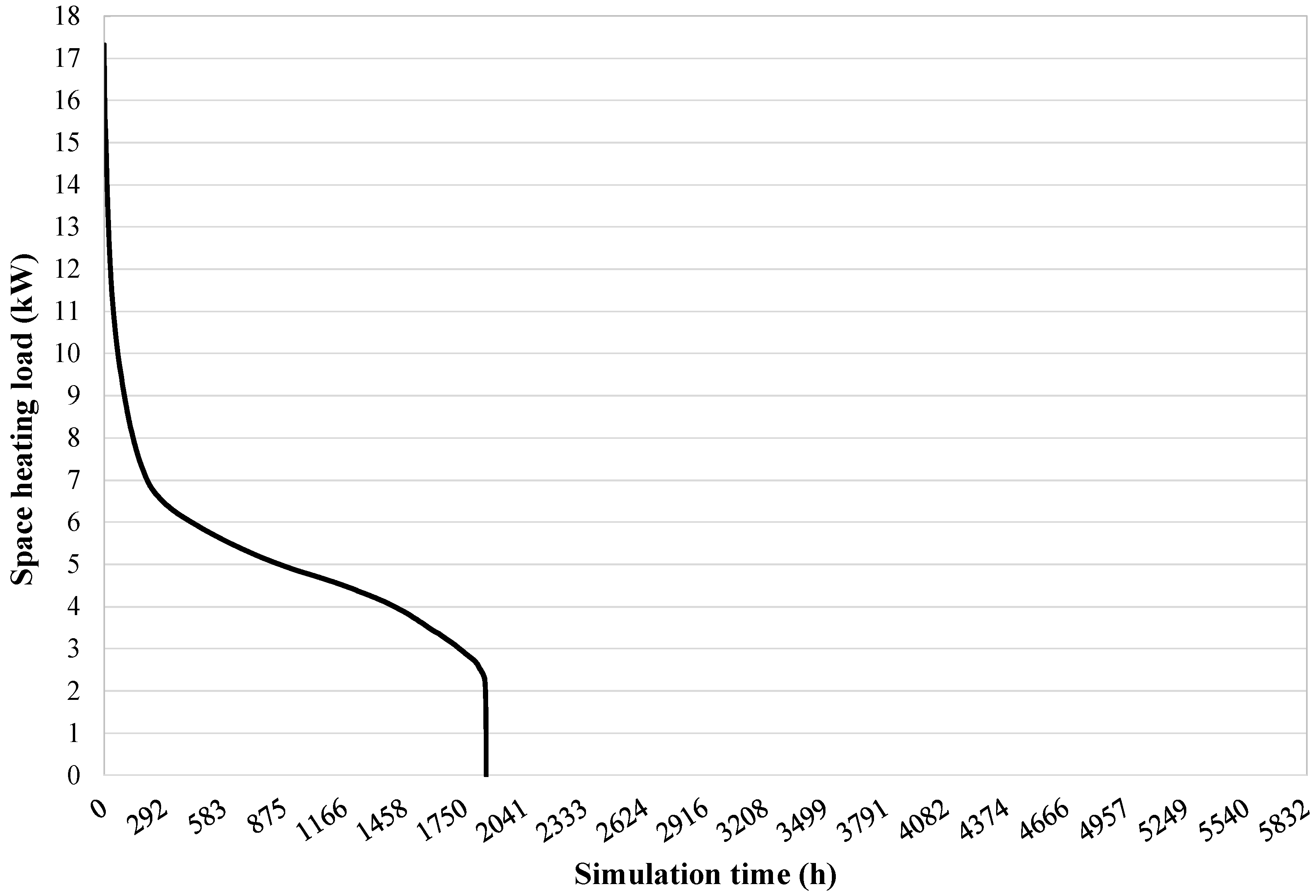

- Solar energy is recovered by the solar thermal collectors only from approximately 9:25 up to approximately 16:00, i.e., when the switch-on temperature difference ∆TON is higher than 8.0 °C. The solar circuit pump is switched off in the case of ∆TON becomes lower than 4.0 °C. The maximum thermal power recovered by the solar field is approximately 4.3 kW, while the maximum temperature at the outlet of solar thermal collectors is equal to approximately 56 °C;

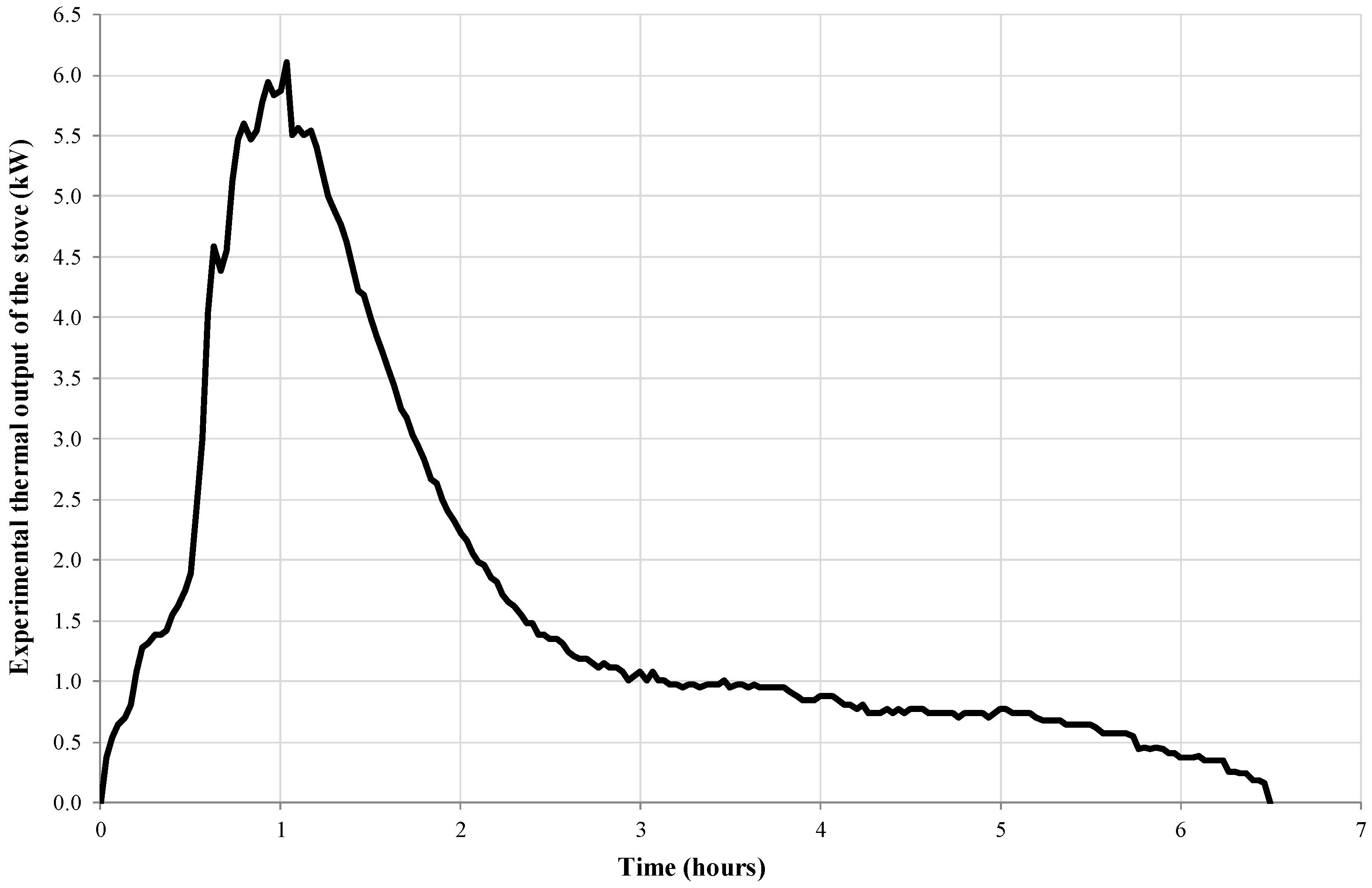

- The coal-burning produces the thermal power reported in Figure 7a, but its thermal output is delivered to the space heating circuit only when the radiators pump is on (RP control signal = 1);

- The maximum temperature at the outlet of the coal-burning stove is 58.2 °C;

- The temperature at the top of the thermal energy storage is between 40.0 °C and 53.4 °C due to the contributions of the solar field, the electric heater as well as the stove.

- The contribution of the solar source is significant when taking into account that the solar energy recovered from the solar thermal collectors and then injected into the storage is equal to approximately 38.0% of the total thermal energy supplied by the combination of solar source, electric heater and stove. The remaining thermal energy required for heating purposes is supplied by both the electric heater (by approximately 32.2%) as well as the coal-burning stove (by approximately 29.8%);

- The electricity consumption of both pumps is not negligible, with it representing approximately 7.4% of the overall electric demand due to both pumps and electric heater (with the electric energy consumed by the radiators circuit pump approximately 27.6% greater than that one required by the solar circuit pump);

- The heat losses associated with the pipes of both the solar circuit as well as the radiators circuit are relevant (approximately 20.3% of the overall thermal energy demand of the house).

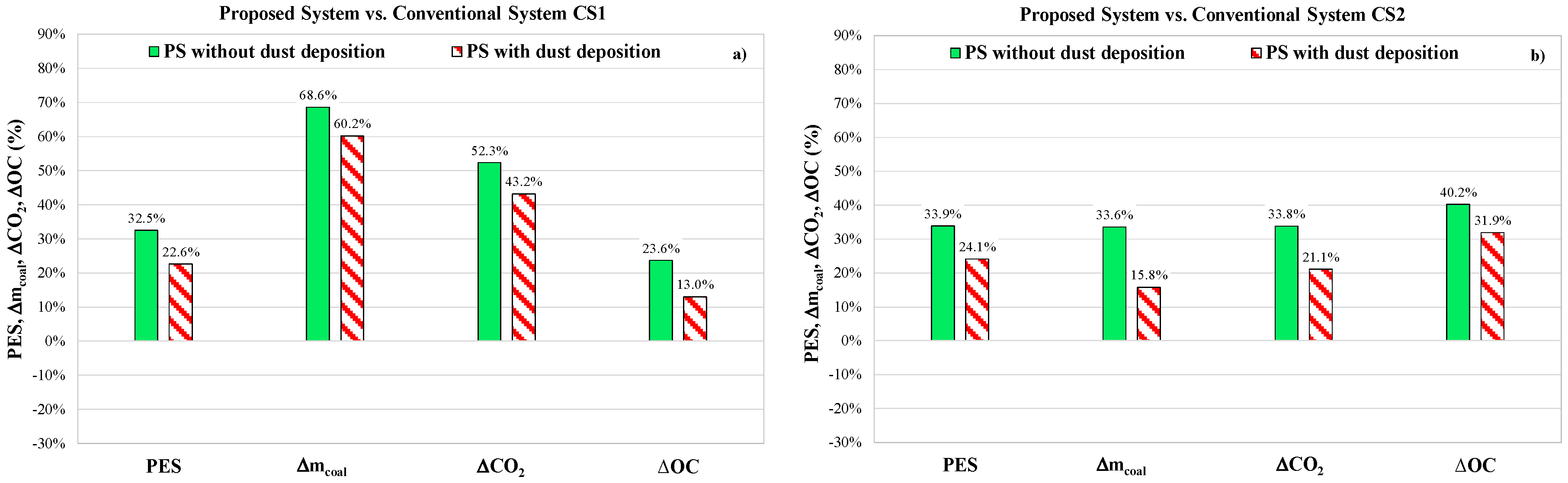

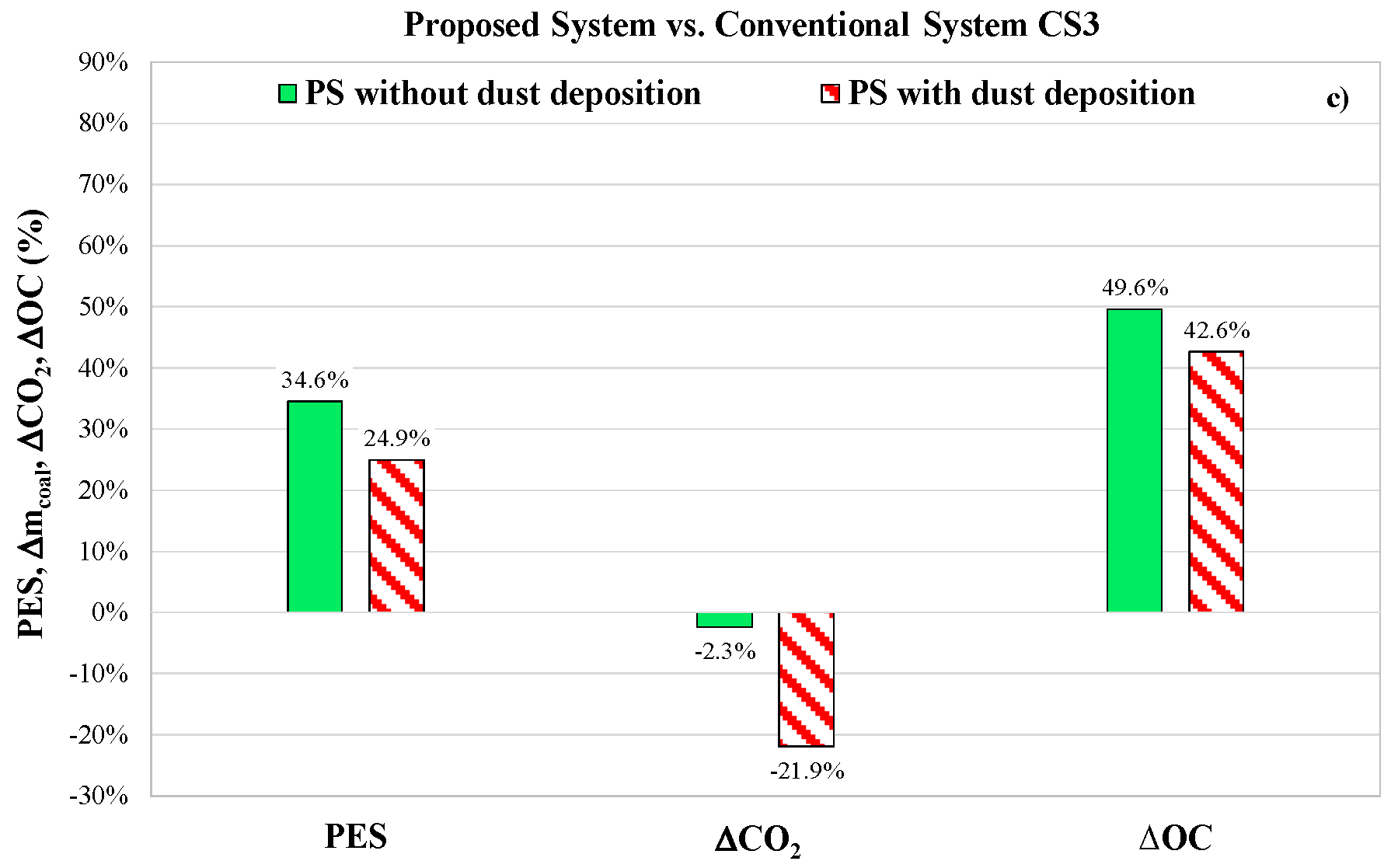

- The proposed system is able to achieve relevant reductions in terms of both the amount of coal that is burned as well as the carbon dioxide equivalent emissions in comparison to the conventional heating systems CS1 and CS2. In particular, the values of ∆mcoal range from 15.8% up to 68.6%, while ∆CO2 is between 21.1% and 52.3%. The maximum value of both ∆mcoal and ∆CO2 are obtained when the proposed system (without the dust deposition effects) is compared with the conventional system CS1, while both ∆mcoal and ∆CO2 assume the lowest values when the proposed system (with the soiling effects) is contrasted with the conventional system CS2;

- The conventional system CS3 is characterized by lower carbon dioxide equivalent emissions with respect to the proposed system, even if the total primary energy consumption of PS is lower than CS3. This is mainly due to the fact that the CO2 equivalent emission factor associated with the coal-burning (0.78 kg CO2/kWhp) is very high. In particular, the difference is negligible (∆CO2 = −2.3%) in the case of the soiling effects not being considered, but it becomes quite relevant (∆CO2 = −21.9%) when the impact of the dust deposition is taken into account;

- The proposed system significantly reduces the primary energy consumption (PES > 0), whatever the conventional system assumed as a reference. In particular, the maximum PES (+34.6%) is obtained when the proposed system (without the dust deposition effects) is compared with the conventional system CS3, while the minimum PES (+22.6%) is achieved when the proposed system (with the soiling effects) is contrasted with the conventional system CS1;

- The proposed system is also able to reduce the operating costs by a percentage in the range 13.0% ÷ 49.6% (the maximum value of ∆OC can be obtained in the case of the conventional heating system CS3 is assumed as a reference without considering the soiling effects, while the minimum saving in terms of operating costs relates to the case when the proposed system is contrasted with CS1 taking into account the effects of dust deposition);

- In comparison to the conventional system CS1 (that is the most common heating system in the Ger districts of Ulaanbaatar taking into account that 98% of the total households use only raw coal to satisfy the heating demand [1]), the proposed system obtains significant benefits due to the reduction of primary energy consumption by approximately 32.5%, the amount of coal that is burned by approximately 68.6%, the carbon dioxide equivalent emissions by approximately 52.3% and operating costs by approximately 23.3% in the case of the soiling effects not being considered;

- The impact of dust deposition on the overall energy, environmental and economic performance of the proposed system is very significant. In comparison to the performance of the proposed system with perfectly clean glass tubes, the soiling effect reduces the potential PES by approximately 9.7 ÷ 10.0%, the potential ∆mcoal by approximately 8.4 ÷ 17.8%, the potential ∆CO2 by approximately 9.1 ÷ 19.6% as well as the potential ∆OC by approximately 7.0 ÷ 10.6%. The most relevant effects of the dust deposition in terms of both PES (−10.0%) and ∆OC (−10.6%) can be recognized when the proposed system is compared with CS1. This clearly means that an appropriate cleaning strategy and timing of the solar field has to be identified in the future in order to fully exploit the potential benefits associated with the utilization of solar source.

- The duration of the simple pay-back period (32.5–61.9 years) is not acceptable when the proposed system is compared with the conventional system CS1 (mainly due to the capital costs of evacuated tube heat pipe collectors), so that significant economic incentives by the Mongolian Government supporting the application of solar collectors are strictly required;

- The values of SPB are reasonable when the proposed plant is contrasted with the reference systems CS2 and CS3, with the lowest values obtained when the case of the conventional plant CS3 is considered (6.1–7.1 years);

- The impact of dust deposition in terms of the simple pay-back period is relevant, with the values of SPB significantly increasing (from 16% up to 90%) when the soiling effects are taken into account with respect to the case without the dust deposition.

6. Conclusions

- -

- CS1: The conventional system is only equipped with a low-pressure coal-burning stove;

- -

- CS2: The conventional system is equipped with a low-pressure coal-burning stove together with an electric heater installed inside a thermal energy storage;

- -

- CS3: The conventional system is only equipped with an electric heater immersed into a thermal energy storage.

- -

- The proposed system (PS) allows the reduction of the primary energy as well as the operating costs in comparison to all the reference heating systems. The largest savings can be obtained when the performance of PS is contrasted with those associated with CS3;

- -

- The proposed system is not convenient from an environmental point of view only with respect to the conventional system CS3. The largest savings in terms of global CO2 equivalent emissions are achieved in comparison to CS1;

- -

- The expected return on the investment is not acceptable when the proposed system is compared with the conventional system CS1 (economic incentives supporting the application of solar systems are required), while it is reasonable with respect to the reference plants CS2 and CS3.

- in comparison to the Mongolian conventional heating systems assumed as references, the proposed system is potentially able to reduce the primary energy consumption by up to 34.6%, the amount of burned coal by up to 68.6%, the carbon dioxide equivalent emissions by up to 52.3% as well as the operating costs by up to 49.6%;

- The proposed triple system allows a significant reduction of primary energy consumption (by approximately 32.5%), the amount of coal that is burned (by approximately 68.6%), the carbon dioxide equivalent emissions (by approximately 52.3%) and the operating costs (by approximately 23.6%) in comparison to the most common heating system (CS1) in the Ger districts of Ulaanbaatar [1];

- Using solar thermal collectors for heating purposes can contribute to covering a relevant percentage (approximately 38%) of the heating demand of Mongolian residential applications;

- The effects of the dust deposition on glass tubes on the overall energy, environmental and economic performance of the proposed system are very relevant taking into account that the potential energy, environmental and economic savings are reduced from 7.0% up to 17.8% with respect to the case without the soiling effects. As a consequence, the cleaning strategy and timing of the solar collectors have to be investigated in more detail.

- -

- Contrast the simulation results with the experimental data in order to assess the feasibility of the simulation models;

- -

- Perform a sensitivity analysis with the aim of evaluating the effects of both the size and technology of both the solar collectors as well as the thermal energy storage on the overall energy, environmental and economic performance of the proposed system;

- -

- Evaluate alternative control logics in order to find the one capable of maximizing the associated benefits;

- -

- Define and assess different cleaning strategies of solar collectors in order to identify the one that allows for the maximization of the amount of energy provided by the solar technology for heating purposes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin letters | |

| A | area (m2), empirically-derived constant (m3/mg) |

| a1 | first order efficiency coefficient (W/m2K) |

| a2 | second order efficiency coefficient (W/m2K2) |

| abs | solar absorptance coefficient (-) |

| B | empirically-derived constant (-) |

| C | empirically-derived constant (mm−1) |

| c | specific heat (kJ/kgK) |

| CC | capital cost (€) |

| CO2 | carbon dioxide |

| COS | low-pressure coal-burning stove |

| CS | conventional system |

| CS1 | conventional system 1 |

| CS2 | conventional system 2 |

| CS3 | conventional system 3 |

| D | empirically-derived constant (mm−1) |

| E | energy (kWh, kJ) |

| EH | electric heater |

| f | function |

| G | global solar irradiance (W/m2) |

| h | convective heat transfer coefficient (W/m2K) |

| IHE | internal heat exchanger |

| L | empirically-derived constant (s/m) |

| LHV | lower heating value (kJ/kg) |

| m | mass (kg) |

| N | number of experimentally investigated glass tubes (-) |

| OC | operating cost (€) |

| P | power (kW) |

| PES | primary energy saving (%) |

| PM10 | particles with aerodynamic diameters less than or equal to 10 μm |

| PS | proposed system |

| Q | empirically-derived constant (m/s) |

| R | measurand |

| RAD | radiator |

| RP | radiators pump |

| s | thickness (m) |

| SFC | solar field collectors |

| SP | solar pump |

| SPB | simple pay-back period (years) |

| STD | Standard Temperature Difference (°C) |

| T | temperature (°C) |

| Tamb | outdoor air temperature (°C) |

| Tm | average temperature between inlet and outlet of solar thermal collectors (°C) |

| Troom | indoor air temperature (°C) |

| Troom,target | set-point of indoor air temperature (°C) |

| TTES,6 | temperature at node 6 of the thermal energy storage (°C) |

| TTES,top | temperature at top layer (node 1) of the thermal energy storage (°C) |

| TTES,top,target | target temperature at top layer (node 1) of the thermal energy storage (°C) |

| TES | thermal energy storage |

| U | thermal transmittance (W/m2K) |

| UC | unit cost (€/kWhel, €/kgcoal) |

| u | uncertainty |

| energy output-based emission factor (kg/kWh, kg/kJ) | |

| v | velocity (m/s) |

| volumetric flow rate (m3/h) | |

| w | factor indicating the wind direction (-) |

| x | generic pollutant |

| xi | daily average PM10 emissions during the ith day (mg/m3) |

| yi | daily average wind factor during the ith day (-) |

| z1,i | daily average rain rate during the ith day (mm) |

| z2,i | daily average snow rate during the ith day (mm) |

| Greeks | |

| α | CO2 equivalent emission factor for electricity production (kgCO2/kWhel) |

| β | CO2 equivalent emission factor of coal-burning (kgCO2/kWhp) |

| ∆ | difference |

| ∆TON | switch on temperature difference (°C) |

| η | thermal efficiency |

| η0 | intercept efficiency |

| λ | thermal conductivity (W/mK) |

| ρ | density (kg/m3) |

| τ | glass tube transmittance (-) |

| Superscripts/Subscripts | |

| CO2 | carbon dioxide |

| coal | coal |

| COS | coal-burning stove |

| COS_6kW | 6 kW coal-burning stove |

| COS_9kW | 9 kW coal-burning stove |

| CS | conventional system |

| CS1 | conventional system 1 |

| CS2 | conventional system 2 |

| CS3 | conventional system 3 |

| dust | dust deposition on glass tubes |

| e | external |

| EH | electric heater |

| EH_3kW | 3 kWel electric heater |

| EH_9kW | 9 kWel electric heater |

| el | electric |

| frame | frame of windows |

| glazing | glazing of windows |

| i | internal |

| in | inlet |

| out | outlet |

| p | primary |

| PP | power plant |

| PS | proposed system |

| RP | radiators circuit pump |

| SFC | solar field collectors |

| SP | solar circuit pump |

| TES | thermal energy storage |

| th | thermal |

| w | water, with |

| wall | wall of the house |

| wg | mixture of water and ethylene glycol (50%/50% by volume) |

| window | window of the house |

| w/o | without |

References

- World Bank Group. Mongolia-Heating Stove Market. Trends in Poor, Peri-Urban. Ger Areas of Ulaanbaatar and Selected Markets Outside Ulaanbaatar; Stocktaking Report of the Mongolia Clean Stoves Initiative (English); World Bank Group: Washington, DC, USA, 2013; Available online: http://documents.worldbank.org/curated/en/388091468323667110/Mongolia-Heating-stove-market-trends-in-poor-peri-urban-ger-areas-of-Ulaanbaatar-and-selected-markets-outside-Ulaanbaatar-stocktaking-report-of-the-Mongolia-clean-stoves-initiative (accessed on 27 June 2019).

- Gheorghe, A.; Ankhbayar, B.; van Nieuwenhuyzen, H.; de Sa, R. Mongolia’s Air Pollution Crisis: A Call to Action to Protect Children’s Health; National Center for Public Health and UNICEF: Ulaanbaatar, Mongolia, 2018; Available online: https://www.unicef.org/mongolia/Mongolia_air_pollution_crisis_ENG.pdf (accessed on 13 August 2019).

- Erdenedavaa, P.; Rosato, A.; Adiyabat, A.; Akisawa, A.; Sibilio, S.; Ciervo, A. Model analysis of solar thermal system with the effect of dust deposition on the collectors. Energies 2018, 11, 1795. [Google Scholar] [CrossRef]

- Namjil, E. Overview of Energy/Electricity Demand and Renewable Energy Potential in Mongolia; Asia Super Grid Workshop: Seoul, Korea, 2016; Available online: https://www.renewable-ei.org/images/pdf/20160525/Enebish_Namjil.pdf (accessed on 27 June 2019).

- Pillarisetti, A.; Ma, R.; Buyan, M.; Nanzad, B.; Argo, Y.; Yang, X.; Smith, K.R. Advanced household heat pumps for air pollution control: A pilot field study in Ulaanbaatar, the coldest capital city in the world. Environ. Res. 2019, 176, 108381. [Google Scholar] [CrossRef] [PubMed]

- Dawes, J.; Galbaatar, L.N. Domestic Solar Space Heating in Mongolia: Design and Demonstration. Environ. Eng. Renew. Energy 1998, 109–118. [Google Scholar] [CrossRef]

- Bai, Y.; He, X.; Liu, Y.; Duan, J.; Wang, Y.; Hana, X. Experimental investigation of a solar thermal storage heater assembled with finned heat pipe and collective vacuum tubes. Energy Convers. Manag. 2018, 166, 463–473. [Google Scholar] [CrossRef]

- Mori, T.; Kawamura, A. Design of Solar Water Heating System for Detached House in Cold Climate Area. Energy Procedia 2014, 48, 1393–1400. [Google Scholar] [CrossRef]

- Zambolin, E.; Del Col, D. Experimental analysis of thermal performance of flat plate and evacuated tube solar collectors in stationary standard and daily conditions. Sol. Energy 2010, 84, 1382–1396. [Google Scholar] [CrossRef]

- Kocer, A.; Atmaca, I.; Ertikin, C. A comparison of flat plate and evacuated tube solar collectors with f-chart method. J. Therm. Sci. Technol. 2015, 35, 77–86. [Google Scholar]

- Najera-Trejo, M.; Martin-Domínguez, I.R.; Escobedo-Bretado, J.A. Economic feasibility of flat plate vs. evacuated tube solar collectors in a combisystem. Energy Procedia 2016, 91, 477–485. [Google Scholar] [CrossRef]

- Shuk, R.; Sumathy, K.; Erickson, P.; Gong, J. Recent advances in the solar water heating systems: A review. Renew. Sustain. Energy Rev. 2013, 19, 173–190. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A. Thermal performance analysis of a solar water heating system with heat pipe evacuated tube collector using data from a field trial. Sol. Energy 2013, 90, 17–28. [Google Scholar] [CrossRef]

- Abd-Elhady, M.S.; Nasreldin, M.; Elsheikh, M.N. Improving the performance of evacuated tube heat pipe collectors using oil and foamed metals. Ain Shams Eng. J. 2018, 9, 2683–2689. [Google Scholar] [CrossRef]

- Nkwetta, D.N.; Smyth, M.; Haghighat, F. Experimental performance evaluation and comparative analyses of heat pipe and direct flow augmented solar collectors. Appl. Therm. Eng. 2013, 60, 225–233. [Google Scholar] [CrossRef]

- Ong, K.S.; Tong, W.L. System performance of U-Tube and heat pipe solar water heaters. J. Appl. Sci. Eng. 2012, 15, 105–110. [Google Scholar]

- Jack, S.; Katenbrink, N.; Schubert, F. Evaluation methods for heat pipes in solar thermal collectors e test equipment and first result. In Proceedings of the ISES Solar World Congress, Kassel, Germany, 28 August–2 September 2011. [Google Scholar]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Mani, M.; Pillai, R. Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renew. Sustain. Energy Rev. 2010, 14, 3124–3131. [Google Scholar] [CrossRef]

- Adinoyi, M.J.; Said, S.A.M. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew. Energy 2013, 60, 633–636. [Google Scholar] [CrossRef]

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Wang, K.; Liu, J. Dust effect on thermal performance of flat plate solar collectors. J. Sol. Energy Eng. 2014, 137, 014502. [Google Scholar]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Cuddihy, E.F. Surface soiling: Theoretical mechanisms and evaluation of low soiling coatings. In Proceedings of the Flat-plate Solar Array Project Research Forum on Quantifying Degradation, Williamsburg, VA, USA, 6–8 December 1982. [Google Scholar]

- El-Nashar, A.M. Effect of dust accumulation on the performance of evacuated tube collectors. Sol. Energy 1994, 53, 105–115. [Google Scholar] [CrossRef]

- El-Nashar, A.M. Effect of dust deposition on the performance of a solar desalination plant operating in an arid desert area. Sol. Energy 2003, 75, 421–431. [Google Scholar] [CrossRef]

- El-Nashar, A.M. Seasonal effect of dust deposition on a field of evacuated tube collectors on the performance of a solar desalination plant. Desalination 2009, 239, 66–81. [Google Scholar] [CrossRef]

- Erdenedavaa, P.; Akisawa, A.; Adiyabat, A.; Otgonjanchiv, E. Observation and modeling of dust deposition on glass tube of evacuated solar thermal collectors in Mongolia. Renew. Energy 2019, 130, 613–621. [Google Scholar] [CrossRef]

- TRNSYS. The Transient Energy System Simulation Tool. Available online: http://www.trnsys.com (accessed on 11 June 2019).

- Antoniadis, C.N.; Martinopoulos, G. Optimization of a building integrated solar thermal system with seasonal storage using TRNSYS. Renew. Energy 2019, 137, 56–66. [Google Scholar] [CrossRef]

- Shrivastava, R.L.; Kumar, V.; Untawale, S.P. Modeling and simulation of solar water heater: A TRNSYS perspective. Renew. Sustain. Energy Rev. 2017, 67, 126–143. [Google Scholar] [CrossRef]

- Sibilio, S.; Rosato, A.; Ciampi, G.; Scorpio, M.; Akisawa, A. Building-integrated trigeneration system: Energy, environmental and economic dynamic performance assessment for Italian residential applications. Renew. Sustain. Energy Rev. 2017, 68, 920–933. [Google Scholar] [CrossRef]

- Erdenedavaa, P.; Akisawa, A.; Adiyabat, A.; Otgonjanchiv, E. Performance analysis of solar thermal system for heating of a detached house in harsh cold region of Mongolia. Renew. Energy 2018, 117, 217–226. [Google Scholar] [CrossRef]

- SketchUp Pro. Available online: https://www.sketchup.com/products/sketchup-pro (accessed on 11 June 2019).

- ISO. EUROPEAN STANDARD EN ISO 6946:2007. Building Components and Building Elements–Thermal Resistance and Thermal Transmittance–Calculation Method; ISO: Switzerland, 2007. [Google Scholar]

- ISO. EUROPEAN STANDARD EN ISO 10077-1:2006. Thermal performance of Windows, Doors and Shutters–Calculation of Thermal Transmittance, Part 1: General; ISO: Switzerland, 2006. [Google Scholar]

- Tong, J.C.-K.; Tse, J.M.-Y.; Jones, P.J. Development of thermal evaluation tool for detached houses in Mongolia. Energy Build. 2018, 173, 81–90. [Google Scholar] [CrossRef]

- ISO. EUROPEAN STANDARD EN ISO 7730:2005. Ergonomics of the Thermal Environment–Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- EnergyPlus. Weather Data. Available online: https://energyplus.net/weather-location/asia_wmo_region_2/MNG//MNG_Ulaanbataar.442920_IWEC (accessed on 11 June 2019).

- Jiangsu Sunrain Solar Energy Co. Available online: http://www.cccme.org.cn/shop/cccme6658/index.aspx (accessed on 11 June 2019).

- Test Report, Thermal Performance of a Solar Collector. Available online: https://www.igte.uni-stuttgart.de/en/publications/publikationen-forschungs-und-testzentrum-fuer-solaranlagen-00001/dokumente_tzs/jahresberichte_tests2010.pdf (accessed on 13 August 2019).

- UNI. EUROPEAN STANDARD UNI EN 12975-2:2006, Thermal Solar Systems and Components—Solar Collectors—Part 2: Test Methods; UNI: Milan, Italy, 2006; Available online: http://store.uni.com/catalogo/index.php/en-12975-2-2006.html?___store=en&josso_back_to=http%3A%2F%2Fstore.uni.com%2Fjosso-security-check.php&josso_cmd=login_optional&josso_partnerapp_host=store.uni.com&___from_store=it (accessed on 11 June 2019).

- Erdenedavaa, P.; Rosato, A.; Akisawa, A.; Adiyabat, A.; Ciervo, A.; Sibilio, S. Performance of solar collectors under Mongolian climatic conditions: Comparison between experimental and preliminary simulation results. In Proceedings of the Grand Renewable Energy 2018—International Conference and Exhibition, Pacifico Yokohama, Japan, 17–22 June 2018. [Google Scholar]

- Гэрийн ба халаалтын зуух. Available online: https://www.slideshare.net/NCRAPM/academid-uguh-hurliin-iltgel (accessed on 13 August 2019).

- ALAVA. Available online: http://www.grupoalava.com/repositorio/13a0/pdf/6942/2/caudalimetro-ultrasonico-de-bajo-coste-portatil---a1tds.pdf?d=1 (accessed on 11 June 2019).

- Eurotherm. Available online: https://www.eurotherm.co.uk/products/sensors/resistance-temperature-detector (accessed on 11 June 2019).

- UNI. UNI CEI ENV 13005:2000. Guide to the Expression of Uncertainty in Measurement (GUM); UNI: Milan, Italy, 2000. [Google Scholar]

- Mastrullo, R.M.A.; Rosato, A.; Vanoli, G.P.; Thome, J.R. A methodology to select the experimental plant instrumentation based on an a priori analysis of measurement errors and instrumentation cost. Int. Commun. Heat Mass Transf. 2008, 35, 689–695. [Google Scholar] [CrossRef]

- Fondital Spa. Available online: http://www.fondital.com/ww/en/ (accessed on 11 June 2019).

- Mongolian Energy Regulatory Commission. Statistics of Power System, Electricity Statistical Book; Mongolian Energy Regulatory Commission: Mongolia, Ulaanbaatar, 2014. [Google Scholar]

- World Bank. Mongolia: Heating in Poor, Peri-Urban Ger Areas of Ulaanbaatar; Asia Sustainable and Alternative Energy Program; World Bank: Washington, DC, USA, 2009. [Google Scholar]

- Chicco, G.; Mancarella, P. Assessment of the greenhouse gas emissions from cogeneration and trigeneration systems. Part I: Models and indicators. Energy 2008, 33, 410–417. [Google Scholar] [CrossRef]

- IGES. List of Grid Emission Factors. Available online: https://pub.iges.or.jp/pub/list-grid-emission-factor (accessed on 11 June 2019).

- Unegui.mn. Available online: https://www.unegui.mn/thrmzh-barilgyin-material-tlsh-thij-ed/tlee-nrstlsh/ulan-bator/ (accessed on 11 June 2019).

- Mongolian Energy Regulatory Commission. Available online: http://erc.gov.mn/index.php?newsid=675# (accessed on 11 June 2019).

- Ramos, A.; Chatzopoulou, M.A.; Guarracino, I.; Freeman, J.; Markides, C.N. Hybrid photovoltaic-thermal solar systems for combined heating, cooling and power provision in the urban environment. Energy Convers. Manag. 2017, 150, 838–850. [Google Scholar] [CrossRef]

- Paradigma. PS9000. Available online: http://www.paradigmaitalia.it/serbatoio-accumuloacqua-calda-riscaldamento/boiler-accumulo-acqua-calda/accumulo-solaretermico (accessed on 30 July 2019).

| Layer Material (from Outside to Inside) | Thickness s (m) | Thermal Conductivity λ (W/mK) | |

|---|---|---|---|

| Floor of Base Section | Concrete | 0.300 | 1.160 |

| Floor of Additional Section | Concrete | 0.150 | 1.160 |

| Roof (Part 1 and Part 2) of Base Section and Roof of Additional Section | Timber block | 0.005 | 0.140 |

| Expanded polystyrene | 0.070 | 0.033 | |

| Timber panel | 0.015 | 0.033 | |

| Gypsum panel | 0.005 | 0.170 | |

| Vertical walls of Base Section | Bricks | 0.100 | 0.810 |

| Glass wool | 0.030 | 0.037 | |

| Timber block | 0.150 | 0.140 | |

| Gypsum panel | 0.005 | 0.170 | |

| Vertical walls of Additional Section | Bricks | 0.250 | 0.810 |

| Cement render | 0.010 | 0.350 | |

| Internal wall | Sand and cement render | 0.010 | 0.350 |

| Timber block | 0.150 | 0.140 | |

| Gypsum panel | 0.005 | 0.170 |

| BASE SECTION | ||||||

| Element Type | Orientation/Azimuth (°) | Surface Slope (°) | Wall Area without Windows (m2) | absi,wall/abse,wall (-) | hi,wall/he,wall (W/m2K) | Uwall (W/m2K) |

| Floor | Horizontal/- | 0 | 48.00 | 0.6/0.6 | 0.70/20.00 | 3.87 |

| Roof (Part 1) | South/10 | 25 | 26.48 | 0.6/0.6 | 5.00/20.00 | 0.38 |

| Roof (Part 2) | North/190 | 25 | 26.48 | 0.6/0.6 | 5.00/20.00 | 0.38 |

| Front wall | South/10 | 90 | 15.40 | 0.6/0.6 | 2.50/20.00 | 0.49 |

| Back wall | North/190 | 90 | 18.40 | 0.6/0.6 | 2.50/20.00 | 0.49 |

| Left side wall | West/100 | 90 | 16.50 | 0.6/0.6 | 2.50/20.00 | 0.49 |

| Right side wall (Part 1) | East/280 | 90 | 8.80 | 0.6/0.6 | 2.50/20.00 | 0.49 |

| Right side wall (Part 2) | Internal wall | 90 | 6.30 | 0.6/0.6 | 2.50/2.50 | 0.89 |

| ADDITIONAL SECTION | ||||||

| Floor | Horizontal/- | 0 | 10.00 | 0.6/0.6 | 0.70/20.00 | 7.73 |

| Roof | East/280 | 4.35 | 10.03 | 0.6/0.6 | 5.00/20.00 | 0.38 |

| Front wall | South/10 | 90 | 2.62 | 0.6/0.6 | 2.50/20.00 | 2.97 |

| Back wall | North/190 | 90 | 5.52 | 0.6/0.6 | 2.50/20.00 | 2.97 |

| Right side wall | East/280 | 90 | 6.65 | 0.6/0.6 | 2.50/20.00 | 2.97 |

| Left side wall | Internal wall | 90 | 6.30 | 0.6/0.6 | 2.50/2.50 | 0.89 |

| BASIS SECTION | ||||||||

| Number of Windows | Orientation/Azimuth (°) | hi,window/he,window (W/m2K) | Uframe/Uglazing (W/m2K) | Window Type | Spacing Gas | Geometry (mm) | Aframe (m2) | Awindow (m2) |

| 2 | South/10 | 2.50/20.00 | 6.00/2.83 | Double glazing | Air | 4/16/4 | 0.225 | 1.275 |

| 1 | West/100 | |||||||

| ADDITIONAL SECTION | ||||||||

| 1 | South/10 | 2.50/20.00 | 6.00/2.83 | Double glazing | Air | 4/16/4 | 0.435 | 2.465 |

| Tank volume | 0.5 m3 |

| Tank internal height | 1.695 m |

| Height of flow inlet/outlet | 0.2 m/1.6 m |

| Tank loss coefficient | 2.34 kJ/hm2K |

| Height of heat exchanger inlet | 1.4 m |

| Height of heat exchanger outlet | 0.25 m |

| Heat exchanger inside diameter | 0.021 m |

| Heat exchanger outside diameter | 0.024 m |

| Total surface area of heat exchanger | 1.3 m2 |

| Heat exchanger length | 17.5 m |

| Heat exchanger material conductivity | 1436.4 kJ/hmK |

| Component | ON | OFF |

|---|---|---|

| Solar circuit pump (during normal operation) | ∆TON = (TSFC,out − TTES,6) ≥ 8 °C | ∆TON = (TSFC,out − TTES,6) < 4 °C |

| Radiators pump from 7.00 a.m. to 11.00 p.m. | Troom ≤ Troom,target − 1.5 °C | Troom ≥ Troom,target + 1.5 °C |

| Electric heater from 4.30 a.m. to 11.00 p.m. | TTES,top ≤ TTES,top,target − 5 °C | TTES,top ≥ TTES,top,target |

| Activation State | TTES,top,target (°C) | |||

|---|---|---|---|---|

| Solar Circuit Pump | Radiators Pump | 4.30 a.m.–7.00 a.m. | 7.00 a.m.–11.00 p.m. | |

| Tamb > −10 °C | OFF or ON | OFF or ON | 35 | 35 |

| Tamb ≤ −10 °C | OFF | ON | 55 | 55 |

| OFF | 55 | 35 | ||

| ON | ON | 55 | 35 | |

| OFF | ||||

| Charging Times of the Stove (hh:mm) | Component | |||

|---|---|---|---|---|

| Radiators Pump | Electric Heater | |||

| Conventional system CS1 | 7:00 9:00 10:30 12:00 13:30 15:00 16:30 18:00 19:30 21:00 22:30 | ON | Troom ≤ Troom,target − 1.5 °C | - |

| OFF | Troom ≥ Troom,target + 1.5 °C | - | ||

| Conventional system CS2 | 7:00 10:30 14:00 17:30 21:00 | ON | Troom ≤ Troom,target − 1.5 °C | TTES,top ≤ 45 °C AND Radiators pump ON |

| OFF | Troom ≥ Troom,target + 1.5 °C | TTES,top ≥ 55 °C OR Radiators pump OFF | ||

| Conventional system CS3 | - | ON | Troom ≤ Troom,target − 1.5 °C | TTES,top ≤ 40 °C |

| OFF | Troom ≥ Troom,target + 1.5 °C | TTES,top ≥ 55 °C | ||

| Without Dust Deposition | With Dust Deposition | |

|---|---|---|

| PS vs. CS1 | 32.5 years | 61.9 years |

| PS vs. CS2 | 8.5 years | 10.7 years |

| PS vs. CS3 | 6.1 years | 7.1 years |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosato, A.; Erdenedavaa, P.; Ciervo, A.; Akisawa, A.; Adiyabat, A.; Sibilio, S. A Solar Thermal Application for Mongolian Detached Houses: An Energy, Environmental, and Economic Analysis Based on Dynamic Simulations. Buildings 2019, 9, 185. https://doi.org/10.3390/buildings9080185

Rosato A, Erdenedavaa P, Ciervo A, Akisawa A, Adiyabat A, Sibilio S. A Solar Thermal Application for Mongolian Detached Houses: An Energy, Environmental, and Economic Analysis Based on Dynamic Simulations. Buildings. 2019; 9(8):185. https://doi.org/10.3390/buildings9080185

Chicago/Turabian StyleRosato, Antonio, Purevdalai Erdenedavaa, Antonio Ciervo, Atsushi Akisawa, Amarbayar Adiyabat, and Sergio Sibilio. 2019. "A Solar Thermal Application for Mongolian Detached Houses: An Energy, Environmental, and Economic Analysis Based on Dynamic Simulations" Buildings 9, no. 8: 185. https://doi.org/10.3390/buildings9080185

APA StyleRosato, A., Erdenedavaa, P., Ciervo, A., Akisawa, A., Adiyabat, A., & Sibilio, S. (2019). A Solar Thermal Application for Mongolian Detached Houses: An Energy, Environmental, and Economic Analysis Based on Dynamic Simulations. Buildings, 9(8), 185. https://doi.org/10.3390/buildings9080185